NISSAN TERRANO 2002 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 1491 of 1767

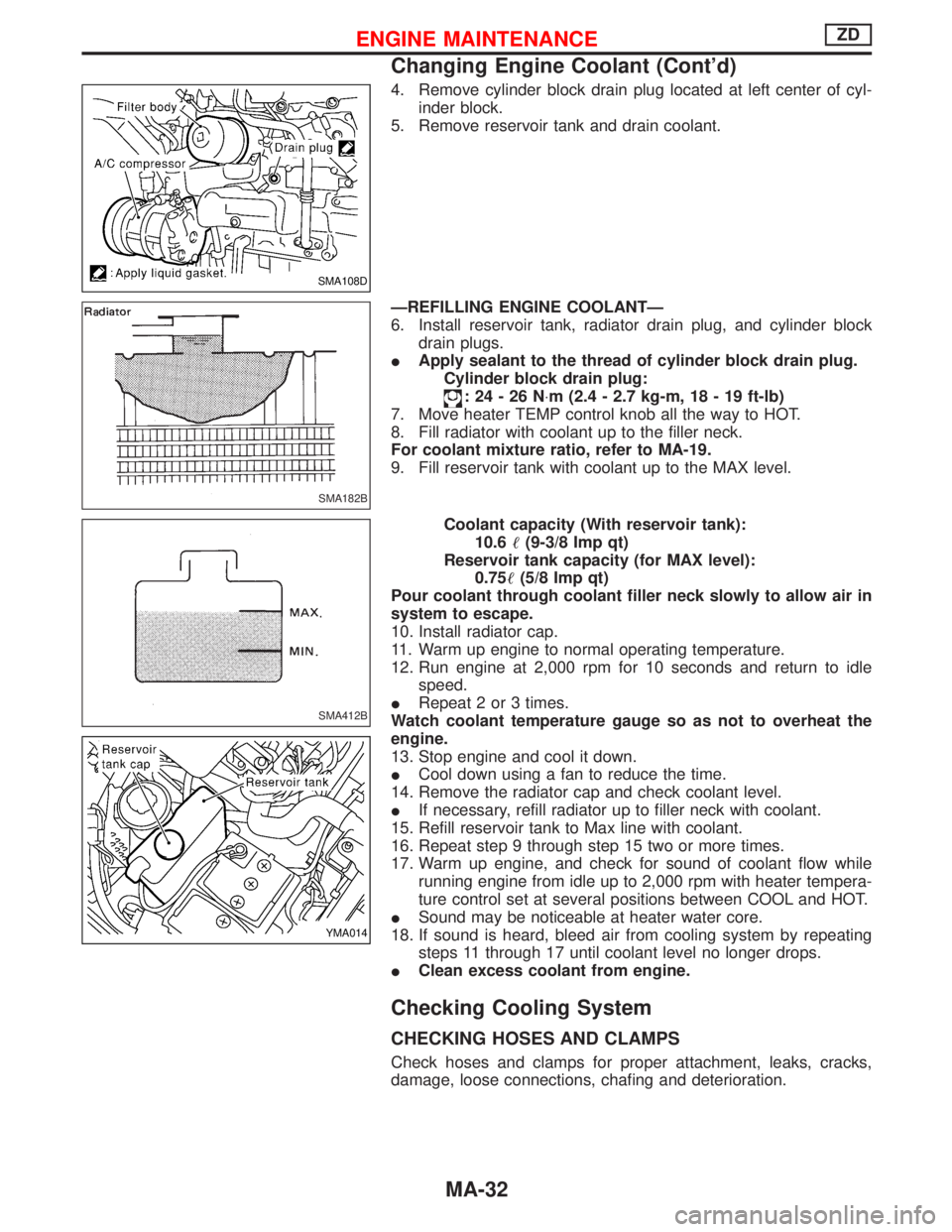

4. Remove cylinder block drain plug located at left center of cyl-

inder block.

5. Remove reservoir tank and drain coolant.

ÐREFILLING ENGINE COOLANTÐ

6. Install reservoir tank, radiator drain plug, and cylinder block

drain plugs.

IApply sealant to the thread of cylinder block drain plug.

Cylinder block drain plug:

:24-26N×m (2.4 - 2.7 kg-m, 18 - 19 ft-lb)

7. Move heater TEMP control knob all the way to HOT.

8. Fill radiator with coolant up to the filler neck.

For coolant mixture ratio, refer to MA-19.

9. Fill reservoir tank with coolant up to the MAX level.

Coolant capacity (With reservoir tank):

10.6(9-3/8 Imp qt)

Reservoir tank capacity (for MAX level):

0.75(5/8 Imp qt)

Pour coolant through coolant filler neck slowly to allow air in

system to escape.

