NISSAN TEANA 2008 Service Manual

Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 901 of 5121

PRECAUTIONS

BR-5

< PRECAUTION >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

Precaution for Procedure without Cowl Top CoverINFOID:0000000003890162

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Precaution for Brake SystemINFOID:0000000003811170

WARNING:

Clean any dust from the front brake and rear brake with a vacuum dust collector. Never blow with com-

pressed air.

CAUTION:

Only use “DOT 3 or DOT 4” brake fluid. Refer to MA-11, "

Fluids and Lubricants".

Never reuse drained brake fluid.

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with water if it gets on a painted surface.

Always clean with new brake fluid when cleaning the master cylinder, brake caliper and other com-

ponents.

Never use mineral oils such as gasoline or light oil to clean. They may damage rubber parts and

cause improper operation.

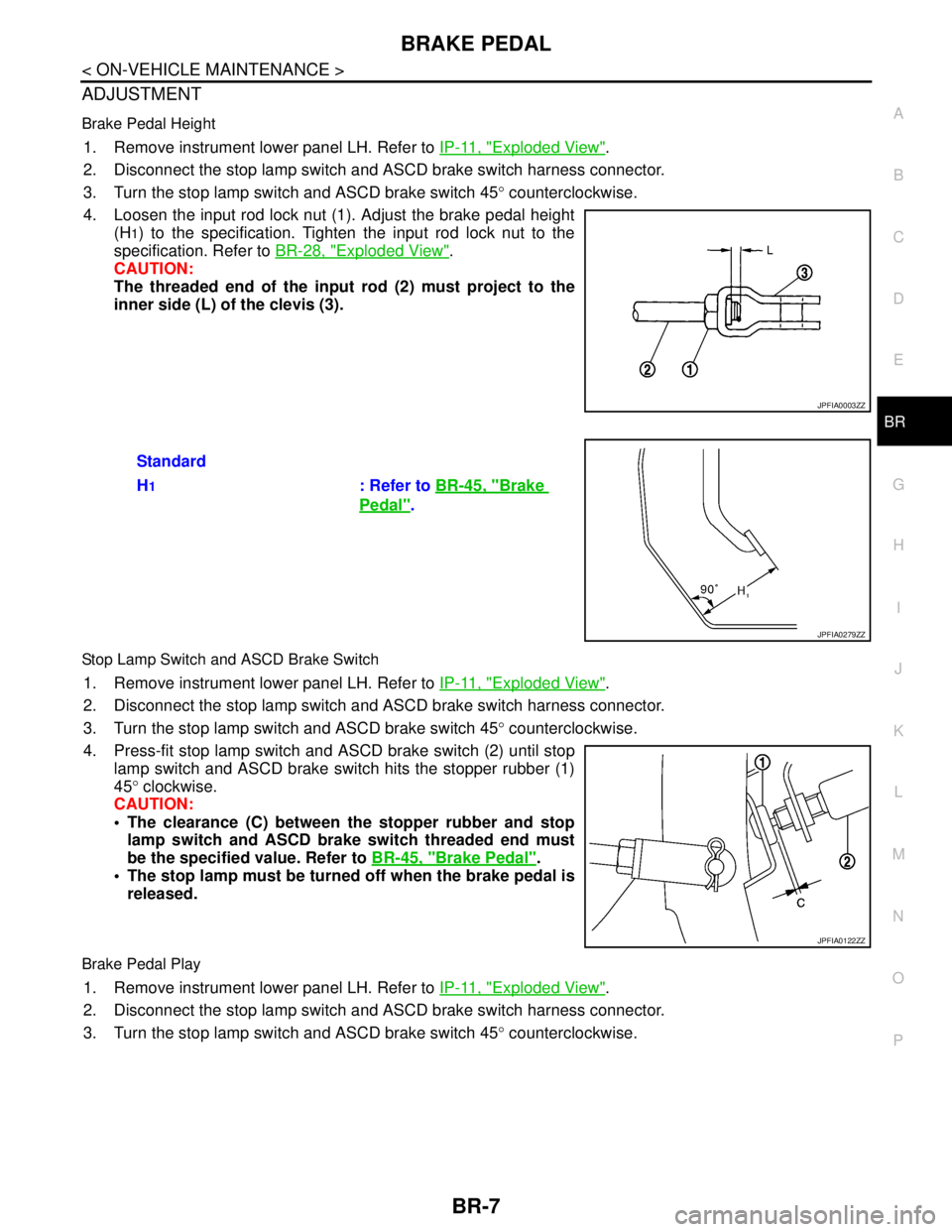

Always loosen the brake tube flare nut with a flare nut wrench.

