NISSAN TEANA 2014 Service Manual

Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 2631 of 4801

OIL

HA-25

< PERIODIC MAINTENANCE >

C

D E

F

G H

J

K L

M A

B

HA

N

O P

OIL

DescriptionINFOID:0000000009463930

MAINTENANCE OF OIL LEVEL

The compressor oil is circulating in the system together wi th the refrigerant. It is necessary to fill compressor

with oil when replacing A/C system parts or when a large amount of refrigerant leakage is detected. It is impor-

tant to always maintain oil level within the spec ified level, otherwise the following conditions may occur:

• Insufficient oil amount: Stuck compressor

• Excessive oil amount: Insufficient coo ling (caused by insufficient heat exchange)

InspectionINFOID:0000000009463931

If a compressor is malfunctioning (internal noise, insufficient cooling), check the compressor oil.

1.COMPRESSOR OIL JUDGMENT

1. Remove the compressor. Refer to HA-30, "COMPRESSOR : Removal and Installation"

.

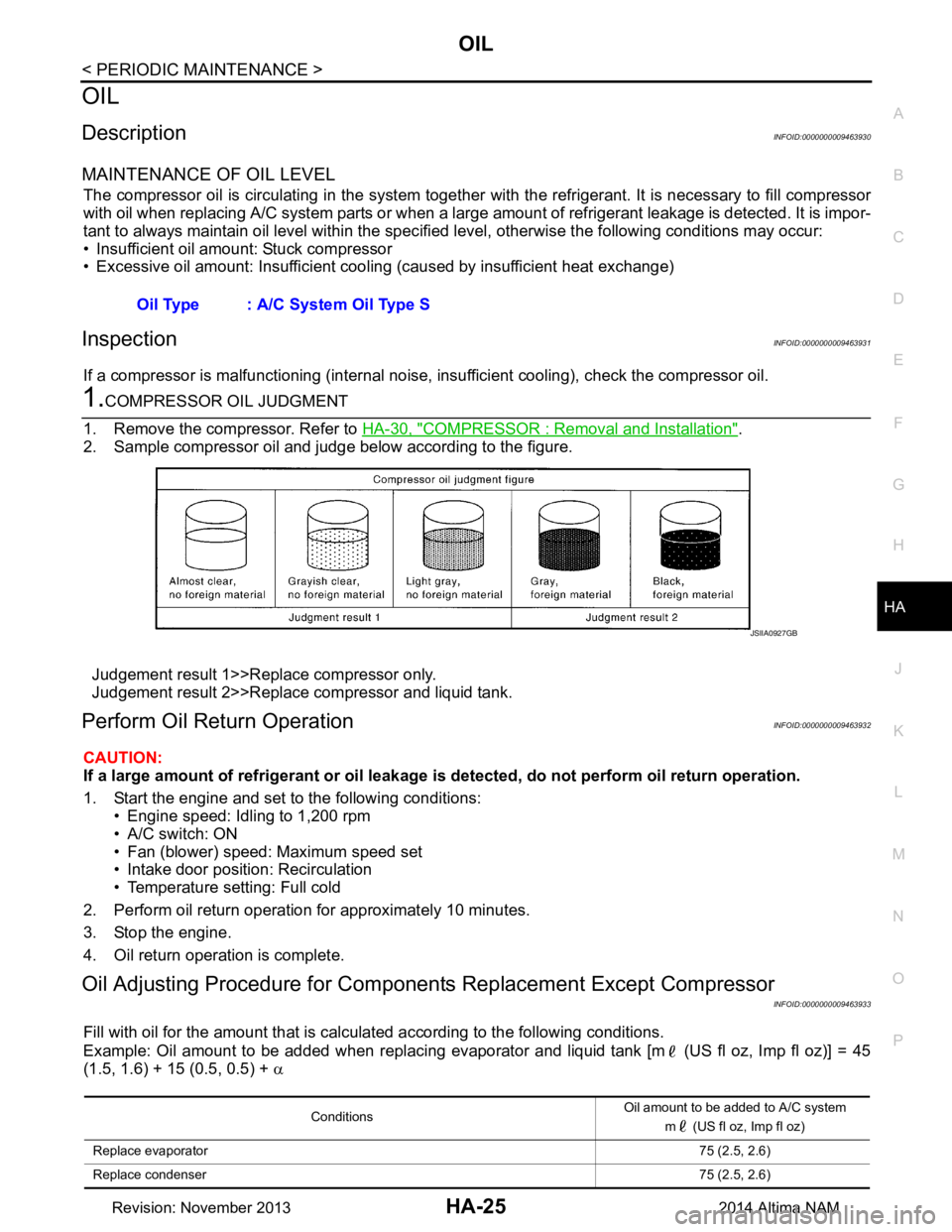

2. Sample compressor oil and judge below according to the figure.

Judgement result 1>>Replace compressor only.

Judgement result 2>>Replace compressor and liquid tank.

Perform Oil Return OperationINFOID:0000000009463932

CAUTION:

If a large amount of refrigerant or oil leakage is detected, do not perform oil return operation.

1. Start the engine and set to the following conditions: • Engine speed: Idling to 1,200 rpm

• A/C switch: ON

• Fan (blower) speed: Maximum speed set

• Intake door position: Recirculation

• Temperature setting: Full cold

2. Perform oil return operation for approximately 10 minutes.

3. Stop the engine.

4. Oil return operation is complete.

Oil Adjusting Procedure for Component s Replacement Except Compressor

INFOID:0000000009463933

Fill with oil for the amount that is calculated according to the following conditions.