10. Install radiator cap.

11. Warm up engine to normal operating temperature.

12. Run engine at 2,000 rpm for 10 seconds and return to idle

speed.

IRepeat 2 or 3 times.

Watch coolant temperature gauge so as not to overheat the

engine.

13. Stop engine and cool it down.

ICool down using a fan to reduce the time.

14. Remove the radiator cap and check coolant level.

IIf necessary, refill radiator up to filler neck with coolant.

15. Refill reservoir tank to Max line with coolant.

16. Repeat step 9 through step 15 two or more times.

17. Warm up engine, and check for sound of coolant flow while

running engine from idle up to 2,000 rpm with heater tempera-

ture control set at several positions between COOL and HOT.

ISound may be noticeable at heater water core.

18. If sound is heard, bleed air from cooling system by repeating

steps 11 through 17 until coolant level no longer drops.

IClean excess coolant from engine.

Checking Cooling System

CHECKING HOSES AND CLAMPS

Check hoses and clamps for proper attachment, leaks, cracks,

damage, loose connections, chafing and deterioration.

SMA108D

SMA182B

SMA412B

YMA014

ENGINE MAINTENANCEZD

Changing Engine Coolant (Cont'd)

MA-32

Page 1492 of 1767

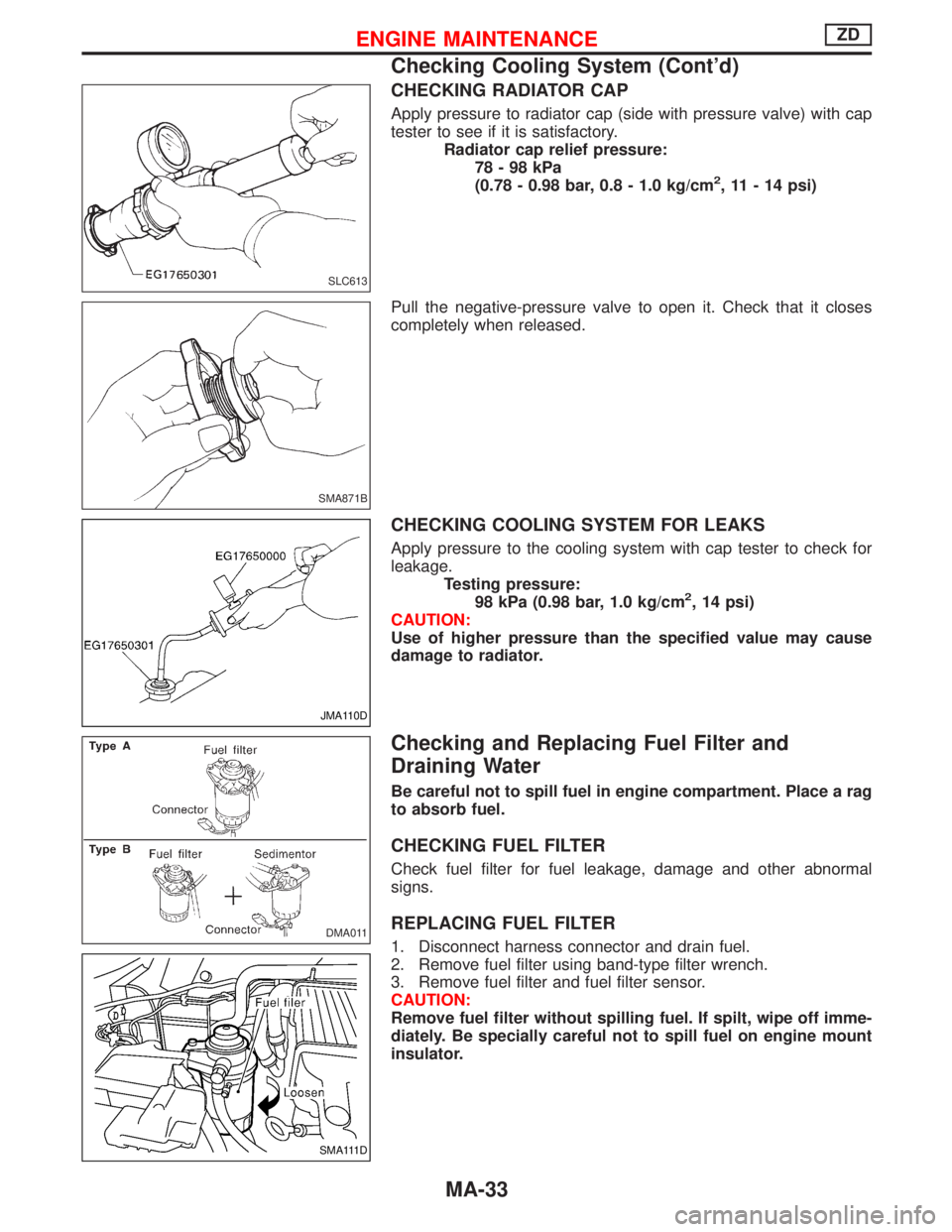

CHECKING RADIATOR CAP

Apply pressure to radiator cap (side with pressure valve) with cap

tester to see if it is satisfactory.