Tighten the brake tube flare nut to the specified torque with

torque wrench (A).

Always confirm the specified tightening torque when install-

ing the brake pipes.

Turn the ignition switch OFF and disconnect the ABS actuator

and electric unit (control unit) connector or the battery nega-

tive terminal before performing the work.

Check that no brake fluid leakage is present after replacing

the parts.

Burnish the brake contact surfaces after refinishing or replac-

ing rotors, after replacing pads, or if a soft pedal occurs at

very low mileage.

- Front brake pad: refer to BR-13, "

BRAKE PAD : Inspection and Adjustment".

- Front disc rotor: refer to BR-13, "

DISC ROTOR : Inspection and Adjustment".

- Rear brake pad: refer to BR-15, "

BRAKE PAD : Inspection and Adjustment".

- Rear disc rotor: refer to BR-15, "

DISC ROTOR : Inspection and Adjustment".

PIIB3706J

JPFIA0061ZZ

Page 902 of 5121

BR-6

< ON-VEHICLE MAINTENANCE >

BRAKE PEDAL

ON-VEHICLE MAINTENANCE

BRAKE PEDAL

Inspection and AdjustmentINFOID:0000000003811172

INSPECTION

Brake Pedal Height

Check the brake pedal height (H1) between the dash lower panel (1)

and the brake pedal upper surface.

CAUTION:

Remove the floor trim.

Stop Lamp Switch and ASCD Brake Switch

Check the clearance (C) between stopper rubber (1) and stop lamp

switch and ASCD brake switch (2) threaded end.

CAUTION:

The stop lamp must be turned off when the brake pedal is

released.

NOTE:

Pull the brake pedal pad to make the clearance between stopper

rubber and stop lamp switch and ASCD brake switch threaded end.

Brake Pedal Play

Press the brake pedal. Check the brake pedal play (A).

Depressed Brake Pedal Height

Check the brake pedal height (H2) between the dash lower panel (1)

and the brake pedal upper surface when depressing the brake pedal

at 490 N (50 kg, 110 lb) while turning engine ON.

CAUTION:

Remove the floor trim.Standard

H

1: Refer to BR-45, "Brake

Pedal".

JPFIA0065ZZ

Standard

C : Refer to BR-45, "

Brake

Pedal".

JPFIA0122ZZ

Standard

A : Refer to BR-45, "

Brake

Pedal".

JPFIA0121ZZ

Standard

H

2: Refer to BR-45, "Brake

Pedal".

