NISSAN TERRANO 2002 Service Repair Manual

TERRANO 2002

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57393/w960_57393-0.png

NISSAN TERRANO 2002 Service Repair Manual

Trending: oil reset, timing belt, Brake, service indicator, tires, engine, auxiliary battery

Page 1511 of 1767

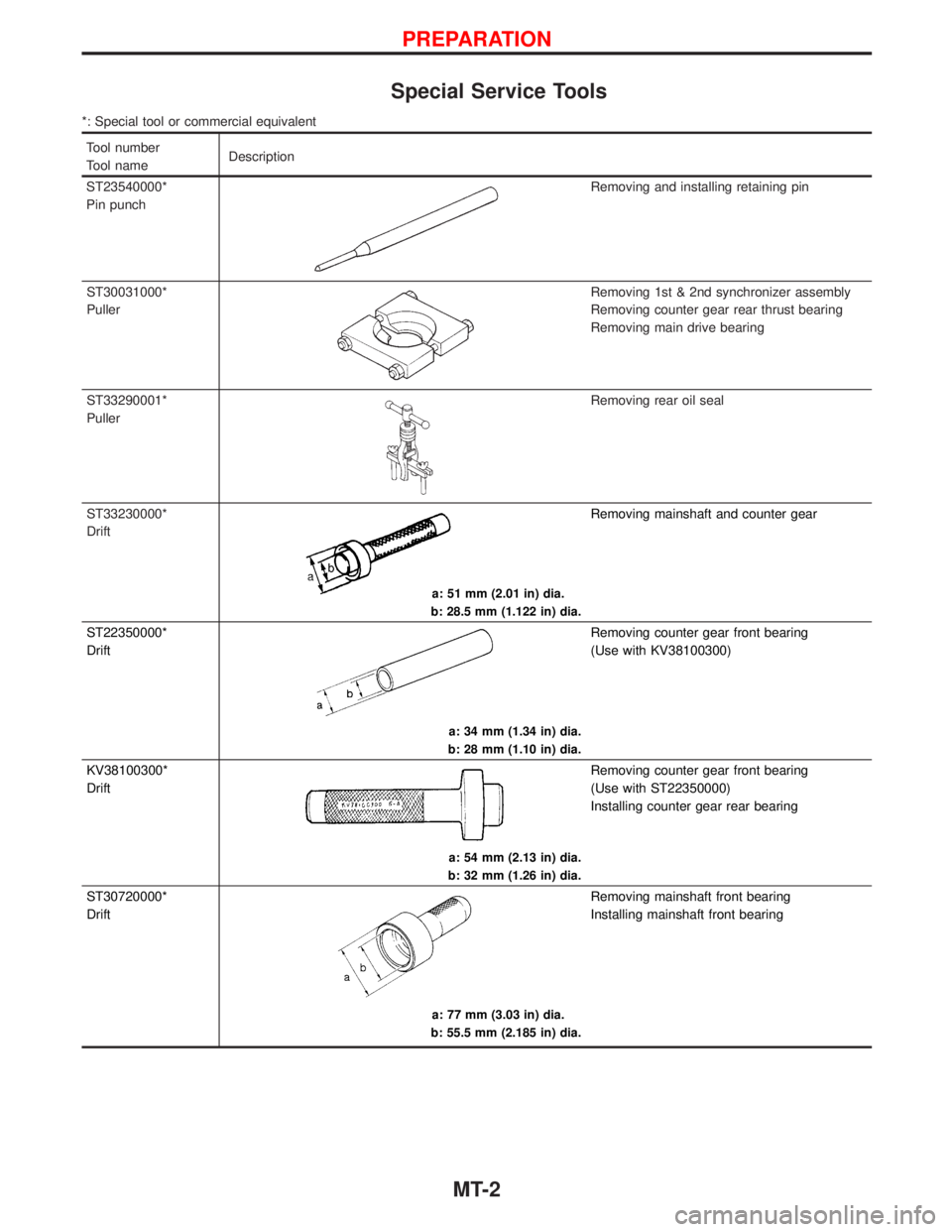

Special Service Tools

*: Special tool or commercial equivalent

Tool number

Tool nameDescription

ST23540000*

Pin punch

Removing and installing retaining pin

ST30031000*

Puller

Removing 1st & 2nd synchronizer assembly

Removing counter gear rear thrust bearing

Removing main drive bearing

ST33290001*

Puller

Removing rear oil seal

ST33230000*

Drift

a: 51 mm (2.01 in) dia.

b: 28.5 mm (1.122 in) dia.

Removing mainshaft and counter gear

ST22350000*

Drift

a: 34 mm (1.34 in) dia.

b: 28 mm (1.10 in) dia.

Removing counter gear front bearing

(Use with KV38100300)

KV38100300*

Drift

a: 54 mm (2.13 in) dia.

b: 32 mm (1.26 in) dia.

Removing counter gear front bearing

(Use with ST22350000)

Installing counter gear rear bearing

ST30720000*

Drift

a: 77 mm (3.03 in) dia.

b: 55.5 mm (2.185 in) dia.

