Ignition NISSAN TERRANO 2004 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 520 of 1833

ECM Terminals and Reference Value

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may damage the

ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL NO. WIRE

COLOR ITEM CONDITION DATA (DC Voltage)

16 G/W Glow indicator lamp Ignition switch ªONº

Glow indicator lamp is ªONº

Approximately 1V

Ignition switch ªONº

Glow indicator lamp is ªOFFº BATTERY VOLTAGE

(11 - 14V)

111 LG Glow relay Refer to ªSYSTEM DESCRIPTIONº, EC-244.

GLOW CONTROL SYSTEMZD30DDTi

EC-245

http://vnx.su/

Page 522 of 1833

Diagnostic Procedure

1 INSPECTION START

Check fuel level, fuel supplying system, starter motor, etc.OK or NG

OK EGO TO 2.

NG ECorrect.

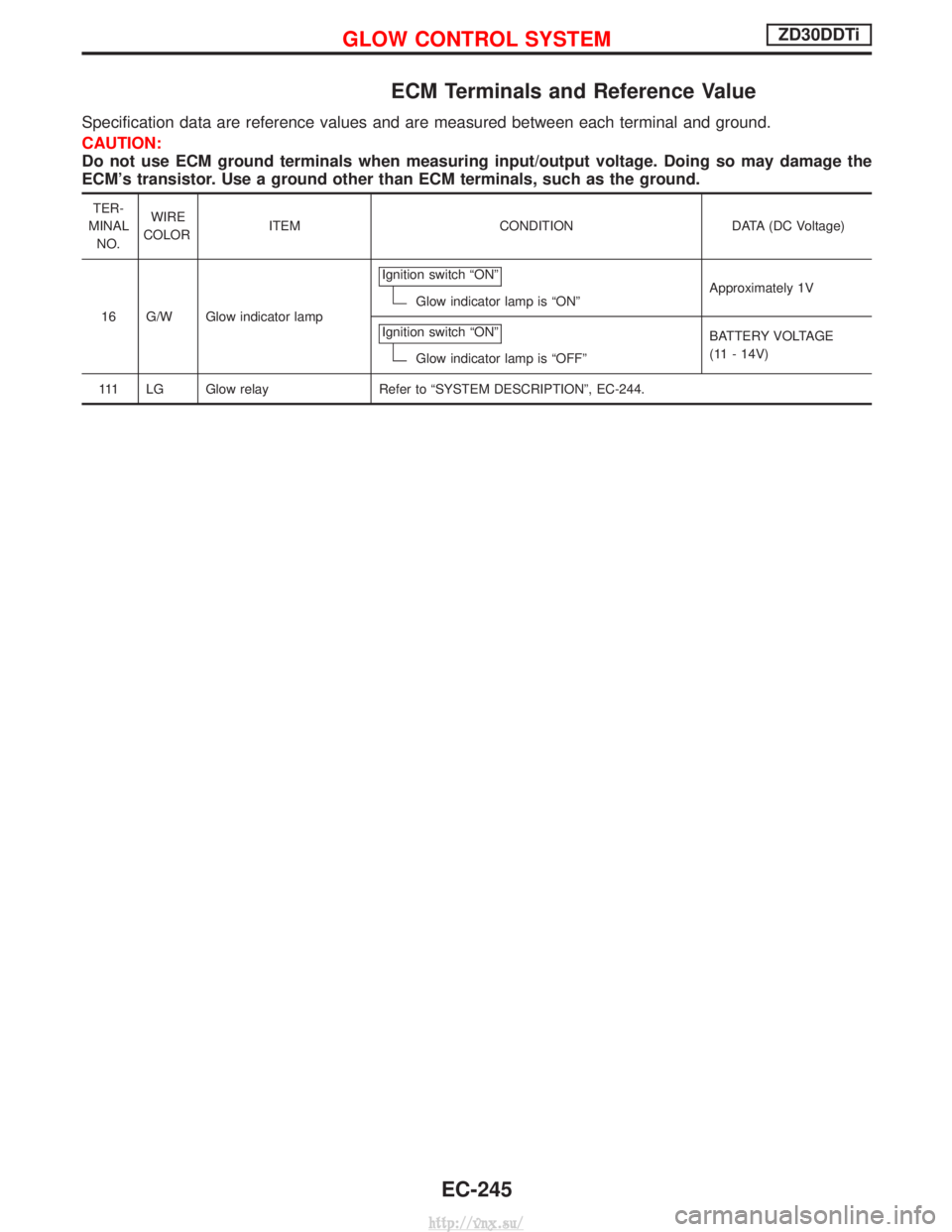

2 CHECK INSTALLATION

Check that all glow plug connecting plate nuts are installed properly.

MEC002E

OK or NG

OK (With CONSULT-II) EGO TO 3.

OK (Without CONSULT-II) EGO TO 4.

NG EInstall properly.

