NISSAN TEANA 2014 Service Manual

Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 101 of 4801

PREPARATIONBR-5

< PREPARATION >

C

D E

G H

I

J

K L

M A

B

BR

N

O P

PREPARATION

PREPARATION

Special Service ToolINFOID:0000000009463679

The actual shape of the tools may di ffer from those illustrated here.

Commercial Service ToolINFOID:0000000009463680

Tool number

(TechMate No.)

Tool name Description

—

(J-46532)

Brake height tool Measuring brake pedal height

38-PFM92

(—)

Pro-Cut 9.2 Lathe Refinishing rotors

LFIA0227E

ALFIA0092ZZ

Tool name

Description

1. Flare nut crowfoot

2. Torque wrench Removing and installing brake piping

a: 10mm (0.39 in)/12mm (0.47 in)

Power tool Loosening nuts, screws and bolts

NT360

PIIB1407E

Revision: November 20132014 Altima NAM

Page 102 of 4801

BR-6

< SYSTEM DESCRIPTION >

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

SYSTEM DESCRIPTION

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

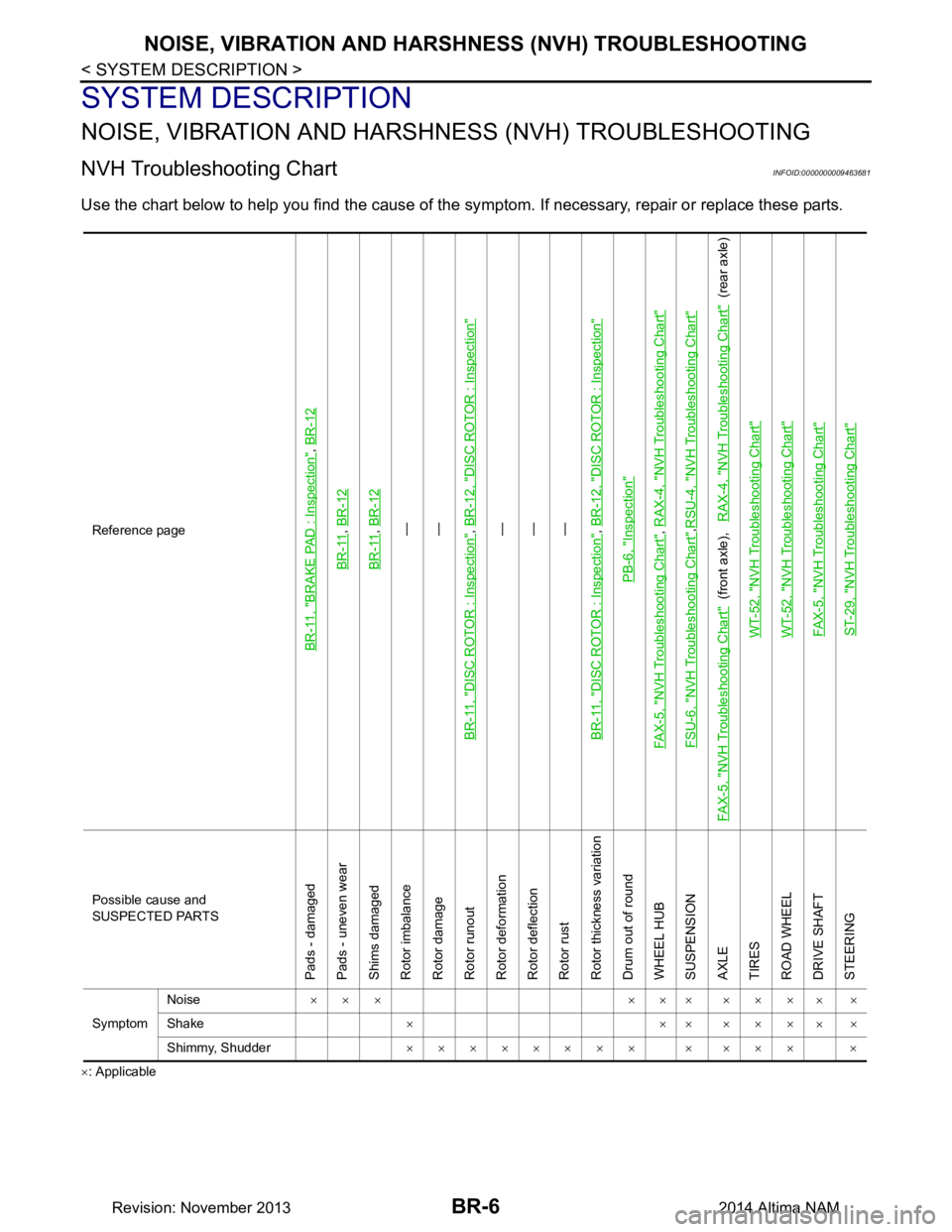

NVH Troubleshooting ChartINFOID:0000000009463681

Use the chart below to help you find the cause of the sy mptom. If necessary, repair or replace these parts.