Example: Oil amount to be added when replacing evaporator and liquid tank [m (US fl oz, Imp fl oz)] = 45

(1.5, 1.6) + 15 (0.5, 0.5) + α

Oil Type : A/C System Oil Type S

JSIIA0927GB

Conditions

Oil amount to be added to A/C system

m (US fl oz, Imp fl oz)

Replace evaporator 75 (2.5, 2.6)

Replace condenser 75 (2.5, 2.6)

Revision: November 20132014 Altima NAM

Page 2632 of 4801

HA-26

< PERIODIC MAINTENANCE >

OIL

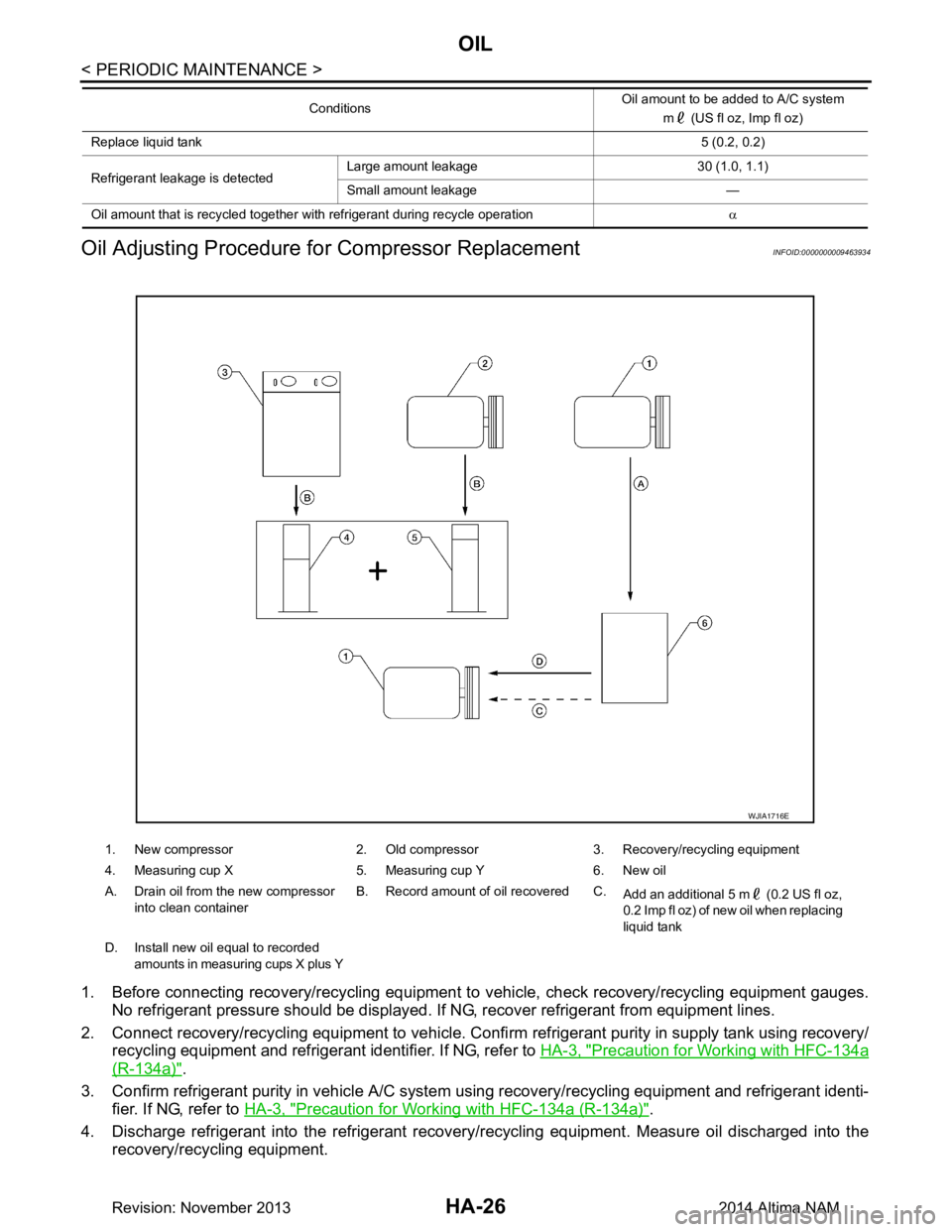

Oil Adjusting Procedure fo r Compressor Replacement

INFOID:0000000009463934

1. Before connecting recovery/recycling equipment to vehicle, check recovery/recycling equipment gauges.

No refrigerant pressure should be displayed. If NG, recover refrigerant from equipment lines.

2. Connect recovery/recycling equipment to vehicle. Confi rm refrigerant purity in supply tank using recovery/

recycling equipment and refrigerant identifier. If NG, refer to HA-3, "Precaution for Working with HFC-134a

(R-134a)".

3. Confirm refrigerant purity in vehi cle A/C system using recovery/recycling equipment and refrigerant identi-

fier. If NG, refer to HA-3, "Precaution for Working with HFC-134a (R-134a)"

.

4. Discharge refrigerant into the refrigerant recove ry/recycling equipment. Measure oil discharged into the

recovery/recycling equipment.

Replace liquid tank 5 (0.2, 0.2)

Refrigerant leakage is detected Large amount leakage 30 (1.0, 1.1)

Small amount leakage —

Oil amount that is recycled together with refrigerant during recycle operation α

Conditions

Oil amount to be added to A/C system

m (US fl oz, Imp fl oz)

1. New compressor 2. Old compressor 3. Recovery/recycling equipment

4. Measuring cup X 5. Measuring cup Y 6. New oil

A. Drain oil from the new compressor into clean container B. Record amount of oil recovered C.

Add an additional 5 m (0.2 US fl oz,

0.2 Imp fl oz) of new oil when replacing

liquid tank

D. Install new oil equal to recorded amounts in measuring cups X plus Y

WJIA1716E

Revision: November 20132014 Altima NAM

Page 2633 of 4801

OIL

HA-27

< PERIODIC MAINTENANCE >

C

D E

F

G H

J

K L

M A

B

HA

N

O P

5. Drain the oil from the “old” (removed) compress or into a graduated container and recover the amount of

oil drained.

6. Drain the oil from the “new” compressor into a separate, clean container.

7. Measure an amount of new oil installed equal to am ount drained from “old” compressor. Add this oil to

“new” compressor through the suction port opening.

8. Measure an amount of new oil equal to the amount recovered during discharging. Add this oil to “new” compressor through the suction port opening.