Radiator cap relief pressure:

78-98kPa

(0.78 - 0.98 bar, 0.8 - 1.0 kg/cm

2, 11 - 14 psi)

Pull the negative-pressure valve to open it. Check that it closes

completely when released.

CHECKING COOLING SYSTEM FOR LEAKS

Apply pressure to the cooling system with cap tester to check for

leakage.

Testing pressure:

98 kPa (0.98 bar, 1.0 kg/cm

2, 14 psi)

CAUTION:

Use of higher pressure than the specified value may cause

damage to radiator.

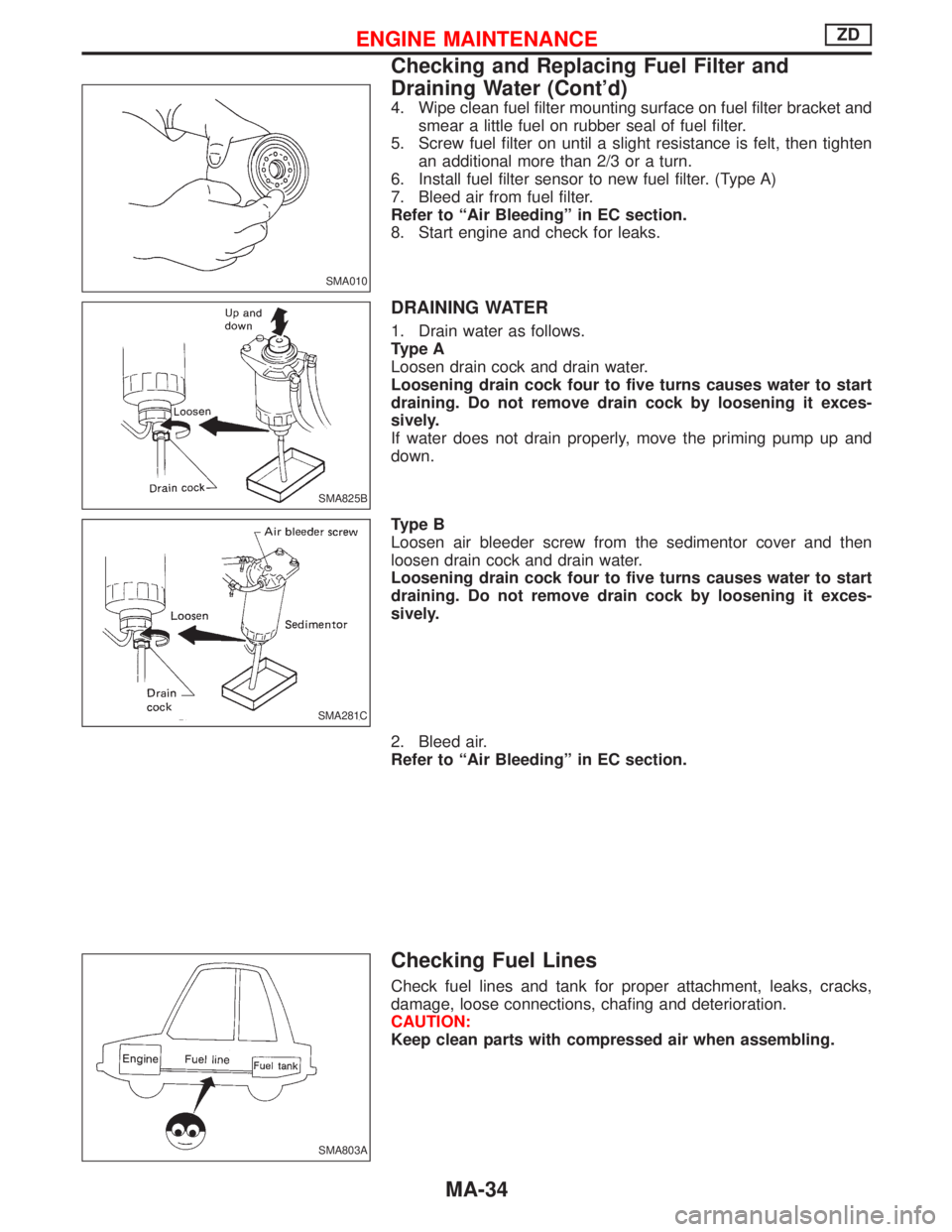

Checking and Replacing Fuel Filter and

Draining Water

Be careful not to spill fuel in engine compartment. Place a rag

to absorb fuel.

