esp NISSAN TEANA 2014 Owners Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 2162 of 4801

![NISSAN TEANA 2014 Owners Manual

EM-164

< REMOVAL AND INSTALLATION >[VQ35DE]

FUEL INJECTOR AND FUEL TUBE

6. Remove the electric throttle cont

rol actuator bolts in the reverse

order as shown and remove the electric throttle control NISSAN TEANA 2014 Owners Manual

EM-164

< REMOVAL AND INSTALLATION >[VQ35DE]

FUEL INJECTOR AND FUEL TUBE

6. Remove the electric throttle cont

rol actuator bolts in the reverse

order as shown and remove the electric throttle control](/img/5/57390/w960_57390-2161.png)

EM-164

< REMOVAL AND INSTALLATION >[VQ35DE]

FUEL INJECTOR AND FUEL TUBE

6. Remove the electric throttle cont

rol actuator bolts in the reverse

order as shown and remove the electric throttle control actuator

and position aside.

CAUTION:

• Handle carefully to avoid any shock to the electric throttle

control actuator.

• Do not disassemble.

7. Remove intake manifold collector. Refer to EM-146, "Removal and Installation"

.

8. When separating fuel feed hose and fuel tube connection, disconnect quick connector as follows:

a. Remove quick connector cap from quick connector.

b. Disconnect quick connector from fuel tube as follows: CAUTION:

Disconnect quick connector by using the quick connector release (commercial service tool: J-

45488), not by picking out retainer tabs.

i. With the sleeve side of quick connector release fa cing to quick connector, install the quick connector

release onto fuel tube.

ii. Insert the quick connector release (A) into quick connector (2) until sleeve (B) contacts and goes no further. Hold quick connec-

tor release on that position.

CAUTION:

Inserting quick connector re lease hard will not disconnect

quick connector. Hold qui ck connector release where it

contacts and goes no further.

iii. Draw and pull out quick connector straight from fuel tube (1). CAUTION:

• Do not reuse O-ring.

• Pull quick connector (E) ho lding position (D) as shown.

• Do not pull with lateral force applied. O-ring inside quick connector may be damaged.

• Prepare container and cloth beforehand as fuel will leak out.

• Avoid fire and sparks.

• Keep parts away from heat source. Especially, be careful when welding is performed around

them.

• Do not expose parts to battery electrolyte or other acids.

• Do not bend or twist connection between quick connector and fuel feed hose (with damper) dur-

ing installati on/removal.

• To keep clean the connecting portion and to avoid dam-

age and foreign materials, cover them completely with

plastic bags, etc. (A) or something similar.

9. Disconnect harness connector from fuel injector.

SEM711G

(C) : Insert and retain

JPBIA0033ZZ

JPBIA0035ZZ

Revision: November 20132014 Altima NAM

Page 2223 of 4801

![NISSAN TEANA 2014 Owners Manual

CYLINDER BLOCKEM-225

< UNIT DISASSEMBLY AND ASSEMBLY > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

CAUTION:

• Apply new engine oil to parts as marked in illustrations before installation.

• Place NISSAN TEANA 2014 Owners Manual

CYLINDER BLOCKEM-225

< UNIT DISASSEMBLY AND ASSEMBLY > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

CAUTION:

• Apply new engine oil to parts as marked in illustrations before installation.

• Place](/img/5/57390/w960_57390-2222.png)

CYLINDER BLOCKEM-225

< UNIT DISASSEMBLY AND ASSEMBLY > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

CAUTION:

• Apply new engine oil to parts as marked in illustrations before installation.

• Place removed parts such as bearings and bear ing caps in their proper order and direction.

• When installing the connecting ro d nuts, and main bearing cap bolts, apply new engine oil to the

threads and mating surfaces

• Do not allow any magnetic materials to contact the signal plate teeth on the drive plate.

DISASSEMBLY

1. Remove the engine assembly. Refer to EM-220, "Removal and Installation".

2. Remove drive plate. • Loosen bolts in diagonal order.

CAUTION:

• Do not disassemble drive plate.

• Place the drive plate with signal plate surface facing

upward.

• Be careful not to damage or scratch drive plate. Espe- cially avoiding deforming and damaging of signal plate

teeth.

• Keep magnetic materials away from signal plate.

