esp NISSAN TEANA 2014 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 2487 of 4801

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLYFL-7

< REMOVAL AND INSTALLATION >

C

D E

F

G H

I

J

K L

M A

FL

NP

O

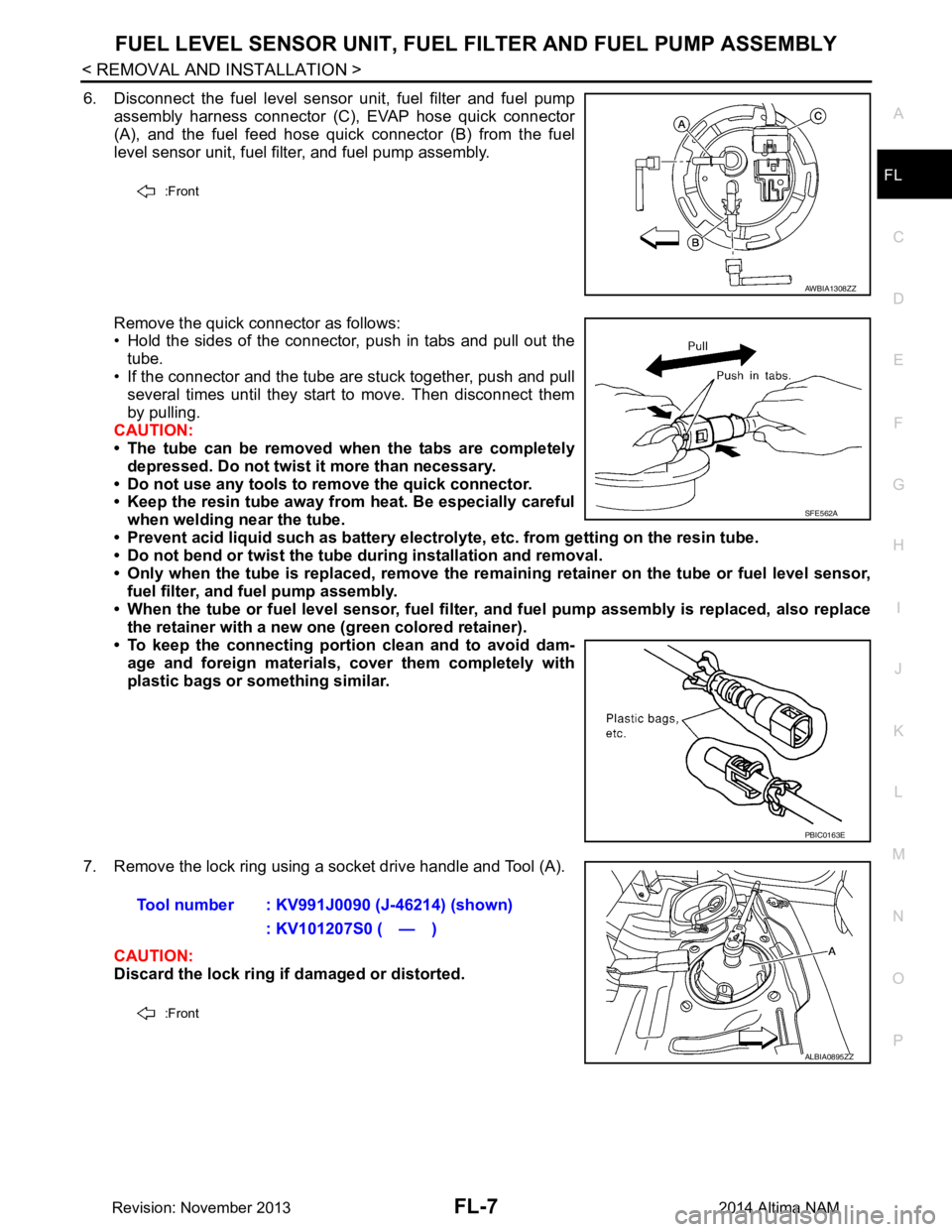

6. Disconnect the fuel level sensor unit, fuel filter and fuel pump

assembly harness connector (C), EVAP hose quick connector

(A), and the fuel feed hose quick connector (B) from the fuel

level sensor unit, fuel filter, and fuel pump assembly.