JPFIA0068ZZ

Page 903 of 5121

BRAKE PEDAL

BR-7

< ON-VEHICLE MAINTENANCE >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

ADJUSTMENT

Brake Pedal Height

1. Remove instrument lower panel LH. Refer to IP-11, "Exploded View".

2. Disconnect the stop lamp switch and ASCD brake switch harness connector.

3. Turn the stop lamp switch and ASCD brake switch 45° counterclockwise.

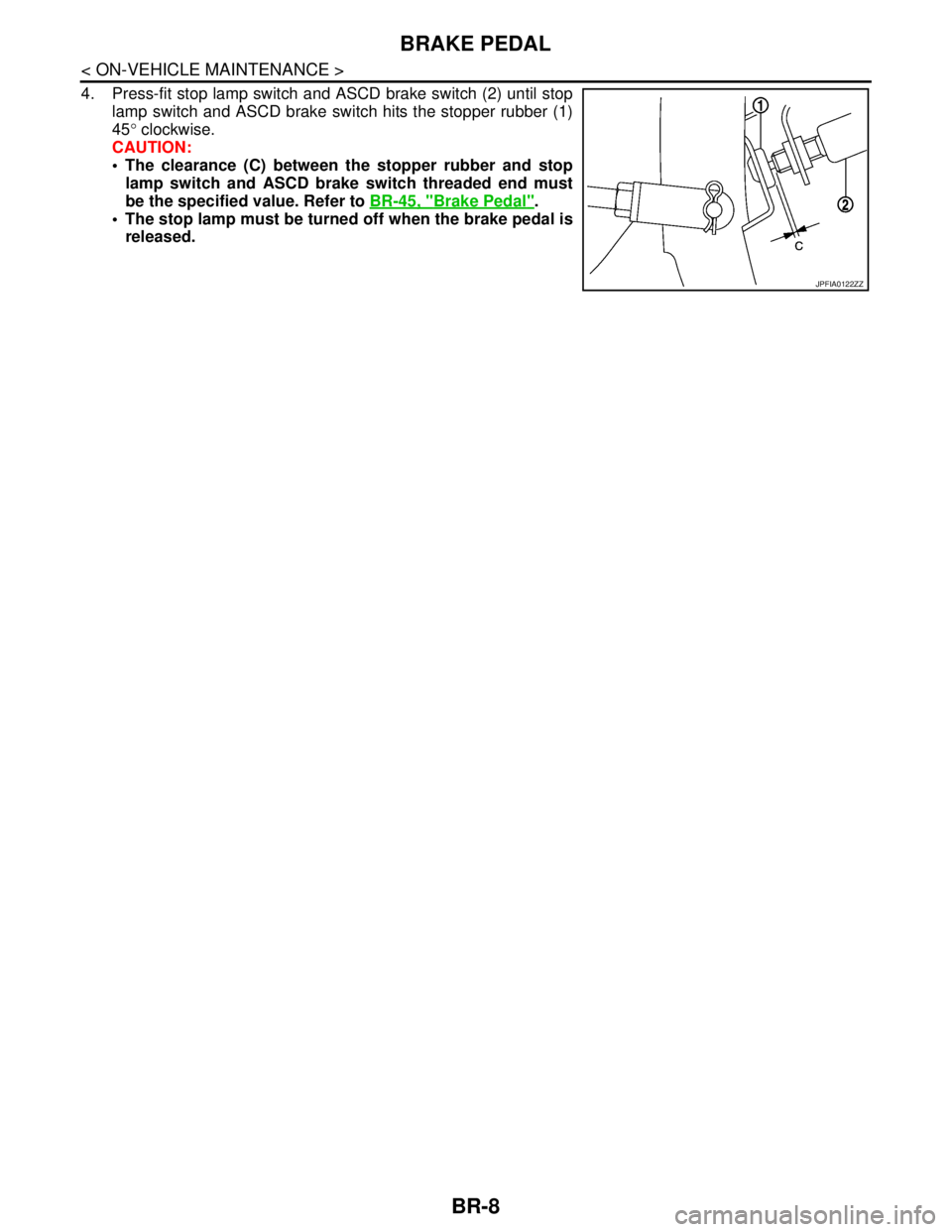

4. Loosen the input rod lock nut (1). Adjust the brake pedal height

(H

1) to the specification. Tighten the input rod lock nut to the

specification. Refer to BR-28, "

Exploded View".

CAUTION:

The threaded end of the input rod (2) must project to the

inner side (L) of the clevis (3).

