NISSAN TEANA 2014 Service Manual

Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 2611 of 4801

PRECAUTIONSHA-5

< PRECAUTION >

C

D E

F

G H

J

K L

M A

B

HA

N

O P

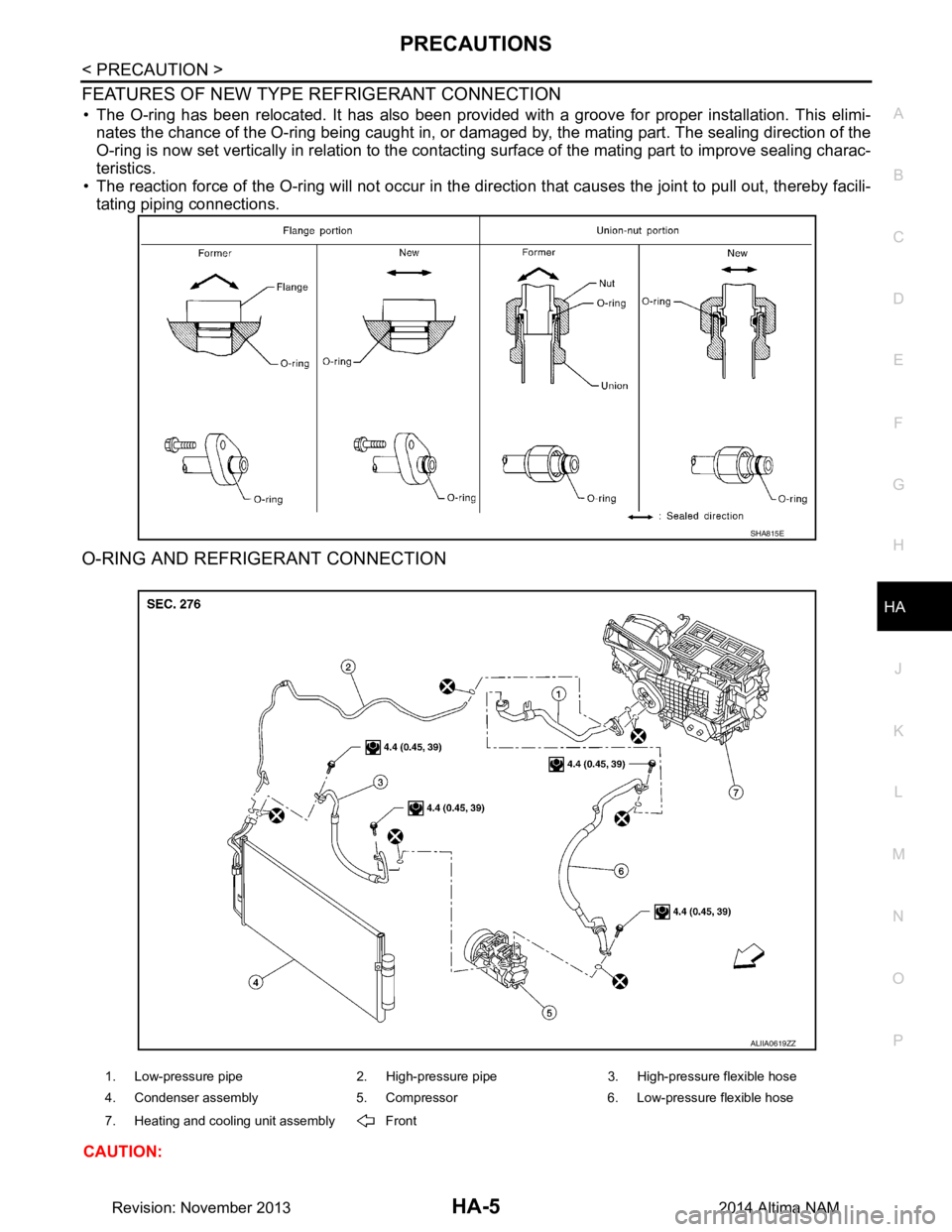

FEATURES OF NEW TYPE REFRIGERANT CONNECTION

• The O-ring has been relocated. It has also been provided with a groove for proper installation. This elimi- nates the chance of the O-ring being caught in, or damaged by, the mating part. The sealing direction of the

O-ring is now set vertically in relation to the contacti ng surface of the mating part to improve sealing charac-

teristics.

• The reaction force of the O-ring will not occur in the dire ction that causes the joint to pull out, thereby facili-

tating piping connections.

O-RING AND REFRIGERANT CONNECTION

CAUTION:

SHA815E

1. Low-pressure pipe 2. High-pressure pipe 3. High-pressure flexible hose

4. Condenser assembly 5. Compressor 6. Low-pressure flexible hose

7. Heating and cooling unit assembly Front

ALIIA0619ZZ

Revision: November 20132014 Altima NAM

Page 2612 of 4801

HA-6

< PRECAUTION >

PRECAUTIONS

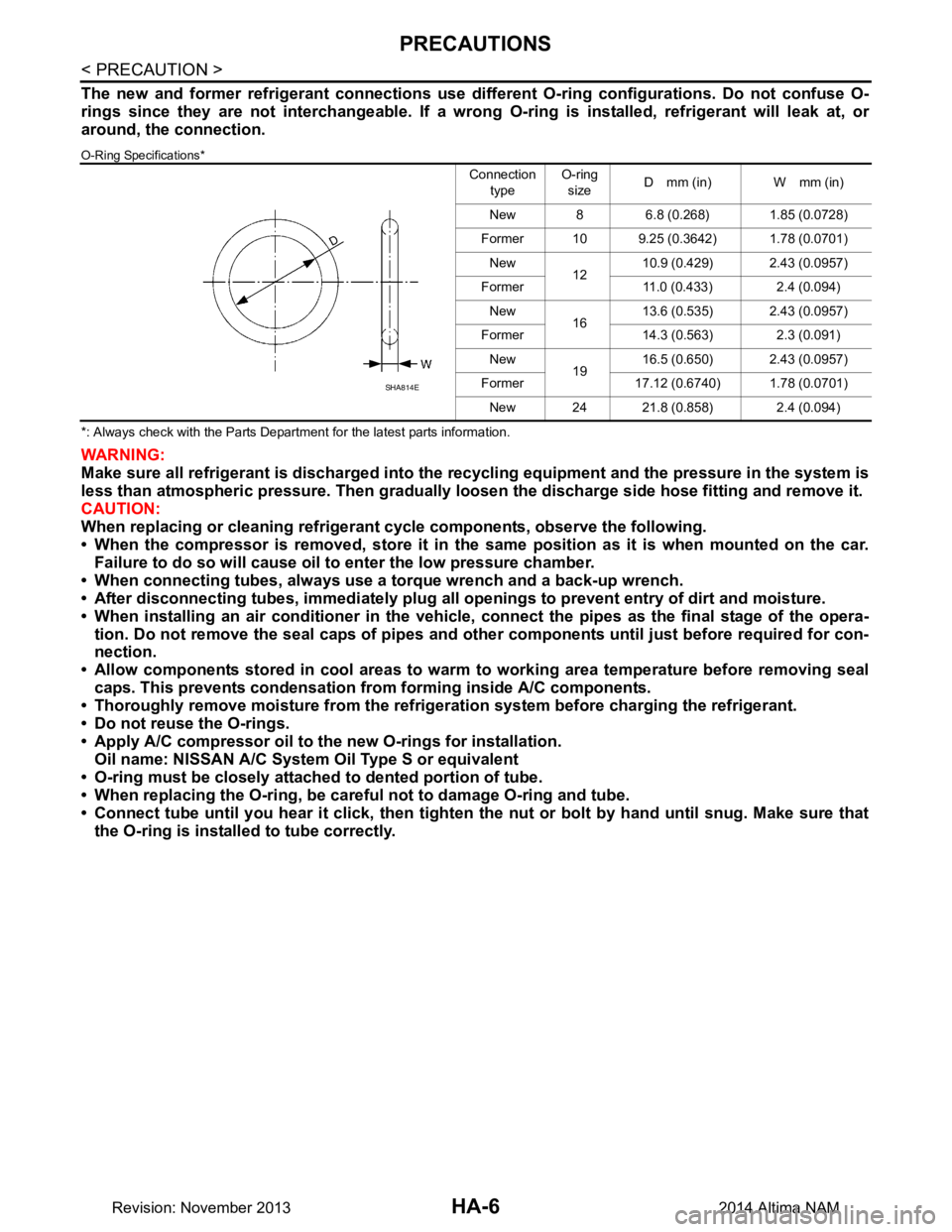

The new and former refrigerant connections use different O-ring configurations. Do not confuse O-

rings since they are not interchangeable. If a wrong O-ring is installed, refrigerant will leak at, or

around, the connection.

O-Ring Specifications*

*: Always check with the Parts Department for the latest parts information.

WARNING:

Make sure all refrigerant is discharged into the recycling equipment and the pressure in the system is

less than atmospheric pressure. Then gradually loo sen the discharge side hose fitting and remove it.

CAUTION:

When replacing or cleaning refrigeran t cycle components, observe the following.

• When the compressor is removed, store it in the same position as it is when mounted on the car.

Failure to do so will cause oil to enter the low pressure chamber.

• When connecting tubes, always use a torque wrench and a back-up wrench.

• After disconnecting tubes, immedi ately plug all openings to prevent entry of dirt and moisture.

• When installing an air conditioner in the vehicle, connect the pipes as the final stage of the opera-

tion. Do not remove the seal caps of pipes and othe r components until just before required for con-

nection.

• Allow components stored in cool areas to warm to working area temperature before removing seal

caps. This prevents condensation from forming inside A/C components.

• Thoroughly remove moisture from the refrigerat ion system before charging the refrigerant.

• Do not reuse the O-rings.

• Apply A/C compressor oil to th e new O-rings for installation.

Oil name: NISSAN A/C System Oil Type S or equivalent

• O-ring must be closely attached to dented portion of tube.

• When replacing the O-ring, be careful not to damage O-ring and tube.

• Connect tube until you hear it cl ick, then tighten the nut or bolt by hand until snug. Make sure that

the O-ring is installed to tube correctly.