3. Remove pilot converter using Tool.

4. Install the engine on the engine stand. CAUTION:

• Use an engine stand that has a load capacity [approximately 240kg (529) or more] large enough

for supporting the engine weight.

• Before removing the hanging chains, make sure th e engine stand is stable and there is no risk of

overturning.

5. Remove the knock sensors. CAUTION:

Carefully handle sensors avoiding shocking it.

1. Reinforcement plate 2. Drive plate 3. Rear oil seal retainer

4. Rear oil seal 5. Sub harness 6. Knock sensor

7. Cylinder block 8. Thrust bearing (upper) 9. Main bearing (upper)

10. Crankshaft 11. Crankshaft key 12. Thrust bearing (lower)

13. Main bearing (lower) 14. Main bearing cap 15. Main bearing cap bolt

16. Main bearing beam 17. Baffle plate 18. Connecting rod bolt

19. Connecting rod bearing cap 20. Connecting rod bearing 21. Connecting rod

22. Snap ring 23. Piston pin 24. Piston

25. Oil ring 26. Second ring 27. Top ring

28. Pilot converter 29. Oil jet 30. Gasket (for Canada)

31. Cylinder block heater (for Canada) A. Crankshaft side B. Chamfered

C. Follow the assembly procedure D. Front mark

SEM760G

Tool number : ST16610001 (J-23907)

SEM005G

Revision: November 20132014 Altima NAM

Page 2224 of 4801

![NISSAN TEANA 2014 Owners Manual

EM-226

< UNIT DISASSEMBLY AND ASSEMBLY >[VQ35DE]

CYLINDER BLOCK

6. Drain the engine of all coolant and oil.

7. Remove the oil pan. Refer to EM-157, "Removal and Installation (Upper Oil Pan)"

.

8. R NISSAN TEANA 2014 Owners Manual

EM-226

< UNIT DISASSEMBLY AND ASSEMBLY >[VQ35DE]

CYLINDER BLOCK

6. Drain the engine of all coolant and oil.

7. Remove the oil pan. Refer to EM-157, "Removal and Installation (Upper Oil Pan)"

.

8. R](/img/5/57390/w960_57390-2223.png)

EM-226

< UNIT DISASSEMBLY AND ASSEMBLY >[VQ35DE]

CYLINDER BLOCK

6. Drain the engine of all coolant and oil.

7. Remove the oil pan. Refer to EM-157, "Removal and Installation (Upper Oil Pan)"

.

8. Remove the timing chain primary and secondary. Refer to EM-182, "Removal and Installation"

.

9. Remove the cylinder head. Refer to EM-207, "Removal and Installation"

.

10. Cut away liquid gasket and remove rear oil seal retainer using Tool. Refer to EM-124, "Precaution for Liquid Gasket"

.

CAUTION:

• Be careful not to damage mounting surface.

• If rear oil seal retainer is removed, replace it with a new one.

NOTE:

Rear oil seal and retainer form a single part and are handled as

an assembly.

11. Remove the piston and connecting rod assemblies.

a. Position the crankshaft pin corresponding to the connecting rod to be removed onto the bottom dead center.

b. Remove the connecting rod cap.

c. Using a hammer handle or similar tool, push the piston and con- necting rod assembly out to the cylinder head side.

• Before removing the piston and connecting rod assembly, check the connecting rod side clearance. Refer to EM-234,

"Inspection".

12. Remove the connecting rod bearings. CAUTION:

• When removing the connecting rod side bearings, note the installation position. Keep them in

the correct order.

13. Remove the piston rings from the piston. • Use a piston ring expander.

CAUTION:

• When removing the piston rings, be careful not to damage the piston. Do not exp and the rings excessively.

• Be careful to mark the rings if they are to be reused so

they are installed in their original position.

• Before removing the piston rings, check the piston ring side clear- ance. Refer to EM-234, "Inspection"

.

14. Remove the piston from the connecting rod as follows.

a. Using a snap ring pliers, remove the snap ring. CAUTION:

Do not reuse snap rings. Tool number : KV10111100 (J-37228)

SEM830E

PBIC0086E

PBIC0087E

PBIC0260E

Revision: November 20132014 Altima NAM

Page 2230 of 4801

![NISSAN TEANA 2014 Owners Manual

EM-232

< UNIT DISASSEMBLY AND ASSEMBLY >[VQ35DE]

CYLINDER BLOCK

c. Install the snap ring into the front of the piston pin-groove.