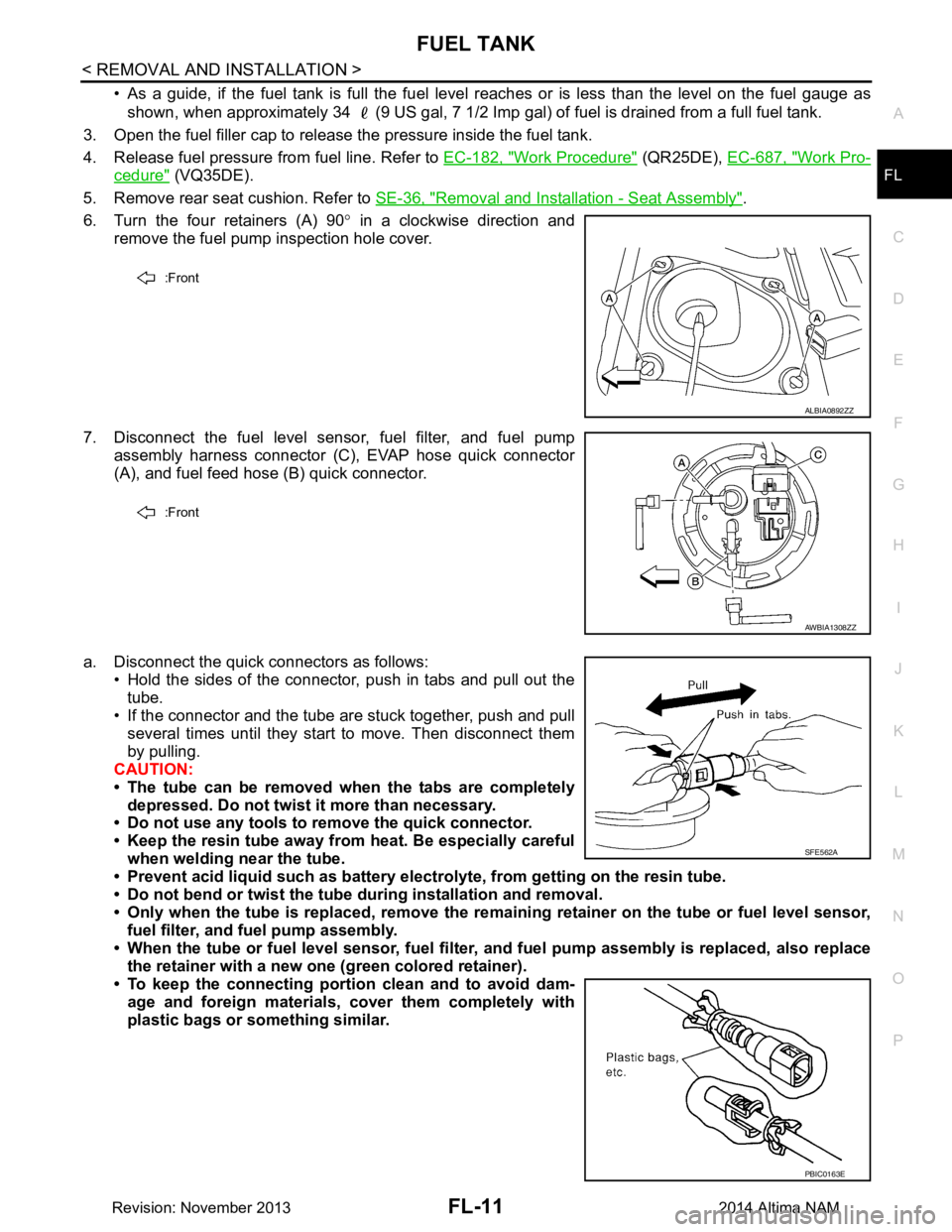

Remove the quick connector as follows:

• Hold the sides of the connector, push in tabs and pull out the

tube.

• If the connector and the tube are stuck together, push and pull several times until they start to move. Then disconnect them

by pulling.

CAUTION:

• The tube can be removed when the tabs are completely

depressed. Do not twist it more than necessary.

• Do not use any tools to remove the quick connector.

• Keep the resin tube away from heat. Be especially careful

when welding near the tube.

• Prevent acid liquid such as battery electroly te, etc. from getting on the resin tube.

• Do not bend or twist the tube during installation and removal.

• Only when the tube is replaced, remove the remaining retainer on the tube or fuel level sensor,

fuel filter, and fuel pump assembly.

• When the tube or fuel level sen sor, fuel filter, and fuel pump assembly is replaced, also replace

the retainer with a new one (green colored retainer).

• To keep the connecting portio n clean and to avoid dam-

age and foreign materials, cover them completely with

plastic bags or something similar.

7. Remove the lock ring using a socket drive handle and Tool (A). CAUTION:

Discard the lock ring if damaged or distorted.

:Front

AWBIA1308ZZ

SFE562A

PBIC0163E

Tool number : KV991J0090 (J-46214) (shown)

: KV101207S0 ( — )

:Front

ALBIA0895ZZ

Revision: November 20132014 Altima NAM

Page 2491 of 4801

FUEL TANKFL-11

< REMOVAL AND INSTALLATION >

C

D E

F

G H

I

J

K L

M A

FL

NP

O

• As a guide, if the fuel tank is full the fuel leve

l reaches or is less than the level on the fuel gauge as

shown, when approximately 34 (9 US gal, 7 1/2 Imp gal) of fuel is drained from a full fuel tank.

3. Open the fuel filler cap to release the pressure inside the fuel tank.

4. Release fuel pressure from fuel line. Refer to EC-182, "Work Procedure"

(QR25DE), EC-687, "Work Pro-

cedure" (VQ35DE).

5. Remove rear seat cushion. Refer to SE-36, "Removal and Installation - Seat Assembly"

.

6. Turn the four retainers (A) 90 ° in a clockwise direction and

remove the fuel pump inspection hole cover.

7. Disconnect the fuel level sensor, fuel filter, and fuel pump assembly harness connector (C), EVAP hose quick connector

(A), and fuel feed hose (B) quick connector.

a. Disconnect the quick connectors as follows: • Hold the sides of the connector, push in tabs and pull out the

tube.

• If the connector and the tube are stuck together, push and pull

several times until they start to move. Then disconnect them

by pulling.

CAUTION:

• The tube can be removed when the tabs are completely depressed. Do not twist it more than necessary.

• Do not use any tools to remove the quick connector.

• Keep the resin tube away from heat. Be especially careful

when welding near the tube.

• Prevent acid liquid such as battery elect rolyte, from getting on the resin tube.

• Do not bend or twist the tube during installation and removal.

• Only when the tube is replaced, remove the remaining retainer on the tube or fuel level sensor,

fuel filter, and fuel pump assembly.

• When the tube or fuel level sen sor, fuel filter, and fuel pump assembly is replaced, also replace

the retainer with a new one (green colored retainer).

• To keep the connecting portio n clean and to avoid dam-

age and foreign materials, cover them completely with

plastic bags or something similar.