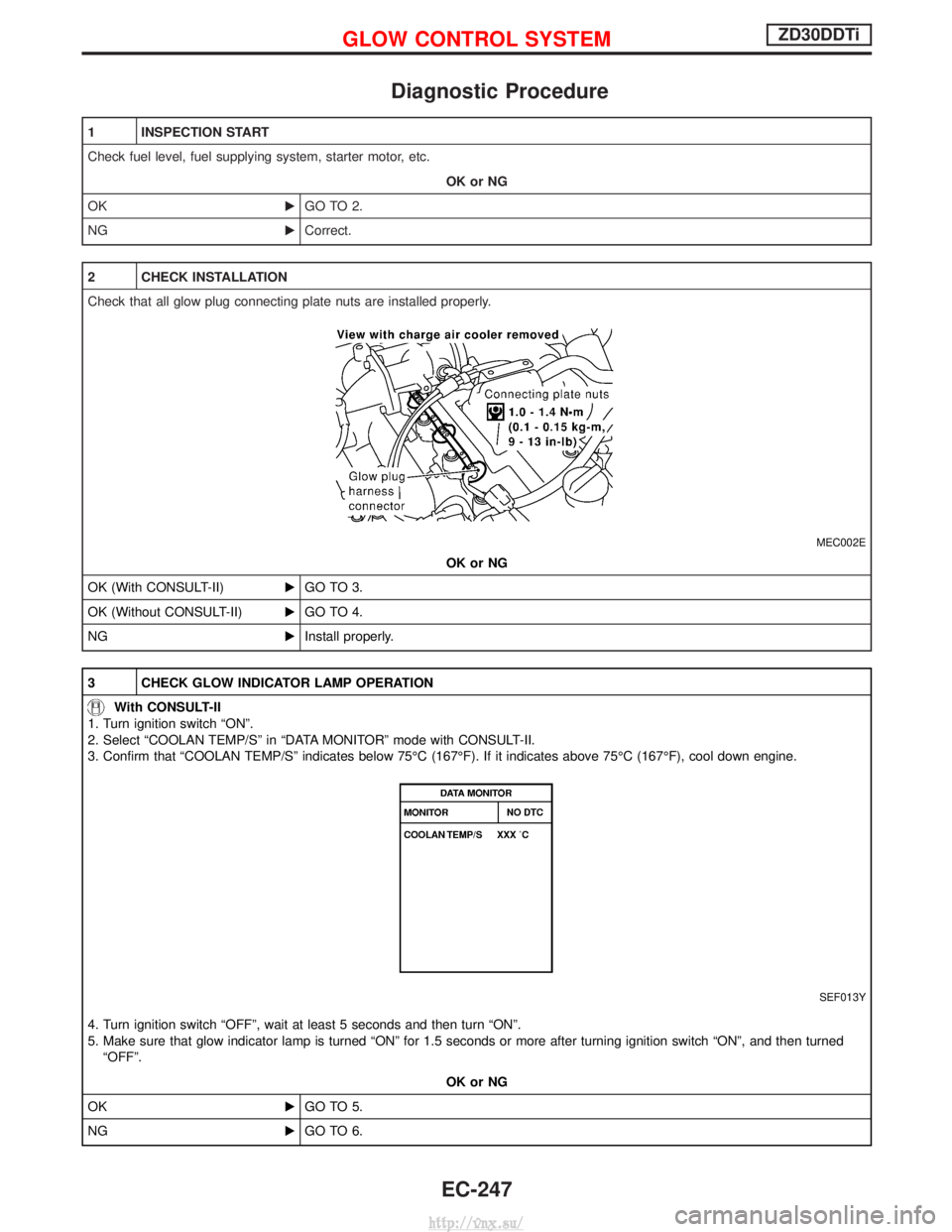

3 CHECK GLOW INDICATOR LAMP OPERATION

With CONSULT-II

1. Turn ignition switch ªONº.

2. Select ªCOOLAN TEMP/Sº in ªDATA MONITORº mode with CONSULT-II.

3. Confirm that ªCOOLAN TEMP/Sº indicates below 75ÉC (167ÉF). If it indicates above 75ÉC (167ÉF), cool down engine.

SEF013Y

4. Turn ignition switch ªOFFº, wait at least 5 seconds and then turn ªONº.

5. Make sure that glow indicator lamp is turned ªONº for 1.5 seconds or more after turning ignition switch ªONº, and then turned ªOFFº.

OK or NG

OK EGO TO 5.

NG EGO TO 6.

GLOW CONTROL SYSTEMZD30DDTi

EC-247

http://vnx.su/

Page 523 of 1833

4 CHECK GLOW INDICATOR LAMP OPERATION

Without CONSULT-II

1. Turn ignition switch ªONº.

2. Confirm that the voltage between ECM terminal 19 and ground is above 1.36V. If it is below 1.36V, cool down engine.

SEF430Y

3. Turn ignition switch ªOFFº, wait at least 5 seconds and then turn ªONº.

4. Make sure that glow indicator lamp is turned ªONº for 1.5 seconds or more after turning ignition switch ªONº, and then turned ªOFFº.

OK or NG

OK EGO TO 5.

NG EGO TO 6.

