NISSAN TEANA 2008 Service Manual

Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 5011 of 5121

WT-4

< ON-VEHICLE REPAIR >

ROAD WHEEL TIRE ASSEMBLY

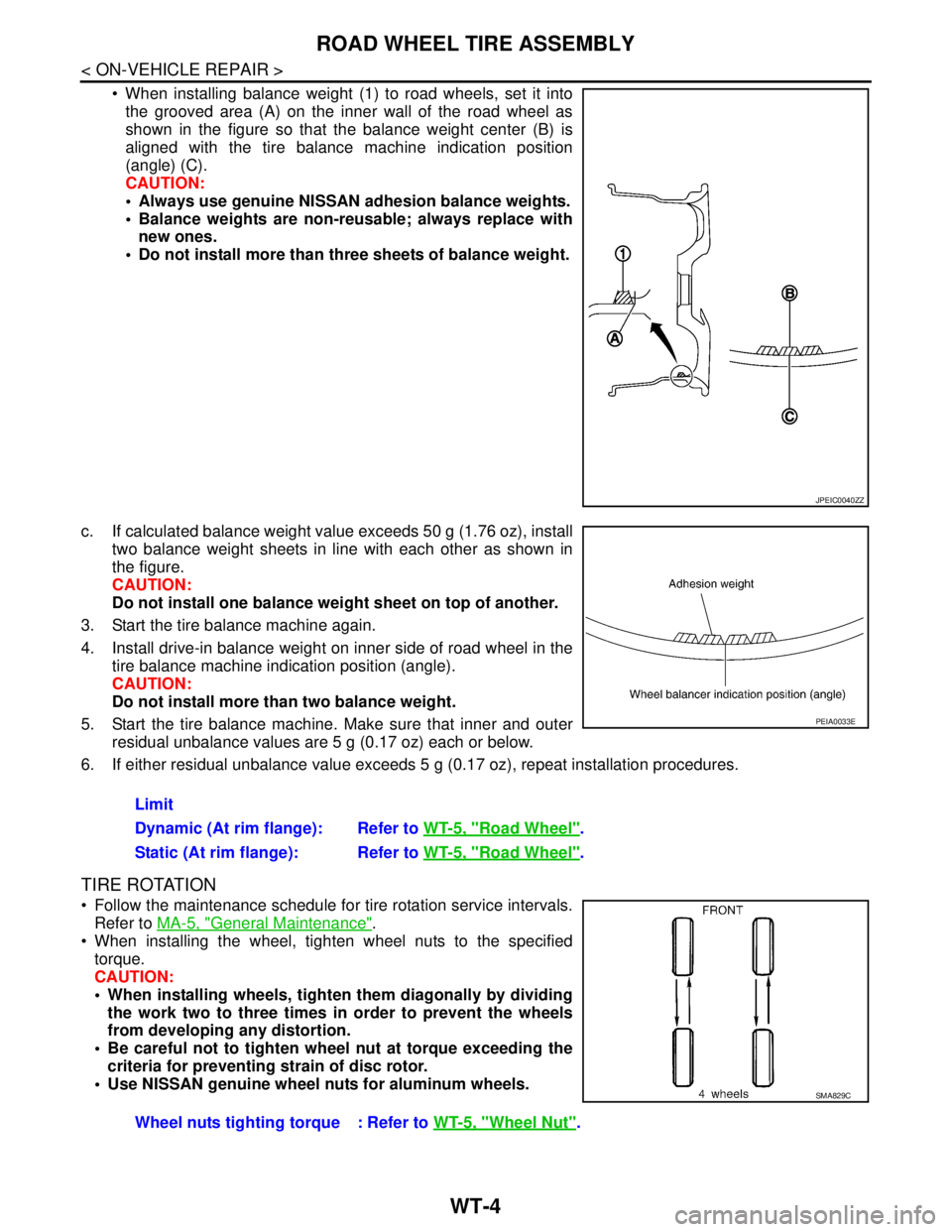

When installing balance weight (1) to road wheels, set it into

the grooved area (A) on the inner wall of the road wheel as

shown in the figure so that the balance weight center (B) is

aligned with the tire balance machine indication position

(angle) (C).

CAUTION:

Always use genuine NISSAN adhesion balance weights.

Balance weights are non-reusable; always replace with

new ones.

Do not install more than three sheets of balance weight.