×: ApplicableReference page

BR-11, "BRAKE PAD : Inspection"

,

BR-12

BR-11

, BR-12

BR-11

, BR-12—

—

BR-11, "DISC ROTOR : Inspection", BR-12, "DISC ROTOR : Inspection"—

—

—

BR-11, "DISC ROTOR : Inspection", BR-12, "DISC ROTOR : Inspection"

PB-6, "Inspection"

FAX-5, "NVH Troubleshooting Chart"

, RAX-4, "NVH Troubleshooting Chart"

FSU-6, "NVH Troubleshooting Chart"

,RSU-4, "NVH Troubleshooting Chart"

FAX-5, "NVH Troubleshooting Chart"

(front axle), RAX-4, "NVH Troubleshooting Chart"

(rear axle)

WT-52, "NVH Troubleshooting Chart"

WT-52, "NVH Troubleshooting Chart"FAX-5, "NVH Troubleshooting Chart"ST-29, "NVH Troubleshooting Chart"

Possible cause and

SUSPECTED PARTS

Pads - damaged

Pads - uneven wear

Shims damaged

Rotor imbalance

Rotor damage

Rotor runout

Rotor deformation

Rotor deflection

Rotor rust

Rotor thickness variation

Drum out of round

WHEEL HUB

SUSPENSION

AXLE

TIRES

ROAD WHEEL

DRIVE SHAFT

STEERING

Symptom Noise

××× ××× ×××

××

Shake × ×× ×××

××

Shimmy, Shudder ×××××××× × ××× ×

Revision: November 20132014 Altima NAM

Page 103 of 4801

BRAKE PEDALBR-7

< BASIC INSPECTION >

C

D E

G H

I

J

K L

M A

B

BR

N

O P

BASIC INSPECTION

BRAKE PEDAL

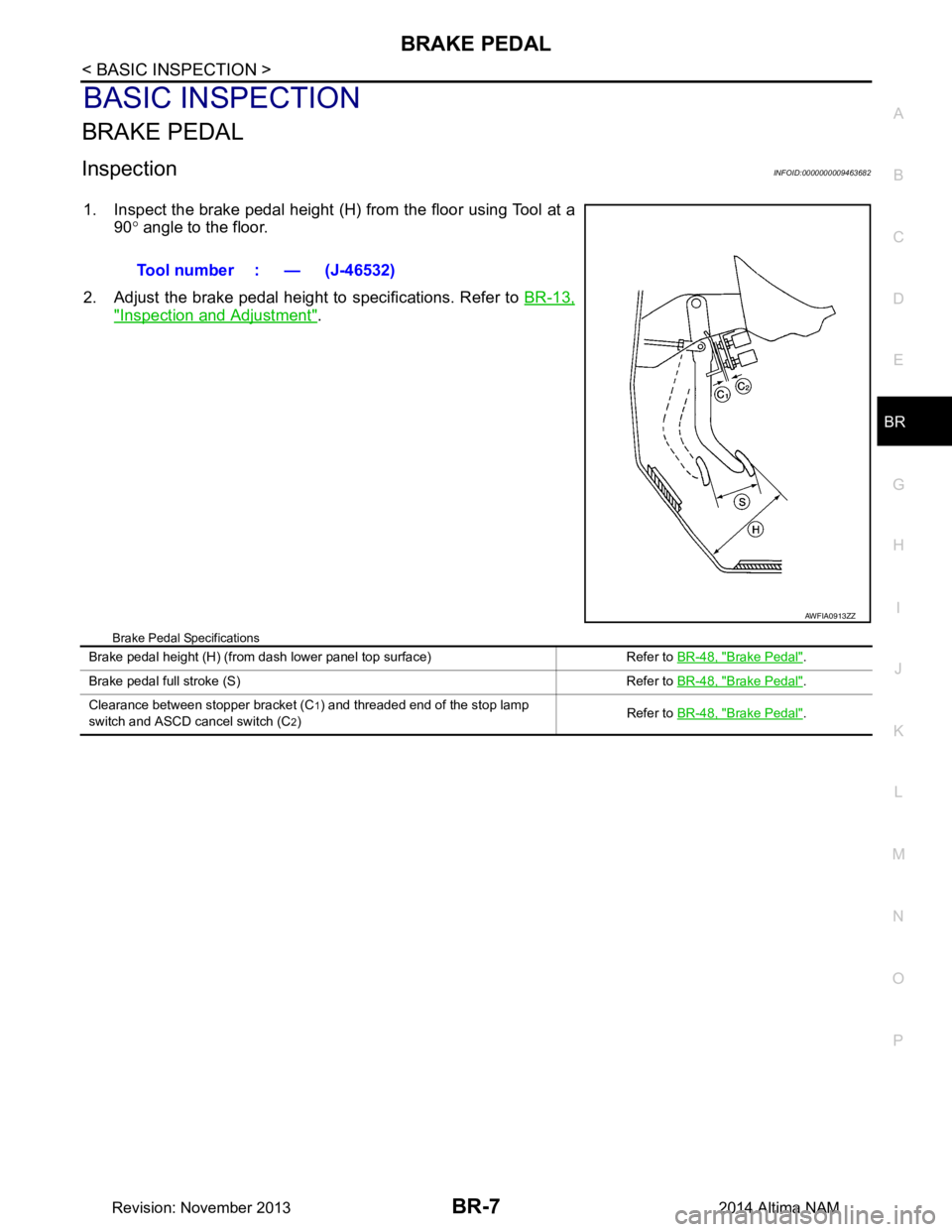

InspectionINFOID:0000000009463682

1. Inspect the brake pedal height (H) from the floor using Tool at a 90° angle to the floor.

2. Adjust the brake pedal height to specifications. Refer to BR-13,

"Inspection and Adjustment".

Brake Pedal Specifications

Tool number : — (J-46532)

AWFIA0913ZZ

Brake pedal height (H) (from dash lower panel top surface) Refer to BR-48, "Brake Pedal".

Brake pedal full stroke (S) Refer to BR-48, "Brake Pedal"

.

Clearance between stopper bracket (C

1) and threaded end of the stop lamp

switch and ASCD cancel switch (C

2) Refer to

BR-48, "Brake Pedal".

