esp NISSAN TEANA 2014 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 3580 of 4801

![NISSAN TEANA 2014 Service Manual

SYSTEMPWC-73

< SYSTEM DESCRIPTION > [LH & RH FRONT ANTI-PINCH]

C

D E

F

G H

I

J

L

M A

B

PWC

N

O P

POWER WINDOW OPERATION

• Power window system activated by the power window swit ch when the igniti NISSAN TEANA 2014 Service Manual

SYSTEMPWC-73

< SYSTEM DESCRIPTION > [LH & RH FRONT ANTI-PINCH]

C

D E

F

G H

I

J

L

M A

B

PWC

N

O P

POWER WINDOW OPERATION

• Power window system activated by the power window swit ch when the igniti](/img/5/57390/w960_57390-3579.png)

SYSTEMPWC-73

< SYSTEM DESCRIPTION > [LH & RH FRONT ANTI-PINCH]

C

D E

F

G H

I

J

L

M A

B

PWC

N

O P

POWER WINDOW OPERATION

• Power window system activated by the power window swit ch when the ignition switch is in the ON position

or during the retained power operation after ignition switch turns OFF.

• Power window main switch (driver side) can open/close all windows.

• Front & rear power window switch can open/close the corresponding windows.

• If door glass receives resistance that is more than the specified value and the power window is in the AUTO-

UP operation (Front LH & RH), power window will move in the reverse direction (Anti-Pinch Function).

POWER WINDOW AUTO-OPERATION (FRONT LH & RH)

• AUTO UP/DOWN operation can be performed when main power window and door lock/unlock switch &

power window and door lock/unlock switch RH turns to AUTO.

• Encoder continues detecting the movement of power window motor and transmits to power window switch

as the encoder pulse signal while power window motor is operating.

• Power window switch reads the changes of encoder signal and stops AUTO operation when door glass is at fully opened/closed position.

• Power window motor is operable in case encoder is malfunctioning.

• AUTO function does not operate if encoder is malfunctioning.

RETAINED POWER OPERATION

• Retained power operation is an additional power supply function that enables power window system to oper-

ate during the 45 seconds even when ignition switch is turned OFF

Retained power function cancel conditions • Front door CLOSE (door switch OFF) →OPEN (door switch ON).

• When ignition switch is ON.

• When timer time passes. (45 seconds)

POWER WINDOW LOCK FUNCTION

Ground circuit inside power window main switch shuts off when power window lock switch is ON. This inhibits

power window switch operation except with the power window switch.

ANTI-PINCH OPERATION (FRONT LH & RH)

• Pinch foreign material in the door glass during AUTO-U P operation, and it is the anti-pinch function that low-

ers the door glass 150 mm (5.9 in.) or 2 seconds when detected.

• Encoder continues detecting the movement of power window motor and transmits to power window switch

as the encoder pulse signal while power window motor is operating.

• Resistance is applied to the power window motor ro tation that changes the frequency of encoder pulse sig-

nal if foreign material is trapped in the door glass.

• Power window switch controls to lower the window glas s for 150 mm (5.9 in.) or 2 seconds after it detects

encoder pulse signal frequency change.

OPERATION CONDITION

• When all door glass AUTO-UP operation is performed ( anti-pinch function does not operate just before the

door glass closes and is fully closed)

NOTE:

Depending on environment and driving conditions, if a similar impact or load is applied to the door glass, it

may lower.

KEY CYLINDER SWITCH OPERATION

Hold the door key cylinder to the LOCK or UNLOCK dire ction for more than 1 second to OPEN or CLOSE front

power windows when ignition switch is OFF. In addition, it stops when key position is moved to NEUTRAL

when operating.

OPERATION CONDITION

• Ignition switch OFF

Item Input signal to front power window

switch Front power window switch

function Actuator

Power window and

door lock/unlock

switch RH Front power window motor RH UP/

DOWN signal Power window control Front power window motor RH

Encoder Encoder pulse signal

BCM RAP signal

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3602 of 4801

![NISSAN TEANA 2014 Service Manual

POWER SUPPLY AND GROUND CIRCUITPWC-95

< DTC/CIRCUIT DIAGNOSIS > [LH & RH FRONT ANTI-PINCH]

C

D E

F

G H

I

J

L

M A

B

PWC

N

O P

DTC/CIRCUIT DIAGNOSIS

POWER SUPPLY AND GROUND CIRCUIT

BCM

BCM : Diagnosi NISSAN TEANA 2014 Service Manual

POWER SUPPLY AND GROUND CIRCUITPWC-95

< DTC/CIRCUIT DIAGNOSIS > [LH & RH FRONT ANTI-PINCH]

C

D E

F

G H

I

J

L

M A

B

PWC

N

O P

DTC/CIRCUIT DIAGNOSIS

POWER SUPPLY AND GROUND CIRCUIT

BCM

BCM : Diagnosi](/img/5/57390/w960_57390-3601.png)

POWER SUPPLY AND GROUND CIRCUITPWC-95

< DTC/CIRCUIT DIAGNOSIS > [LH & RH FRONT ANTI-PINCH]

C

D E

F

G H

I

J

L

M A

B

PWC

N

O P

DTC/CIRCUIT DIAGNOSIS

POWER SUPPLY AND GROUND CIRCUIT

BCM

BCM : Diagnosis ProcedureINFOID:0000000009955268

Regarding Wiring Diagram information, refer to BCS-55, "Wiring Diagram".