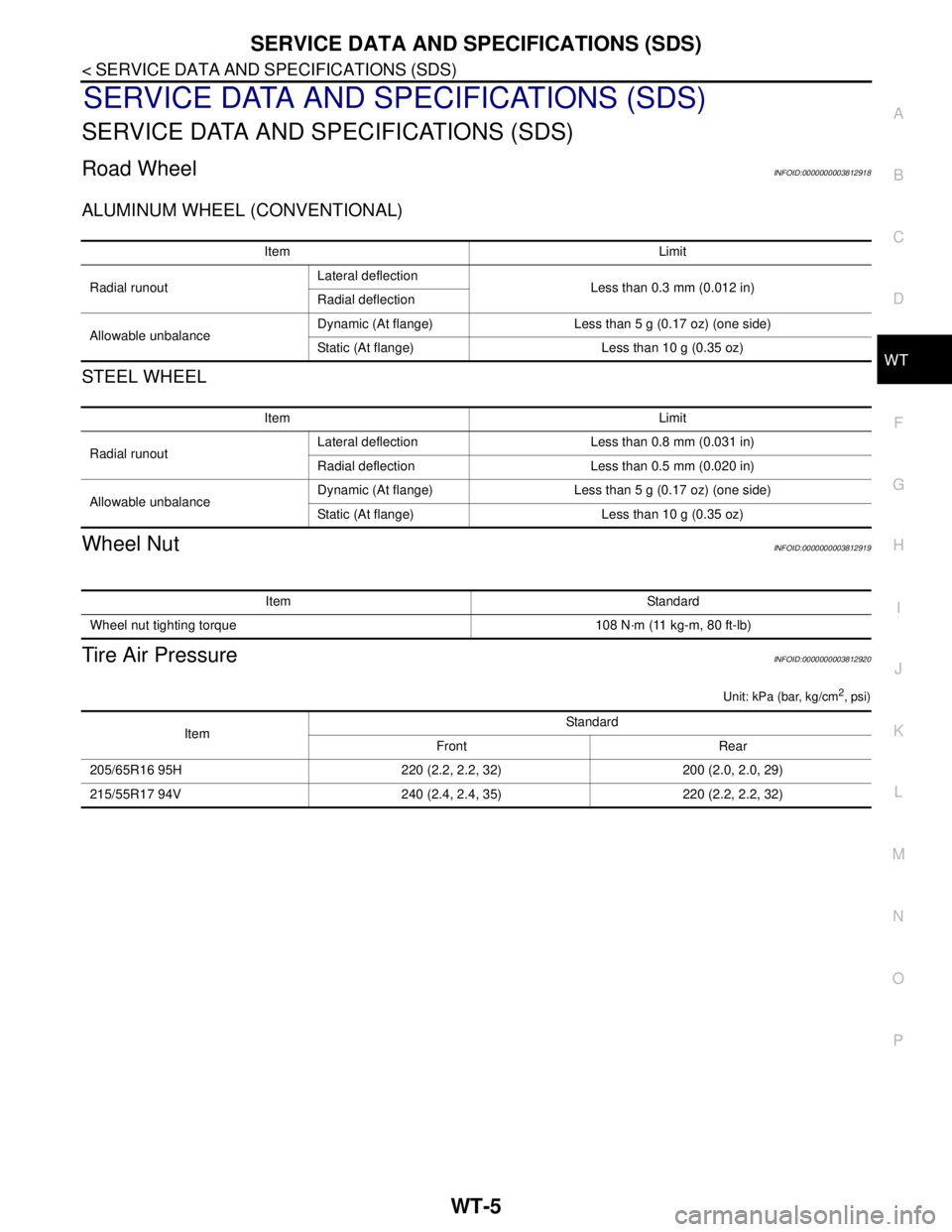

c. If calculated balance weight value exceeds 50 g (1.76 oz), install

two balance weight sheets in line with each other as shown in

the figure.

CAUTION:

Do not install one balance weight sheet on top of another.

3. Start the tire balance machine again.

4. Install drive-in balance weight on inner side of road wheel in the

tire balance machine indication position (angle).

CAUTION:

Do not install more than two balance weight.

5. Start the tire balance machine. Make sure that inner and outer

residual unbalance values are 5 g (0.17 oz) each or below.

6. If either residual unbalance value exceeds 5 g (0.17 oz), repeat installation procedures.

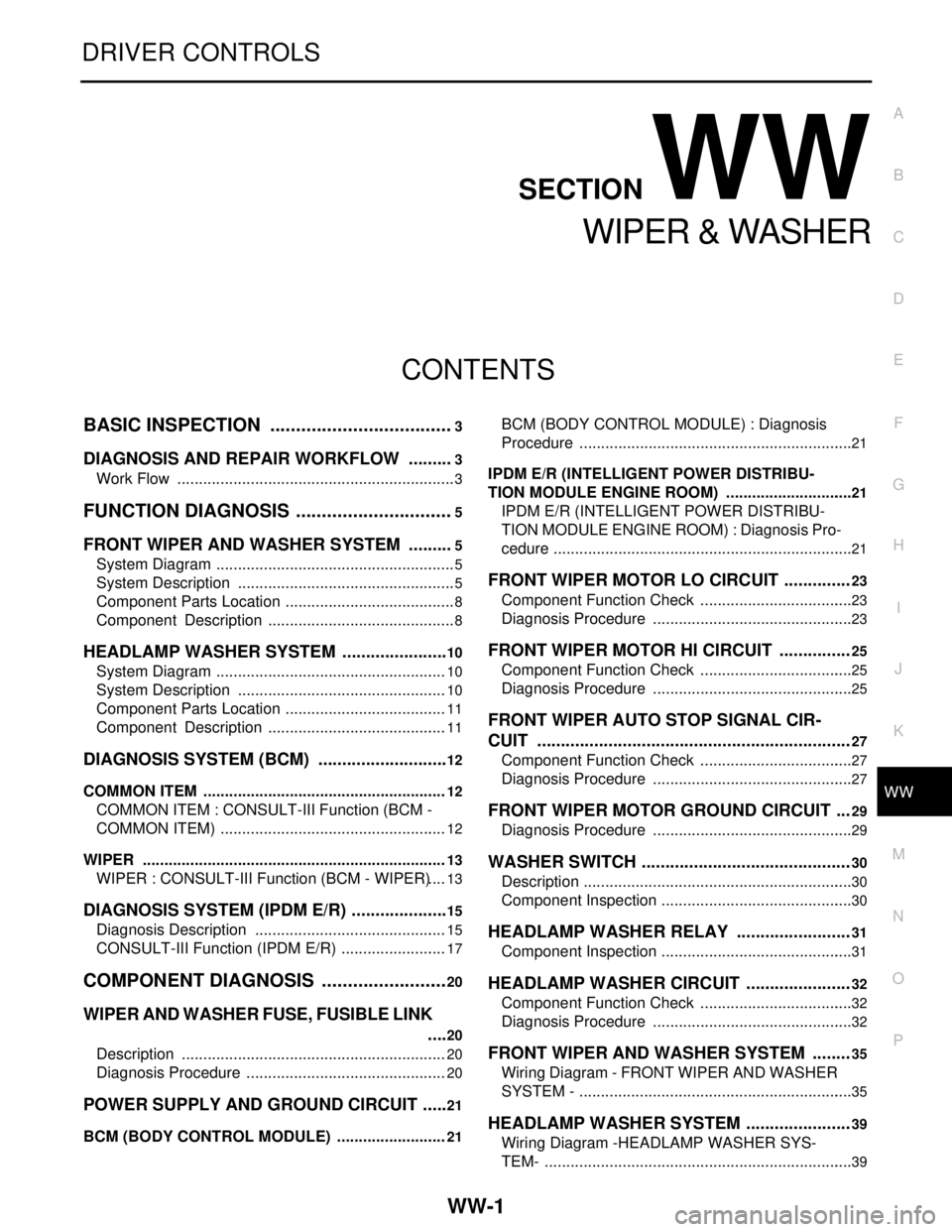

TIRE ROTATION

Follow the maintenance schedule for tire rotation service intervals.

Refer to MA-5, "

General Maintenance".

When installing the wheel, tighten wheel nuts to the specified

torque.