Revision: November 20132014 Altima NAM

Page 104 of 4801

BR-8

< BASIC INSPECTION >

BRAKE FLUID

BRAKE FLUID

InspectionINFOID:0000000009463683

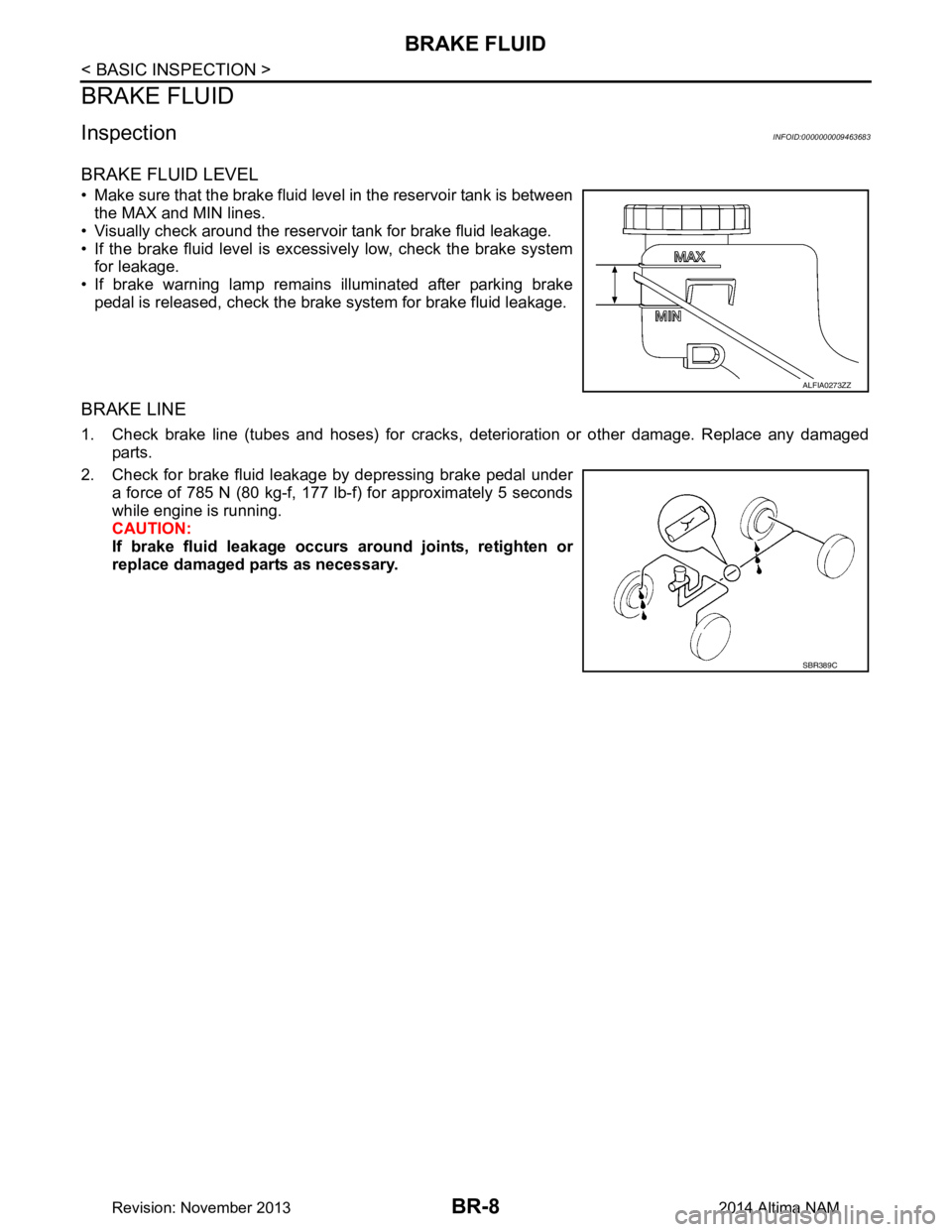

BRAKE FLUID LEVEL

• Make sure that the brake fluid level in the reservoir tank is betweenthe MAX and MIN lines.

• Visually check around the reservoir tank for brake fluid leakage.

• If the brake fluid level is excessively low, check the brake system for leakage.

• If brake warning lamp remains illuminated after parking brake pedal is released, check the brake system for brake fluid leakage.

BRAKE LINE

1. Check brake line (tubes and hoses) for cracks, deterioration or other damage. Replace any damaged

parts.

2. Check for brake fluid leakage by depressing brake pedal under a force of 785 N (80 kg-f, 177 lb-f) for approximately 5 seconds

while engine is running.

CAUTION:

If brake fluid leakage occurs around joints, retighten or

replace damaged parts as necessary.

ALFIA0273ZZ

SBR389C

Revision: November 20132014 Altima NAM

Page 105 of 4801

BRAKE MASTER CYLINDERBR-9

< BASIC INSPECTION >

C

D E

G H

I

J

K L

M A

B

BR

N

O P

BRAKE MASTER CYLINDER

InspectionINFOID:0000000009463684

Check for brake fluid leakage at the following areas:

• Master cylinder mounting face

• Reservoir tank mounting face

• Brake tube and brake tube connections

• Brake hose and brake hose connections

If any brake fluid leakage is found, repair as necessary.

On Board InspectionINFOID:0000000009463685

LEAK INSPECTION

Check for leaks in the master cylinder installation surf ace, reservoir tank installation surface, and brake pipe

and hose connections.