1. CHECK FUSE AND FUSIBLE LINK

Check that the following fuse and fusible link are not blown.

Is the fuse or fusible link blown?

YES >> Replace the blown fuse or fusible link after repairing the affected circuit.

NO >> GO TO 2

2. CHECK POWER SUPPLY CIRCUIT

1. Disconnect BCM connector M21.

2. Check voltage between BCM connector M21 terminals 131, 139 and ground.

Is the inspection result normal?

YES >> GO TO 3

NO >> Repair or replace harness or connectors.

3. CHECK GROUND CIRCUIT

Check continuity between BCM connector M21 terminals 134, 143 and ground.

Is the inspection result normal?

YES >> Inspection End.

NO >> Repair or replace harness or connectors.

POWER WINDOW MAIN SWITCH

POWER WINDOW MAIN SWITCH : DescriptionINFOID:0000000009460913

• BCM supplies power.

• It operates each power window motor via corresponding power window switch and makes window move up/

down when main power window and door lock/unlock switch is operated.

Terminal No. Signal name Fuse and fusible link No.

139 Fusible link battery power I (40A)

131 BCM battery fuse 1 (10A)

BCM GroundVo l ta g e

(Approx.)

Connector Terminal

M21 131

—Batteryvoltage

139

BCM Ground Continuity

Connector Terminal

M21 134

—Yes

143

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3700 of 4801

SQUEAK AND RATTLE TROUBLE DIAGNOSESRF-35

< SYMPTOM DIAGNOSIS >

C

D E

F

G H

I

J

L

M A

B

RF

N

O P

SQUEAK AND RATTLE TROUBLE DIAGNOSES

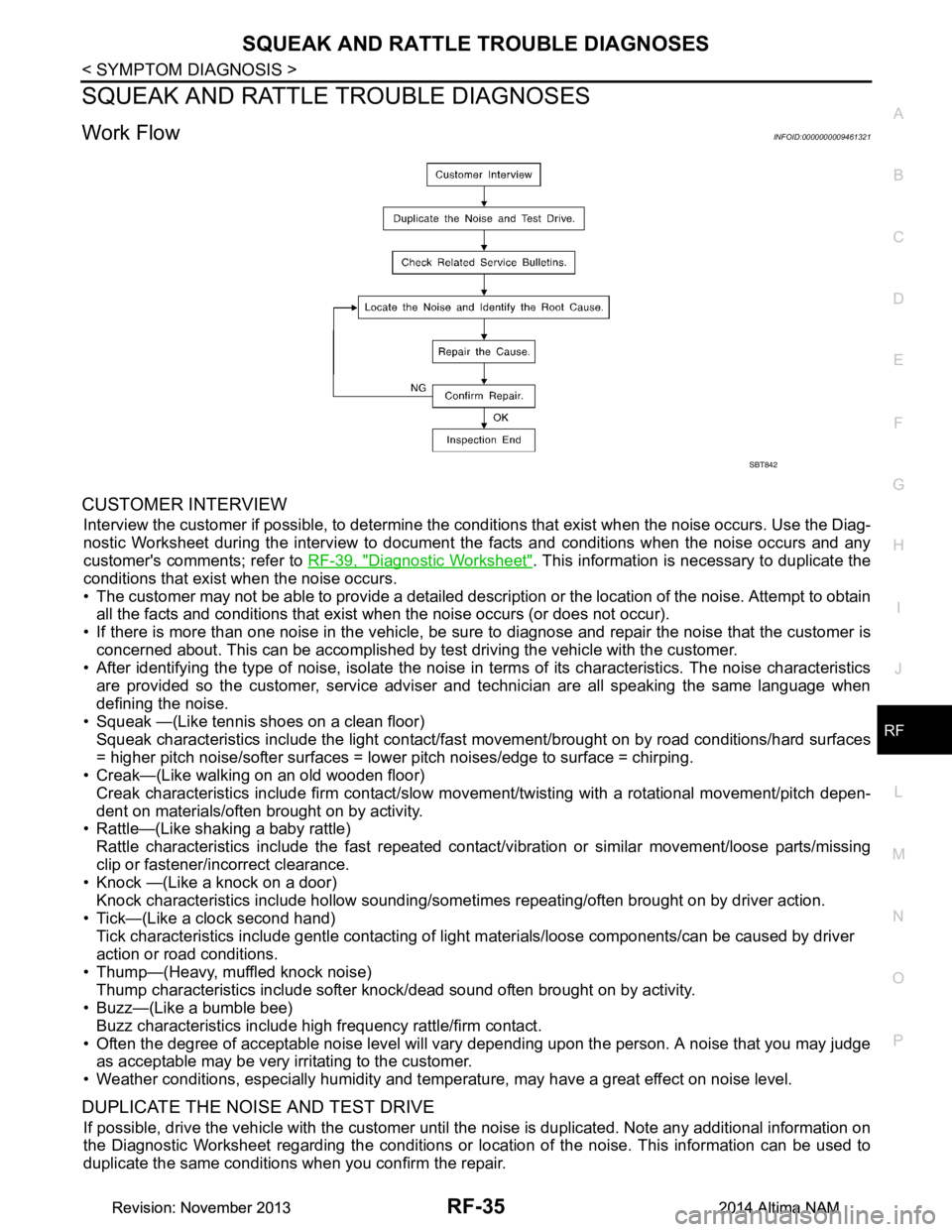

Work FlowINFOID:0000000009461321

CUSTOMER INTERVIEW

Interview the customer if possible, to determine the c onditions that exist when the noise occurs. Use the Diag-

nostic Worksheet during the interv iew to document the facts and conditions when the noise occurs and any

customer's comments; refer to RF-39, "Diagnostic Worksheet"

