NISSAN TEANA 2014 Service Manual

TEANA 2014

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57390/w960_57390-0.png

NISSAN TEANA 2014 Service Manual

Trending: oil dipstick, wiper blades, oil, fuse, fuel pump, headrest, coolant

Page 291 of 4801

BODY COMPONENT PARTSBRM-13

< PREPARATION >

C

D E

F

G H

I

J

L

M A

B

BRM

N

O P

BODY COMPONENT PARTS

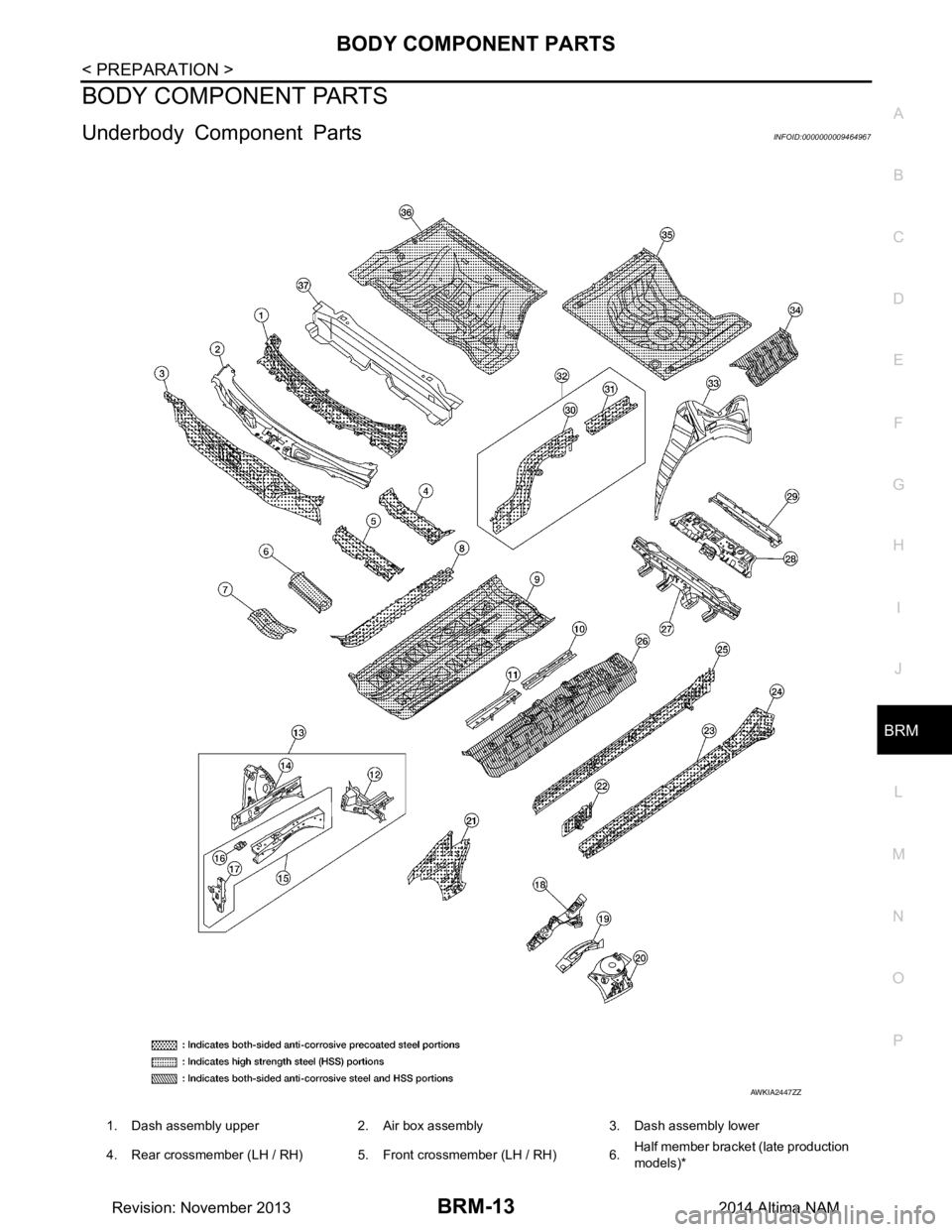

Underbody Component PartsINFOID:0000000009464967

1. Dash assembly upper 2. Air box assembly 3. Dash assembly lower

4. Rear crossmember (LH / RH) 5 . Front crossmember (LH / RH) 6. Half member bracket (late production

models)*

AWKIA2447ZZ

Revision: November 20132014 Altima NAM