Removing mainshaft front bearing

Installing mainshaft front bearing

PREPARATION

MT-2

Page 1512 of 1767

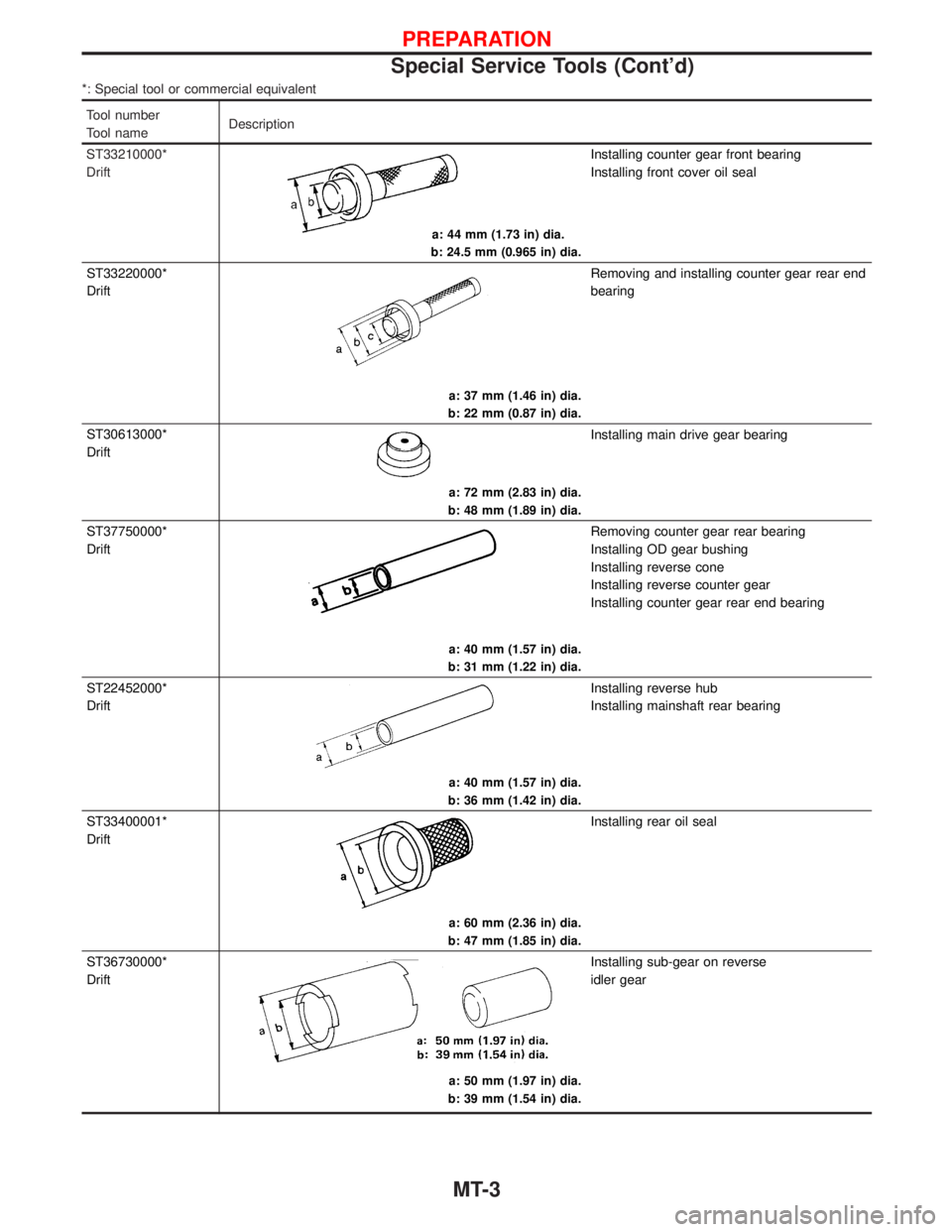

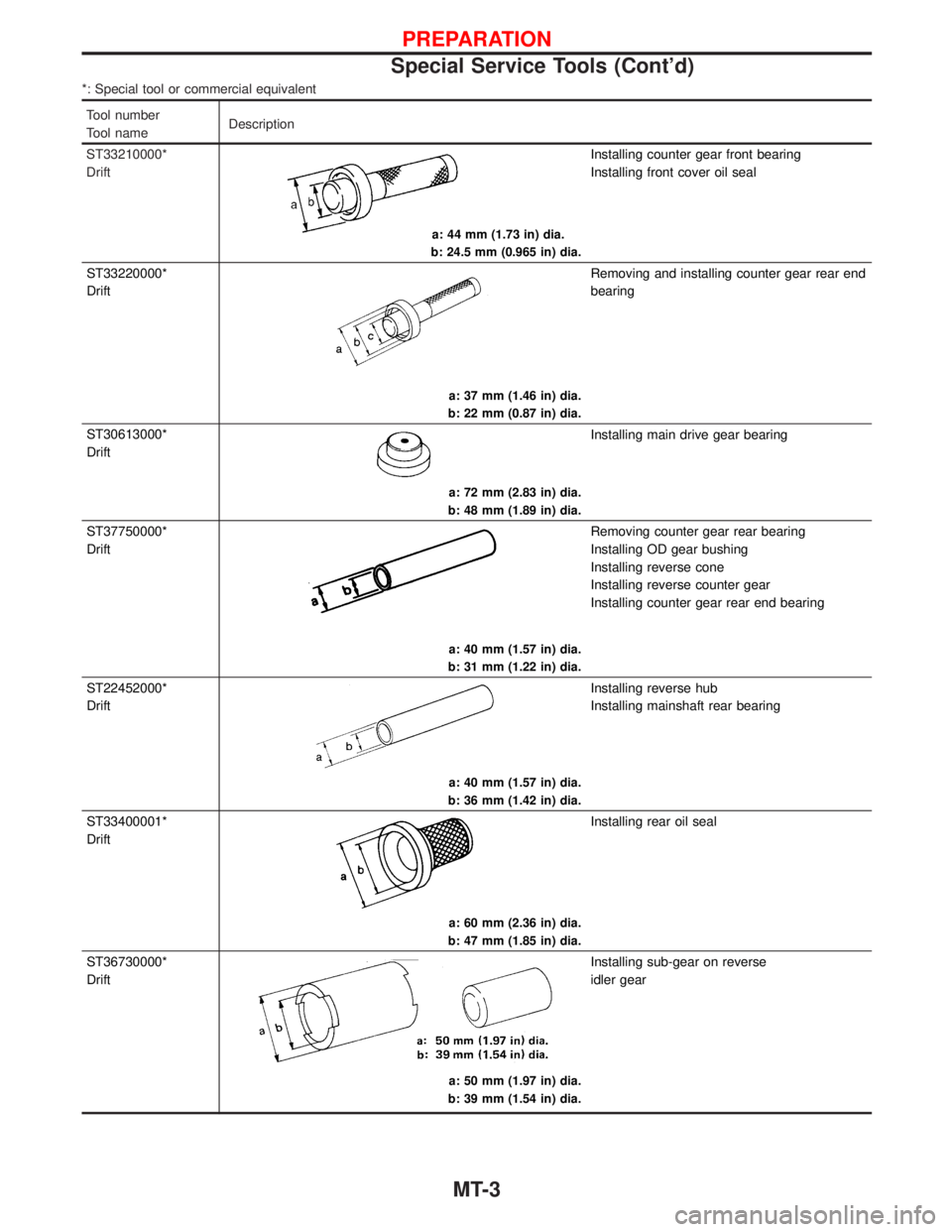

*: Special tool or commercial equivalent

Tool number

Tool nameDescription

ST33210000*

Drift

a: 44 mm (1.73 in) dia.

b: 24.5 mm (0.965 in) dia.

Installing counter gear front bearing

Installing front cover oil seal

ST33220000*

Drift

a: 37 mm (1.46 in) dia.

b: 22 mm (0.87 in) dia.

Removing and installing counter gear rear end

bearing

ST30613000*

Drift

a: 72 mm (2.83 in) dia.

b: 48 mm (1.89 in) dia.

Installing main drive gear bearing

ST37750000*

Drift

a: 40 mm (1.57 in) dia.

b: 31 mm (1.22 in) dia.

Removing counter gear rear bearing

Installing OD gear bushing

Installing reverse cone

Installing reverse counter gear

Installing counter gear rear end bearing

ST22452000*

Drift

a: 40 mm (1.57 in) dia.

b: 36 mm (1.42 in) dia.

Installing reverse hub

Installing mainshaft rear bearing

ST33400001*

Drift

a: 60 mm (2.36 in) dia.

b: 47 mm (1.85 in) dia.

Installing rear oil seal

ST36730000*

Drift

a: 50 mm (1.97 in) dia.

b: 39 mm (1.54 in) dia.

Installing sub-gear on reverse

idler gear

PREPARATION

Special Service Tools (Cont'd)

MT-3

Page 1513 of 1767

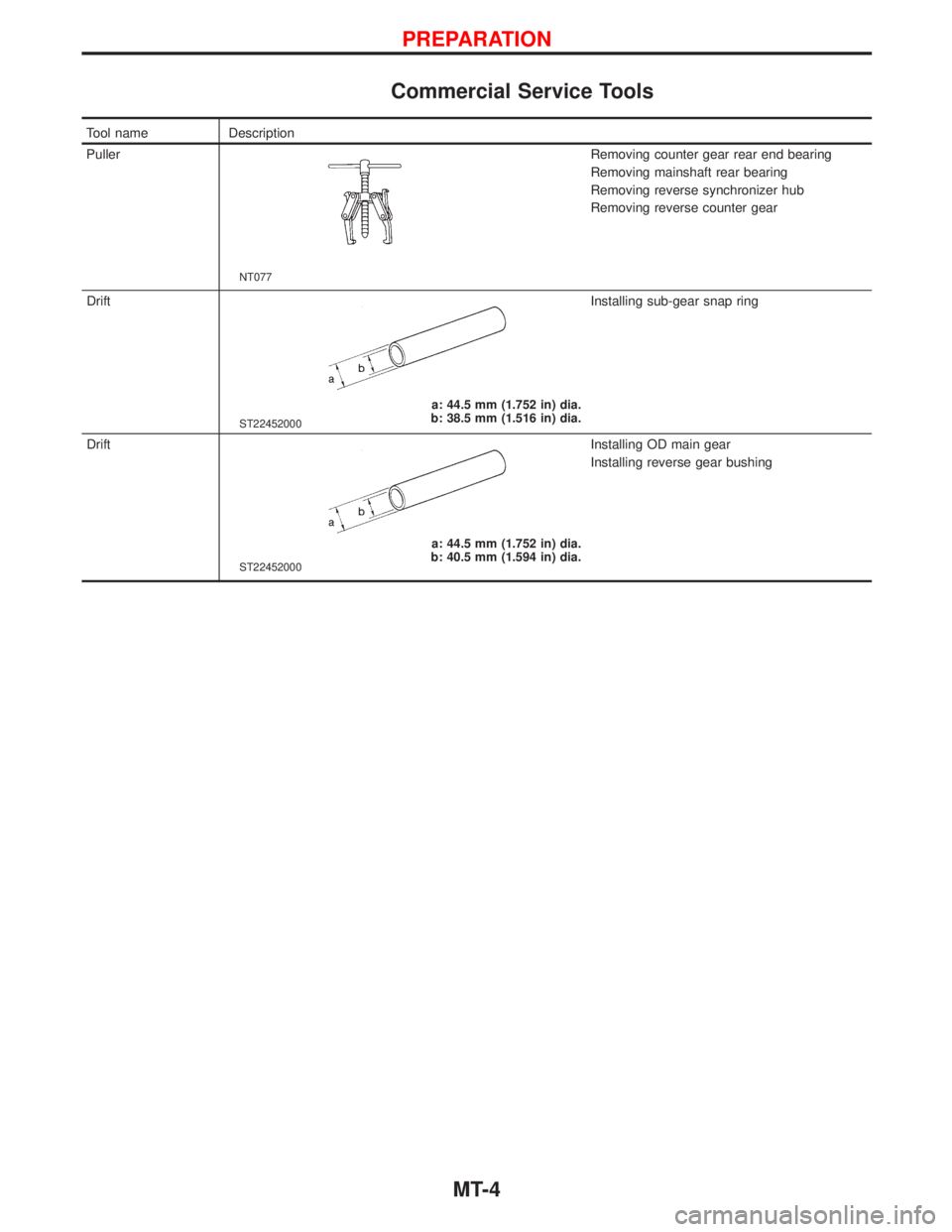

Commercial Service Tools

Tool name Description

Puller

NT077

Removing counter gear rear end bearing

Removing mainshaft rear bearing

Removing reverse synchronizer hub

Removing reverse counter gear

Drift

ST22452000

a: 44.5 mm (1.752 in) dia.

b: 38.5 mm (1.516 in) dia.

Installing sub-gear snap ring

Drift

ST22452000

a: 44.5 mm (1.752 in) dia.

b: 40.5 mm (1.594 in) dia.

Installing OD main gear

Installing reverse gear bushing

PREPARATION

MT-4

Page 1514 of 1767

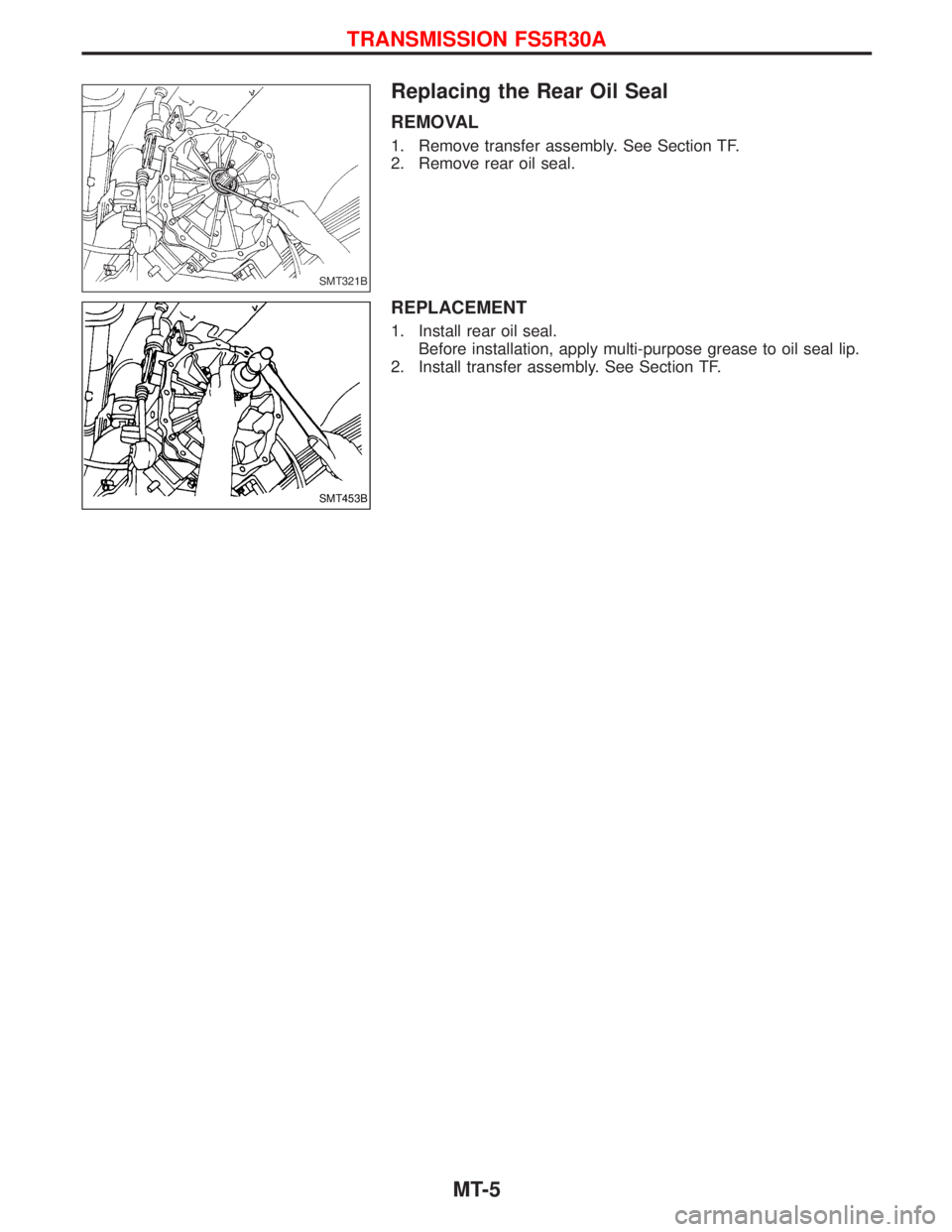

Replacing the Rear Oil Seal

REMOVAL

1. Remove transfer assembly. See Section TF.

2. Remove rear oil seal.

REPLACEMENT

1. Install rear oil seal.

Before installation, apply multi-purpose grease to oil seal lip.

2. Install transfer assembly. See Section TF.

SMT321B

SMT453B

TRANSMISSION FS5R30A

MT-5

Page 1515 of 1767

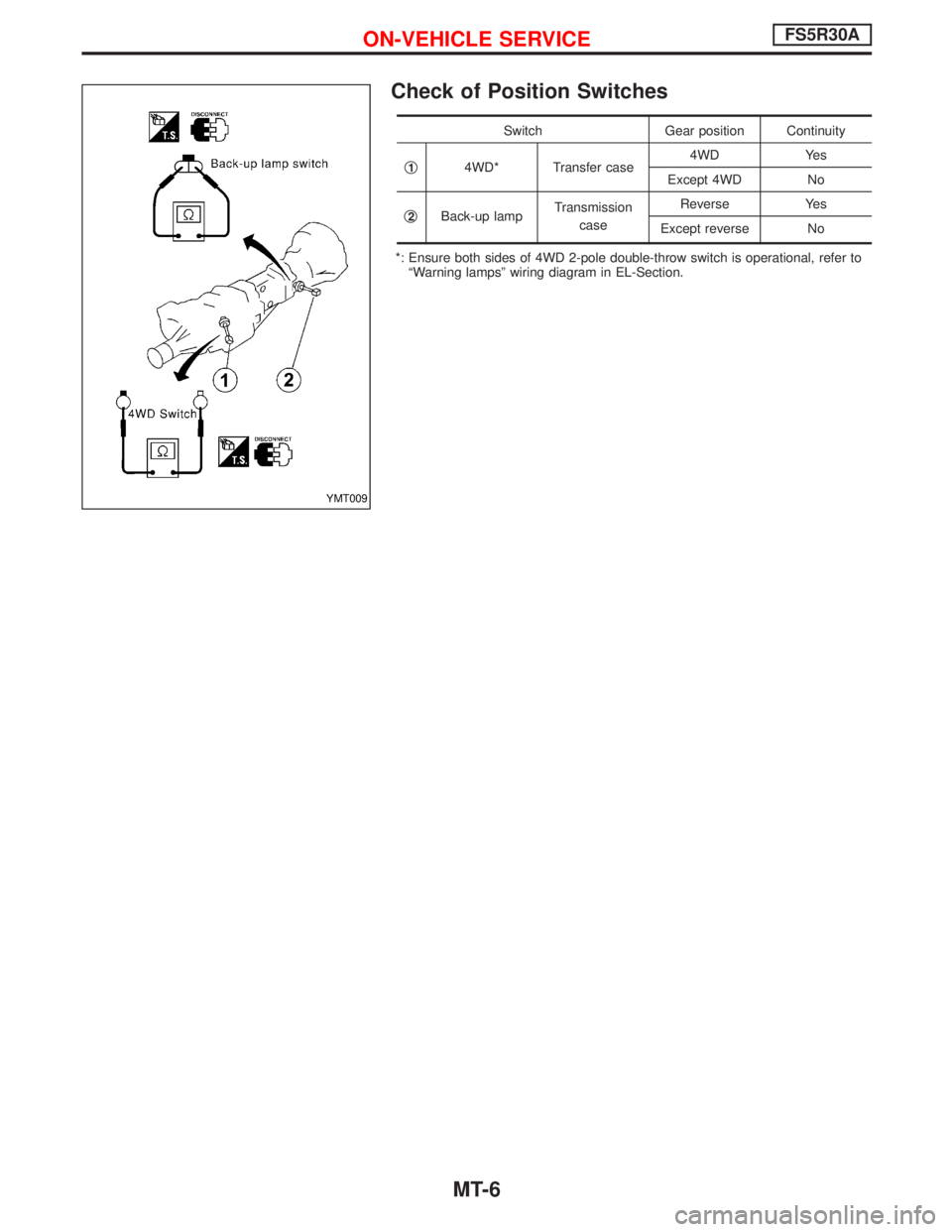

Check of Position Switches

Switch Gear position Continuity

q

14WD* Transfer case4WD Yes

Except 4WD No

q

2Back-up lampTransmission

caseReverse Yes

Except reverse No

*: Ensure both sides of 4WD 2-pole double-throw switch is operational, refer to

ªWarning lampsº wiring diagram in EL-Section.

YMT009

ON-VEHICLE SERVICEFS5R30A

MT-6

Page 1516 of 1767

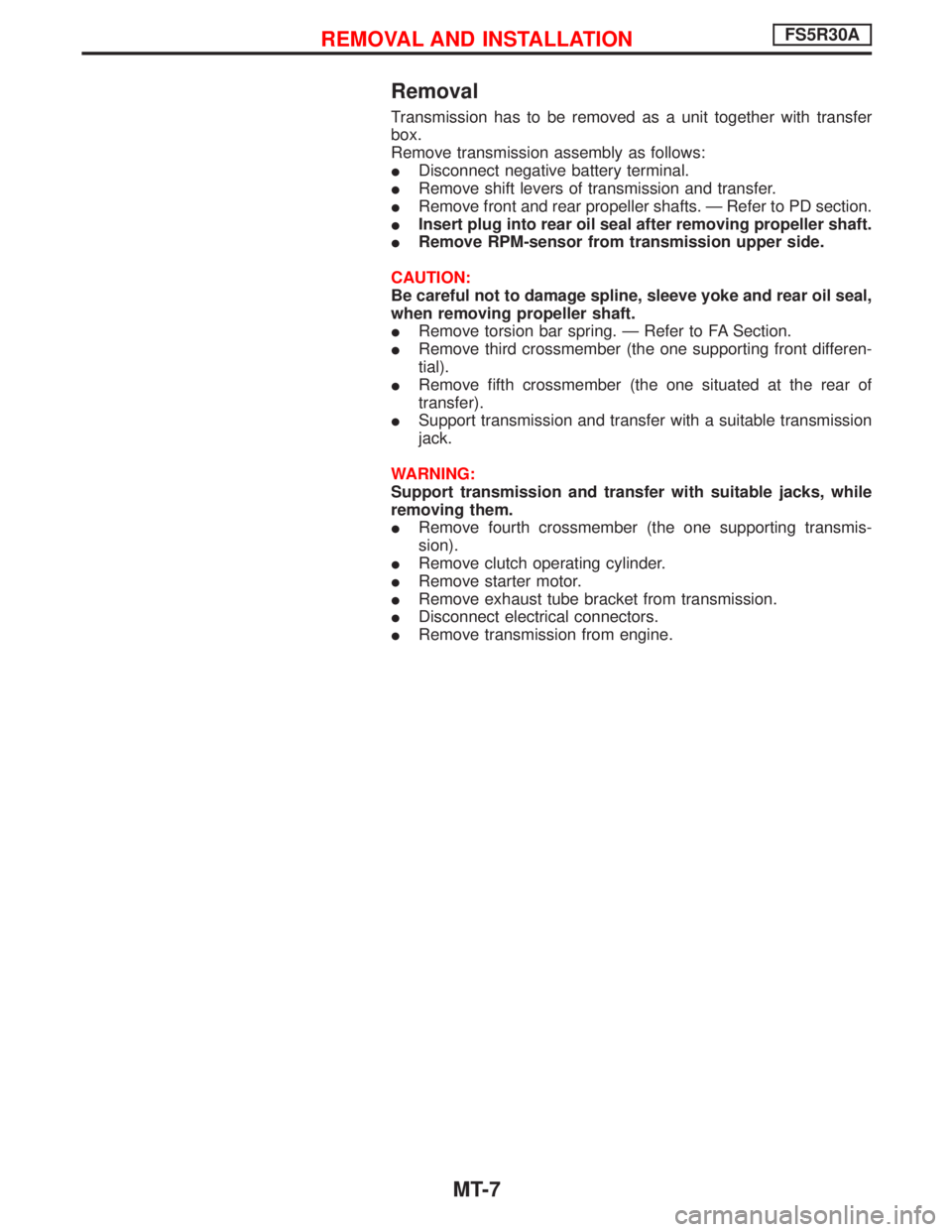

Removal

Transmission has to be removed as a unit together with transfer

box.

Remove transmission assembly as follows:

IDisconnect negative battery terminal.

IRemove shift levers of transmission and transfer.

IRemove front and rear propeller shafts. Ð Refer to PD section.

IInsert plug into rear oil seal after removing propeller shaft.

IRemove RPM-sensor from transmission upper side.

CAUTION:

Be careful not to damage spline, sleeve yoke and rear oil seal,

when removing propeller shaft.

IRemove torsion bar spring. Ð Refer to FA Section.

IRemove third crossmember (the one supporting front differen-

tial).

IRemove fifth crossmember (the one situated at the rear of

transfer).

ISupport transmission and transfer with a suitable transmission

jack.

WARNING:

Support transmission and transfer with suitable jacks, while

removing them.

IRemove fourth crossmember (the one supporting transmis-

sion).

IRemove clutch operating cylinder.

IRemove starter motor.

IRemove exhaust tube bracket from transmission.

IDisconnect electrical connectors.

IRemove transmission from engine.

REMOVAL AND INSTALLATIONFS5R30A

MT-7

Page 1517 of 1767

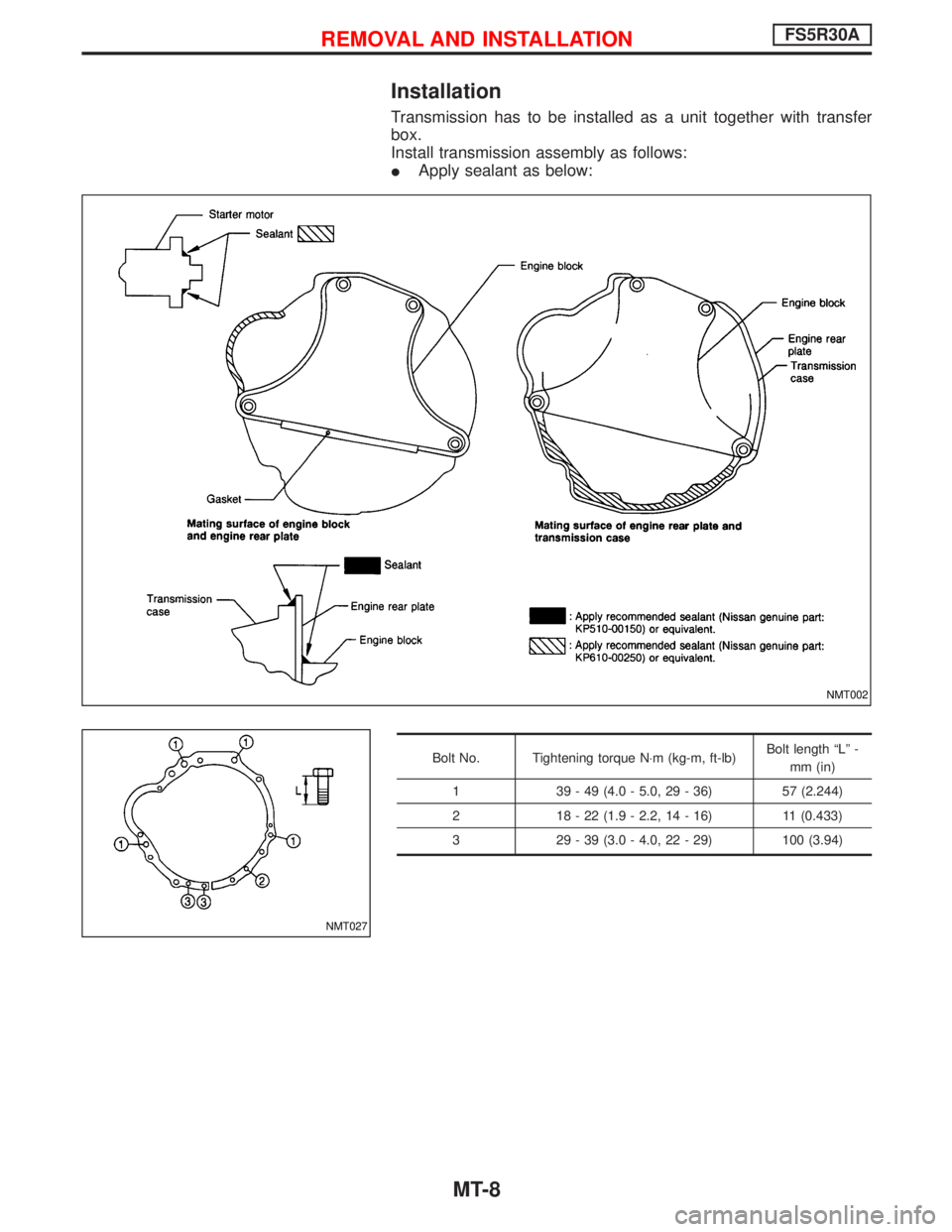

Installation

Transmission has to be installed as a unit together with transfer

box.

Install transmission assembly as follows:

IApply sealant as below:

Bolt No. Tightening torque N×m (kg-m, ft-lb)Bolt length ªLº -

mm (in)

1 39 - 49 (4.0 - 5.0, 29 - 36) 57 (2.244)

2 18 - 22 (1.9 - 2.2, 14 - 16) 11 (0.433)

3 29 - 39 (3.0 - 4.0, 22 - 29) 100 (3.94)

NMT002

NMT027

REMOVAL AND INSTALLATIONFS5R30A

MT-8

Page 1518 of 1767

IRaise the unit with a hoist.

IPosition the transmission assembly on a portable jack and

secure it with a suitable tool.

Lift the assembly until the gearbox input shaft faces its hous-

ing.

Move the assembly towards the engine. The assembly must be

rotated slightly so that the starter motor housing clears the

projection on the companion floor. Insert input shaft into its

housing (slightly raising the rear of the transfer box may facili-

tate the introduction of the shaft into its housing).

ITighten the screws securing the gearbox to the engine.

:39-49N×m (4.0 - 5.0 kg-m, 29 - 36 ft-lb)

IConnect the electrical wiring. Secure with the respective clips.

IFit the RPM-sensor to the transmission upper side.

IFit the exhaust pipe support bracket to the transfer box.

:13-16N×m (1.3 - 1.6 kg-m,9-12ft-lb)

IFit the starter motor. Secure the earth wire to the starter motor

lower screw.

:31-41N×m (3.2 - 4.2 kg-m, 23 - 30 ft-lb)

IFit the clutch slave cylinder.

:30-40N×m (3.1 - 4.1 kg-m, 22 - 30 ft-lb)

IInstall fourth crossmember (Note the ªfrontº mark).

Crossmember fixing bolts to chassis:

:41-52N×m (4.2 - 5.3 kg-m, 30 - 38 ft-lb)

Crossmember fixing bolts to transmission:

:68-87N×m (6.9 - 8.9 kg-m, 50 - 64 ft-lb)

ITake away the portable jack holding boxes assembly.

IInstall fifth crossmember.

:59-78N×m (6.0 - 8.0 kg-m, 43 - 58 ft-lb)

IInstall third crossmember.

: Screws: 41 - 52 N×m (4.2 - 5.3 kg-m,

30 - 38 ft-lb)

Nuts: 68 - 87 N×m (6.9 - 8.9 kg-m,

50 - 64 ft-lb)

IInstall torsion bar springs. Ð Refer to FA section.

IInstall front and rear propeller shafts. Ð Refer to PD section.

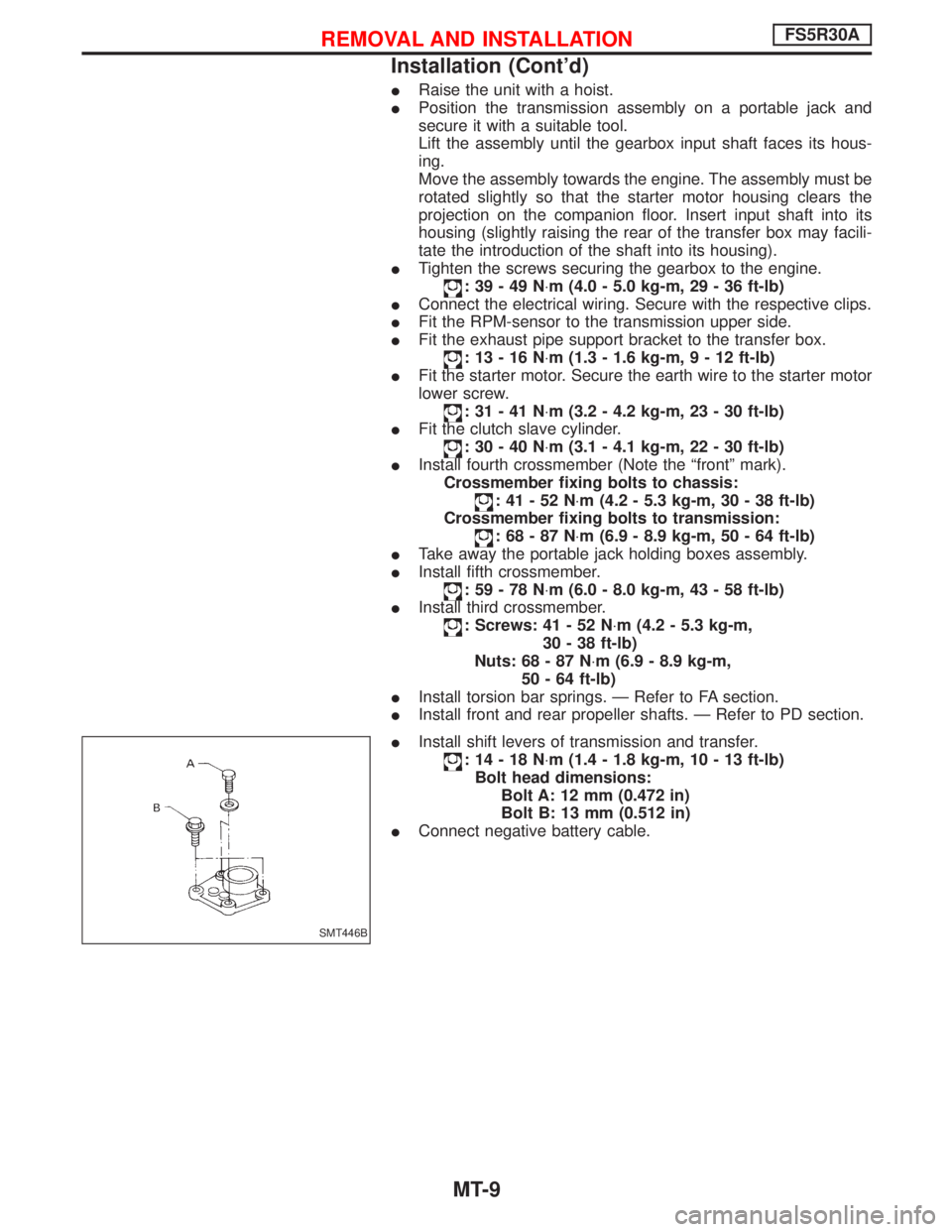

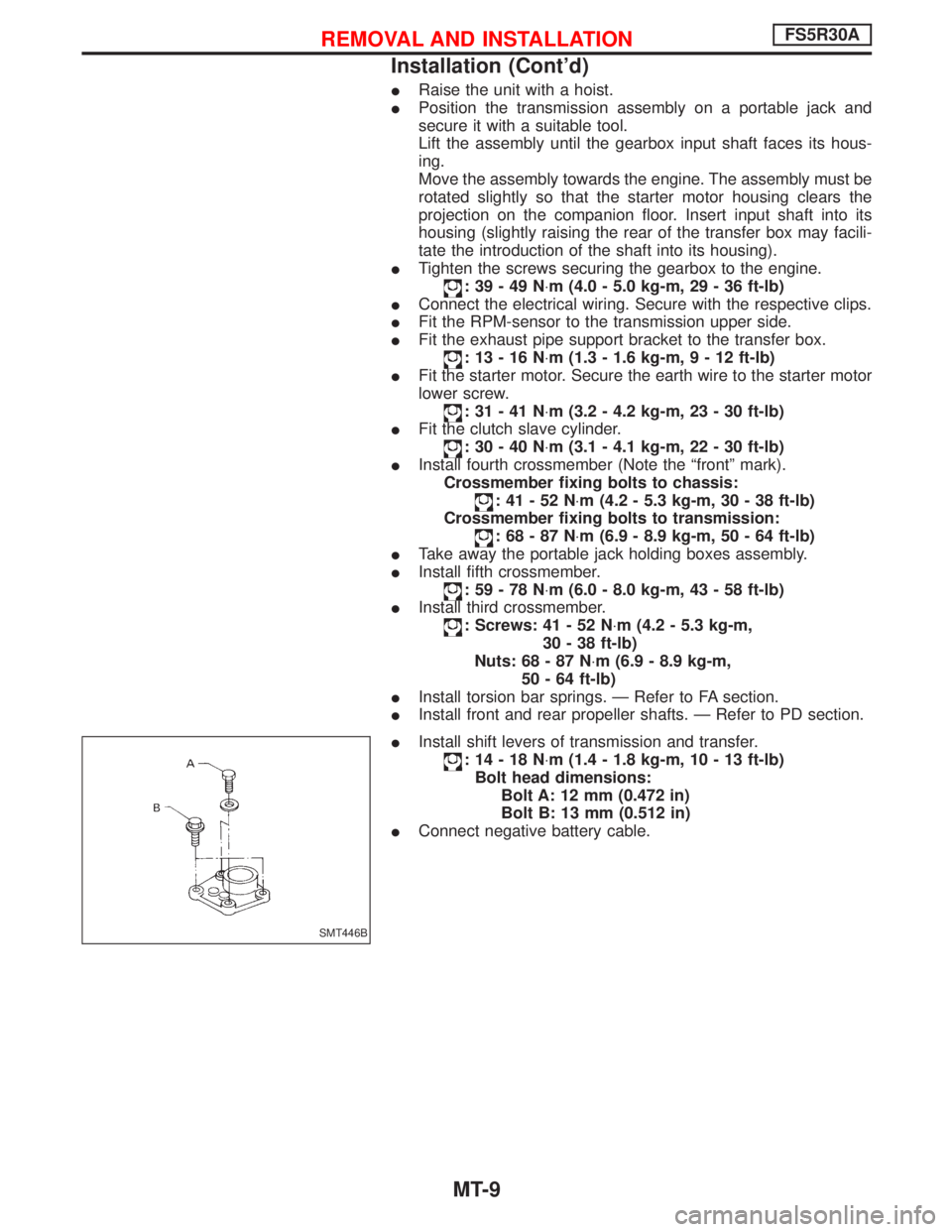

IInstall shift levers of transmission and transfer.

:14-18N×m (1.4 - 1.8 kg-m, 10 - 13 ft-lb)

Bolt head dimensions:

Bolt A: 12 mm (0.472 in)

Bolt B: 13 mm (0.512 in)

IConnect negative battery cable.

SMT446B

REMOVAL AND INSTALLATIONFS5R30A

Installation (Cont'd)

MT-9

Page 1519 of 1767

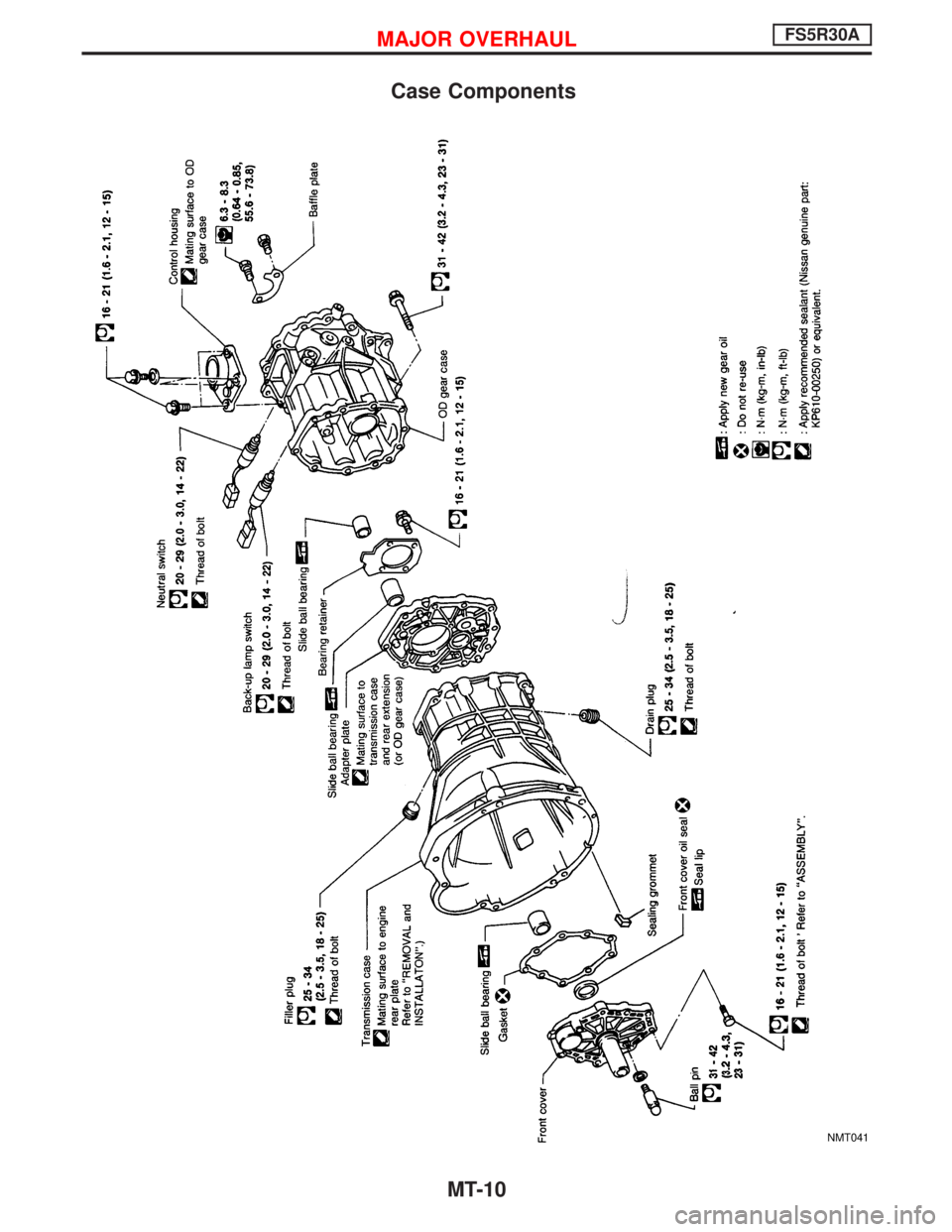

Case Components

NMT041

MAJOR OVERHAULFS5R30A

MT-10

Page 1520 of 1767

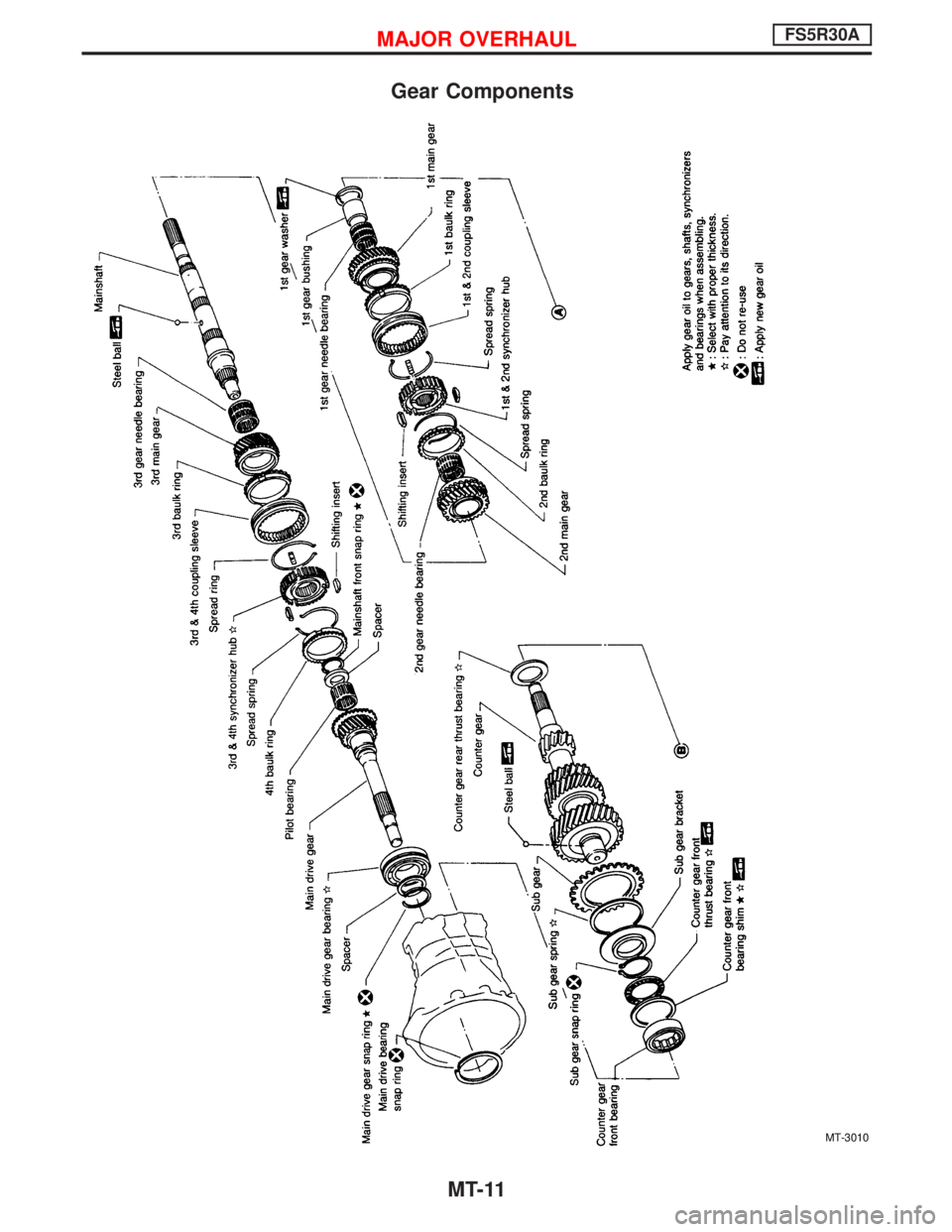

Gear Components

MT-3010

MAJOR OVERHAULFS5R30A

MT-11

Trending: seats, weight, OBD port, fuse box diagram, boot, audio, oil capacity