. This information is necessary to duplicate the

conditions that exist when the noise occurs.

• The customer may not be able to provide a detailed descr iption or the location of the noise. Attempt to obtain

all the facts and conditions that exist when the noise occurs (or does not occur).

• If there is more than one noise in the vehicle, be sure to diagnose and repair the noise that the customer is

concerned about. This can be accomplished by test driving the vehicle with the customer.

• After identifying the type of noise, isolate the noise in terms of its characteristics. The noise characteristics

are provided so the customer, service adviser and technician are all speaking the same language when

defining the noise.

• Squeak —(Like tennis shoes on a clean floor)

Squeak characteristics include the light contact/fast movement/brought on by road conditions/hard surfaces

= higher pitch noise/softer surfaces = lower pitch noises/edge to surface = chirping.

• Creak—(Like walking on an old wooden floor)

Creak characteristics include firm contact/slow mo vement/twisting with a rotational movement/pitch depen-

dent on materials/often brought on by activity.

• Rattle—(Like shaking a baby rattle)

Rattle characteristics include the fast repeated contac t/vibration or similar movement/loose parts/missing

clip or fastener/incorrect clearance.

• Knock —(Like a knock on a door)

Knock characteristics include hollow sounding/someti mes repeating/often brought on by driver action.

• Tick—(Like a clock second hand) Tick characteristics include gentle contacting of li ght materials/loose components/can be caused by driver

action or road conditions.

• Thump—(Heavy, muffled knock noise) Thump characteristics include softer k nock/dead sound often brought on by activity.

• Buzz—(Like a bumble bee)

Buzz characteristics include high frequency rattle/firm contact.

• Often the degree of acceptable noise level will vary depending upon the person. A noise that you may judge as acceptable may be very irritating to the customer.

• Weather conditions, especially humidity and temperature, may have a great effect on noise level.

DUPLICATE THE NOISE AND TEST DRIVE

If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Worksheet regarding the conditions or lo cation of the noise. This information can be used to

duplicate the same conditions when you confirm the repair.

