low oil pressure NISSAN TEANA 2008 Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 2580 of 5121

COMPRESSOR SYSTEM SYMPTOMS

HA-11

< SYMPTOM DIAGNOSIS >

C

D

E

F

G

H

J

K

L

MA

B

HA

N

O

P

COMPRESSOR SYSTEM SYMPTOMS

Symptom TableINFOID:0000000003795808

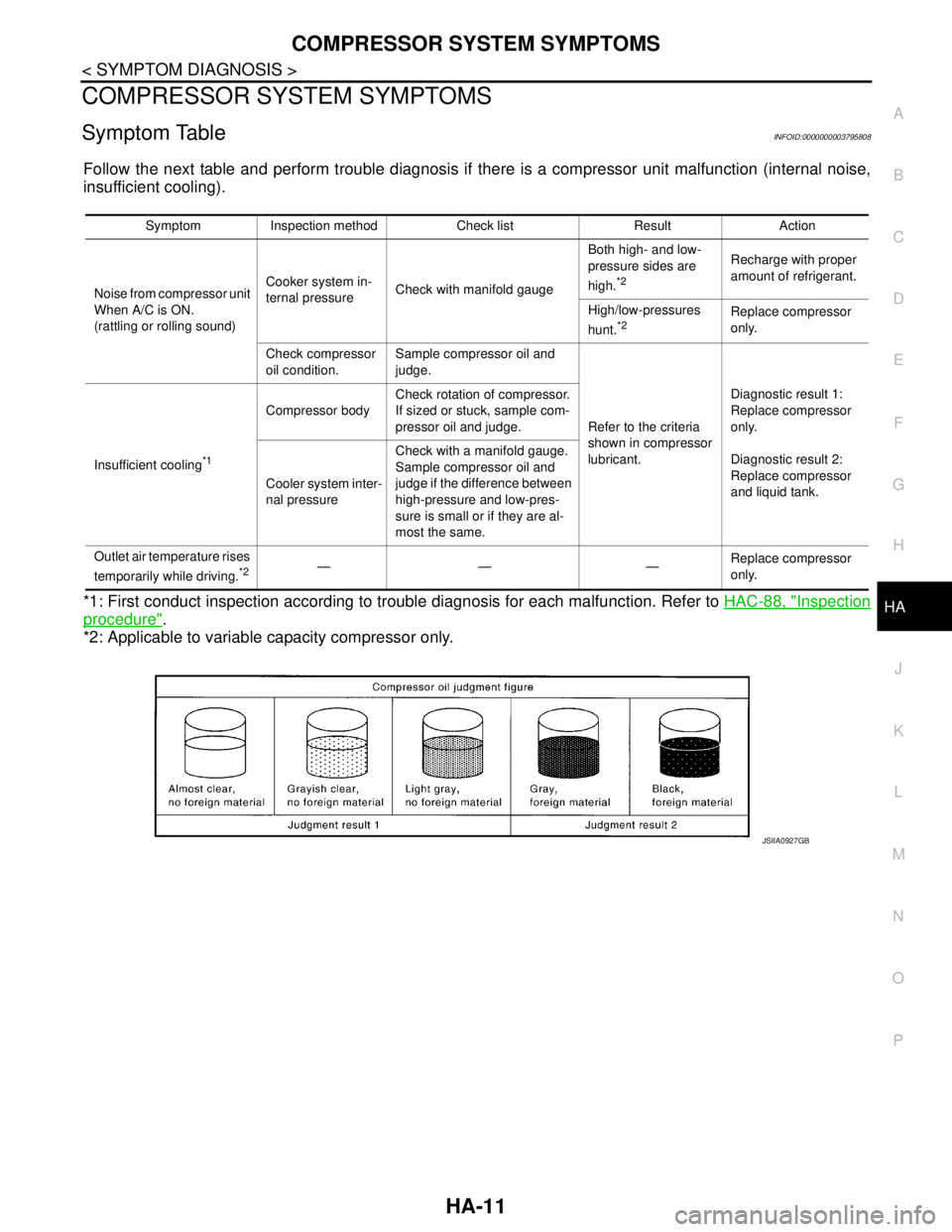

Follow the next table and perform trouble diagnosis if there is a compressor unit malfunction (internal noise,

insufficient cooling).

*1: First conduct inspection according to trouble diagnosis for each malfunction. Refer to HAC-88, "

Inspection

procedure".

*2: Applicable to variable capacity compressor only.

Symptom Inspection method Check list Result Action

Noise from compressor unit

When A/C is ON.

(rattling or rolling sound)Cooker system in-

ternal pressureCheck with manifold gaugeBoth high- and low-

pressure sides are

high.

*2

Recharge with proper

amount of refrigerant.

High/low-pressures

hunt.

*2Replace compressor

only.

Check compressor

oil condition.Sample compressor oil and

judge.

Refer to the criteria

shown in compressor

lubricant.Diagnostic result 1:

Replace compressor

only.

Diagnostic result 2:

Replace compressor

and liquid tank. Insufficient cooling

*1

Compressor bodyCheck rotation of compressor.

If sized or stuck, sample com-

pressor oil and judge.

Cooler system inter-

nal pressureCheck with a manifold gauge.

Sample compressor oil and

judge if the difference between

high-pressure and low-pres-

sure is small or if they are al-

most the same.

Outlet air temperature rises

temporarily while driving.

*2—— —Replace compressor

only.