• After installing, check that the connecting rod pivots smoothlyo NISSAN TEANA 2014 Owners Manual

EM-232

< UNIT DISASSEMBLY AND ASSEMBLY >[VQ35DE]

CYLINDER BLOCK

c. Install the snap ring into the front of the piston pin-groove.

• After installing, check that the connecting rod pivots smoothlyo](/img/5/57390/w960_57390-2229.png)

EM-232

< UNIT DISASSEMBLY AND ASSEMBLY >[VQ35DE]

CYLINDER BLOCK

c. Install the snap ring into the front of the piston pin-groove.

• After installing, check that the connecting rod pivots smoothlyon the pin.

CAUTION:

Do not reuse snap rings.

11. Using a piston ring expander, install the piston rings. CAUTION:

• Be careful not to damage the piston.

• When the piston rings are not replaced, remount the rings

in their original positions.

• When replacing the piston ri ngs, those without stamped

surface (A) can be mounted either side up.

• Install the second ring with the stamped surface (B) facing upward. If the ring is not stamped it can face in either

direction.

• Position each ring with the gap as shown, referring to the pis- ton front mark.

12. Install the connecting rod bearings to the connecting rod and the connecting rod cap.

• When installing the connecting rod bearings, apply engine oil to the bearing surface (crankshaft side). Do not apply oil to the

back surface (connecting rod and cap side), but thoroughly

clean it.

• When installing, align the connecting rod bearing protrusion

with the notch of the connecting rod to install.

• Check that the oil holes on the connecting rod and on the cor- responding bearing are aligned.

PBIC0260E

To p r i n g ( A ) : —

Second ring (B) : 2AJPBIA0263ZZ

PBIC0808E

PBIC0266E

Revision: November 20132014 Altima NAM

Page 2231 of 4801

![NISSAN TEANA 2014 Owners Manual

CYLINDER BLOCKEM-233

< UNIT DISASSEMBLY AND ASSEMBLY > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

13. Install the piston and connecting rod assembly into the corre-

sponding cylinder.

• Position t NISSAN TEANA 2014 Owners Manual

CYLINDER BLOCKEM-233

< UNIT DISASSEMBLY AND ASSEMBLY > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

13. Install the piston and connecting rod assembly into the corre-

sponding cylinder.

• Position t](/img/5/57390/w960_57390-2230.png)

CYLINDER BLOCKEM-233

< UNIT DISASSEMBLY AND ASSEMBLY > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

13. Install the piston and connecting rod assembly into the corre-

sponding cylinder.

• Position the crankshaft pin corresponding to the connecting

rod to be installed onto the bottom dead center.

• Apply engine oil sufficiently to the cylinder bore, piston, and crankshaft pin.

• Match the cylinder position wit h the cylinder No. (B) on the

connecting rod to install.

• Install the piston with the piston front mark (A) on the crown

facing the front of the engine ( ), using a suitable tool.

- Oil hole (C)

CAUTION:

Be careful not to damage the crankshaft pin and cyl inder wall, resulting from an interference of the

connecting rod big end.

14. Install the connecting rod cap. • Match the stamped cylinder number marks on the connectingrod with those on the cylinder cap for installation.

• Install the piston connecting rod assembly and cap so that the front mark on the cap and piston are facing the front of the

engine.

• Lubricate the threads and seat surfaces with new engine

oil.

15. Check the connecting rod cap bolts before reusing, then install

in their original position in the connecting rod. The bolts should

screw in smoothly by hand.

• Measure the outer diameter of the connecting rod cap bolts as

shown.

16. Tighten the connecting rod cap bolts in two stages using Tool: CAUTION:

Always use either an angle wr ench or protractor. Avoid

tightening based on visual check alone.

• Apply engine oil to the threads and seats of the connecting rod cap bolts.

• After tightening the connecting rod cap bolts, make sure that the crankshaft rotates smoothly.

• Check the connecting rod side clearance. If beyond t he limit, replace the connecting rod and/or crank-

shaft.