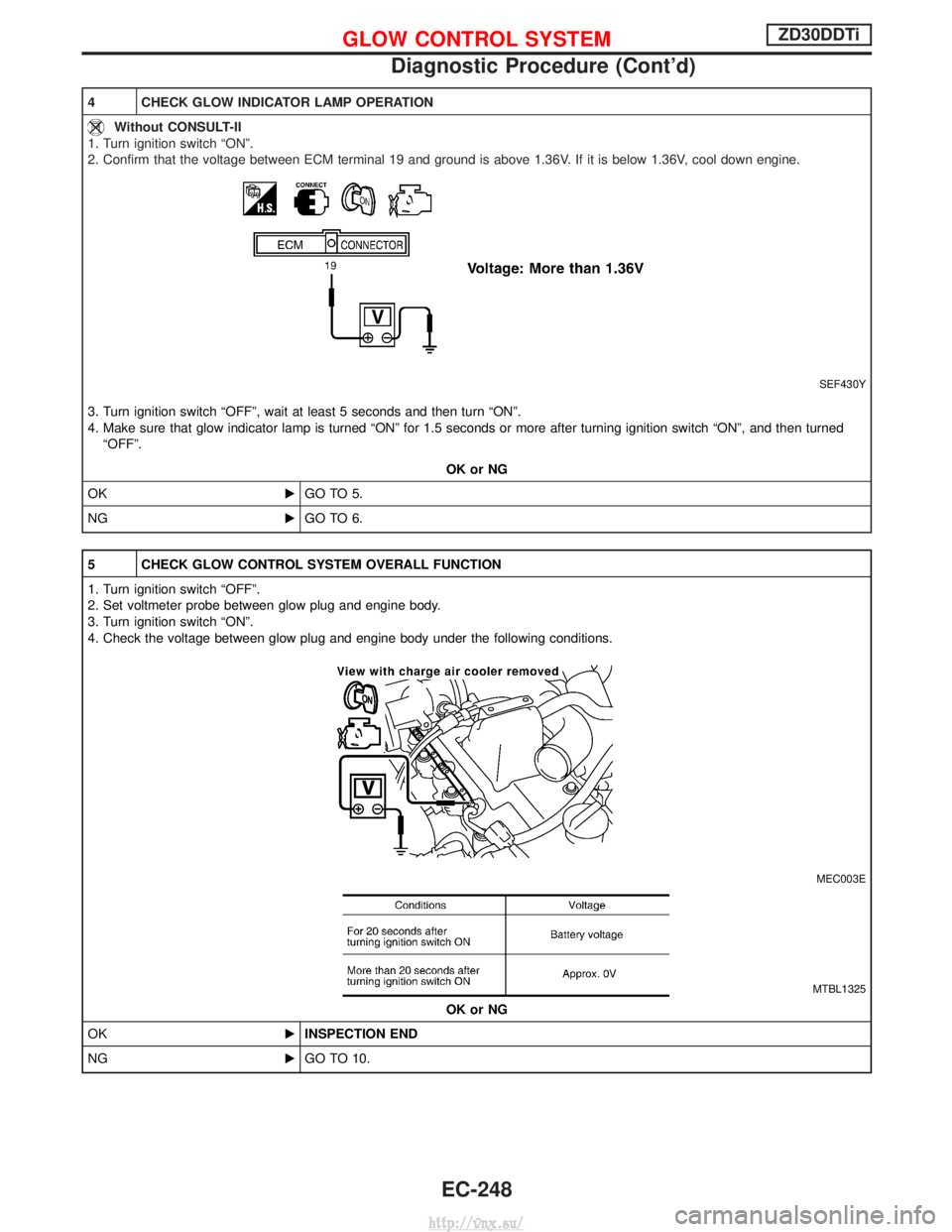

5 CHECK GLOW CONTROL SYSTEM OVERALL FUNCTION

1. Turn ignition switch ªOFFº.

2. Set voltmeter probe between glow plug and engine body.

3. Turn ignition switch ªONº.

4. Check the voltage between glow plug and engine body under the following conditions.

MEC003E

MTBL1325

OK or NG

OK EINSPECTION END

NG EGO TO 10.

GLOW CONTROL SYSTEMZD30DDTi

Diagnostic Procedure (Cont'd)

EC-248

http://vnx.su/

Page 524 of 1833

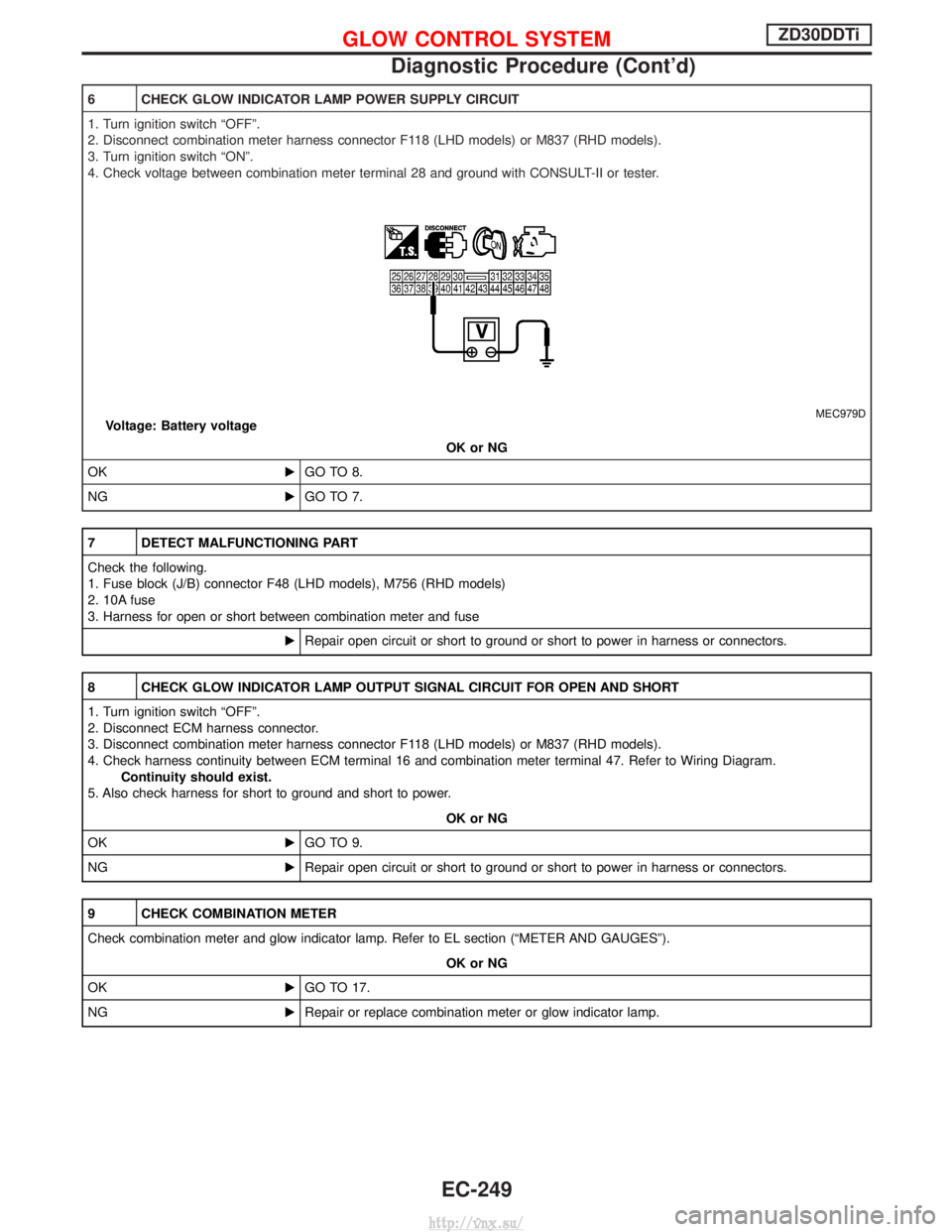

6 CHECK GLOW INDICATOR LAMP POWER SUPPLY CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect combination meter harness connector F118 (LHD models) or M837 (RHD models).