CAUTION:

When installing wheels, tighten them diagonally by dividing

the work two to three times in order to prevent the wheels

from developing any distortion.

Be careful not to tighten wheel nut at torque exceeding the

criteria for preventing strain of disc rotor.

Use NISSAN genuine wheel nuts for aluminum wheels.

JPEIC0040ZZ

Limit

Dynamic (At rim flange): Refer to WT-5, "

Road Wheel".

Static (At rim flange): Refer to WT-5, "

Road Wheel".

PEIA0033E

Wheel nuts tighting torque : Refer to WT-5, "Wheel Nut".

SMA829C

Page 5012 of 5121

SERVICE DATA AND SPECIFICATIONS (SDS)

WT-5

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

D

F

G

H

I

J

K

L

MA

B

WT

N

O

P

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Road WheelINFOID:0000000003812918

ALUMINUM WHEEL (CONVENTIONAL)

STEEL WHEEL

Wheel NutINFOID:0000000003812919

Tire Air PressureINFOID:0000000003812920

Unit: kPa (bar, kg/cm2, psi)

Item Limit

Radial runoutLateral deflection

Less than 0.3 mm (0.012 in)

Radial deflection

Allowable unbalanceDynamic (At flange) Less than 5 g (0.17 oz) (one side)

Static (At flange) Less than 10 g (0.35 oz)

Item Limit

Radial runoutLateral deflection Less than 0.8 mm (0.031 in)

Radial deflection Less than 0.5 mm (0.020 in)

Allowable unbalanceDynamic (At flange) Less than 5 g (0.17 oz) (one side)

Static (At flange) Less than 10 g (0.35 oz)

Item Standard

Wheel nut tighting torque 108 N·m (11 kg-m, 80 ft-lb)

ItemStandard

Front Rear

205/65R16 95H 220 (2.2, 2.2, 32) 200 (2.0, 2.0, 29)

215/55R17 94V 240 (2.4, 2.4, 35) 220 (2.2, 2.2, 32)

Page 5013 of 5121

WW-1

DRIVER CONTROLS

C

D

E

F

G

H

I

J

K

M

SECTION WW

A

B

WW

N

O

P

CONTENTS

WIPER & WASHER

BASIC INSPECTION ....................................3

DIAGNOSIS AND REPAIR WORKFLOW ..........3

Work Flow .................................................................3

FUNCTION DIAGNOSIS ...............................5

FRONT WIPER AND WASHER SYSTEM ..........5

System Diagram ........................................................5

System Description ...................................................5

Component Parts Location ........................................8

Component Description ............................................8

HEADLAMP WASHER SYSTEM .......................10

System Diagram ......................................................10

System Description .................................................10

Component Parts Location ......................................11

Component Description ..........................................11

DIAGNOSIS SYSTEM (BCM) ............................12

COMMON ITEM .........................................................12

COMMON ITEM : CONSULT-III Function (BCM -

COMMON ITEM) .....................................................

12

WIPER .......................................................................13

WIPER : CONSULT-III Function (BCM - WIPER) ....13

DIAGNOSIS SYSTEM (IPDM E/R) .....................15

Diagnosis Description .............................................15

CONSULT-III Function (IPDM E/R) .........................17

COMPONENT DIAGNOSIS .........................20

WIPER AND WASHER FUSE, FUSIBLE LINK

....

20

Description ..............................................................20

Diagnosis Procedure ...............................................20

POWER SUPPLY AND GROUND CIRCUIT ......21

BCM (BODY CONTROL MODULE) ..........................21

BCM (BODY CONTROL MODULE) : Diagnosis

Procedure ................................................................

21

IPDM E/R (INTELLIGENT POWER DISTRIBU-

TION MODULE ENGINE ROOM) ..............................

21

IPDM E/R (INTELLIGENT POWER DISTRIBU-

TION MODULE ENGINE ROOM) : Diagnosis Pro-

cedure ......................................................................

21

FRONT WIPER MOTOR LO CIRCUIT ..............23

Component Function Check ....................................23

Diagnosis Procedure ...............................................23

FRONT WIPER MOTOR HI CIRCUIT ...............25

Component Function Check ....................................25

Diagnosis Procedure ...............................................25

FRONT WIPER AUTO STOP SIGNAL CIR-

CUIT ..................................................................

27

Component Function Check ....................................27

Diagnosis Procedure ...............................................27

FRONT WIPER MOTOR GROUND CIRCUIT ...29

Diagnosis Procedure ...............................................29

WASHER SWITCH ............................................30

Description ...............................................................30

Component Inspection .............................................30

HEADLAMP WASHER RELAY ........................31

Component Inspection .............................................31

HEADLAMP WASHER CIRCUIT ......................32

Component Function Check ....................................32

Diagnosis Procedure ...............................................32

FRONT WIPER AND WASHER SYSTEM ........35

Wiring Diagram - FRONT WIPER AND WASHER

SYSTEM - ................................................................

35

HEADLAMP WASHER SYSTEM ......................39

Wiring Diagram -HEADLAMP WASHER SYS-

TEM- ........................................................................

39

Page 5014 of 5121

WW-2

ECU DIAGNOSIS ........................................42

BCM (BODY CONTROL MODULE) ..................42

Reference Value .....................................................42

Wiring Diagram - BCM - .........................................65

Fail-safe ..................................................................71

DTC Inspection Priority Chart ..............................73

DTC Index ..............................................................74

IPDM E/R (INTELLIGENT POWER DISTRI-

BUTION MODULE ENGINE ROOM) .................

76

Reference Value .....................................................76

Wiring Diagram - IPDM E/R - ..................................84

Fail-safe ..................................................................87

DTC Index ..............................................................89

SYMPTOM DIAGNOSIS .............................90

FRONT WIPER AND WASHER SYSTEM

SYMPTOMS .......................................................

90

Symptom Table ......................................................90

NORMAL OPERATING CONDITION ................92

Description ..............................................................92

FRONT WIPER DOES NOT OPERATE ............93

Description ..............................................................93

Diagnosis Procedure ..............................................93

HEADLAMP WASHER DOES NOT OPER-

ATE ....................................................................

95

Description ..............................................................95

Diagnosis Procedure ..............................................95

PRECAUTION .............................................96

PRECAUTIONS .................................................96

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .................................................................