Stop Lamp Switch and ASCD Brake Switch

1. Remove instrument lower panel LH. Refer to IP-11, "Exploded View".

2. Disconnect the stop lamp switch and ASCD brake switch harness connector.

3. Turn the stop lamp switch and ASCD brake switch 45° counterclockwise.

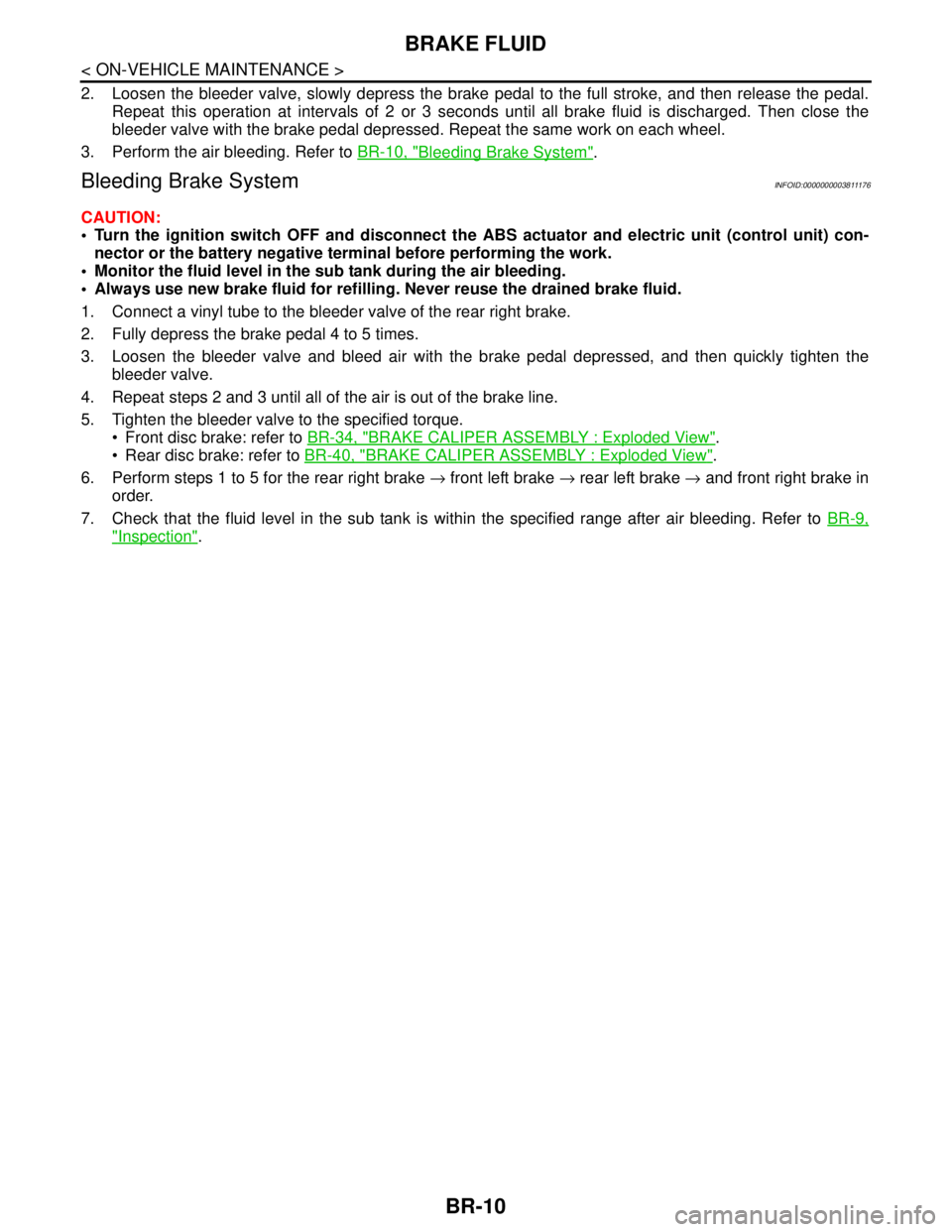

4. Press-fit stop lamp switch and ASCD brake switch (2) until stop

lamp switch and ASCD brake switch hits the stopper rubber (1)

45° clockwise.

CAUTION:

The clearance (C) between the stopper rubber and stop

lamp switch and ASCD brake switch threaded end must

be the specified value. Refer to BR-45, "

Brake Pedal".

The stop lamp must be turned off when the brake pedal is

released.

Brake Pedal Play

1. Remove instrument lower panel LH. Refer to IP-11, "Exploded View".

2. Disconnect the stop lamp switch and ASCD brake switch harness connector.

3. Turn the stop lamp switch and ASCD brake switch 45° counterclockwise.

JPFIA0003ZZ

Standard

H

1: Refer to BR-45, "Brake

Pedal".