SBT842

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3766 of 4801

SQUEAK AND RATTLE TROUBLE DIAGNOSESSE-17

< SYMPTOM DIAGNOSIS >

C

D E

F

G H

I

K L

M A

B

SE

N

O P

SYMPTOM DIAGNOSIS

SQUEAK AND RATTLE TROUBLE DIAGNOSES

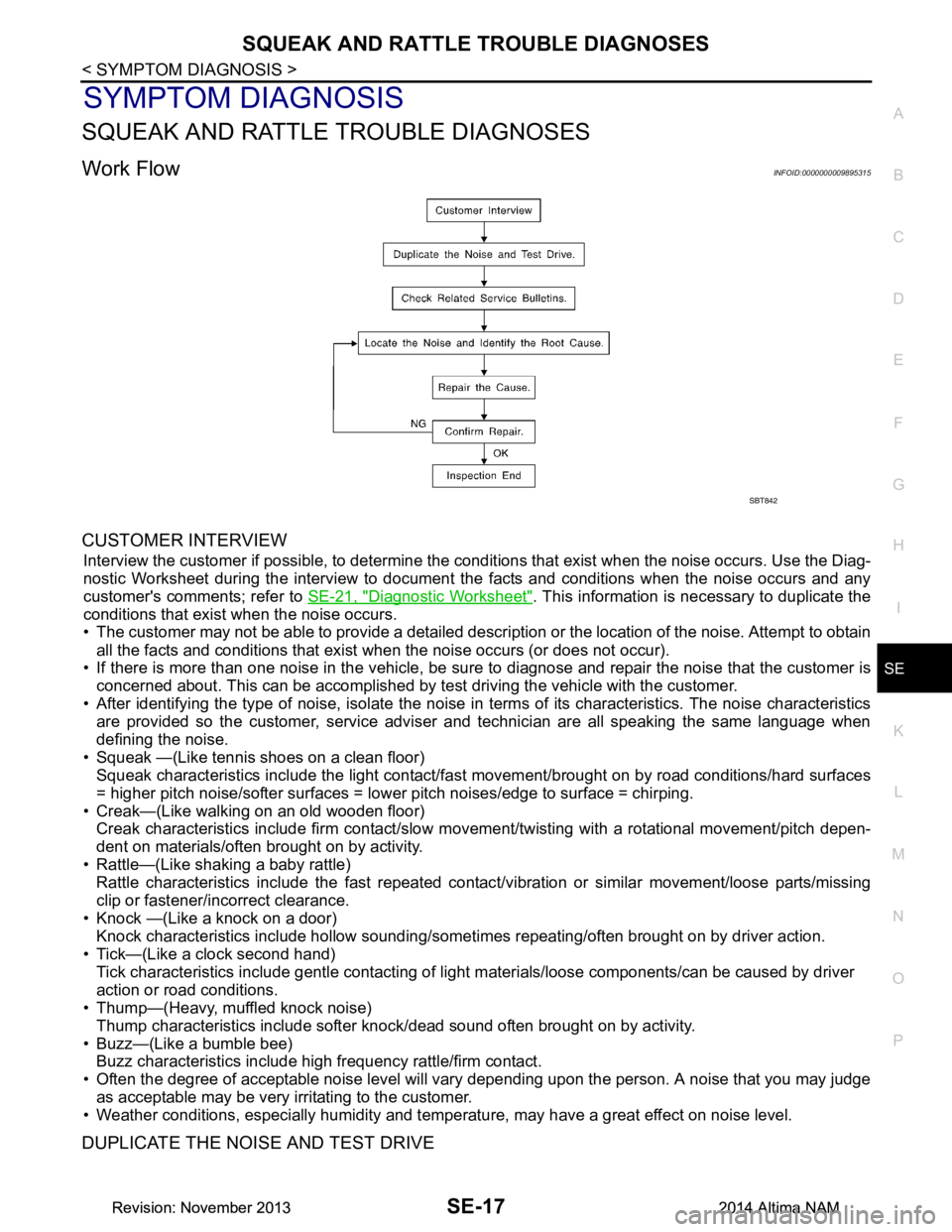

Work FlowINFOID:0000000009895315

CUSTOMER INTERVIEW

Interview the customer if possible, to determine the c onditions that exist when the noise occurs. Use the Diag-

nostic Worksheet during the interv iew to document the facts and conditions when the noise occurs and any

customer's comments; refer to SE-21, "Diagnostic Worksheet"

. This information is necessary to duplicate the

conditions that exist when the noise occurs.

• The customer may not be able to provide a detailed descr iption or the location of the noise. Attempt to obtain

all the facts and conditions that exist when the noise occurs (or does not occur).

• If there is more than one noise in the vehicle, be sure to diagnose and repair the noise that the customer is

concerned about. This can be accomplished by test driving the vehicle with the customer.

• After identifying the type of noise, isolate the noise in terms of its characteristics. The noise characteristics

are provided so the customer, service adviser and technician are all speaking the same language when

defining the noise.

• Squeak —(Like tennis shoes on a clean floor) Squeak characteristics include the light contact/fast movement/brought on by road conditions/hard surfaces

= higher pitch noise/softer surfaces = lower pitch noises/edge to surface = chirping.

• Creak—(Like walking on an old wooden floor) Creak characteristics include firm contact/slow mo vement/twisting with a rotational movement/pitch depen-

dent on materials/often brought on by activity.

• Rattle—(Like shaking a baby rattle) Rattle characteristics include the fast repeated contac t/vibration or similar movement/loose parts/missing

clip or fastener/incorrect clearance.

• Knock —(Like a knock on a door) Knock characteristics include hollow sounding/someti mes repeating/often brought on by driver action.

• Tick—(Like a clock second hand) Tick characteristics include gentle contacting of li ght materials/loose components/can be caused by driver

action or road conditions.

• Thump—(Heavy, muffled knock noise)

Thump characteristics include softer k nock/dead sound often brought on by activity.

• Buzz—(Like a bumble bee) Buzz characteristics include high frequency rattle/firm contact.

• Often the degree of acceptable noise level will vary depending upon the person. A noise that you may judge

as acceptable may be very irritating to the customer.

• Weather conditions, especially humidity and temperature, may have a great effect on noise level.