Connection

type O-ring

size D mm (in) W mm (in)

New 8 6.8 (0.268) 1.85 (0.0728)

Former 10 9.25 (0.3642) 1.78 (0.0701) New 1210.9 (0.429) 2.43 (0.0957)

Former 11.0 (0.433) 2.4 (0.094) New 1613.6 (0.535) 2.43 (0.0957)

Former 14.3 (0.563) 2.3 (0.091) New 1916.5 (0.650) 2.43 (0.0957)

Former 17.12 (0.6740) 1.78 (0.0701) New 24 21.8 (0.858) 2.4 (0.094)

SHA814E

Revision: November 20132014 Altima NAM

Page 2613 of 4801

PRECAUTIONSHA-7

< PRECAUTION >

C

D E

F

G H

J

K L

M A

B

HA

N

O P

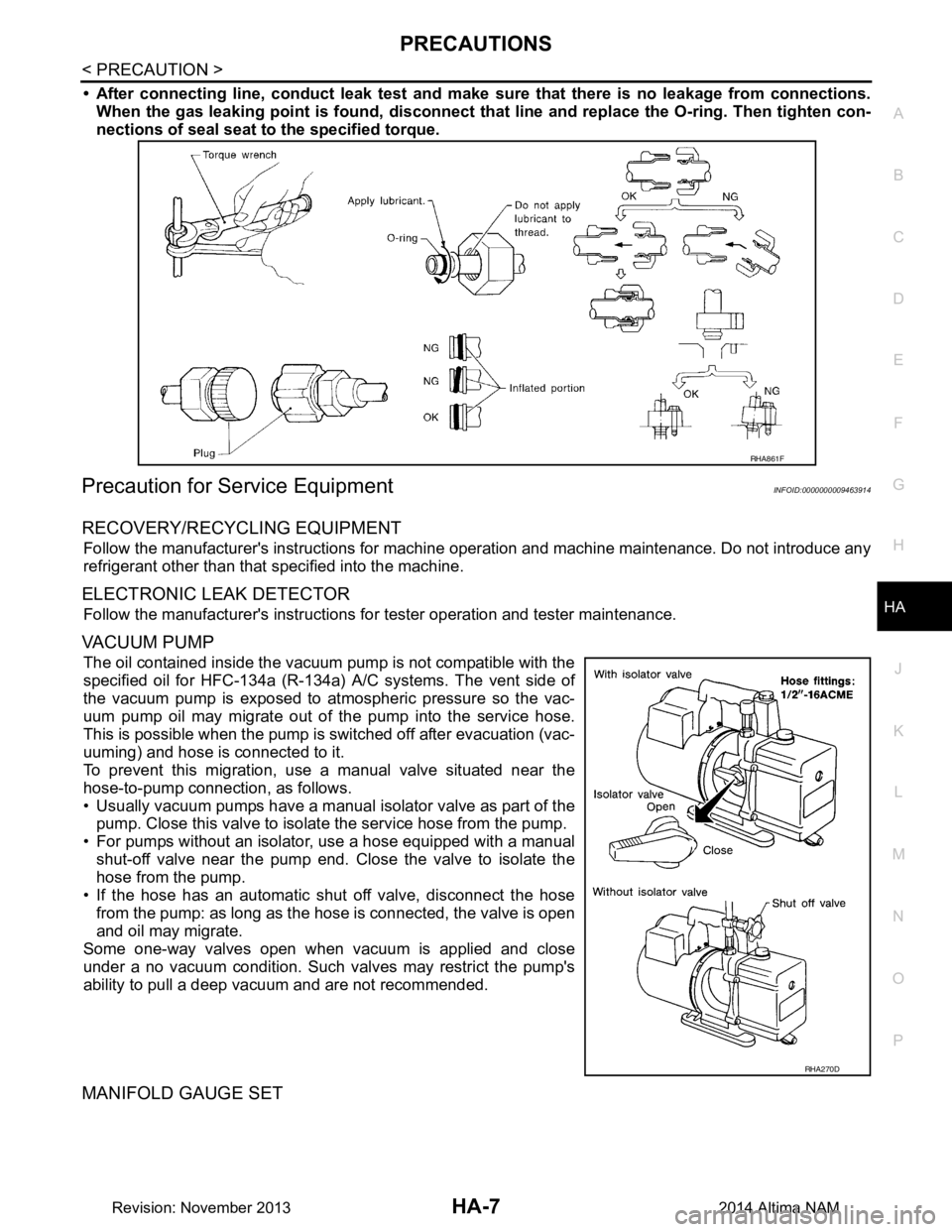

• After connecting line, conduct leak test and make sure that there is no leakage from connections.

When the gas leaking point is f ound, disconnect that line and replace the O-ring. Then tighten con-

nections of seal seat to the specified torque.

Precaution for Service EquipmentINFOID:0000000009463914

RECOVERY/RECYCLING EQUIPMENT

Follow the manufacturer's instructions for machine operation and machine maintenance. Do not introduce any

refrigerant other than that specified into the machine.

ELECTRONIC LEAK DETECTOR

Follow the manufacturer's instructions fo r tester operation and tester maintenance.

VACUUM PUMP

The oil contained inside the vacuum pump is not compatible with the

specified oil for HFC-134a (R-134a) A/C systems. The vent side of

the vacuum pump is exposed to atmospheric pressure so the vac-

uum pump oil may migrate out of the pump into the service hose.

This is possible when the pump is switched off after evacuation (vac-

uuming) and hose is connected to it.

To prevent this migration, use a manual valve situated near the

hose-to-pump connection, as follows.

• Usually vacuum pumps have a manual isolator valve as part of the

pump. Close this valve to isolate the service hose from the pump.

• For pumps without an isolator, use a hose equipped with a manual shut-off valve near the pump end. Close the valve to isolate the

hose from the pump.

• If the hose has an automatic shut off valve, disconnect the hose from the pump: as long as the hos e is connected, the valve is open

and oil may migrate.

Some one-way valves open when vacuum is applied and close

under a no vacuum condition. Such valves may restrict the pump's

ability to pull a deep vacuum and are not recommended.