JPFIA0279ZZ

JPFIA0122ZZ

Page 904 of 5121

BR-8

< ON-VEHICLE MAINTENANCE >

BRAKE PEDAL

4. Press-fit stop lamp switch and ASCD brake switch (2) until stop

lamp switch and ASCD brake switch hits the stopper rubber (1)

45° clockwise.

CAUTION:

The clearance (C) between the stopper rubber and stop

lamp switch and ASCD brake switch threaded end must

be the specified value. Refer to BR-45, "

Brake Pedal".

The stop lamp must be turned off when the brake pedal is

released.

JPFIA0122ZZ

Page 905 of 5121

BRAKE FLUID

BR-9

< ON-VEHICLE MAINTENANCE >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

BRAKE FLUID

InspectionINFOID:0000000003811173

BRAKE FLUID LEVEL

Check that the fluid level in the sub tank is within the specified

range (MAX – MIN lines).

Visually check for any brake fluid leakage around the sub tank,

reservoir tank and hose.

Check the brake system for any leakage if the fluid level is

extremely low (lower than MIN).

Check the brake system for fluid leakage if the warning lamp

remains illuminated even after the parking brake is released.

BRAKE LINE

1. Check brake line (tubes and hoses) for cracks, deterioration or other damage. Replace any damaged

parts.

2. Check for fluid leakage by fully depressing brake pedal while

engine is running.

CAUTION:

If leakage occurs around joints, retighten or, if necessary,

replace damaged parts.

DrainingINFOID:0000000003811174

CAUTION:

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with water if it gets on a painted surface.

Turn the ignition switch OFF and disconnect the ABS actuator and electric unit (control unit) con-

nector or the battery negative terminal before draining.

1. Connect a vinyl tube to the bleed valve.

2. Depress the brake pedal and loosen the bleeder valve to gradu-

ally discharge brake fluid.

RefillingINFOID:0000000003811175

CAUTION:

Turn the ignition switch OFF and disconnect the ABS actuator and electric unit (control unit) connec-

tor or the battery negative terminal before refilling.

1. Check that there is no foreign material in the sub tank, and refill with new brake fluid.

CAUTION:

Never reuse drained brake fluid.

JPFIA0007ZZ

SBR389C

BRA0007D

Page 906 of 5121

BR-10

< ON-VEHICLE MAINTENANCE >

BRAKE FLUID

2. Loosen the bleeder valve, slowly depress the brake pedal to the full stroke, and then release the pedal.

Repeat this operation at intervals of 2 or 3 seconds until all brake fluid is discharged. Then close the

bleeder valve with the brake pedal depressed. Repeat the same work on each wheel.

3. Perform the air bleeding. Refer to BR-10, "

Bleeding Brake System".

Bleeding Brake SystemINFOID:0000000003811176

CAUTION:

Turn the ignition switch OFF and disconnect the ABS actuator and electric unit (control unit) con-

nector or the battery negative terminal before performing the work.

Monitor the fluid level in the sub tank during the air bleeding.

Always use new brake fluid for refilling. Never reuse the drained brake fluid.

1. Connect a vinyl tube to the bleeder valve of the rear right brake.

2. Fully depress the brake pedal 4 to 5 times.

3. Loosen the bleeder valve and bleed air with the brake pedal depressed, and then quickly tighten the

bleeder valve.

4. Repeat steps 2 and 3 until all of the air is out of the brake line.

5. Tighten the bleeder valve to the specified torque.

Front disc brake: refer to BR-34, "

BRAKE CALIPER ASSEMBLY : Exploded View".

Rear disc brake: refer to BR-40, "

BRAKE CALIPER ASSEMBLY : Exploded View".

6. Perform steps 1 to 5 for the rear right brake → front left brake → rear left brake → and front right brake in

order.

7. Check that the fluid level in the sub tank is within the specified range after air bleeding. Refer to BR-9,

"Inspection".