DUPLICATE THE NOISE AND TEST DRIVE

SBT842

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3943 of 4801

SEC-118

< DTC/CIRCUIT DIAGNOSIS >

B2617 STARTER RELAY CIRCUIT

B2617 STARTER RELAY CIRCUIT

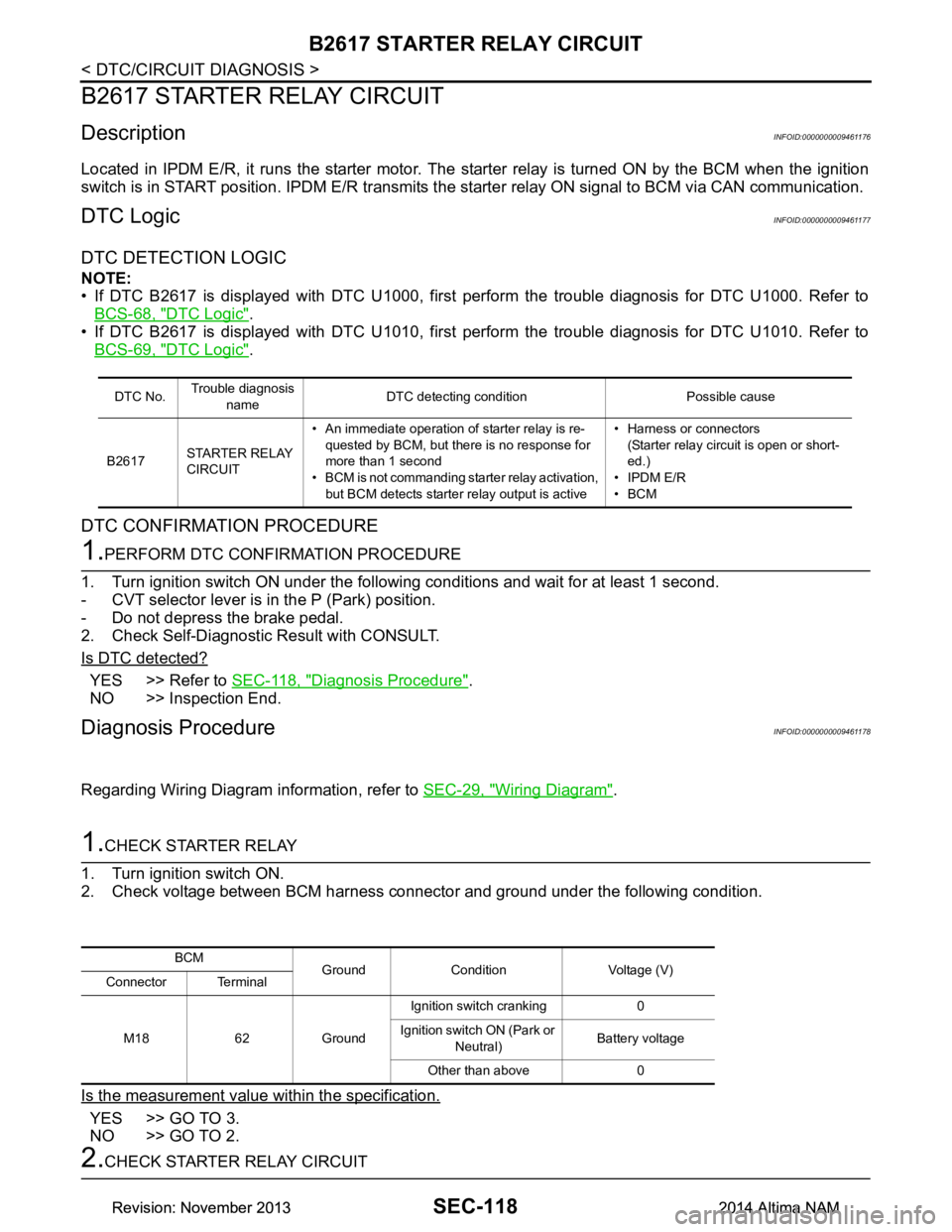

DescriptionINFOID:0000000009461176

Located in IPDM E/R, it runs the starter motor. The starter relay is turned ON by the BCM when the ignition

switch is in START position. IPDM E/R transmits t he starter relay ON signal to BCM via CAN communication.

DTC LogicINFOID:0000000009461177

DTC DETECTION LOGIC

NOTE:

• If DTC B2617 is displayed with DTC U1000, first perform the trouble diagnosis for DTC U1000. Refer to

BCS-68, "DTC Logic"

.

• If DTC B2617 is displayed with DTC U1010, first perform the trouble diagnosis for DTC U1010. Refer to BCS-69, "DTC Logic"

.

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Turn ignition switch ON under the following conditions and wait for at least 1 second.

- CVT selector lever is in the P (Park) position.

- Do not depress the brake pedal.

2. Check Self-Diagnostic Result with CONSULT.

Is DTC detected?

YES >> Refer to SEC-118, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis ProcedureINFOID:0000000009461178

Regarding Wiring Diagram information, refer to SEC-29, "Wiring Diagram".

1.CHECK STARTER RELAY

1. Turn ignition switch ON.

2. Check voltage between BCM harness connector and ground under the following condition.

Is the measurement value within the specification.

YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK STARTER RELAY CIRCUIT

DTC No. Trouble diagnosis

name DTC detecting condition Possible cause

B2617 STARTER RELAY

CIRCUIT • An immediate operation of starter relay is re-

quested by BCM, but there is no response for

more than 1 second

• BCM is not commanding starter relay activation, but BCM detects starter relay output is active • Harness or connectors

(Starter relay circuit is open or short-

ed.)

• IPDM E/R

•BCM

BCM Ground Condition Voltage (V)