Page 292 of 4801

BRM-14

< PREPARATION >

BODY COMPONENT PARTS

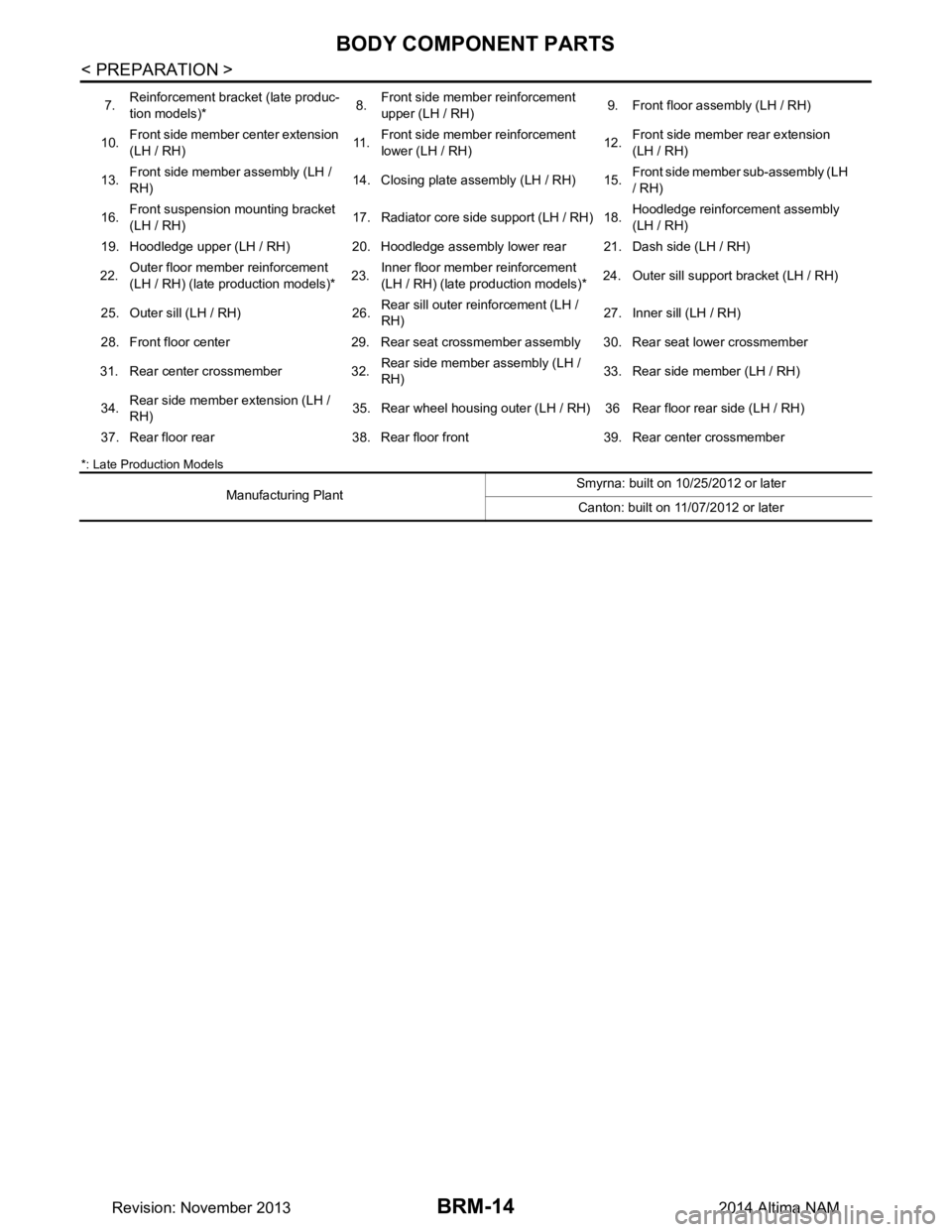

*: Late Production Models

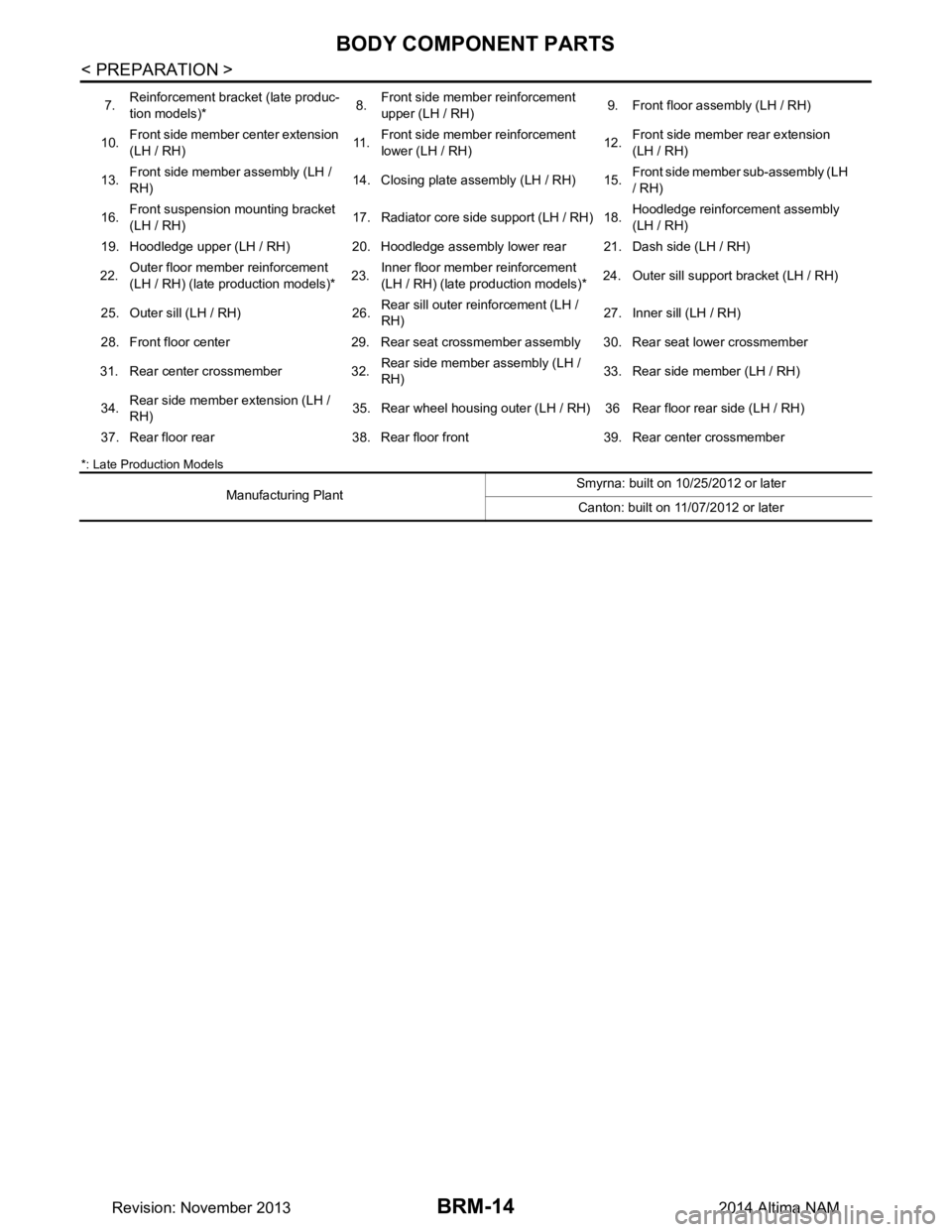

7.Reinforcement bracket (late produc-

tion models)* 8.

Front side member reinforcement

upper (LH / RH) 9. Front floor assembly (LH / RH)

10. Front side member center extension

(LH / RH) 11 .Front side member reinforcement

lower (LH / RH) 12.Front side member rear extension

(LH / RH)

13. Front side member assembly (LH /

RH) 14. Closing plate assembly (LH / RH) 15. Front side member sub-assembly (LH

/ RH)

16. Front suspension mounting bracket

(LH / RH) 17. Radiator core side support (LH / RH) 18.