AWBIA0029ZZ

SEM457G

Outer diameter (d) of th e connecting rod cap bolt

Standard : 7.90 - 8.00 mm (0.3110 - 0.3150 in)

Limit : 7.75 mm (0.3051 in)

SEM538G

Stage 1 : 19.6 N·m (2.0 kg-m, 14 ft-lb)

Stage 2 : 90 ° - 95 ° degrees clockwise

Tool number : KV10112100 (BT-8653-A)

Connecting rod side clearance:

Standard : 0.20 - 0.35 mm (0.0079 - 0.0138 in)

Limit : 0.40 mm (0.0157 in)

SEM953E

Revision: November 20132014 Altima NAM

Page 2235 of 4801

![NISSAN TEANA 2014 Owners Manual

CYLINDER BLOCKEM-237

< UNIT DISASSEMBLY AND ASSEMBLY > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

• Install the connecting rod cap without the connecting rod bearing

installed. After tightening the NISSAN TEANA 2014 Owners Manual

CYLINDER BLOCKEM-237

< UNIT DISASSEMBLY AND ASSEMBLY > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

• Install the connecting rod cap without the connecting rod bearing

installed. After tightening the](/img/5/57390/w960_57390-2234.png)

CYLINDER BLOCKEM-237

< UNIT DISASSEMBLY AND ASSEMBLY > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

• Install the connecting rod cap without the connecting rod bearing

installed. After tightening the connecting rod nut to the specified

torque, measure the connecting rod bearing housing big end inner

diameter using an inside micrometer.

CONNECTING ROD BUSHING OIL CLEARANCE (SMALL END)

Inner Diameter of Con necting Rod (Small End)

• Measure inner diameter of piston pin bushing.

Outer Diameter of Piston Pin

• Measure outer diameter of piston pin.

Connecting Rod Bushing Oil Clearance (Small End)

(Connecting rod small end oil clearance) = (Inner diameter of con-

necting rod small end) – (Outer diameter of piston pin)

• If the measured value exceeds the standard, replace the connect- ing rod assembly and/or piston and piston pin assembly.

• If replacing the piston and piston pin assembly, use the Table for

Selective Fitting for Piston to select the piston corresponding to the

applicable bore grade of the cylinder block to be used. Follow the

"PISTON-TO-CYLINDER BORE CLEARANCE" procedure.

Factory installed parts grading: Standard : 55.000 - 55.013 mm (2.1654 - 2.1659 in)

PBIC0119E

Standard Grade No. 0

: 22.000 - 22.006 mm (0.8661 - 0.8664 in)

Grade No. 1

: 22.006 - 22.012 mm (0.8664 - 0.8666 in)

PBIC0120E

Standard Grade No. 0 : 21.989 - 21.995 mm (0.8657 - 0.8659 in)

Grade No. 1

: 21.995 - 22.001 mm (0.8659 - 0.8662 in)

PBIC0117E

Standard : 0.005 - 0.017 mm (0.0002 - 0.0007 in)

Limit : 0.030 mm (0.0012 in)

SEM457G

Revision: November 20132014 Altima NAM

Page 2240 of 4801

![NISSAN TEANA 2014 Owners Manual

EM-242

< UNIT DISASSEMBLY AND ASSEMBLY >[VQ35DE]

CYLINDER BLOCK

a. The grade number of each cylinder block main journal is

punched on the respective cylinder block. These numbers are

punched in eith NISSAN TEANA 2014 Owners Manual

EM-242

< UNIT DISASSEMBLY AND ASSEMBLY >[VQ35DE]

CYLINDER BLOCK

a. The grade number of each cylinder block main journal is

punched on the respective cylinder block. These numbers are

punched in eith](/img/5/57390/w960_57390-2239.png)

EM-242

< UNIT DISASSEMBLY AND ASSEMBLY >[VQ35DE]

CYLINDER BLOCK

a. The grade number of each cylinder block main journal is

punched on the respective cylinder block. These numbers are

punched in either Arabic or Roman numerals. If measured diam-

eter is out of the grade punched, decide suitable grade from

available main bearings.

b. The grade number of each crankshaft main journal is punched on the crankshaft end. These numbers are punched in either

Arabic or Roman numerals. If measured diameter is out of grade

punched, decide the suitable grade from available main bear-

ings.

c. Select the main bearing suitable thickness according to the following table:

SEM756G

SEM452G

PBIC0814E

Revision: November 20132014 Altima NAM

Page 2278 of 4801

EXL-12

< SYSTEM DESCRIPTION >

SYSTEM

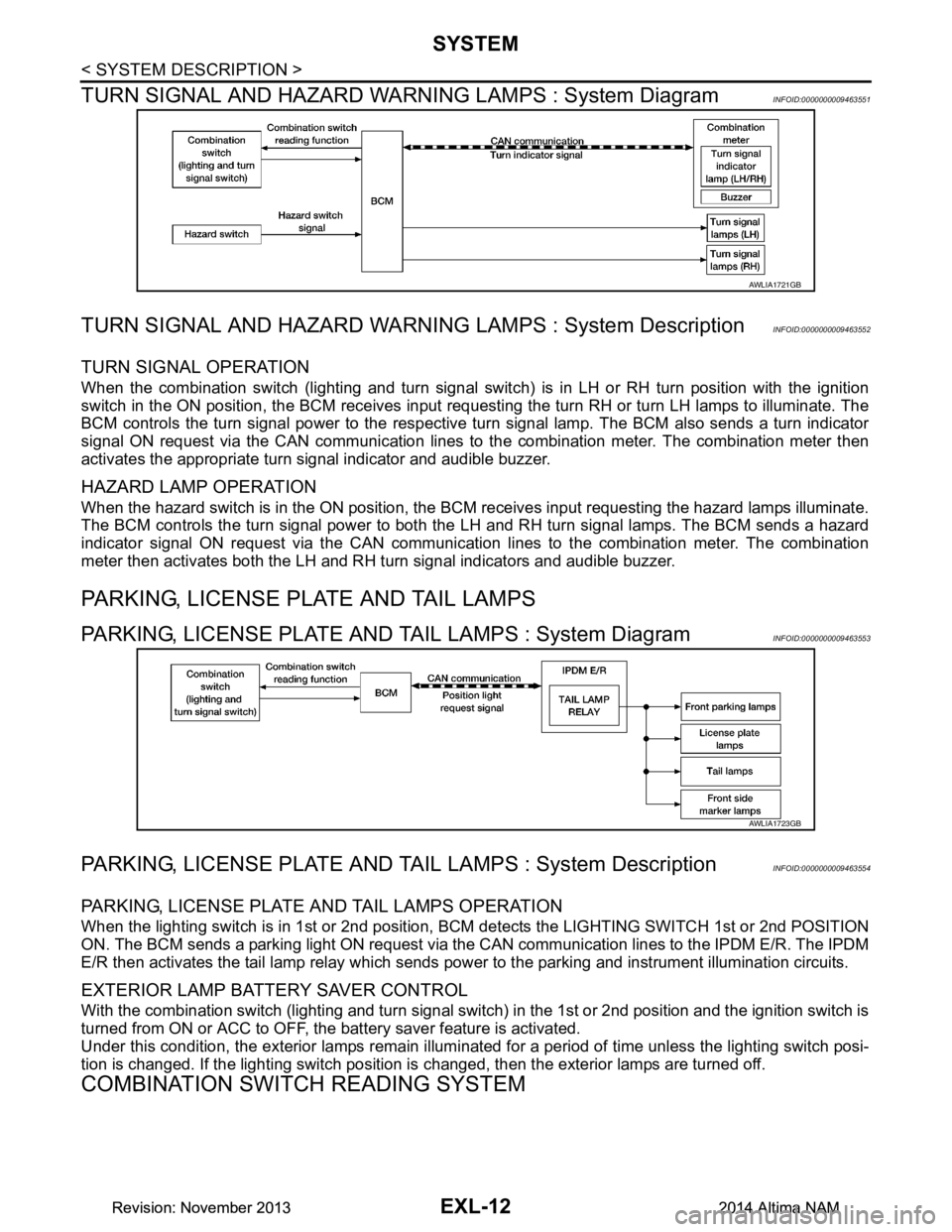

TURN SIGNAL AND HAZARD WARNI NG LAMPS : System Diagram

INFOID:0000000009463551

TURN SIGNAL AND HAZARD WARNING LAMPS : System DescriptionINFOID:0000000009463552

TURN SIGNAL OPERATION

When the combination switch (lighting and turn signal swit ch) is in LH or RH turn position with the ignition

switch in the ON position, the BCM receives input reques ting the turn RH or turn LH lamps to illuminate. The

BCM controls the turn signal power to the respective turn signal lamp. The BCM also sends a turn indicator

signal ON request via the CAN communication lines to the combination meter. The combination meter then

activates the appropriate turn signal indicator and audible buzzer.