9. If the liquid tank also needs to be replaced, add an additional 5 m (0.2 US fl oz, 0.2 Imp fl oz) of oil at this

time.

CAUTION:

Do not add the 5 m (0.2 US fl oz, 0.2 Imp fl oz) of oil if only replacing the compressor and not the

liquid tank.

Revision: November 20132014 Altima NAM

Page 2634 of 4801

HA-28

< PERIODIC MAINTENANCE >

PERFORMANCE TEST

PERFORMANCE TEST

InspectionINFOID:0000000009463935

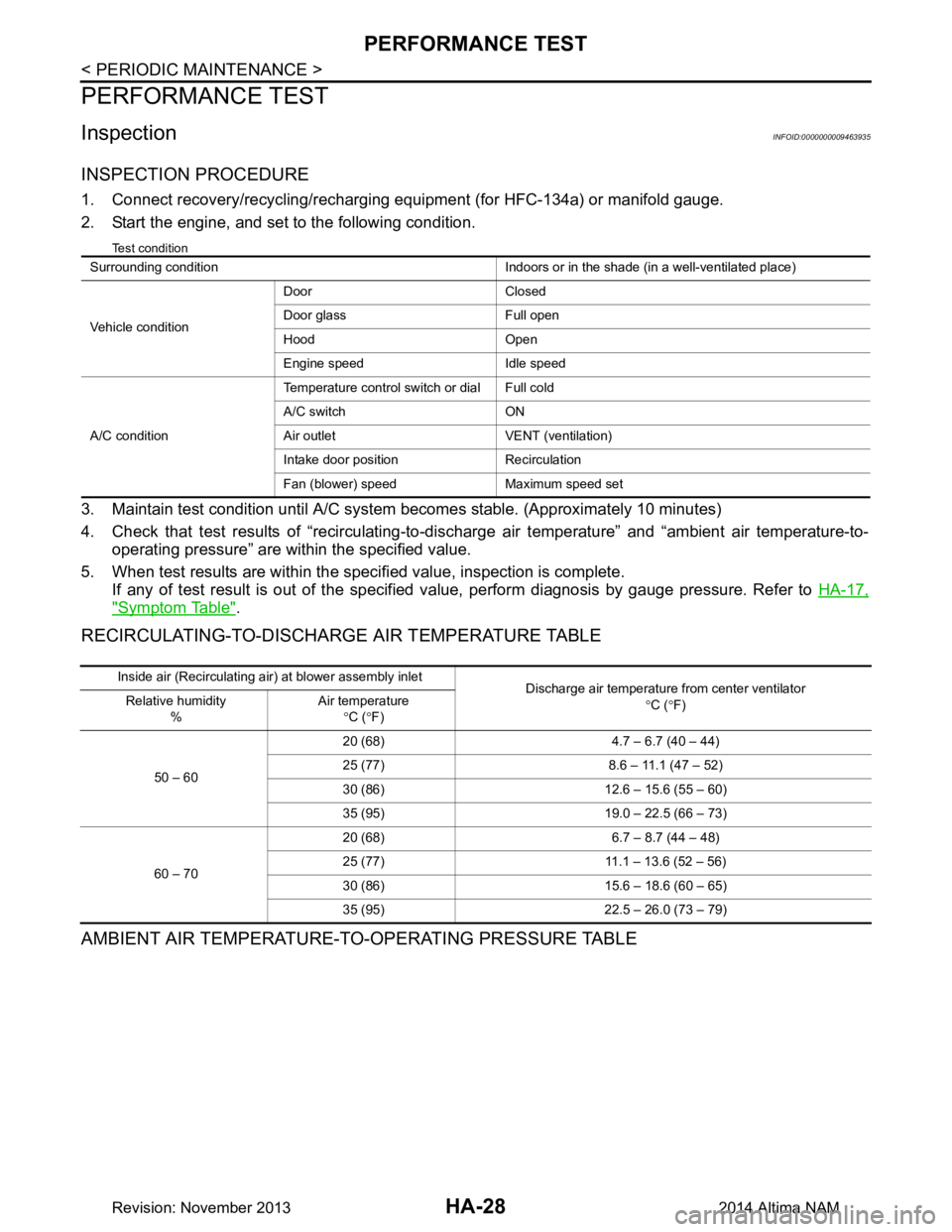

INSPECTION PROCEDURE

1. Connect recovery/recycling/recharging equipment (for HFC-134a) or manifold gauge.

2. Start the engine, and set to the following condition.

Test condition

3. Maintain test condition until A/C system becomes stable. (Approximately 10 minutes)

4. Check that test results of “recirculating-to-disc harge air temperature” and “ambient air temperature-to-

operating pressure” are within the specified value.

5. When test results are within the spec ified value, inspection is complete.

If any of test result is out of the specifi ed value, perform diagnosis by gauge pressure. Refer to HA-17,

"Symptom Table".

RECIRCULATING-TO-DISCHARGE AIR TEMPERATURE TABLE

AMBIENT AIR TEMPERATURE-TO-OPERATING PRESSURE TABLE

Surrounding condition Indoors or in the shade (in a well-ventilated place)

Vehicle condition Door Closed

Door glass Full open

Hood Open

Engine speed Idle speed

A/C condition Temperature control switch or dial Full cold

A/C switch ON

Air outlet VENT (ventilation)

Intake door position Recirculation

Fan (blower) speed Maximum speed set

Inside air (Recirculating air) at blower assembly inlet Discharge air temperature from center ventilator

°C ( °F)

Relative humidity

% Air temperature

°C ( °F)

50 – 60 20 (68) 4.7 – 6.7 (40 – 44)

25 (77) 8.6 – 11.1 (47 – 52)

30 (86) 12.6 – 15.6 (55 – 60)

35 (95) 19.0 – 22.5 (66 – 73)

60 – 70 20 (68) 6.7 – 8.7 (44 – 48)

25 (77) 11.1 – 13.6 (52 – 56)

30 (86) 15.6 – 18.6 (60 – 65)

35 (95) 22.5 – 26.0 (73 – 79)