96

Precaution for Procedure without Cowl Top Cover ...96

ON-VEHICLE REPAIR ...............................97

HEADLAMP WASHER NOZZLE AND TUBE ...97

Exploded View ........................................................97

Hydraulic Layout .....................................................97

Removal and Installation .........................................97

Inspection ................................................................98

WASHER TANK ................................................99

Exploded View ........................................................99

Removal and Installation .........................................99

WASHER PUMP ...............................................100

Exploded View ......................................................100

Removal and Installation .......................................100

HEADLAMP WASHER PUMP .........................101

Exploded View ......................................................101

Removal and Installation .......................................101

FRONT WASHER NOZZLE AND TUBE ..........102

Hydraulic Layout ...................................................102

Removal and Installation .......................................102

Inspection and Adjustment ....................................102

FRONT WIPER ARM ........................................105

Exploded View ......................................................105

Removal and Installation .......................................105

Adjustment ............................................................105

FRONT WIPER DRIVE ASSEMBLY ................107

Exploded View ......................................................107

Removal and Installation .......................................107

Disassembly and Assembly ..................................108

FRONT WIPER AND WASHER SWITCH ........109

Exploded View ......................................................109

Page 5015 of 5121

DIAGNOSIS AND REPAIR WORKFLOW

WW-3

< BASIC INSPECTION >

C

D

E

F

G

H

I

J

K

MA

B

WW

N

O

P

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORKFLOW

Work FlowINFOID:0000000003761571

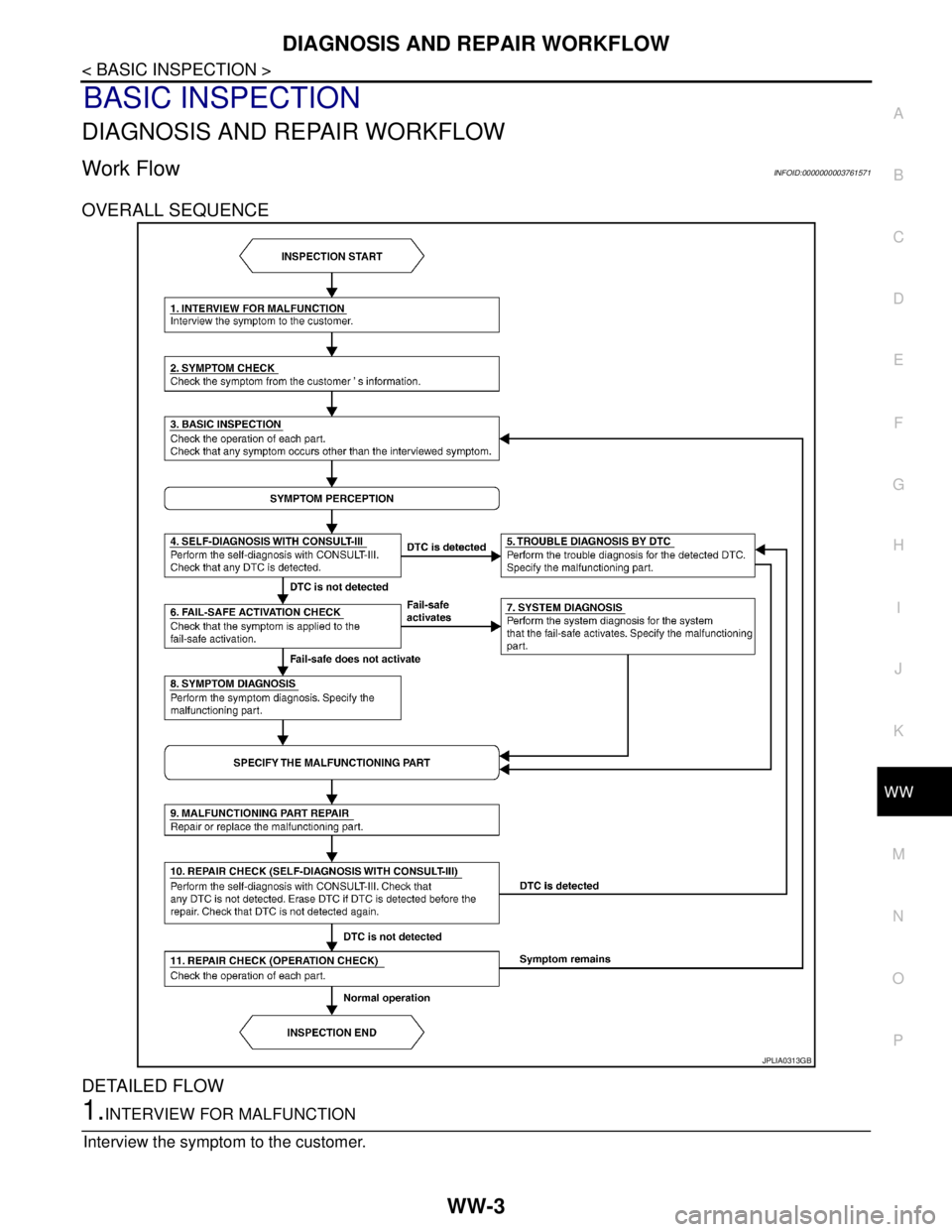

OVERALL SEQUENCE

DETAILED FLOW

1.INTERVIEW FOR MALFUNCTION

Interview the symptom to the customer.

JPLIA0313GB

Page 5016 of 5121

WW-4

< BASIC INSPECTION >

DIAGNOSIS AND REPAIR WORKFLOW

>> GO TO 2.

2.SYMPTOM CHECK

Check the symptom from the customer's information.

>> GO TO 3.

3.BASIC INSPECTION

Check the operation of each part. Check that any symptom occurs other than the interviewed symptom.

>> GO TO 4.

4.SELF-DIAGNOSIS WITH CONSULT-III

Perform the self-diagnosis with CONSULT-III. Check that any DTC is detected.

Is any DTC detected?

YES >> GO TO 5.

NO >> GO TO 6.

5.TROUBLE DIAGNOSIS BY DTC

Perform the trouble diagnosis for the detected DTC. Specify the malfunctioning part.

>> GO TO 9.

6.FAIL-SAFE ACTIVATION CHECK

Check that the symptom is applied to the fail-safe activation.

Does the fail-safe activate?

YES >> GO TO 7.

NO >> GO TO 8.

7.SYSTEM DIAGNOSIS

Perform the system diagnosis for the system that the fail-safe activates. Specify the malfunctioning part.

