Start NISSAN TERRANO 2002 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 1173 of 1767

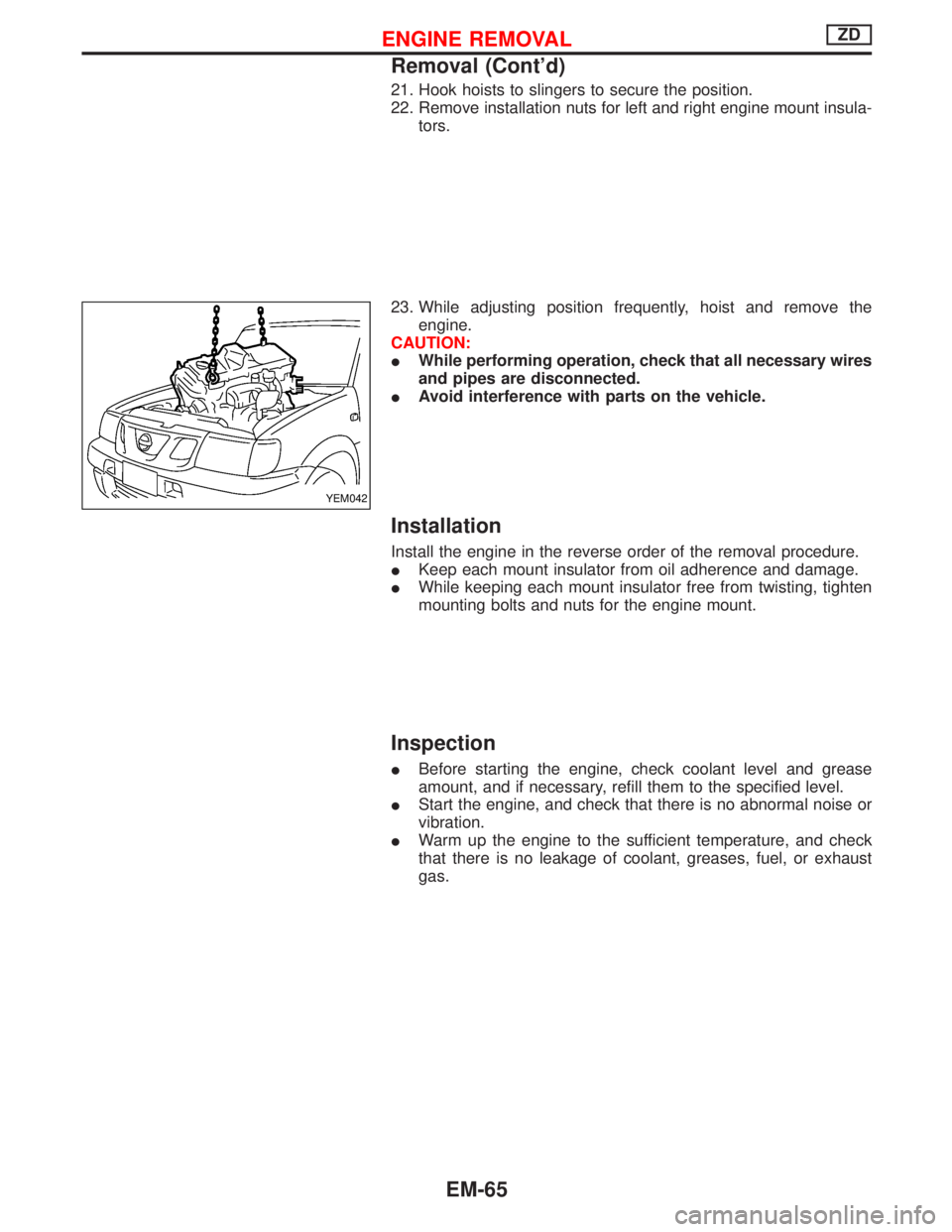

21. Hook hoists to slingers to secure the position.

22. Remove installation nuts for left and right engine mount insula-

tors.

23. While adjusting position frequently, hoist and remove the

engine.

CAUTION:

IWhile performing operation, check that all necessary wires

and pipes are disconnected.

IAvoid interference with parts on the vehicle.

Installation

Install the engine in the reverse order of the removal procedure.

IKeep each mount insulator from oil adherence and damage.

IWhile keeping each mount insulator free from twisting, tighten

mounting bolts and nuts for the engine mount.

Inspection

IBefore starting the engine, check coolant level and grease

amount, and if necessary, refill them to the specified level.

IStart the engine, and check that there is no abnormal noise or

vibration.

IWarm up the engine to the sufficient temperature, and check

that there is no leakage of coolant, greases, fuel, or exhaust

gas.

YEM042

ENGINE REMOVALZD

Removal (Cont'd)

EM-65

Page 1247 of 1767

(2) Apply engine oil to crankshaft journal and pin and install crank-

shaft.

(3) Install main bearings caps.

a) Install main bearing cap with the lowest number facing the front

of vehicle.

b) Apply engine oil to main bearing cap and cylinder block contact

surfaces.

c) Install rear oil seal assembly. Apply engine oil to contact surface

of rear end oil seal and crankshaft.

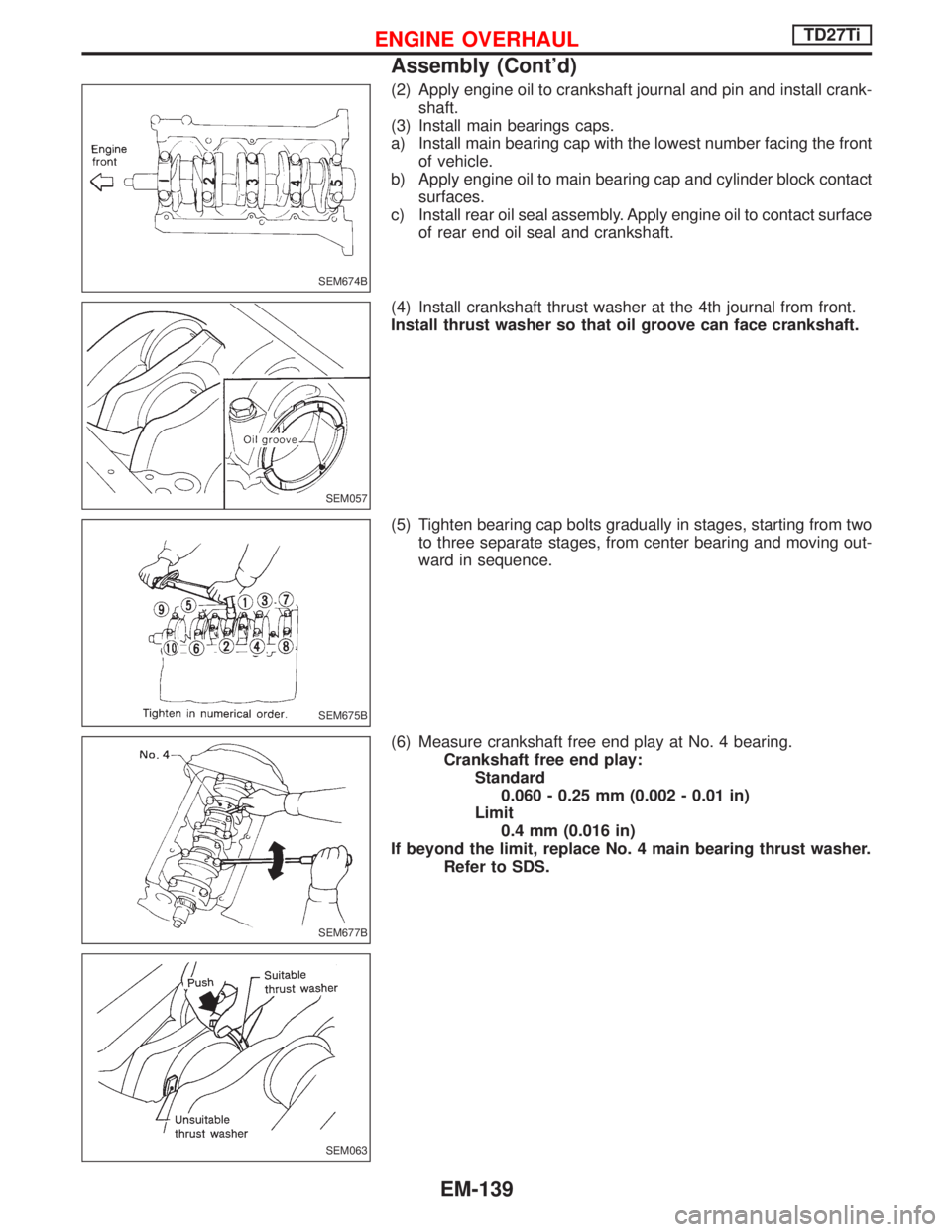

(4) Install crankshaft thrust washer at the 4th journal from front.

Install thrust washer so that oil groove can face crankshaft.

(5) Tighten bearing cap bolts gradually in stages, starting from two

to three separate stages, from center bearing and moving out-

ward in sequence.

(6) Measure crankshaft free end play at No. 4 bearing.

Crankshaft free end play:

Standard

0.060 - 0.25 mm (0.002 - 0.01 in)

Limit

0.4 mm (0.016 in)

If beyond the limit, replace No. 4 main bearing thrust washer.

Refer to SDS.

SEM674B

SEM057

SEM675B

SEM677B

SEM063

ENGINE OVERHAULTD27Ti

Assembly (Cont'd)

EM-139

Page 1249 of 1767

TIMING GEAR CASE

Installation

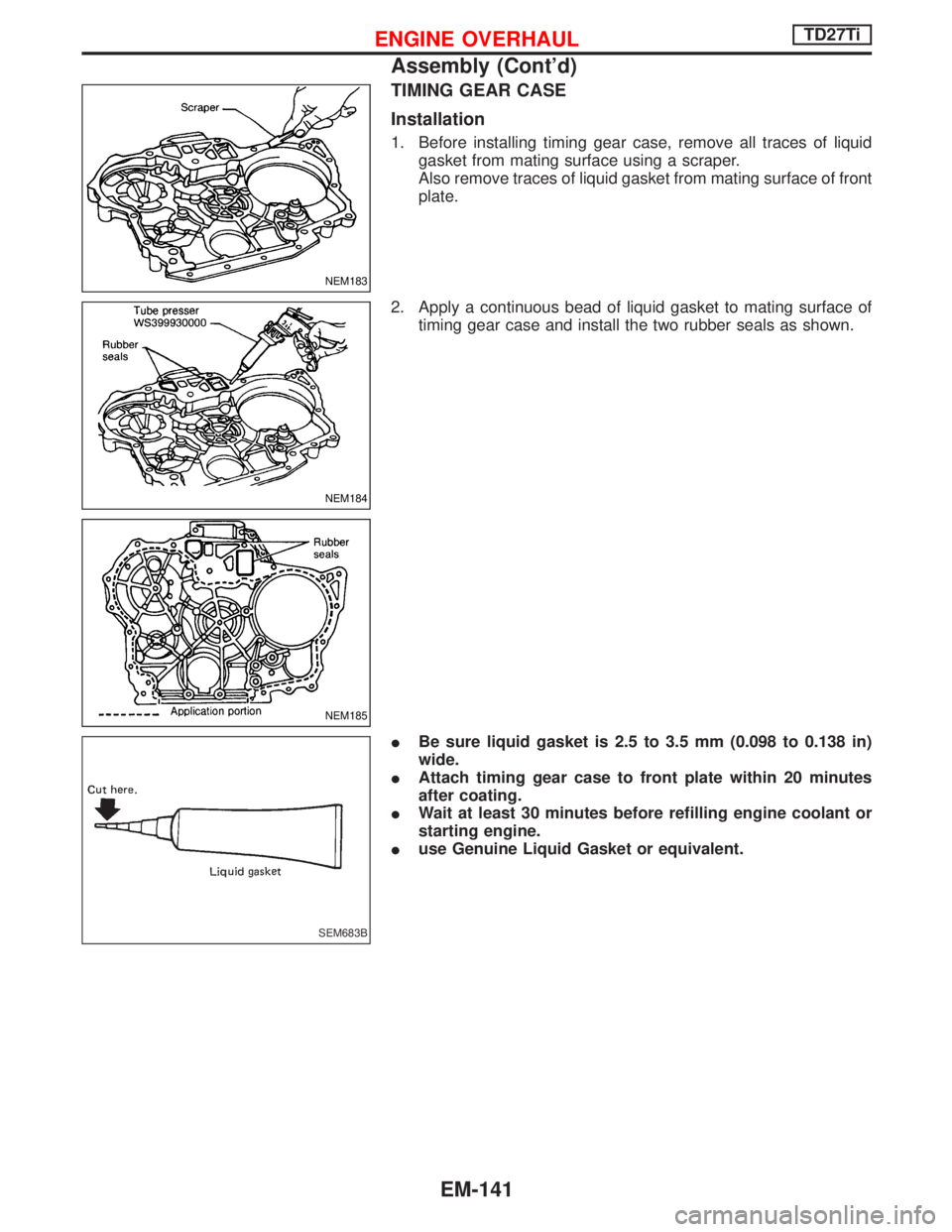

1. Before installing timing gear case, remove all traces of liquid

gasket from mating surface using a scraper.

Also remove traces of liquid gasket from mating surface of front

plate.

2. Apply a continuous bead of liquid gasket to mating surface of

timing gear case and install the two rubber seals as shown.

IBe sure liquid gasket is 2.5 to 3.5 mm (0.098 to 0.138 in)

wide.

IAttach timing gear case to front plate within 20 minutes

after coating.

IWait at least 30 minutes before refilling engine coolant or

starting engine.

Iuse Genuine Liquid Gasket or equivalent.

NEM183

NEM184

NEM185

SEM683B

ENGINE OVERHAULTD27Ti

Assembly (Cont'd)

EM-141

Page 1265 of 1767

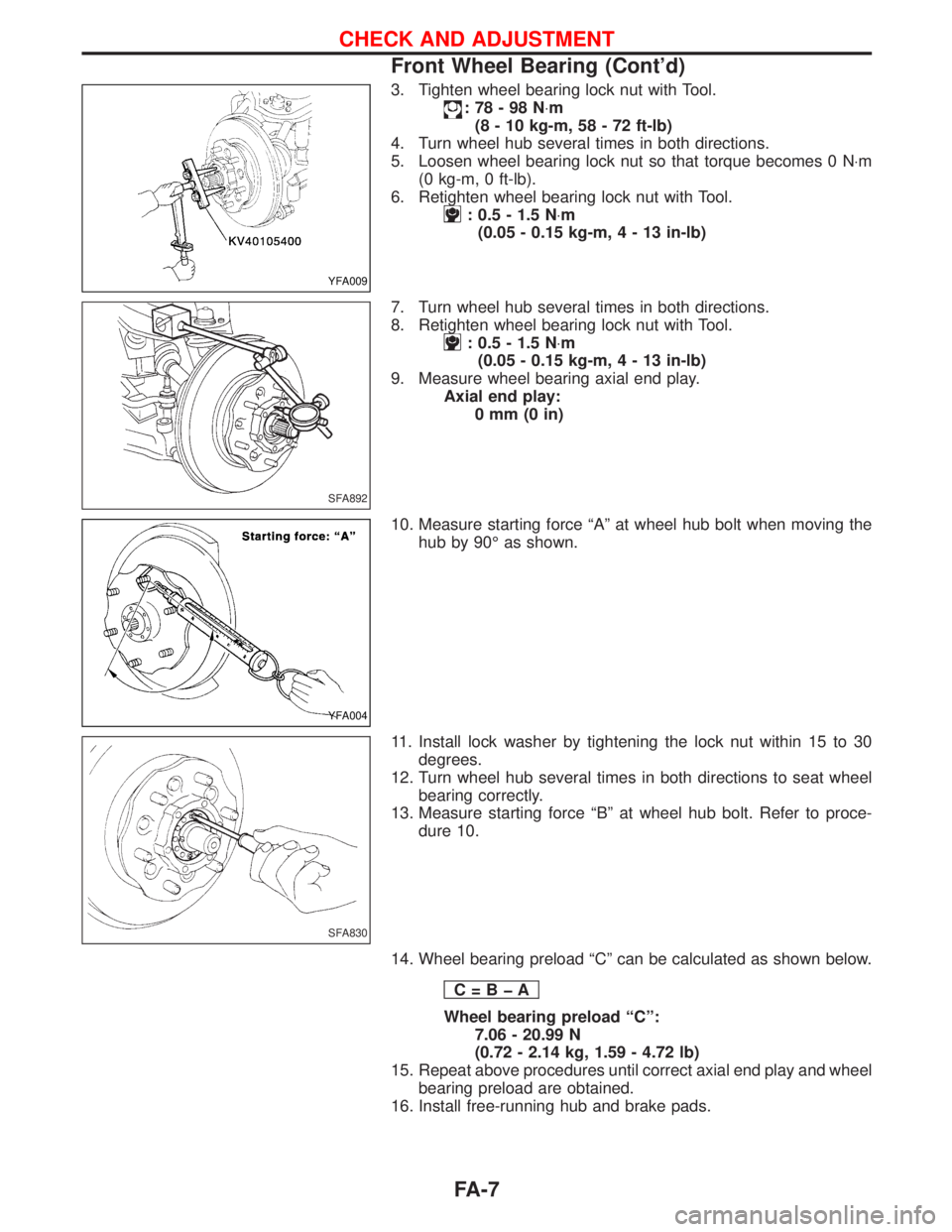

3. Tighten wheel bearing lock nut with Tool.

:78-98N×m

(8 - 10 kg-m, 58 - 72 ft-lb)

4. Turn wheel hub several times in both directions.

5. Loosen wheel bearing lock nut so that torque becomes 0 N×m

(0 kg-m, 0 ft-lb).

6. Retighten wheel bearing lock nut with Tool.

: 0.5 - 1.5 N×m

(0.05 - 0.15 kg-m,4-13in-lb)

7. Turn wheel hub several times in both directions.

8. Retighten wheel bearing lock nut with Tool.

: 0.5 - 1.5 N×m

(0.05 - 0.15 kg-m,4-13in-lb)

9. Measure wheel bearing axial end play.

Axial end play:

0mm(0in)

10. Measure starting force ªAº at wheel hub bolt when moving the

hub by 90É as shown.

11. Install lock washer by tightening the lock nut within 15 to 30

degrees.

12. Turn wheel hub several times in both directions to seat wheel

bearing correctly.

13. Measure starting force ªBº at wheel hub bolt. Refer to proce-

dure 10.

14. Wheel bearing preload ªCº can be calculated as shown below.

C=BþA

Wheel bearing preload ªCº:

7.06 - 20.99 N

(0.72 - 2.14 kg, 1.59 - 4.72 lb)

15. Repeat above procedures until correct axial end play and wheel

bearing preload are obtained.

16. Install free-running hub and brake pads.

YFA009

SFA892

YFA004

SFA830

CHECK AND ADJUSTMENT

Front Wheel Bearing (Cont'd)

FA-7

Page 1274 of 1767

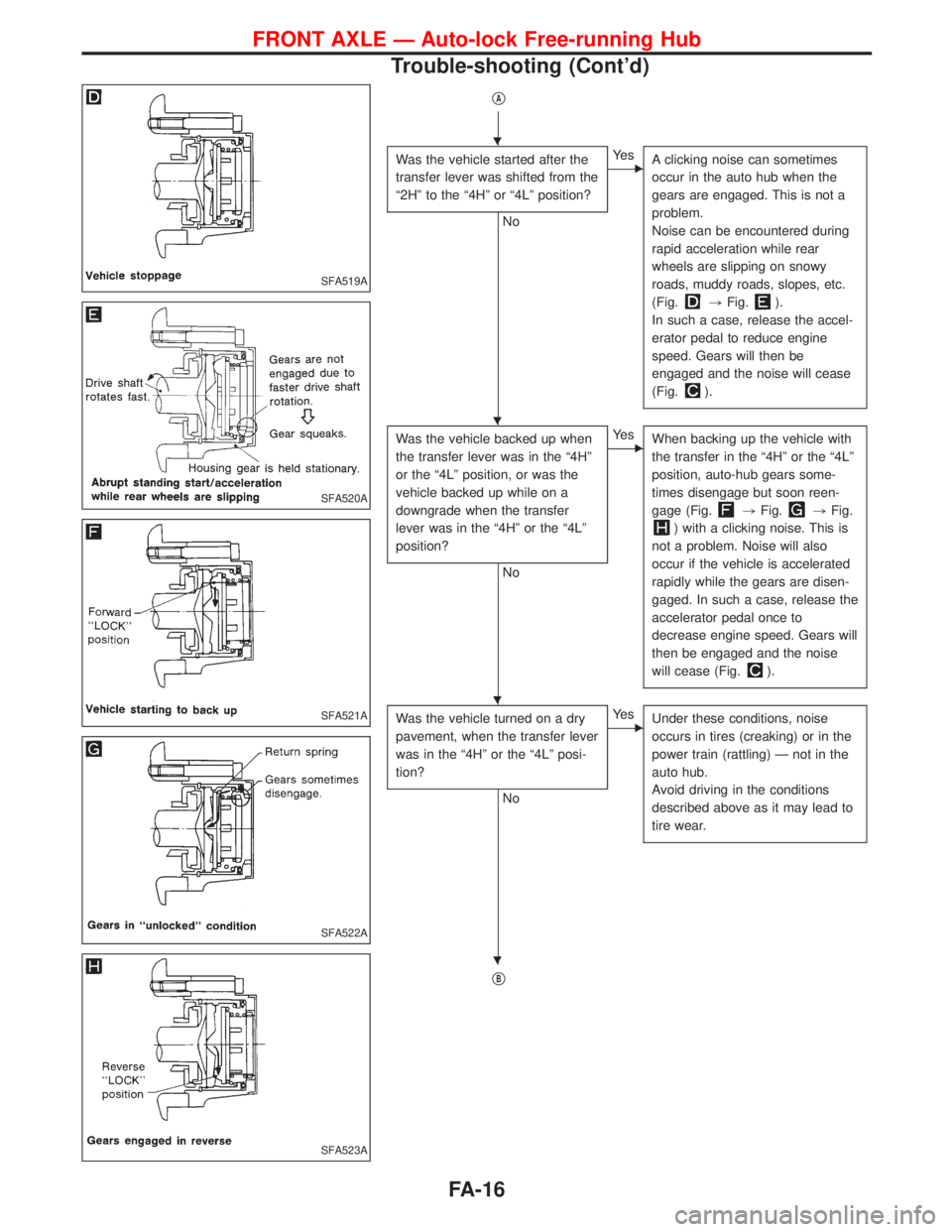

qA

Was the vehicle started after the

transfer lever was shifted from the

ª2Hº to the ª4Hº or ª4Lº position?

No

EYe s

A clicking noise can sometimes

occur in the auto hub when the

gears are engaged. This is not a

problem.

Noise can be encountered during

rapid acceleration while rear

wheels are slipping on snowy

roads, muddy roads, slopes, etc.

(Fig.

,Fig.).

In such a case, release the accel-

erator pedal to reduce engine

speed. Gears will then be

engaged and the noise will cease

(Fig.

).

Was the vehicle backed up when

the transfer lever was in the ª4Hº

or the ª4Lº position, or was the

vehicle backed up while on a

downgrade when the transfer

lever was in the ª4Hº or the ª4Lº

position?

No

EYe s

When backing up the vehicle with

the transfer in the ª4Hº or the ª4Lº

position, auto-hub gears some-

times disengage but soon reen-

gage (Fig.

,Fig.,Fig.

) with a clicking noise. This is

not a problem. Noise will also

occur if the vehicle is accelerated

rapidly while the gears are disen-

gaged. In such a case, release the

accelerator pedal once to

decrease engine speed. Gears will

then be engaged and the noise

will cease (Fig.

).

Was the vehicle turned on a dry

pavement, when the transfer lever

was in the ª4Hº or the ª4Lº posi-

tion?

No

EYe s

Under these conditions, noise

occurs in tires (creaking) or in the

power train (rattling) Ð not in the

auto hub.

Avoid driving in the conditions

described above as it may lead to

tire wear.

qB

SFA519A

SFA520A

SFA521A

SFA522A

SFA523A

H

H

H

H

FRONT AXLE Ð Auto-lock Free-running Hub

Trouble-shooting (Cont'd)

FA-16

Page 1303 of 1767

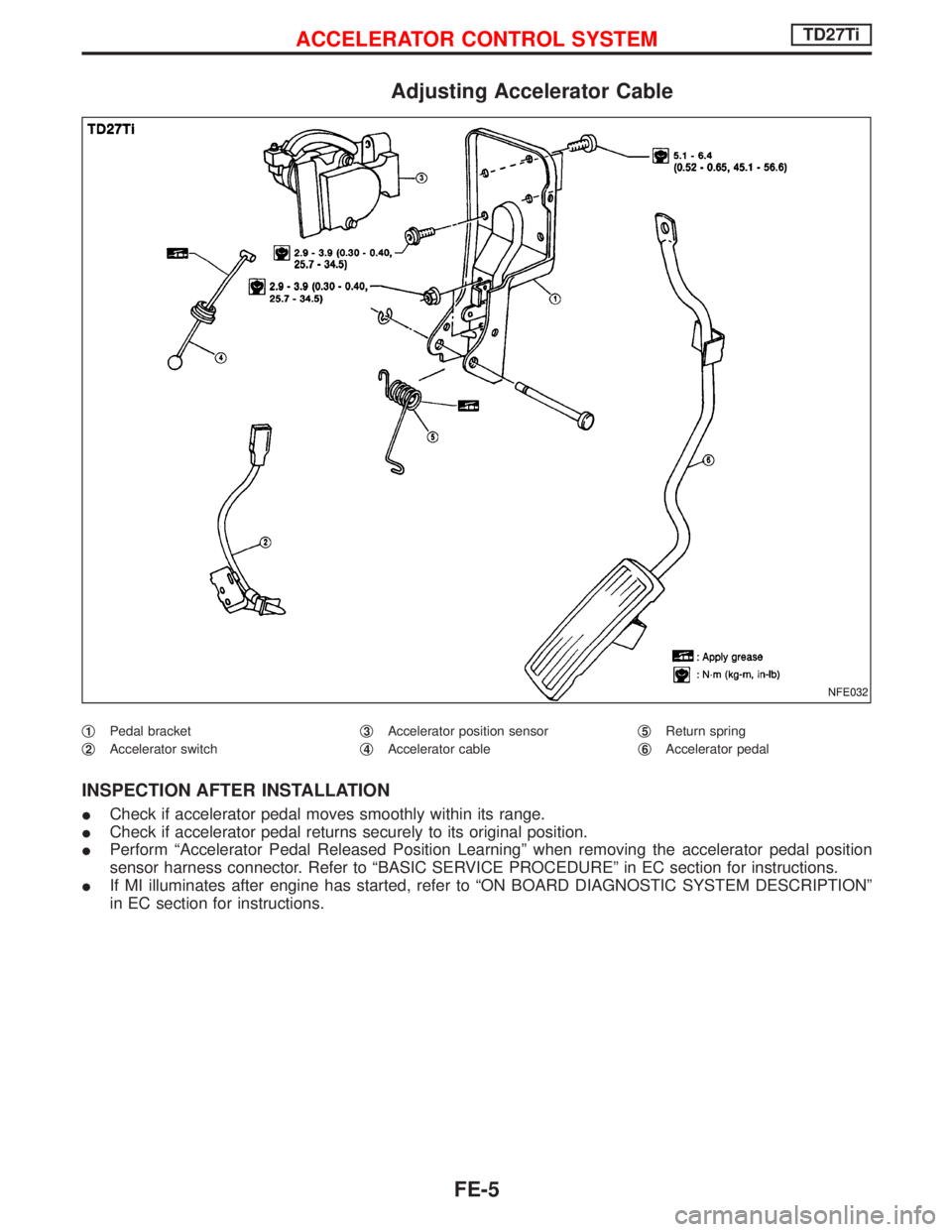

Adjusting Accelerator Cable

q1Pedal bracket

q

2Accelerator switchq

3Accelerator position sensor

q

4Accelerator cableq

5Return spring

q

6Accelerator pedal

INSPECTION AFTER INSTALLATION

ICheck if accelerator pedal moves smoothly within its range.

ICheck if accelerator pedal returns securely to its original position.

IPerform ªAccelerator Pedal Released Position Learningº when removing the accelerator pedal position

sensor harness connector. Refer to ªBASIC SERVICE PROCEDUREº in EC section for instructions.

IIf MI illuminates after engine has started, refer to ªON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONº

in EC section for instructions.

NFE032

ACCELERATOR CONTROL SYSTEMTD27Ti

FE-5

Page 1317 of 1767

Observe the following precautions to ensure safe and proper

servicing. These precautions are not described in each indi-

vidual section.

1. Do not operate the engine for an extended period of time with-

out proper exhaust ventilation.

Keep the work area well ventilated and free of any inflammable

materials. Special care should be taken when handling any

inflammable or poisonous materials, such as gasoline, refriger-

ant gas, etc. When working in a pit or other enclosed area, be

sure to properly ventilate the area before working with hazard-

ous materials.

Do not smoke while working on the vehicle.

2. Before jacking up the vehicle, apply wheel chocks or other tire

blocks to the wheels to prevent the vehicle from moving. After

jacking up the vehicle, support the vehicle weight with safety

stands at the points designated for proper lifting and towing

before working on the vehicle.

These operations should be done on a level surface.

3. When removing a heavy component such as the engine or

transaxle/transmission, take care not to lose your balance and

drop it. Also, do not allow it to strike adjacent parts, especially

the brake tubes and master cylinder.

4. Before starting repairs which do not require battery power,

always turn off the ignition switch, then disconnect the ground

cable from the battery to prevent accidental short circuit.

5. To prevent serious burns, avoid contact with hot metal parts

such as the radiator, exhaust manifold, tail pipe and muffler. Do

not remove the radiator cap when the engine is hot.

SGI285

SGI231

SGI232

SGI233

PRECAUTIONS

GI-2

Page 1319 of 1767

insulation (either just before the harness connectors or for

the complete harness), for easy identification.

Precautions for NATS

NATS (Nissan Anti-Theft System)

NATS will immobilize the engine if someone tries to start it without

the registered key of NATS.

Both of the originally supplied ignition key IDs have been NATS

registered.

The NATS security indicator is located on the instrument panel. The

indicator blinks when the ignition switch is in ªOFFº or ªACCº posi-

tion. Therefore, NATS warns outsiders that the vehicle is equipped

with the anti-theft system.

IWhen NATS detects trouble, the malfunction indicator lamp

(MIL) blinks.

This blinking indicates that the anti-theft is not functioning, so

prompt service is required.

IIf the malfunction indicator lamp comes on while the engine is

running, return the vehicle to the workshop before turning the

ignition switch ªOFFº.

Once the ignition switch is turned ªOFFº, the engine can not be

started.

IWhen servicing NATS (trouble diagnoses, system initialization

and additional registration of other NATS ignition key IDs) CON-

SULT-II hardware and CONSULT-II NATS software is neces-

sary.

Regarding the procedures of NATS initialization and NATS igni-

tion key ID registration, refer to CONSULT-II operation manual,

NATS.

Therefore, CONSULT-II NATS software (program card and

operation manual) must be kept strictly confidential to main-

tain the integrity of the anti-theft function.

IWhen servicing NATS (trouble diagnoses, system initialization

and additional registration of other NATS ignition key IDs), it

may be necessary to re-register original key identification.

Therefore, be sure to receive all keys from vehicle owner.

A maximum of five key IDs can be registered into NATS.

IWhen failing to start the engine first-time using the key of

NATS, starts as follows:

(1) Turn ignition key to ªOFFº.

(2) Wait approx. 5 seconds.

(3) Turn ignition key to ªSTARTº again while keeping the key

apart from any others on key-chain.

SGI916

PRECAUTIONS

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

(Dual Air Bag System) (Cont'd)

GI-4

Page 1320 of 1767

Precautions for Multiport Fuel Injection System

or Engine Control System

1. Before connecting or disconnecting any harness connector for

the multiport fuel injection system or ECM (Engine Control

Module):

Turn ignition switch to ªOFFº position.

Disconnect negative battery terminal.

Otherwise, there may be damage to ECM.

2. Before disconnecting pressurized fuel line from fuel pump to

injectors, be sure to release fuel pressure to eliminate danger.

3. Be careful not to jar components such as control unit and air

flow meter.

Precautions for Catalyst

If a large amount of unburned fuel enters the converter, the con-

verter temperature will rise to excessively high values. To prevent

this, follow the procedure below:

1. Use unleaded gasoline only. Leaded gasoline will seriously

damage the catalytic converter.

2. When checking for ignition spark or measuring engine

compression, perform tests quickly and only when necessary.

3. Do not run engine when the fuel tank level is low, as a result

the engine may misfire causing damage to the converter.

4. Do not place the vehicle on inflammable material. Keep inflam-

mable material off the exhaust pipe.

Precautions for Turbocharger

The turbocharger turbine revolves at extremely high speeds and

becomes very hot. Therefore, it is essential to maintain a clean

supply of oil flowing through the turbocharger and to follow all

required maintenance instructions and operating procedures.

For proper operation of the system, follow the procedure below:

1. Always use the recommended oil. Follow the instructions for

proper time to change the oil and proper oil level.

2. Avoid accelerating engine to a high rpm immediately after start-

ing.

3. If engine had been operating at high rpm for an extended period

of time, let it idle for a few minutes prior to shutting it off.

SGI787

SGI290

SGI292

PRECAUTIONS

GI-5

Page 1338 of 1767

Incident Simulation Tests

INTRODUCTION

Sometimes the symptom is not present when the vehicle is brought in for service. If possible, re-create the

conditions present at the time of the incident. Doing so may help avoid a No Trouble Found Diagnosis. The

following section illustrates ways to simulate the conditions/environment under which the owner experiences

an electrical incident.

The section is broken into the six following topics:

IVehicle vibration

IHeat sensitive

IFreezing

IWater intrusion

IElectrical load

ICold or hot start up

Get a thorough description of the incident from the customer. It is important for simulating the conditions of

the problem.

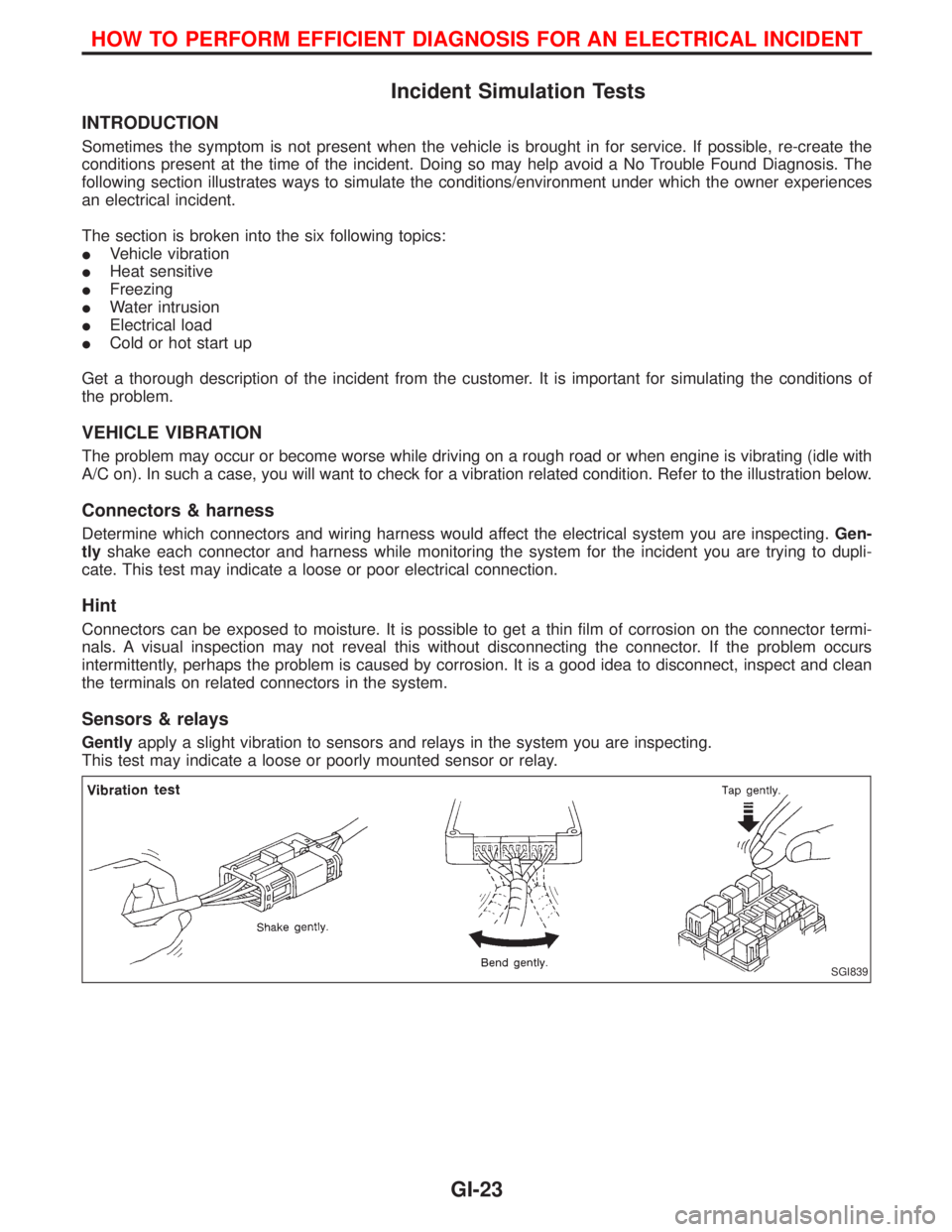

VEHICLE VIBRATION

The problem may occur or become worse while driving on a rough road or when engine is vibrating (idle with

A/C on). In such a case, you will want to check for a vibration related condition. Refer to the illustration below.

Connectors & harness

Determine which connectors and wiring harness would affect the electrical system you are inspecting.Gen-

tlyshake each connector and harness while monitoring the system for the incident you are trying to dupli-

cate. This test may indicate a loose or poor electrical connection.

Hint

Connectors can be exposed to moisture. It is possible to get a thin film of corrosion on the connector termi-

nals. A visual inspection may not reveal this without disconnecting the connector. If the problem occurs

intermittently, perhaps the problem is caused by corrosion. It is a good idea to disconnect, inspect and clean

the terminals on related connectors in the system.

Sensors & relays

Gentlyapply a slight vibration to sensors and relays in the system you are inspecting.

This test may indicate a loose or poorly mounted sensor or relay.

SGI839

HOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENT

GI-23