Hoodledge reinforcement assembly

(LH / RH)

19. Hoodledge upper (LH / RH) 20. Hoodledge assembly lower rear 21. Dash side (LH / RH)

22. Outer floor member

reinforcement

(LH / RH) (late production models)* 23.

Inner floor member reinforcement

(LH / RH) (late production models)* 24. Outer sill support bracket (LH / RH)

25. Outer sill (LH / RH) 26. Rear sill outer reinforcement (LH /

RH) 27. Inner sill (LH / RH)

28. Front floor center 29. Rear seat crossmember assembly 30. Rear seat lower crossmember

31. Rear center crossmember 32. Rear side member assembly (LH /

RH) 33. Rear side member (LH / RH)

34. Rear side member extension (LH /

RH) 35. Rear wheel housing outer (LH / RH) 36 Rear floor rear side (LH / RH)

37. Rear floor rear 38. Rear floor front 39. Rear center crossmember

Manufacturing Plant Smyrna: built on 10/25/2012 or later

Canton: built on 11/07/2012 or later

Revision: November 20132014 Altima NAM

Page 293 of 4801

BODY COMPONENT PARTSBRM-15

< PREPARATION >

C

D E

F

G H

I

J

L

M A

B

BRM

N

O P

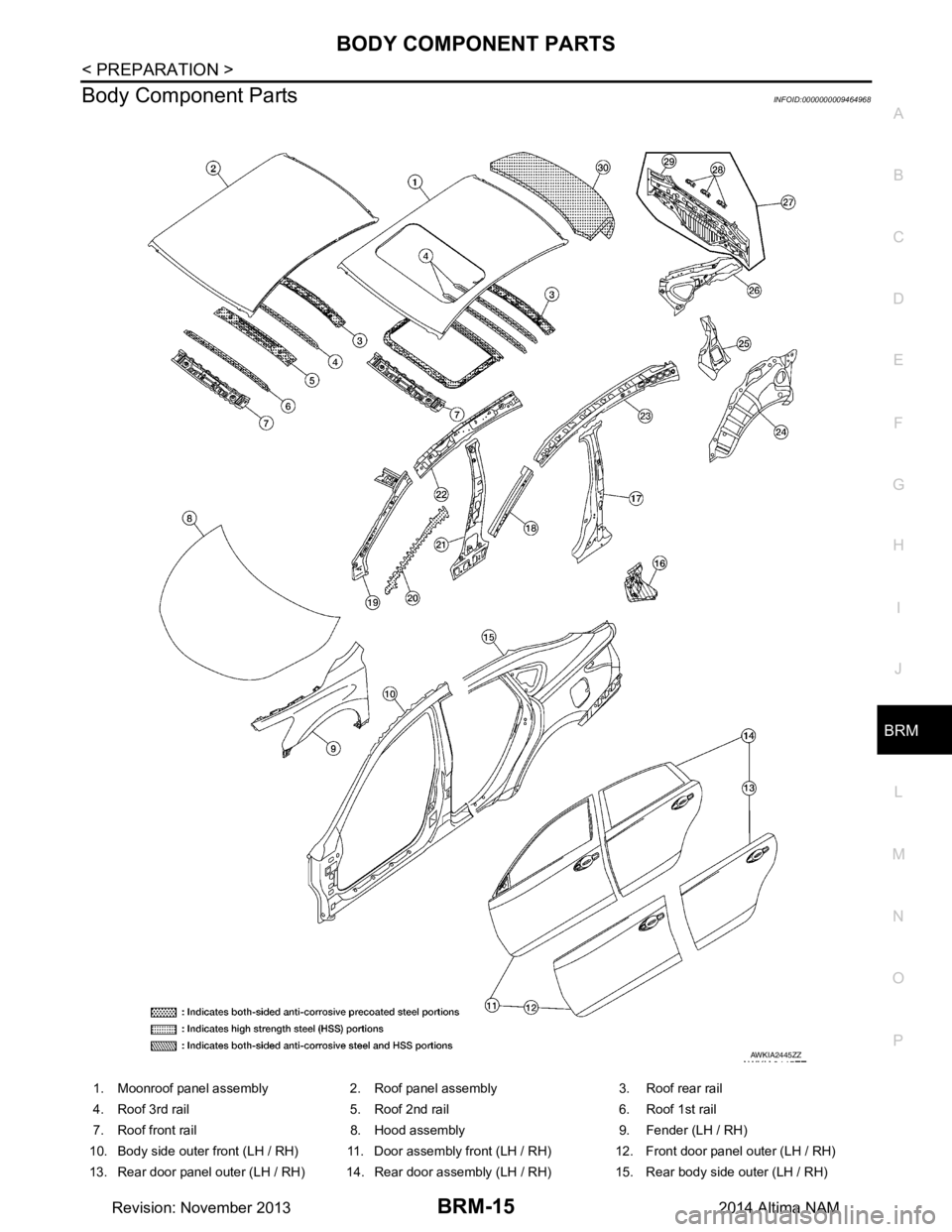

Body Component PartsINFOID:0000000009464968

1. Moonroof panel assembly 2. Roof panel assembly 3. Roof rear rail

4. Roof 3rd rail 5. Roof 2nd rail 6. Roof 1st rail

7. Roof front rail 8. Hood assembly 9. Fender (LH / RH)

10. Body side outer front (LH / RH) 11. Door assembly front (LH / RH) 12. Front door panel outer (LH / RH)

13. Rear door panel outer (LH / RH) 14. Rear door assembly (LH / RH) 15. Rear body side outer (LH / RH)

AWKIA2445ZZ

Revision: November 20132014 Altima NAM

Page 294 of 4801

BRM-16

< PREPARATION >

BODY COMPONENT PARTS

*: Late Production Models

16.Rear fender corner (LH / RH)

17.Center pillar reinforcement (LH / RH)

18.Front pillar outer

reinforcement (LH /

RH)

19. Front pillar inner (LH / RH) 20. Front pillar inner reinforcement (LH /

RH) (late production models)* 21. Center pillar inner (LH / RH)

