NISSAN TEANA 2014 Service Manual

Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 2601 of 4801

REAR REGULATORGW-21

< REMOVAL AND INSTALLATION >

C

D E

F

G H

I

J

L

M A

B

GW

N

O P

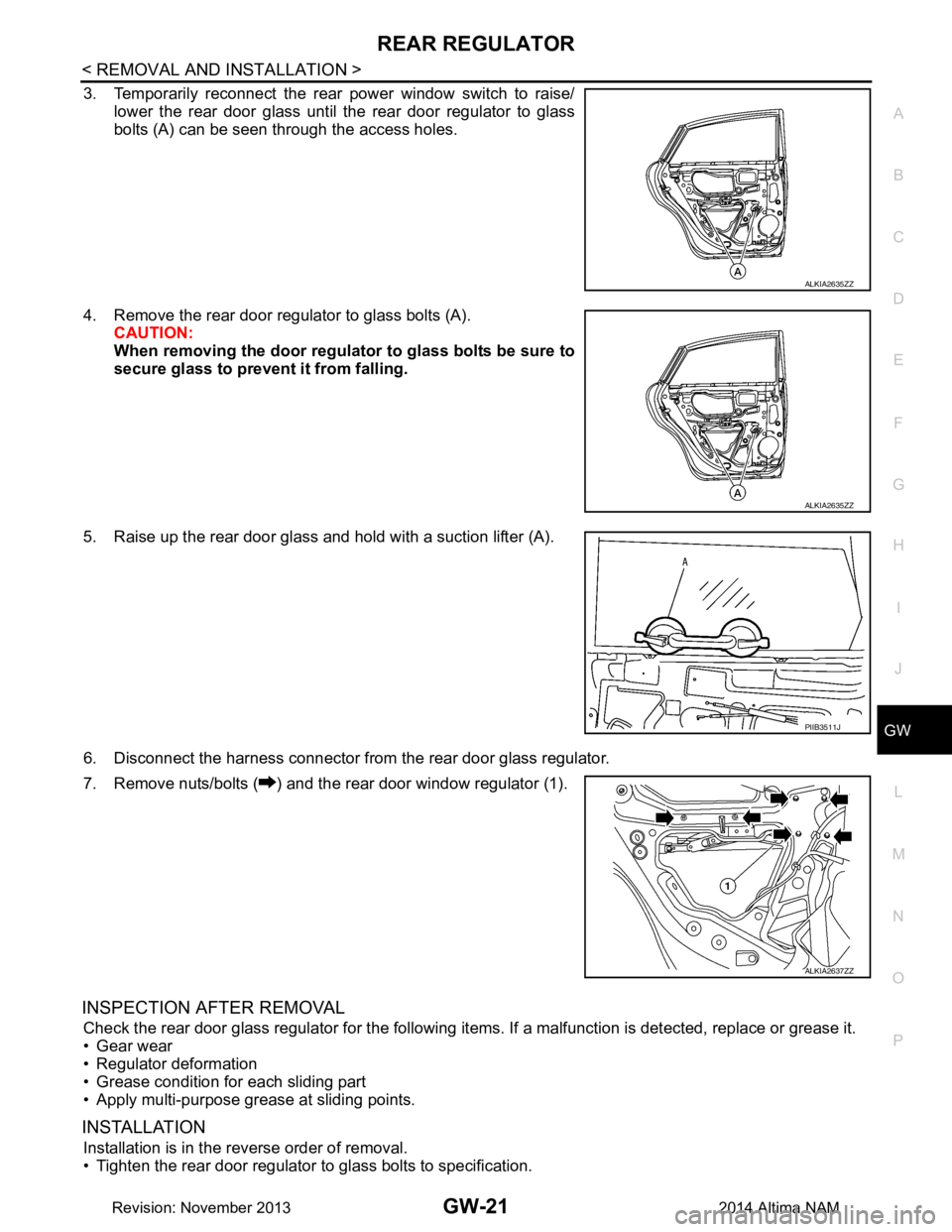

3. Temporarily reconnect the rear power window switch to raise/ lower the rear door glass until the rear door regulator to glass

bolts (A) can be seen through the access holes.

4. Remove the rear door regulator to glass bolts (A). CAUTION:

When removing the door regula tor to glass bolts be sure to

secure glass to prevent it from falling.

5. Raise up the rear door glass and hold with a suction lifter (A).

6. Disconnect the harness connector from the rear door glass regulator.

7. Remove nuts/bolts ( ) and the rear door window regulator (1).

INSPECTION AFTER REMOVAL

Check the rear door glass regul ator for the following items. If a malf unction is detected, replace or grease it.

• Gear wear

• Regulator deformation

• Grease condition for each sliding part

• Apply multi-purpose grease at sliding points.

INSTALLATION

Installation is in the reverse order of removal.

• Tighten the rear door regulator to glass bolts to specification.