Page 907 of 5121

BRAKE MASTER CYLINDER

BR-11

< ON-VEHICLE MAINTENANCE >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

BRAKE MASTER CYLINDER

InspectionINFOID:0000000003811177

FLUID LEAK

Check for brake fluid leakage from the master cylinder mounting face, reservoir tank mounting face, and brake

tube connections.

Page 908 of 5121

BR-12

< ON-VEHICLE MAINTENANCE >

BRAKE BOOSTER

BRAKE BOOSTER

InspectionINFOID:0000000003811178

OPERATION

Depress the brake pedal several times at 5-second intervals with the

engine stopped. Start the engine with the brake pedal fully

depressed. Check that the clearance between brake pedal and dash

lower panel decreases.

NOTE:

A slight impact with a small click may be felt on the pedal when the

brake pedal is fully depressed. This is a normal phenomenon due to

the brake system operation.

AIR TIGHT

Idle the engine for 1 minute to apply vacuum to the brake booster,

and stop the engine. Then depress the brake pedal several times

at 5-second intervals until the accumulated vacuum is released to

atmospheric pressure. Check that the clearance between brake

pedal and dash lower panel gradually increases (A → B → C) each

time the brake pedal is depressed during this operation.

Depress the brake pedal with the engine running. Then stop the

engine while holding down the brake pedal. Check that the brake

pedal stroke does not change after holding down the brake pedal

for 30 seconds or more.

NOTE:

A slight impact with a small click may be felt on the pedal when the

brake pedal is fully depressed. This is a normal phenomenon due

to the brake system operation.