JSIIA0927GB

Page 2584 of 5121

PRECAUTIONS

HA-15

< PRECAUTION >

C

D

E

F

G

H

J

K

L

MA

B

HA

N

O

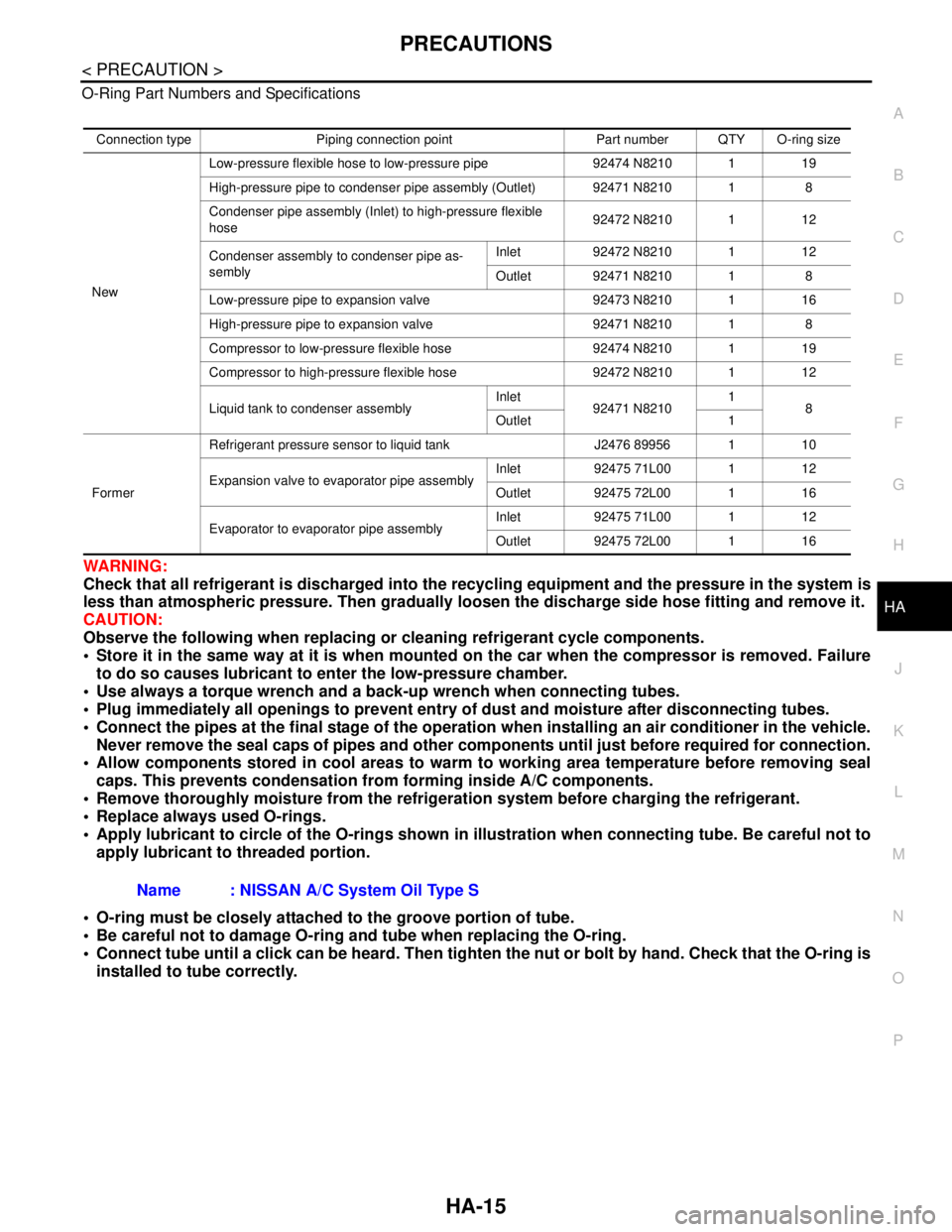

P O-Ring Part Numbers and Specifications

WARNING:

Check that all refrigerant is discharged into the recycling equipment and the pressure in the system is

less than atmospheric pressure. Then gradually loosen the discharge side hose fitting and remove it.

CAUTION:

Observe the following when replacing or cleaning refrigerant cycle components.

Store it in the same way at it is when mounted on the car when the compressor is removed. Failure

to do so causes lubricant to enter the low-pressure chamber.

Use always a torque wrench and a back-up wrench when connecting tubes.

Plug immediately all openings to prevent entry of dust and moisture after disconnecting tubes.

Connect the pipes at the final stage of the operation when installing an air conditioner in the vehicle.

Never remove the seal caps of pipes and other components until just before required for connection.

Allow components stored in cool areas to warm to working area temperature before removing seal

caps. This prevents condensation from forming inside A/C components.

Remove thoroughly moisture from the refrigeration system before charging the refrigerant.

Replace always used O-rings.

Apply lubricant to circle of the O-rings shown in illustration when connecting tube. Be careful not to

apply lubricant to threaded portion.

O-ring must be closely attached to the groove portion of tube.

Be careful not to damage O-ring and tube when replacing the O-ring.

Connect tube until a click can be heard. Then tighten the nut or bolt by hand. Check that the O-ring is

installed to tube correctly.