MANIFOLD GAUGE SET

RHA861F

RHA270D

Revision: November 20132014 Altima NAM

Page 2614 of 4801

HA-8

< PRECAUTION >

PRECAUTIONS

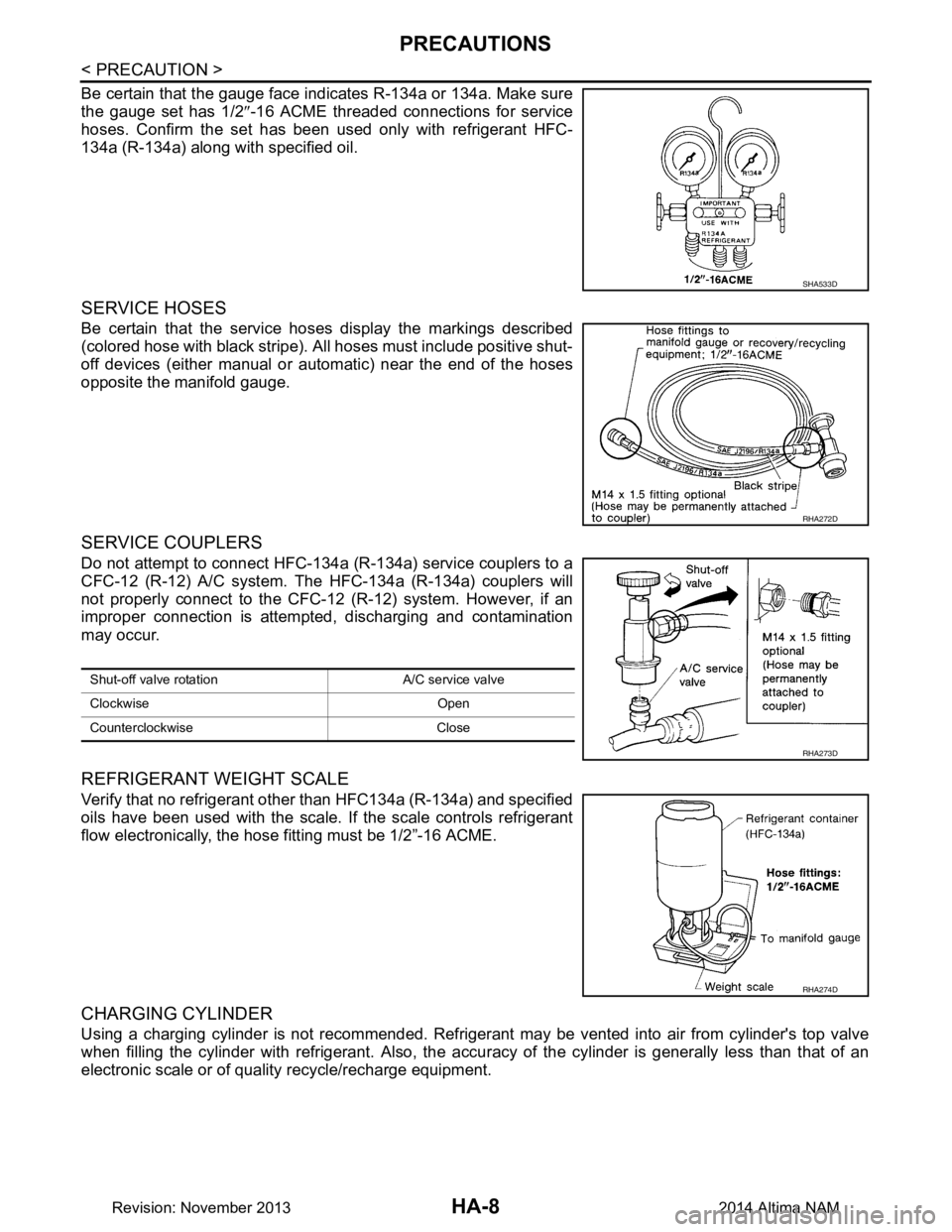

Be certain that the gauge face indicates R-134a or 134a. Make sure

the gauge set has 1/2 ″-16 ACME threaded connections for service

hoses. Confirm the set has been used only with refrigerant HFC-

134a (R-134a) along with specified oil.

SERVICE HOSES

Be certain that the service hoses display the markings described

(colored hose with black stripe). All hoses must include positive shut-

off devices (either manual or aut omatic) near the end of the hoses

opposite the manifold gauge.

SERVICE COUPLERS

Do not attempt to connect HFC-134a (R-134a) service couplers to a

CFC-12 (R-12) A/C system. The HFC-134a (R-134a) couplers will

not properly connect to the CFC-12 (R-12) system. However, if an

improper connection is attempted, discharging and contamination

may occur.

REFRIGERANT WEIGHT SCALE

Verify that no refrigerant other than HFC134a (R-134a) and specified

oils have been used with the scale. If the scale controls refrigerant

flow electronically, the hose fitting must be 1/2”-16 ACME.

CHARGING CYLINDER

Using a charging cylinder is not recommended. Refrigerant may be vented into air from cylinder's top valve

when filling the cylinder with refrigerant. Also, the accu racy of the cylinder is generally less than that of an

electronic scale or of quality recycle/recharge equipment.

SHA533D

RHA272D

Shut-off valve rotati on A/C service valve

Clockwise Open

Counterclockwise Close

RHA273D

RHA274D

Revision: November 20132014 Altima NAM

Page 2615 of 4801

PREPARATIONHA-9

< PREPARATION >

C

D E

F

G H

J

K L

M A

B

HA

N

O P

PREPARATION

PREPARATION

Special Service ToolINFOID:0000000009463915

The actual shapes of the tools may differ from those illustrated here.