>> GO TO 9.

8.SYMPTOM DIAGNOSIS

Perform the symptom diagnosis. Specify the malfunctioning part.

>> GO TO 9.

9.MALFUNCTION PART REPAIR

Repair or replace the malfunctioning part.

>> GO TO 10.

10.REPAIR CHECK (SELF-DIAGNOSIS WITH CONSULT-III)

Perform the self-diagnosis with CONSULT-III. Check that any DTC is not detected. Erase DTC if DTC is

detected before the repair. Check that DTC is not detected again.

Is any DTC detected?

YES >> GO TO 5.

NO >> GO TO 11.

11 .REPAIR CHECK (OPERATION CHECK)

Check the operation of each part.

Does it operate normally?

YES >> INSPECTION END

NO >> GO TO 3.

Page 5017 of 5121

FRONT WIPER AND WASHER SYSTEM

WW-5

< FUNCTION DIAGNOSIS >

C

D

E

F

G

H

I

J

K

MA

B

WW

N

O

P

FUNCTION DIAGNOSIS

FRONT WIPER AND WASHER SYSTEM

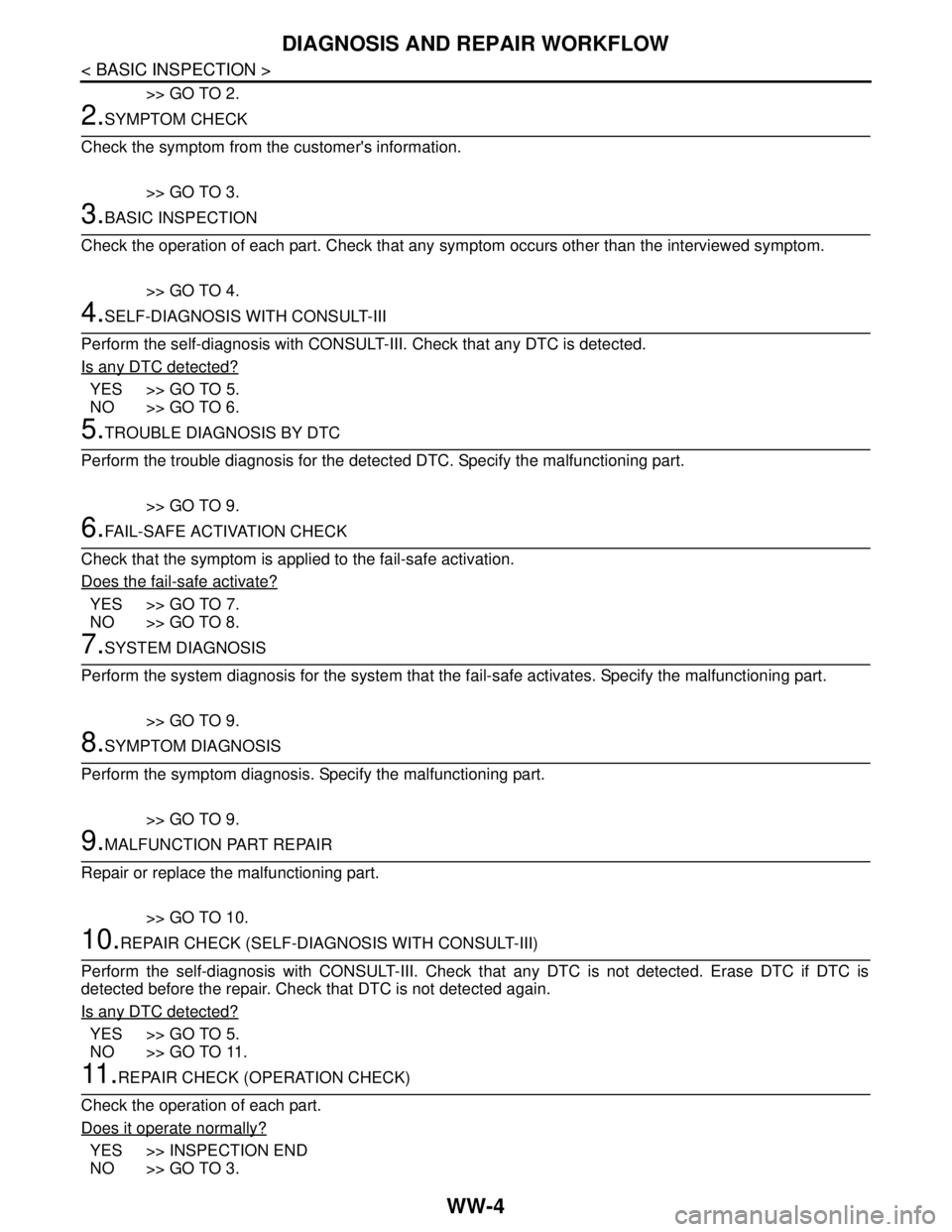

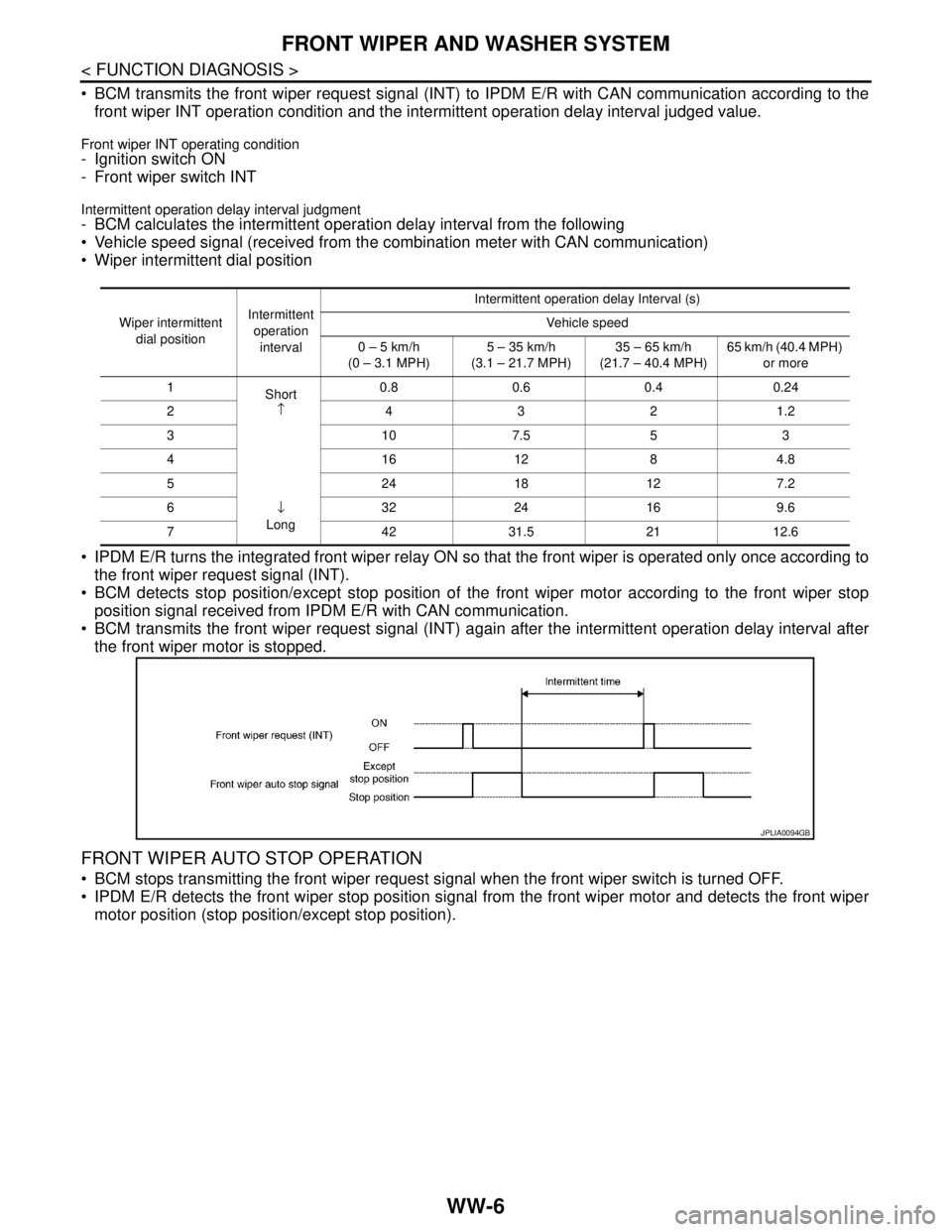

System DiagramINFOID:0000000003774860

System DescriptionINFOID:0000000003774861

OUTLINE

The front wiper is controlled by each function of BCM and IPDM E/R.

Control by BCM

• Combination switch reading function

Front wiper control function

Control by IPDM E/R

Front wiper control function

Relay control function

FRONT WIPER BASIC OPERATION

BCM detects the combination switch condition by the combination switch reading function.

BCM transmits the front wiper request signal to IPDM E/R with CAN communication depending on each

operating condition of the front wiper.

IPDM E/R turns ON/OFF the integrated front wiper relay and the front wiper high relay according to the front

wiper request signal. IPDM E/R provides the power supply to operate the front wiper HI/LO operation.

FRONT WIPER LO OPERATION

BCM transmits the front wiper request signal (LO) to IPDM E/R with CAN communication according to the

front wiper LO operating condition.

Front wiper LO operating condition

- Ignition switch ON

- Front wiper switch LO or front wiper switch MIST (while pressing)

IPDM E/R turns ON the integrated front wiper relay according to the front wiper request signal (LO).

FRONT WIPER HI OPERATION

BCM transmits the front wiper request signal (HI) to IPDM E/R with CAN communication according to the

front wiper HI operating condition.

Front wiper HI operating condition

- Ignition switch ON

- Front wiper switch HI

IPDM E/R turns ON the integrated front wiper relay and the front wiper high relay according to the front wiper

request signal (HI).

FRONT WIPER INT OPERATION (LINKED WITH VEHICLE SPEED)