BRA0037D

JPFIA0043ZZ

JPFIA0044ZZ

Page 909 of 5121

FRONT DISC BRAKE

BR-13

< ON-VEHICLE MAINTENANCE >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

FRONT DISC BRAKE

BRAKE PAD

BRAKE PAD : Inspection and AdjustmentINFOID:0000000003811179

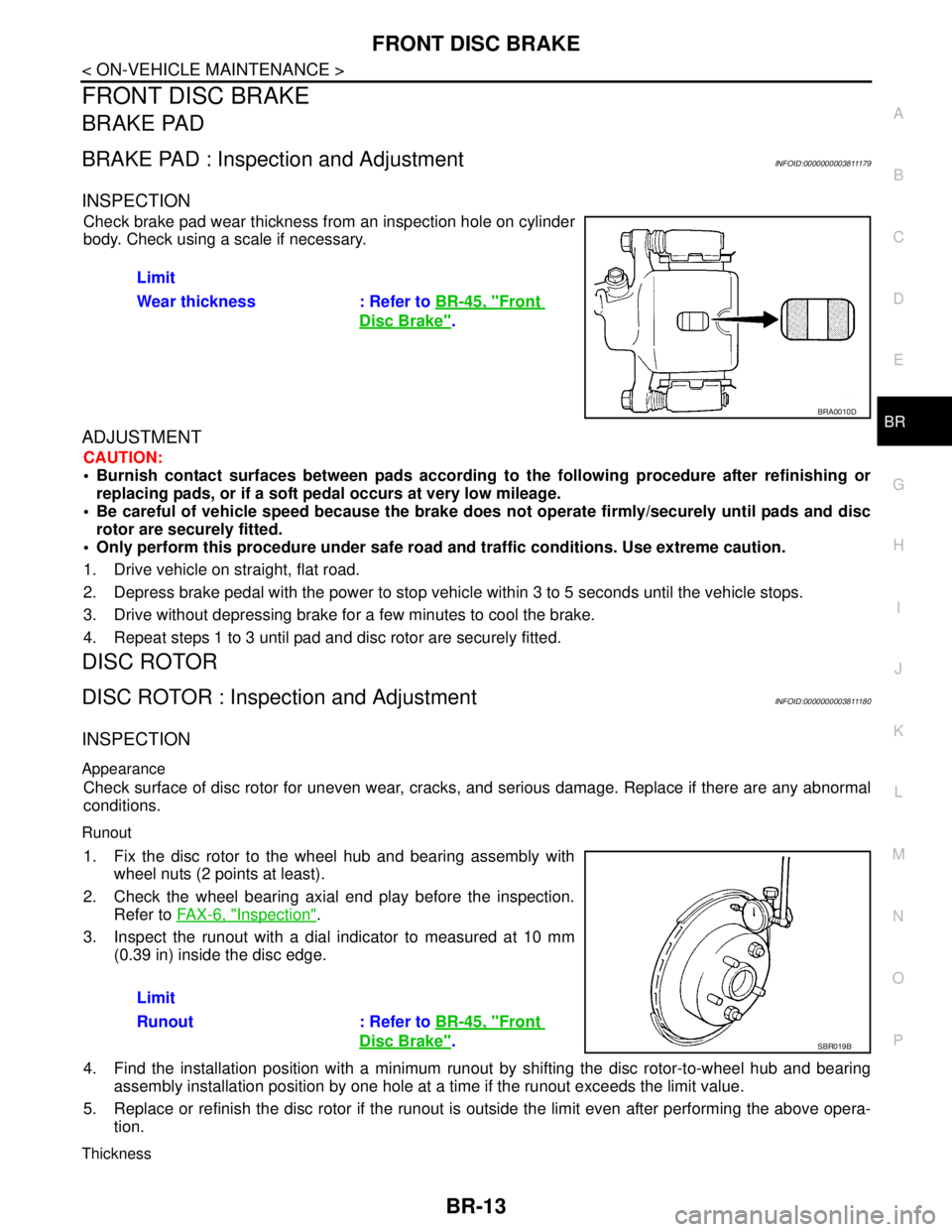

INSPECTION

Check brake pad wear thickness from an inspection hole on cylinder

body. Check using a scale if necessary.

ADJUSTMENT

CAUTION:

Burnish contact surfaces between pads according to the following procedure after refinishing or

replacing pads, or if a soft pedal occurs at very low mileage.

Be careful of vehicle speed because the brake does not operate firmly/securely until pads and disc

rotor are securely fitted.

Only perform this procedure under safe road and traffic conditions. Use extreme caution.

1. Drive vehicle on straight, flat road.

2. Depress brake pedal with the power to stop vehicle within 3 to 5 seconds until the vehicle stops.

3. Drive without depressing brake for a few minutes to cool the brake.

4. Repeat steps 1 to 3 until pad and disc rotor are securely fitted.

DISC ROTOR

DISC ROTOR : Inspection and AdjustmentINFOID:0000000003811180

INSPECTION

Appearance

Check surface of disc rotor for uneven wear, cracks, and serious damage. Replace if there are any abnormal

conditions.

Runout

1. Fix the disc rotor to the wheel hub and bearing assembly with

wheel nuts (2 points at least).

2. Check the wheel bearing axial end play before the inspection.

Refer to FA X - 6 , "

Inspection".

3. Inspect the runout with a dial indicator to measured at 10 mm

(0.39 in) inside the disc edge.

4. Find the installation position with a minimum runout by shifting the disc rotor-to-wheel hub and bearing

assembly installation position by one hole at a time if the runout exceeds the limit value.

5. Replace or refinish the disc rotor if the runout is outside the limit even after performing the above opera-

tion.

Thickness

Limit

Wear thickness : Refer to BR-45, "

Front

Disc Brake".

BRA0010D

Limit

Runout : Refer to BR-45, "