HFC-134a (R-134a) Servic e Tool and EquipmentINFOID:0000000009463916

Do not mix HFC-134a (R-134a) refrigerant and/or its specif ied oil with CFC-12 (R-12) refrigerant and/or its oil.

Separate and non-interchangeable service equipment must be used for handling each type of refrigerant/oil.

Refrigerant container fittings, service hose fittings and service equipment fittings (equipment which handles

refrigerant and/or oil) are different between CFC-12 (R-12) and HFC-134a (R-134a). This is to avoid mixed

use of the refrigerants/oil.

Adapters that convert one size fitting to another must not be used refrigerant/oil contamination will occur and

compressor failure will result.

Tool number

(TechMate No.)

Tool name Description

—

(J-41425-NIS)

Aluminum tube repair kit Repairing leaks in A/C tubes

—

(J-38873-A)

Drive plate installer Installing pulley

—

(J-46534)

Trim Tool Set Removing trim components

ALIIA0390ZZ

WJIA0367E

AWJIA0483ZZ

Revision: November 20132014 Altima NAM

Page 2616 of 4801

HA-10

< PREPARATION >

PREPARATION

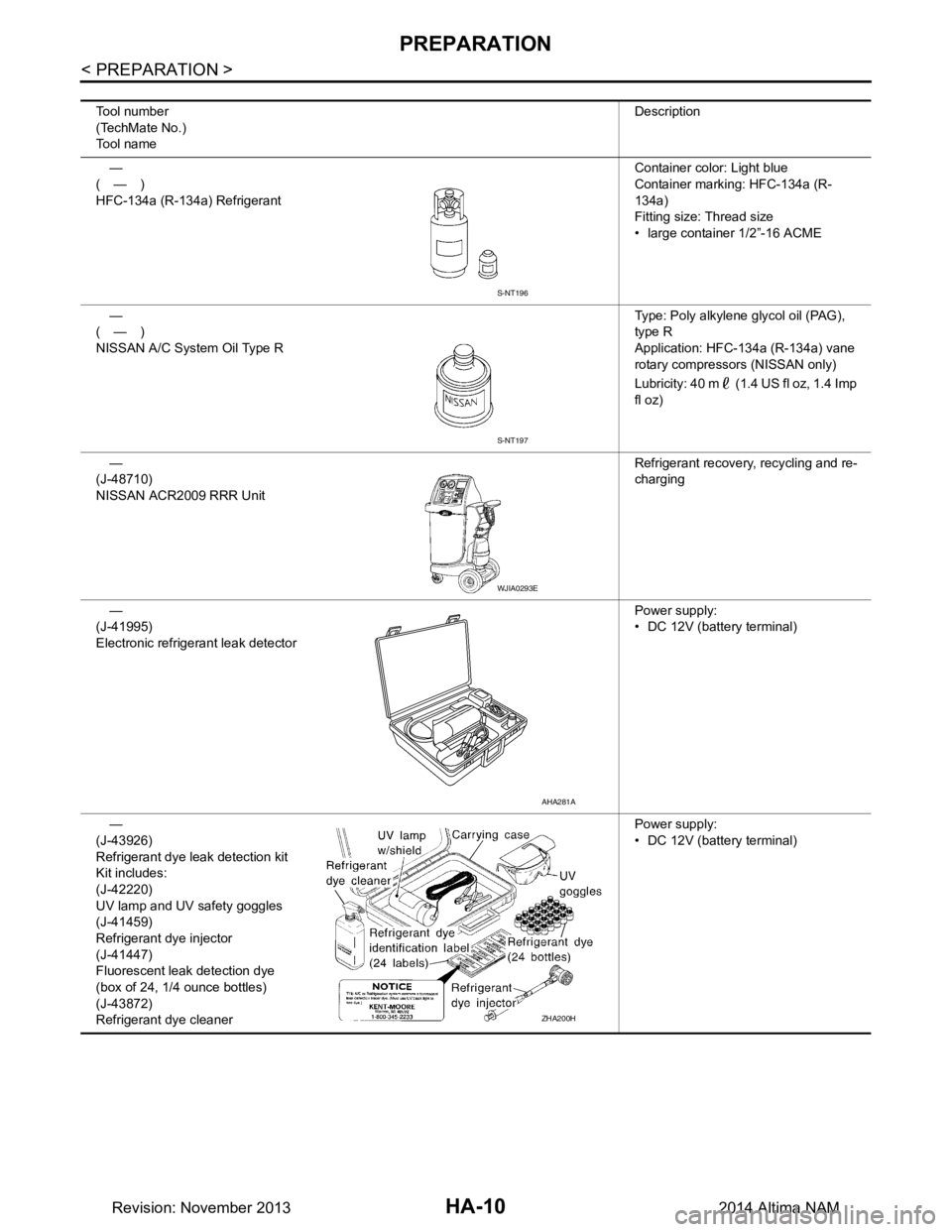

Tool number

(TechMate No.)