:Front

ALBIA0892ZZ

:Front

AWBIA1308ZZ

SFE562A

PBIC0163E

Revision: November 20132014 Altima NAM

Page 2526 of 4801

SERVICE DATA AND SPECIFICATIONS (SDS)FSU-25

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

D

F

G H

I

J

K L

M A

B

FSU

N

O P

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

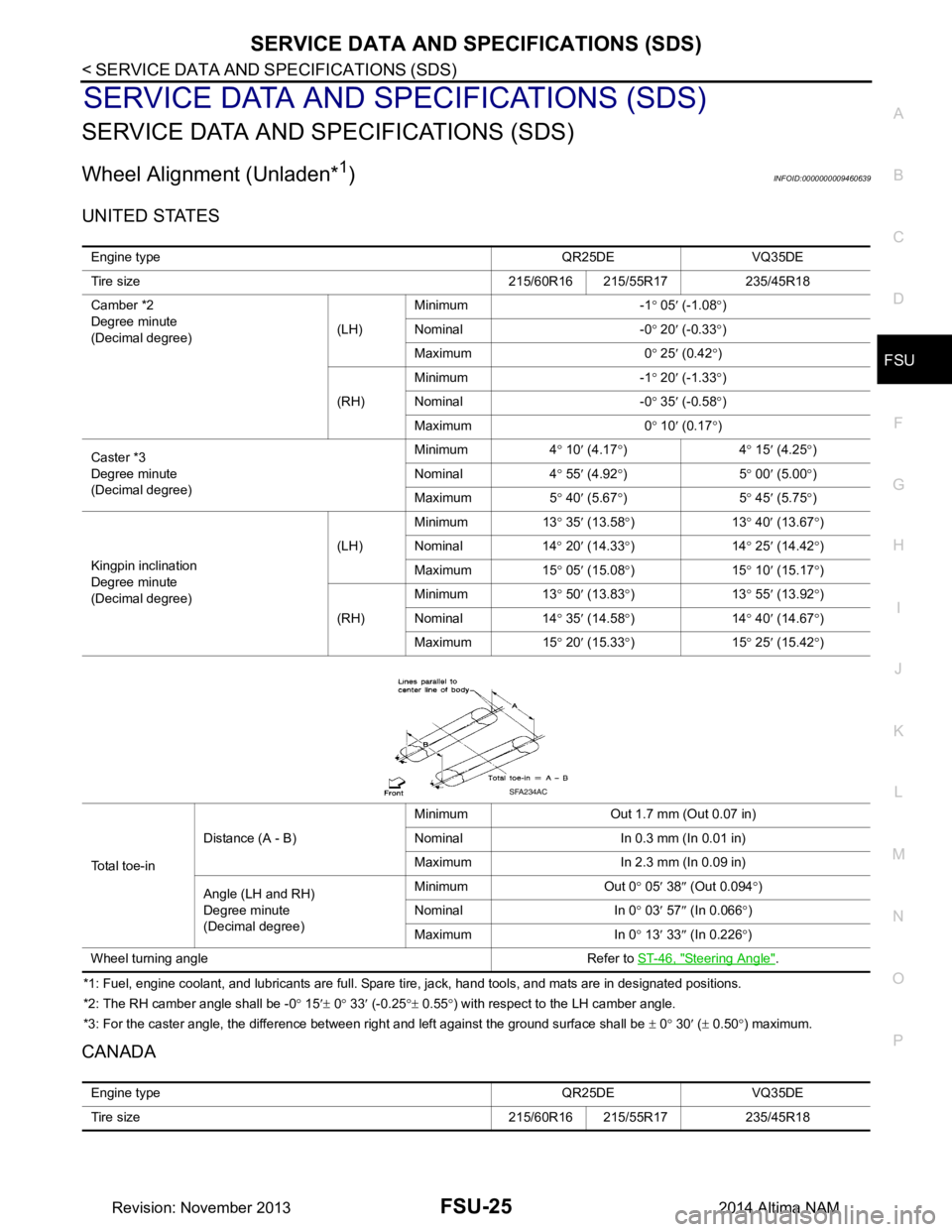

Wheel Alignment (Unladen*1)INFOID:0000000009460639

UNITED STATES

*1: Fuel, engine coolant, and lubricants are full. Spare tire, jack, hand tools, and mats are in designated positions.

*2: The RH camber angle shall be -0 ° 15 ′± 0 ° 33 ′ (-0.25 °± 0.55 °) with respect to the LH camber angle.

*3: For the caster angle, the difference between right and left against the ground surface shall be ± 0 ° 30 ′ ( ± 0.50 °) maximum.

CANADA

Engine type QR25DE VQ35DE

Tire size 215/60R16 215/55R17 235/45R18

Camber *2

Degree minute

(Decimal degree) (LH)Minimum -1

° 05 ′ (-1.08 °)

Nominal -0 ° 20 ′ (-0.33 °)

Maximum 0 ° 25 ′ (0.42 °)

(RH) Minimum -1

° 20 ′ (-1.33 °)

Nominal -0 ° 35 ′ (-0.58 °)

Maximum 0 ° 10 ′ (0.17 °)

Caster *3

Degree minute

(Decimal degree) Minimum 4

° 10 ′ (4.17 °)4 ° 15 ′ (4.25 °)

Nominal 4 ° 55 ′ (4.92 °)5 ° 00 ′ (5.00 °)

Maximum 5 ° 40 ′ (5.67 °)5 ° 45 ′ (5.75 °)

Kingpin inclination

Degree minute

(Decimal degree) (LH)

Minimum 13

° 35 ′ (13.58 °)13 ° 40

′ (13.67 °)

Nominal 14 ° 20 ′ (14.33 °)14 ° 25 ′ (14.42 °)

Maximum 15 ° 05 ′ (15.08 °)15 ° 10 ′ (15.17 °)

(RH) Minimum 13

° 50 ′ (13.83 °)13 ° 55 ′ (13.92 °)

Nominal 14 ° 35 ′ (14.58 °)14 ° 40 ′ (14.67 °)

Maximum 15 ° 20 ′ (15.33 °)15 ° 25 ′ (15.42 °)

To t a l t o e - i n Distance (A - B)

Minimum Out 1.7 mm (Out 0.07 in)

Nominal In 0.3 mm (In 0.01 in)

Maximum In 2.3 mm (In 0.09 in)

Angle (LH and RH)

Degree minute

(Decimal degree) Minimum Out 0

° 05 ′ 38 ″ (Out 0.094 °)

Nominal In 0 ° 03 ′ 57 ″ (In 0.066 °)

Maximum In 0 ° 13 ′ 33 ″ (In 0.226 °)

Wheel turning angle Refer to ST-46, "Steering Angle"

.

SFA234AC

Engine type QR25DE VQ35DE

Tire size 215/60R16 215/55R17 235/45R18

Revision: November 20132014 Altima NAM

Page 2527 of 4801

FSU-26

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

*1: Fuel, engine coolant, and lubricants are full. Spare tire, jack, hand tools, and mats are in designated positions.

*2: The RH camber angle shall be -0 ° 15 ′± 0 ° 33 ′ (-0.25 °± 0.55 °) with respect to the LH camber angle.

*3: For the caster angle, the difference between right and left against the ground surface shall be ± 0 ° 30 ′ ( ± 0.50 °) maximum.