Connection type Piping connection point Part number QTY O-ring size

NewLow-pressure flexible hose to low-pressure pipe 92474 N8210 1 19

High-pressure pipe to condenser pipe assembly (Outlet) 92471 N8210 1 8

Condenser pipe assembly (Inlet) to high-pressure flexible

hose92472 N8210 1 12

Condenser assembly to condenser pipe as-

semblyInlet 92472 N8210 1 12

Outlet 92471 N8210 1 8

Low-pressure pipe to expansion valve 92473 N8210 1 16

High-pressure pipe to expansion valve 92471 N8210 1 8

Compressor to low-pressure flexible hose 92474 N8210 1 19

Compressor to high-pressure flexible hose 92472 N8210 1 12

Liquid tank to condenser assemblyInlet

92471 N82101

8

Outlet 1

FormerRefrigerant pressure sensor to liquid tank J2476 89956 1 10

Expansion valve to evaporator pipe assemblyInlet 92475 71L00 1 12

Outlet 92475 72L00 1 16

Evaporator to evaporator pipe assemblyInlet 92475 71L00 1 12

Outlet 92475 72L00 1 16

Name : NISSAN A/C System Oil Type S

Page 2591 of 5121

HA-22

< PREPARATION >

PREPARATION

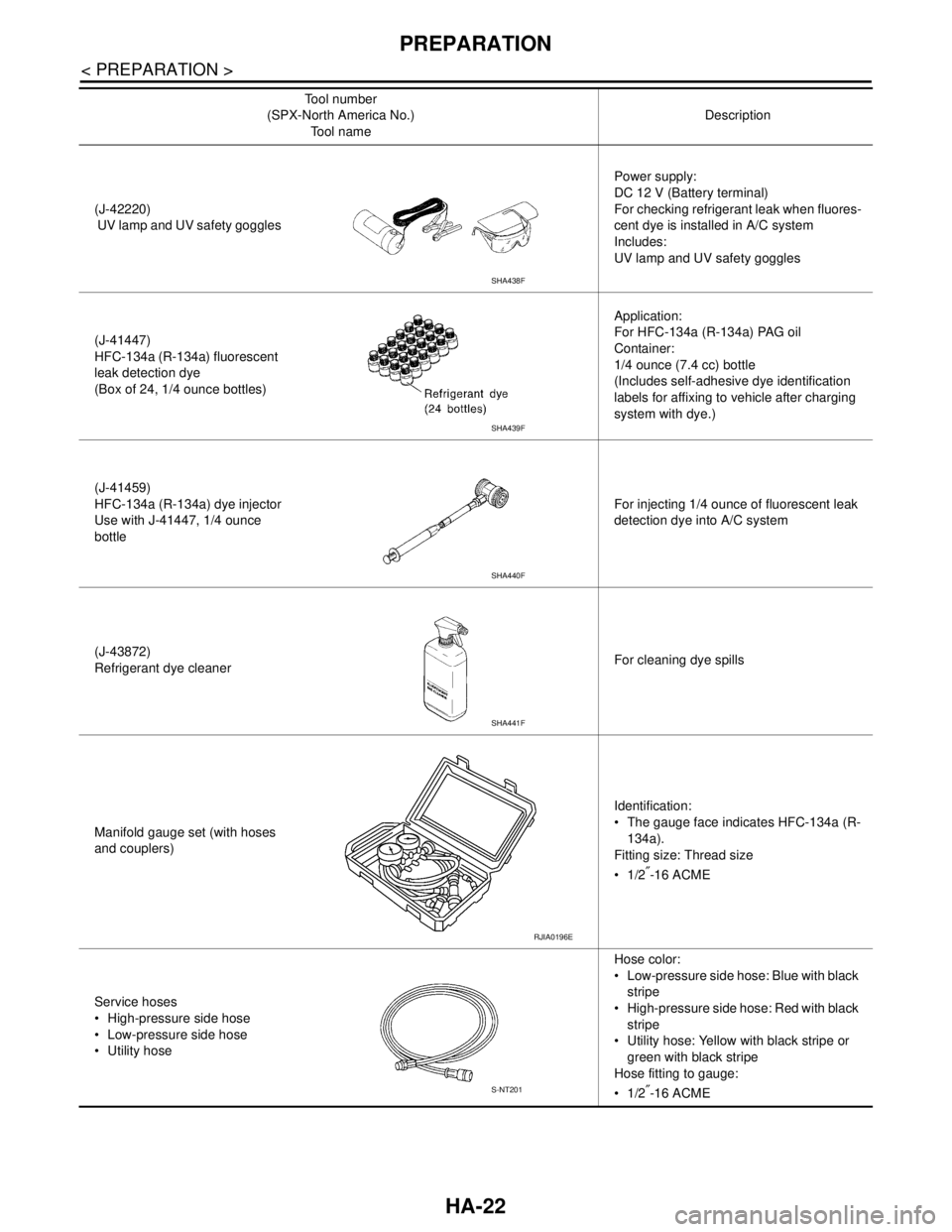

(J-42220)

UV lamp and UV safety gogglesPower supply:

DC 12 V (Battery terminal)

For checking refrigerant leak when fluores-

cent dye is installed in A/C system

Includes:

UV lamp and UV safety goggles

(J-41447)

HFC-134a (R-134a) fluorescent

leak detection dye

(Box of 24, 1/4 ounce bottles)Application:

For HFC-134a (R-134a) PAG oil

Container:

1/4 ounce (7.4 cc) bottle

(Includes self-adhesive dye identification

labels for affixing to vehicle after charging

system with dye.)

(J-41459)

HFC-134a (R-134a) dye injector

Use with J-41447, 1/4 ounce

bottleFor injecting 1/4 ounce of fluorescent leak

detection dye into A/C system

(J-43872)

Refrigerant dye cleanerFor cleaning dye spills

Manifold gauge set (with hoses

and couplers)Identification:

The gauge face indicates HFC-134a (R-

134a).

Fitting size: Thread size

1/2

″-16 ACME

Service hoses

High-pressure side hose

Low-pressure side hose

Utility hoseHose color:

Low-pressure side hose: Blue with black

stripe

High-pressure side hose: Red with black

stripe

Utility hose: Yellow with black stripe or

green with black stripe

Hose fitting to gauge:

1/2

″-16 ACME Tool number

(SPX-North America No.)