ALKIA2635ZZ

ALKIA2635ZZ

PIIB3511J

ALKIA2637ZZ

Revision: November 20132014 Altima NAM

Page 2602 of 4801

GW-22

< REMOVAL AND INSTALLATION >

REAR REGULATOR

Removal and Installation - Rear Power Window Motor

INFOID:0000000009463671

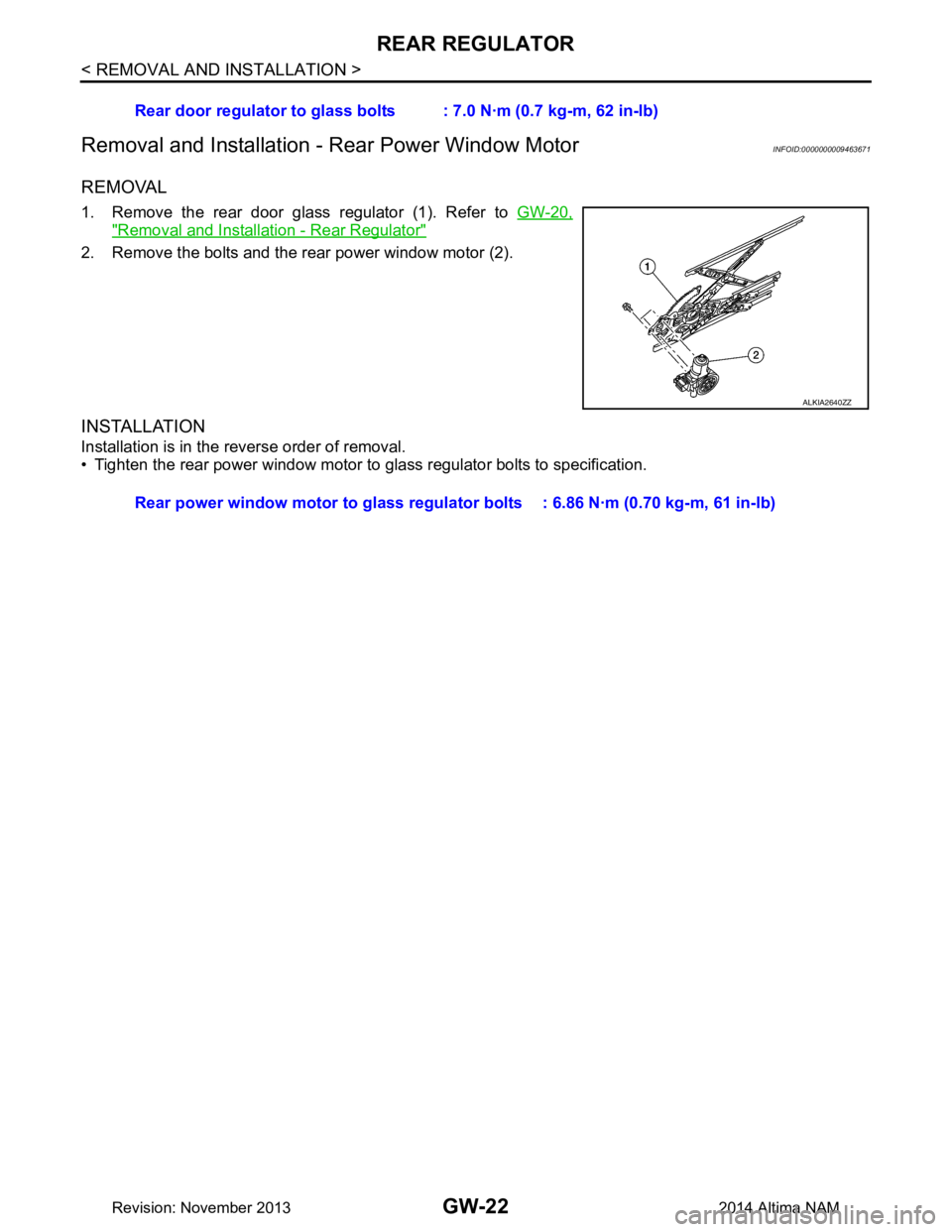

REMOVAL

1. Remove the rear door glass regulator (1). Refer to GW-20,

"Removal and Installation - Rear Regulator"

2. Remove the bolts and the rear power window motor (2).

INSTALLATION

Installation is in the reverse order of removal.

• Tighten the rear power window motor to glass regulator bolts to specification. Rear door regulator to glass bolts : 7.0 N·m (0.7 kg-m, 62 in-lb)

ALKIA2640ZZ

Rear power window motor to glass regulat

or bolts : 6.86 N·m (0.70 kg-m, 61 in-lb)