Revision: November 20132014 Altima NAM

Page 106 of 4801

BR-10

< BASIC INSPECTION >

BRAKE BOOSTER

BRAKE BOOSTER

InspectionINFOID:0000000009463686

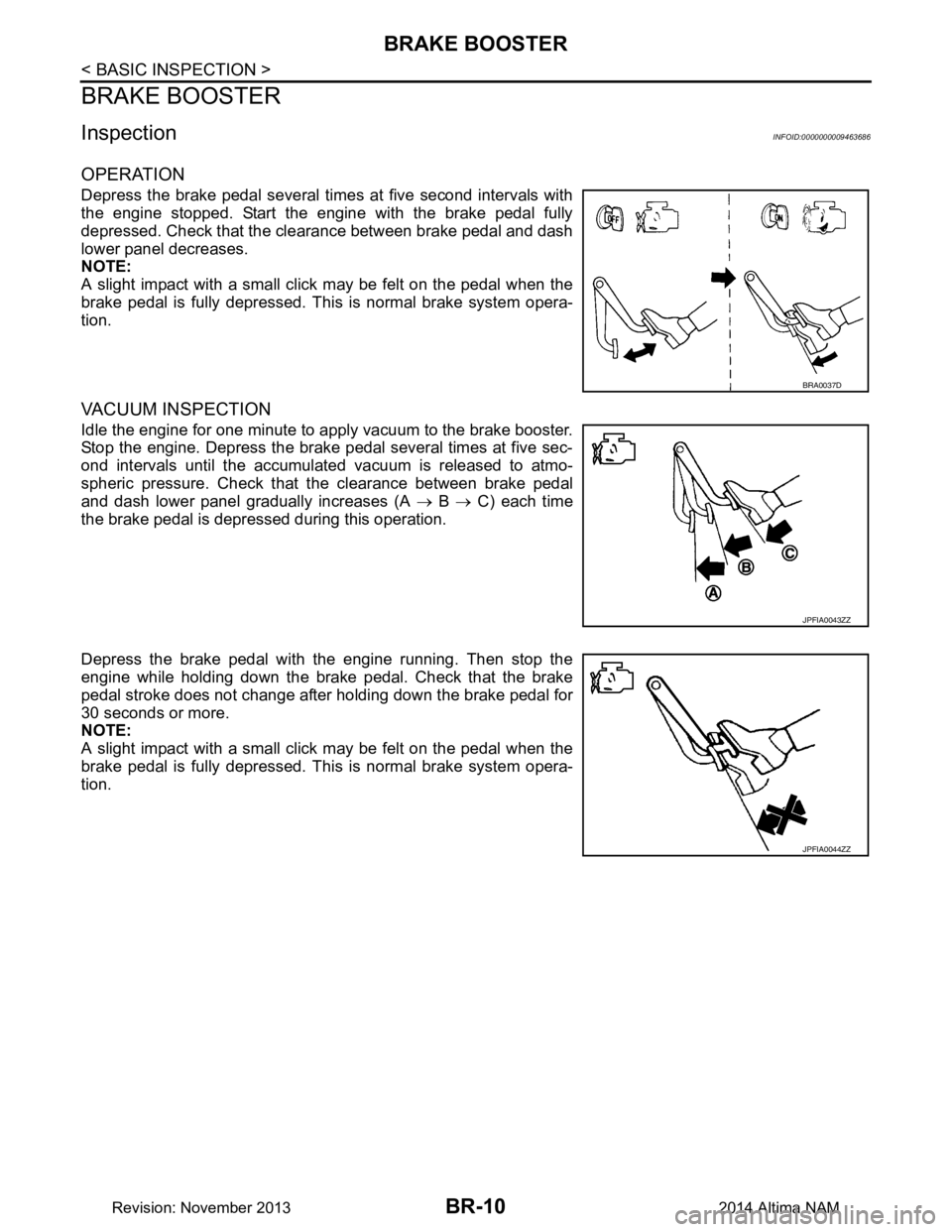

OPERATION

Depress the brake pedal several times at five second intervals with

the engine stopped. Start the engine with the brake pedal fully

depressed. Check that the cl earance between brake pedal and dash

lower panel decreases.

NOTE:

A slight impact with a small click may be felt on the pedal when the

brake pedal is fully depressed. Th is is normal brake system opera-

tion.

