NISSAN TEANA 2014 Service Manual

Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 2621 of 4801

DIAGNOSIS AND REPAIR WORKFLOWHA-15

< BASIC INSPECTION >

C

D E

F

G H

J

K L

M A

B

HA

N

O P

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORKFLOW

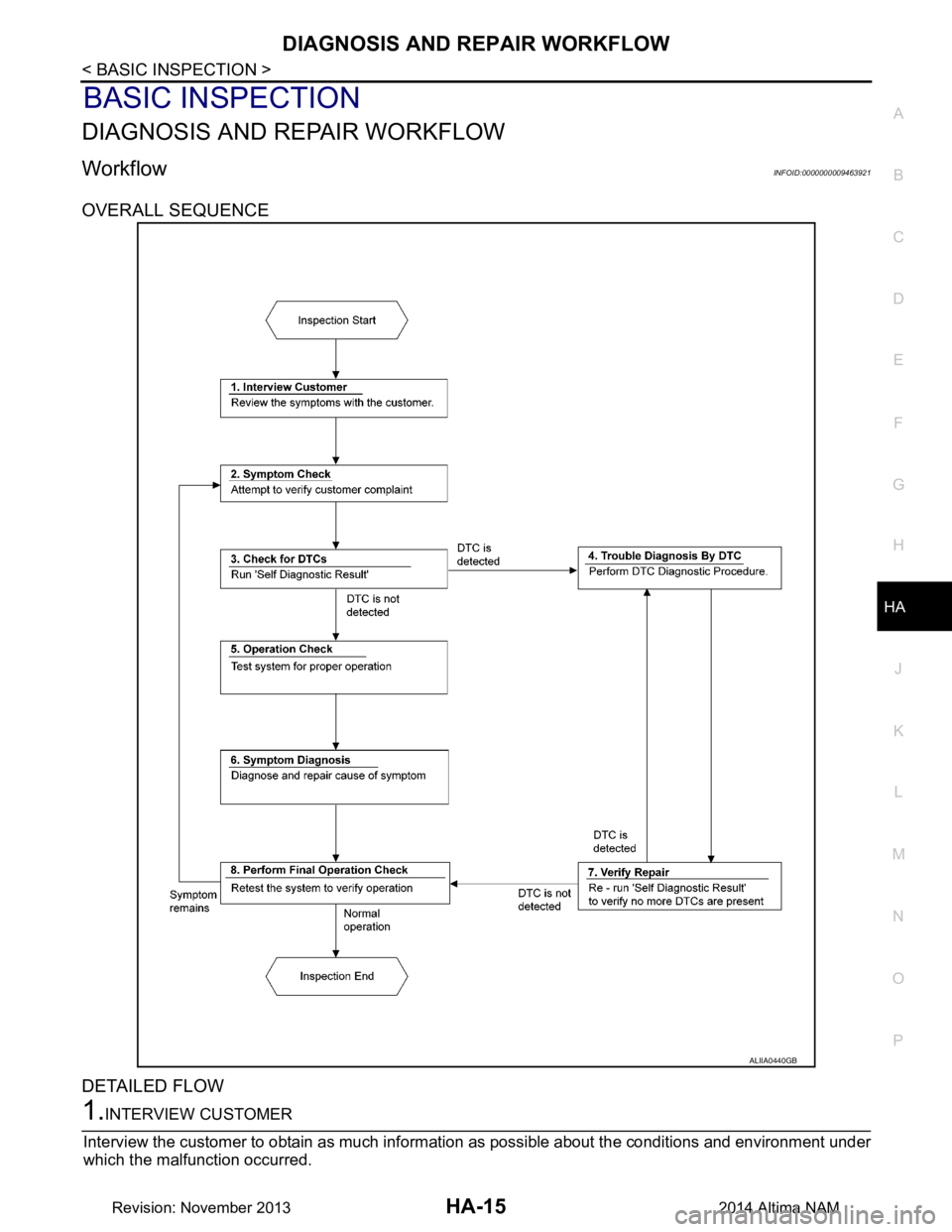

WorkflowINFOID:0000000009463921

OVERALL SEQUENCE

DETAILED FLOW

1.INTERVIEW CUSTOMER

Interview the customer to obtain as much informa tion as possible about the conditions and environment under

which the malfunction occurred.

ALIIA0440GB

Revision: November 20132014 Altima NAM

Page 2622 of 4801

HA-16

< BASIC INSPECTION >

DIAGNOSIS AND REPAIR WORKFLOW

>> GO TO 2.

2.SYMPTOM CHECK

Verify symptoms.

>> GO TO 3.

3.CHECK FOR DTCS

With CONSULT

1. Turn ignition switch ON.

2. Select “Self Diagnostic Result” mode of “HVAC” using CONSULT.

3. Check DTC.

Is any DTC detected?

YES >> GO TO 4.

NO >> GO TO 5.

4.PERFORM DTC DIAGNOSTIC PROCEDURE

Perform the diagnostic procedure for the detected DTC. Refer to HAC-30, "DTC Inspection Priority Chart"

.

>> GO TO 7.

5.OPERATION CHECK

Perform the operation check. Refer to HAC-48, "Work Procedure"

(automatic A/C) or HAC-140, "Work Proce-

dure" (manual A/C).

>> GO TO 6.

6.SYMPTOM DIAGNOSIS

Check the symptom diagnosis table. Refer to HA-17, "Symptom Table"

.

>> GO TO 8.