Tool nameDescription

SHA438F

SHA439F

SHA440F

SHA441F

RJIA0196E

S-NT201

Page 2592 of 5121

PREPARATION

HA-23

< PREPARATION >

C

D

E

F

G

H

J

K

L

MA

B

HA

N

O

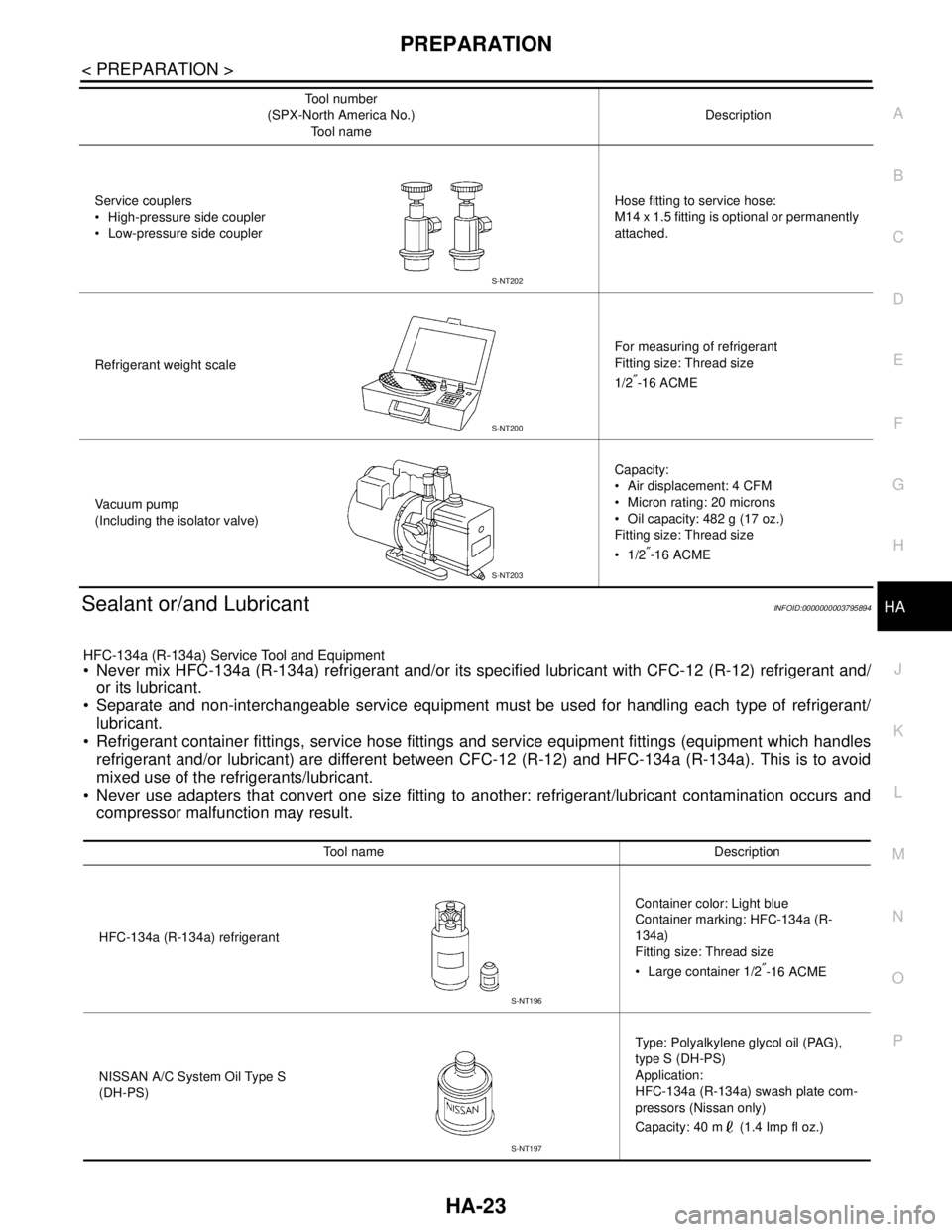

PSealant or/and LubricantINFOID:0000000003795894

HFC-134a (R-134a) Service Tool and Equipment Never mix HFC-134a (R-134a) refrigerant and/or its specified lubricant with CFC-12 (R-12) refrigerant and/

or its lubricant.

Separate and non-interchangeable service equipment must be used for handling each type of refrigerant/

lubricant.

Refrigerant container fittings, service hose fittings and service equipment fittings (equipment which handles

refrigerant and/or lubricant) are different between CFC-12 (R-12) and HFC-134a (R-134a). This is to avoid

mixed use of the refrigerants/lubricant.

Never use adapters that convert one size fitting to another: refrigerant/lubricant contamination occurs and

compressor malfunction may result.

Service couplers

High-pressure side coupler

Low-pressure side couplerHose fitting to service hose:

M14 x 1.5 fitting is optional or permanently

attached.

Refrigerant weight scaleFor measuring of refrigerant

Fitting size: Thread size

1/2

″-16 ACME

Va c u u m p u m p

(Including the isolator valve)Capacity:

Air displacement: 4 CFM

Micron rating: 20 microns

Oil capacity: 482 g (17 oz.)

Fitting size: Thread size

1/2

″-16 ACME Tool number

(SPX-North America No.)

Tool nameDescription

S-NT202

S-NT200

S-NT203

Tool name Description

HFC-134a (R-134a) refrigerantContainer color: Light blue

Container marking: HFC-134a (R-

134a)

Fitting size: Thread size

Large container 1/2

″-16 ACME

NISSAN A/C System Oil Type S

(DH-PS)Type: Polyalkylene glycol oil (PAG),

type S (DH-PS)

Application:

HFC-134a (R-134a) swash plate com-

pressors (Nissan only)

Capacity: 40 m (1.4 Imp fl oz.)

S-NT196

S-NT197

Page 2594 of 5121

REFRIGERANT

HA-25

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

J

K

L

MA

B

HA

N

O

P

WARNING:

Never breath A/C refrigerant and lubricant vapor or mist. Exposure may irritate eyes, nose and throat.

Use only approved recovery/recycling recharging equipment to discharge HFC-134a (R-134a) refriger-

ant. Ventilate work area before resuming service if accidental system discharge occurs. Additional

health and safety information may be obtained from refrigerant and lubricant manufacturers.

1.CHECK A/C SYSTEM

1. Check that A/C system operates normally. Refer to the following.

-HAC-8, "

Description & Inspection" (WITHOUT 7 INCH DISPLAY)

-HAC-108, "

WITHOUT INTELLIGENT AIR CONDITIONER SYSTEM : Description & Inspection" [WITH 7

INCH DISPLAY (WITHOUT INTELLIGENT AIR CONDITIONER SYSTEM)]

-HAC-112, "

WITH INTELLIGENT AIR CONDITIONER SYSTEM : Description & Inspection" [WITH 7 INCH

DISPLAY (WITH INTELLIGENT AIR CONDITIONER SYSTEM)]

2. Check if there is a large amount of leakage of refrigerant or oil.

CAUTION:

Never perform the lubricant return operation if a large amount of leakage of lubricant is detected.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Check for refrigerant leakage. Refer to HA-32, "

Inspection".