Ball JointINFOID:0000000009460640

Wheelarch Height (Unladen*1)INFOID:0000000009460641

UNITED STATES

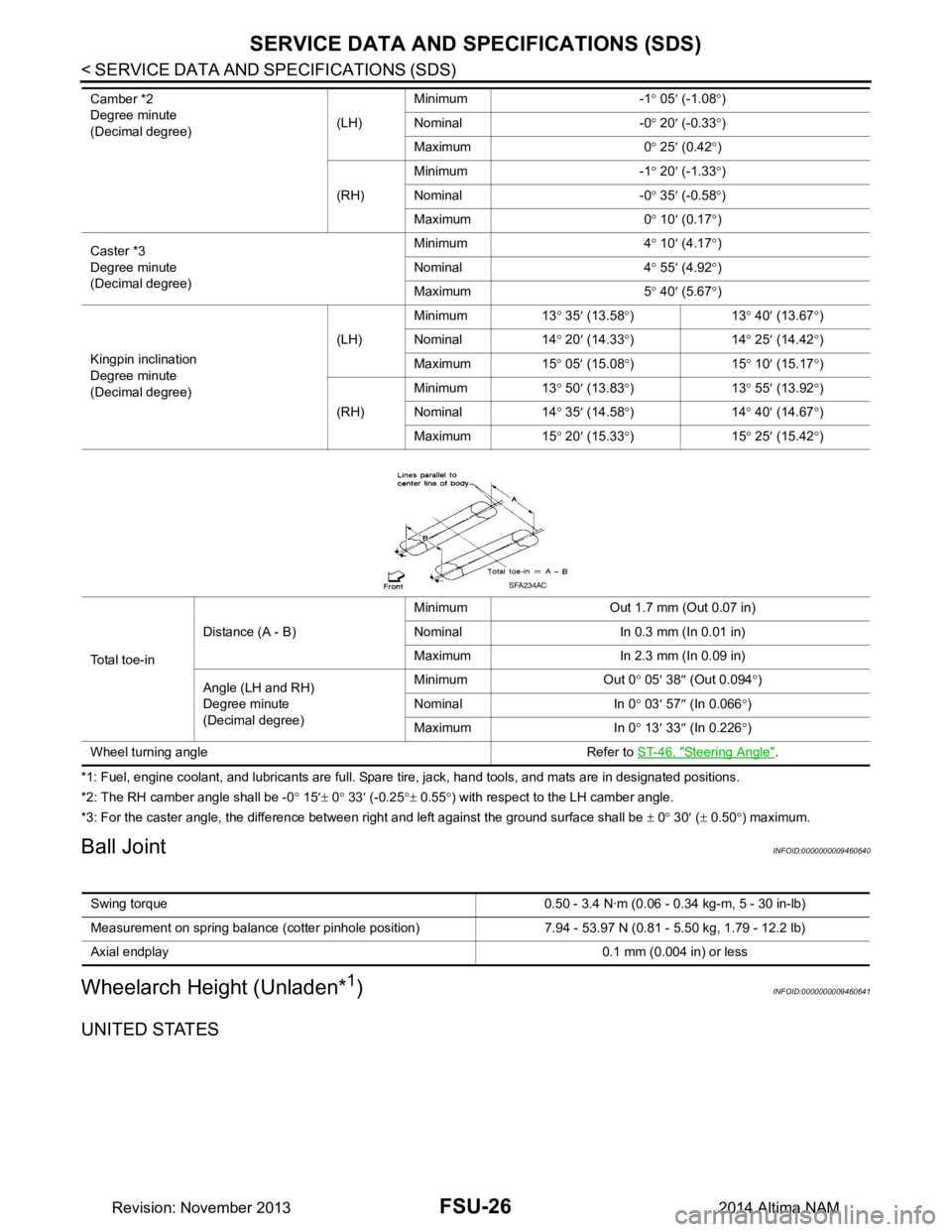

Camber *2

Degree minute

(Decimal degree) (LH)Minimum -1

° 05 ′ (-1.08 °)

Nominal -0 ° 20 ′ (-0.33 °)

Maximum 0 ° 25 ′ (0.42 °)

(RH) Minimum -1

° 20 ′ (-1.33 °)

Nominal -0 ° 35 ′ (-0.58 °)

Maximum 0 ° 10 ′ (0.17 °)

Caster *3

Degree minute

(Decimal degree) Minimum 4

° 10 ′ (4.17 °)

Nominal 4 ° 55 ′ (4.92 °)

Maximum 5 ° 40 ′ (5.67 °)

Kingpin inclination

Degree minute

(Decimal degree) (LH)

Minimum 13

° 35 ′ (13.58 °)13 ° 40 ′ (13.67 °)

Nominal 14 ° 20 ′ (14.33 °)14 ° 25 ′ (14.42 °)

Maximum 15 ° 05 ′ (15.08 °)15 ° 10 ′ (15.17 °)

(RH) Minimum 13

° 50 ′ (13.83 °)13 ° 55 ′ (13.92 °)

Nominal 14 ° 35 ′ (14.58 °)14 ° 40 ′ (14.67 °)

Maximum 15 ° 20 ′ (15.33 °)15 ° 25 ′ (15.42 °)

Total toe-in Distance (A - B)

Minimum Out 1.7 mm (Out 0.07 in)

Nominal In 0.3 mm (In 0.01 in)

Maximum In 2.3 mm (In 0.09 in)

Angle (LH and RH)

Degree minute

(Decimal degree) Minimum Out 0

° 05 ′ 38 ″ (Out 0.094 °)

Nominal In 0 ° 03 ′ 57 ″ (In 0.066 °)

Maximum In 0 ° 13 ′ 33 ″ (In 0.226 °)

Wheel turning angle Refer to ST-46, "Steering Angle"

.

SFA234AC

Swing torque 0.50 - 3.4 N·m (0 .06 - 0.34 kg-m, 5 - 30 in-lb)

Measurement on spring balance (cotter pinhole position) 7.94 - 53.97 N (0.81 - 5.50 kg, 1.79 - 12.2 lb)