Revision: November 20132014 Altima NAM

Page 2603 of 4801

SIDE WINDOW GLASSGW-23

< REMOVAL AND INSTALLATION >

C

D E

F

G H

I

J

L

M A

B

GW

N

O P

SIDE WINDOW GLASS

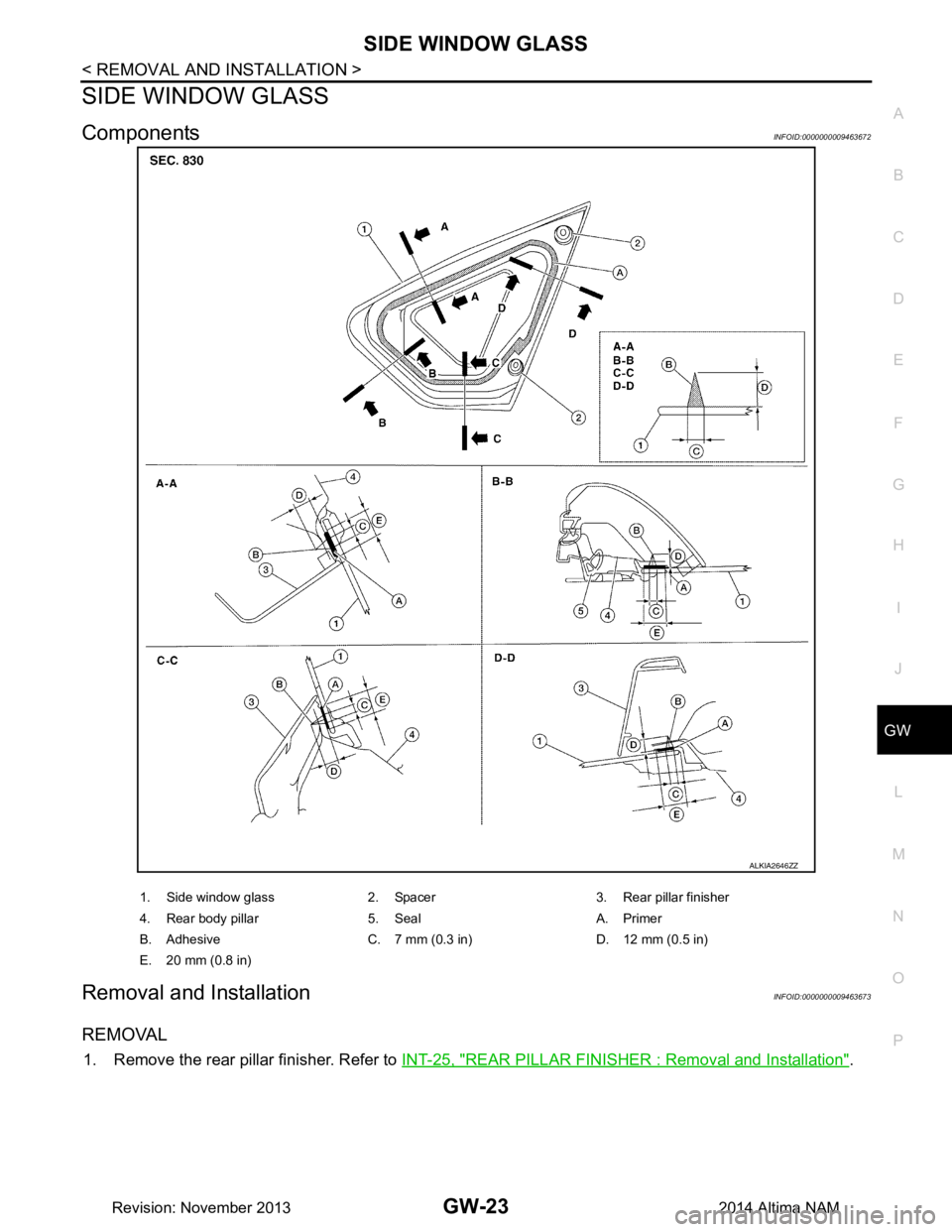

ComponentsINFOID:0000000009463672

Removal and InstallationINFOID:0000000009463673

REMOVAL

1. Remove the rear pillar finisher. Refer to INT-25, "REAR PILLAR FINISHER : Removal and Installation".

ALKIA2646ZZ

1. Side window glass 2. Spacer 3. Rear pillar finisher

4. Rear body pillar 5. Seal A. Primer

B. Adhesive C. 7 mm (0.3 in) D. 12 mm (0.5 in)

E. 20 mm (0.8 in)

Revision: November 20132014 Altima NAM

Page 2604 of 4801

GW-24

< REMOVAL AND INSTALLATION >

SIDE WINDOW GLASS

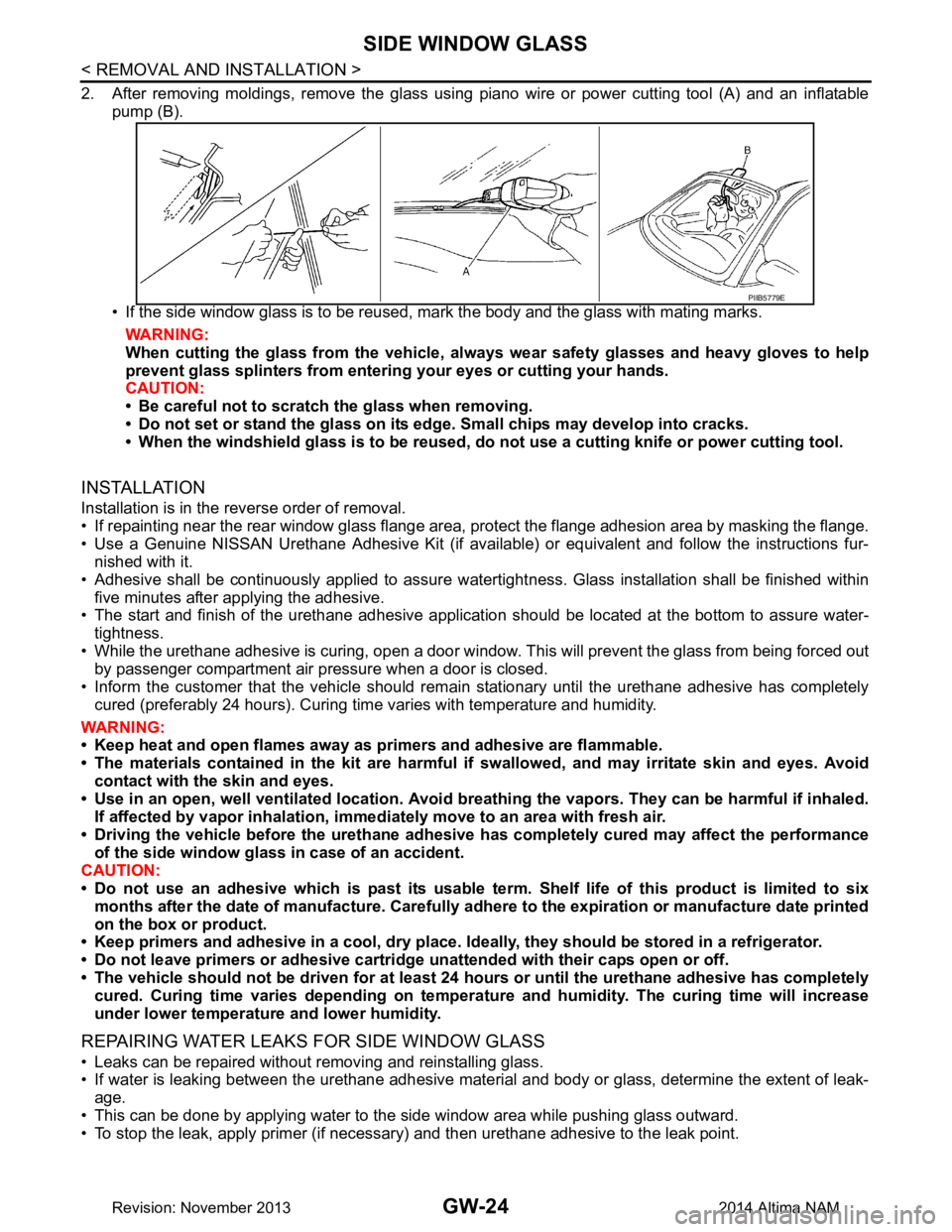

2. After removing moldings, remove the glass using piano wire or power cutting tool (A) and an inflatablepump (B).

• If the side window glass is to be reused, mark the body and the glass with mating marks. WARNING:

When cutting the glass from the vehicle, al ways wear safety glasses and heavy gloves to help

prevent glass splinters from entering your eyes or cutting your hands.

CAUTION:

• Be careful not to scratch the glass when removing.

• Do not set or stand the glass on its edge. Small chips may develop into cracks.

• When the windshield glass is to be reused, do not use a cutting knife or power cutting tool.

INSTALLATION

Installation is in the reverse order of removal.

• If repainting near the rear window glass flange area, protect the flange adhesion area by masking the flange.

• Use a Genuine NISSAN Urethane Adhesive Kit (if availabl e) or equivalent and follow the instructions fur-

nished with it.

• Adhesive shall be continuously applied to assure watert ightness. Glass installation shall be finished within

five minutes after applying the adhesive.

• The start and finish of the urethane adhesive application should be located at the bottom to assure water-

tightness.