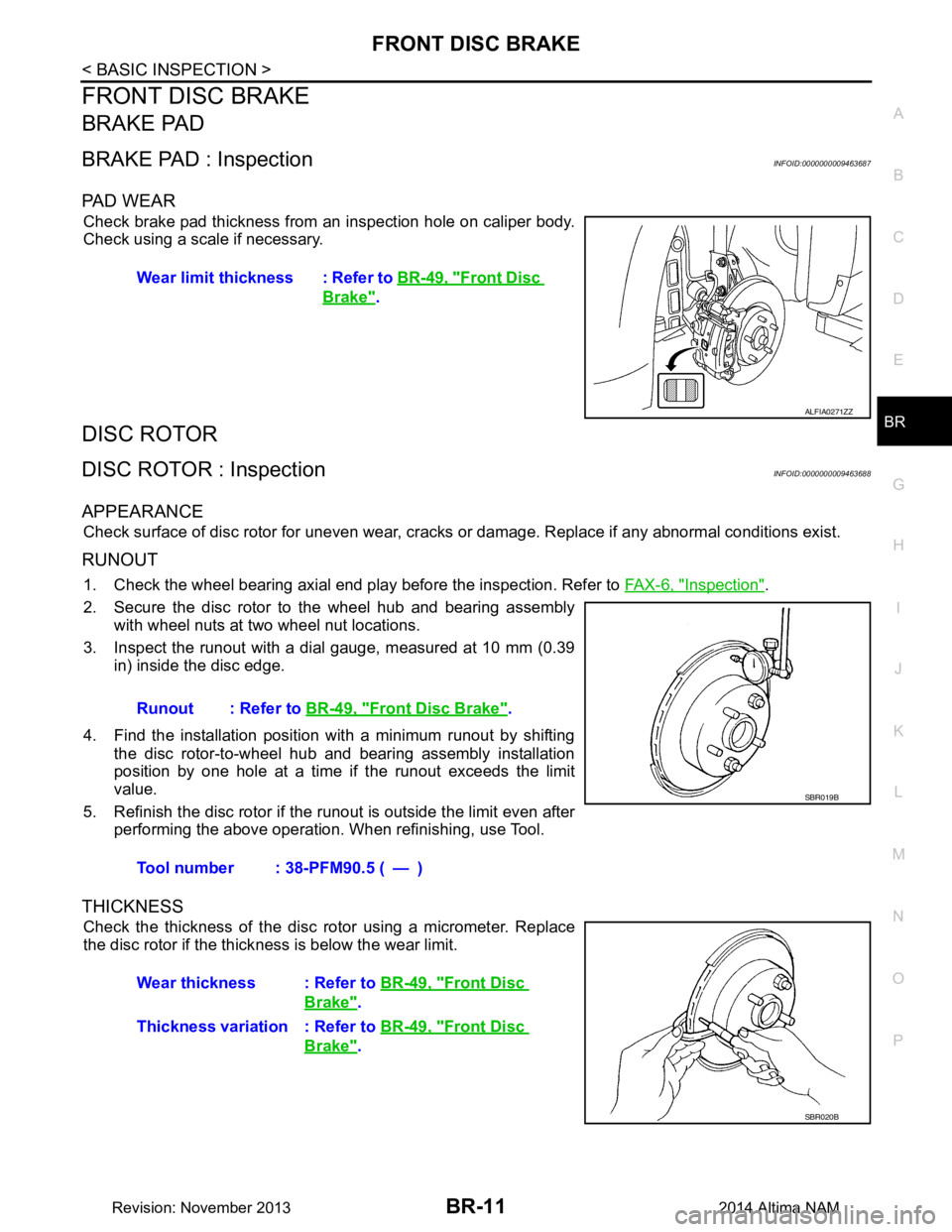

VACUUM INSPECTION

Idle the engine for one minute to apply vacuum to the brake booster.

Stop the engine. Depress the brake pedal several times at five sec-

ond intervals until the accumulated vacuum is released to atmo-

spheric pressure. Check that the clearance between brake pedal

and dash lower panel gradually increases (A → B → C) each time

the brake pedal is depressed during this operation.

Depress the brake pedal with the engine running. Then stop the

engine while holding down the brake pedal. Check that the brake

pedal stroke does not change after holding down the brake pedal for

30 seconds or more.

NOTE:

A slight impact with a small click may be felt on the pedal when the

brake pedal is fully depressed. Th is is normal brake system opera-

tion.