Axial endplay 0.1 mm (0.004 in) or less

Revision: November 20132014 Altima NAM

Page 2537 of 4801

HOW TO READ WIRING DIAGRAMSGI-9

< HOW TO USE THIS MANUAL >

C

D E

F

G H

I

J

K L

M B

GI

N

O PHOW TO READ WIRING DIAGRAMS

Connector symbolsINFOID:0000000009462976

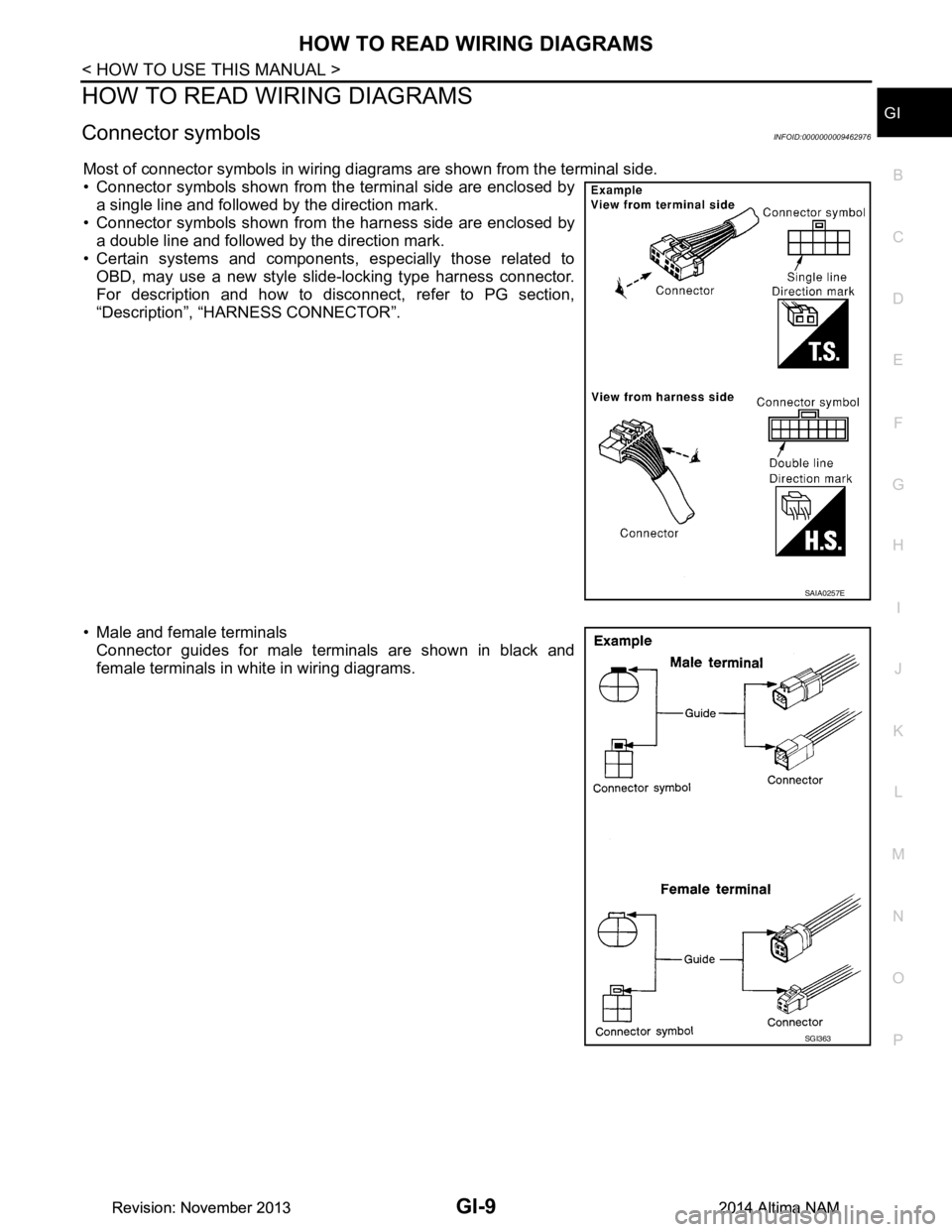

Most of connector symbols in wiring diagrams are shown from the terminal side.

• Connector symbols shown from the terminal side are enclosed by a single line and followed by the direction mark.

• Connector symbols shown from the harness side are enclosed by

a double line and followed by the direction mark.

• Certain systems and components, especially those related to

OBD, may use a new style slide-locking type harness connector.

For description and how to disconnect, refer to PG section,

“Description”, “HARNESS CONNECTOR”.

• Male and female terminals Connector guides for male terminals are shown in black and

female terminals in white in wiring diagrams.

SAIA0257E

SGI363

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2542 of 4801

GI-14

< HOW TO USE THIS MANUAL >

ABBREVIATIONS

E

F

G

H

ABBREVIATION DESCRIPTION E/T Exhaust temperature

EBD Electric brake force distribution EC Engine control

ECL Engine coolant level

ECM Engine control module ECT Engine coolant temperature

ECV Electrical control valve

EEPROM Electrically erasable pr ogrammable read only memory

EFT Engine fuel temperature

EGR Exhaust gas recirculation

EGRT Exhaust gas recirculation temperature EGT Exhaust gas temperature

EOP Engine oil pressure EP Exhaust pressure

EPR Exhaust pressure regulator EPS Electronically cont rolled power steering

ESP Electronic stability program system

EVAP canister Evaporative emission canister EVSE Electric vehicle supply equipmentEXC Exhaust control

ABBREVIATION DESCRIPTION FC Fan control

FCW Forward collision warning FIC Fuel injector controlFP Fuel pump

FR Front

FRP Fuel rail pressure

FRT Fuel rail temperatureFTP Fuel tank pressure FTT Fuel tank temperature

ABBREVIATION DESCRIPTION GND GroundGPS Global positioning systemGST Generic scan tool

ABBREVIATION DESCRIPTION HBMC Hydraulic body-motion control systemHDD Hard disk drive

HO2S Heated oxygen sensor HOC Heated oxidation catalyst

HPCM Hybrid power train control module

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2555 of 4801

PRECAUTIONSGI-27

< PRECAUTION >

C

D E

F

G H

I

J

K L

M B

GI

N

O P

• Install the xenon bulb secure ly. (Insufficient bulb socket

installation may melt the bu lb, the connector, the housing,

etc, by high-voltage leakage or corona discharge.)

• Never perform HID circuit inspection with a tester.

• Never touch the xenon bulb gl ass with hands. Never put oil

and grease on it.

• Dispose of the used xenon bulb after packing it in thick vinyl

without breaking it.

• Never wipe out dirt and contam ination with organic solvent

(thinner, gasoline, etc.).