3. Turn ignition switch ªONº.

4. Check voltage between combination meter terminal 28 and ground with CONSULT-II or tester.

MEC979DVoltage: Battery voltageOK or NG

OK EGO TO 8.

NG EGO TO 7.

7 DETECT MALFUNCTIONING PART

Check the following.

1. Fuse block (J/B) connector F48 (LHD models), M756 (RHD models)

2. 10A fuse

3. Harness for open or short between combination meter and fuse

ERepair open circuit or short to ground or short to power in harness or connectors.

8 CHECK GLOW INDICATOR LAMP OUTPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Disconnect combination meter harness connector F118 (LHD models) or M837 (RHD models).

4. Check harness continuity between ECM terminal 16 and combination meter terminal 47. Refer to Wiring Diagram.

Continuity should exist.

5. Also check harness for short to ground and short to power.

OK or NG

OK EGO TO 9.

NG ERepair open circuit or short to ground or short to power in harness or connectors.

9 CHECK COMBINATION METER

Check combination meter and glow indicator lamp. Refer to EL section (ªMETER AND GAUGESº).

OK or NG

OK EGO TO 17.

NG ERepair or replace combination meter or glow indicator lamp.

GLOW CONTROL SYSTEMZD30DDTi

Diagnostic Procedure (Cont'd)

EC-249

http://vnx.su/

Page 525 of 1833

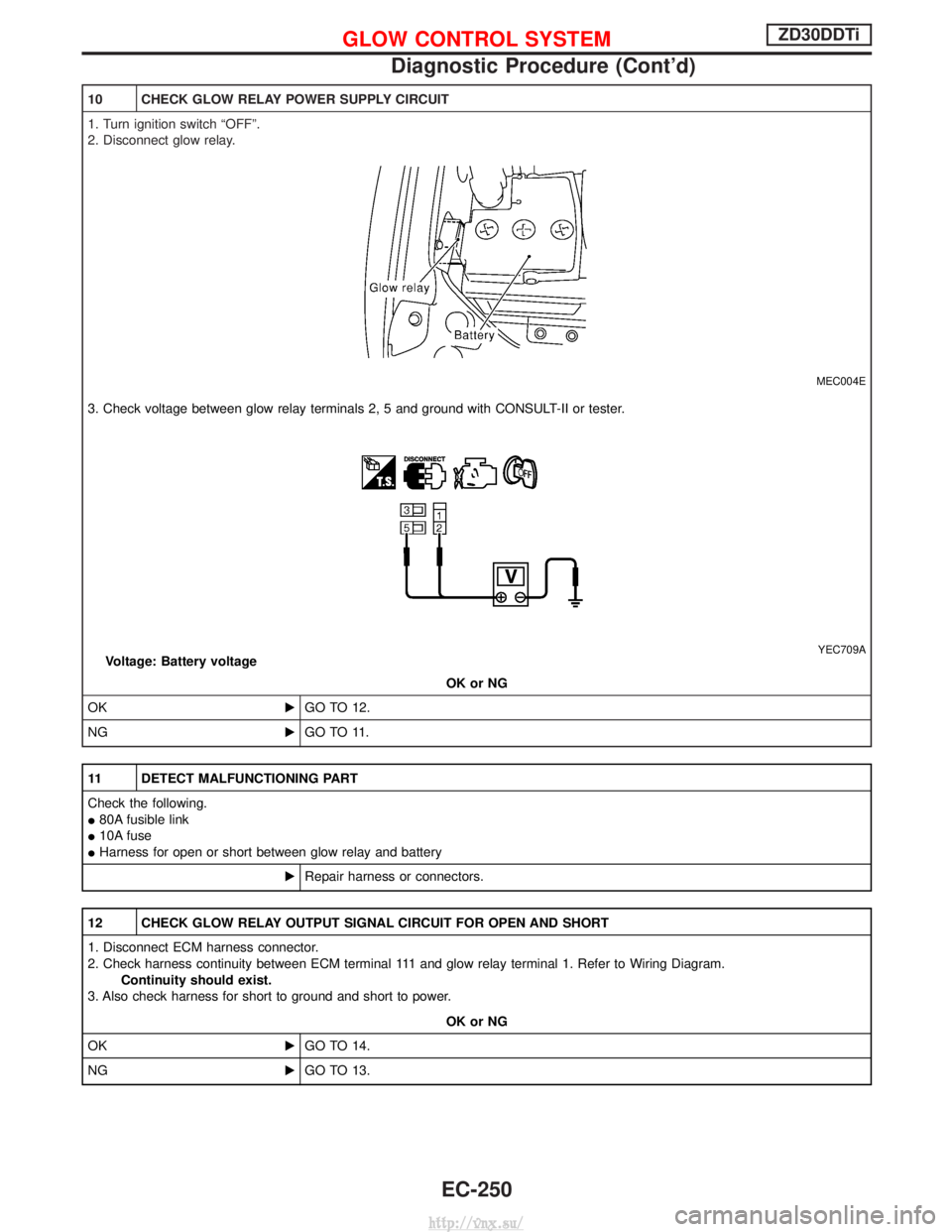

10 CHECK GLOW RELAY POWER SUPPLY CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect glow relay.

MEC004E

3. Check voltage between glow relay terminals 2, 5 and ground with CONSULT-II or tester.

YEC709AVoltage: Battery voltageOK or NG

OK EGO TO 12.

NG EGO TO 11.

11 DETECT MALFUNCTIONING PART

Check the following.