22. Roof side rail inner (LH / RH) 23. Roof side rail reinforcement (LH / RH) 24. Rear wheel well housing outer (LH /

RH)

25. Rear pillar reinforcement (LH / RH) 26. Rear pillar inner reinforcement (LH /

RH) 27. Rear panel assembly

28. Rear bumper fascia bracket (LH, cen-

ter, RH) 29. Rear panel 30. Trunk lid assembly

Manufacturing Plant Smyrna: built on 10/25/2012 or later

Canton: built on 11/07/2012 or later

Revision: November 20132014 Altima NAM

Page 295 of 4801

CORROSION PROTECTIONBRM-17

< REMOVAL AND INSTALLATION >

C

D E

F

G H

I

J

L

M A

B

BRM

N

O P

REMOVAL AND INSTALLATION

CORROSION PROTECTION

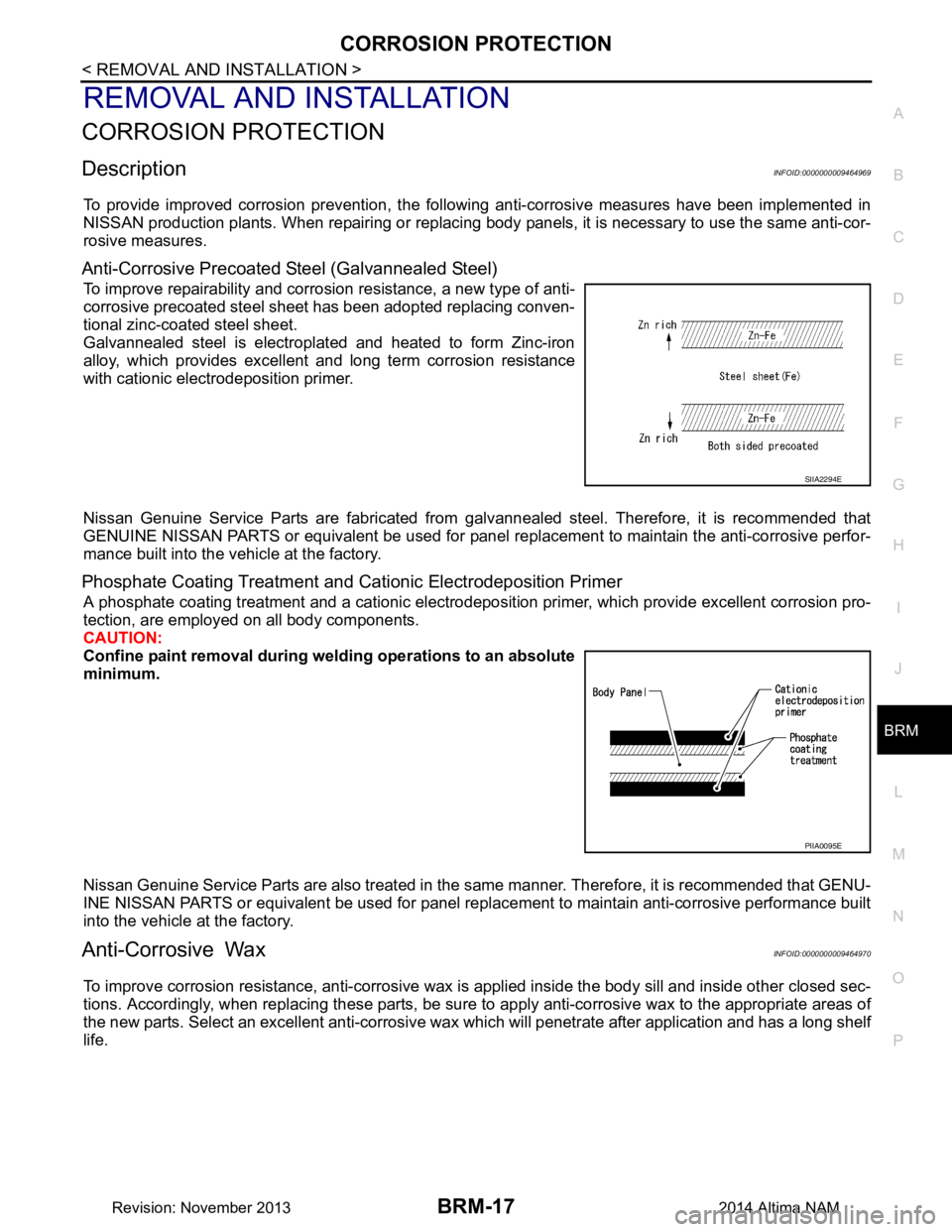

DescriptionINFOID:0000000009464969

To provide improved corrosion prevention, the follo wing anti-corrosive measures have been implemented in

NISSAN production plants. When repairi ng or replacing body panels, it is necessary to use the same anti-cor-

rosive measures.