2.LUBRICANT RETURN OPERATION

1. Start the engine and run it as follows.

- Engine speed: Idle - 1,200 rpm

- A/C switch: ON

- Blower speed: Max. position

- Air inlet: Recirculation (REC)

- Set temperature: FULL HOT

2. Perform lubricant return operation for approximately 10 minutes.

3. Stop the engine.

>> GO TO 3.

3.CHECK RECOVERY/RECYCLING RECHARGING EQUIPMENT

1. Operate recovery/recycling recharging equipment.

CAUTION:

Follow the instructions of the manufacturer for the handling or maintenance of the equipment.

Never fill the equipment with undesignated refrigerant.

2. Check the gauge pressure of recovery/recycling recharging equipment.

Is there pressure?

YES >> GO TO 4.

NO >> GO TO 5.

4.DISCHARGE REFRIGERANT INSIDE PIPES

Discharge the refrigerant from the high-pressure hose and low-pressure hose of recovery/recycling recharging

equipment.

>> GO TO 5.

5.CONNECT RECOVERY/RECYCLING RECHARGING EQUIPMENT

1. Remove the service valve caps from the vehicle.

2. Connect recovery/recycling recharging equipment to the service valves.

>> GO TO 6.

6.DISCHARGE REFRIGERANT FROM THE VEHICLE

Operate recovery/recycling recharging equipment to discharge the refrigerant from the vehicle.

Page 2601 of 5121

HA-32

< ON-VEHICLE MAINTENANCE >

FLUORESCENT LEAK DETECTOR

FLUORESCENT LEAK DETECTOR

InspectionINFOID:0000000003795981

CHECKING SYSTEM FOR LEAKAGES USING THE FLUORESCENT LEAK DETECTOR

1. Check A/C system for leakages using the UV lamp and safety goggles (SST: J-42220) in a low sunlight

area (area without windows preferable). Illuminate all components, fittings and lines. The dye appears as

a bright green/yellow area at the point of leakage. Fluorescent dye observed at the evaporator drain open-

ing indicates an evaporator core assembly (tubes, core or expansion valve) leakage.

2. Use an adjustable mirror or wipe the area with a clean shop rag or cloth, with the UV lamp for dye residue

if the suspected area is difficult to see.

3. Remove any residual dye using dye cleaner (SST: J-43872) to prevent future misdiagnosis after the leak-

age is repaired.

4. Perform a system performance check and verify the leakage repair with an approved electrical leak detec-

tor.

NOTE:

Other gases in the work area or substances on the A/C components, for example, anti-freeze, windshield

washer fluid, solvents and lubricants, may falsely trigger the leak detector. Make sure the surfaces to be

checked are clean.

Clean with a dry cloth or blow off with shop air.

Do not allow the sensor tip of the detector to contact with any substance. This may also cause false readings

and may damage the detector.

DYE INJECTION

(This procedure is only necessary when recharging the system or when the compressor has seized and was

replaced.)

1. Check A/C system static (at rest) pressure. Pressure must be at least 345 kPa (3.45 bar, 3.52 kg/cm

2, 50

psi).

2. Pour one bottle (1/4 ounce / 7.4 cc) of the A/C refrigerant dye into the injector tool (SST: J-41459).

3. Connect the injector tool to the A/C low-pressure side service valve.

4. Start the engine. Then switch A/C ON.

5. Inject one bottle (1/4 ounce / 7.4 cc) of fluorescent dye through the low-pressure service valve using dye

injector tool (SST: J-41459) (refer to the manufacture’s operating instructions) when the A/C operating

(compressor running).

6. Disconnect the injector tool from the service valve with the engine still running.

CAUTION:

Be careful when replacing the A/C system or a component, pour the dye directly into the open sys-

tem connection and proceed with the service procedures.

7. Operate the A/C system for a minimum of 20 minutes to mix the dye with the system oil. Depending on the

leakage size, operating conditions and location of the leakage, it may take from minutes to days for the

dye to penetrate a leakage and become visible.