Connector Terminal

M18 62 Ground Ignition switch cranking 0

Ignition switch ON (Park or Neutral) Battery voltage

Other than above 0

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4002 of 4801

COMPONENT PARTSSRC-9

< SYSTEM DESCRIPTION >

C

D E

F

G

I

J

K L

M A

B

SRC

N

O P

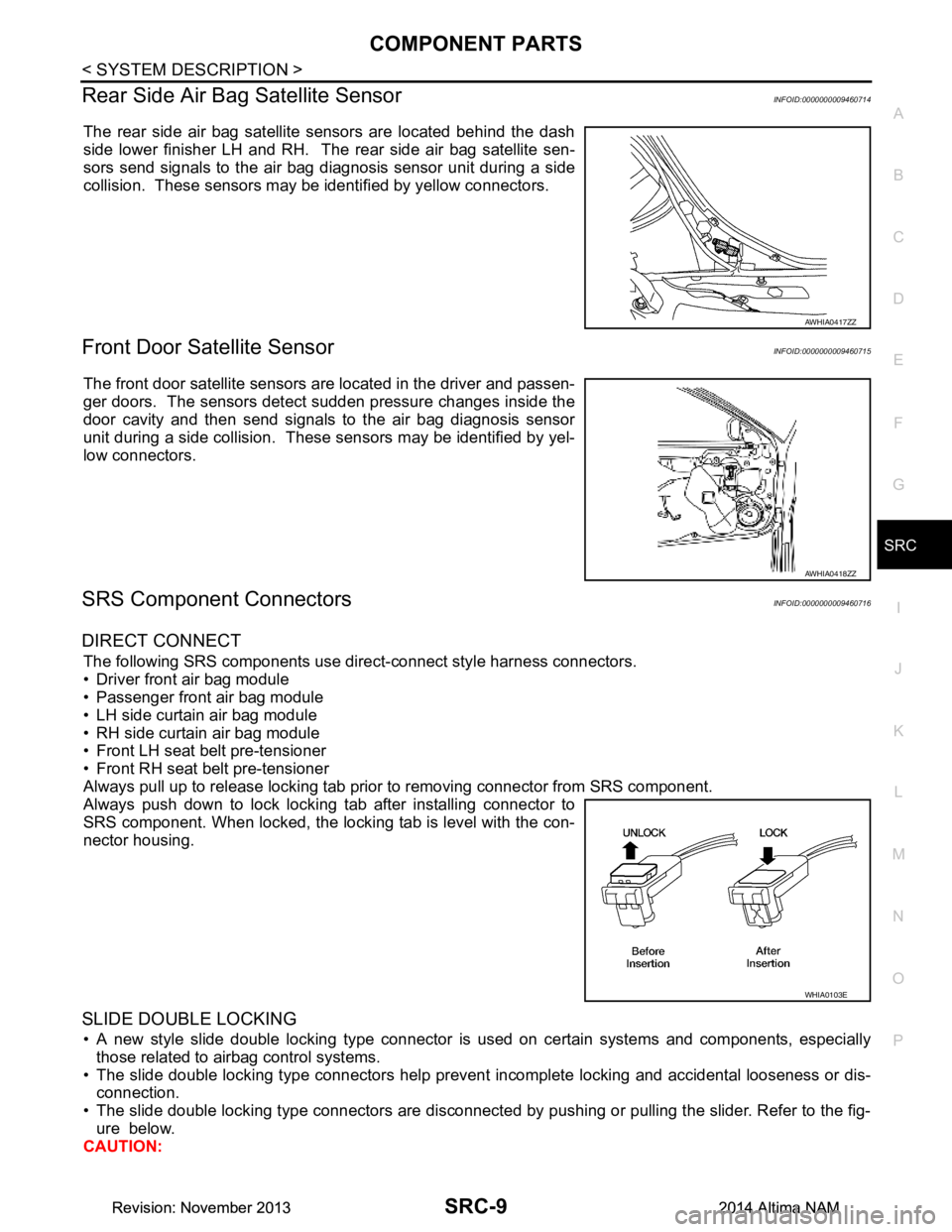

Rear Side Air Bag Satellite SensorINFOID:0000000009460714

The rear side air bag satellite sensors are located behind the dash

side lower finisher LH and RH. The rear side air bag satellite sen-

sors send signals to the air bag diagnosis sensor unit during a side

collision. These sensors may be identified by yellow connectors.

Front Door Satellite SensorINFOID:0000000009460715

The front door satellite sensors are located in the driver and passen-

ger doors. The sensors detect sudden pressure changes inside the

door cavity and then send signals to the air bag diagnosis sensor

unit during a side collision. These sensors may be identified by yel-

low connectors.

SRS Component ConnectorsINFOID:0000000009460716

DIRECT CONNECT

The following SRS components use dire ct-connect style harness connectors.

• Driver front air bag module

• Passenger front air bag module

• LH side curtain air bag module

• RH side curtain air bag module

• Front LH seat belt pre-tensioner

• Front RH seat belt pre-tensioner

Always pull up to release locking tab prior to removing connector from SRS component.

Always push down to lock locking tab after installing connector to

SRS component. When locked, the locking tab is level with the con-

nector housing.

SLIDE DOUBLE LOCKING

• A new style slide double locking type connector is used on certain systems and components, especially those related to airbag control systems.

• The slide double locking type connectors help prevent incomplete locking and accidental looseness or dis- connection.

• The slide double locking type connectors are disconnected by pushing or pulling the slider. Refer to the fig-

ure below.

CAUTION:

AWHIA0417ZZ

AWHIA0418ZZ

WHIA0103E

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4239 of 4801

![NISSAN TEANA 2014 Service Manual

TM-24

< SYSTEM DESCRIPTION >[CVT: RE0F10D]

STRUCTURE AND OPERATION

The groove width changes according to wrapping radius of

steel belt and pulley from low status to overdrive

status continuously wit NISSAN TEANA 2014 Service Manual

TM-24

< SYSTEM DESCRIPTION >[CVT: RE0F10D]

STRUCTURE AND OPERATION

The groove width changes according to wrapping radius of

steel belt and pulley from low status to overdrive

status continuously wit](/img/5/57390/w960_57390-4238.png)

TM-24

< SYSTEM DESCRIPTION >[CVT: RE0F10D]

STRUCTURE AND OPERATION

The groove width changes according to wrapping radius of

steel belt and pulley from low status to overdrive

status continuously with non-step. It is controlled wit h the oil pressures of primary pulley and secondary pulley.