Tool name Description

—

(—)

HFC-134a (R-134a) Refrigerant Container color: Light blue

Container marking: HFC-134a (R-

134a)

Fitting size: Thread size

• large container 1/2”-16 ACME

—

(—)

NISSAN A/C System Oil Type R Type: Poly alkylene glycol oil (PAG),

type R

Application: HFC-134a (R-134a) vane

rotary compressors (NISSAN only)

Lubricity: 40 m (1.4 US fl oz, 1.4 Imp

fl oz)

—

(J-48710)

NISSAN ACR2009 RRR Unit Refrigerant recovery, recycling and re-

charging

—

(J-41995)

Electronic refrigerant leak detector Power supply:

• DC 12V (batte ry terminal)

—

(J-43926)

Refrigerant dye leak detection kit

Kit includes:

(J-42220)

UV lamp and UV safety goggles

(J-41459)

Refrigerant dye injector

(J-41447)

Fluorescent leak detection dye

(box of 24, 1/4 ounce bottles)

(J-43872)

Refrigerant dye cleaner Power supply:

• DC 12V (batte ry terminal)

S-NT196

S-NT197

WJIA0293E

AHA281A

ZHA200H

Revision: November 20132014 Altima NAM

Page 2617 of 4801

PREPARATIONHA-11

< PREPARATION >

C

D E

F

G H

J

K L

M A

B

HA

N

O P

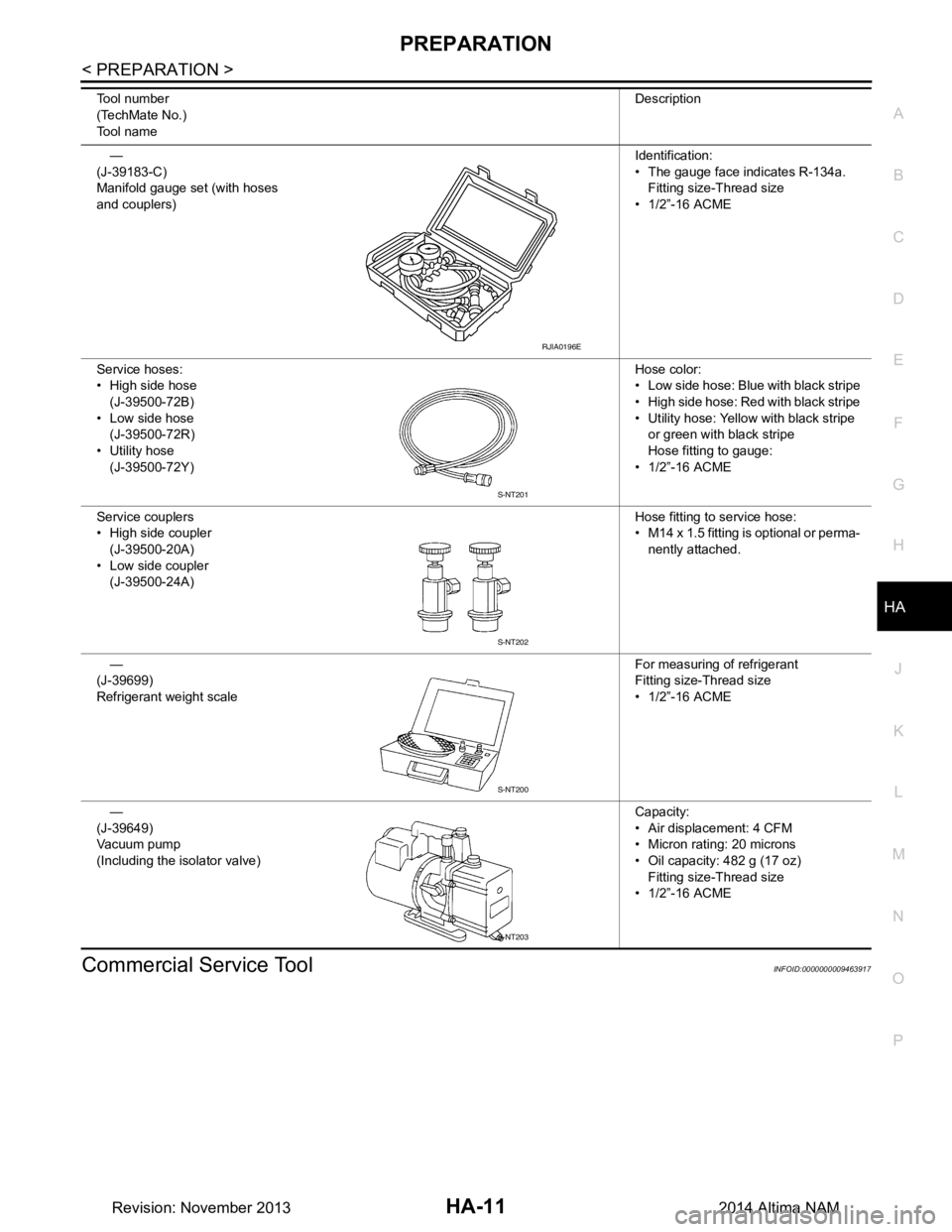

Commercial Service ToolINFOID:0000000009463917

—

(J-39183-C)

Manifold gauge set (with hoses

and couplers) Identification:

• The gauge face indicates R-134a. Fitting size-Thread size

• 1/2”-16 ACME

Service hoses:

• High side hose (J-39500-72B)

• Low side hose (J-39500-72R)

• Utility hose

(J-39500-72Y) Hose color:

• Low side hose: Blue with black stripe

• High side hose: Red with black stripe

• Utility hose: Yellow with black stripe or green with black stripe

Hose fitting to gauge:

• 1/2”-16 ACME

Service couplers

• High side coupler (J-39500-20A)

• Low side coupler

(J-39500-24A) Hose fitting to service hose:

• M14 x 1.5 fitting is optional or perma- nently attached.