Revision: November 20132014 Altima NAM

Page 2635 of 4801

PERFORMANCE TESTHA-29

< PERIODIC MAINTENANCE >

C

D E

F

G H

J

K L

M A

B

HA

N

O P

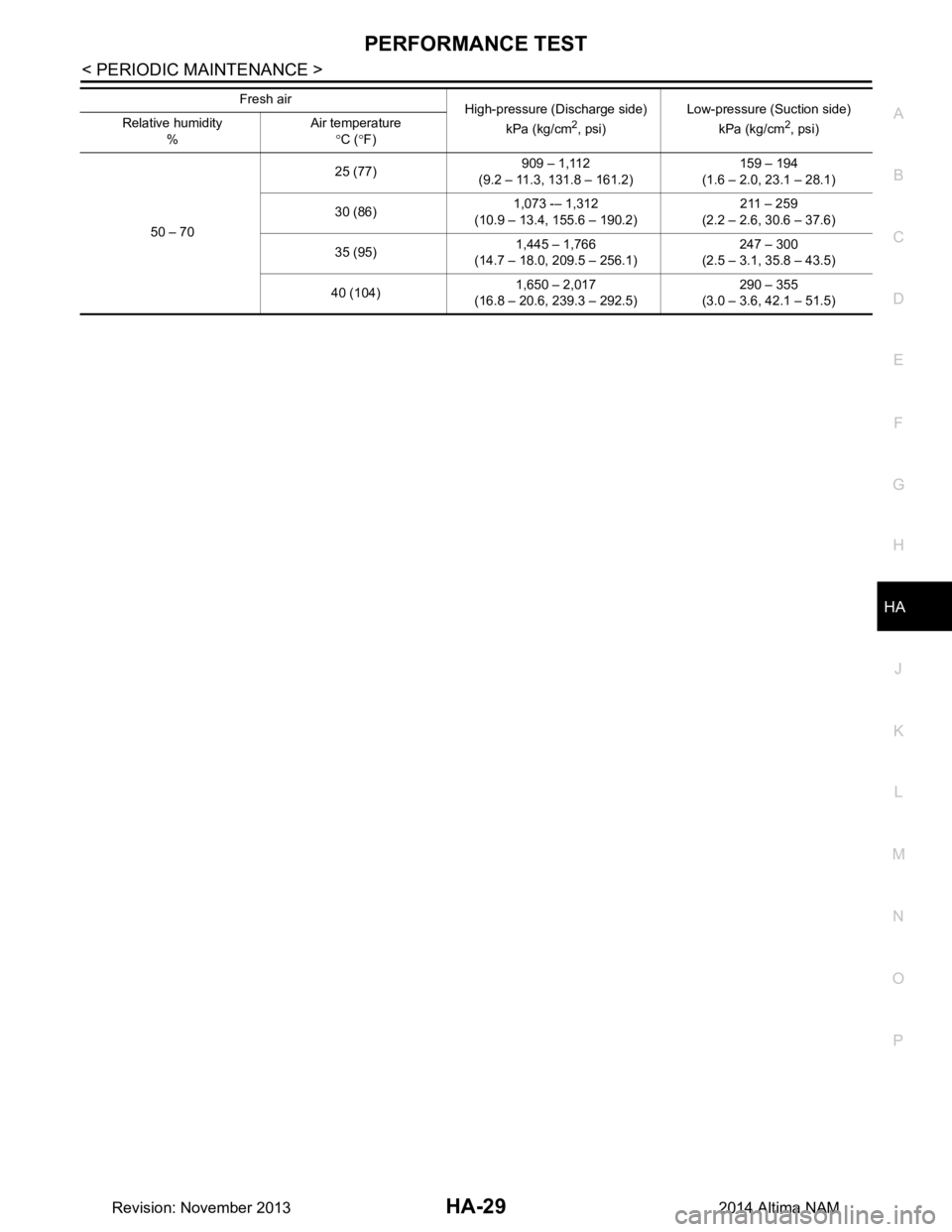

Fresh air High-pressure (Discharge side)

kPa (kg/cm

2, psi) Low-pressure (Suction side)

kPa (kg/cm2, psi)

Relative humidity

% Air temperature

°C ( °F)

50 – 70 25 (77)

909 – 1,112

(9.2 – 11.3, 131.8 – 161.2) 159 – 194

(1.6 – 2.0, 23.1 – 28.1)

30 (86) 1,073 -– 1,312

(10.9 – 13.4, 155.6 – 190.2) 211 – 259

(2.2 – 2.6, 30.6 – 37.6)

35 (95) 1,445 – 1,766

(14.7 – 18.0, 209.5 – 256.1) 247 – 300

(2.5 – 3.1, 35.8 – 43.5)

40 (104) 1,650 – 2,017

(16.8 – 20.6, 239.3 – 292.5) 290 – 355

(3.0 – 3.6, 42.1 – 51.5)