I80A fusible link

I 10A fuse

I Harness for open or short between glow relay and battery

ERepair harness or connectors.

12 CHECK GLOW RELAY OUTPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 111 and glow relay terminal 1. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK EGO TO 14.

NG EGO TO 13.

GLOW CONTROL SYSTEMZD30DDTi

Diagnostic Procedure (Cont'd)

EC-250

http://vnx.su/

Page 529 of 1833

Diagnostic Procedure

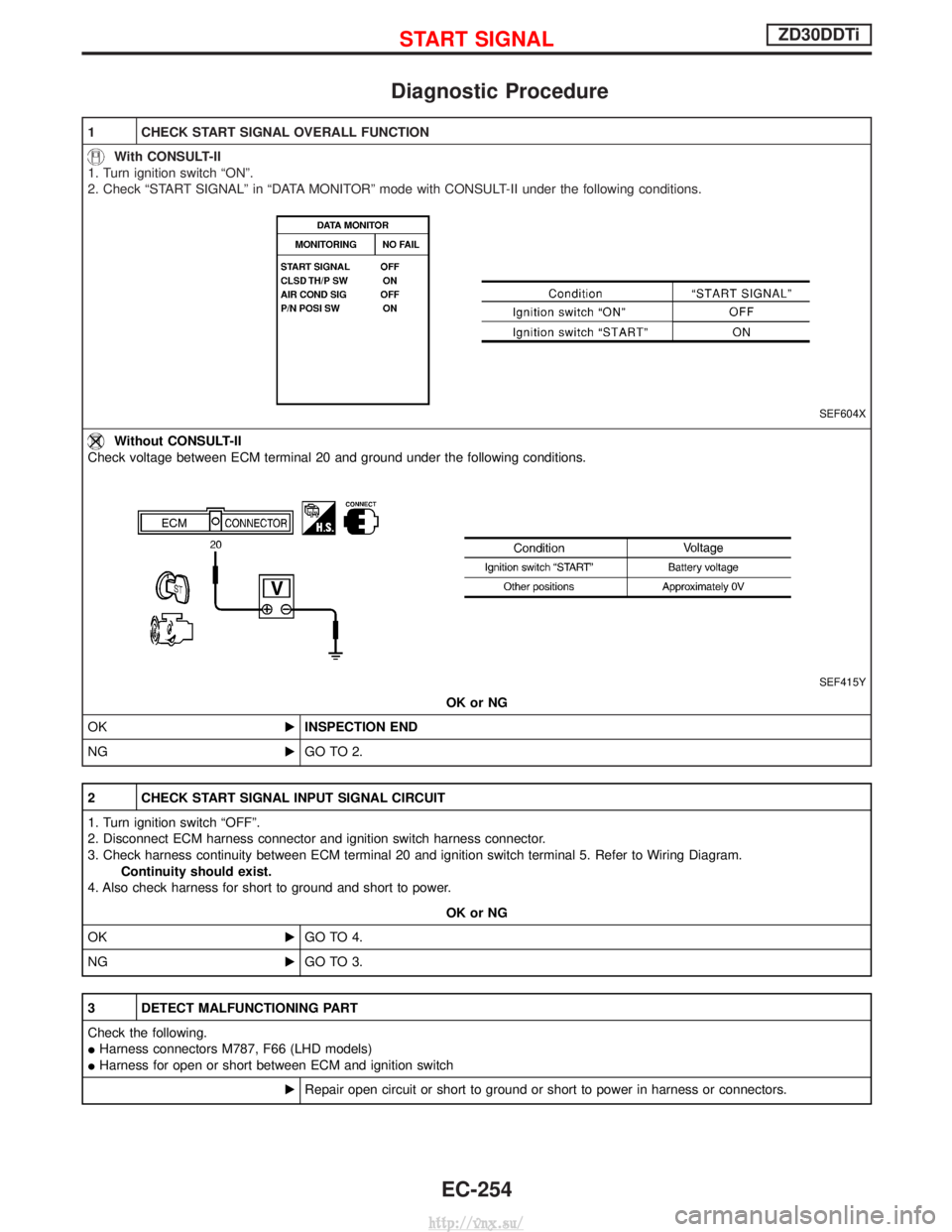

1 CHECK START SIGNAL OVERALL FUNCTION

With CONSULT-II

1. Turn ignition switch ªONº.

2. Check ªSTART SIGNALº in ªDATA MONITORº mode with CONSULT-II under the following conditions.

SEF604X

Without CONSULT-II

Check voltage between ECM terminal 20 and ground under the following conditions.

SEF415Y

OK or NG

OK EINSPECTION END

NG EGO TO 2.

2 CHECK START SIGNAL INPUT SIGNAL CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector and ignition switch harness connector.

3. Check harness continuity between ECM terminal 20 and ignition switch terminal 5. Refer to Wiring Diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK EGO TO 4.

NG EGO TO 3.

3 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors M787, F66 (LHD models)

I Harness for open or short between ECM and ignition switch

ERepair open circuit or short to ground or short to power in harness or connectors.

START SIGNALZD30DDTi

EC-254

http://vnx.su/

Page 531 of 1833

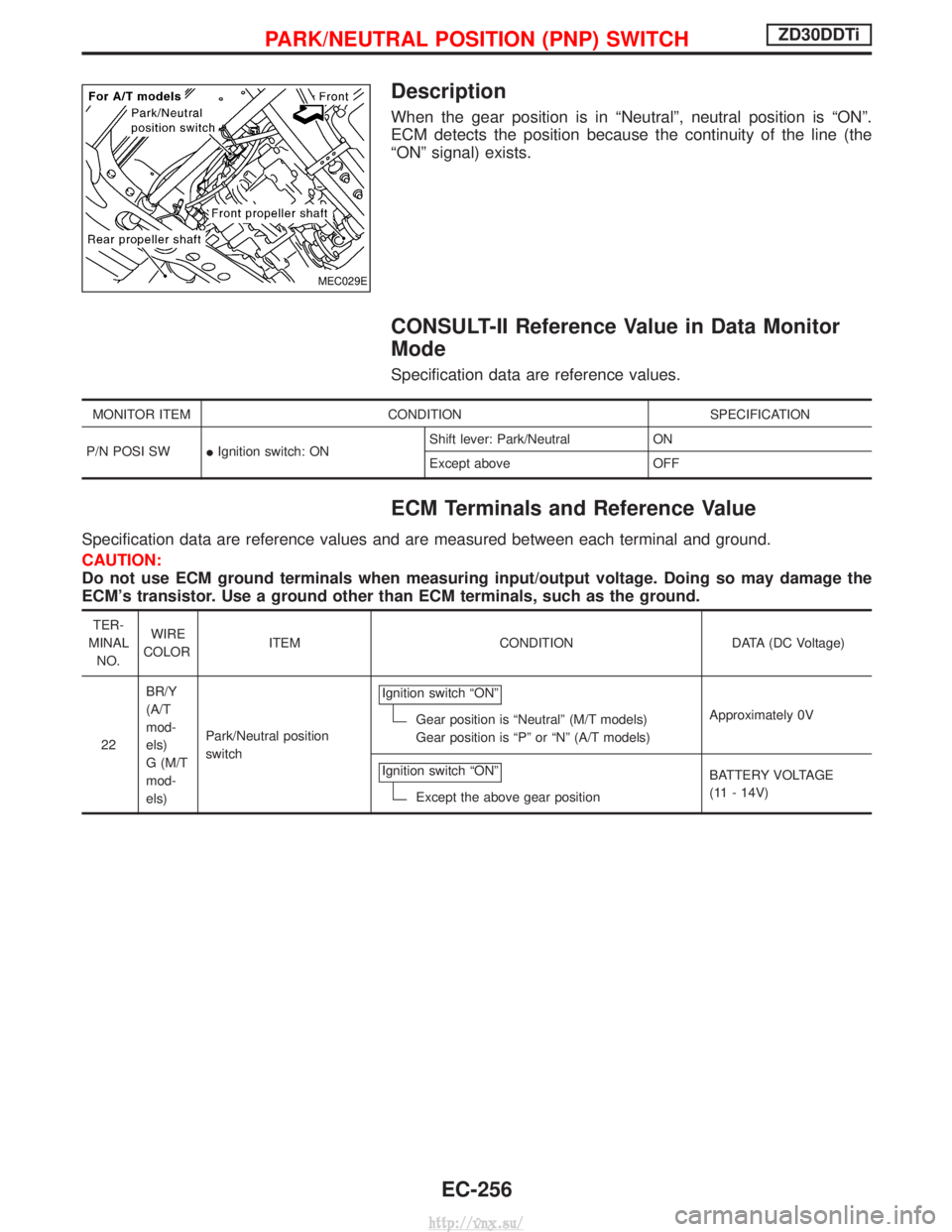

Description

When the gear position is in ªNeutralº, neutral position is ªONº.

ECM detects the position because the continuity of the line (the

ªONº signal) exists.

CONSULT-II Reference Value in Data Monitor

Mode

Specification data are reference values.

MONITOR ITEMCONDITION SPECIFICATION

P/N POSI SW IIgnition switch: ON Shift lever: Park/Neutral ON

Except above OFF

ECM Terminals and Reference Value

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may damage the

ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL NO. WIRE

COLOR ITEM CONDITION DATA (DC Voltage)

22 BR/Y

(A/T

mod-

els)

G (M/T

mod-

els) Park/Neutral position

switch

Ignition switch ªONº

Gear position is ªNeutralº (M/T models)

Gear position is ªPº or ªNº (A/T models)

Approximately 0V

Ignition switch ªONº

Except the above gear position BATTERY VOLTAGE

(11 - 14V)

MEC029E

PARK/NEUTRAL POSITION (PNP) SWITCHZD30DDTi

EC-256

http://vnx.su/

Page 533 of 1833

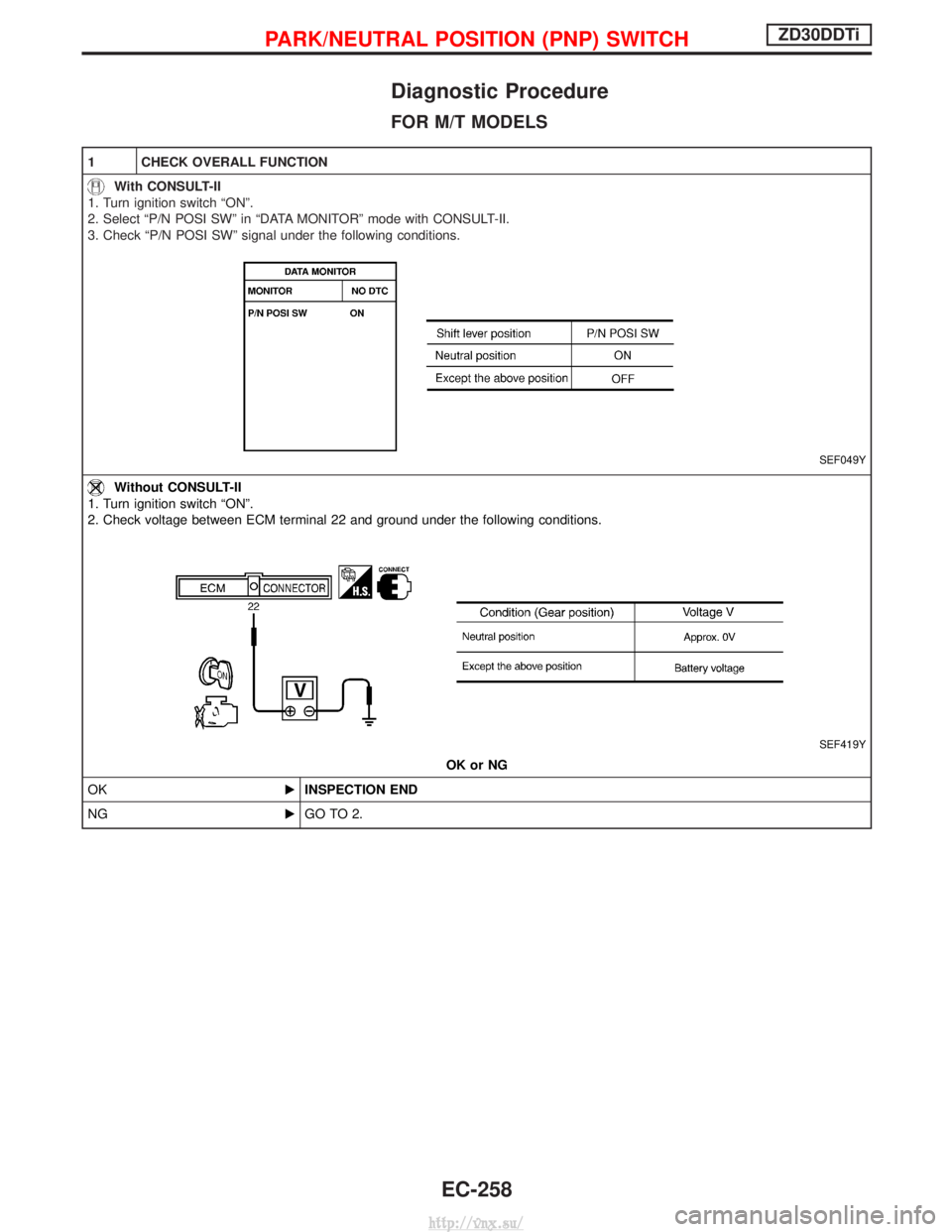

Diagnostic Procedure

FOR M/T MODELS

1 CHECK OVERALL FUNCTION

With CONSULT-II

1. Turn ignition switch ªONº.

2. Select ªP/N POSI SWº in ªDATA MONITORº mode with CONSULT-II.

3. Check ªP/N POSI SWº signal under the following conditions.

SEF049Y

Without CONSULT-II

1. Turn ignition switch ªONº.

2. Check voltage between ECM terminal 22 and ground under the following conditions.

SEF419Y

OK or NG

OK EINSPECTION END

NG EGO TO 2.

PARK/NEUTRAL POSITION (PNP) SWITCHZD30DDTi

EC-258

http://vnx.su/

Page 534 of 1833

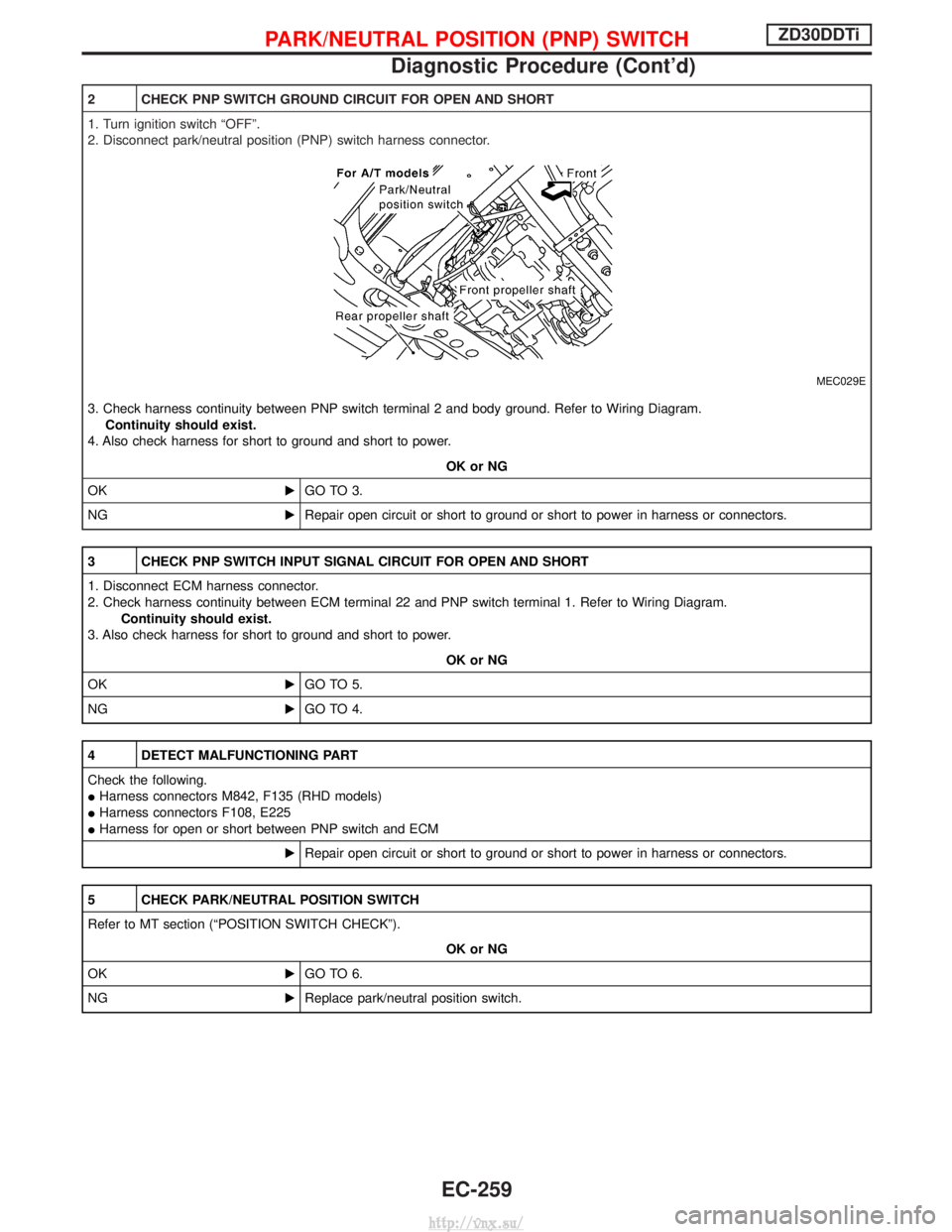

2 CHECK PNP SWITCH GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect park/neutral position (PNP) switch harness connector.