CHECKING FUEL FILTER

Check fuel filter for fuel leakage, damage and other abnormal

signs.

REPLACING FUEL FILTER

1. Disconnect harness connector and drain fuel.

2. Remove fuel filter using band-type filter wrench.

3. Remove fuel filter and fuel filter sensor.

CAUTION:

Remove fuel filter without spilling fuel. If spilt, wipe off imme-

diately. Be specially careful not to spill fuel on engine mount

insulator.

SLC613

SMA871B

JMA110D

DMA011

SMA111D

ENGINE MAINTENANCEZD

Checking Cooling System (Cont'd)

MA-33

Page 1493 of 1767

4. Wipe clean fuel filter mounting surface on fuel filter bracket and

smear a little fuel on rubber seal of fuel filter.

5. Screw fuel filter on until a slight resistance is felt, then tighten

an additional more than 2/3 or a turn.

6. Install fuel filter sensor to new fuel filter. (Type A)

7. Bleed air from fuel filter.

Refer to ªAir Bleedingº in EC section.

8. Start engine and check for leaks.

DRAINING WATER

1. Drain water as follows.

Type A

Loosen drain cock and drain water.

Loosening drain cock four to five turns causes water to start

draining. Do not remove drain cock by loosening it exces-

sively.

If water does not drain properly, move the priming pump up and

down.

Type B

Loosen air bleeder screw from the sedimentor cover and then

loosen drain cock and drain water.

Loosening drain cock four to five turns causes water to start

draining. Do not remove drain cock by loosening it exces-

sively.

2. Bleed air.

Refer to ªAir Bleedingº in EC section.

Checking Fuel Lines

Check fuel lines and tank for proper attachment, leaks, cracks,

damage, loose connections, chafing and deterioration.

CAUTION:

Keep clean parts with compressed air when assembling.

SMA010

SMA825B

SMA281C

SMA803A

ENGINE MAINTENANCEZD

Checking and Replacing Fuel Filter and

Draining Water (Cont'd)

MA-34

Page 1494 of 1767

Cleaning and Replacing Air Cleaner Filter

VISCOUS PAPER TYPE

The viscous paper type air cleaner filter does not require any clean-

ing operation between renewal.

SMA151D

ENGINE MAINTENANCEZD

MA-35

Page 1495 of 1767

Checking Exhaust System

Check exhaust pipes, muffler and mounting for proper attachment,

leaks, cracks, damage, loose connections, chafing and deteriora-

tion. Replace all defective parts.