Revision: November 20132014 Altima NAM

Page 2636 of 4801

HA-30

< REMOVAL AND INSTALLATION >

COMPRESSOR

REMOVAL AND INSTALLATION

COMPRESSOR

COMPRESSOR

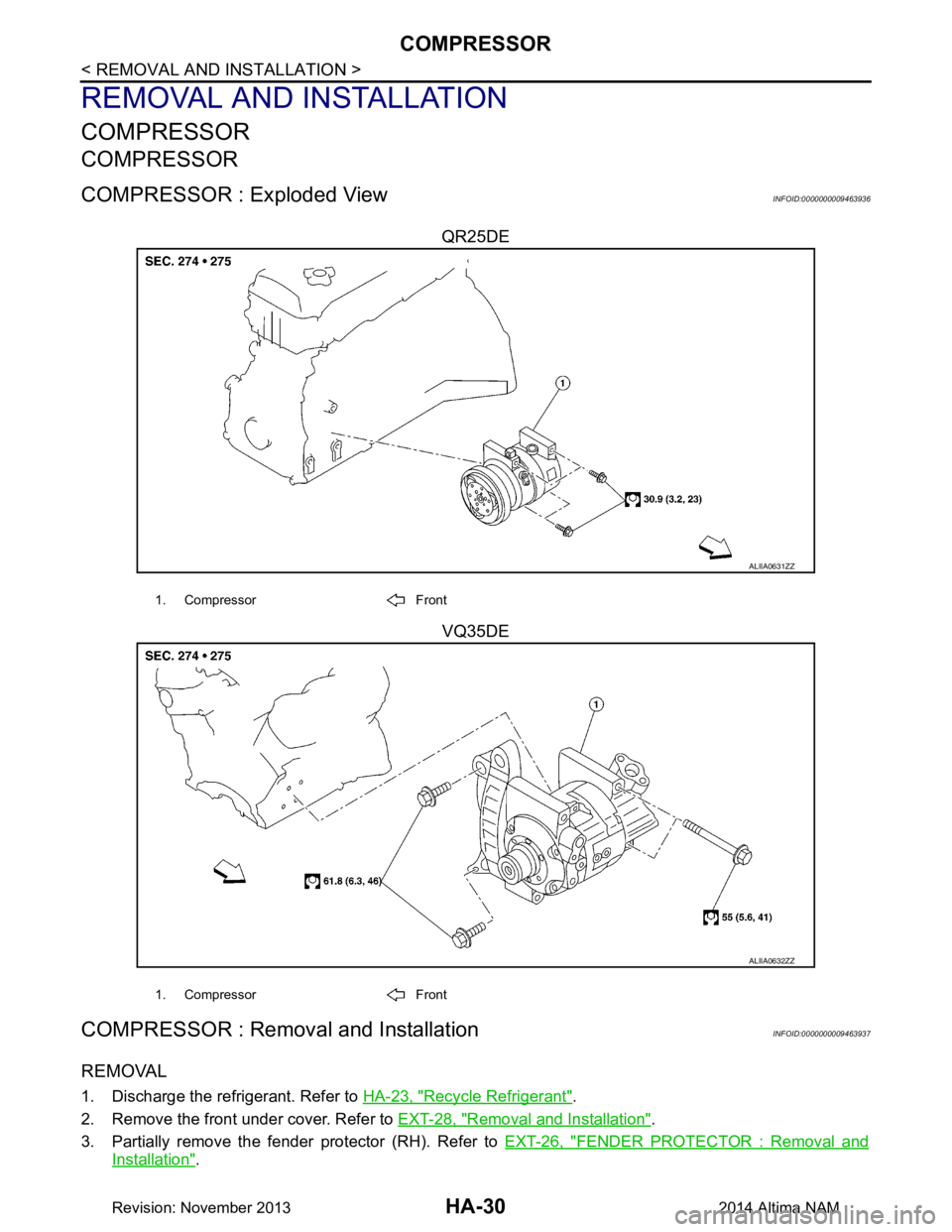

COMPRESSOR : Exploded ViewINFOID:0000000009463936

QR25DEVQ35DE

COMPRESSOR : Removal and InstallationINFOID:0000000009463937

REMOVAL

1. Discharge the refrigerant. Refer to HA-23, "Recycle Refrigerant".

2. Remove the front under cover. Refer to EXT-28, "Removal and Installation"

.

3. Partially remove the fender protector (RH). Refer to EXT-26, "FENDER PROTECTOR : Removal and

Installation".

ALIIA0631ZZ

1. Compressor Front

ALIIA0632ZZ

1. Compressor Front

Revision: November 20132014 Altima NAM

Page 2637 of 4801

COMPRESSORHA-31

< REMOVAL AND INSTALLATION >

C

D E

F

G H

J

K L

M A

B

HA

N

O P

4. Remove the drive belt. Refer to EM-19, "Removal and Installation" (QR25DE), or EM-134, "Removal and

Installation" (VQ35DE).

5. Reposition the power steering line. Refer to ST-40, "Exploded View"

.

6. Disconnect the A/C pipes from the compressor. CAUTION:

Cap or wrap the joint of the A/C pipes with suitable material such as vinyl tape to avoid the entry of

air.

7. Disconnect the harness connector from the compressor.

8. Remove the compressor bolts and the compressor.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Do not reuse the O-rings.

• Apply A/C compressor oil to th e new O-rings for installation.

• After charging the A/C refriger ant, check for leaks. Refer to HA-21, "Leak Test"

.

• Tighten the compressor bolts to specification. Refer to HA-30, "COMPRESSOR : Exploded View"

.

MAGNET CLUTCH

MAGNET CLUTCH : Removal and InstallationINFOID:0000000009463938

REMOVAL

1. Remove the front under cover. Refer to EXT-28, "Removal and Installation".

2. Partially remove the fender protector (RH). Refer to EXT-26, "FENDER PROTECTOR : Removal and

Installation".

3. Remove the drive belt. Refer to EM-19, "Removal and Installation"

(QR25DE), or EM-134, "Removal and

Installation" (VQ35DE).

4. Remove the center bolt by holding the clutch disc steady using a suitable tool.

5. Remove the clutch disc and shims. CAUTION:

Retain all the shim s for installation.