• While the urethane adhesive is curing, open a door window . This will prevent the glass from being forced out

by passenger compartment air pressure when a door is closed.

• Inform the customer that the vehicle should rema in stationary until the urethane adhesive has completely

cured (preferably 24 hours). Curing time varies with temperature and humidity.

WARNING:

• Keep heat and open flames away as primers and adhesive are flammable.

• The materials contained in the kit are harmful if swallowed, and may irritate skin and eyes. Avoid

contact with the skin and eyes.

• Use in an open, well ventilated location. Avoid br eathing the vapors. They can be harmful if inhaled.

If affected by vapor inhalation, imme diately move to an area with fresh air.

• Driving the vehicle before the urethane adhesive has completely cured may affect the performance

of the side window gl ass in case of an accident.

CAUTION:

• Do not use an adhesive which is past its usable te rm. Shelf life of this product is limited to six

months after the date of manufacture. Carefully a dhere to the expiration or manufacture date printed

on the box or product.

• Keep primers and adhesive in a c ool, dry place. Ideally, they should be stored in a refrigerator.

• Do not leave primers or adhesive cartridge unattended with their caps open or off.

• The vehicle should not be driven for at least 24 hours or until the urethane adhesive has completely

cured. Curing time varies depe nding on temperature and humidity . The curing time will increase

under lower temperature and lower humidity.

REPAIRING WATER LEAKS FOR SIDE WINDOW GLASS

• Leaks can be repaired without removing and reinstalling glass.

• If water is leaking between the urethane adhesive material and body or glass, determine the extent of leak-

age.

• This can be done by applying water to the side window area while pushing glass outward.

• To stop the leak, apply primer (if necessary) and then urethane adhesive to the leak point.