—

(J-39699)

Refrigerant weight scale For measuring of refrigerant

Fitting size-Thread size

• 1/2”-16 ACME

—

(J-39649)

Va c u u m p u m p

(Including the isolator valve) Capacity:

• Air displacement: 4 CFM

• Micron rating: 20 microns

• Oil capacity: 482 g (17 oz)

Fitting size-Thread size

• 1/2”-16 ACME

Tool number

(TechMate No.)

Tool name Description

RJIA0196E

S-NT201

S-NT202

S-NT200

S-NT203

Revision: November 20132014 Altima NAM

Page 2618 of 4801

HA-12

< PREPARATION >

PREPARATION

(TechMate No.)

Tool name Description

(J-41810-NI)

Refrigerant identifier equipment (R-

134a) For checking refrigerant purity and

system contamination

(—)

Power tool Loosening nuts, screws and bolts

RJIA0197E

PIIB1407E

Revision: November 20132014 Altima NAM

Page 2619 of 4801

REFRIGERATION SYSTEMHA-13

< SYSTEM DESCRIPTION >

C

D E

F

G H

J

K L

M A

B

HA

N

O P

SYSTEM DESCRIPTION

REFRIGERATION SYSTEM

Refrigerant CycleINFOID:0000000009463918

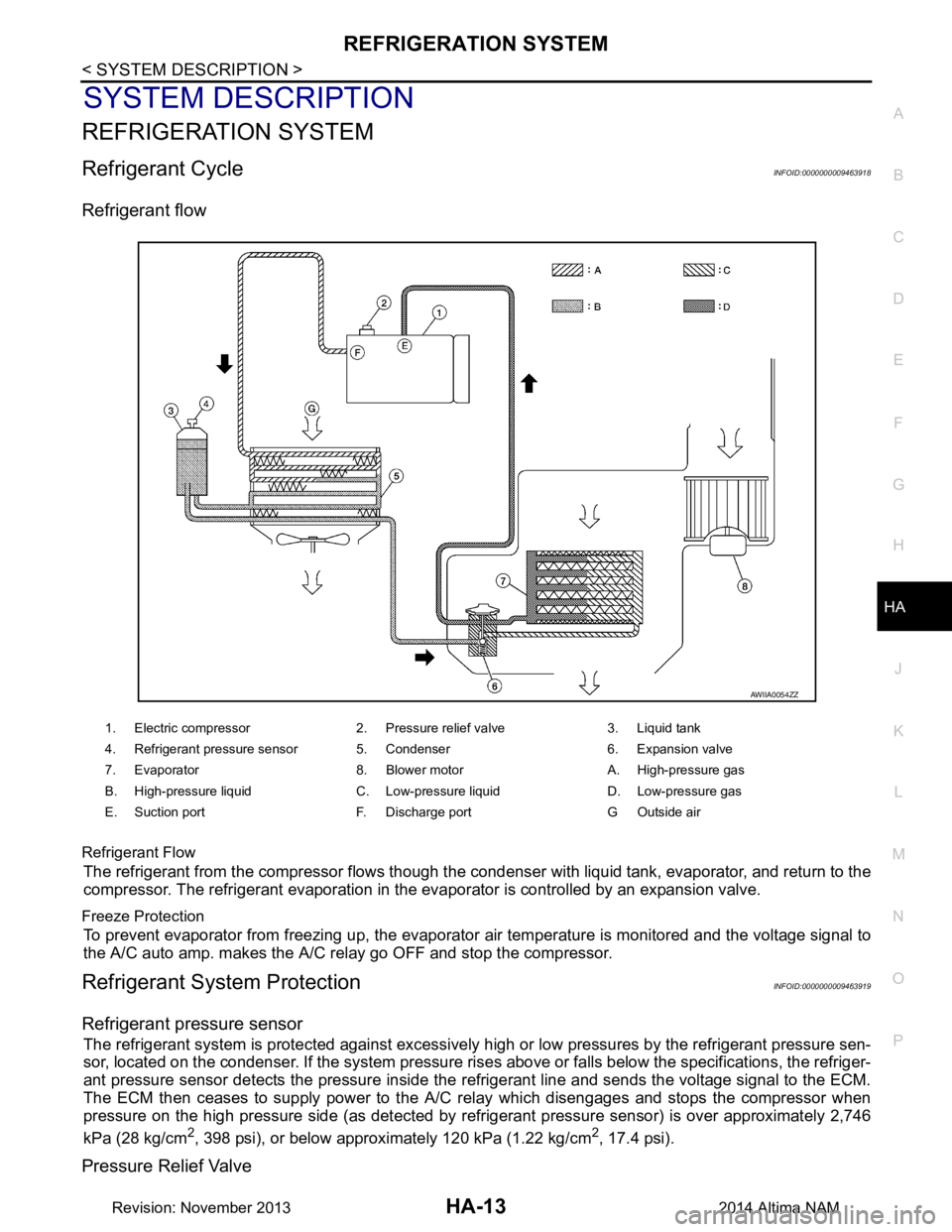

Refrigerant flow

Refrigerant Flow

The refrigerant from the compressor flows though the c ondenser with liquid tank, evaporator, and return to the

compressor. The refrigerant evaporation in the evaporator is controlled by an expansion valve.

Freeze Protection

To prevent evaporator from freezing up, the evaporator air temperature is monitored and the voltage signal to

the A/C auto amp. makes the A/C relay go OFF and stop the compressor.

Refrigerant System ProtectionINFOID:0000000009463919

Refrigerant pressure sensor

The refrigerant system is protected against excessively hi gh or low pressures by the refrigerant pressure sen-

sor, located on the condenser. If the system pressure rise s above or falls below the specifications, the refriger-

ant pressure sensor detects the pressure inside the refrigerant line and sends the voltage signal to the ECM.

The ECM then ceases to supply power to the A/C relay which disengages and stops the compressor when

pressure on the high pressure side (as detected by refr igerant pressure sensor) is over approximately 2,746

kPa (28 kg/cm

2, 398 psi), or below approximately 120 kPa (1.22 kg/cm2, 17.4 psi).

Pressure Relief Valve

1. Electric compressor 2. Pressure relief valve 3. Liquid tank

4. Refrigerant pressure sensor 5. Condenser 6. Expansion valve

7. Evaporator 8. Blower motor A. High-pressure gas

B. High-pressure liquid C. Low-pressure liquid D. Low-pressure gas

E. Suction port F. Discharge port G Outside air

AWIIA0054ZZ

Revision: November 20132014 Altima NAM

Page 2620 of 4801

HA-14

< SYSTEM DESCRIPTION >

REFRIGERATION SYSTEM

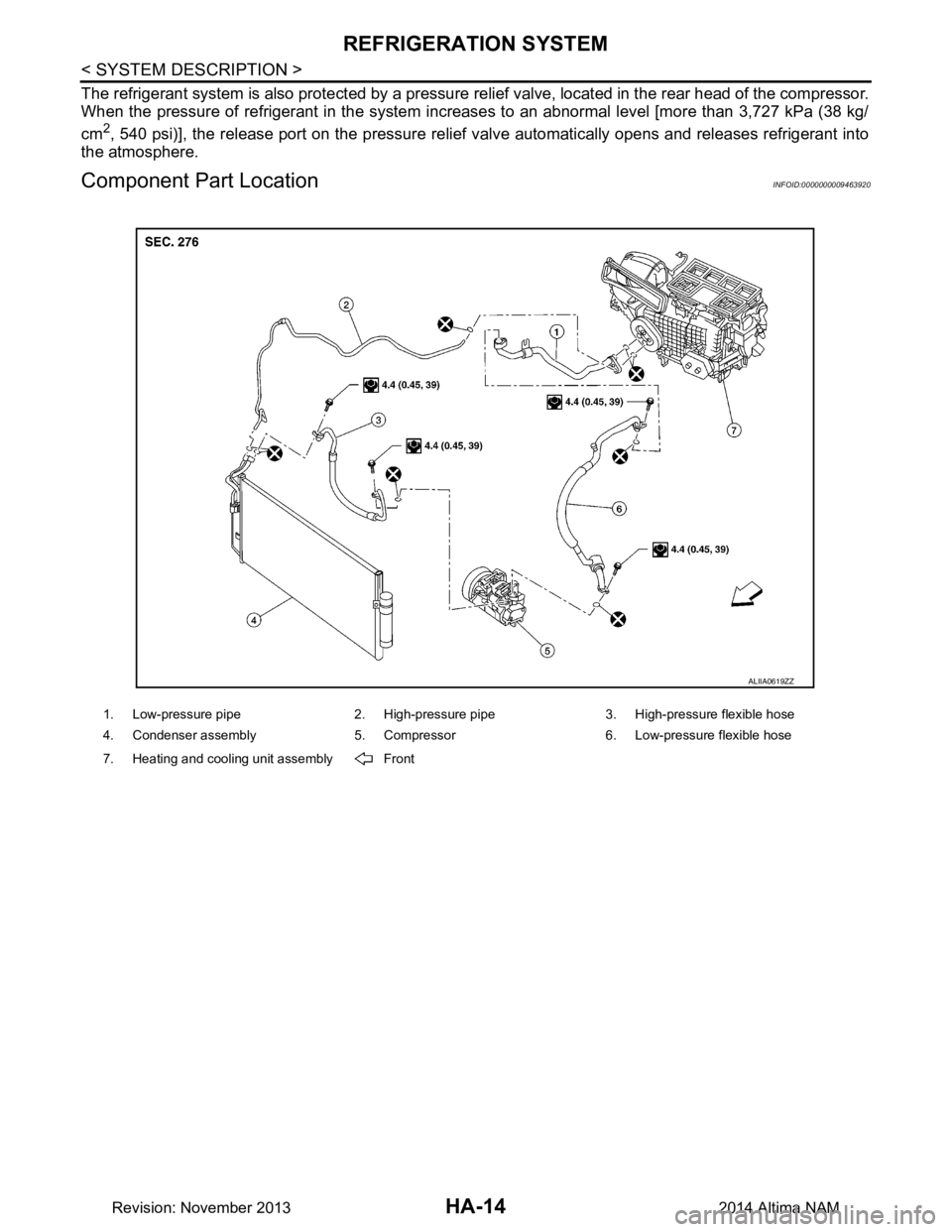

The refrigerant system is also protected by a pressure relief valve, located in the rear head of the compressor.

When the pressure of refrigerant in the system increases to an abnormal level [more than 3,727 kPa (38 kg/

cm

2, 540 psi)], the release port on the pressure relief valve automatically opens and releases refrigerant into

the atmosphere.

Component Part LocationINFOID:0000000009463920

1. Low-pressure pipe 2. High-pressure pipe 3. High-pressure flexible hose

4. Condenser assembly 5. Compressor 6. Low-pressure flexible hose

7. Heating and cooling unit assembly Front

ALIIA0619ZZ

Revision: November 20132014 Altima NAM