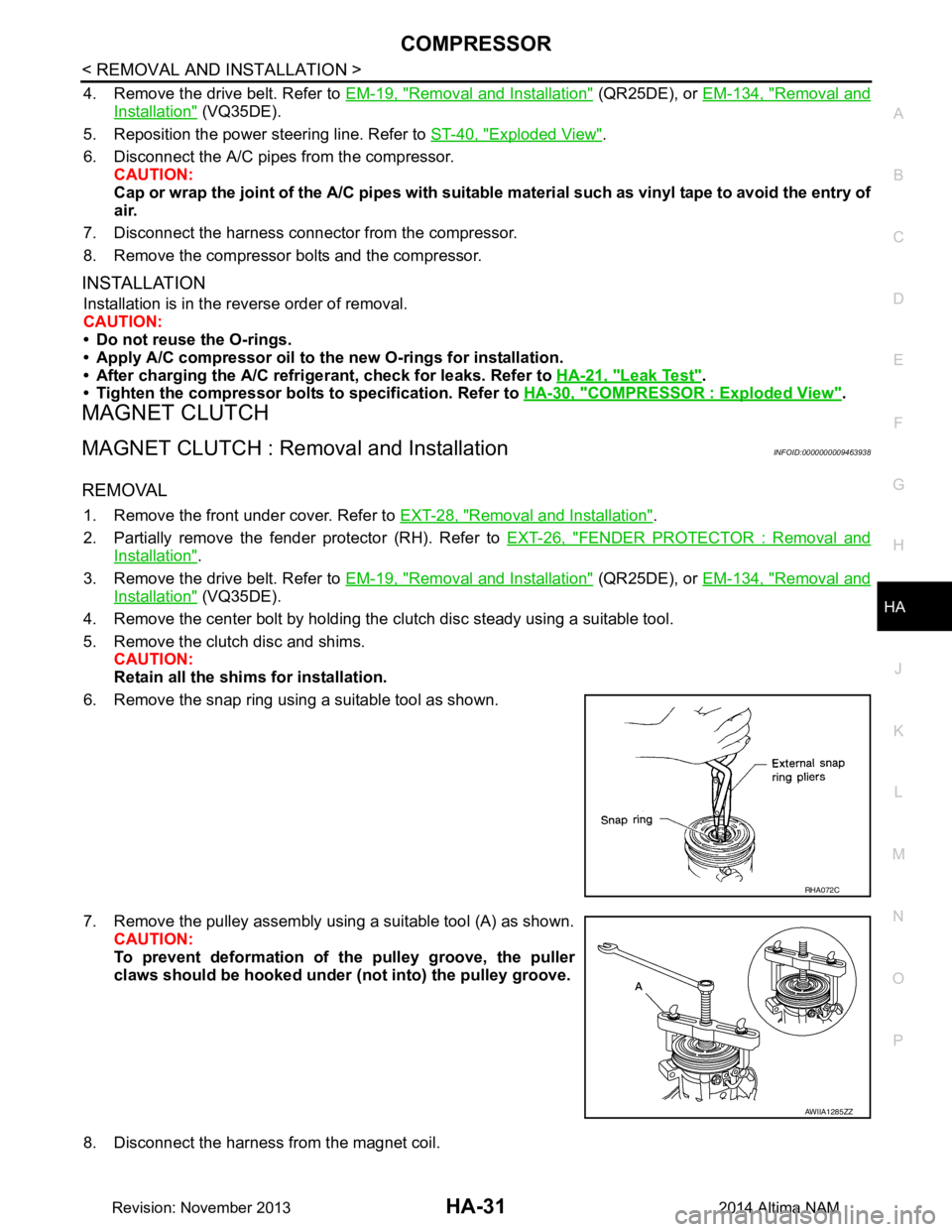

6. Remove the snap ring using a suitable tool as shown.

7. Remove the pulley assembly using a suitable tool (A) as shown. CAUTION:

To prevent deformation of th e pulley groove, the puller

claws should be hooked under (not into) the pulley groove.