Procedures without Cowl Top CoverINFOID:0000000009462994

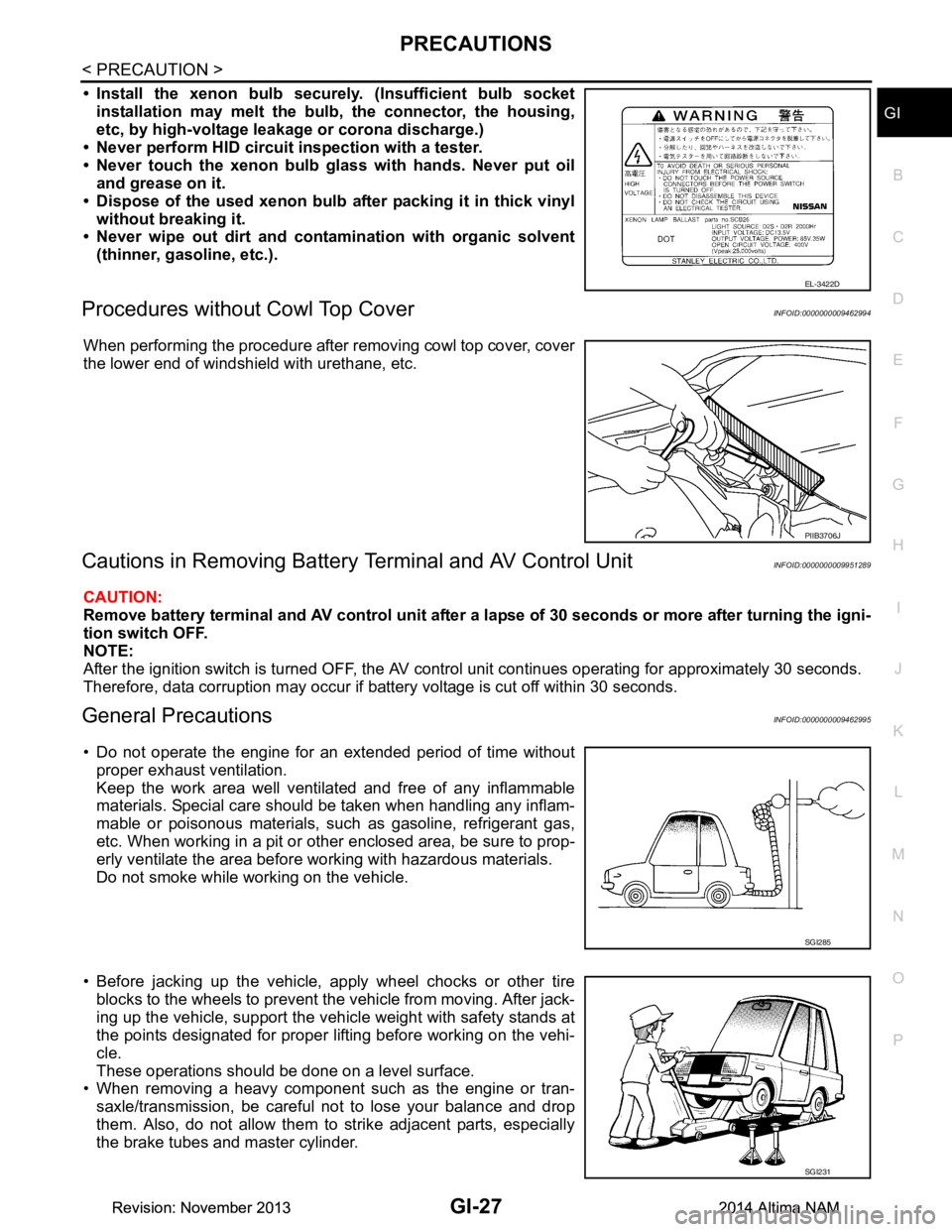

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Cautions in Removing Battery Terminal and AV Control UnitINFOID:0000000009951289

CAUTION:

Remove battery terminal and AV control unit after a lapse of 30 seconds or more after turning the igni-

tion switch OFF.

NOTE:

After the ignition switch is turned OFF, the AV cont rol unit continues operating for approximately 30 seconds.

Therefore, data corruption may occur if battery voltage is cut off within 30 seconds.

General PrecautionsINFOID:0000000009462995

• Do not operate the engine for an extended period of time without proper exhaust ventilation.

Keep the work area well ventilated and free of any inflammable

materials. Special care should be taken when handling any inflam-

mable or poisonous materials, such as gasoline, refrigerant gas,

etc. When working in a pit or ot her enclosed area, be sure to prop-

erly ventilate the area before working with hazardous materials.

Do not smoke while working on the vehicle.

• Before jacking up the vehicle, apply wheel chocks or other tire blocks to the wheels to prevent t he vehicle from moving. After jack-

ing up the vehicle, support the vehicle weight with safety stands at

the points designated for proper lifting before working on the vehi-

cle.

These operations should be done on a level surface.

• When removing a heavy component such as the engine or tran-

saxle/transmission, be careful not to lose your balance and drop

them. Also, do not allow them to strike adjacent parts, especially

the brake tubes and master cylinder.

EL-3422D

PIIB3706J

SGI285

SGI231

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2585 of 4801

SQUEAK AND RATTLE TROUBLE DIAGNOSESGW-5

< SYMPTOM DIAGNOSIS >

C

D E

F

G H

I

J

L

M A

B

GW

N

O P

SYMPTOM DIAGNOSIS

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Work FlowINFOID:0000000009463657