8. Attach a blue label if necessary.

Page 2608 of 5121

LOW-PRESSURE FLEXIBLE HOSE

HA-39

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

J

K

L

MA

B

HA

N

O

P

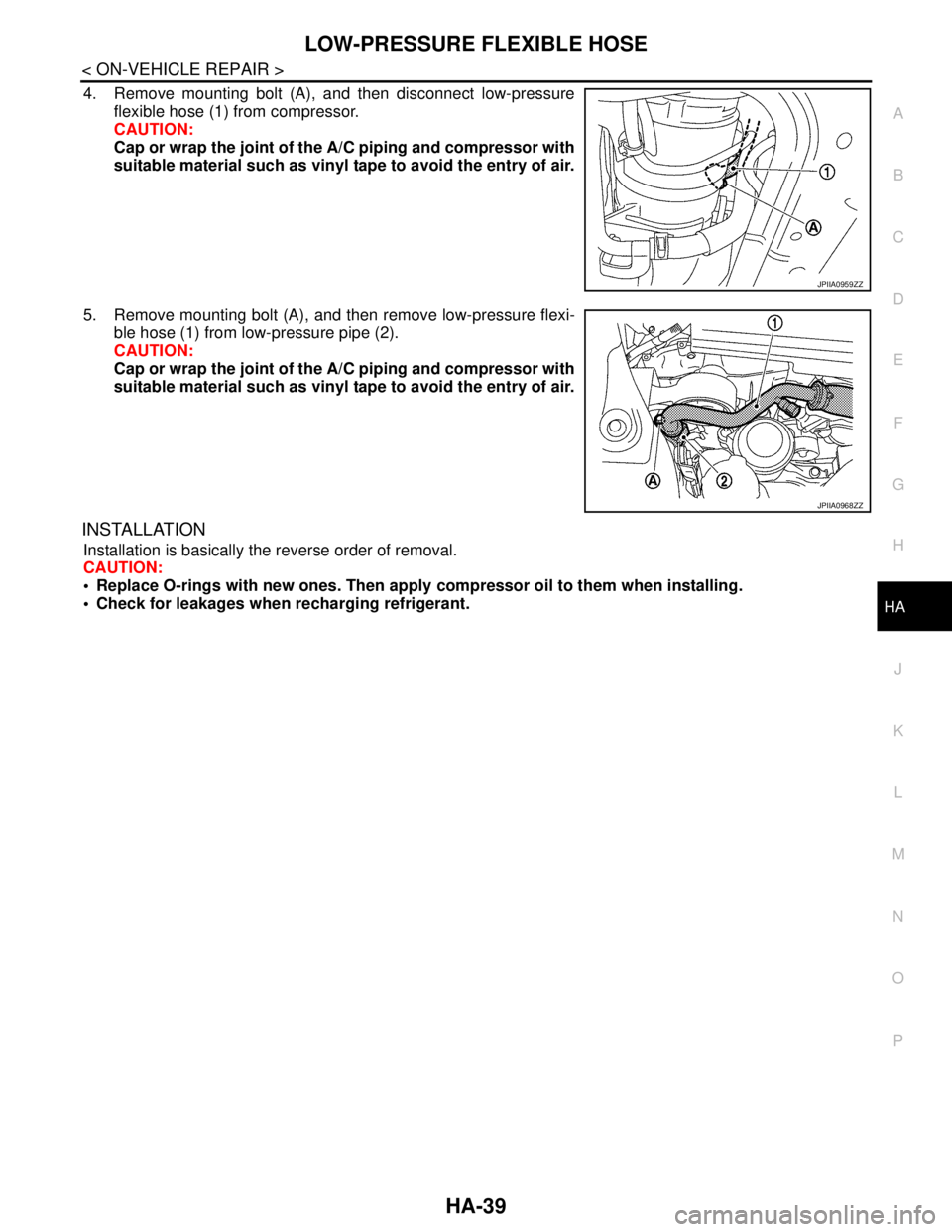

4. Remove mounting bolt (A), and then disconnect low-pressure

flexible hose (1) from compressor.

CAUTION:

Cap or wrap the joint of the A/C piping and compressor with

suitable material such as vinyl tape to avoid the entry of air.

5. Remove mounting bolt (A), and then remove low-pressure flexi-

ble hose (1) from low-pressure pipe (2).

CAUTION:

Cap or wrap the joint of the A/C piping and compressor with

suitable material such as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is basically the reverse order of removal.

CAUTION:

Replace O-rings with new ones. Then apply compressor oil to them when installing.

Check for leakages when recharging refrigerant.