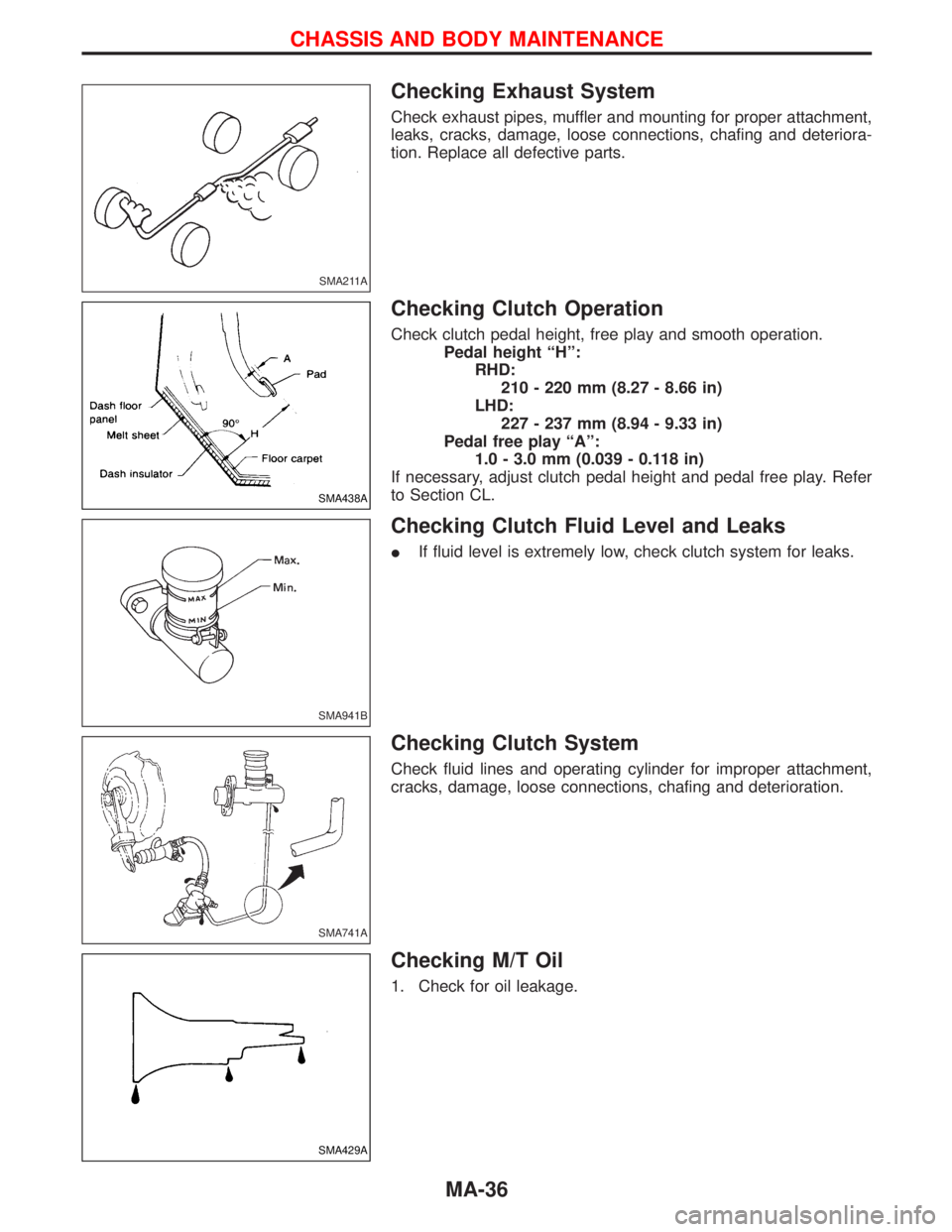

Checking Clutch Operation

Check clutch pedal height, free play and smooth operation.

Pedal height ªHº:

RHD:

210 - 220 mm (8.27 - 8.66 in)

LHD:

227 - 237 mm (8.94 - 9.33 in)

Pedal free play ªAº:

1.0 - 3.0 mm (0.039 - 0.118 in)

If necessary, adjust clutch pedal height and pedal free play. Refer

to Section CL.

Checking Clutch Fluid Level and Leaks

IIf fluid level is extremely low, check clutch system for leaks.

Checking Clutch System

Check fluid lines and operating cylinder for improper attachment,

cracks, damage, loose connections, chafing and deterioration.