PIIB5779E

Revision: November 20132014 Altima NAM

Page 2605 of 4801

REAR WINDOW GLASSGW-25

< REMOVAL AND INSTALLATION >

C

D E

F

G H

I

J

L

M A

B

GW

N

O P

REAR WINDOW GLASS

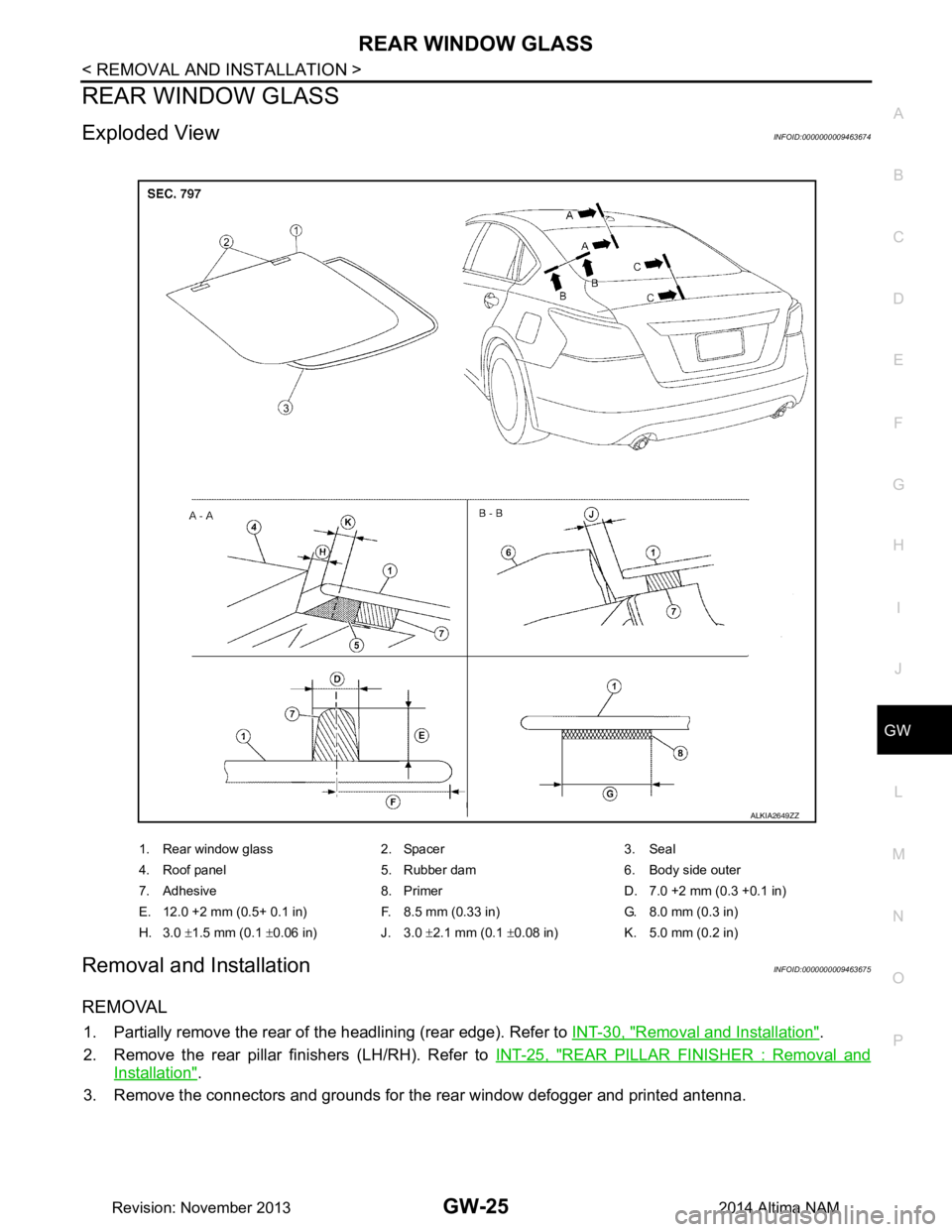

Exploded ViewINFOID:0000000009463674

Removal and InstallationINFOID:0000000009463675

REMOVAL

1. Partially remove the rear of the headlining (rear edge). Refer to INT-30, "Removal and Installation".

2. Remove the rear pillar finishers (LH/RH). Refer to INT-25, "REAR PILLAR FINISHER : Removal and

Installation".