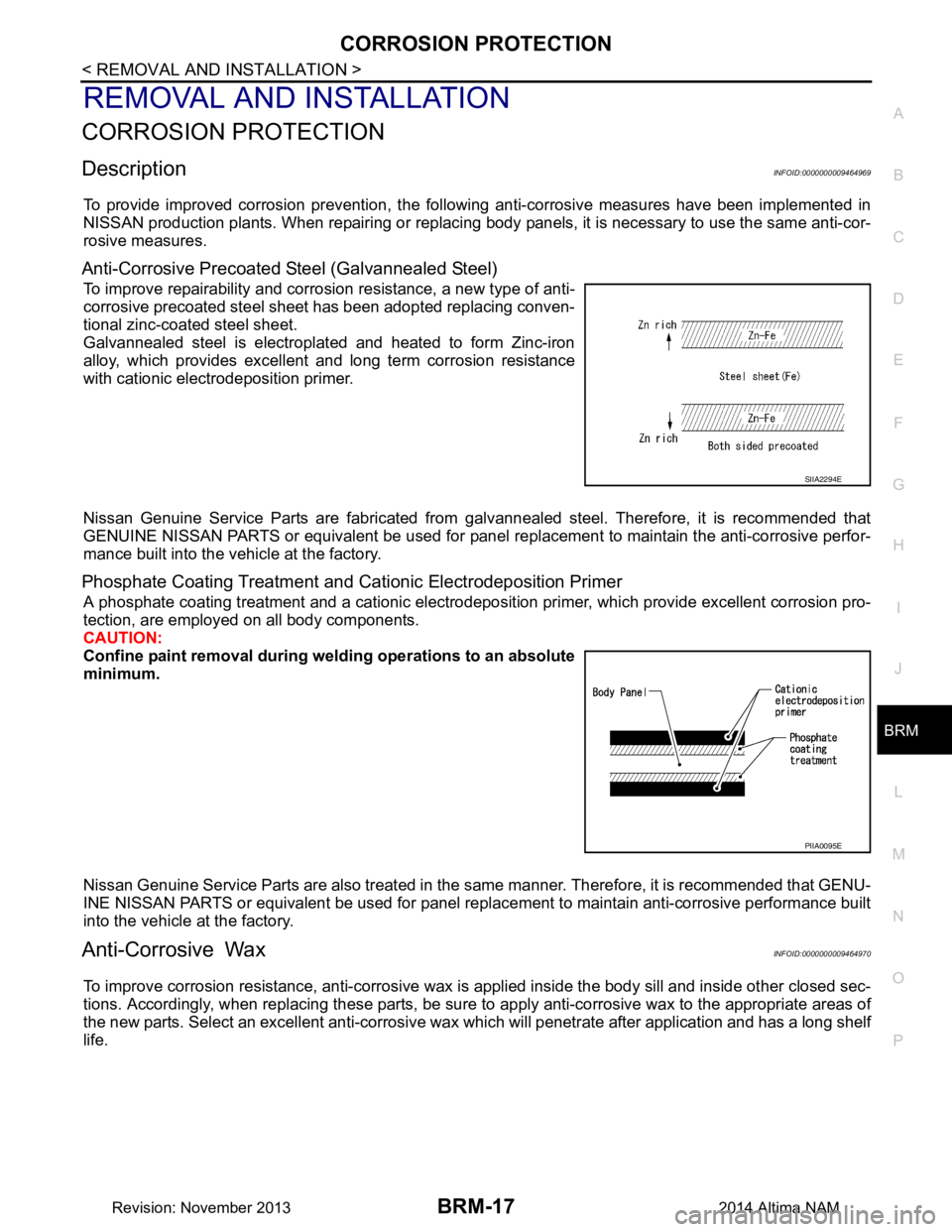

Anti-Corrosive Precoated Steel (Galvannealed Steel)

To improve repairability and corrosion resistance, a new type of anti-

corrosive precoated steel sheet has been adopted replacing conven-

tional zinc-coated steel sheet.

Galvannealed steel is electroplated and heated to form Zinc-iron

alloy, which provides excellent and long term corrosion resistance

with cationic electrodeposition primer.

Nissan Genuine Service Parts are fabricated from galvannealed steel. Therefore, it is recommended that

GENUINE NISSAN PARTS or equivalent be used for panel replacement to maintain the anti-corrosive perfor-

mance built into the vehicle at the factory.

Phosphate Coating Treatment and Cationic Electrodeposition Primer

A phosphate coating treatment and a cationic electrodeposit ion primer, which provide excellent corrosion pro-

tection, are employed on all body components.

CAUTION:

Confine paint removal during weld ing operations to an absolute

minimum.

Nissan Genuine Service Parts are also treated in the same manner. Therefore, it is recommended that GENU-

INE NISSAN PARTS or equivalent be used for panel repl acement to maintain anti-corrosive performance built

into the vehicle at the factory.

Anti-Corrosive WaxINFOID:0000000009464970

To improve corrosion resistance, anti-corrosive wax is applied inside the body sill and inside other closed sec-

tions. Accordingly, when replacing these parts, be sure to apply anti-corrosive wax to the appropriate areas of

the new parts. Select an excellent anti-corrosive wax which will penetrate after application and has a long shelf

life.

SIIA2294E

PIIA0095E

Revision: November 20132014 Altima NAM

Page 296 of 4801

BRM-18

< REMOVAL AND INSTALLATION >

CORROSION PROTECTION

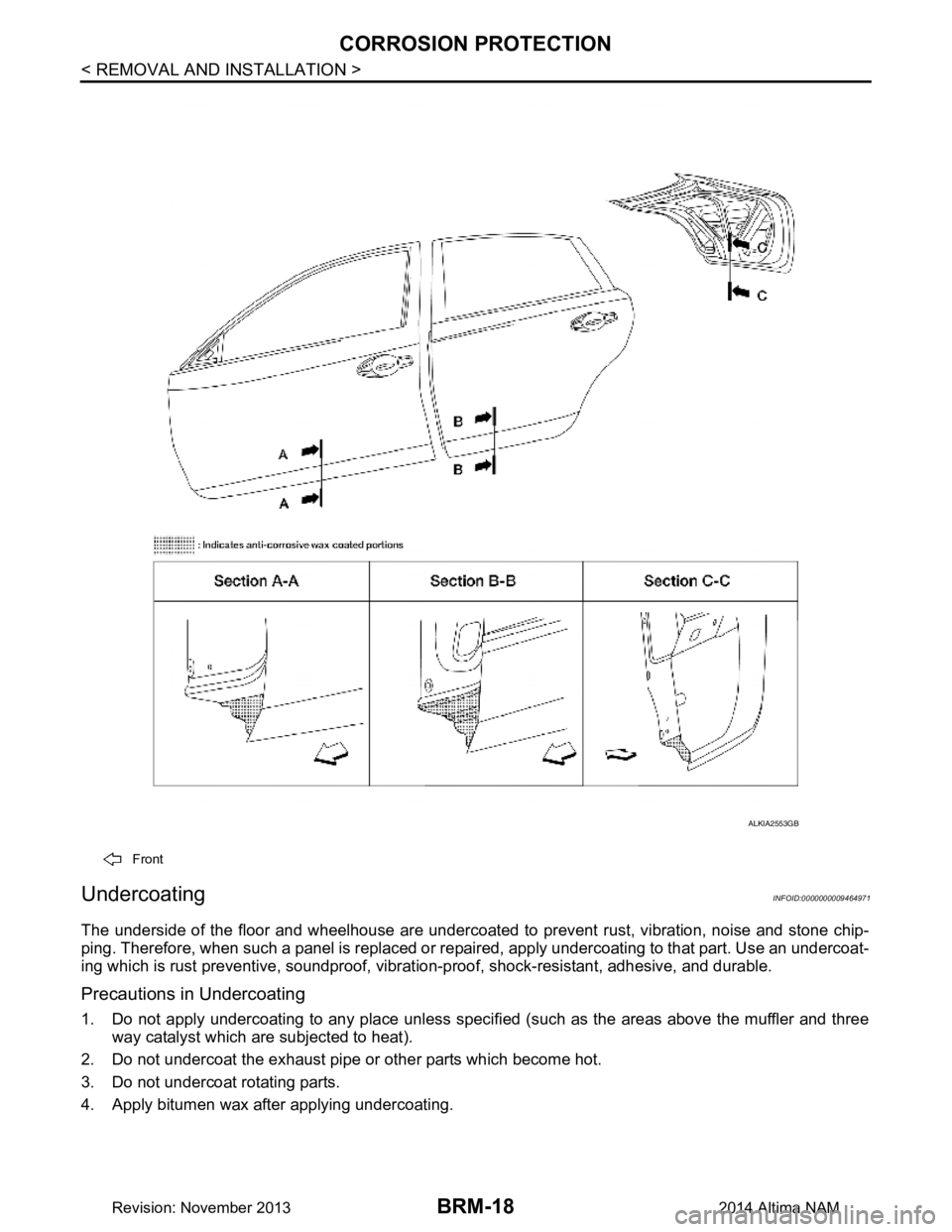

Undercoating

INFOID:0000000009464971

The underside of the floor and wheelhouse are undercoated to prevent rust, vibration, noise and stone chip-

ping. Therefore, when such a panel is replaced or re paired, apply undercoating to that part. Use an undercoat-

ing which is rust preventive, soundproof, vibr ation-proof, shock-resistant, adhesive, and durable.

Precautions in Undercoating

1. Do not apply undercoating to any place unless specif ied (such as the areas above the muffler and three

way catalyst which are subjected to heat).