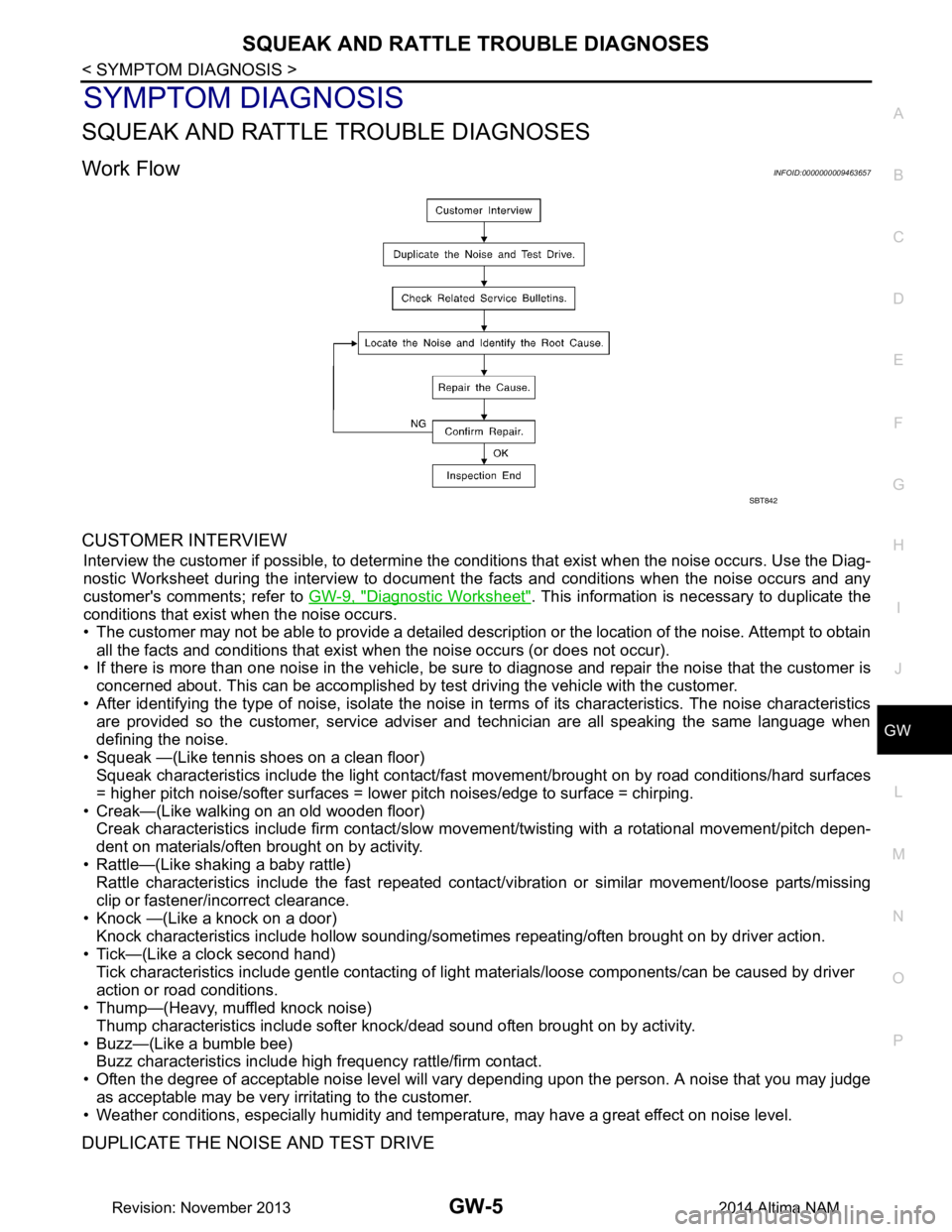

CUSTOMER INTERVIEW

Interview the customer if possible, to determine the c onditions that exist when the noise occurs. Use the Diag-

nostic Worksheet during the interv iew to document the facts and conditions when the noise occurs and any

customer's comments; refer to GW-9, "Diagnostic Worksheet"

. This information is necessary to duplicate the

conditions that exist when the noise occurs.

• The customer may not be able to provide a detailed descr iption or the location of the noise. Attempt to obtain

all the facts and conditions that exist when the noise occurs (or does not occur).

• If there is more than one noise in the vehicle, be sure to diagnose and repair the noise that the customer is

concerned about. This can be accomplished by test driving the vehicle with the customer.

• After identifying the type of noise, isolate the noise in terms of its characteristics. The noise characteristics

are provided so the customer, service adviser and technician are all speaking the same language when

defining the noise.

• Squeak —(Like tennis shoes on a clean floor) Squeak characteristics include the light contact/fast movement/brought on by road conditions/hard surfaces

= higher pitch noise/softer surfaces = lower pitch noises/edge to surface = chirping.

• Creak—(Like walking on an old wooden floor) Creak characteristics include firm contact/slow mo vement/twisting with a rotational movement/pitch depen-

dent on materials/often brought on by activity.

• Rattle—(Like shaking a baby rattle) Rattle characteristics include the fast repeated contac t/vibration or similar movement/loose parts/missing

clip or fastener/incorrect clearance.

• Knock —(Like a knock on a door) Knock characteristics include hollow sounding/someti mes repeating/often brought on by driver action.

• Tick—(Like a clock second hand) Tick characteristics include gentle contacting of li ght materials/loose components/can be caused by driver

action or road conditions.

• Thump—(Heavy, muffled knock noise)

Thump characteristics include softer k nock/dead sound often brought on by activity.

• Buzz—(Like a bumble bee) Buzz characteristics include high frequency rattle/firm contact.

• Often the degree of acceptable noise level will vary depending upon the person. A noise that you may judge

as acceptable may be very irritating to the customer.

• Weather conditions, especially humidity and temperature, may have a great effect on noise level.

DUPLICATE THE NOISE AND TEST DRIVE

SBT842

Revision: November 20132014 Altima NAM

Page 2659 of 4801

![NISSAN TEANA 2014 Service Manual

HAC-10

< SYSTEM DESCRIPTION >[AUTOMATIC AIR CONDITIONER]

COMPONENT PARTS

Component Description

INFOID:0000000009463092

1. ECM 2. IPDM E/R 3. BCM (view with combination meter removed)

4. A/C auto amp NISSAN TEANA 2014 Service Manual

HAC-10

< SYSTEM DESCRIPTION >[AUTOMATIC AIR CONDITIONER]

COMPONENT PARTS

Component Description

INFOID:0000000009463092

1. ECM 2. IPDM E/R 3. BCM (view with combination meter removed)

4. A/C auto amp](/img/5/57390/w960_57390-2658.png)

HAC-10

< SYSTEM DESCRIPTION >[AUTOMATIC AIR CONDITIONER]

COMPONENT PARTS

Component Description

INFOID:0000000009463092

1. ECM 2. IPDM E/R 3. BCM (view with combination meter removed)

4. A/C auto amp. (view with A/C switch assembly removed) 5. A/C switch assembly 6. A/C Compressor

7. Sunload sensor 8. Refrigerant pressure sensor (view with front bumper fascia removed)9. Ambient sensor

10. Fuse Block (J/B), Front blower motor relay 11. In-vehicle sensor 12. Accessory relay-2 (view with instru-

ment panel removed)

13. Blower motor (view with front A/C as- sembly removed from vehicle) 14. Intake door motor 15. Mode door motor

16. Air mix door motor LH 17. Air mix door motor RH 18. Intake sensor

ALIIA0599ZZ

Component Description

A/C auto amp. A/C auto amp. controls front automatic air conditioning system by inputting and calculating signals

from each sensor and each switch.

A/C Compressor Vaporized refrigerant is drawn into the A/C compressor from the evaporator, where it is compressed

to a high pressure, high temperature vapor. The hot, compressed vapor is then discharged to the con-

denser.

A/C switch assembly The A/C switch assembly controls the operation of the A/C and heating system based on inputs from

the temperature control knob, the mode switches, the blower control dial, the ambient temperature

sensor, the intake sensor, and inputs received from the ECM across the CAN. Diagnosis of the A/C

switch assembly can be performed using the CONSULT. There is no self-diagnostic feature available.