JPIIA0959ZZ

JPIIA0968ZZ

Page 2612 of 5121

LOW-PRESSURE PIPE

HA-43

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

J

K

L

MA

B

HA

N

O

P

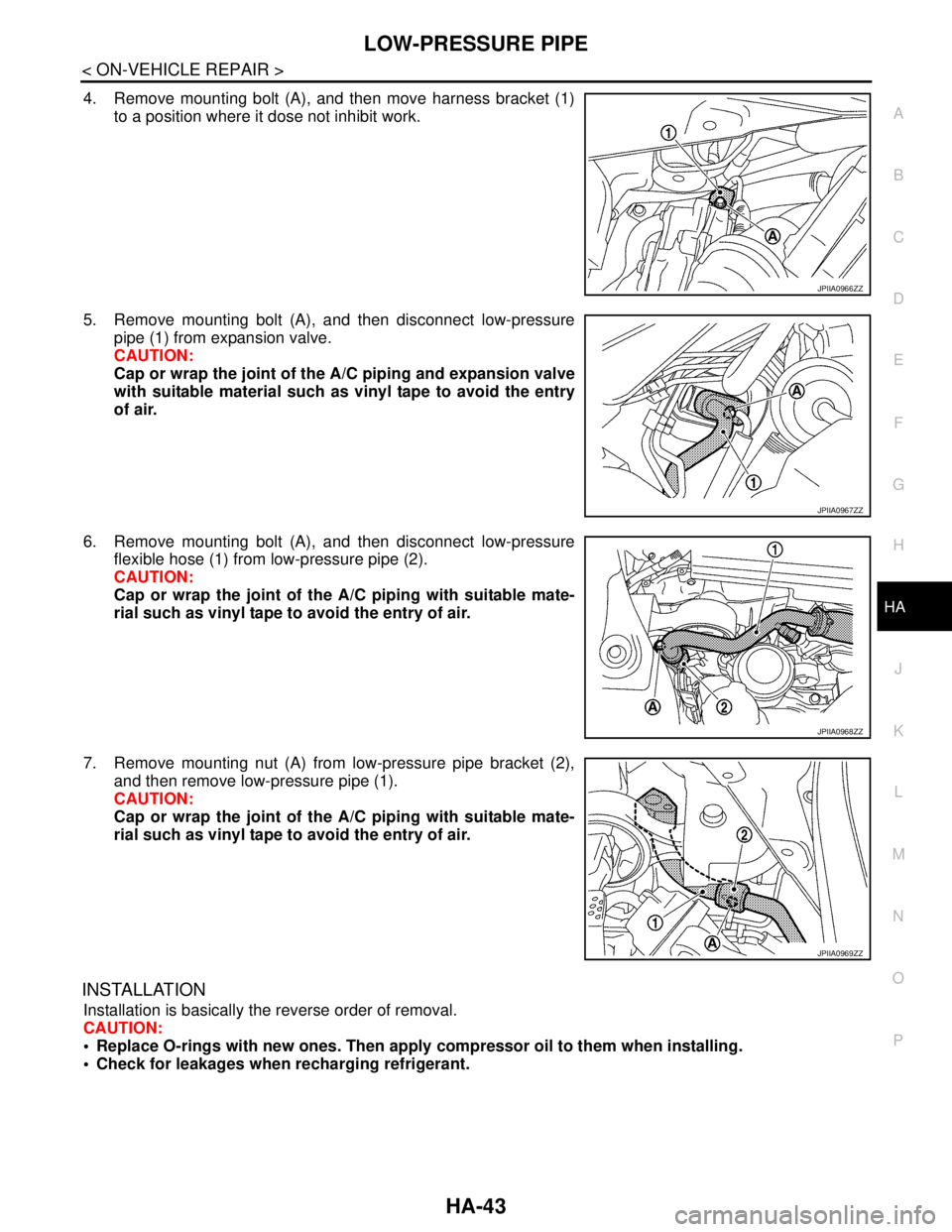

4. Remove mounting bolt (A), and then move harness bracket (1)

to a position where it dose not inhibit work.

5. Remove mounting bolt (A), and then disconnect low-pressure

pipe (1) from expansion valve.

CAUTION:

Cap or wrap the joint of the A/C piping and expansion valve

with suitable material such as vinyl tape to avoid the entry

of air.

6. Remove mounting bolt (A), and then disconnect low-pressure

flexible hose (1) from low-pressure pipe (2).

CAUTION:

Cap or wrap the joint of the A/C piping with suitable mate-

rial such as vinyl tape to avoid the entry of air.

7. Remove mounting nut (A) from low-pressure pipe bracket (2),

and then remove low-pressure pipe (1).

CAUTION:

Cap or wrap the joint of the A/C piping with suitable mate-

rial such as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is basically the reverse order of removal.

CAUTION:

Replace O-rings with new ones. Then apply compressor oil to them when installing.

Check for leakages when recharging refrigerant.

JPIIA0966ZZ

JPIIA0967ZZ

JPIIA0968ZZ

JPIIA0969ZZ

Page 2619 of 5121

HA-50

< ON-VEHICLE REPAIR >

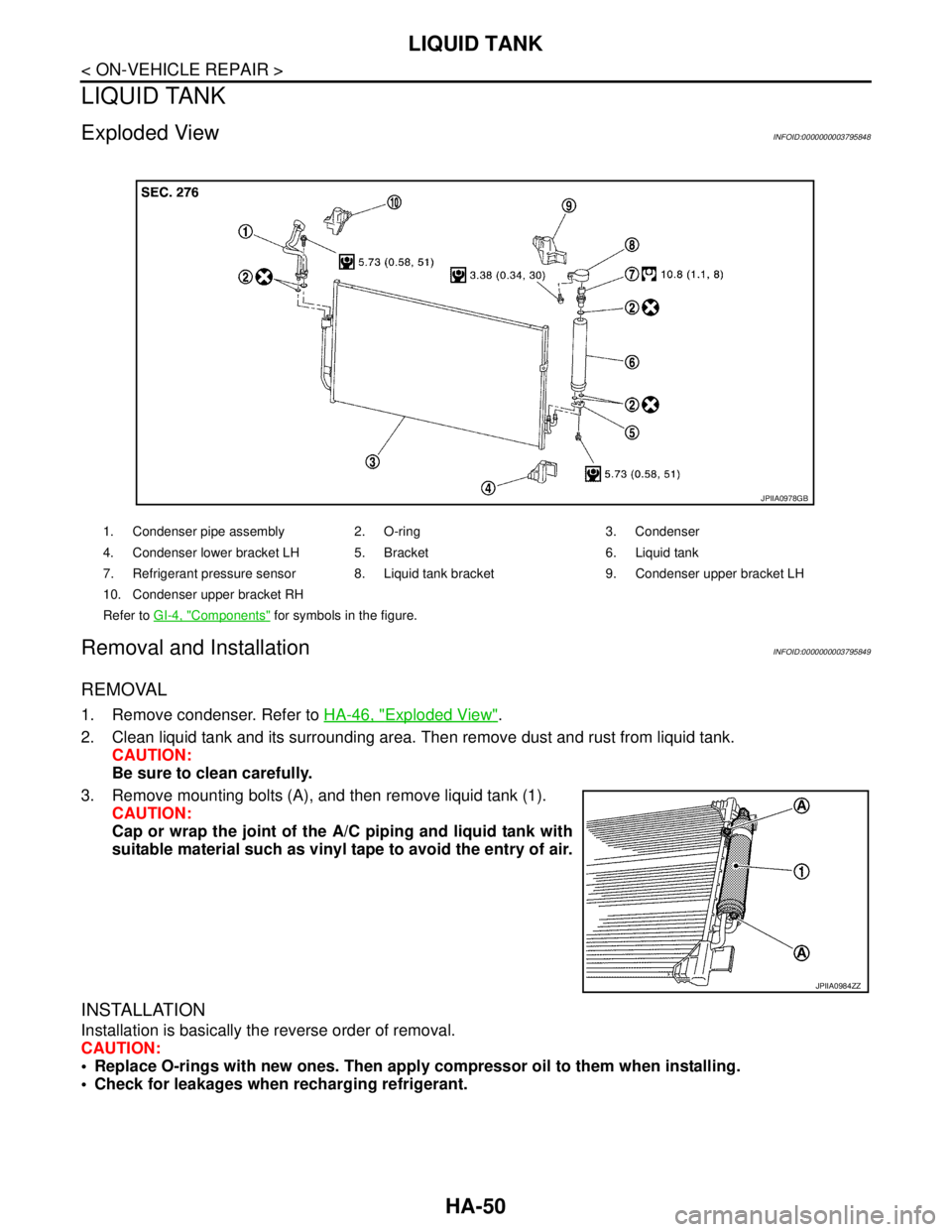

LIQUID TANK

LIQUID TANK

Exploded ViewINFOID:0000000003795848

Removal and InstallationINFOID:0000000003795849

REMOVAL

1. Remove condenser. Refer to HA-46, "Exploded View".

2. Clean liquid tank and its surrounding area. Then remove dust and rust from liquid tank.

CAUTION:

Be sure to clean carefully.

