NISSAN TERRANO 2002 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 1501 of 1767

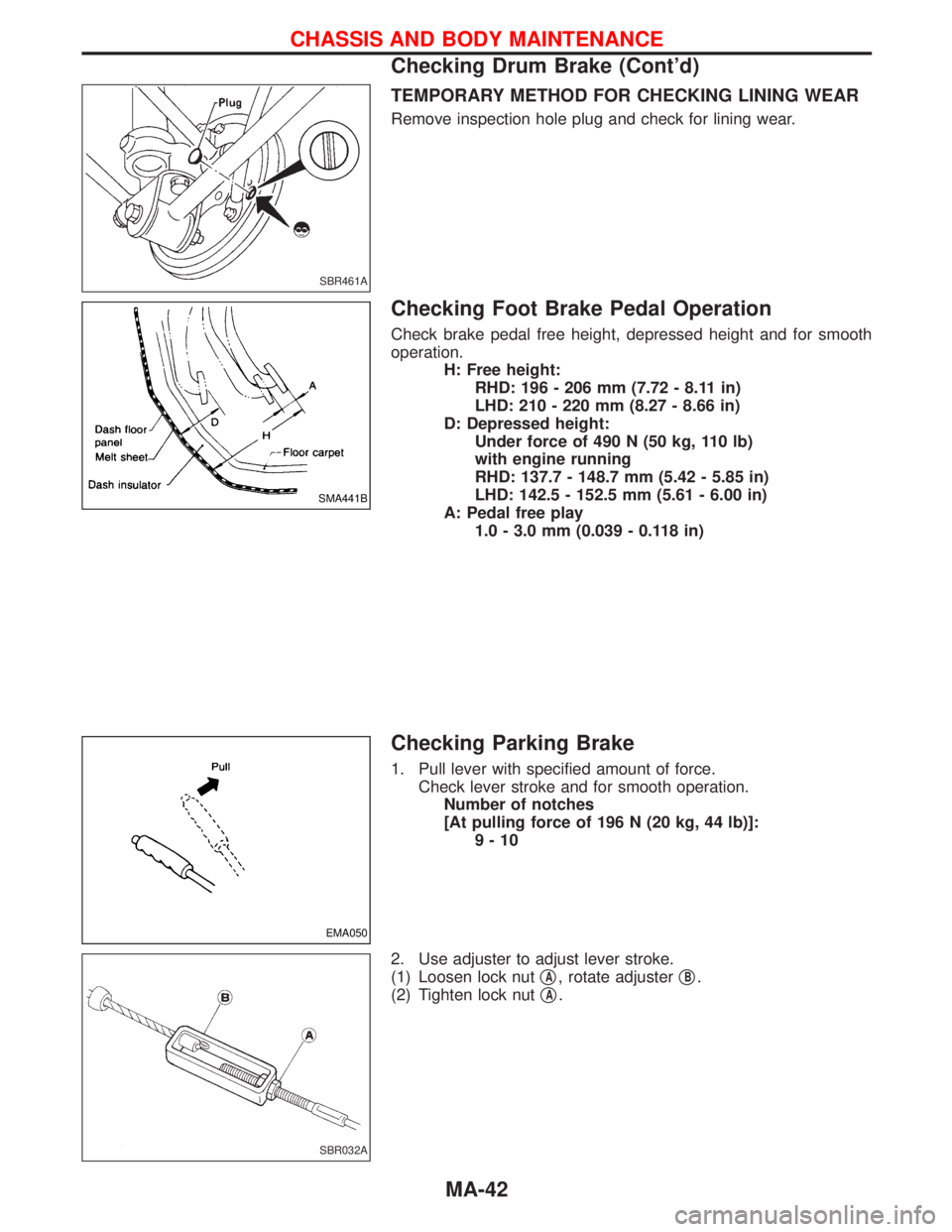

TEMPORARY METHOD FOR CHECKING LINING WEAR

Remove inspection hole plug and check for lining wear.

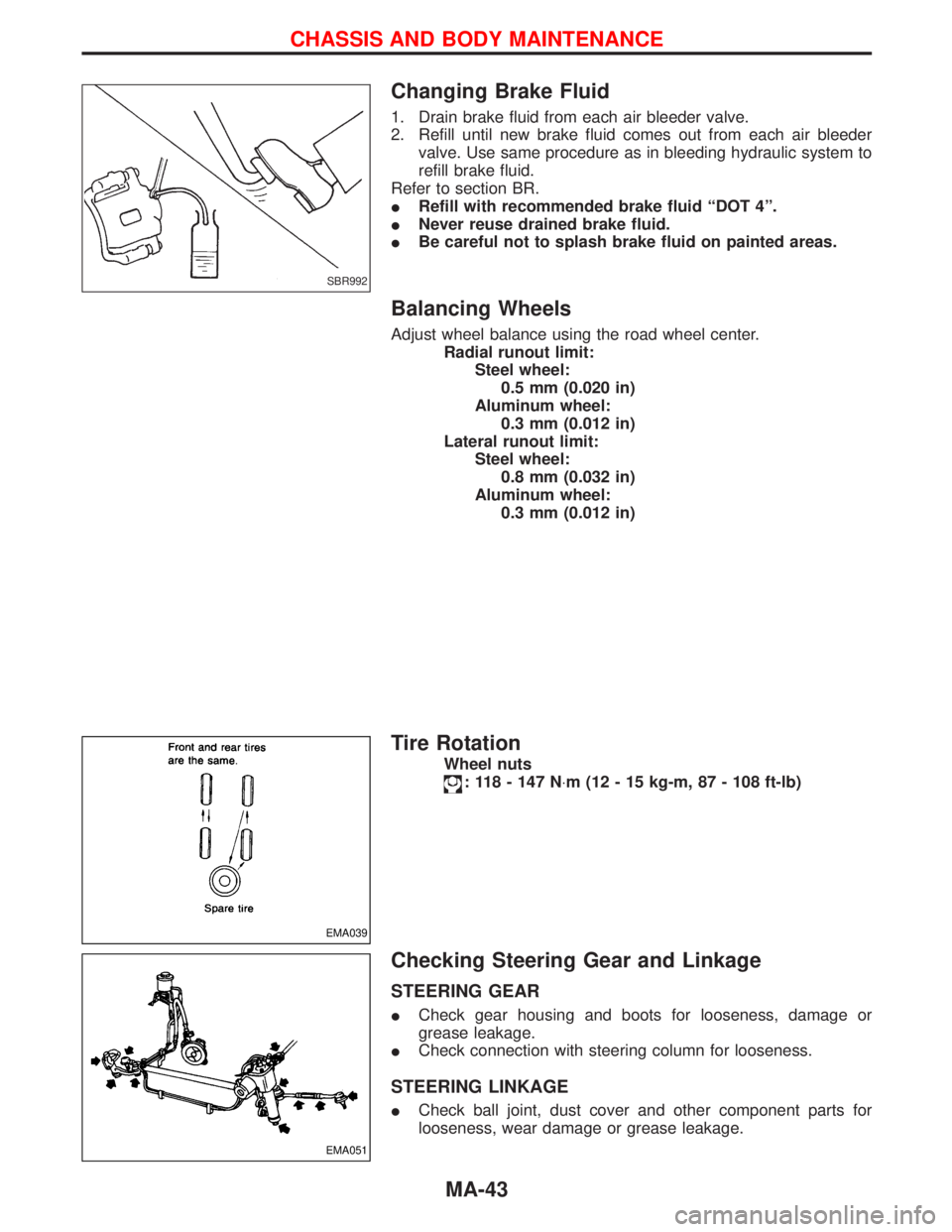

Checking Foot Brake Pedal Operation

Check brake pedal free height, depressed height and for smooth

operation.

H: Free height:

RHD: 196 - 206 mm (7.72 - 8.11 in)

LHD: 210 - 220 mm (8.27 - 8.66 in)

D: Depressed height:

Under force of 490 N (50 kg, 110 lb)

with engine running

RHD: 137.7 - 148.7 mm (5.42 - 5.85 in)

LHD: 142.5 - 152.5 mm (5.61 - 6.00 in)

A: Pedal free play

1.0 - 3.0 mm (0.039 - 0.118 in)

Checking Parking Brake

1. Pull lever with specified amount of force.

Check lever stroke and for smooth operation.

Number of notches

[At pulling force of 196 N (20 kg, 44 lb)]:

9-10

2. Use adjuster to adjust lever stroke.

(1) Loosen lock nutq

A, rotate adjusterqB.

(2) Tighten lock nutq

A.

SBR461A

SMA441B

EMA050

SBR032A

CHASSIS AND BODY MAINTENANCE

Checking Drum Brake (Cont'd)

MA-42

Page 1502 of 1767

Changing Brake Fluid

1. Drain brake fluid from each air bleeder valve.

2. Refill until new brake fluid comes out from each air bleeder

valve. Use same procedure as in bleeding hydraulic system to

refill brake fluid.

Refer to section BR.

IRefill with recommended brake fluid ªDOT 4º.

INever reuse drained brake fluid.

IBe careful not to splash brake fluid on painted areas.

Balancing Wheels

Adjust wheel balance using the road wheel center.

Radial runout limit:

Steel wheel:

0.5 mm (0.020 in)

Aluminum wheel:

0.3 mm (0.012 in)

Lateral runout limit:

Steel wheel:

0.8 mm (0.032 in)

Aluminum wheel:

0.3 mm (0.012 in)

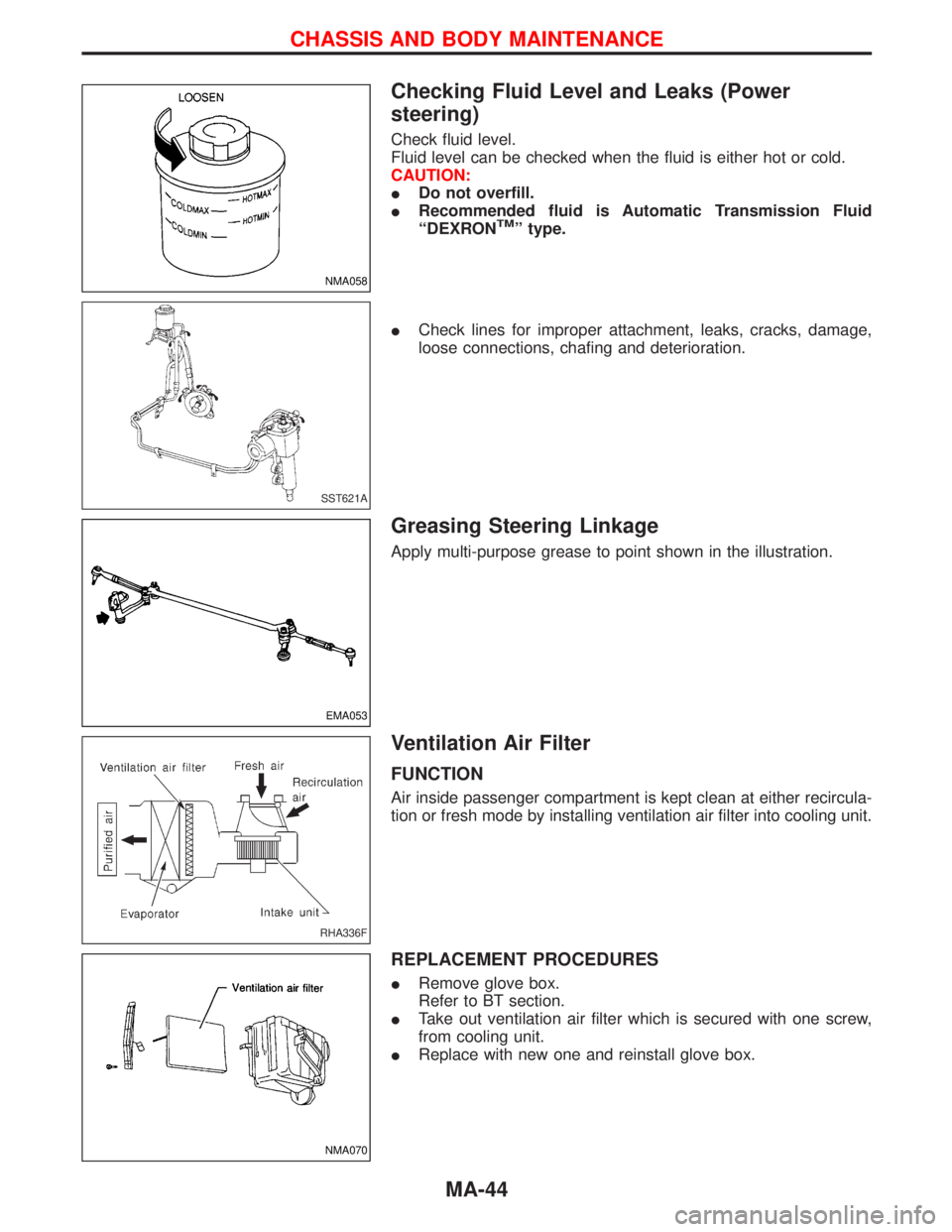

Tire Rotation

Wheel nuts

: 118 - 147 N×m (12 - 15 kg-m, 87 - 108 ft-lb)

Checking Steering Gear and Linkage

STEERING GEAR

ICheck gear housing and boots for looseness, damage or

grease leakage.

ICheck connection with steering column for looseness.

STEERING LINKAGE

ICheck ball joint, dust cover and other component parts for

looseness, wear damage or grease leakage.

SBR992

EMA039

EMA051

CHASSIS AND BODY MAINTENANCE

MA-43

Page 1503 of 1767

Checking Fluid Level and Leaks (Power

steering)

Check fluid level.

Fluid level can be checked when the fluid is either hot or cold.

CAUTION:

IDo not overfill.

IRecommended fluid is Automatic Transmission Fluid

ªDEXRON

TMº type.

ICheck lines for improper attachment, leaks, cracks, damage,

loose connections, chafing and deterioration.

Greasing Steering Linkage

Apply multi-purpose grease to point shown in the illustration.

Ventilation Air Filter

FUNCTION

Air inside passenger compartment is kept clean at either recircula-

tion or fresh mode by installing ventilation air filter into cooling unit.

REPLACEMENT PROCEDURES

IRemove glove box.

Refer to BT section.

ITake out ventilation air filter which is secured with one screw,

from cooling unit.

IReplace with new one and reinstall glove box.

NMA058

SST621A

EMA053

RHA336F

NMA070

CHASSIS AND BODY MAINTENANCE

MA-44

Page 1504 of 1767

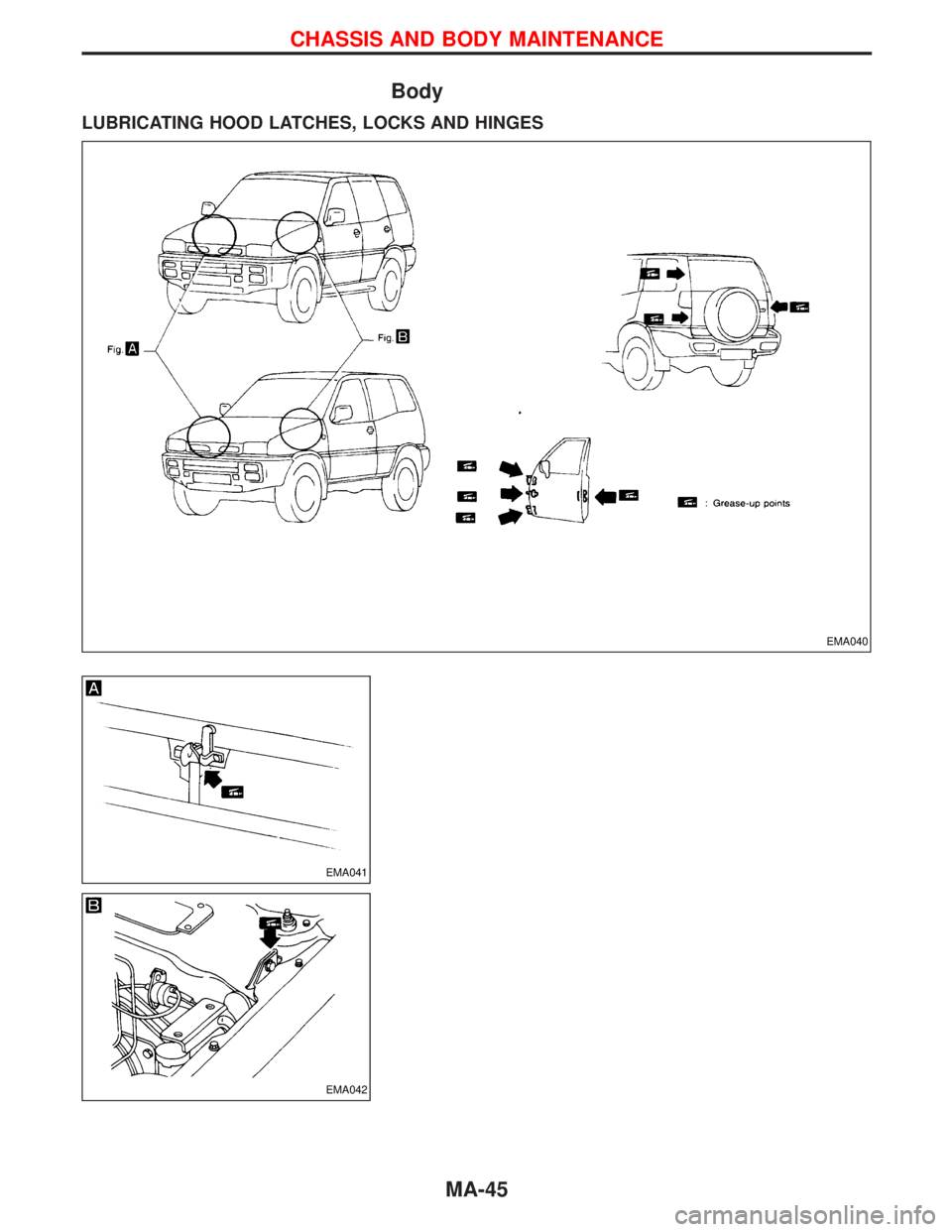

Body

LUBRICATING HOOD LATCHES, LOCKS AND HINGES

EMA040

EMA041

EMA042

CHASSIS AND BODY MAINTENANCE

MA-45

Page 1505 of 1767

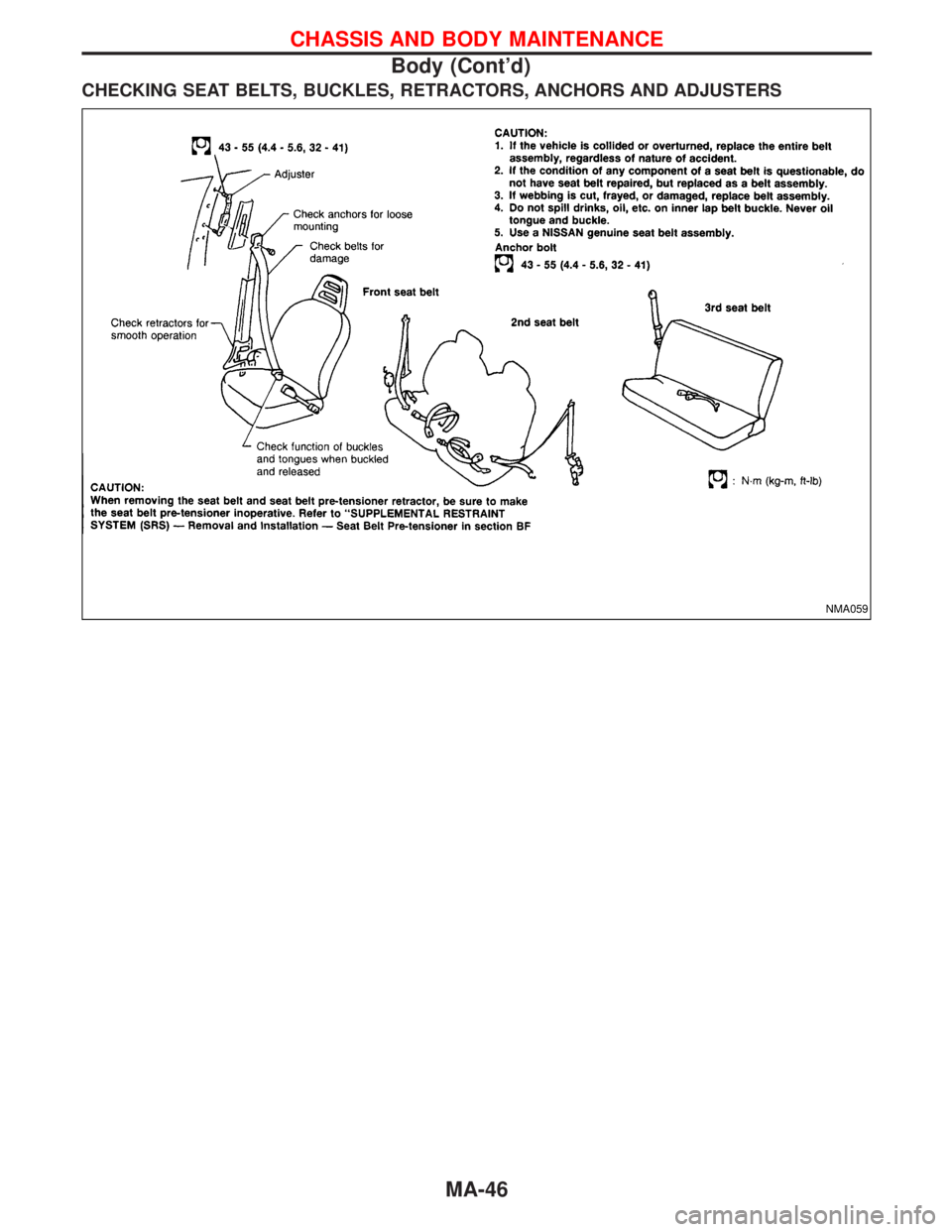

CHECKING SEAT BELTS, BUCKLES, RETRACTORS, ANCHORS AND ADJUSTERS

NMA059

CHASSIS AND BODY MAINTENANCE

Body (Cont'd)

MA-46

Page 1506 of 1767

Checking Body Corrosion

Visually check the body sheet metal panel for corrosion, paint damage (scratches, chipping, rubbing, etc.) or

damage to the anti-corrosion materials. In particular, check the following locations.

Hemmed portion

Hood front end, door lower end, trunk lid rear end, etc.

Panel joint

Side sill of rear fender and center pillar, rear wheel housing of rear fender, around strut lower in engine

compartment, etc.

Panel edge

Trunk lid opening, sun roof opening, fender wheel-arch flange, fuel filler lid flange, around holes in panel, etc.

Parts contact

Waist moulding, windshield moulding, bumper, etc.

Protectors

Damage or condition of mudguard, fender protector, chipping protector, etc.

Anti-corrosion materials

Damage or separation of anti-corrosion materials under the body.

Drain holes

Condition of drain holes at door and side sill.

When repairing corroded areas, refer to the Corrosion Repair Manual.

CHASSIS AND BODY MAINTENANCE

MA-47

Page 1507 of 1767

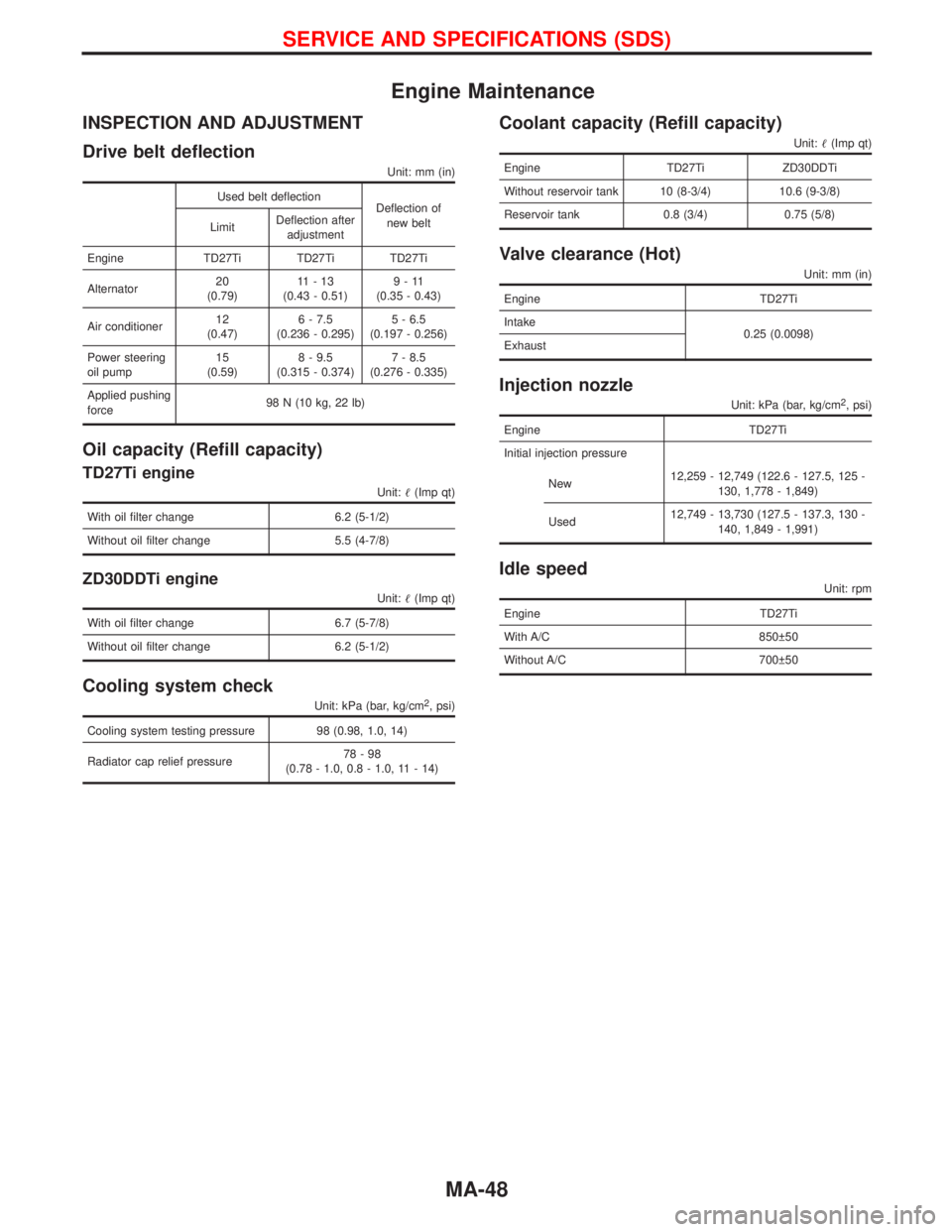

Engine Maintenance

INSPECTION AND ADJUSTMENT

Drive belt deflection

Unit: mm (in)

Used belt deflection

Deflection of

new belt

LimitDeflection after

adjustment

Engine TD27Ti TD27Ti TD27Ti

Alternator20

(0.79)11-13

(0.43 - 0.51)9-11

(0.35 - 0.43)

Air conditioner12

(0.47)6 - 7.5

(0.236 - 0.295)5 - 6.5

(0.197 - 0.256)

Power steering

oil pump15

(0.59)8 - 9.5

(0.315 - 0.374)7 - 8.5

(0.276 - 0.335)

Applied pushing

force98 N (10 kg, 22 lb)

Oil capacity (Refill capacity)

TD27Ti engine

Unit:(Imp qt)

With oil filter change 6.2 (5-1/2)

Without oil filter change 5.5 (4-7/8)

ZD30DDTi engine

Unit:(Imp qt)

With oil filter change 6.7 (5-7/8)

Without oil filter change 6.2 (5-1/2)

Cooling system check

Unit: kPa (bar, kg/cm2, psi)

Cooling system testing pressure 98 (0.98, 1.0, 14)

Radiator cap relief pressure78-98

(0.78 - 1.0, 0.8 - 1.0, 11 - 14)

Coolant capacity (Refill capacity)

Unit:(Imp qt)

Engine TD27Ti ZD30DDTi

Without reservoir tank 10 (8-3/4) 10.6 (9-3/8)

Reservoir tank 0.8 (3/4) 0.75 (5/8)

Valve clearance (Hot)

Unit: mm (in)

Engine TD27Ti

Intake

0.25 (0.0098)

Exhaust

Injection nozzle

Unit: kPa (bar, kg/cm2, psi)

Engine TD27Ti

Initial injection pressure

New12,259 - 12,749 (122.6 - 127.5, 125 -

130, 1,778 - 1,849)

Used12,749 - 13,730 (127.5 - 137.3, 130 -

140, 1,849 - 1,991)

Idle speed

Unit: rpm

Engine TD27Ti

With A/C 850 50

Without A/C 700 50

SERVICE AND SPECIFICATIONS (SDS)

MA-48

Page 1508 of 1767

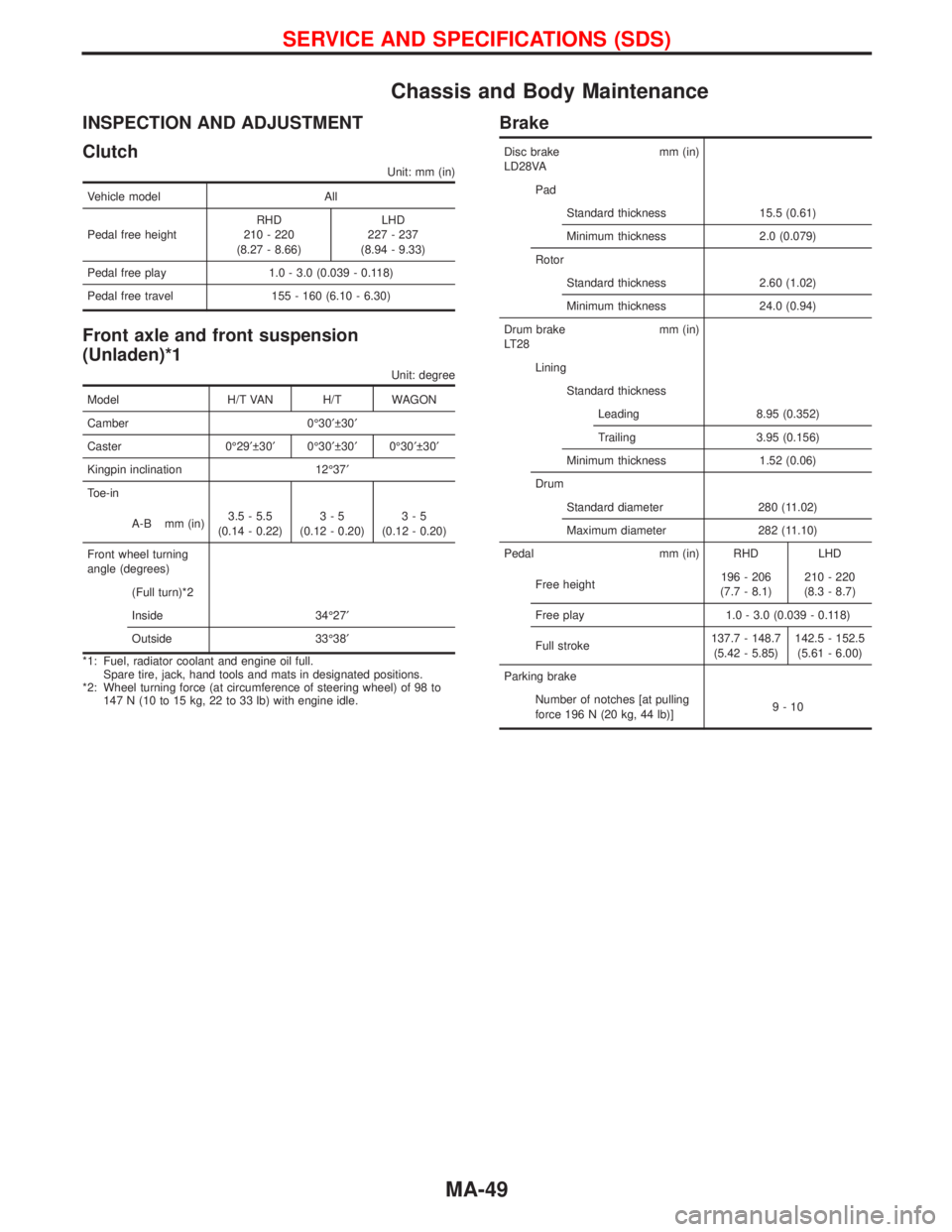

Chassis and Body Maintenance

INSPECTION AND ADJUSTMENT

Clutch

Unit: mm (in)

Vehicle model All

Pedal free heightRHD

210 - 220

(8.27 - 8.66)LHD

227 - 237

(8.94 - 9.33)

Pedal free play 1.0 - 3.0 (0.039 - 0.118)

Pedal free travel 155 - 160 (6.10 - 6.30)

Front axle and front suspension

(Unladen)*1

Unit: degree

Model H/T VAN H/T WAGON

Camber 0É30¢ 30¢

Caster 0É29¢ 30¢0É30¢ 30¢0É30¢ 30¢

Kingpin inclination 12É37¢

Toe-in

A-B mm (in)3.5 - 5.5

(0.14 - 0.22)3-5

(0.12 - 0.20)3-5

(0.12 - 0.20)

Front wheel turning

angle (degrees)

(Full turn)*2

Inside 34É27¢

Outside 33É38¢

*1: Fuel, radiator coolant and engine oil full.

Spare tire, jack, hand tools and mats in designated positions.

*2: Wheel turning force (at circumference of steering wheel) of 98 to

147 N (10 to 15 kg, 22 to 33 lb) with engine idle.

Brake

Disc brake mm (in)

LD28VA

Pad

Standard thickness 15.5 (0.61)

Minimum thickness 2.0 (0.079)

Rotor

Standard thickness 2.60 (1.02)

Minimum thickness 24.0 (0.94)

Drum brake mm (in)

LT28

Lining

Standard thickness

Leading 8.95 (0.352)

Trailing 3.95 (0.156)

Minimum thickness 1.52 (0.06)

Drum

Standard diameter 280 (11.02)

Maximum diameter 282 (11.10)

Pedal mm (in) RHD LHD

Free height196 - 206

(7.7 - 8.1)210 - 220

(8.3 - 8.7)

Free play 1.0 - 3.0 (0.039 - 0.118)

Full stroke137.7 - 148.7

(5.42 - 5.85)142.5 - 152.5

(5.61 - 6.00)

Parking brake

Number of notches [at pulling

force 196 N (20 kg, 44 lb)]9-10

SERVICE AND SPECIFICATIONS (SDS)

MA-49

Page 1509 of 1767

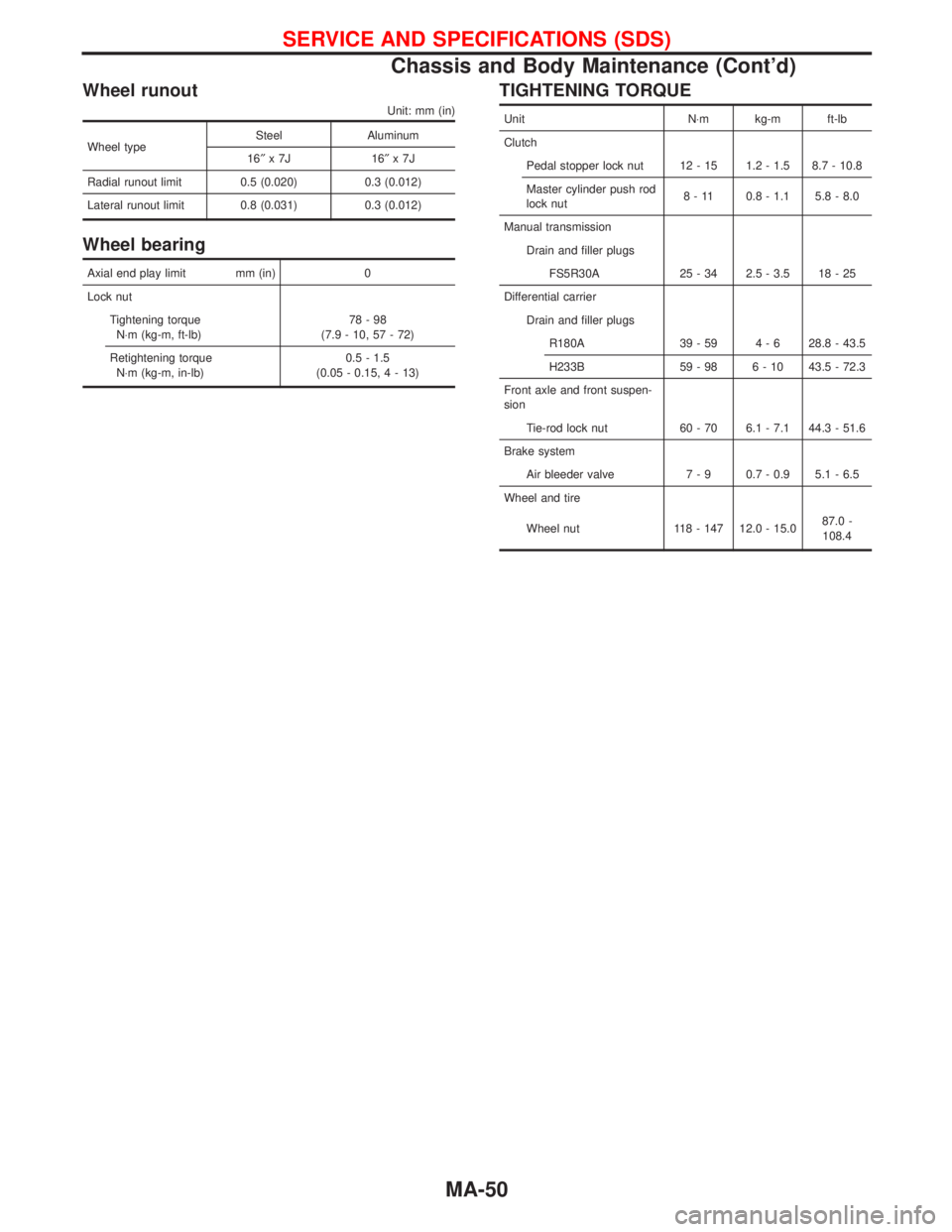

Wheel runout

Unit: mm (in)

Wheel typeSteel Aluminum

16²x7J 16²x7J

Radial runout limit 0.5 (0.020) 0.3 (0.012)

Lateral runout limit 0.8 (0.031) 0.3 (0.012)

Wheel bearing

Axial end play limit mm (in) 0

Lock nut

Tightening torque

N×m (kg-m, ft-lb)78-98

(7.9 - 10, 57 - 72)

Retightening torque

N×m (kg-m, in-lb)0.5 - 1.5

(0.05 - 0.15,4-13)

TIGHTENING TORQUE

Unit N×m kg-m ft-lb

Clutch

Pedal stopper lock nut 12 - 15 1.2 - 1.5 8.7 - 10.8

Master cylinder push rod

lock nut8 - 11 0.8 - 1.1 5.8 - 8.0

Manual transmission

Drain and filler plugs

FS5R30A 25 - 34 2.5 - 3.5 18 - 25

Differential carrier

Drain and filler plugs

R180A 39 - 59 4 - 6 28.8 - 43.5

H233B 59 - 98 6 - 10 43.5 - 72.3

Front axle and front suspen-

sion

Tie-rod lock nut 60 - 70 6.1 - 7.1 44.3 - 51.6

Brake system

Air bleeder valve 7 - 9 0.7 - 0.9 5.1 - 6.5

Wheel and tire

Wheel nut 118 - 147 12.0 - 15.087.0 -

108.4

SERVICE AND SPECIFICATIONS (SDS)

Chassis and Body Maintenance (Cont'd)

MA-50

Page 1510 of 1767

MANUAL TRANSMISSION

SECTION

MT

CONTENTS

PREPARATION................................................................2

Special Service Tools ..................................................2

Commercial Service Tools ...........................................4

TRANSMISSION FS5R30A.............................................5

Replacing the Rear Oil Seal ........................................5

FS5R30A

ON-VEHICLE SERVICE..................................................6

Check of Position Switches .........................................6

REMOVAL AND INSTALLATION....................................7

Removal .......................................................................7

Installation ....................................................................8

MAJOR OVERHAUL.....................................................10

Case Components .....................................................10

Gear Components ..................................................... 11

Shift Control Components .........................................13DISASSEMBLY..............................................................14

Case Components .....................................................14

Shift Control Components .........................................15

Gear Components .....................................................16

INSPECTION..................................................................21

Shift Control Components .........................................21

Gear Components .....................................................21

ASSEMBLY....................................................................23

Gear Components .....................................................23

Shift Control Components .........................................31

Case Components .....................................................32

SERVICE DATA AND SPECIFICATIONS (SDS)..........34

General Specifications ...............................................34

Inspection and Adjustment ........................................35