2. Do not undercoat the exhaust pipe or other parts which become hot.

3. Do not undercoat rotating parts.

4. Apply bitumen wax after applying undercoating.

Front

ALKIA2553GB

Revision: November 20132014 Altima NAM

Page 297 of 4801

CORROSION PROTECTIONBRM-19

< REMOVAL AND INSTALLATION >

C

D E

F

G H

I

J

L

M A

B

BRM

N

O P

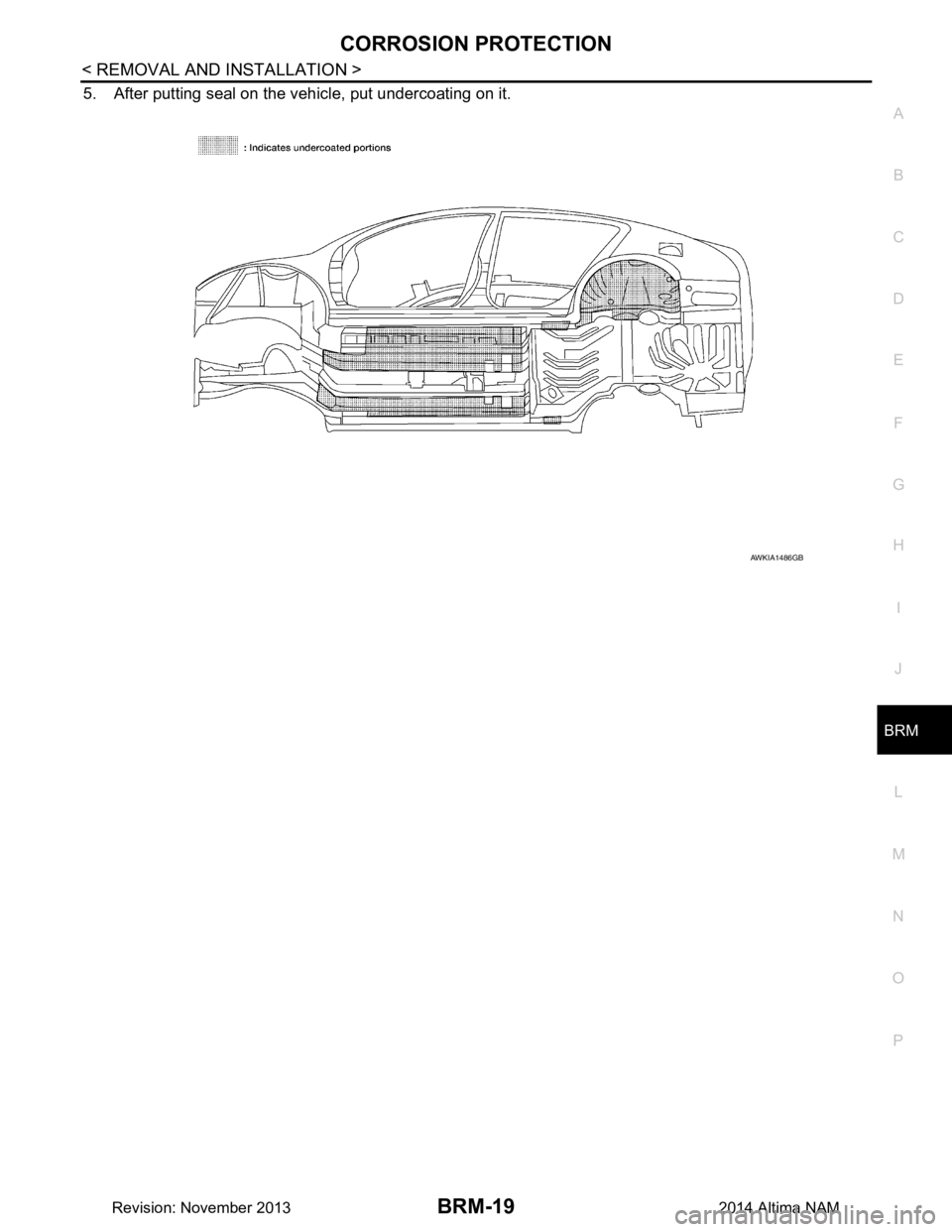

5. After putting seal on the vehicle, put undercoating on it.

AWKIA1486GB

Revision: November 20132014 Altima NAM

Page 298 of 4801

BRM-20

< REMOVAL AND INSTALLATION >

BODY SEALING

BODY SEALING

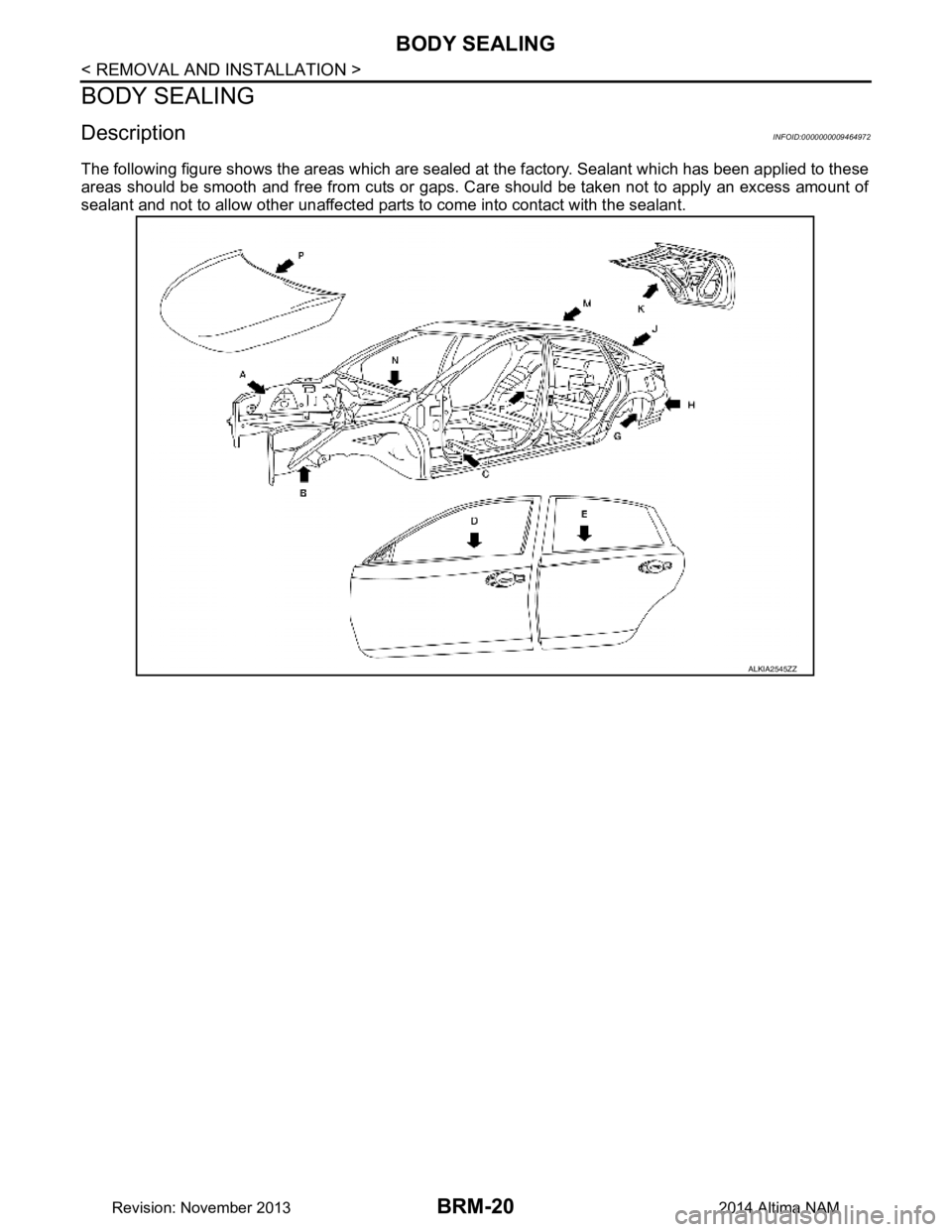

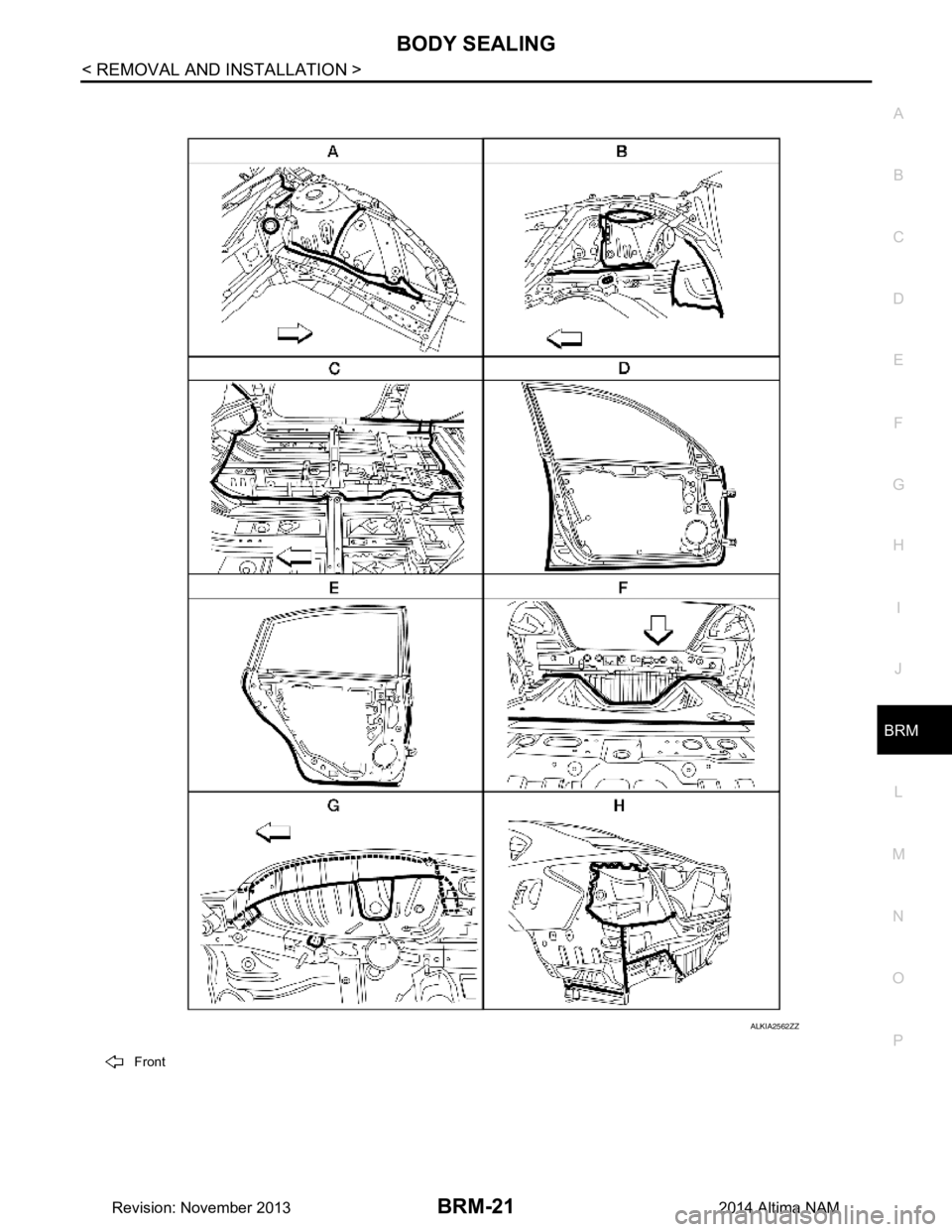

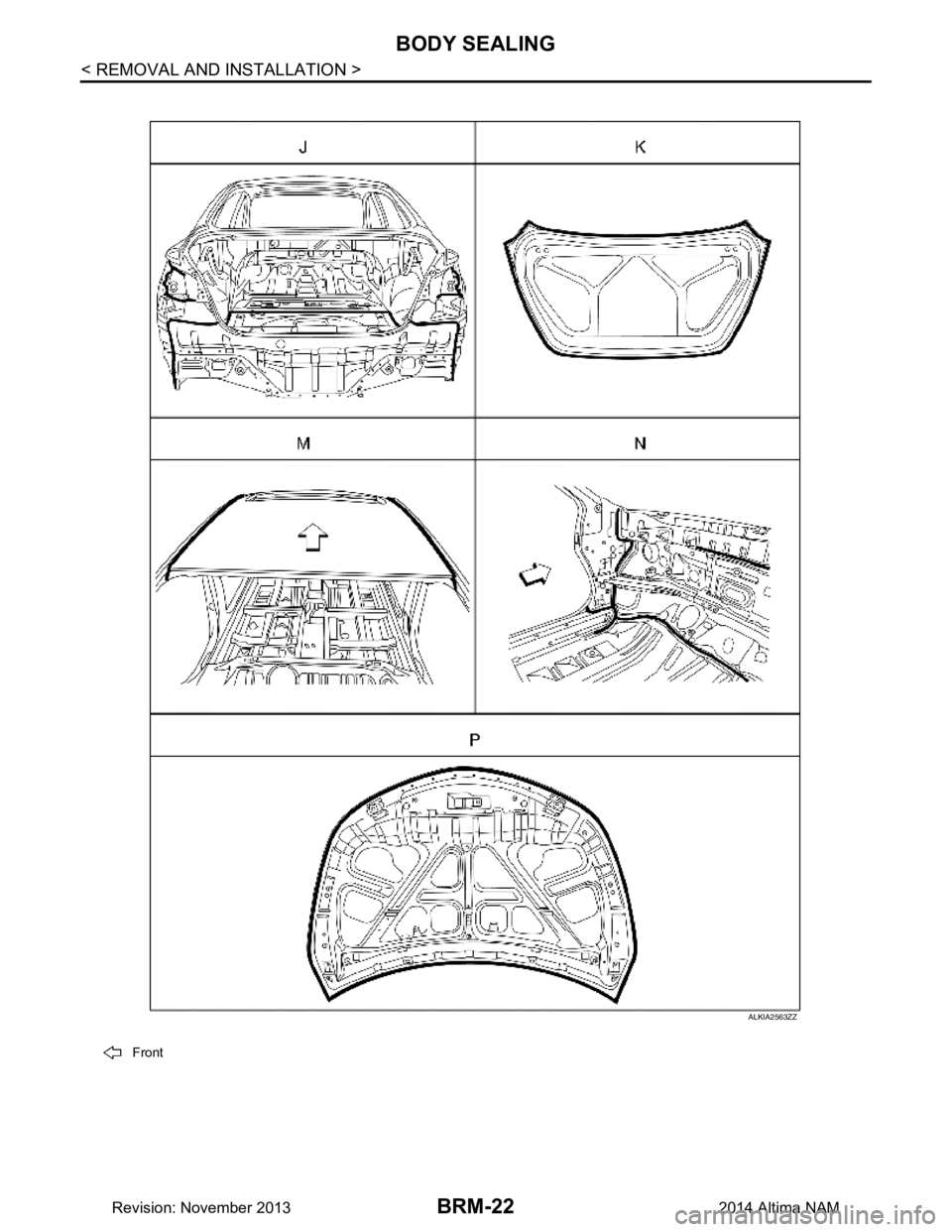

DescriptionINFOID:0000000009464972

The following figure shows the areas which are sealed at the factory. Sealant which has been applied to these

areas should be smooth and free from cuts or gaps. Care should be taken not to apply an excess amount of

sealant and not to allow other unaffected parts to come into contact with the sealant.

ALKIA2545ZZ

Revision: November 20132014 Altima NAM

Page 299 of 4801

BODY SEALINGBRM-21

< REMOVAL AND INSTALLATION >

C

D E

F

G H

I

J

L

M A

B

BRM

N

O P

Front

ALKIA2562ZZ

Revision: November 20132014 Altima NAM

Page 300 of 4801

BRM-22

< REMOVAL AND INSTALLATION >

BODY SEALING

Front

ALKIA2563ZZ

Revision: November 20132014 Altima NAM

Trending: fuse, Pri pressure sec pressure, hood release, suspension, tire pressure, load capacity, change key battery