7.VERIFY REPAIR.

With CONSULT

1. Turn ignition switch ON.

2. Select “Self Diagnostic Result” mode of “HVAC” using CONSULT.

3. Check DTC.

Is any DTC detected?

YES >> GO TO 4.

NO >> GO TO 8.

8.PERFORM FINAL OPERATION CHECK

Perform the operation check. Refer to HAC-48, "Work Procedure"

(automatic A/C) or HAC-140, "Work Proce-

dure" (manual A/C).

Does it operate normally?

YES >> Inspection End.

NO >> GO TO 2.

Revision: November 20132014 Altima NAM

Page 2623 of 4801

HEATER AND AIR CONDITIONING SYSTEM SYMPTOMS

HA-17

< SYMPTOM DIAGNOSIS >

C

D E

F

G H

J

K L

M A

B

HA

N

O P

SYMPTOM DIAGNOSIS

HEATER AND AIR CONDITIONING SYSTEM SYMPTOMS

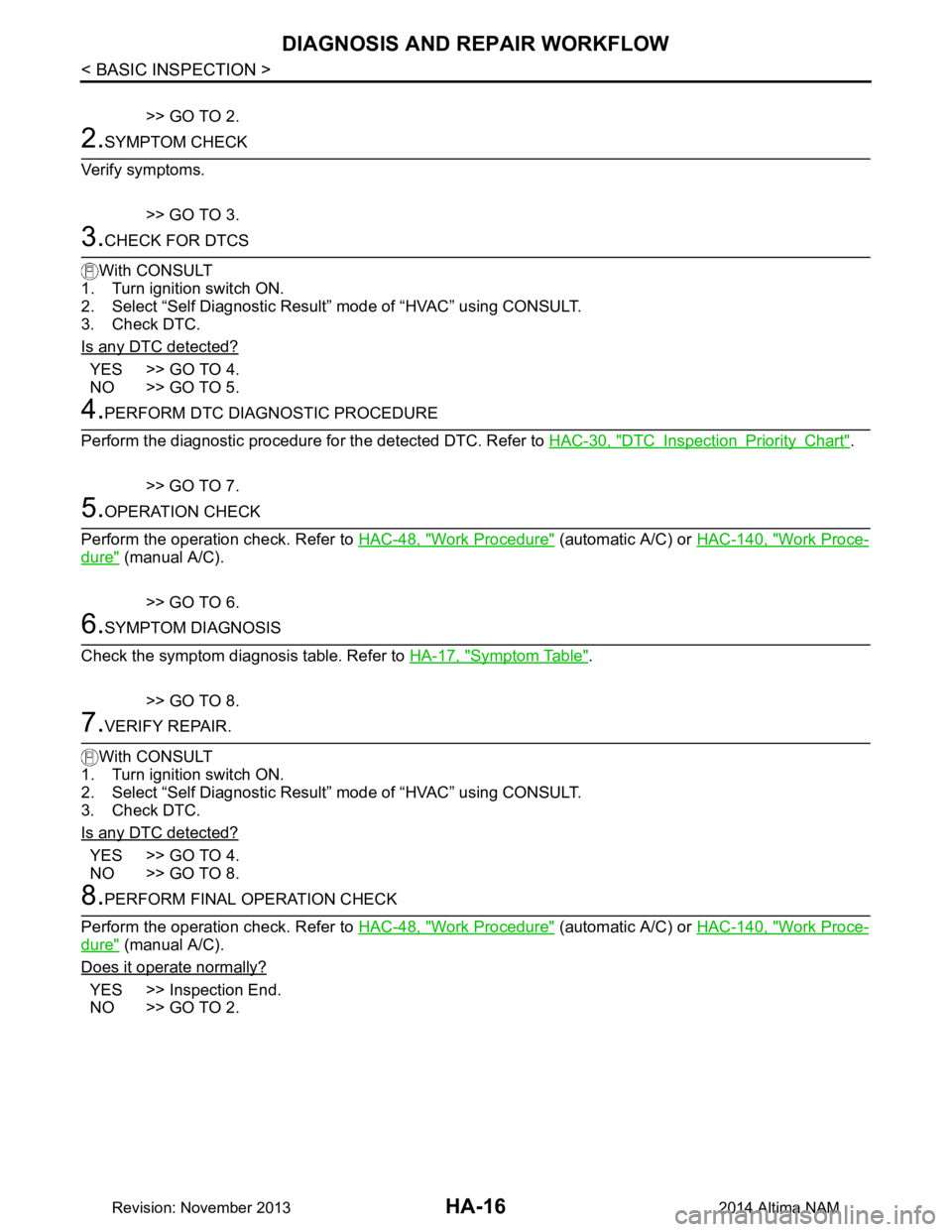

Symptom TableINFOID:0000000009463922

SYMPTOM TABLE

Symptom Reference Page

A/C system does not come on. Go to Trouble Diagnosis Procedure for A/C System. HAC-159

(manual A/C)

HAC-99

(automatic A/C)

A/C system cannot be controlled. Go to Self-diagnosis Function. HAC-139

(manual A/C)

HAC-46

(automatic A/C)

Air outlet does not change. Go to Trouble Diagnosis Procedure for Mode Door

Motor. HAC-142

(manual A/C)

HAC-73

(automatic A/C)

Mode door motor is malfunctioning.

Discharge air temperature does not change.

Go to Trouble Diagnosis Procedure for Air Mix Door

Motor. HAC-144

(manual A/C)

HAC-69

(automatic A/C driver side)

HAC-71

(automatic A/C passen-

ger side)

Air mix door motor is malfunctioning.

Intake door does not change.

Go to Trouble Diagnosis Procedure for Intake Door

Motor. HAC-146

(manual A/C)

HAC-75

(automatic A/C)

Intake door motor is malfunctioning.

Blower motor operation is malfunctioning. Go to Trouble Diagnosis Procedure for Blower Mo-

tor. HAC-148

(manual A/C)

HAC-84

(automatic A/C)

Magnet clutch does not engage. Go to Trouble Diagnosis Procedure for Magnet

Clutch. HAC-151

(manual A/C)

HAC-87

(automatic A/C)

Insufficient cooling. Go to Trouble Diagnosis Procedure for Insufficient

Cooling. HAC-155

(manual A/C)

HAC-96

(automatic A/C)

Insufficient heating. Go to Trouble Diagnosis Procedure for Insufficient

Heating. HAC-157

(manual A/C)

HAC-98

(automatic A/C)

Noise. Go to Trouble Diagnosis Procedure for Noise. HA-20

A/C switch LED does not illuminate. Go to Trouble Diagnosis Procedure for A/C System.HAC-152 (manual A/C)

HAC-83

(automatic A/C)

Mode button LED(s) does not illuminate. Go to Trouble Diagnosis Procedure for A/C System. HAC-152

(manual A/C)

HAC-83

(automatic A/C)

Both high- and low-pressure sides are too

high. Go to Trouble Diagnosis Procedure for Abnormal

Pressure. HA-18

High-pressure side is too high and low-pres-

sure side is too low. Go to Trouble Diagnosis Procedure for Abnormal

Pressure. HA-18

High-pressure side is too low and low-pres-

sure side is too high. Go to Trouble Diagnosis Procedure for Abnormal

Pressure. HA-18

Both high- and low-pressure side some-

times becomes negative. Go to Trouble Diagnosis Procedure for Abnormal

Pressure. HA-18

Low-pressure side sometimes becomes

negative. Go to Trouble Diagnosis Procedure for Abnormal

Pressure. HA-18

Low-pressure side becomes negative.

Go to Trouble Diagnosis Procedure for Abnormal

Pressure. HA-18

Revision: November 20132014 Altima NAM

Page 2624 of 4801

HA-18

< SYMPTOM DIAGNOSIS >

REFRIGERATION SYSTEM SYMPTOMS

REFRIGERATION SYSTEM SYMPTOMS

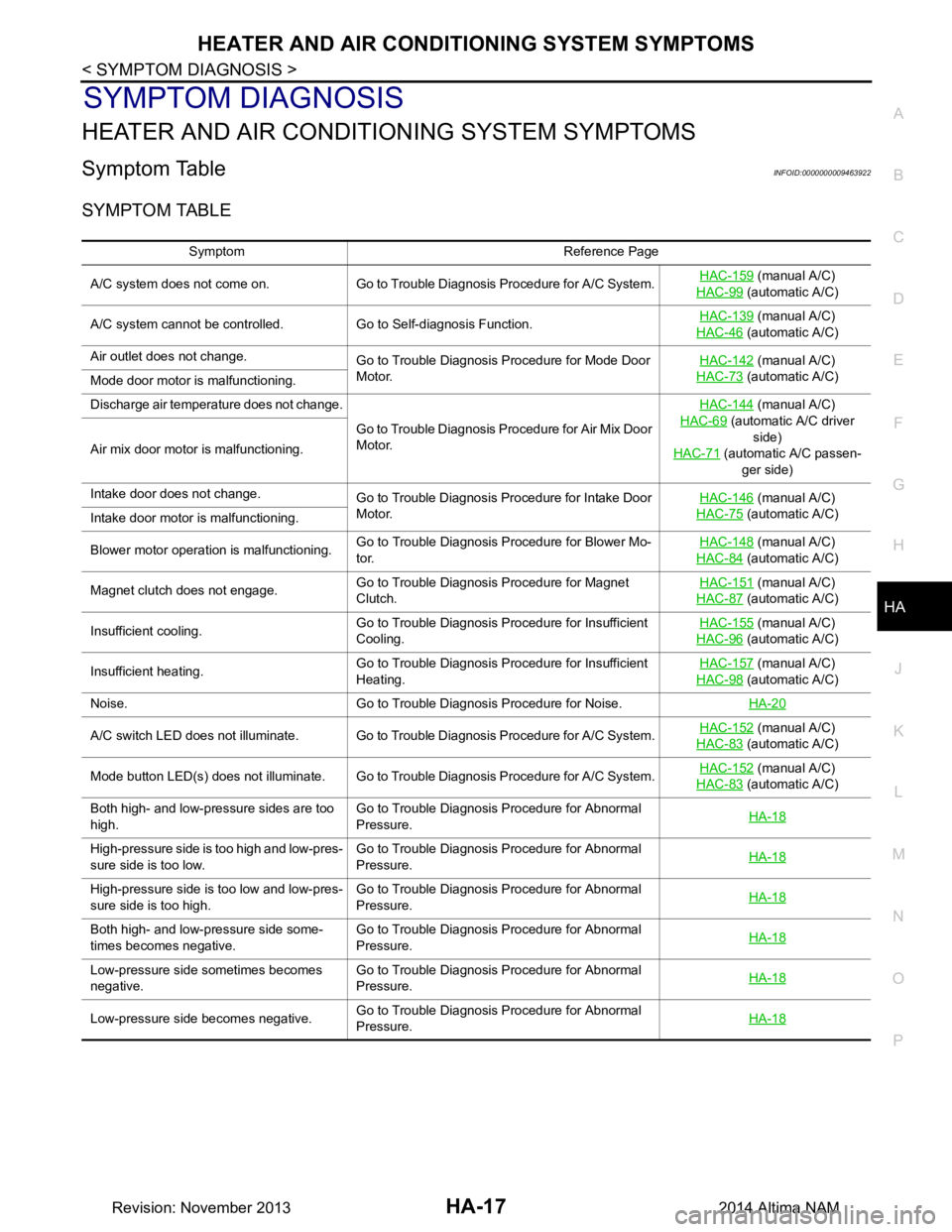

Trouble Diagnosis For Unusual PressureINFOID:0000000009463923

Diagnose using a manifold gauge whenever system’s high and/or low side pressure(s) is/are unusual. The

marker above the gauge scale in the following tables indicates the standard (usual) pressure range. Refer to

above table (Ambient air temperature-to-operating pres sure table) since the standard (usual) pressure, how-

ever, differs from vehicle to vehicle.

Symptom TableINFOID:0000000009463924

Gauge indication Refrigerant cycle Probable cause Corrective action

Both high and low pressure sides

are too high. The pressure returns to nor-

mal soon after sprinkling wa-

ter on condenser. Overfilled refrigerant. Collect all refrigerant, evacuate

refrigerant cycle again, and

then refill it with the specified

amount of refrigerant.

Air flow to condenser is insuf-

ficient. Insufficient condenser cooling

performance.

• Poor fan rotation of radiator and condenser.

• Improper installation of air

guide.

• Clogged or dirty condenser fins. • Repair or replace malfunc-

tioning parts.

• Clean and repair condenser

fins.

When compressor is stopped,

a high-pressure reading

quickly drops by approximate-

ly 196 kPa (2 kg/cm

2, 28 psi).

It then gradually decreases. Air mixed in refrigerant cycle.

Collect all refrigerant, evacuate

refrigerant cycle again, and

then refill it with the specified

amount of refrigerant.

• Low-pressure pipe is cooler than the outlet of evapora-

tor.

• Low-pressure pipe is frost- ed. Expansion valve opened too

much (excessive flow of refrig-

erant). Replace expansion valve.

High-pressure side is excessively

high and low-pressure side is too

low.

High-pressure pipe and upper

side of condenser become

hot, however, liquid tank does

not become so hot. Clogged or crushed high-pres-

sure pipe located between

compressor and condenser. Repair or replace the malfunc-

tioning parts.

High-pressure side is too low and

low-pressure side is too high. • The readings of both sides

become equal soon after

compressor operation

stops.

• There is no temperature dif- ference between high- and

low-pressure sides. Malfunction in compressor sys-

tem (insufficient compressor

pressure operation).

• Damage or breakage of

valve.

• Malfunctioning gaskets. Replace compressor.

AC359A

AC360A

AC356A

Revision: November 20132014 Altima NAM

Page 2625 of 4801

REFRIGERATION SYSTEM SYMPTOMSHA-19

< SYMPTOM DIAGNOSIS >

C

D E

F

G H

J

K L

M A

B

HA

N

O P

Both high and low pressure sides

are too low. • The area around evapora-

tor outlet does not become

cold.

• The area around evapora- tor inlet becomes frosted. Clogged expansion valve.

• Breakage of temperature sensor.

• Clogging by foreign material. Eliminate foreign material from

expansion valve or replace it.

• There is a temperature dif- ference between the areas

around outlet and inlet

pipes of liquid tank.

• Liquid tank becomes frost- ed. Malfunction in inner liquid tank

(clogged strainer). Replace liquid tank.

Evaporator becomes frosted. Clogged or crushed low-pres-

sure pipe. Repair or replace malfunction-

ing parts.

Malfunction in intake air tem-

perature sensor. Check intake sensor system.

Refer to HAC-64, "Component

Inspection".

There is a small temperature

difference between the high

and low pressure pipes for re-

frigerant cycle. • Shortage of refrigerant.

• Leakage of refrigerant. • Check for leakage.

• Collect all refrigerant, evacu-

ate refrigerant cycle again,

and then refill it with the spec-

ified amount of refrigerant.

Low-pressure side sometimes be-

comes negative. • Sometimes the area

around evaporator outlet

does not become cold.

• Sometimes the area

around evaporator inlet is

frosted. • Icing caused by the mixing of

water in cooler cycle.

• Deteriorated dryer in liquid

tank. • Collect all refrigerant.

• Evacuate refrigerant cycle completely, and then refill it

with the specified amount of

refrigerant. At this time, al-

ways replace liquid tank.

Hunting in high-pressure side. There is no temperature dif-

ference between high- and

low-pressure sides. Malfunctioning variable valve

in compressor. • Replace compressor.

• Check ECV system.

Gauge indication Refrigerant cycle Probable cause Corrective action

AC353A

AC354A

Revision: November 20132014 Altima NAM

Page 2626 of 4801

HA-20

< SYMPTOM DIAGNOSIS >

NOISE

NOISE

Symptom TableINFOID:0000000009463925

Symptom Noise source Probable cause Corrective action

Unusual noise from compressor

when A/C is ON. Inside of compressor

Wear, breakage or clogging of foreign

material in inner parts. Check compressor oil. Re-

fer to HA-25, "Inspection"

.

Magnet clutch Contact of clutch disc with pulley. Check clearance between

clutch disc and pulley.

Compressor body Loosened compressor mounting bolts. Check bolts for tightness.

Refer to HA-30, "COM-

PRESSOR : Exploded

View".

Unusual noise from cooler piping. Cooler piping (pipe and

flexible hose) Improper installation of clip and brack-

et. Check the installation condi-

tion of the cooler piping. Re-

fer to HA-34, "Exploded

View".

Unusual noise from expansion

valve when A/C is ON. Expansion valveShortage of refrigerant. • Check for leakage.

• Collect all refrigerant,

evacuate refrigerant cycle

again, and then refill it

with the specified amount

of refrigerant.

Wear, breakage or clogging of foreign

material in inner parts. Eliminate foreign material

from expansion valve or re-

place it.

Unusual noise from belt. — Loosened beltCheck belt tension. Refer to

MA-13, "DRIVE BELTS :

Checking Drive Belts"

(QR25DE) or MA-22,

"DRIVE BELTS : Checking

Drive Belts" (VQ35DE).

Internal compressor parts get locked Replace compressor. Refer

to HA-30, "COMPRESSOR

: Removal and Installation".

Revision: November 20132014 Altima NAM

Page 2627 of 4801

REFRIGERANTHA-21

< PERIODIC MAINTENANCE >

C

D E

F

G H

J

K L

M A

B

HA

N

O P

PERIODIC MAINTENANCE

REFRIGERANT

DescriptionINFOID:0000000009463926

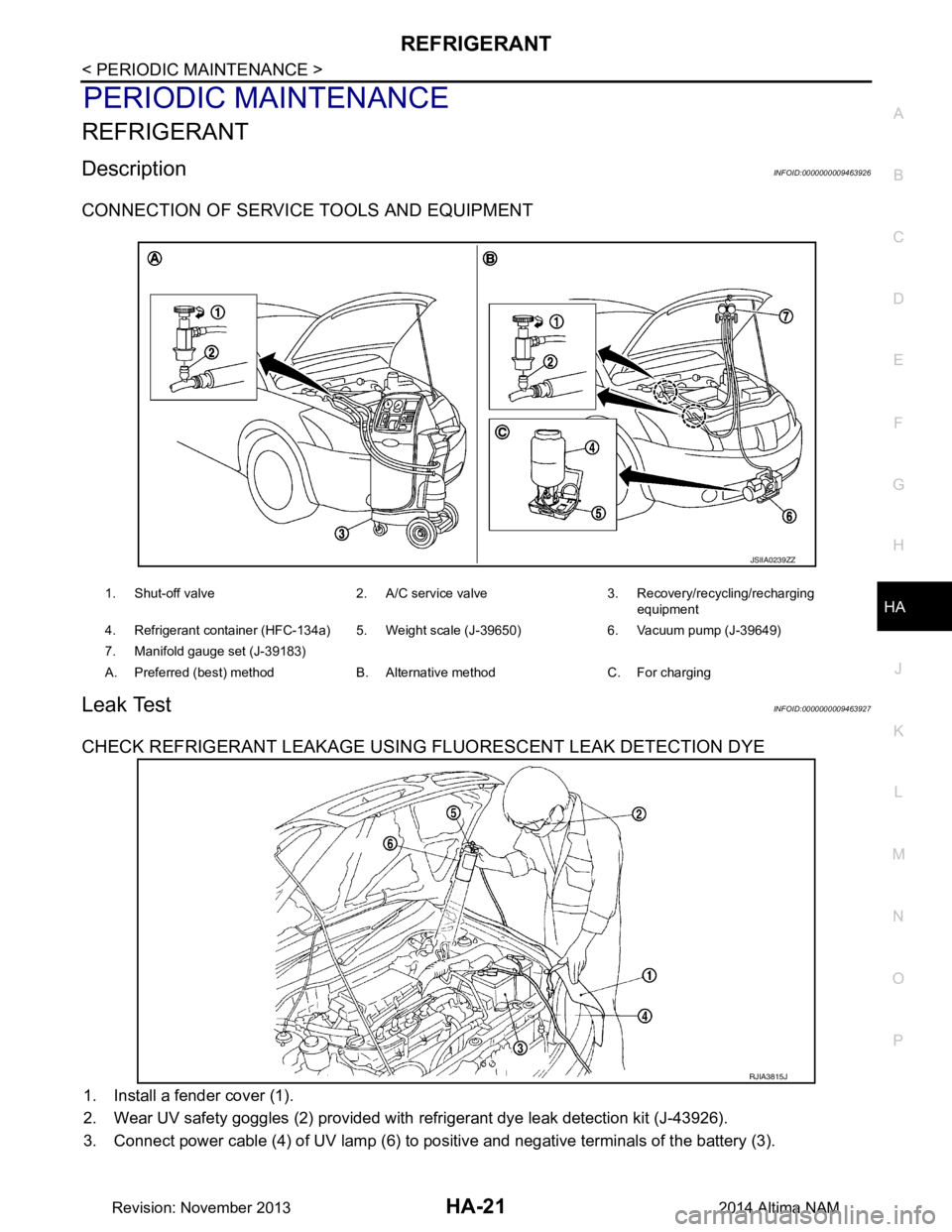

CONNECTION OF SERVICE TOOLS AND EQUIPMENT

Leak TestINFOID:0000000009463927

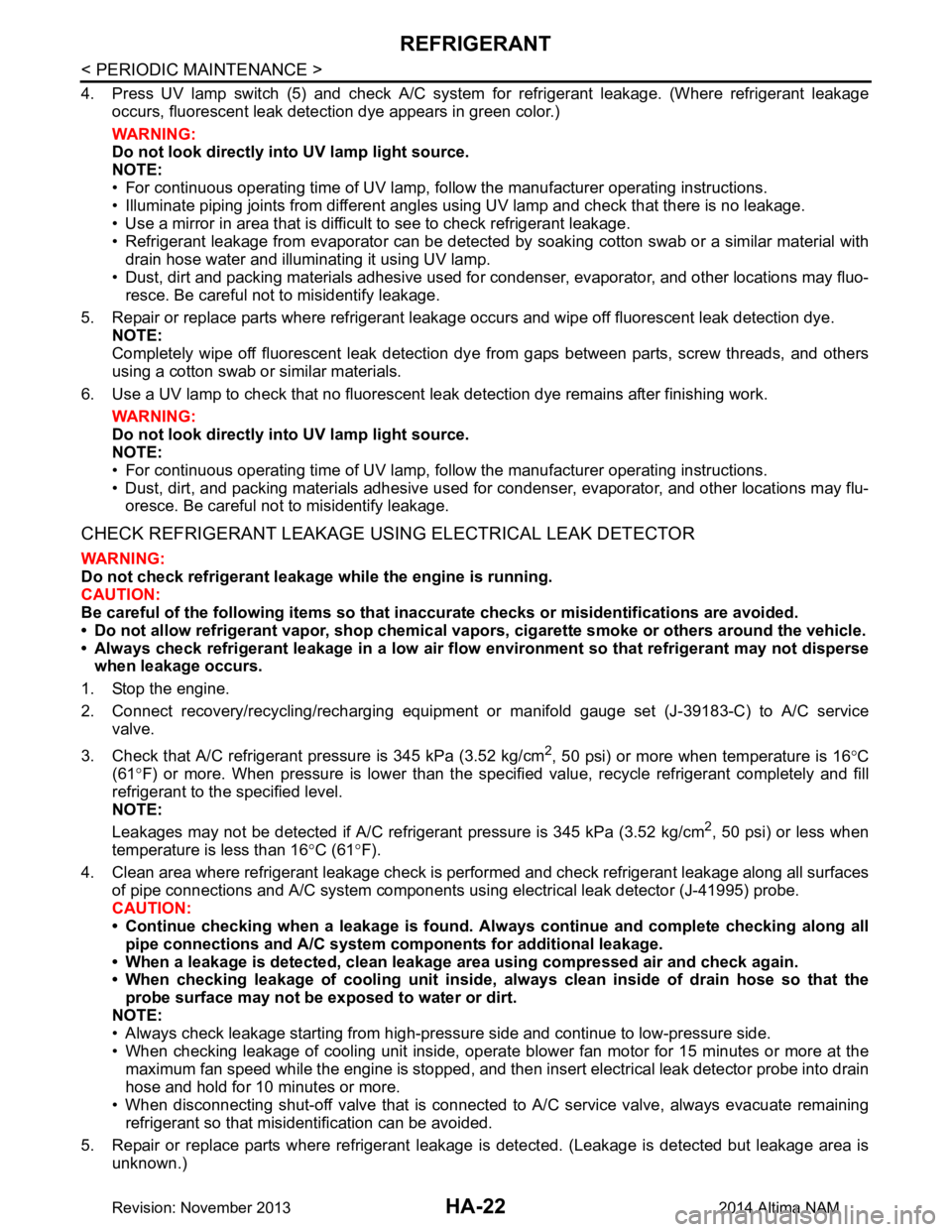

CHECK REFRIGERANT LEAKAGE USING FLUORESCENT LEAK DETECTION DYE

1. Install a fender cover (1).

2. Wear UV safety goggles (2) provided with refrigerant dye leak detection kit (J-43926).

3. Connect power cable (4) of UV lamp (6) to positive and negative terminals of the battery (3).

1. Shut-off valve 2. A/C service valve 3. Recovery/recycling/recharging

equipment

4. Refrigerant container (HFC-134a) 5. Weight scale (J-39650) 6. Vacuum pump (J-39649)

7. Manifold gauge set (J-39183)

A. Preferred (best) method B. Alternative method C. For charging

JSIIA0239ZZ

RJIA3815J

Revision: November 20132014 Altima NAM

Page 2628 of 4801

HA-22

< PERIODIC MAINTENANCE >

REFRIGERANT

4. Press UV lamp switch (5) and check A/C system for refrigerant leakage. (Where refrigerant leakage

occurs, fluorescent leak detec tion dye appears in green color.)

WARNING:

Do not look directly into UV lamp light source.

NOTE:

• For continuous operating time of UV lamp, follow the manufacturer operating instructions.

• Illuminate piping joints from different angles using UV lamp and check that there is no leakage.

• Use a mirror in area that is difficult to see to check refrigerant leakage.

• Refrigerant leakage from evaporator can be detected by soaking cotton swab or a similar material with

drain hose water and illuminating it using UV lamp.

• Dust, dirt and packing materials adhesive used for condenser, evaporator, and other locations may fluo- resce. Be careful not to misidentify leakage.

5. Repair or replace parts where refrigerant leakage occurs and wipe off fluorescent leak detection dye. NOTE:

Completely wipe off fluorescent leak detection dy e from gaps between parts, screw threads, and others

using a cotton swab or similar materials.

6. Use a UV lamp to check that no fluorescent leak detection dye remains after finishing work.

WARNING:

Do not look directly into UV lamp light source.

NOTE:

• For continuous operating time of UV lamp, follow the manufacturer operating instructions.

• Dust, dirt, and packing materials adhesive used for condenser, evaporator, and other locations may flu-

oresce. Be careful not to misidentify leakage.

CHECK REFRIGERANT LEAKAGE USING ELECTRICAL LEAK DETECTOR

WARNING:

Do not check refrigerant leakage while the engine is running.

CAUTION:

Be careful of the following it ems so that inaccurate checks or misidentifications are avoided.

• Do not allow refrigerant vapor, shop chemical vapor s, cigarette smoke or others around the vehicle.

• Always check refrigerant leakage in a low air flow en vironment so that refrigerant may not disperse

when leakage occurs.

1. Stop the engine.

2. Connect recovery/recycling/recharging equipment or manifold gauge set (J-39183-C) to A/C service

valve.

3. Check that A/C refrigerant pressure is 345 kPa (3.52 kg/cm

2, 50 psi) or more when temperature is 16 °C

(61 °F) or more. When pressure is lower than the specif ied value, recycle refrigerant completely and fill

refrigerant to the specified level.

NOTE:

Leakages may not be detected if A/C refrigerant pressure is 345 kPa (3.52 kg/cm

2, 50 psi) or less when

temperature is less than 16 °C (61 °F).

4. Clean area where refrigerant leakage check is performed and check refrigerant leakage along all surfaces of pipe connections and A/C system components us ing electrical leak detector (J-41995) probe.

CAUTION:

• Continue checking when a leakag e is found. Always continue and complete checking along all

pipe connections and A/C system components for additional leakage.

• When a leakage is detected, clean leakage area using compressed air and check again.

• When checking leakage of cooling unit inside, always clean inside of drain hose so that the

probe surface may not be exposed to water or dirt.

NOTE:

• Always check leakage starting from high-pressure side and continue to low-pressure side.

• When checking leakage of cooling unit inside, operate bl ower fan motor for 15 minutes or more at the

maximum fan speed while the engine is stopped, and then in sert electrical leak detector probe into drain

hose and hold for 10 minutes or more.

• When disconnecting shut-off valve that is connected to A/C service valve, always evacuate remaining

refrigerant so that misidentification can be avoided.

5. Repair or replace parts where refrigerant leak age is detected. (Leakage is detected but leakage area is

unknown.)

Revision: November 20132014 Altima NAM

Page 2629 of 4801

REFRIGERANTHA-23

< PERIODIC MAINTENANCE >

C

D E

F

G H

J

K L

M A

B

HA

N

O P

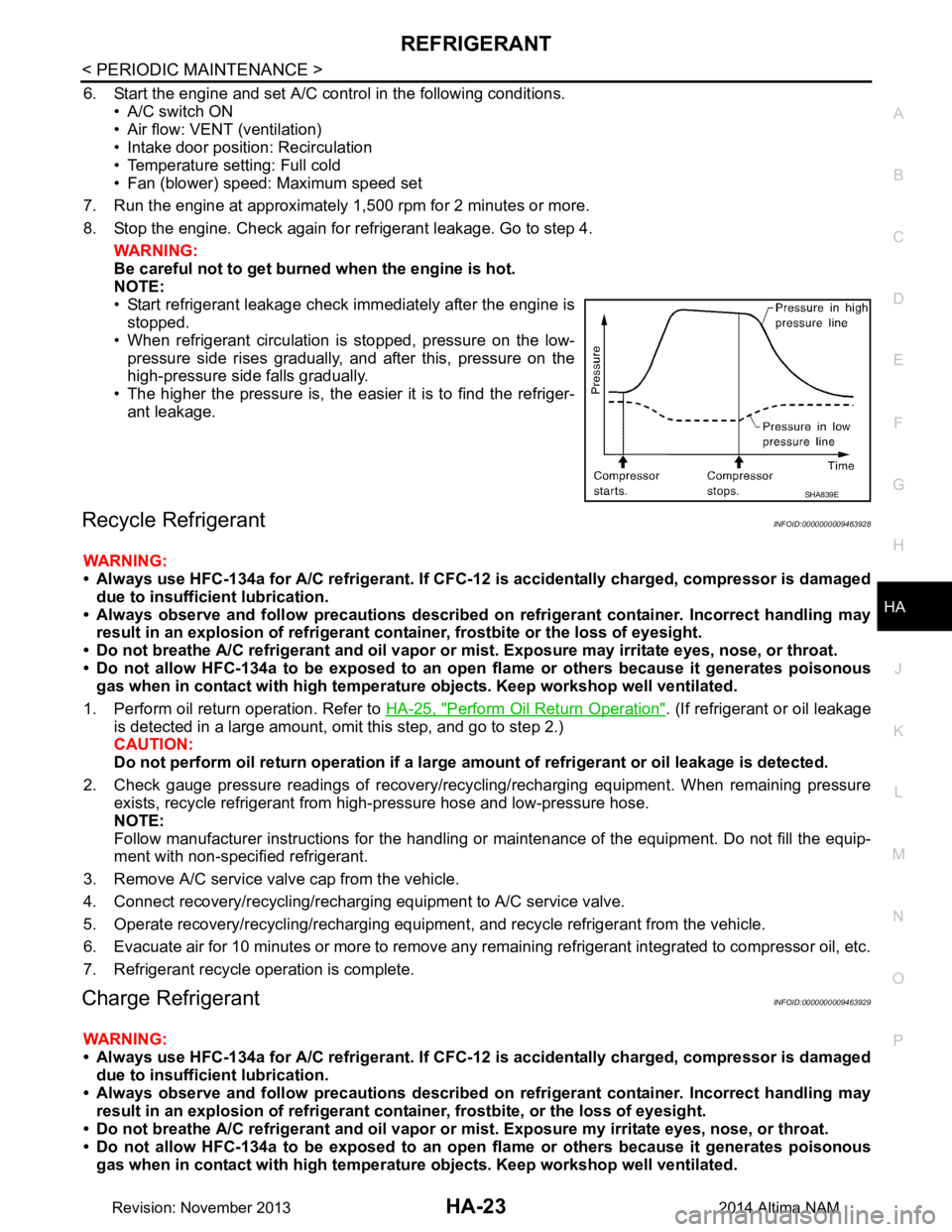

6. Start the engine and set A/C control in the following conditions. • A/C switch ON

• Air flow: VENT (ventilation)

• Intake door position: Recirculation

• Temperature setting: Full cold

• Fan (blower) speed: Maximum speed set

7. Run the engine at approximately 1,500 rpm for 2 minutes or more.

8. Stop the engine. Check again for refrigerant leakage. Go to step 4. WARNING:

Be careful not to get burned when the engine is hot.

NOTE:

• Start refrigerant leakage check immediately after the engine is stopped.

• When refrigerant circulation is stopped, pressure on the low- pressure side rises gradually, and after this, pressure on the

high-pressure side falls gradually.

• The higher the pressure is, the easier it is to find the refriger-

ant leakage.

Recycle RefrigerantINFOID:0000000009463928

WARNING:

• Always use HFC-134a for A/C refrigerant. If CFC-12 is accidentally charged, compressor is damaged

due to insufficient lubrication.

• Always observe and follow precaution s described on refrigerant container. Incorrect handling may

result in an explosion of refrigerant co ntainer, frostbite or the loss of eyesight.

• Do not breathe A/C refrigerant and oil vapor or mi st. Exposure may irritate eyes, nose, or throat.

• Do not allow HFC-134a to be exposed to an open flame or others because it generates poisonous

gas when in contact with high temperatur e objects. Keep workshop well ventilated.

1. Perform oil return operation. Refer to HA-25, "Perform Oil Return Operation"

. (If refrigerant or oil leakage

is detected in a large amount, omit this step, and go to step 2.)

CAUTION:

Do not perform oil return operation if a large am ount of refrigerant or oil leakage is detected.

2. Check gauge pressure readings of recovery/recyc ling/recharging equipment. When remaining pressure

exists, recycle refrigerant from high-pressure hose and low-pressure hose.

NOTE:

Follow manufacturer instructions for the handling or maintenance of the equipment. Do not fill the equip-

ment with non-specified refrigerant.

3. Remove A/C service valve cap from the vehicle.

4. Connect recovery/recycling/recharging equipment to A/C service valve.

5. Operate recovery/recycling/recharging equipment , and recycle refrigerant from the vehicle.

6. Evacuate air for 10 minutes or more to remove any remaining refrigerant integrated to compressor oil, etc.

7. Refrigerant recycle operation is complete.

Charge RefrigerantINFOID:0000000009463929

WARNING:

• Always use HFC-134a for A/C refrigerant. If CFC-12 is accidentally charged, compressor is damaged

due to insufficient lubrication.

• Always observe and follow precaution s described on refrigerant container. Incorrect handling may

result in an explosion of refrigerant co ntainer, frostbite, or the loss of eyesight.

• Do not breathe A/C refrigerant and oil vapor or mi st. Exposure my irritate eyes, nose, or throat.

• Do not allow HFC-134a to be exposed to an open flame or others because it generates poisonous

gas when in contact with high temperatur e objects. Keep workshop well ventilated.

SHA839E

Revision: November 20132014 Altima NAM

Page 2630 of 4801

HA-24

< PERIODIC MAINTENANCE >

REFRIGERANT

1. Connect recovery/recycling/recharging equipment to the A/C service valve.

2. Operate recovery/recycling/recharging equipment, and evacuate air from A/C system for 25 minutes or

more.

CAUTION:

Evacuate air for 15 minutes or more if the parts are replaced.

3. Check the airtightness of A/C system for 25 minutes or more. If pressure raises more than the specified

level, charge A/C system with approximately 200g refriger ant and check that there is no refrigerant leak-

age. Refer to HA-21, "Leak Test"

.

CAUTION:

Check the airtightness for 15 minutes or more if the parts are replaced.

4. If parts other than compressor are replaced, fill co mpressor oil according to parts that are replaced.

5. Charge the specified amount of refrigerant to A/C system.

6. Check that A/C system operates normally.

7. Disconnect recovery/recycling/recharging equipment. (Col lect the refrigerant from the high-pressure hose

and low-pressure hose of recovery/recycling/recharging equipment.)

8. Install A/C service valve cap.

9. Refrigerant charge is complete.

Revision: November 20132014 Altima NAM