BRA0037D

JPFIA0043ZZ

JPFIA0044ZZ

Revision: November 20132014 Altima NAM

Page 107 of 4801

FRONT DISC BRAKEBR-11

< BASIC INSPECTION >

C

D E

G H

I

J

K L

M A

B

BR

N

O P

FRONT DISC BRAKE

BRAKE PAD

BRAKE PAD : InspectionINFOID:0000000009463687

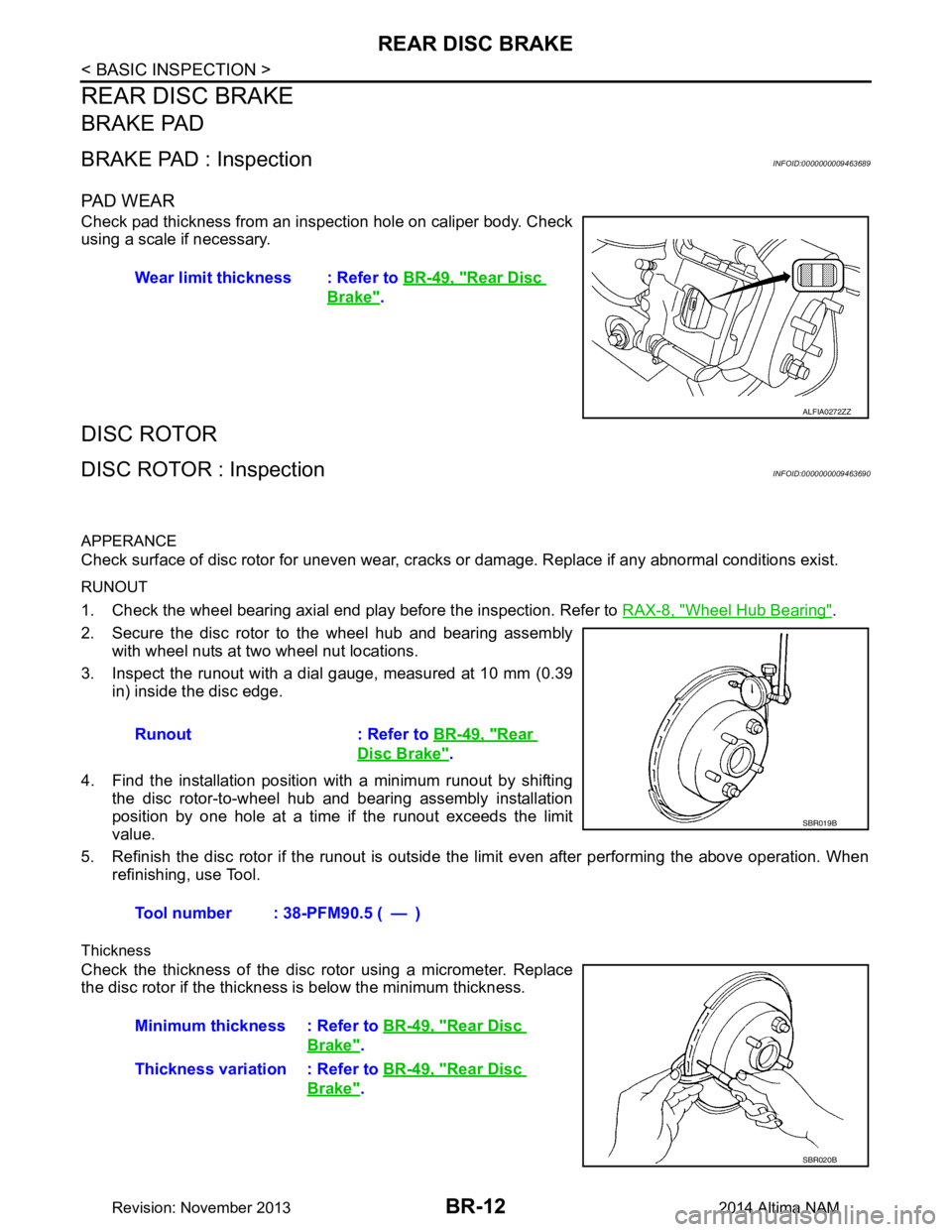

PA D W E A R

Check brake pad thickness from an inspection hole on caliper body.

Check using a scale if necessary.

DISC ROTOR

DISC ROTOR : InspectionINFOID:0000000009463688

APPEARANCE

Check surface of disc rotor for uneven wear, cracks or damage. Replace if any abnormal conditions exist.

RUNOUT

1. Check the wheel bearing axial end play before the inspection. Refer to FAX-6, "Inspection".

2. Secure the disc rotor to the wheel hub and bearing assembly with wheel nuts at two wheel nut locations.

3. Inspect the runout with a dial gauge, measured at 10 mm (0.39 in) inside the disc edge.

4. Find the installation position with a minimum runout by shifting the disc rotor-to-wheel hub and bearing assembly installation

position by one hole at a time if the runout exceeds the limit

value.

5. Refinish the disc rotor if the runout is outside the limit even after performing the above operation. When refinishing, use Tool.

THICKNESS

Check the thickness of the disc rotor using a micrometer. Replace

the disc rotor if the thick ness is below the wear limit.

Wear limit thickness : Refer to

BR-49, "Front Disc

Brake".

ALFIA0271ZZ

Runout : Refer to BR-49, "Front Disc Brake".

Tool number : 38-PFM90.5 ( — )

SBR019B

Wear thickness : Refer to BR-49, "Front Disc

Brake".

Thickness variation : Refer to BR-49, "Front Disc

Brake".

SBR020B

Revision: November 20132014 Altima NAM

Page 108 of 4801

BR-12

< BASIC INSPECTION >

REAR DISC BRAKE

REAR DISC BRAKE

BRAKE PAD

BRAKE PAD : InspectionINFOID:0000000009463689

PA D W E A R

Check pad thickness from an inspection hole on caliper body. Check

using a scale if necessary.

DISC ROTOR

DISC ROTOR : InspectionINFOID:0000000009463690

APPERANCE

Check surface of disc rotor for uneven wear, cracks or damage. Replace if any abnormal conditions exist.

RUNOUT

1. Check the wheel bearing axial end play before the inspection. Refer to RAX-8, "Wheel Hub Bearing".

2. Secure the disc rotor to the wheel hub and bearing assembly with wheel nuts at two wheel nut locations.

3. Inspect the runout with a dial gauge, measured at 10 mm (0.39 in) inside the disc edge.

4. Find the installation position with a minimum runout by shifting the disc rotor-to-wheel hub and bearing assembly installation

position by one hole at a time if the runout exceeds the limit

value.

5. Refinish the disc rotor if the runout is outside t he limit even after performing the above operation. When

refinishing, use Tool.

Thickness

Check the thickness of the disc ro tor using a micrometer. Replace

the disc rotor if the thickness is below the minimum thickness. Wear limit thickness : Refer to

BR-49, "Rear Disc

Brake".

ALFIA0272ZZ

Runout : Refer to BR-49, "Rear

Disc Brake".

Tool number : 38-PFM90.5 ( — )

SBR019B

Minimum thickness : Refer to BR-49, "Rear Disc

Brake".

Thickness variation : Refer to BR-49, "Rear Disc

Brake".