JSLIA0135GB

Page 5018 of 5121

WW-6

< FUNCTION DIAGNOSIS >

FRONT WIPER AND WASHER SYSTEM

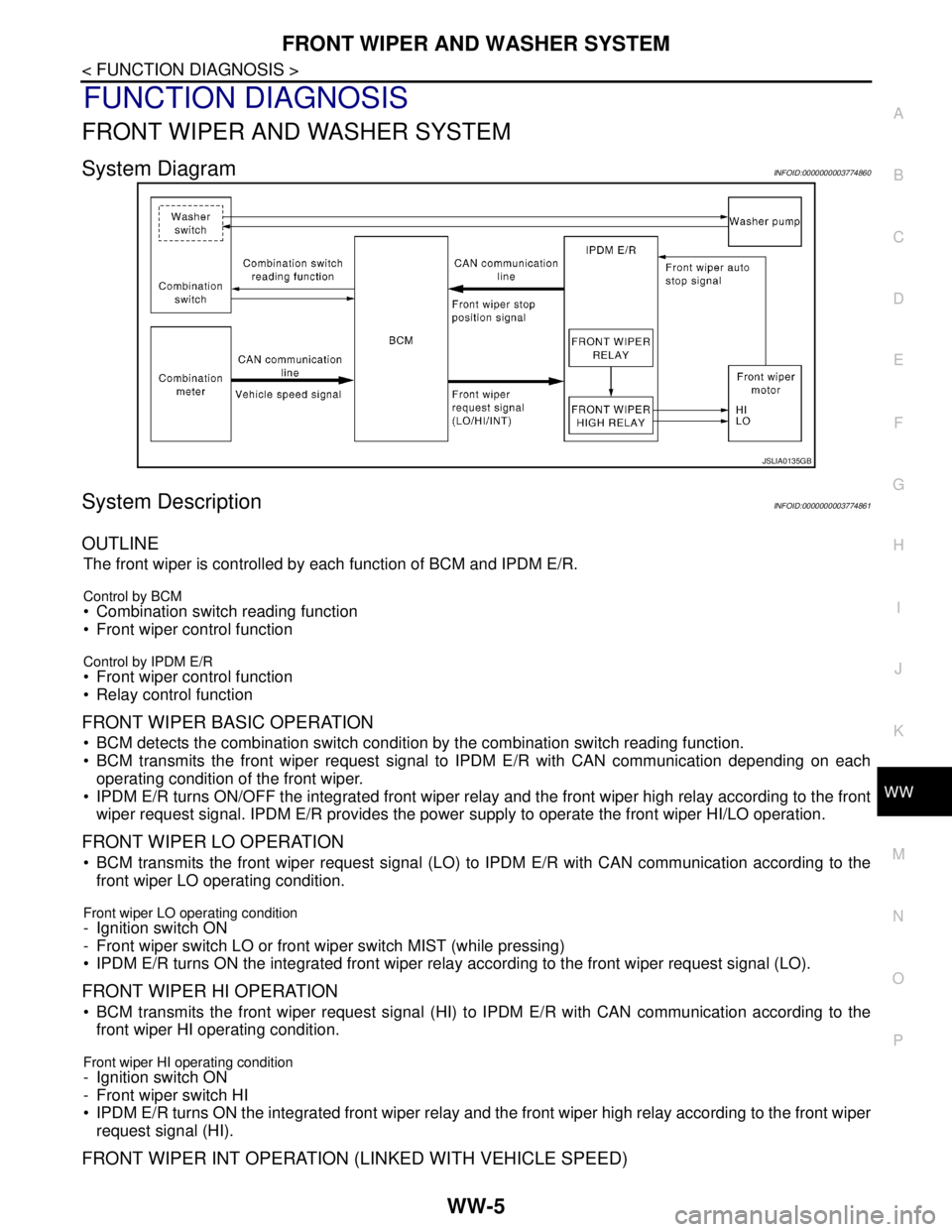

BCM transmits the front wiper request signal (INT) to IPDM E/R with CAN communication according to the

front wiper INT operation condition and the intermittent operation delay interval judged value.

Front wiper INT operating condition- Ignition switch ON

- Front wiper switch INT

Intermittent operation delay interval judgment- BCM calculates the intermittent operation delay interval from the following

Vehicle speed signal (received from the combination meter with CAN communication)

Wiper intermittent dial position

IPDM E/R turns the integrated front wiper relay ON so that the front wiper is operated only once according to

the front wiper request signal (INT).

BCM detects stop position/except stop position of the front wiper motor according to the front wiper stop

position signal received from IPDM E/R with CAN communication.

BCM transmits the front wiper request signal (INT) again after the intermittent operation delay interval after

the front wiper motor is stopped.

FRONT WIPER AUTO STOP OPERATION

BCM stops transmitting the front wiper request signal when the front wiper switch is turned OFF.

IPDM E/R detects the front wiper stop position signal from the front wiper motor and detects the front wiper

motor position (stop position/except stop position).

Wiper intermittent

dial positionIntermittent

operation

intervalIntermittent operation delay Interval (s)

Vehicle speed

0 – 5 km/h

(0 – 3.1 MPH)5 – 35 km/h

(3.1 – 21.7 MPH)35 – 65 km/h

(21.7 – 40.4 MPH)65 km/h (40.4 MPH)

or more

1

Short

↑

↓

Long0.8 0.6 0.4 0.24

24321.2

3107.553

4161284.8

5 2418127.2

6 3224169.6

7 4231.52112.6

JPLIA0094GB

Page 5019 of 5121

FRONT WIPER AND WASHER SYSTEM

WW-7

< FUNCTION DIAGNOSIS >

C

D

E

F

G

H

I

J

K

MA

B

WW

N

O

P

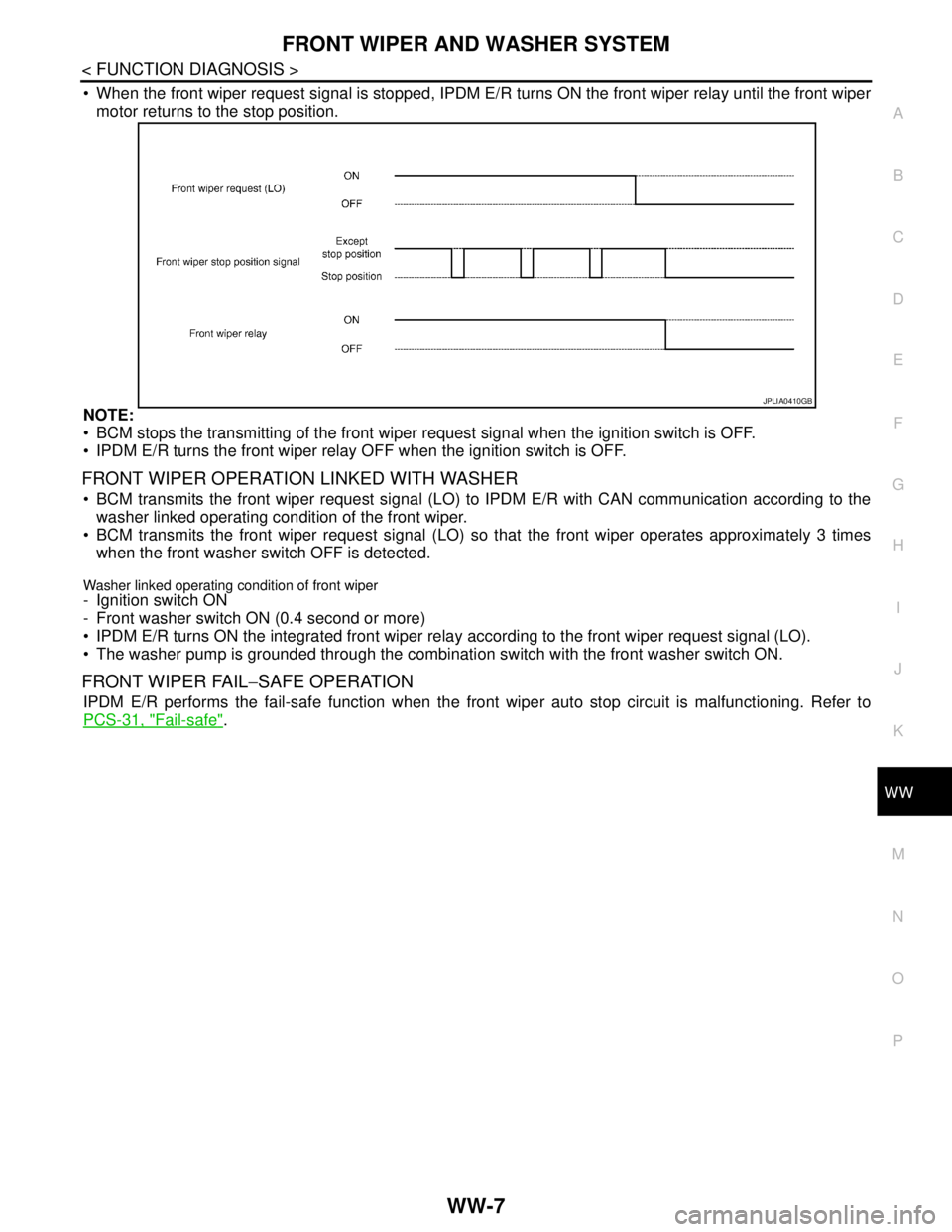

When the front wiper request signal is stopped, IPDM E/R turns ON the front wiper relay until the front wiper

motor returns to the stop position.