MEC029E

3. Check harness continuity between PNP switch terminal 2 and body ground. Refer to Wiring Diagram.Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK EGO TO 3.

NG ERepair open circuit or short to ground or short to power in harness or connectors.

3 CHECK PNP SWITCH INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 22 and PNP switch terminal 1. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK EGO TO 5.

NG EGO TO 4.

4 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors M842, F135 (RHD models)

I Harness connectors F108, E225

I Harness for open or short between PNP switch and ECM

ERepair open circuit or short to ground or short to power in harness or connectors.

5 CHECK PARK/NEUTRAL POSITION SWITCH

Refer to MT section (ªPOSITION SWITCH CHECKº).

OK or NG

OK EGO TO 6.

NG EReplace park/neutral position switch.

PARK/NEUTRAL POSITION (PNP) SWITCHZD30DDTi

Diagnostic Procedure (Cont'd)

EC-259

http://vnx.su/

Page 535 of 1833

6 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-78.EINSPECTION END

FOR A/T MODELS

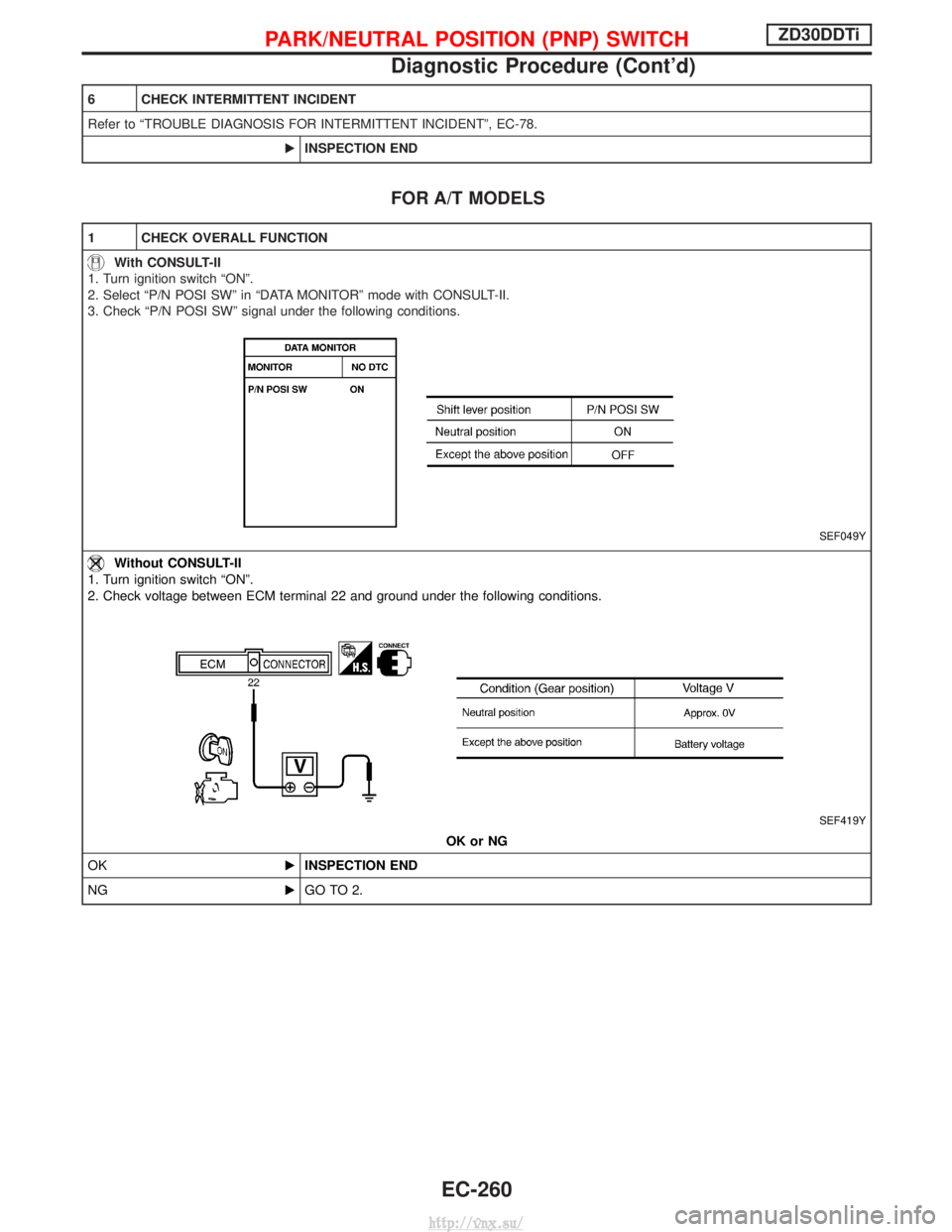

1 CHECK OVERALL FUNCTION

With CONSULT-II

1. Turn ignition switch ªONº.

2. Select ªP/N POSI SWº in ªDATA MONITORº mode with CONSULT-II.

3. Check ªP/N POSI SWº signal under the following conditions.

SEF049Y

Without CONSULT-II

1. Turn ignition switch ªONº.

2. Check voltage between ECM terminal 22 and ground under the following conditions.

SEF419Y

OK or NG

OK EINSPECTION END

NG EGO TO 2.

PARK/NEUTRAL POSITION (PNP) SWITCHZD30DDTi

Diagnostic Procedure (Cont'd)

EC-260

http://vnx.su/