SBR020B

Revision: November 20132014 Altima NAM

Page 109 of 4801

BRAKE PEDALBR-13

< PERIODIC MAINTENANCE >

C

D E

G H

I

J

K L

M A

B

BR

N

O P

PERIODIC MAINTENANCE

BRAKE PEDAL

Inspection and AdjustmentINFOID:0000000009463691

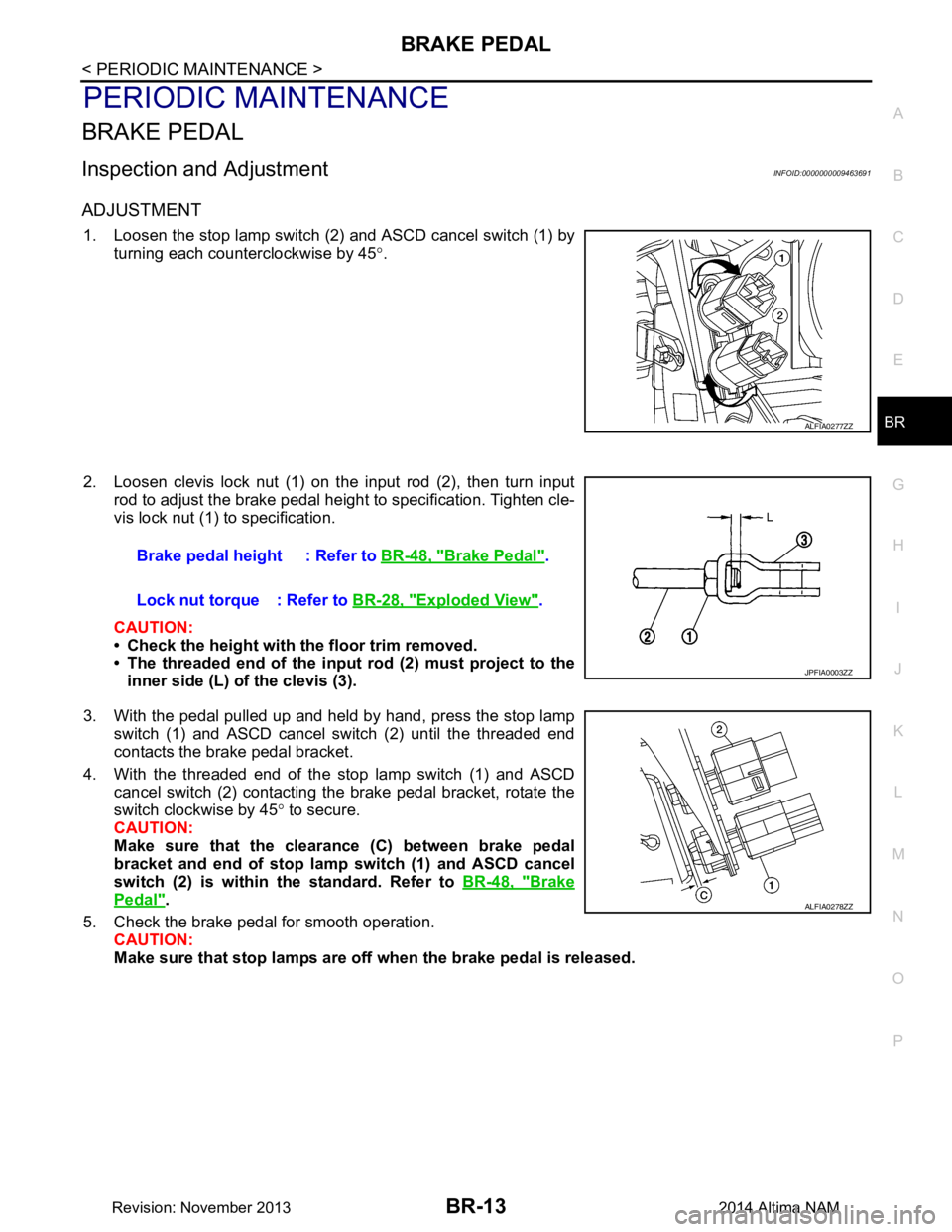

ADJUSTMENT

1. Loosen the stop lamp switch (2) and ASCD cancel switch (1) by turning each counterclockwise by 45 °.

2. Loosen clevis lock nut (1) on the input rod (2), then turn input rod to adjust the brake pedal height to specification. Tighten cle-

vis lock nut (1) to specification.

CAUTION:

• Check the height with the floor trim removed.

• The threaded end of the input rod (2) must project to the

inner side (L) of the clevis (3).

3. With the pedal pulled up and held by hand, press the stop lamp switch (1) and ASCD cancel switch (2) until the threaded end

contacts the brake pedal bracket.

4. With the threaded end of the stop lamp switch (1) and ASCD cancel switch (2) contacting the brake pedal bracket, rotate the

switch clockwise by 45 ° to secure.

CAUTION:

Make sure that the clearance (C) between brake pedal

bracket and end of stop lamp switch (1) and ASCD cancel

switch (2) is within the standard. Refer to BR-48, "Brake

Pedal".

5. Check the brake pedal for smooth operation. CAUTION:

Make sure that stop lamps are off when the brake pedal is released.

ALFIA0277ZZ

Brake pedal height : Refer to BR-48, "Brake Pedal".

Lock nut torque : Refer to BR-28, "Exploded View"

.

JPFIA0003ZZ

ALFIA0278ZZ

Revision: November 20132014 Altima NAM

Page 110 of 4801

BR-14

< PERIODIC MAINTENANCE >

BRAKE FLUID

BRAKE FLUID

Drain and RefillINFOID:0000000009463692

CAUTION:

• Do not spill or splash brake fluid on painted surf aces. Brake fluid may damage paint. If brake fluid is

splashed on painted areas, wash it away with water immediately.

• Prior to repair, turn the ignition switch OFF, disconnect the ABS actuator and electric unit (control

unit) connector or negative battery terminal. Refer to PG-73, "Removal and Installation (Battery)"

.

• Refill brake system with new brake fluid. Refer to MA-11, "FOR USA AND CANADA : Fluids and

Lubricants".

• Do not reuse drained brake fluid.