HAZARD LAMP OPERATION

When the hazard switch is in the ON position, the BC M receives input requesting the hazard lamps illuminate.

The BCM controls the turn signal power to both the LH and RH turn signal lamps. The BCM sends a hazard

indicator signal ON request via the CAN communication lines to the combination meter. The combination

meter then activates both the LH and RH turn signal indicators and audible buzzer.

PARKING, LICENSE PLATE AND TAIL LAMPS

PARKING, LICENSE PLATE AND TAIL LAMPS : System DiagramINFOID:0000000009463553

PARKING, LICENSE PLATE AND TA IL LAMPS : System DescriptionINFOID:0000000009463554

PARKING, LICENSE PLATE AND TAIL LAMPS OPERATION

When the lighting switch is in 1st or 2nd position, BCM detects the LIGHTING SWITCH 1st or 2nd POSITION

ON. The BCM sends a parking light ON request via the CAN communication lines to the IPDM E/R. The IPDM

E/R then activates the tail lamp relay which sends power to the parking and instrument illumination circuits.

EXTERIOR LAMP BATTERY SAVER CONTROL

With the combination switch (lighting and turn signal switch) in the 1st or 2nd position and the ignition switch is

turned from ON or ACC to OFF, the battery saver feature is activated.

Under this condition, the exterior lamps remain illumi nated for a period of time unless the lighting switch posi-

tion is changed. If the lighting switch position is changed, then the exterior lamps are turned off.