8. Disconnect the harness from the magnet coil.

RHA072C

AWIIA1285ZZ

Revision: November 20132014 Altima NAM

Page 2638 of 4801

HA-32

< REMOVAL AND INSTALLATION >

COMPRESSOR

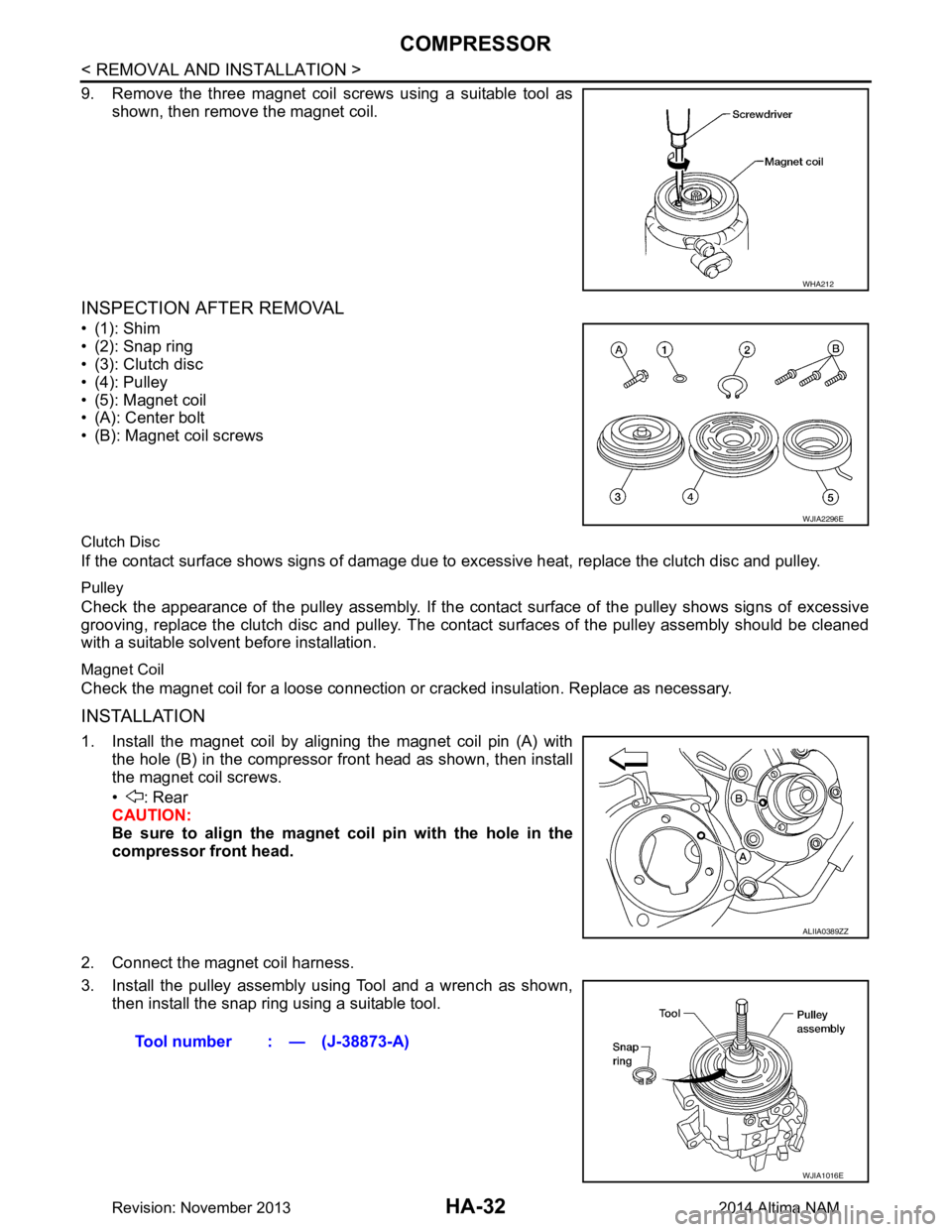

9. Remove the three magnet coil screws using a suitable tool asshown, then remove the magnet coil.

INSPECTION AFTER REMOVAL

•(1): Shim

• (2): Snap ring

• (3): Clutch disc

• (4): Pulley

• (5): Magnet coil

• (A): Center bolt

• (B): Magnet coil screws

Clutch Disc

If the contact surface shows signs of damage due to excessive heat, replace the clutch disc and pulley.

Pulley

Check the appearance of the pulley assembly. If the cont act surface of the pulley shows signs of excessive

grooving, replace the clutch disc and pulley. The contact surfaces of the pulley assembly should be cleaned

with a suitable solvent before installation.

Magnet Coil

Check the magnet coil for a loose connection or cracked insulation. Replace as necessary.

INSTALLATION

1. Install the magnet coil by aligning the magnet coil pin (A) with

the hole (B) in the compressor front head as shown, then install

the magnet coil screws.

• : Rear

CAUTION:

Be sure to align the magnet coil pin with the hole in the

compressor front head.

2. Connect the magnet coil harness.

3. Install the pulley assembly using Tool and a wrench as shown, then install the snap ring using a suitable tool.

WHA212

WJIA2296E

ALIIA0389ZZ

Tool number : — (J-38873-A)

WJIA1016E

Revision: November 20132014 Altima NAM

Page 2639 of 4801

COMPRESSORHA-33

< REMOVAL AND INSTALLATION >

C

D E

F

G H

J

K L

M A

B

HA

N

O P

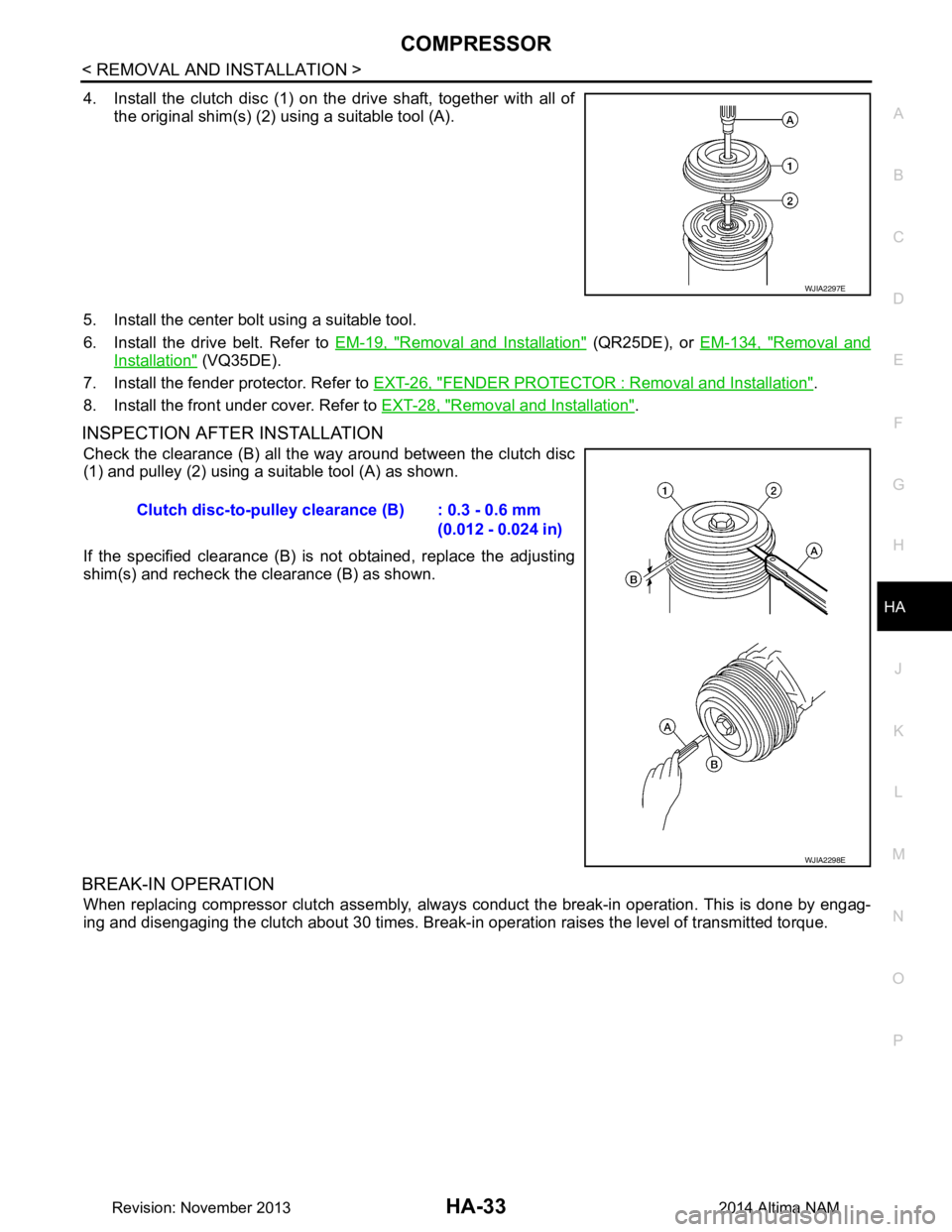

4. Install the clutch disc (1) on the drive shaft, together with all of the original shim(s) (2) using a suitable tool (A).