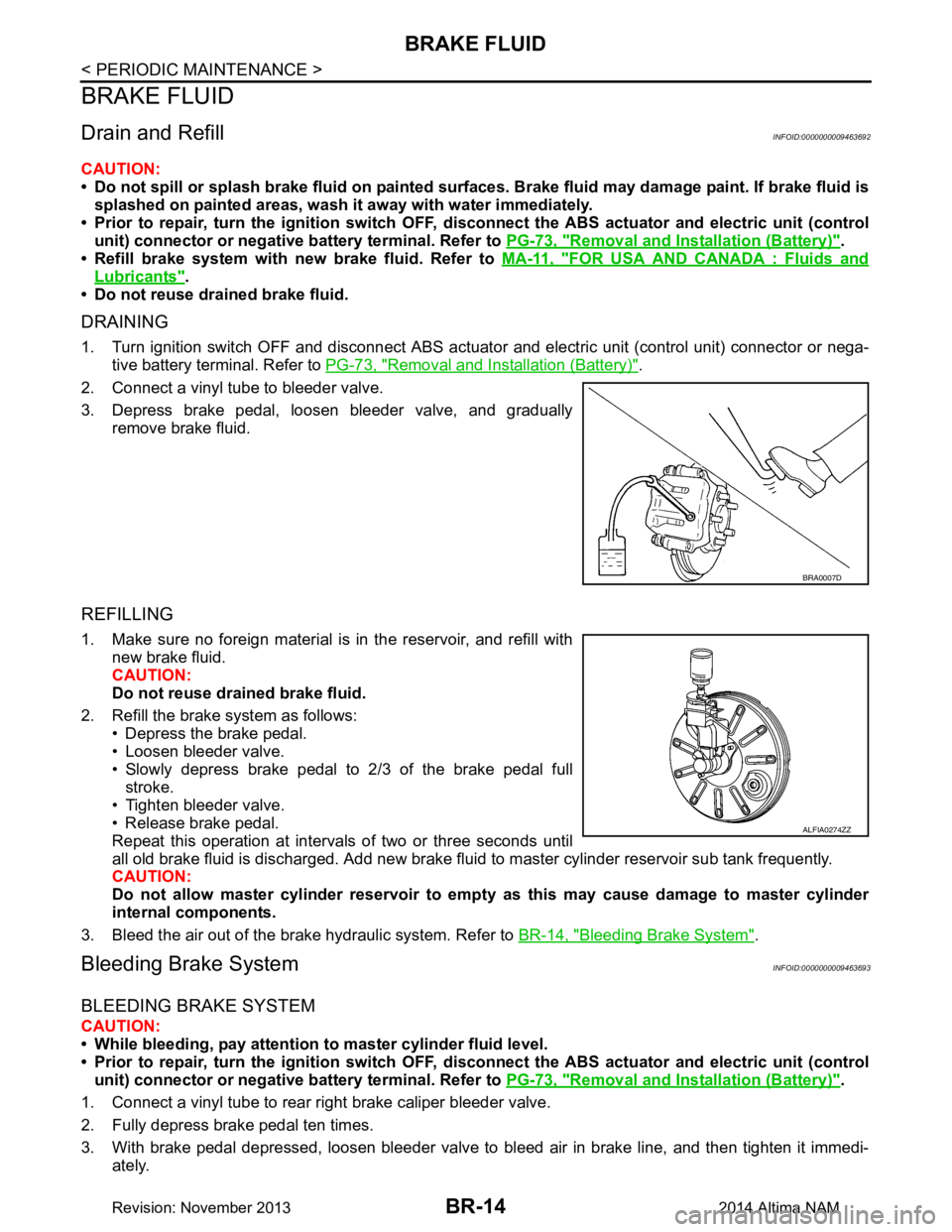

DRAINING

1. Turn ignition switch OFF and disconnect ABS actuat or and electric unit (control unit) connector or nega-

tive battery terminal. Refer to PG-73, "Removal and Installation (Battery)"

.

2. Connect a vinyl tube to bleeder valve.

3. Depress brake pedal, loosen bleeder valve, and gradually remove brake fluid.

REFILLING

1. Make sure no foreign material is in the reservoir, and refill withnew brake fluid.

CAUTION:

Do not reuse drained brake fluid.

2. Refill the brake system as follows: • Depress the brake pedal.

• Loosen bleeder valve.

• Slowly depress brake pedal to 2/3 of the brake pedal full

stroke.

• Tighten bleeder valve.

• Release brake pedal.

Repeat this operation at intervals of two or three seconds until

all old brake fluid is discharged. Add new brake flui d to master cylinder reservoir sub tank frequently.

CAUTION:

Do not allow master cylinder reservoir to empt y as this may cause damage to master cylinder

internal components.

3. Bleed the air out of the brake hydraulic system. Refer to BR-14, "Bleeding Brake System"

.

Bleeding Brake SystemINFOID:0000000009463693

BLEEDING BRAKE SYSTEM

CAUTION:

• While bleeding, pay attention to master cylinder fluid level.

• Prior to repair, turn the ignition switch OFF, disconnect the ABS actuator and electric unit (control

unit) connector or negative battery terminal. Refer to PG-73, "Removal and Installation (Battery)"

.

1. Connect a vinyl tube to rear right brake caliper bleeder valve.

2. Fully depress brake pedal ten times.

3. With brake pedal depressed, loosen bleeder valve to bleed air in brake line, and then tighten it immedi-

ately.

BRA0007D

ALFIA0274ZZ

Revision: November 20132014 Altima NAM