Front

Disc Brake".SBR019B

Page 910 of 5121

BR-14

< ON-VEHICLE MAINTENANCE >

FRONT DISC BRAKE

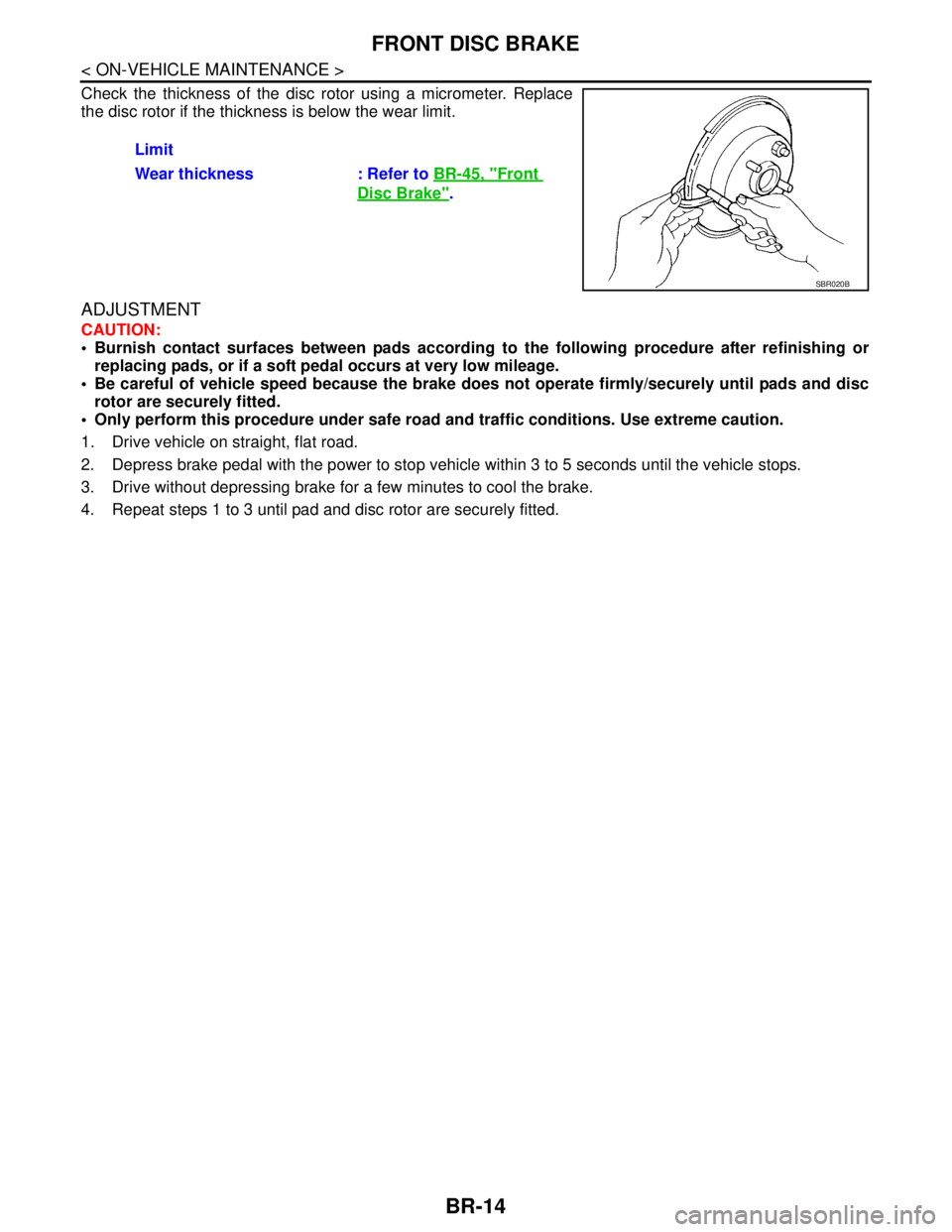

Check the thickness of the disc rotor using a micrometer. Replace

the disc rotor if the thickness is below the wear limit.

ADJUSTMENT

CAUTION:

Burnish contact surfaces between pads according to the following procedure after refinishing or

replacing pads, or if a soft pedal occurs at very low mileage.

Be careful of vehicle speed because the brake does not operate firmly/securely until pads and disc

rotor are securely fitted.

Only perform this procedure under safe road and traffic conditions. Use extreme caution.

1. Drive vehicle on straight, flat road.

2. Depress brake pedal with the power to stop vehicle within 3 to 5 seconds until the vehicle stops.

3. Drive without depressing brake for a few minutes to cool the brake.

4. Repeat steps 1 to 3 until pad and disc rotor are securely fitted.Limit

Wear thickness : Refer to BR-45, "

Front

Disc Brake".

SBR020B