Checking M/T Oil

1. Check for oil leakage.

SMA211A

SMA438A

SMA941B

SMA741A

SMA429A

CHASSIS AND BODY MAINTENANCE

MA-36

Page 1496 of 1767

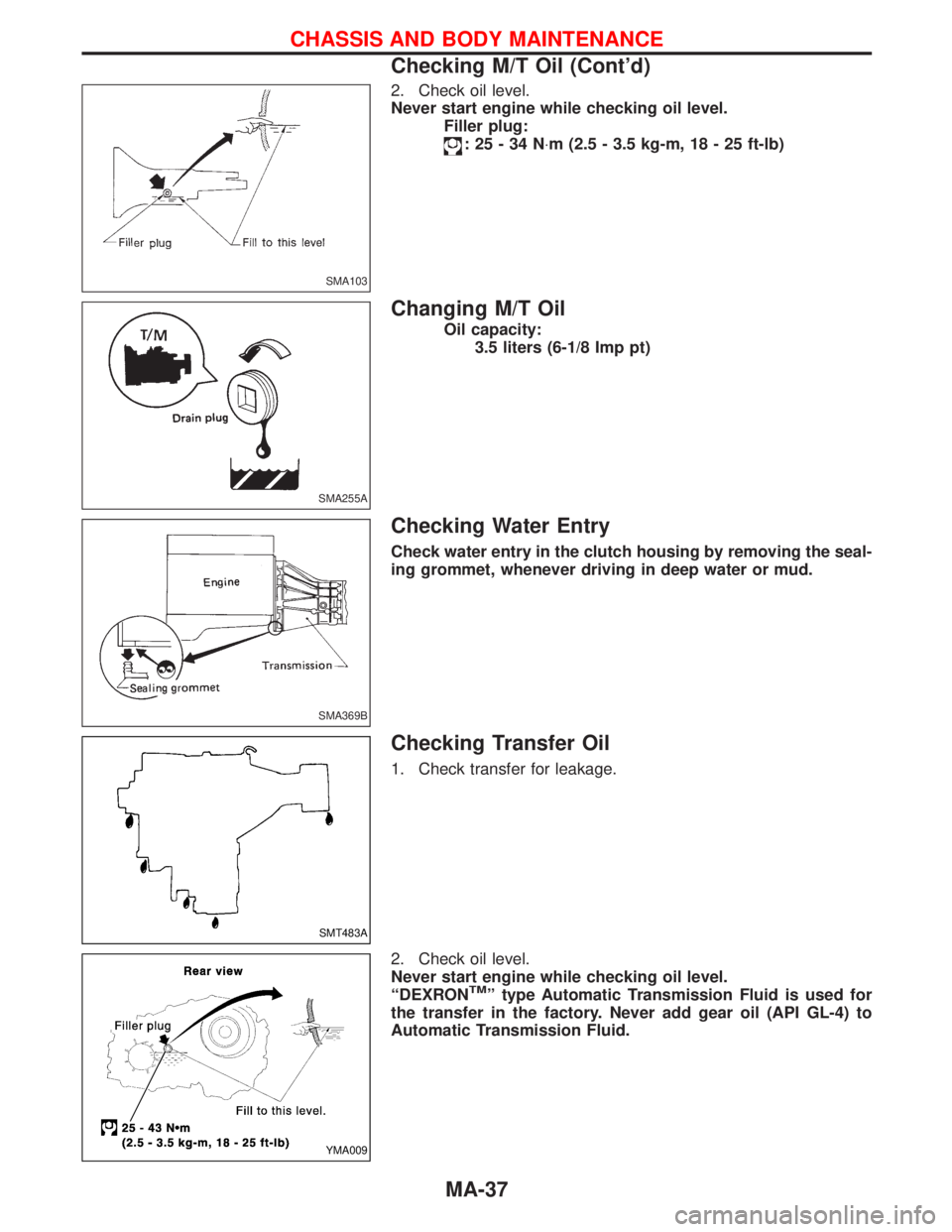

2. Check oil level.

Never start engine while checking oil level.

Filler plug:

:25-34N×m (2.5 - 3.5 kg-m, 18 - 25 ft-lb)

Changing M/T Oil

Oil capacity:

3.5 liters (6-1/8 Imp pt)

Checking Water Entry

Check water entry in the clutch housing by removing the seal-

ing grommet, whenever driving in deep water or mud.

Checking Transfer Oil

1. Check transfer for leakage.

2. Check oil level.

Never start engine while checking oil level.

ªDEXRON

TMº type Automatic Transmission Fluid is used for

the transfer in the factory. Never add gear oil (API GL-4) to

Automatic Transmission Fluid.

SMA103

SMA255A

SMA369B

SMT483A

YMA009

CHASSIS AND BODY MAINTENANCE

Checking M/T Oil (Cont'd)