COMBINATION SWITCH READING SYSTEM

AWLIA1721GB

AWLIA1723GB

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2280 of 4801

EXL-14

< SYSTEM DESCRIPTION >

SYSTEM

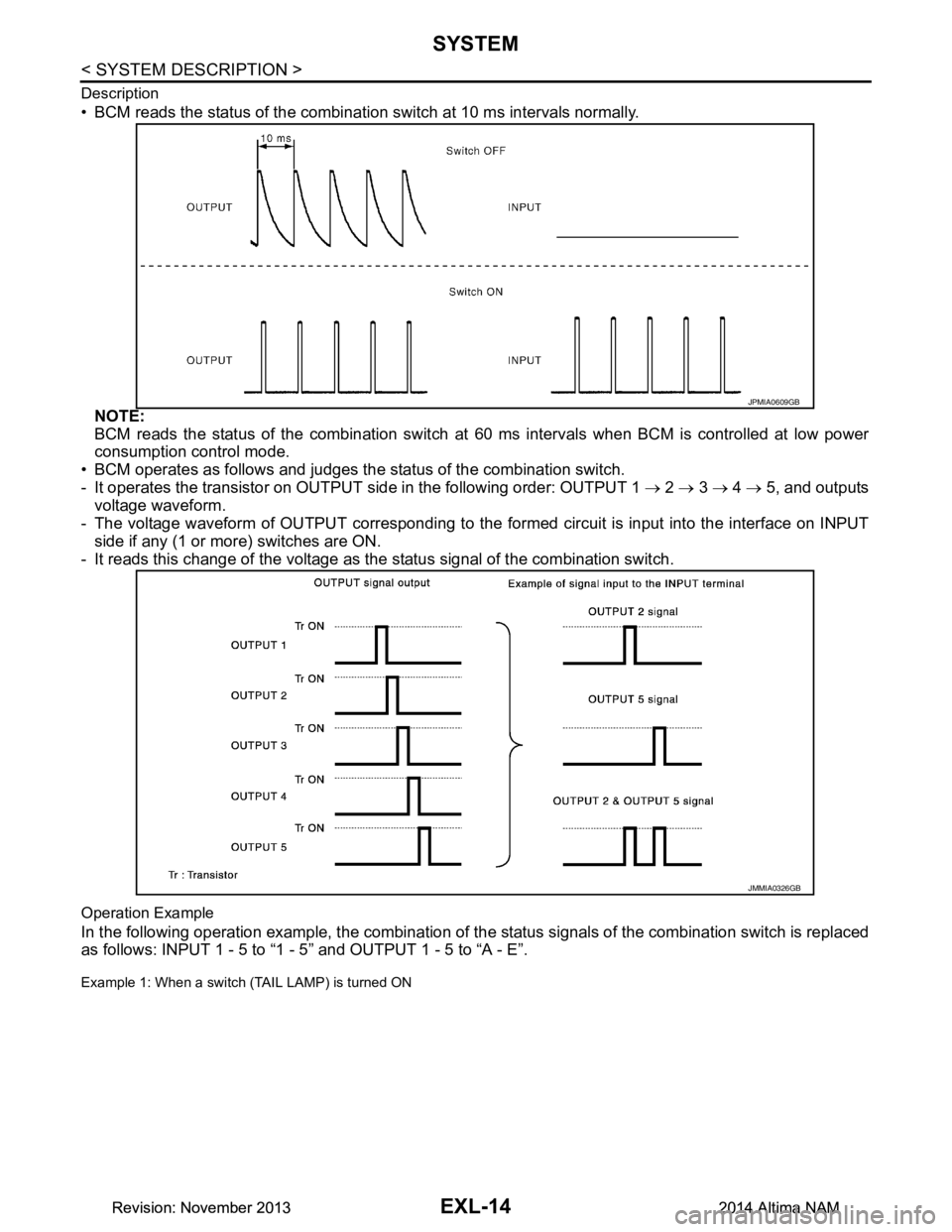

Description

• BCM reads the status of the combination switch at 10 ms intervals normally.NOTE:

BCM reads the status of the combination switch at 60 ms intervals when BCM is controlled at low power

consumption control mode.

• BCM operates as follows and judges the status of the combination switch.

- It operates the transistor on OUTPUT side in the following order: OUTPUT 1 → 2 → 3 → 4 → 5, and outputs

voltage waveform.

- The voltage waveform of OUTPUT corresponding to the formed circuit is input into the interface on INPUT

side if any (1 or more) switches are ON.

- It reads this change of the voltage as the status signal of the combination switch.

Operation Example

In the following operation example, the combination of t he status signals of the combination switch is replaced

as follows: INPUT 1 - 5 to “1 - 5” and OUTPUT 1 - 5 to “A - E”.