NOTE:

BCM stops the transmitting of the front wiper request signal when the ignition switch is OFF.

IPDM E/R turns the front wiper relay OFF when the ignition switch is OFF.

FRONT WIPER OPERATION LINKED WITH WASHER

BCM transmits the front wiper request signal (LO) to IPDM E/R with CAN communication according to the

washer linked operating condition of the front wiper.

BCM transmits the front wiper request signal (LO) so that the front wiper operates approximately 3 times

when the front washer switch OFF is detected.

Washer linked operating condition of front wiper

- Ignition switch ON

- Front washer switch ON (0.4 second or more)

IPDM E/R turns ON the integrated front wiper relay according to the front wiper request signal (LO).

The washer pump is grounded through the combination switch with the front washer switch ON.

FRONT WIPER FAIL−SAFE OPERATION

IPDM E/R performs the fail-safe function when the front wiper auto stop circuit is malfunctioning. Refer to

PCS-31, "

Fail-safe".

JPLIA0410GB

Page 5020 of 5121

WW-8

< FUNCTION DIAGNOSIS >

FRONT WIPER AND WASHER SYSTEM

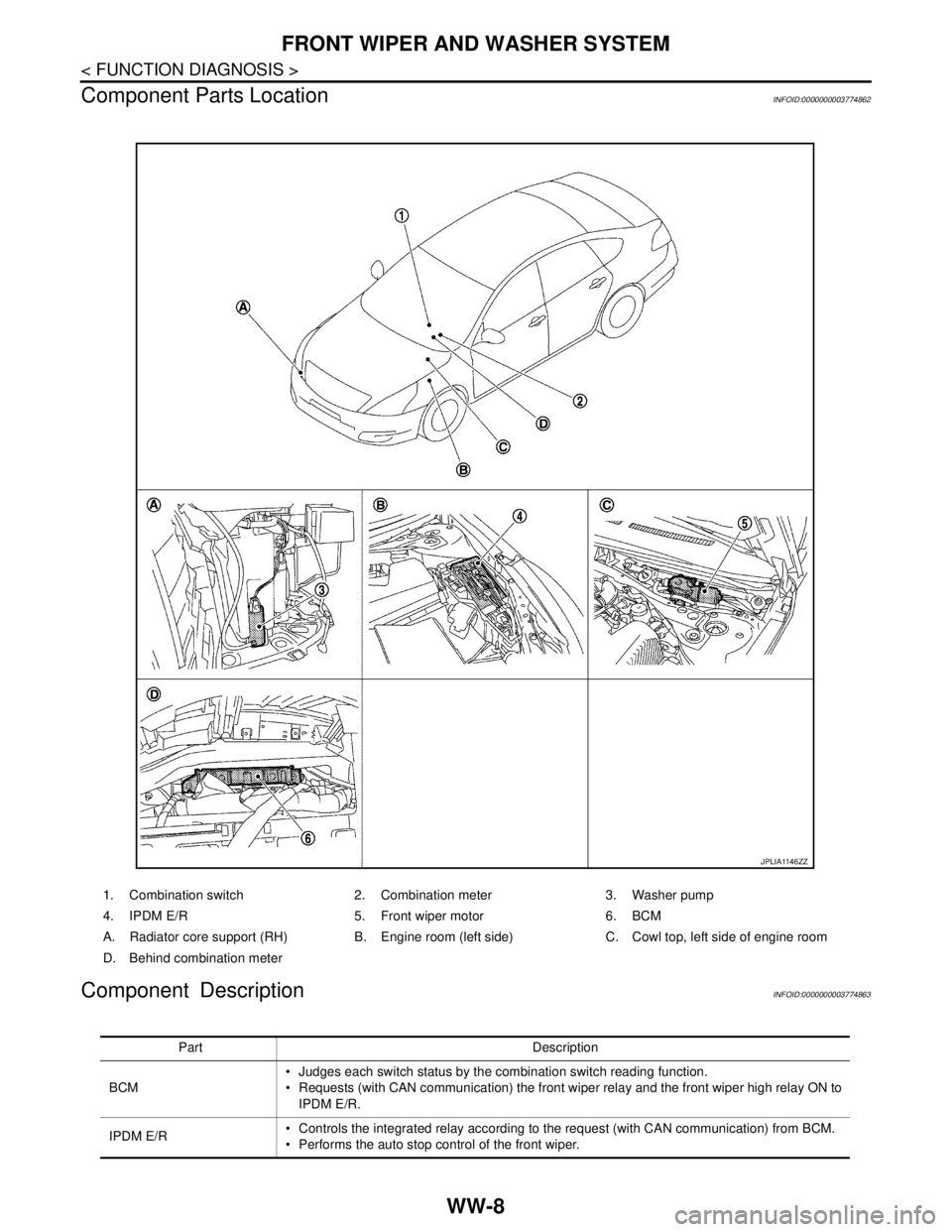

Component Parts Location

INFOID:0000000003774862

Component DescriptionINFOID:0000000003774863

1. Combination switch 2. Combination meter 3. Washer pump

4. IPDM E/R 5. Front wiper motor 6. BCM

A. Radiator core support (RH) B. Engine room (left side) C. Cowl top, left side of engine room

D. Behind combination meter

JPLIA1146ZZ

Part Description

BCM Judges each switch status by the combination switch reading function.

Requests (with CAN communication) the front wiper relay and the front wiper high relay ON to

IPDM E/R.

IPDM E/R Controls the integrated relay according to the request (with CAN communication) from BCM.

Performs the auto stop control of the front wiper.