MA-37

Page 1497 of 1767

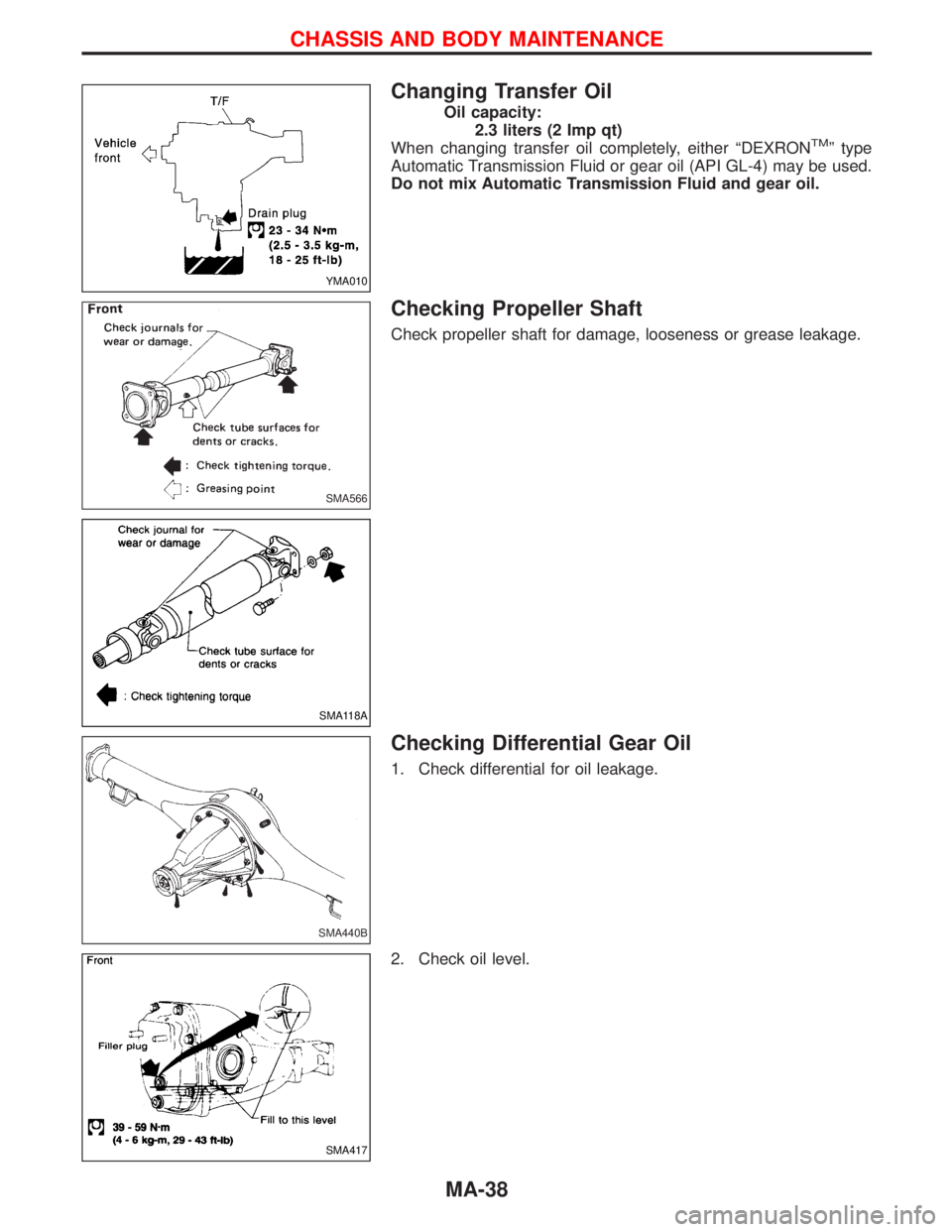

Changing Transfer Oil

Oil capacity:

2.3 liters (2 Imp qt)

When changing transfer oil completely, either ªDEXRON

TMº type

Automatic Transmission Fluid or gear oil (API GL-4) may be used.

Do not mix Automatic Transmission Fluid and gear oil.

Checking Propeller Shaft

Check propeller shaft for damage, looseness or grease leakage.