Example 1: When a switch (TAIL LAMP) is turned ON

JPMIA0609GB

JMMIA0326GB

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2424 of 4801

EXT-10

< PERIODIC MAINTENANCE >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

PERIODIC MAINTENANCE

SQUEAK AND RATTLE TROUBLE DIAGNOSES

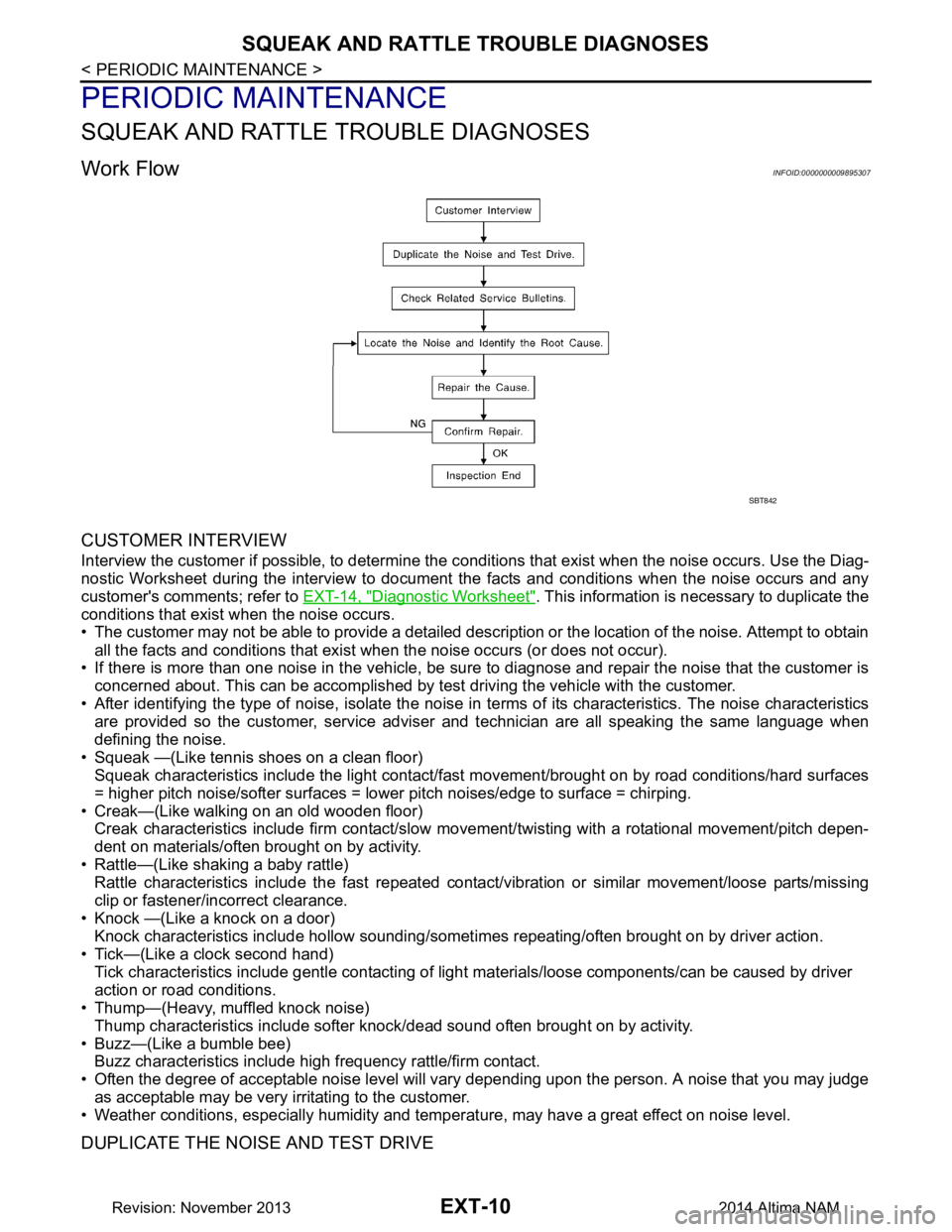

Work FlowINFOID:0000000009895307

CUSTOMER INTERVIEW

Interview the customer if possible, to determine the conditions that exist when the noise occurs. Use the Diag-

nostic Worksheet during the interview to document the facts and conditions when the noise occurs and any

customer's comments; refer to EXT-14, "Diagnostic Worksheet"

. This information is necessary to duplicate the

conditions that exist when the noise occurs.

• The customer may not be able to provide a detailed description or the location of the noise. Attempt to obtain

all the facts and conditions that exist w hen the noise occurs (or does not occur).

• If there is more than one noise in the vehicle, be sure to diagnose and repair the noise that the customer is

concerned about. This can be accomplished by test driving the vehicle with the customer.

• After identifying the type of noise, isolate the noise in terms of its characteristics. The noise characteristics

are provided so the customer, service adviser and technician are all speaking the same language when

defining the noise.

• Squeak —(Like tennis shoes on a clean floor) Squeak characteristics include the light contact/fast movement/brought on by road conditions/hard surfaces

= higher pitch noise/softer surfaces = lower pitch noises/edge to surface = chirping.

• Creak—(Like walking on an old wooden floor) Creak characteristics include firm contact/slow mo vement/twisting with a rotational movement/pitch depen-

dent on materials/often brought on by activity.

• Rattle—(Like shaking a baby rattle) Rattle characteristics include the fast repeated contac t/vibration or similar movement/loose parts/missing

clip or fastener/incorrect clearance.

• Knock —(Like a knock on a door) Knock characteristics include hollow sounding/someti mes repeating/often brought on by driver action.

• Tick—(Like a clock second hand) Tick characteristics include gentle contacting of light materials/loose components/can be caused by driver

action or road conditions.

• Thump—(Heavy, muffled knock noise)

Thump characteristics include softer k nock/dead sound often brought on by activity.

• Buzz—(Like a bumble bee) Buzz characteristics include hi gh frequency rattle/firm contact.

• Often the degree of acceptable noise level will vary depending upon the person. A noise that you may judge

as acceptable may be very irritating to the customer.

• Weather conditions, especially humidity and temperat ure, may have a great effect on noise level.

DUPLICATE THE NOISE AND TEST DRIVE

SBT842

Revision: November 20132014 Altima NAM