3. Remove the connectors and grounds for the rear window defogger and printed antenna.

1. Rear window glass 2. Spacer 3. Seal

4. Roof panel 5. Rubber dam 6. Body side outer

7. Adhesive 8. Primer D. 7.0 +2 mm (0.3 +0.1 in)

E. 12.0 +2 mm (0.5+ 0.1 in) F. 8.5 mm (0.33 in) G. 8.0 mm (0.3 in)

H. 3.0 ±1.5 mm (0.1 ±0.06 in) J. 3.0 ±2.1 mm (0.1 ±0.08 in) K. 5.0 mm (0.2 in)

ALKIA2649ZZ

Revision: November 20132014 Altima NAM

Page 2606 of 4801

GW-26

< REMOVAL AND INSTALLATION >

REAR WINDOW GLASS

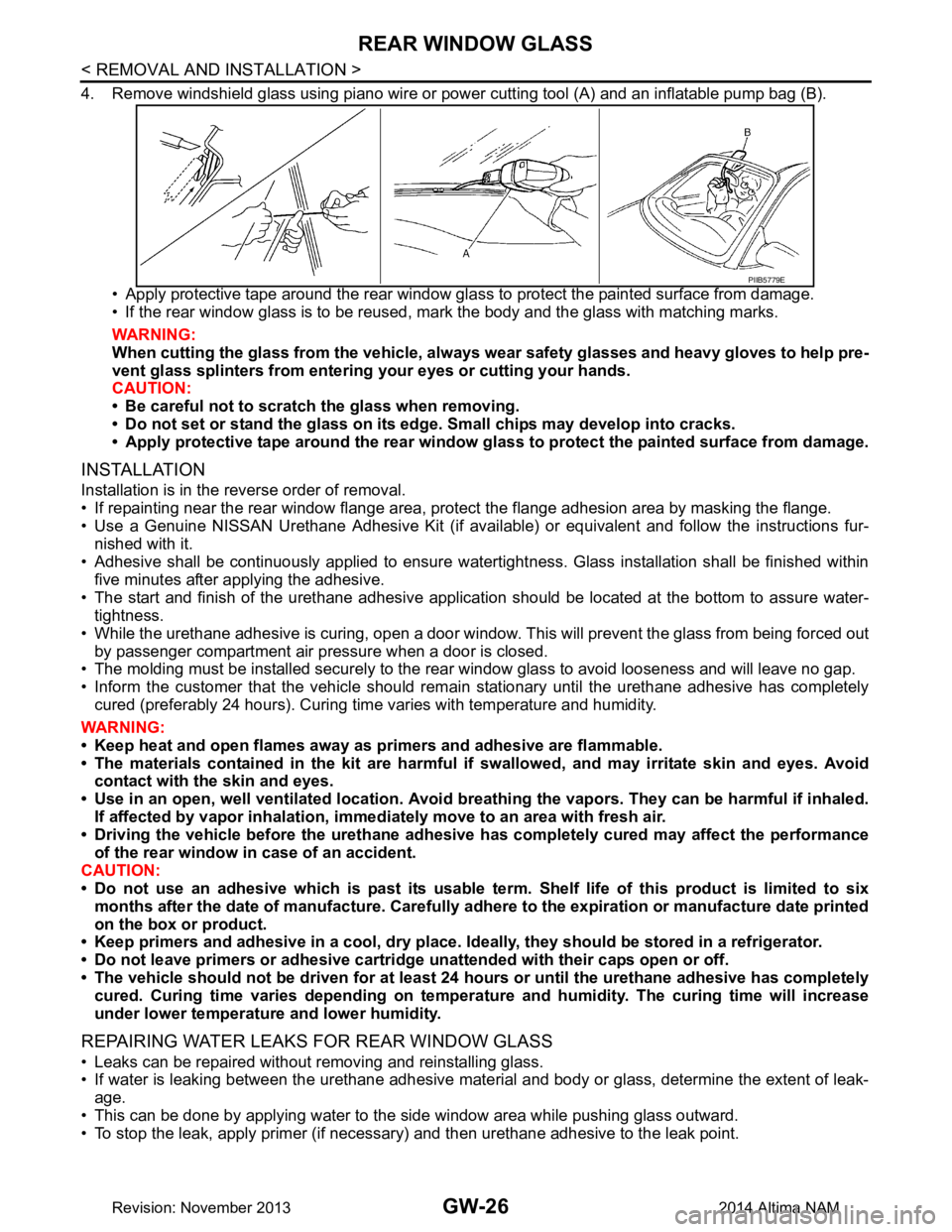

4. Remove windshield glass using piano wire or power cutting tool (A) and an inflatable pump bag (B).

• Apply protective tape around the rear window gla ss to protect the painted surface from damage.

• If the rear window glass is to be reused, mark the body and the glass with matching marks.

WARNING:

When cutting the glass from the vehicle, always wear safety glasses and heavy gloves to help pre-

vent glass splinters from entering your eyes or cutting your hands.

CAUTION:

• Be careful not to scratch the glass when removing.

• Do not set or stand the glass on its ed ge. Small chips may develop into cracks.

• Apply protective tape around th e rear window glass to protect the painted surface from damage.

INSTALLATION

Installation is in the reverse order of removal.

• If repainting near the rear window flange area, protect the flange adhesion area by masking the flange.

• Use a Genuine NISSAN Urethane Adhesive Kit (if availabl e) or equivalent and follow the instructions fur-

nished with it.

• Adhesive shall be continuously applied to ensure watert ightness. Glass installation shall be finished within

five minutes after applying the adhesive.

• The start and finish of the urethane adhesive application should be located at the bottom to assure water-

tightness.

• While the urethane adhesive is curing, open a door window . This will prevent the glass from being forced out

by passenger compartment air pressure when a door is closed.

• The molding must be installed securely to the rear window glass to avoid looseness and will leave no gap.

• Inform the customer that the vehicle should rema in stationary until the urethane adhesive has completely

cured (preferably 24 hours). Curing time varies with temperature and humidity.

WARNING:

• Keep heat and open flames away as primers and adhesive are flammable.

• The materials contained in the kit are harmful if swallowed, and may irritate skin and eyes. Avoid

contact with the skin and eyes.

• Use in an open, well ventilated location. Avoid br eathing the vapors. They can be harmful if inhaled.

If affected by vapor inhalation, imme diately move to an area with fresh air.

• Driving the vehicle before the urethane adhesive has completely cured may affect the performance

of the rear window in case of an accident.

CAUTION:

• Do not use an adhesive which is past its usable te rm. Shelf life of this product is limited to six

months after the date of manufacture. Carefully a dhere to the expiration or manufacture date printed

on the box or product.

• Keep primers and adhesive in a c ool, dry place. Ideally, they should be stored in a refrigerator.

• Do not leave primers or adhesive cartridge unattended with their caps open or off.

• The vehicle should not be driven for at least 24 hours or until the urethane adhesive has completely

cured. Curing time varies depe nding on temperature and humidity . The curing time will increase

under lower temperature and lower humidity.

REPAIRING WATER LEAKS FOR REAR WINDOW GLASS

• Leaks can be repaired without removing and reinstalling glass.

• If water is leaking between the urethane adhesive material and body or glass, determine the extent of leak-

age.

• This can be done by applying water to the side window area while pushing glass outward.

• To stop the leak, apply primer (if necessary) and then urethane adhesive to the leak point.

PIIB5779E

Revision: November 20132014 Altima NAM

Page 2607 of 4801

HA-1

VENTILATION, HEATER & AIR CONDITIONER

C

D E

F

G H

J

K L

M

SECTION HA

A

B

HA

N

O P

CONTENTS

HEATER & AIR CONDITIONING SYSTEM

PRECAUTION ................ ...............................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution for Work ..................................................3

Precaution for Working with HFC-134a (R-134a) ......3

Contaminated Refrigerant .........................................4

Precaution for Leak Detection Dye ...........................4

Precaution for Refrigerant Connection ......................4

Precaution for Service Equipment ....................... ......7

PREPARATION ............................................9

PREPARATION .............................................. .....9

Special Service Tool ........................................... ......9

HFC-134a (R-134a) Service Tool and Equipment ......9

Commercial Service Tool ........................................11

SYSTEM DESCRIPTION .............................13

REFRIGERATION SYSTEM .......................... ....13

Refrigerant Cycle ................................................ ....13

Refrigerant System Protection ................................13

Component Part Location ................................... ....14

BASIC INSPECTION ...................................15

DIAGNOSIS AND REPAIR WORKFLOW ..... ....15

Workflow ............................................................. ....15

SYMPTOM DIAGNOSIS ..............................17

HEATER AND AIR CONDITIONING SYSTEM

SYMPTOMS ................................................... ....

17

Symptom Table ................................................... ....17

REFRIGERATION SYSTEM SYMPTOMS .........18

Trouble Diagnosis For Unusual Pressure ........... ....18

Symptom Table .......................................................18

NOISE .................................................................20

Symptom Table ................................................... ....20

PERIODIC MAINTENANCE ........................21

REFRIGERANT ................................ .................21

Description ........................................................... ....21

Leak Test .................................................................21

Recycle Refrigerant .................................................23

Charge Refrigerant ..................................................23

OIL .....................................................................25

Description ...............................................................25

Inspection ................................................................25

Perform Oil Return Operation ..................................25

Oil Adjusting Procedure for Components Replace-

ment Except Compressor ........................................

25

Oil Adjusting Procedure for Compressor Replace-

ment ..................................................................... ....

26

PERFORMANCE TEST ....................................28

Inspection ................................................................28

REMOVAL AND INSTALLATION ...............30

COMPRESSOR .................................................30

COMPRESSOR ........ ..................................................30

COMPRESSOR : Exploded Vi ew ............................30

COMPRESSOR : Removal an d Installation ............30

MAGNET CLUTCH ................................................ ....31

MAGNET CLUTCH : Removal and Installation .......31

COOLER PIPE AND HOSE ..............................34

Exploded View .........................................................34

LOW-PRESSURE FLEXIBLE HOSE ..................... ....34

LOW-PRESSURE FLEXIBLE HOSE : Removal

and Installation .................................................... ....

34

HIGH-PRESSURE FLEXIBLE HOSE ........................35

HIGH-PRESSURE FLEXIBLE HOSE : Removal

and Installation .................................................... ....

35

Revision: November 20132014 Altima NAM

Page 2608 of 4801

HA-2

LOW-PRESSURE PIPE ............................................35

LOW-PRESSURE PIPE : Removal and Installa-

tion ....................................................................... ...

35

HIGH-PRESSURE PIPE ......................................... ...36

HIGH-PRESSURE PIPE : Removal and Installa-

tion ....................................................................... ...

36

CONDENSER ....................................................38

Exploded View ..................................................... ...38

CONDENSER ......................................................... ...38

CONDENSER : Removal and Installation ..............38

LIQUID TANK ......................................................... ...38

LIQUID TANK : Removal and Installation ...............38

REFRIGERANT PRESSURE SENSOR ....................39

REFRIGERANT PRESSURE SENSOR : Remov-

al and Installation ................................................. ...

39

HEATING AND COOLING UNIT ASSEMBLY ...40

Exploded View ..................................................... ...40

HEATING AND COOLING UNIT ASSEMBLY ....... ...40

HEATING AND COOLING UNIT ASSEMBLY :

Removal and Installation .........................................

41

HEATER CORE ...................................................... ...41

HEATER CORE : Removal and Installation ............42

EVAPORATOR ....................................................... ...42

EVAPORATOR : Removal and Installation .............42

EXPANSION VALVE .............................................. ...42

EXPANSION VALVE : Removal and Installation

for Expansion Valve ............................................. ...

42

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... ...........................................

43

SERVICE DATA AND SPECIFICATIONS

(SDS) .............................................................. ...

43

Service Data and Specification (SDS) ....................43

Revision: November 20132014 Altima NAM

Page 2609 of 4801

PRECAUTIONSHA-3

< PRECAUTION >

C

D E

F

G H

J

K L

M A

B

HA

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000009951784

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. Information necessary to service t he system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three mi nutes before performing any service.

Precaution for WorkINFOID:0000000009463909

• When removing or disassembling each component, be ca reful not to damage or deform it. If a component

may be subject to interference, be sure to protect it with a shop cloth.

• When removing (disengaging) components with a screwdriver or similar tool, be sure to wrap the component with a shop cloth or vinyl tape to protect it.

• Protect the removed parts with a shop cloth and prevent them from being dropped.

• Replace a deformed or damaged clip.

• If a part is specified as a non-reusabl e part, always replace it with a new one.

• Be sure to tighten bolts and nuts securely to the specified torque.

• After installation is complete, be sure to check that each part works properly.

• Follow the steps below to clean components:

- Water soluble dirt:

• Dip a soft cloth into lukewarm water, wring the water out of the cloth and wipe the dirty area.

• Then rub with a soft, dry cloth.

-Oily dirt:

• Dip a soft cloth into lukewarm water with mild detergent (concentration: within 2 to 3%) and wipe the dirty area.

• Then dip a cloth into fresh water, wring the water out of the cloth and wipe the detergent off.

• Then rub with a soft, dry cloth.

- Do not use organic solvent such as thinner, benzene, alcohol or gasoline.

- For genuine leather seats, use a genuine leather seat cleaner.

Precaution for Workin g with HFC-134a (R-134a)INFOID:0000000009463910

WARNING:

• CFC-12 (R-12) refrigerant and HFC-134a (R-134a) refr igerant are not compatible. If the refrigerants

are mixed compressor failure is likely to occur. Refer to HA-21, "Leak Test"

. To determine the purity

of HFC-134a (R-134a) in the vehicle and recovery tank, use Refrigerant Recovery/Recycling Recharg-

ing equipment and Refrigerant Identifier.

Revision: November 20132014 Altima NAM

Page 2610 of 4801

HA-4

< PRECAUTION >

PRECAUTIONS

• Use only specified oil for the HFC-134a (R-134a) A/C system and HFC-134a (R-134a) components. If

oil other than that specified is used , compressor failure is likely to occur.

• The specified HFC-134a (R-134a) oi l rapidly absorbs moisture from the atmosphere. The following

handling precautions must be observed:

- When removing refrigerant components from a vehicle, immediately cap (seal) the component to

minimize the entry of moisture from the atmosphere.

- When installing refrigerant co mponents to a vehicle, do not remove the caps (unseal) until just

before connecting the components . Connect all refrigerant loop components as quickly as possible

to minimize the entry of moisture into system.

- Only use the specified oil from a sealed container. Immediately reseal containers of oil. Without

proper sealing, oil will become moisture saturat ed and should not be used.

- Avoid breathing A/C refrigerant and oil vapor or mist. Exposure may irritate eyes, nose and throat.

Remove HFC-134a (R-134a) from the A/C system usin g certified service equipment meeting require-

ments of SAE J2210 [HFC-134a (R-134a) recycling equipment], or J2209 [HFC-134a (R-134a) recy-

cling equipment], If accidental system discharge occurs, ventilate work area before resuming

service. Additional health and safety information may be obtain ed from refrigerant and oil manufac-

turers.

- Do not allow A/C oil to come in contact with styrofoam parts. Damage may result.

Contaminated RefrigerantINFOID:0000000009463911

If a refrigerant other than pure HFC-134a (R-134a) is identified in a vehicle, your options are:

• Explain to the customer that environmental regulations prohibit the release of contaminated refrigerant into

the atmosphere.

• Explain that recovery of the contaminated refri gerant could damage your service equipment and refrigerant

supply.

• Suggest the customer return the vehicle to the locati on of previous service where the contamination may

have occurred.

• If you choose to perform the repair, recover the refrigerant using only dedicated equipment and contain-

ers. Do not recover contamin ated refrigerant into your existing service equipment. If your facility does

not have dedicated recovery equipment, you may contact a local refrigerant product retailer for available ser-

vice. This refrigerant must be disposed of in acco rdance with all federal and local regulations. In addition,

replacement of all refrigerant system components on the vehicle is recommended.

• If the vehicle is within the warranty period, the air conditioner warranty is void. Please contact NISSAN Cus-

tomer Affairs for further assistance.

Precaution for Leak Detection DyeINFOID:0000000009463912

• The A/C system contains a fluorescent leak detection dye used for locating refrigerant leaks. An ultraviolet

(UV) lamp is required to illuminate the dye when inspecting for leaks.

• Always wear fluorescence enhancing UV safety goggles to protect your eyes and enhance the visibility of

the fluorescent dye.

• A compressor shaft seal should not be repaired because of dye seepage. The compressor shaft seal should only be repaired after confirming the leak with an electronic refrigerant leak detector (J-41995).

• Always remove any dye from the leak area after repairs are complete to avoid a misdiagnosis during a future

service.

• Do not allow dye to come into contact with painted body panels or interior components. If dye is spilled,

clean immediately with the approved dye cleaner. Fluoresc ent dye left on a surface for an extended period of

time cannot be removed .

• Do not spray the fluorescent dye cleaning agent on hot surfaces (engine exhaust manifold, etc.).

• Do not use more than one refrigerant dye bottle (1/4 ounce / 7.4 cc) per A/C system.

• Leak detection dyes for HFC-134a (R-134a) and HC-12 (R- 12) A/C systems are different. Do not use HFC-

134a (R-134a) leak detection dye in R-12 A/C systems or HC-12 (R-12) leak detection dye in HFC-134a (R-

134a) A/C systems or A/C system damage may result.

• The fluorescent properties of the dye will remain for ov er three (3) years unless a compressor failure occurs.

Precaution for Refrigerant ConnectionINFOID:0000000009463913

A new type refrigerant connection has been introduced to al l refrigerant lines except the following locations.

• Expansion valve to cooling unit

• Evaporator pipes to evaporator (inside cooling unit)

• Refrigerant pressure sensor

Revision: November 20132014 Altima NAM