5. Install the center bolt using a suitable tool.

6. Install the drive belt. Refer to EM-19, "Removal and Installation"

(QR25DE), or EM-134, "Removal and

Installation" (VQ35DE).

7. Install the fender protector. Refer to EXT-26, "FENDER PROTECTOR : Removal and Installation"

.

8. Install the front under cover. Refer to EXT-28, "Removal and Installation"

.

INSPECTION AFTER INSTALLATION

Check the clearance (B) all the way around between the clutch disc

(1) and pulley (2) using a suitable tool (A) as shown.

If the specified clearance (B) is not obtained, replace the adjusting

shim(s) and recheck the clearance (B) as shown.

BREAK-IN OPERATION

When replacing compressor clutch assembly, always conduct the break-in operation. This is done by engag-

ing and disengaging the clutch about 30 times. Break-in operation raises the level of transmitted torque.

WJIA2297E

Clutch disc-to-pulley clearance (B) : 0.3 - 0.6 mm

(0.012 - 0.024 in)

WJIA2298E

Revision: November 20132014 Altima NAM

Page 2640 of 4801

HA-34

< REMOVAL AND INSTALLATION >

COOLER PIPE AND HOSE

COOLER PIPE AND HOSE

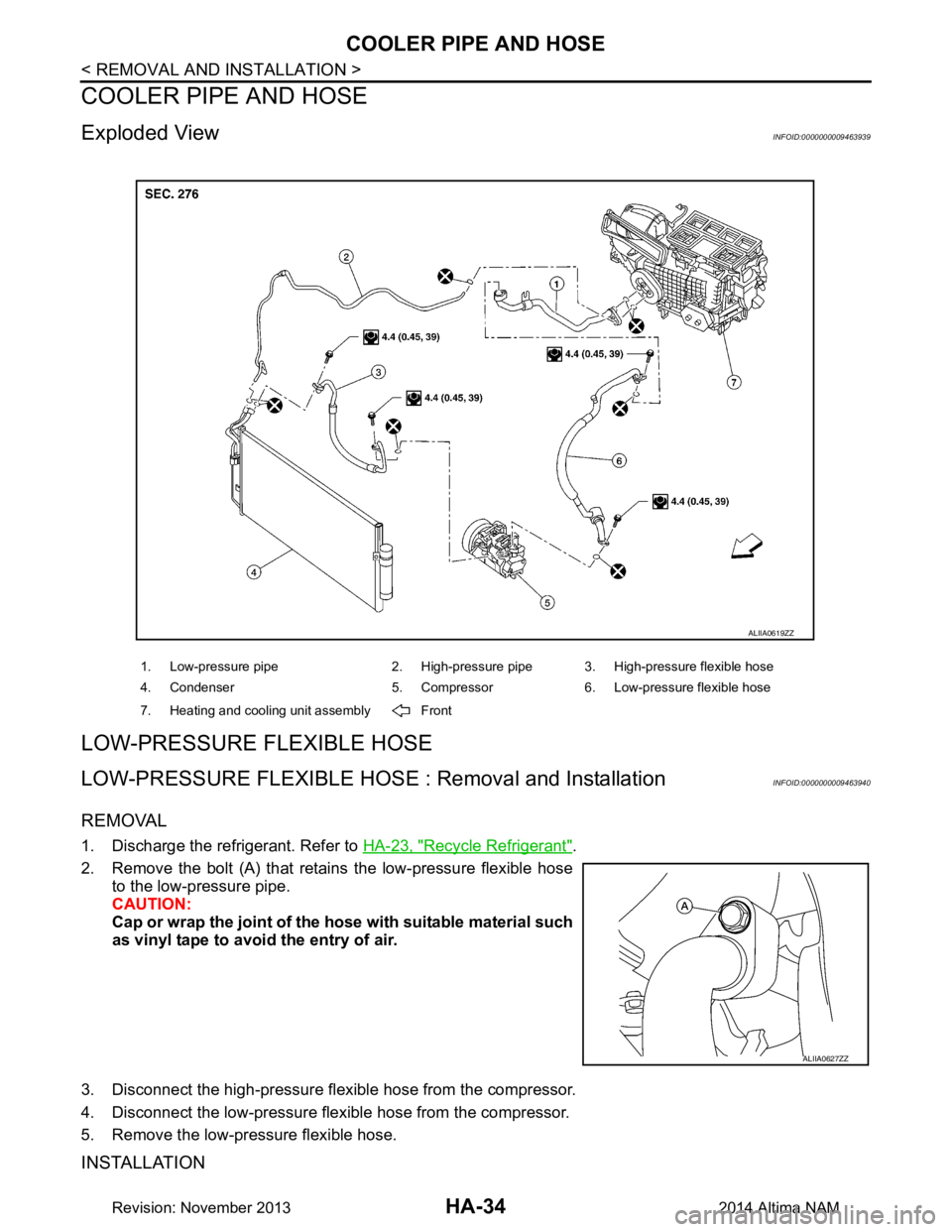

Exploded ViewINFOID:0000000009463939

LOW-PRESSURE FLEXIBLE HOSE

LOW-PRESSURE FLEXIBLE HOSE : Removal and InstallationINFOID:0000000009463940

REMOVAL

1. Discharge the refrigerant. Refer to HA-23, "Recycle Refrigerant".

2. Remove the bolt (A) that retain s the low-pressure flexible hose

to the low-pressure pipe.

CAUTION:

Cap or wrap the joint of the ho se with suitable material such

as vinyl tape to avoid the entry of air.

3. Disconnect the high-pressure flexible hose from the compressor.

4. Disconnect the low-pressure flexible hose from the compressor.

5. Remove the low-pressure flexible hose.

INSTALLATION

1. Low-pressure pipe 2. High-pressure pipe 3. High-pressure flexible hose

4. Condenser 5. Compressor 6. Low-pressure flexible hose

7. Heating and cooling unit assembly Front

ALIIA0619ZZ

ALIIA0627ZZ

Revision: November 20132014 Altima NAM