Steel Belt

It is composed of multiple steel plates (A) and two steel rings (B)

stacked to a several number. The feature of this steel belt transmits

power with compression of the steel plate in contrast with transmis-

sion of power in pulling with a rubber belt. Friction force is required

with the pulley slope to transmit power from the steel plate. The force

is generated with the following mechanism:

Oil pressure applies to the secondary pulley to nip the plate. ⇒The

plate is pushed and extended outward. ⇒The steel ring shows with-

stands. ⇒Pulling force is generated on the steel ring. ⇒The plate of

the primary pulley is nipped between the pulley. ⇒Friction force is

generated between the steel belt and the pulley.

Therefore, responsibilities are divi ded by the steel plate that trans-

mits the power with compression and the steel ring that main tains necessary friction force. In this way, the

tension of the steel ring is distributed on the entire su rface and stress variation is limited, resulting in good

durability.

Pulley

The primary pulley (input shaft side) and the secondary pulley (output shaft side) have the shaft with slope

(fixed cone surface), movable sheave (movable cone surface that can move in the axial direction) and oil pres-

sure chamber at the back of the movable sheave.

JSDIA2428GB

JSDIA2431ZZ

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4242 of 4801

![NISSAN TEANA 2014 Service Manual

STRUCTURE AND OPERATIONTM-27

< SYSTEM DESCRIPTION > [CVT: RE0F10D]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

TRANSAXLE : Component DescriptionINFOID:0000000009463984

FLUID COOLER & FLUID WARMER SYSTEM

Part na NISSAN TEANA 2014 Service Manual

STRUCTURE AND OPERATIONTM-27

< SYSTEM DESCRIPTION > [CVT: RE0F10D]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

TRANSAXLE : Component DescriptionINFOID:0000000009463984

FLUID COOLER & FLUID WARMER SYSTEM

Part na](/img/5/57390/w960_57390-4241.png)

STRUCTURE AND OPERATIONTM-27

< SYSTEM DESCRIPTION > [CVT: RE0F10D]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

TRANSAXLE : Component DescriptionINFOID:0000000009463984

FLUID COOLER & FLUID WARMER SYSTEM

Part name Function

Torque converter Increases engine torque and transmits it to the transaxle.

Oil pump Utilizes a vane-type oil pump that is driven by the engine through the oil pump drive chain in order to

increase efficiency of pump discharge volume in low-speed zone and optimize pump discharge volume

in high-speed zone. Discharged oil from oil pump is tr ansmitted to control valve. It is used as the oil of

primary and secondary pulley operation, the oil of clutch operation, and the lubricant for each part.

Forward clutch The forward clutch is wet and multiple plate type clutch that consists of clutch drum, piston, drive plate,

and driven plate. It is a clutch to move the vehicle forward by activating piston hydraulically, engaging

plates, and directly connecting sun gear and input shaft.

Reverse brake The reverse brake is a wet multiple-plate type brake that consists of transaxle case, piston, drive plate,

and driven plate. It is a brake to move the vehicle in reverse by activating piston hydraulically, engaging

plates, and fixing planetary gear.

Internal gear The internal gear is directly connected to forward clutch drum. It is a gear that moves the outer edge of

pinion planet of planet carrier. It transmits power to move the vehicle in reverse when the planet carrier

is fixed.

Planet carrier Composed of a carrier, pinion planet, and pinion shaft. This gear fixes and releases the planet carrier in

order to switch between forward and reverse driving.

Sun gear Sun gear is a set part with planet carrier and internal gear. It transmits transmitted force to primary fixed

sheave. It rotates in forward or reverse direction according to activation of either forward clutch or re-

verse brake.

Input shaft The input shaft is directly connected to forward clutch drum and transmits traction force from torque con-

verter. In shaft center, there are holes for hydraulic distribution to primary pulley and hydraulic distribution

for lockup ON/OFF.

Primary pulley It is composed of a pair of pulleys (the groove width is changed freely in the axial direction) and the steel belt. The groove width changes according to wrapping radius of steel belt and pulley from low status to

overdrive status continuously with non-step. It is controlled with the oil pressures of primary pulley and

secondary pulley.

Secondary pulley

Steel belt

Manual shaft When the manual shaft is in the P position, the parking rod that is linked to the manual shaft rotates the

parking pole. When the parking pole rotates, it engages with the parking gear, fixing the parking gear. As

a result, the secondary pulley that is integrated with the parking gear is fixed.

Parking rod

Parking pawl

Parking gear

Output gear

The deceleration gears are composed of 2 stages: primary deceleration (output gear, idler gear pair) and

secondary deceleration (reduction gear, final gear pair). All of these gears are helical gears.

Idler gear

Reduction gear

Differential

Torque converter regulator

valve Adjusts the feed pressure to the torque converter to the optimum pressure corresponding to the driving

condition.