Air mix door motor LH The air mix door controls the mix of hot or cold air that enters the ventilation system. It is controlled

by the A/C auto amp. based on the position of the temperature dial. The air mix door motor LH re-

ceives position commands from the A/C auto amp. and reports actual door position back via an LCU

(Local Control Unit) installed inside the motor. Commands and responses are sent across the LIN (Lo-

cal Interconnect Network) to each motor simultaneously, with each motor having its own unique ad-

dress, thereby only responding to requests sent to its specific address. The LCU reads the door

position from a Position Balanced Resistor (PBR), also part of the motor, and returns that information

to the A/C auto amp. The LCU switches the polarity of the circuits connected to the DC motor to drive

the motor forward or backward as requested by the A/C auto amp. If the air mix door moves to a po-

sition less than 5% or more than 95% of its expected or allowed positions, the A/C auto amp. will set

a DTC.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2660 of 4801

![NISSAN TEANA 2014 Service Manual

COMPONENT PARTSHAC-11

< SYSTEM DESCRIPTION > [AUTOMATIC AIR CONDITIONER]

C

D E

F

G H

J

K L

M A

B

HAC

N

O P

Air mix door motor RH The air mix door controls the mix of hot or cold air that enters th NISSAN TEANA 2014 Service Manual

COMPONENT PARTSHAC-11

< SYSTEM DESCRIPTION > [AUTOMATIC AIR CONDITIONER]

C

D E

F

G H

J

K L

M A

B

HAC

N

O P

Air mix door motor RH The air mix door controls the mix of hot or cold air that enters th](/img/5/57390/w960_57390-2659.png)

COMPONENT PARTSHAC-11

< SYSTEM DESCRIPTION > [AUTOMATIC AIR CONDITIONER]

C

D E

F

G H

J

K L

M A

B

HAC

N

O P

Air mix door motor RH The air mix door controls the mix of hot or cold air that enters the ventilation system. It is controlled

by the A/C auto amp. based on the position of the temperature dial. The air mix door motor RH re-

ceives position commands from the A/C auto amp. and reports actual door position back via an LCU

(Local Control Unit) installed inside the motor. Commands and responses are sent across the LIN (Lo-

cal Interconnect Network) to each motor simultaneously, with each motor having its own unique ad-

dress, thereby only responding to requests sent to its specific address. The LCU reads the door

position from a Position Balanced Resistor (PBR), also part of the motor, and returns that information

to the A/C auto amp. The LCU switches the polarity of the circuits connected to the DC motor to drive

the motor forward or backward as requested by the A/C auto amp. If the air mix door moves to a po-

sition less than 5% or more than 95% of its expected or allowed positions, the A/C auto amp. will set

a DTC.

Ambient sensor The ambient sensor measures the temperature of the air surrounding the vehicle. The sensor uses a

thermistor which is sensitive to the change in temperature. The electrical resistance of the thermistor

decreases as temperature increases.

BCM The BCM receives the fan ON and A/C ON signals from the A/C auto amp. and sends a compressor

ON request to the ECM.

Blower motor The blower motor varies the speed at which the air flows through the ventilation system.

ECM The ECM sends a compressor ON request to the IPDM E/R based on the status of engine operation

and load as well as refrigerant pressure information. If all the conditions are met for A/C operation,

the ECM transmits the compressor ON request to the IPDM E/R. The ECM shares the refrigerant

pressure sensor signal, engine RPM, and engine coolant temperature with the A/C auto amp. via

CAN communication line.

Front blower motor relay The front blower motor relay controls the flow of current to fuse 17 and 27 in the Fuse Block (J/B).

The relay is connected directly to ground, and is energized when the ignition switch is in the ON or

START position.

Fuse Block (J/B) Located in the passenger compartment, behind the left lower IP, the Fuse Block (J/B) contains the

front blower motor relay and several fuses required for the air conditioner control system.

Intake door motor The intake door motor controls the position of the intake door. Fresh air is allowed to enter the cabin

in one position, and recirculated inside air is allowed to enter in the other position. At times the A/C

auto amp. may command partial fresh or recirculation based on evaporator or coolant temperatures.

The intake door motor receives position commands from the A/C auto amp. and reports actual door

position back via an LCU (Local Control Unit) installed inside the motor. Commands and responses

are sent across the LIN (Local Interconnect Network) to each motor simultaneously, with each motor

having its own unique address, thereby only responding to requests sent to its specific address. The

LCU reads the door position from a Position Balanced Resistor (PBR), also part of the motor, and re-

turns that information to the A/C auto amp. The LCU switches the polarity of the circuits connected to

the DC motor to drive the motor forward or backward as requested by the A/C auto amp. If the recir-

culation door moves to a position less than 5% or more than 95% of its expected or allowed positions,

the A/C auto amp. will set a DTC.

Intake sensor The intake sensor measures the temperature of the front evaporator fins. The sensor uses a ther-

mistor which is sensitive to the change in temperature. The electrical resistance of the thermistor de-

creases as temperature increases.

In-vehicle sensor In-vehicle sensor measures temperature of intake air that flows through aspirator to passenger room.

The sensor uses a thermistor which is sensitive to the change in temperature. The electrical resis-

tance of the thermistor decreases as temperature increases.

IPDM E/R Refer to PCS-6, "RELAY CONTROL SYSTEM : System Description"

.

Mode door motor The mode door controls the direction the conditioned air passes through the ventilation system.

Through a series of levers and gears, the mode door controls the defrost door, the foot door, and the

vent door. There are 5 preset positions: VENT, B/L, FOOT, D/F, and DEF. The FOOT position can be

set to allow some airflow through to the defroster vent, or to completely block the defroster vent using

the CONSULT. The mode door motor receives position commands from the A/C auto amp. and re-

ports actual door position back via an LCU (Local Control Unit) installed inside the motor. Commands

and responses are sent across the LIN (Local Interconnect Network) to each motor simultaneously,

with each motor having its own unique address, thereby only responding to requests sent to its spe-

cific address. The LCU reads the door position from a Position Balanced Resistor (PBR), also part of

the motor, and returns that information to the A/C auto amp. The LCU switches the polarity of the cir-

cuits connected to the DC motor to drive the motor forward or backward as requested by the A/C auto

amp. The mode door has 5 expected positions and, therefore, can set up to 5 DTCs if the expected

position is not reported back to the A/C auto amp.

Component Description

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM