NISSAN TERRANO 2002 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 781 of 1767

Overall Function Check

Use this procedure to check the overall function of the cooling fan.

During this check, a DTC might not be confirmed.

WARNING:

Never remove the radiator cap when the engine is hot. Serious

burns could be caused by high pressure fluid escaping from

the radiator.

Wrap a thick cloth around the cap. Carefully remove the cap

by turning it a quarter turn to allow built-up pressure to

escape. Then turn the cap all the way off.

WITH CONSULT-II

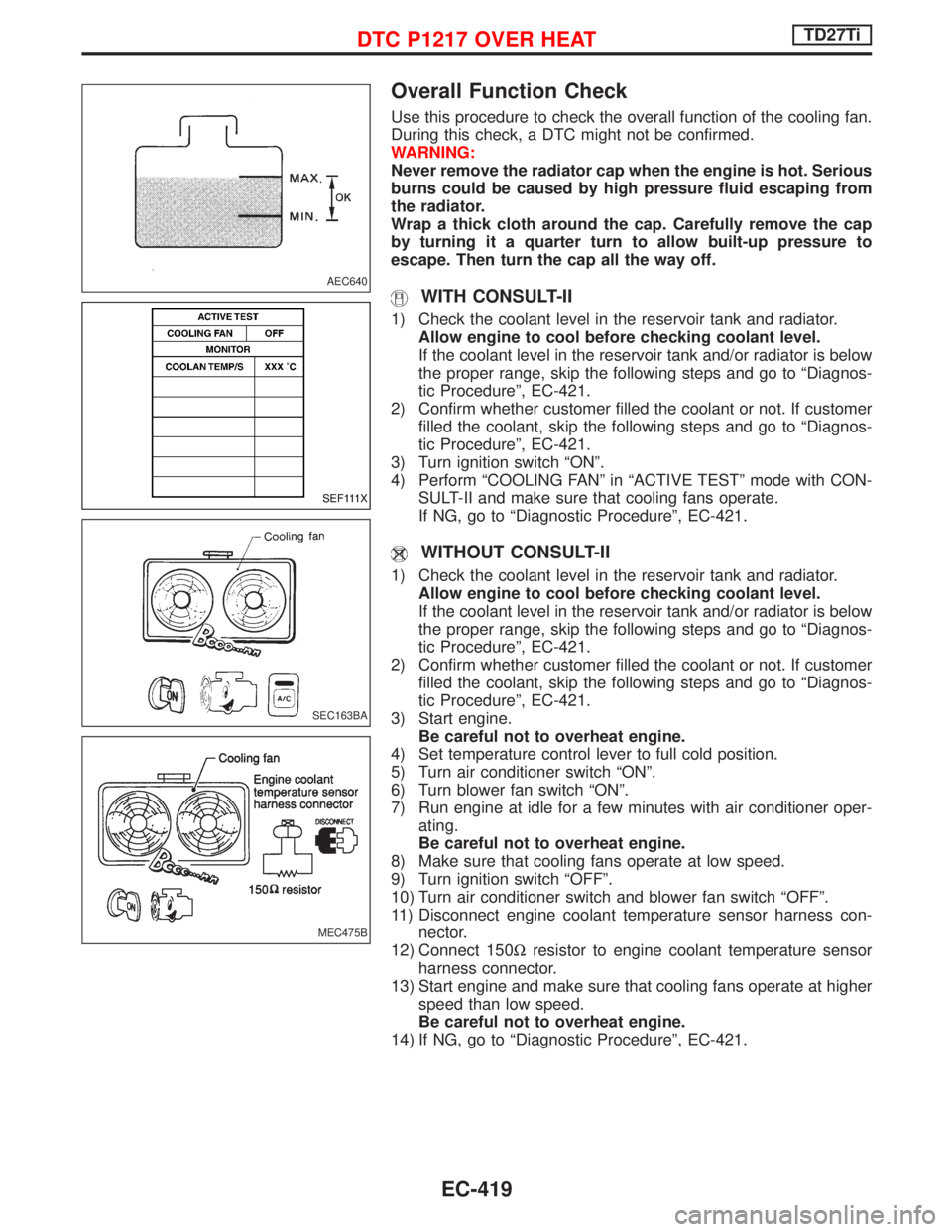

1) Check the coolant level in the reservoir tank and radiator.

Allow engine to cool before checking coolant level.

If the coolant level in the reservoir tank and/or radiator is below

the proper range, skip the following steps and go to ªDiagnos-

tic Procedureº, EC-421.

2) Confirm whether customer filled the coolant or not. If customer

filled the coolant, skip the following steps and go to ªDiagnos-

tic Procedureº, EC-421.

3) Turn ignition switch ªONº.

4) Perform ªCOOLING FANº in ªACTIVE TESTº mode with CON-

SULT-II and make sure that cooling fans operate.

If NG, go to ªDiagnostic Procedureº, EC-421.

WITHOUT CONSULT-II

1) Check the coolant level in the reservoir tank and radiator.

Allow engine to cool before checking coolant level.

If the coolant level in the reservoir tank and/or radiator is below

the proper range, skip the following steps and go to ªDiagnos-

tic Procedureº, EC-421.

2) Confirm whether customer filled the coolant or not. If customer

filled the coolant, skip the following steps and go to ªDiagnos-

tic Procedureº, EC-421.

3) Start engine.

Be careful not to overheat engine.

4) Set temperature control lever to full cold position.

5) Turn air conditioner switch ªONº.

6) Turn blower fan switch ªONº.

7) Run engine at idle for a few minutes with air conditioner oper-

ating.

Be careful not to overheat engine.

8) Make sure that cooling fans operate at low speed.

9) Turn ignition switch ªOFFº.

10) Turn air conditioner switch and blower fan switch ªOFFº.

11) Disconnect engine coolant temperature sensor harness con-

nector.

12) Connect 150Wresistor to engine coolant temperature sensor

harness connector.

13) Start engine and make sure that cooling fans operate at higher

speed than low speed.

Be careful not to overheat engine.

14) If NG, go to ªDiagnostic Procedureº, EC-421.

AEC640

SEF111X

SEC163BA

MEC475B

DTC P1217 OVER HEATTD27Ti

EC-419

Page 782 of 1767

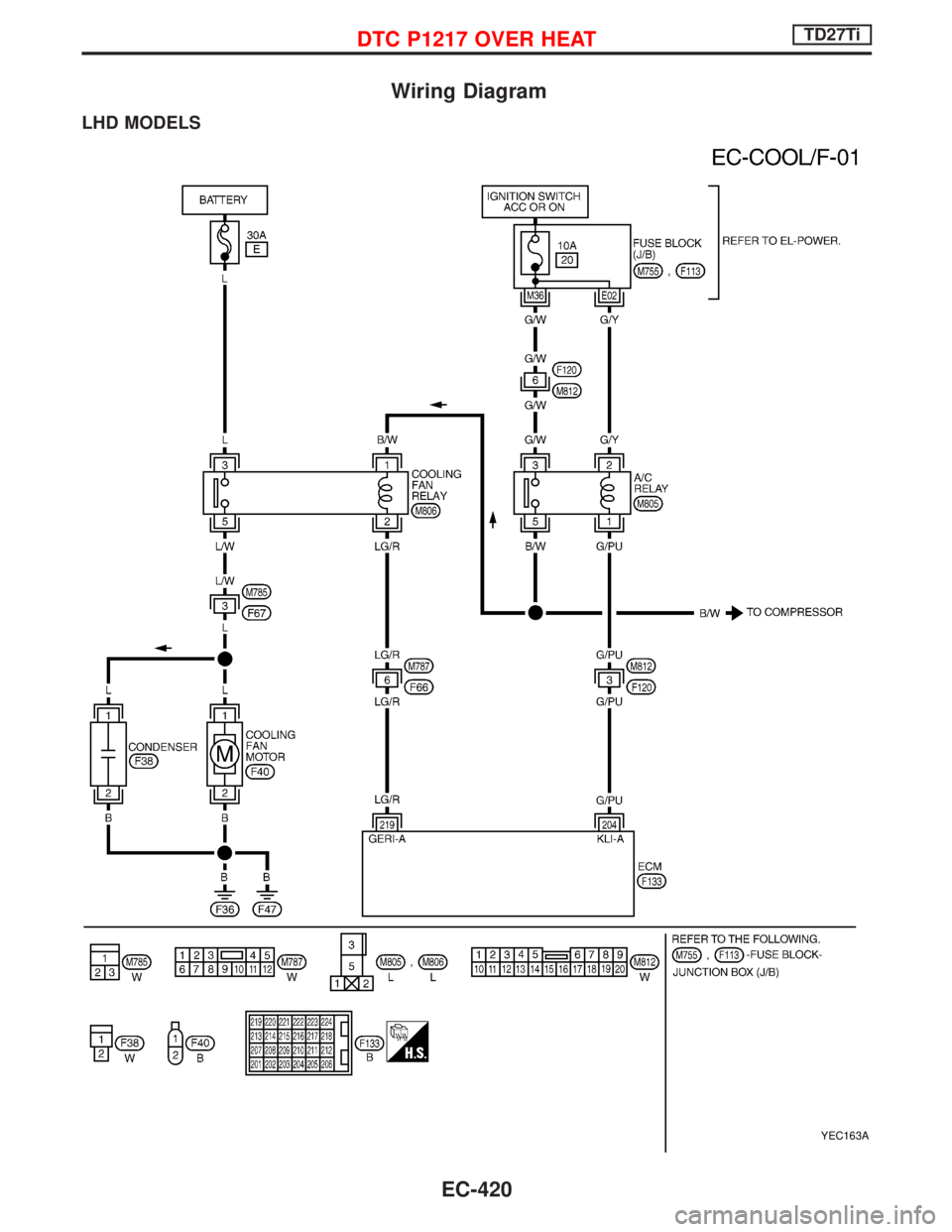

Wiring Diagram

LHD MODELS

YEC163A

DTC P1217 OVER HEATTD27Ti

EC-420

Page 783 of 1767

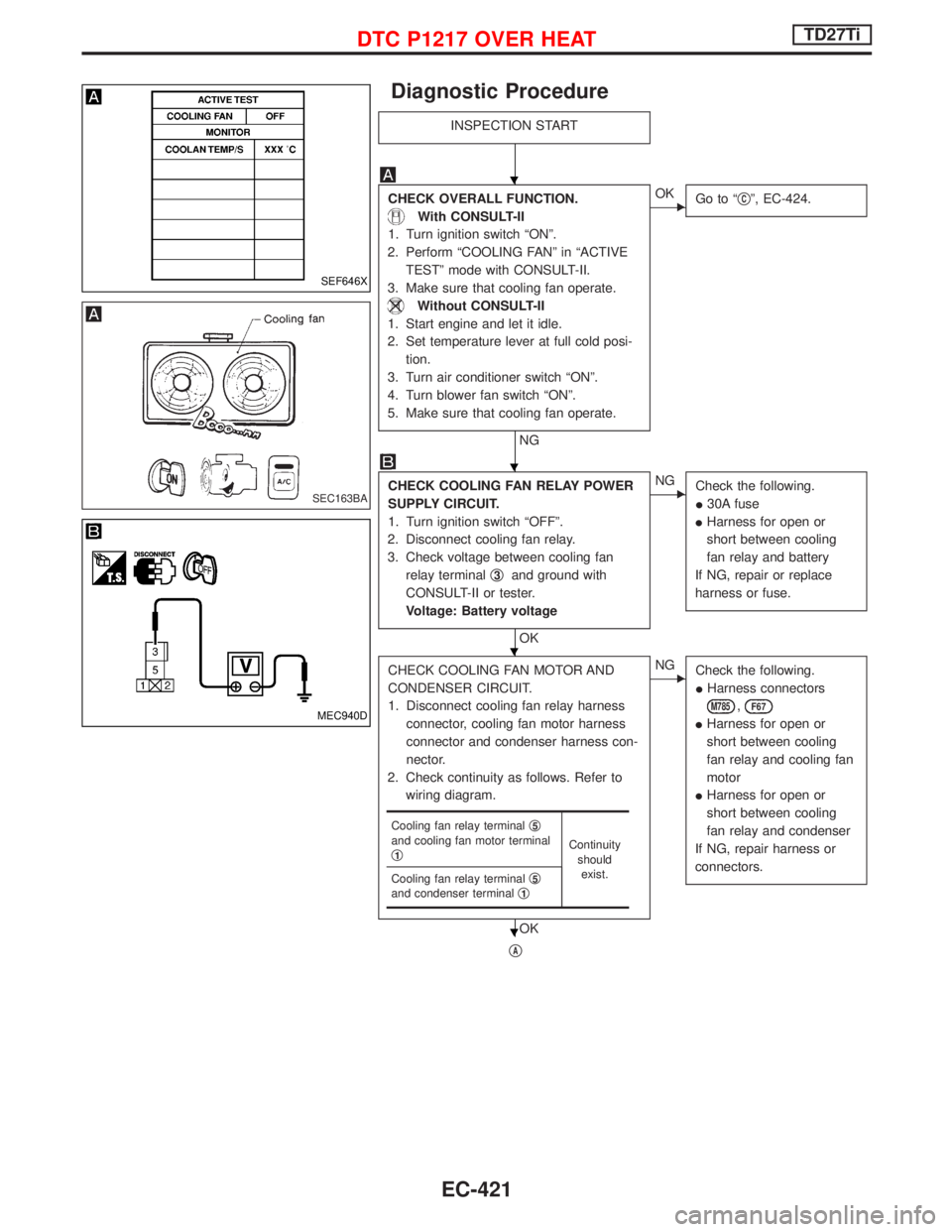

Diagnostic Procedure

INSPECTION START

CHECK OVERALL FUNCTION.

With CONSULT-II

1. Turn ignition switch ªONº.

2. Perform ªCOOLING FANº in ªACTIVE

TESTº mode with CONSULT-II.

3. Make sure that cooling fan operate.

Without CONSULT-II

1. Start engine and let it idle.

2. Set temperature lever at full cold posi-

tion.

3. Turn air conditioner switch ªONº.

4. Turn blower fan switch ªONº.

5. Make sure that cooling fan operate.

NG

EOK

Go to ªqCº, EC-424.

CHECK COOLING FAN RELAY POWER

SUPPLY CIRCUIT.

1. Turn ignition switch ªOFFº.

2. Disconnect cooling fan relay.

3. Check voltage between cooling fan

relay terminalq

3and ground with

CONSULT-II or tester.

Voltage: Battery voltage

OK

ENG

Check the following.

I30A fuse

IHarness for open or

short between cooling

fan relay and battery

If NG, repair or replace

harness or fuse.

CHECK COOLING FAN MOTOR AND

CONDENSER CIRCUIT.

1. Disconnect cooling fan relay harness

connector, cooling fan motor harness

connector and condenser harness con-

nector.

2. Check continuity as follows. Refer to

wiring diagram.

OK

ENG

Check the following.

IHarness connectors

M785,F67

IHarness for open or

short between cooling

fan relay and cooling fan

motor

IHarness for open or

short between cooling

fan relay and condenser

If NG, repair harness or

connectors.

qA

Cooling fan relay terminalq5and cooling fan motor terminal

q1Continuity

should

exist.

Cooling fan relay terminalq

5and condenser terminalq1

SEF646X

SEC163BA

MEC940D

H

H

H

H

DTC P1217 OVER HEATTD27Ti

EC-421

Page 784 of 1767

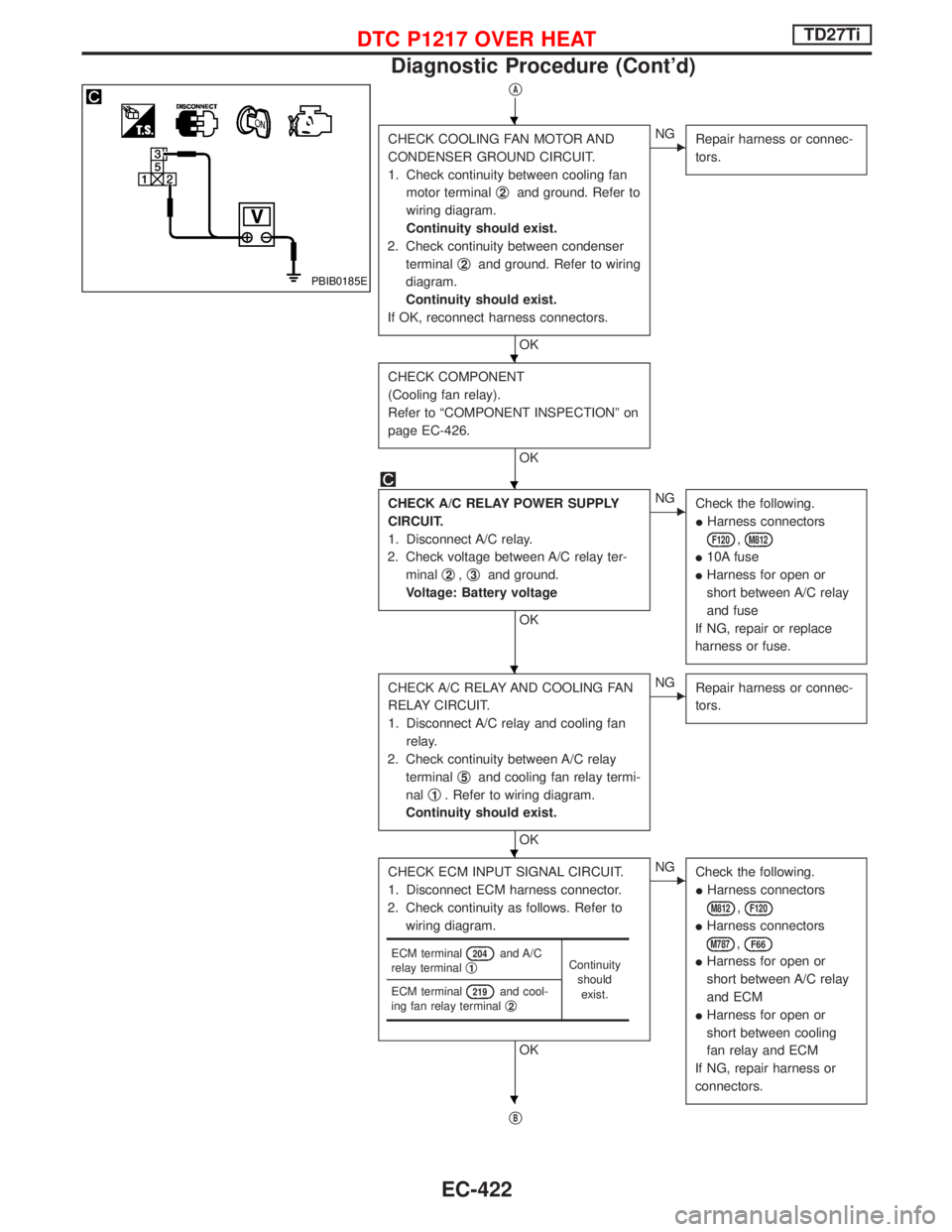

qA

CHECK COOLING FAN MOTOR AND

CONDENSER GROUND CIRCUIT.

1. Check continuity between cooling fan

motor terminalq

2and ground. Refer to

wiring diagram.

Continuity should exist.

2. Check continuity between condenser

terminalq

2and ground. Refer to wiring

diagram.

Continuity should exist.

If OK, reconnect harness connectors.

OK

ENG

Repair harness or connec-

tors.

CHECK COMPONENT

(Cooling fan relay).

Refer to ªCOMPONENT INSPECTIONº on

page EC-426.

OK

CHECK A/C RELAY POWER SUPPLY

CIRCUIT.

1. Disconnect A/C relay.

2. Check voltage between A/C relay ter-

minalq

2,q3and ground.

Voltage: Battery voltage

OK

ENG

Check the following.

IHarness connectors

F120,M812

I10A fuse

IHarness for open or

short between A/C relay

and fuse

If NG, repair or replace

harness or fuse.

CHECK A/C RELAY AND COOLING FAN

RELAY CIRCUIT.

1. Disconnect A/C relay and cooling fan

relay.

2. Check continuity between A/C relay

terminalq

5and cooling fan relay termi-

nalq

1. Refer to wiring diagram.

Continuity should exist.

OK

ENG

Repair harness or connec-

tors.

CHECK ECM INPUT SIGNAL CIRCUIT.

1. Disconnect ECM harness connector.

2. Check continuity as follows. Refer to

wiring diagram.

OK

ENG

Check the following.

IHarness connectors

M812,F120

IHarness connectors

M787,F66

IHarness for open or

short between A/C relay

and ECM

IHarness for open or

short between cooling

fan relay and ECM

If NG, repair harness or

connectors.

qB

ECM terminal204and A/C

relay terminalq1Continuity

should

exist. ECM terminal

219and cool-

ing fan relay terminalq2

PBIB0185E

H

H

H

H

H

H

DTC P1217 OVER HEATTD27Ti

Diagnostic Procedure (Cont'd)

EC-422

Page 785 of 1767

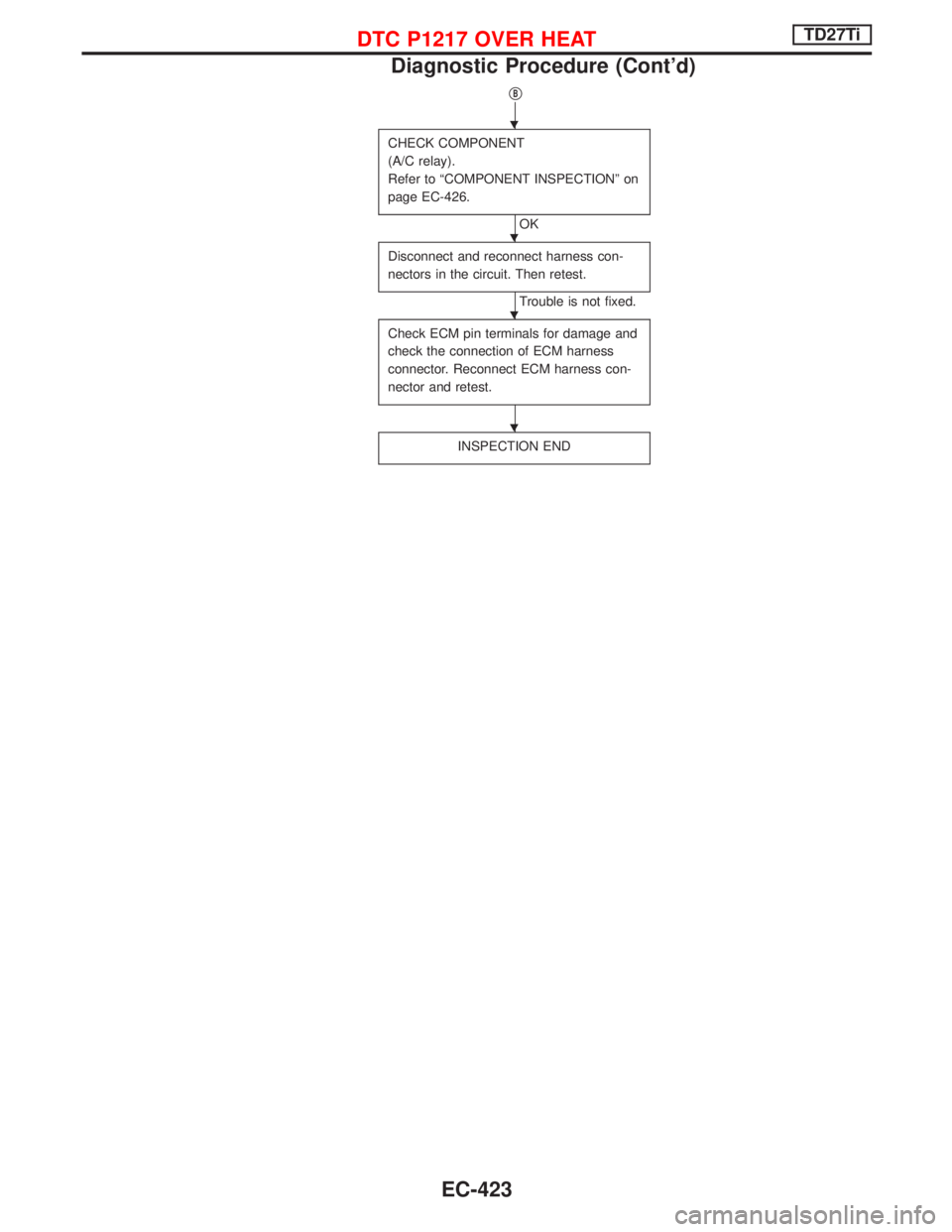

qB

CHECK COMPONENT

(A/C relay).

Refer to ªCOMPONENT INSPECTIONº on

page EC-426.

OK

Disconnect and reconnect harness con-

nectors in the circuit. Then retest.

Trouble is not fixed.

Check ECM pin terminals for damage and

check the connection of ECM harness

connector. Reconnect ECM harness con-

nector and retest.

INSPECTION END

H

H

H

H

DTC P1217 OVER HEATTD27Ti

Diagnostic Procedure (Cont'd)

EC-423

Page 786 of 1767

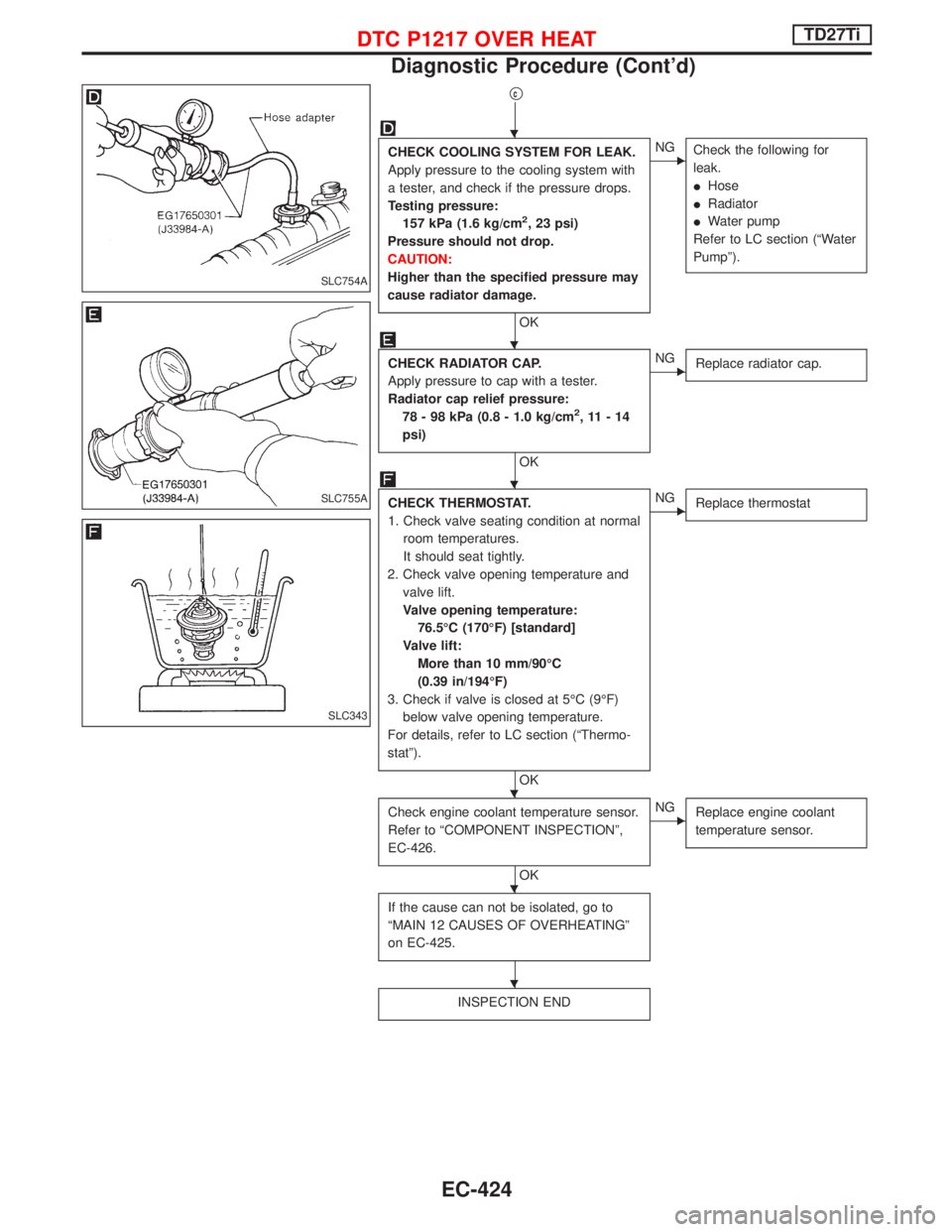

qc

CHECK COOLING SYSTEM FOR LEAK.

Apply pressure to the cooling system with

a tester, and check if the pressure drops.

Testing pressure:

157 kPa (1.6 kg/cm

2, 23 psi)

Pressure should not drop.

CAUTION:

Higher than the specified pressure may

cause radiator damage.

OK

ENG

Check the following for

leak.

IHose

IRadiator

IWater pump

Refer to LC section (ªWater

Pumpº).

CHECK RADIATOR CAP.

Apply pressure to cap with a tester.

Radiator cap relief pressure:

78 - 98 kPa (0.8 - 1.0 kg/cm

2,11-14

psi)

OK

ENG

Replace radiator cap.

CHECK THERMOSTAT.

1. Check valve seating condition at normal

room temperatures.

It should seat tightly.

2. Check valve opening temperature and

valve lift.

Valve opening temperature:

76.5ÉC (170ÉF) [standard]

Valve lift:

More than 10 mm/90ÉC

(0.39 in/194ÉF)

3. Check if valve is closed at 5ÉC (9ÉF)

below valve opening temperature.

For details, refer to LC section (ªThermo-

statº).

OK

ENG

Replace thermostat

Check engine coolant temperature sensor.

Refer to ªCOMPONENT INSPECTIONº,

EC-426.

OK

ENG

Replace engine coolant

temperature sensor.

If the cause can not be isolated, go to

ªMAIN 12 CAUSES OF OVERHEATINGº

on EC-425.

INSPECTION END

SLC754A

SLC755A

SLC343

H

H

H

H

H

H

DTC P1217 OVER HEATTD27Ti

Diagnostic Procedure (Cont'd)

EC-424

Page 787 of 1767

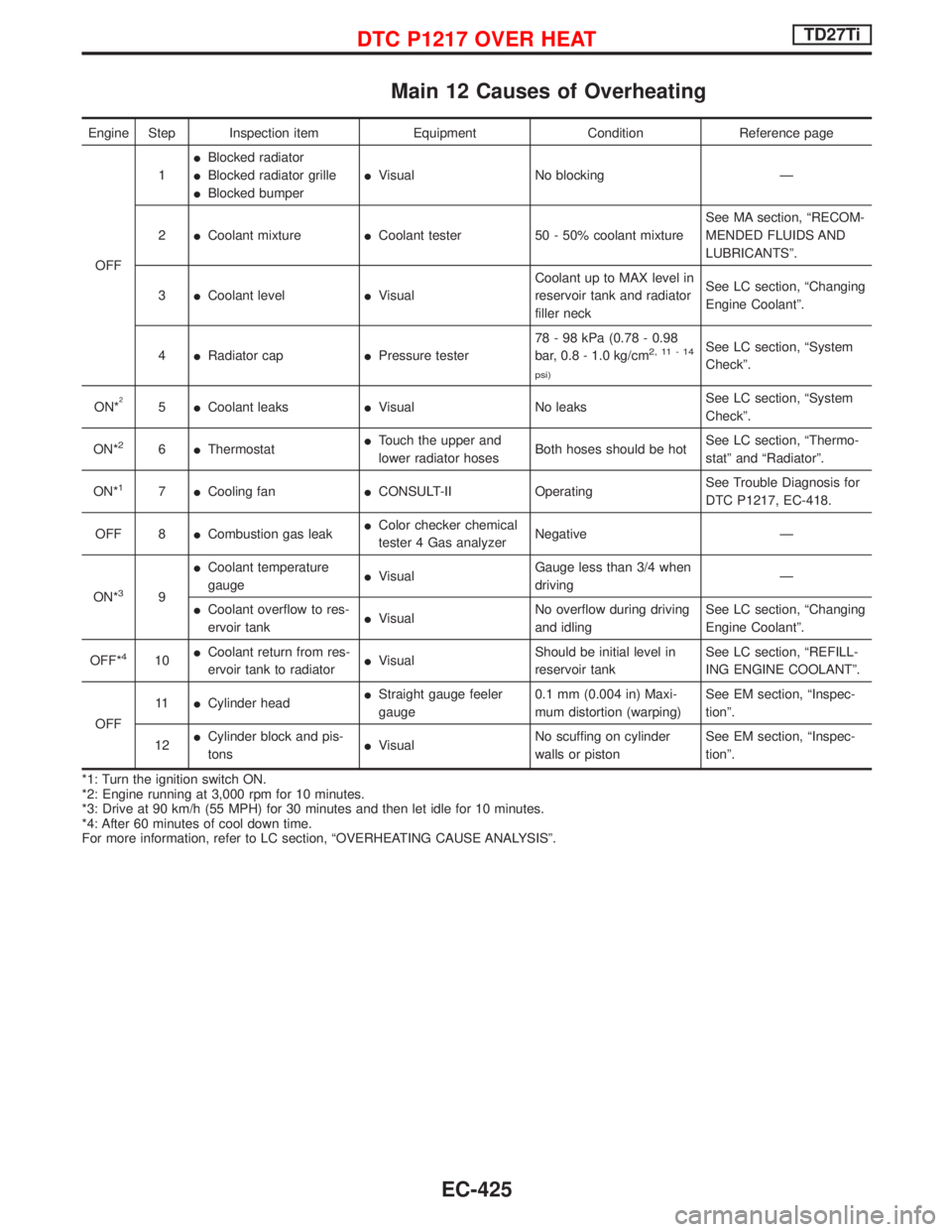

Main 12 Causes of Overheating

Engine Step Inspection item Equipment Condition Reference page

OFF1IBlocked radiator

IBlocked radiator grille

IBlocked bumperIVisual No blocking Ð

2ICoolant mixtureICoolant tester 50 - 50% coolant mixtureSee MA section, ªRECOM-

MENDED FLUIDS AND

LUBRICANTSº.

3ICoolant levelIVisualCoolant up to MAX level in

reservoir tank and radiator

filler neckSee LC section, ªChanging

Engine Coolantº.

4IRadiator capIPressure tester78 - 98 kPa (0.78 - 0.98

bar, 0.8 - 1.0 kg/cm

2,11-14

psi)See LC section, ªSystem

Checkº.

ON*

25ICoolant leaksIVisual No leaksSee LC section, ªSystem

Checkº.

ON*

26IThermostatITouch the upper and

lower radiator hosesBoth hoses should be hotSee LC section, ªThermo-

statº and ªRadiatorº.

ON*

17ICooling fanICONSULT-II OperatingSee Trouble Diagnosis for

DTC P1217, EC-418.

OFF 8ICombustion gas leakIColor checker chemical

tester 4 Gas analyzerNegative Ð

ON*

39ICoolant temperature

gaugeIVisualGauge less than 3/4 when

drivingÐ

ICoolant overflow to res-

ervoir tankIVisualNo overflow during driving

and idlingSee LC section, ªChanging

Engine Coolantº.

OFF*

410ICoolant return from res-

ervoir tank to radiatorIVisualShould be initial level in

reservoir tankSee LC section, ªREFILL-

ING ENGINE COOLANTº.

OFF11ICylinder headIStraight gauge feeler

gauge0.1 mm (0.004 in) Maxi-

mum distortion (warping)See EM section, ªInspec-

tionº.

12ICylinder block and pis-

tonsIVisualNo scuffing on cylinder

walls or pistonSee EM section, ªInspec-

tionº.

*1: Turn the ignition switch ON.

*2: Engine running at 3,000 rpm for 10 minutes.

*3: Drive at 90 km/h (55 MPH) for 30 minutes and then let idle for 10 minutes.

*4: After 60 minutes of cool down time.

For more information, refer to LC section, ªOVERHEATING CAUSE ANALYSISº.

DTC P1217 OVER HEATTD27Ti

EC-425

Page 788 of 1767

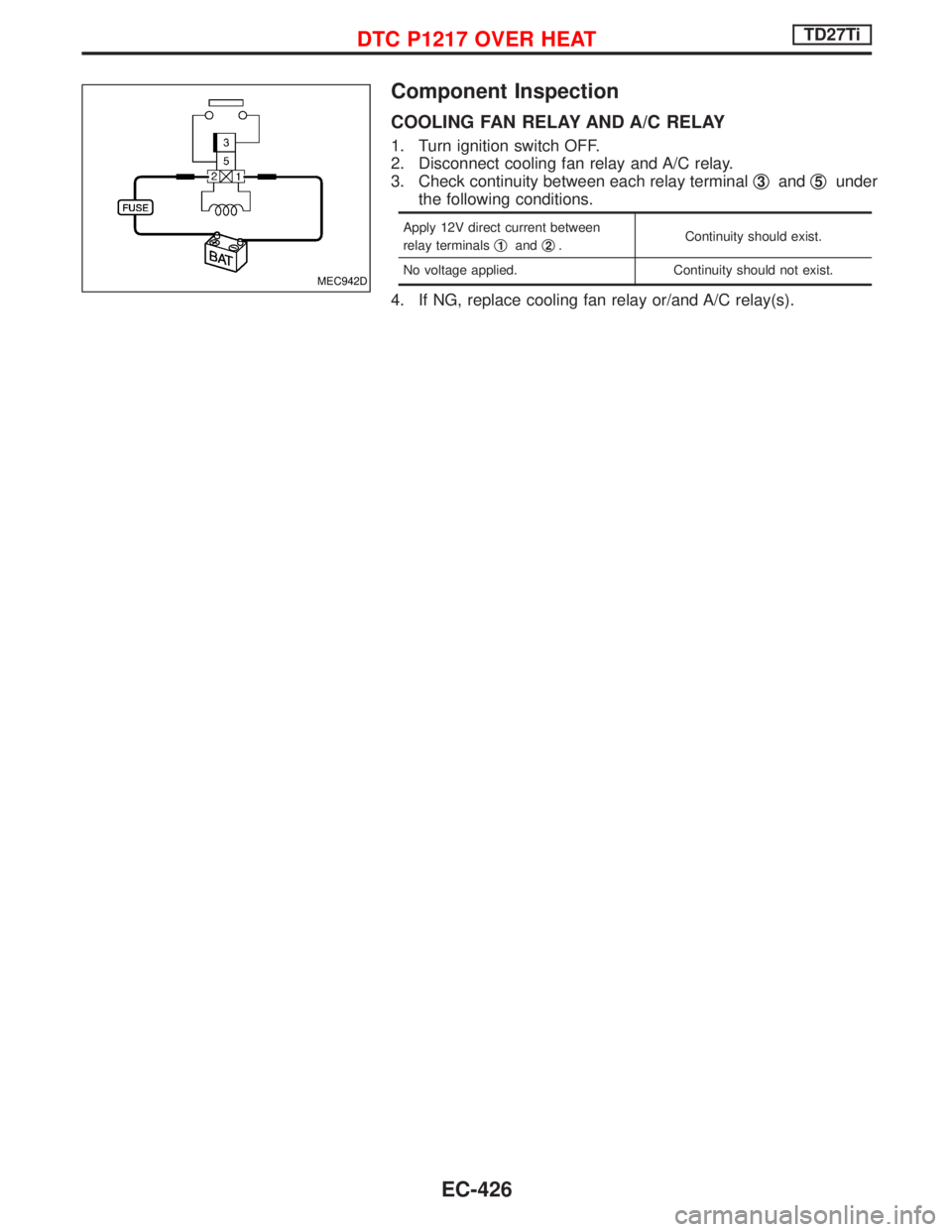

Component Inspection

COOLING FAN RELAY AND A/C RELAY

1. Turn ignition switch OFF.

2. Disconnect cooling fan relay and A/C relay.

3. Check continuity between each relay terminalq

3andq5under

the following conditions.

Apply 12V direct current between

relay terminalsq

1andq2.Continuity should exist.

No voltage applied. Continuity should not exist.

4. If NG, replace cooling fan relay or/and A/C relay(s).

MEC942D

DTC P1217 OVER HEATTD27Ti

EC-426

Page 789 of 1767

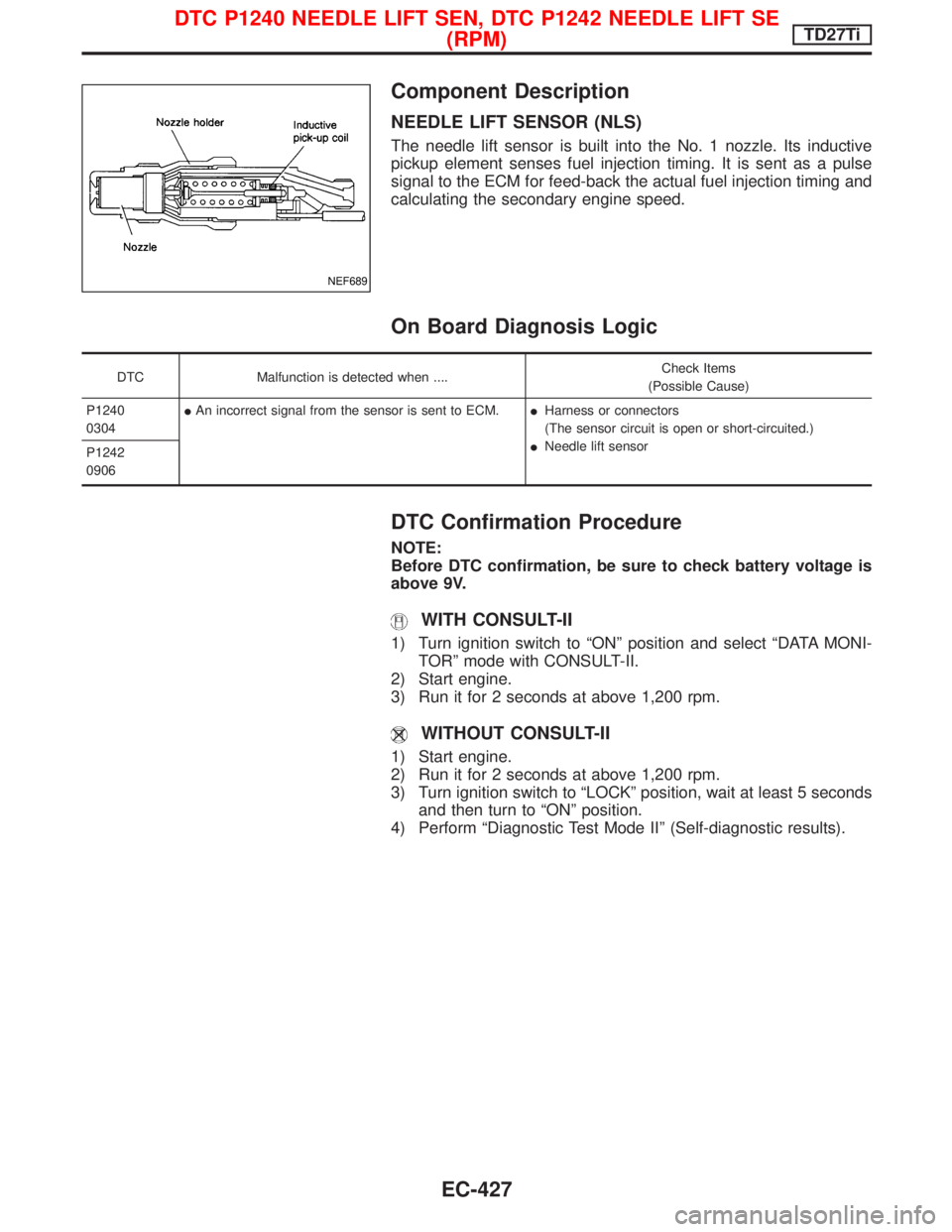

Component Description

NEEDLE LIFT SENSOR (NLS)

The needle lift sensor is built into the No. 1 nozzle. Its inductive

pickup element senses fuel injection timing. It is sent as a pulse

signal to the ECM for feed-back the actual fuel injection timing and

calculating the secondary engine speed.

On Board Diagnosis Logic

DTC Malfunction is detected when ....Check Items

(Possible Cause)

P1240

0304IAn incorrect signal from the sensor is sent to ECM.IHarness or connectors

(The sensor circuit is open or short-circuited.)

INeedle lift sensor

P1242

0906

DTC Confirmation Procedure

NOTE:

Before DTC confirmation, be sure to check battery voltage is

above 9V.

WITH CONSULT-II

1) Turn ignition switch to ªONº position and select ªDATA MONI-

TORº mode with CONSULT-II.

2) Start engine.

3) Run it for 2 seconds at above 1,200 rpm.

WITHOUT CONSULT-II

1) Start engine.

2) Run it for 2 seconds at above 1,200 rpm.

3) Turn ignition switch to ªLOCKº position, wait at least 5 seconds

and then turn to ªONº position.

4) Perform ªDiagnostic Test Mode IIº (Self-diagnostic results).

NEF689

DTC P1240 NEEDLE LIFT SEN, DTC P1242 NEEDLE LIFT SE

(RPM)TD27Ti

EC-427

Page 790 of 1767

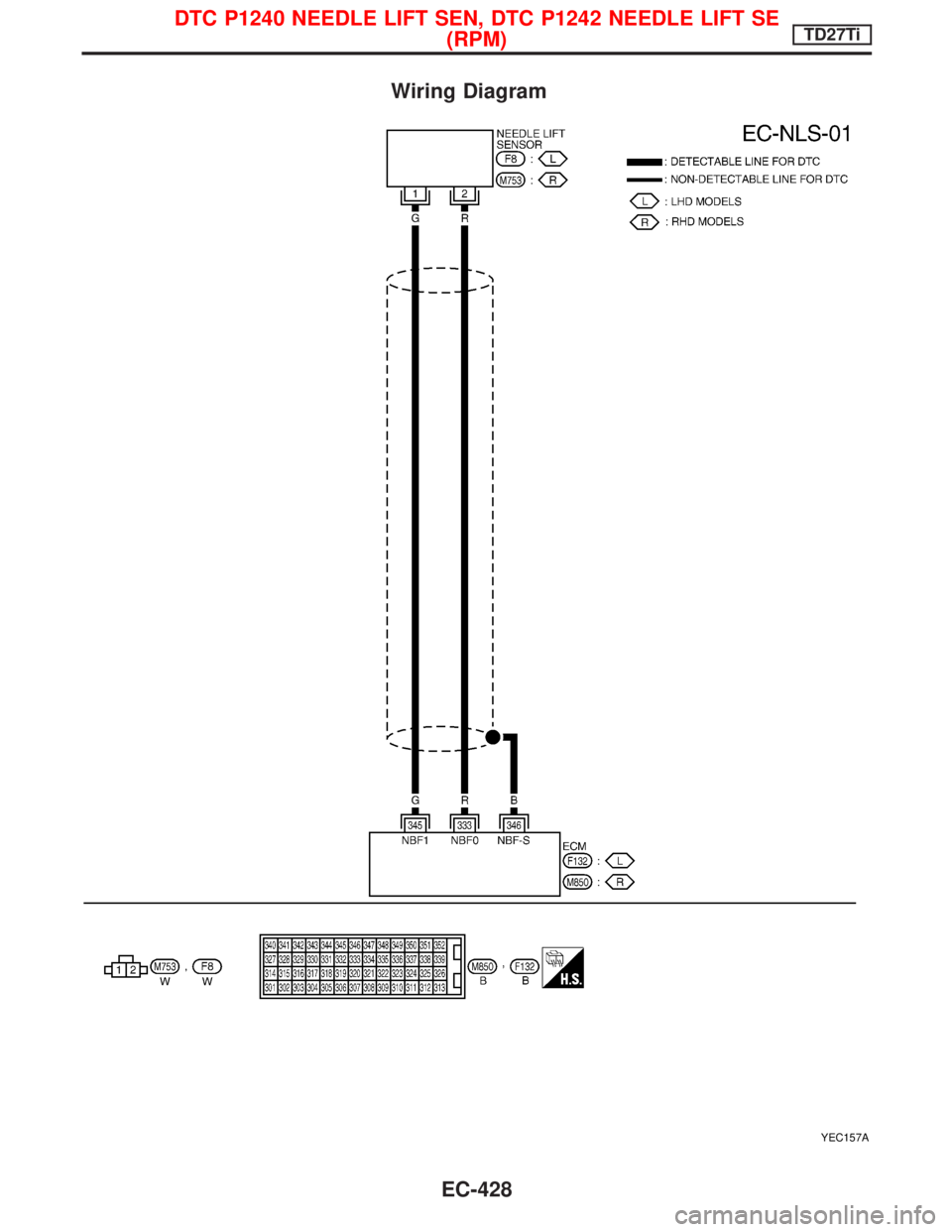

Wiring Diagram

YEC157A

DTC P1240 NEEDLE LIFT SEN, DTC P1242 NEEDLE LIFT SE

(RPM)TD27Ti

EC-428