3. Remove mounting bolts (A), and then remove liquid tank (1).

CAUTION:

Cap or wrap the joint of the A/C piping and liquid tank with

suitable material such as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is basically the reverse order of removal.

CAUTION:

Replace O-rings with new ones. Then apply compressor oil to them when installing.

Check for leakages when recharging refrigerant.

1. Condenser pipe assembly 2. O-ring 3. Condenser

4. Condenser lower bracket LH 5. Bracket 6. Liquid tank

7. Refrigerant pressure sensor 8. Liquid tank bracket 9. Condenser upper bracket LH

10. Condenser upper bracket RH

Refer to GI-4, "

Components" for symbols in the figure.

JPIIA0978GB

JPIIA0984ZZ

Page 2620 of 5121

REFRIGERANT PRESSURE SENSOR

HA-51

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

J

K

L

MA

B

HA

N

O

P

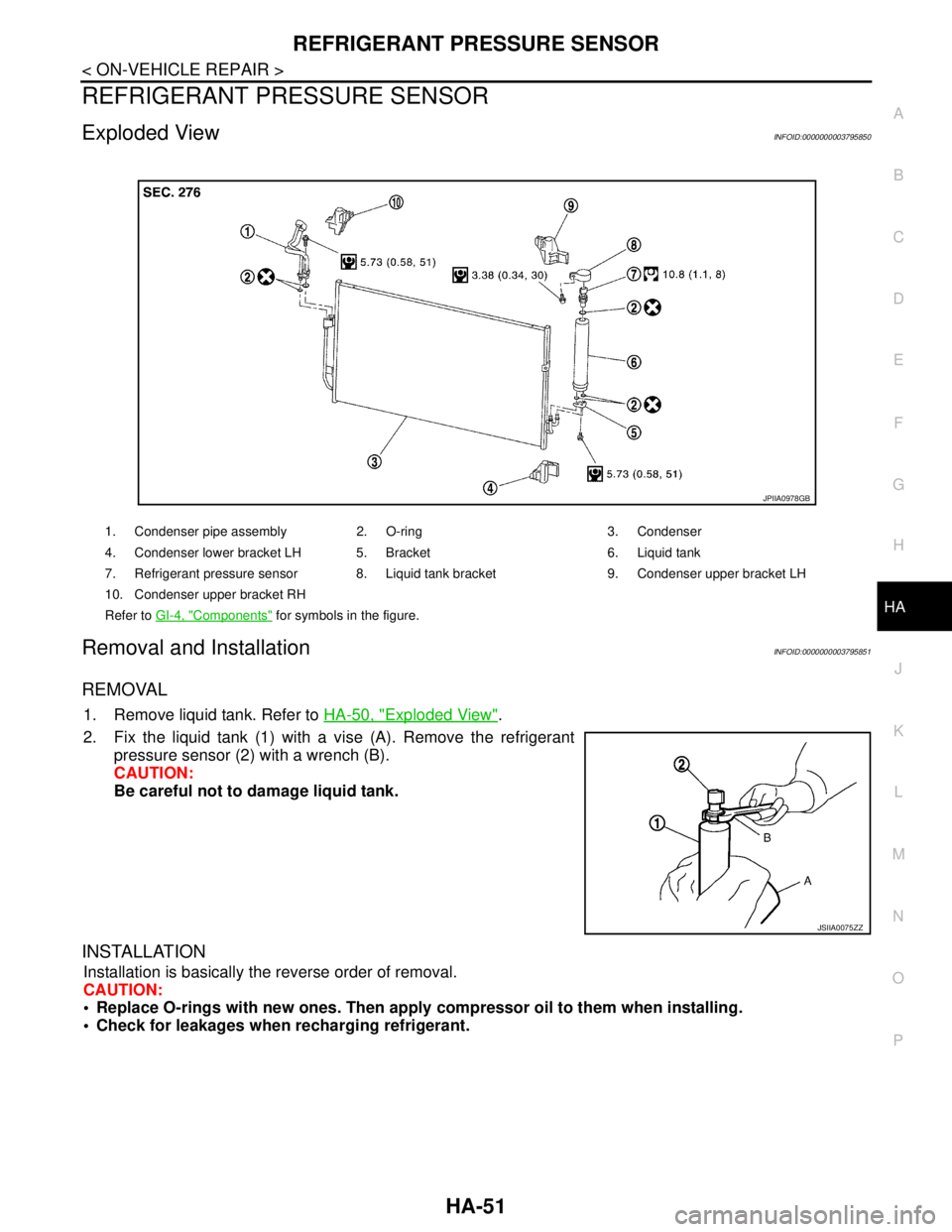

REFRIGERANT PRESSURE SENSOR

Exploded ViewINFOID:0000000003795850

Removal and InstallationINFOID:0000000003795851

REMOVAL

1. Remove liquid tank. Refer to HA-50, "Exploded View".

2. Fix the liquid tank (1) with a vise (A). Remove the refrigerant

pressure sensor (2) with a wrench (B).

CAUTION:

Be careful not to damage liquid tank.

INSTALLATION

Installation is basically the reverse order of removal.

CAUTION:

Replace O-rings with new ones. Then apply compressor oil to them when installing.

Check for leakages when recharging refrigerant.

1. Condenser pipe assembly 2. O-ring 3. Condenser

4. Condenser lower bracket LH 5. Bracket 6. Liquid tank

7. Refrigerant pressure sensor 8. Liquid tank bracket 9. Condenser upper bracket LH

10. Condenser upper bracket RH

Refer to GI-4, "

Components" for symbols in the figure.

JPIIA0978GB

JSIIA0075ZZ