Checking Differential Gear Oil

1. Check differential for oil leakage.

2. Check oil level.

YMA010

SMA566

SMA118A

SMA440B

SMA417

CHASSIS AND BODY MAINTENANCE

MA-38

Page 1498 of 1767

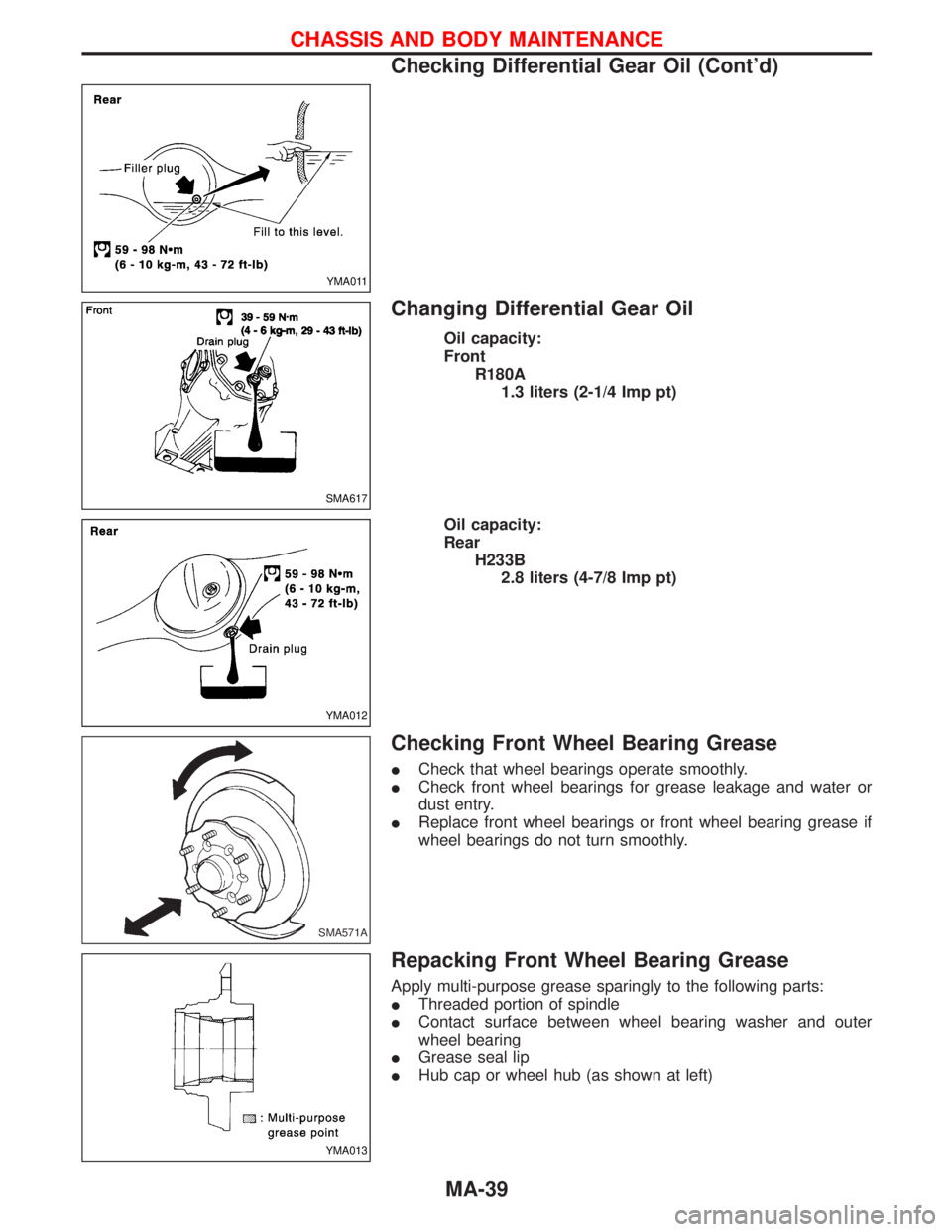

Changing Differential Gear Oil

Oil capacity:

Front

R180A

1.3 liters (2-1/4 Imp pt)

Oil capacity:

Rear

H233B

2.8 liters (4-7/8 Imp pt)

Checking Front Wheel Bearing Grease

ICheck that wheel bearings operate smoothly.

ICheck front wheel bearings for grease leakage and water or

dust entry.

IReplace front wheel bearings or front wheel bearing grease if

wheel bearings do not turn smoothly.

Repacking Front Wheel Bearing Grease

Apply multi-purpose grease sparingly to the following parts:

IThreaded portion of spindle

IContact surface between wheel bearing washer and outer

wheel bearing

IGrease seal lip

IHub cap or wheel hub (as shown at left)

YMA011

SMA617

YMA012

SMA571A

YMA013

CHASSIS AND BODY MAINTENANCE

Checking Differential Gear Oil (Cont'd)

MA-39

Page 1499 of 1767

Checking Free-running Hub Grease

Check free-running hub grease for leakage and water or dust entry.

Checking Brake Fluid Level and Leaks

If fluid level is extremely low, check brake system for leaks.

Checking Brake System

Check brake fluid lines and parking brake cables for improper

attachment, leaks, chafing, abrasion, deterioration, etc.

Checking Brake Booster, Vacuum Hoses,

Connections and Check Valve

Check vacuum lines, connections and check valve for improper

attachment, air tightness, chafing and deterioration.

Checking Disc Brake

Check condition of disc brake components.

ROTOR

Check condition and thickness.

Standard thickness:

26 mm (1.02 in)

Minimum thickness:

24 mm (0.94 in)

SMA946B

SBR991

SMA732A

SBR402A

SMA260A

CHASSIS AND BODY MAINTENANCE

MA-40

Page 1500 of 1767

CALIPER

Check operation and leakage.

PA D

Check wear or damage.

Standard thickness:

15.5 mm (0.610 in)

Minimum thickness:

2.0 mm (0.079 in)

Checking Drum Brake

Check condition of drum brake components.

WHEEL CYLINDER

Check operation and leakage.

DRUM

Check condition of inner surface.

Nominal diameter:

280 mm (11.02 in)

Maximum diameter:

282 mm (11.10 in)

Out of round maximum:

0.05 mm (0.002 in) or less

LINING

Check wear or damage.

Standard thickness:

Trailing: 3.95 mm (0.16 in)

Leading: 8.95 mm (0.35 in)

Lining wear limit (Minimum thickness):

1.52 mm (0.06 in)

SMA922A

SMA364A

SBR205A

SMA139

SMA138

CHASSIS AND BODY MAINTENANCE

Checking Disc Brake (Cont'd)

MA-41