Pressure regulator valve Adjusts the discharge pressure from the oil pump to the optimum pressure (line pressure) corresponding

to the driving condition.

Torque converter clutch

control valve Adjusts the torque converter engage and disengage pressures.

Manual valve Distributes the clutch operation pressure to each circuit according to the selector lever position.

Secondary reducing valve Reduces line pressure and adjusts secondary pressure.

Primary reducing valve Reduces line pressure and adjusts primary pressure.

Pilot valve A Reduces line pressure and adjusts pilot pressure to the solenoid valves listed below.

• Primary pressure solenoid valve

• Secondary pressure solenoid valve

• Select solenoid valve

• Line pressure solenoid valve

Pilot valve B Reduces pilot pressure and adjusts pilot pressure to the torque converter clutch solenoid valve.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4243 of 4801

![NISSAN TEANA 2014 Service Manual

TM-28

< SYSTEM DESCRIPTION >[CVT: RE0F10D]

STRUCTURE AND OPERATION

FLUID COOLER & FLUID WARMER SYSTEM : System Description

INFOID:0000000009463985

CVT FLUID COOLER SCHEMATIC

COMPONENT DESCRIPTION

C NISSAN TEANA 2014 Service Manual

TM-28

< SYSTEM DESCRIPTION >[CVT: RE0F10D]

STRUCTURE AND OPERATION

FLUID COOLER & FLUID WARMER SYSTEM : System Description

INFOID:0000000009463985

CVT FLUID COOLER SCHEMATIC

COMPONENT DESCRIPTION

C](/img/5/57390/w960_57390-4242.png)

TM-28

< SYSTEM DESCRIPTION >[CVT: RE0F10D]

STRUCTURE AND OPERATION

FLUID COOLER & FLUID WARMER SYSTEM : System Description

INFOID:0000000009463985

CVT FLUID COOLER SCHEMATIC

COMPONENT DESCRIPTION

CVT Oil Warmer

• The CVT oil warmer (1) is installed on the front part of transaxle

assembly.

• When engine is started while engine and CVT are cold, engine coolant temperature rises more quickly than CVT fluid tempera-

ture. CVT oil warmer is provided with two circuits for CVT and

engine coolant respectively so that warmed engine coolant warms

CVT quickly. This helps shorten CVT warming up time, improving

fuel economy.

• A cooling effect is obtained when CVT fluid temperature is high.

Heater Thermostat

• The heater thermostat (1) is insta lled on the front part of transaxle

assembly.

• The heater thermostat open and close with set temperature.

SHIFT LOCK SYSTEM

SHIFT LOCK SYSTEM : System DescriptionINFOID:0000000009463986

The shift lever cannot be shifted from the “P” positi on unless the brake pedal is depressed while the ignition

switch is set to ON. The shift lock is unlocked by turn ing the shift lock solenoid ON when the ignition switch is

set to ON, the park position switch is turned ON (selec tor lever is in “P” position), and the stop lamp switch is

turned ON (brake pedal is depressed) as shown in the oper ation chart in the figure. Therefore, the shift lock

solenoid receives no ON signal and the shift lock remains locked if all of the above conditions are not fulfilled.

However, selector operation is allowed if the shift lock release button is pressed.

JSDIA3787GB

JSDIA2280ZZ

JSDIA2585ZZ

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4413 of 4801

![NISSAN TEANA 2014 Service Manual

TM-198

< REMOVAL AND INSTALLATION >[CVT: RE0F10D]

DIFFERENTIAL SIDE OIL SEAL

Install each differential side oil seal evenly using Tool so that differ-

ential side oil seal protrudes by the dimension NISSAN TEANA 2014 Service Manual

TM-198

< REMOVAL AND INSTALLATION >[CVT: RE0F10D]

DIFFERENTIAL SIDE OIL SEAL

Install each differential side oil seal evenly using Tool so that differ-

ential side oil seal protrudes by the dimension](/img/5/57390/w960_57390-4412.png)

TM-198

< REMOVAL AND INSTALLATION >[CVT: RE0F10D]

DIFFERENTIAL SIDE OIL SEAL

Install each differential side oil seal evenly using Tool so that differ-

ential side oil seal protrudes by the dimension (C) and (D) respect-

fully.

NOTE:

The reference is the installation direction of the differential side oil seal.

Drift to be used:

Inspection and AdjustmentINFOID:0000000009464144

INSPECTION AFTER INSTALLATION

Check for CVT fluid leakage. Refer to TM-178, "Inspection".

ADJUSTMENT AFTER INSTALLATION

Adjust the CVT fluid level. Refer to TM-84, "Adjustment".

(A) : Differential side oil seal (LH)

(B) : Differential side oil seal (RH)

JSDIA1836ZZ

Dimension (C) :Height difference from case end surface is within 1.8 ± 0.5 mm (0.071 ±

0.020 in).

Dimension (D) :Height difference from case end surface is within 2.2 ± 0.5 mm (0.087 ±

0.020 in).

Location Commercial Service Tools

Transaxle case side Commercial service tool with outer dia. 56 mm (2.20 in) and in-

ner dia. 50 mm (1.97 in)

Converter housing side

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM