Ignition NISSAN TERRANO 2004 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 568 of 1833

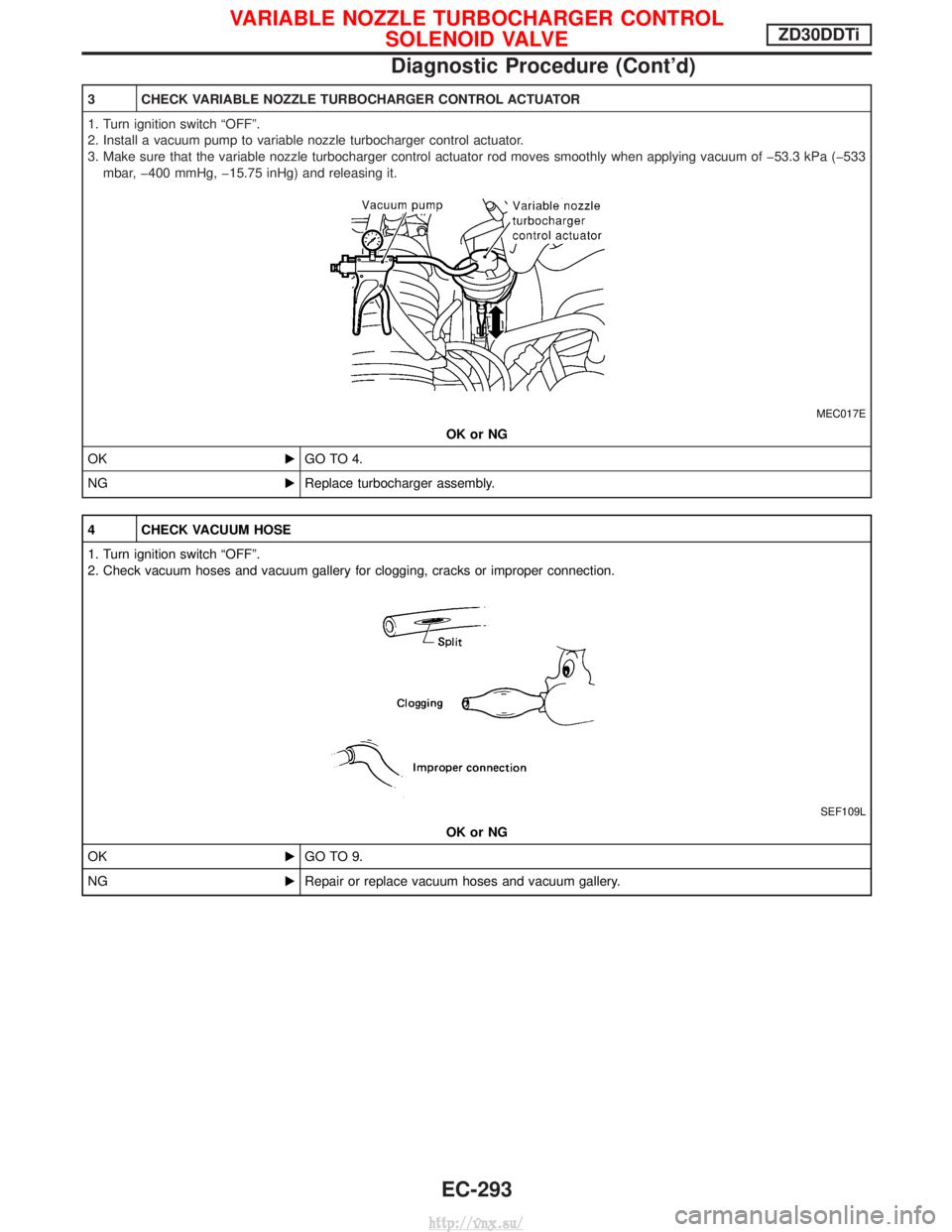

3 CHECK VARIABLE NOZZLE TURBOCHARGER CONTROL ACTUATOR

1. Turn ignition switch ªOFFº.

2. Install a vacuum pump to variable nozzle turbocharger control actuator.

3. Make sure that the variable nozzle turbocharger control actuator rod moves smoothly when applying vacuum of þ53.3 kPa (þ533mbar, þ400 mmHg, þ15.75 inHg) and releasing it.

MEC017E

OK or NG

OK EGO TO 4.

NG EReplace turbocharger assembly.

4 CHECK VACUUM HOSE

1. Turn ignition switch ªOFFº.

2. Check vacuum hoses and vacuum gallery for clogging, cracks or improper connection.

SEF109L

OK or NG

OK EGO TO 9.

NG ERepair or replace vacuum hoses and vacuum gallery.

VARIABLE NOZZLE TURBOCHARGER CONTROL

SOLENOID VALVEZD30DDTi

Diagnostic Procedure (Cont'd)

EC-293

http://vnx.su/

Page 569 of 1833

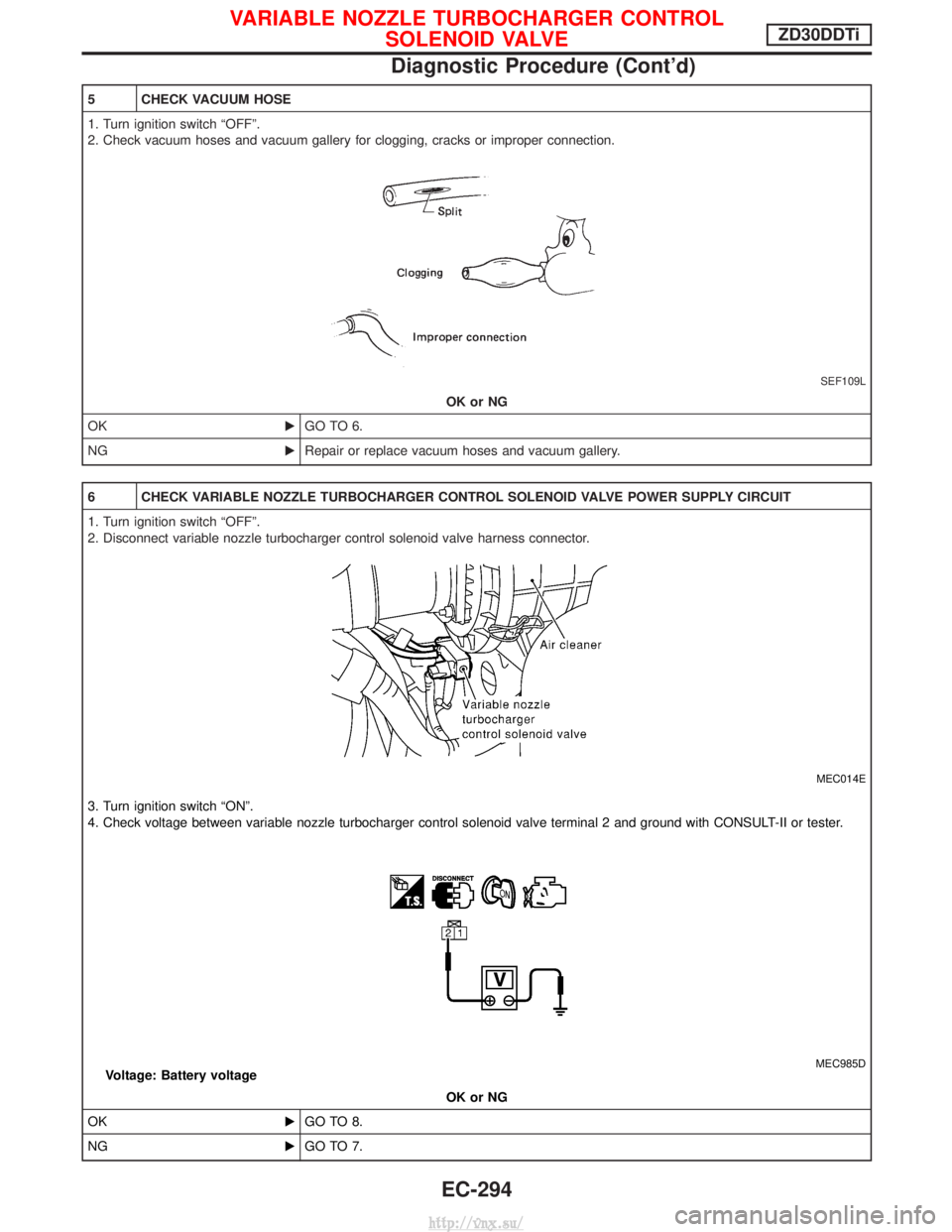

5 CHECK VACUUM HOSE

1. Turn ignition switch ªOFFº.

2. Check vacuum hoses and vacuum gallery for clogging, cracks or improper connection.

SEF109L

OK or NG

OK EGO TO 6.

NG ERepair or replace vacuum hoses and vacuum gallery.

6 CHECK VARIABLE NOZZLE TURBOCHARGER CONTROL SOLENOID VALVE POWER SUPPLY CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect variable nozzle turbocharger control solenoid valve harness connector.

MEC014E

3. Turn ignition switch ªONº.

4. Check voltage between variable nozzle turbocharger control solenoid valve terminal 2 and ground with CONSULT-II or tester.

MEC985DVoltage: Battery voltage

OK or NG

OK EGO TO 8.

NG EGO TO 7.

VARIABLE NOZZLE TURBOCHARGER CONTROL

SOLENOID VALVEZD30DDTi

Diagnostic Procedure (Cont'd)

EC-294

http://vnx.su/

Page 570 of 1833

7 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors M842, F135 (RHD models)

I Fuse block (J/B) connector F48 (LHD models), M756 (RHD models)

I 10A fuse

I Harness for open or short between variable nozzle turbocharger control solenoid valve and fuse

ERepair open circuit or short to ground or short to power in harness or connectors.

8 CHECK VARIABLE NOZZLE TURBOCHARGER CONTROL SOLENOID VALVE OUTPUT SIGNAL CIRCUIT FOR

OPEN OR SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminal 101 and variable nozzle turbocharger control solenoid valve terminal 1. Refer to Wiring Diagram. Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK EGO TO 10.

NG EGO TO 9.

9 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors F135, M842 (RHD models)

I Harness for open or short between variable nozzle turbocharger control solenoid valve and ECM

ERepair open circuit or short to ground or short to power in harness or connectors.

VARIABLE NOZZLE TURBOCHARGER CONTROL

SOLENOID VALVEZD30DDTi

Diagnostic Procedure (Cont'd)

EC-295

http://vnx.su/

Page 572 of 1833

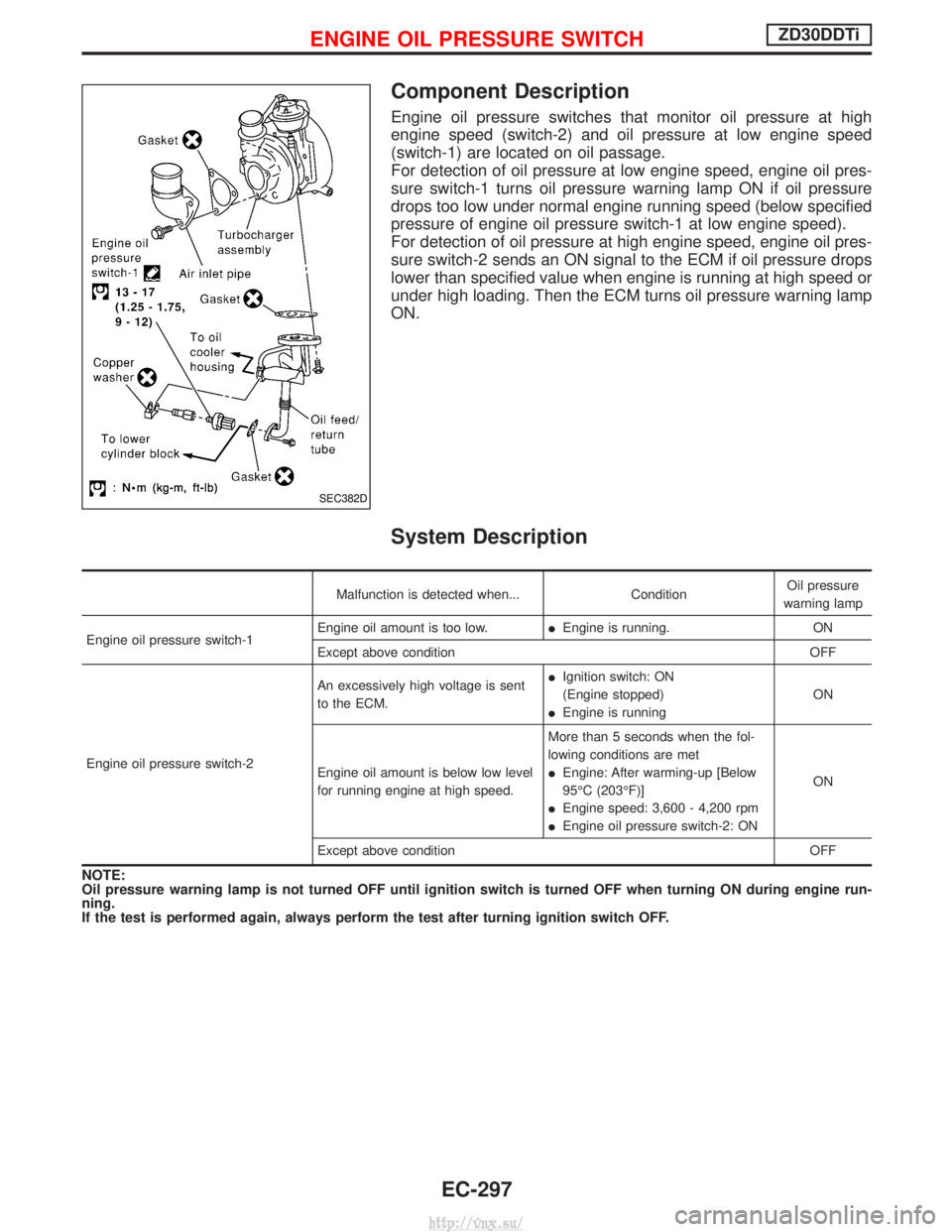

Component Description

Engine oil pressure switches that monitor oil pressure at high

engine speed (switch-2) and oil pressure at low engine speed

(switch-1) are located on oil passage.

For detection of oil pressure at low engine speed, engine oil pres-

sure switch-1 turns oil pressure warning lamp ON if oil pressure

drops too low under normal engine running speed (below specified

pressure of engine oil pressure switch-1 at low engine speed).

For detection of oil pressure at high engine speed, engine oil pres-

sure switch-2 sends an ON signal to the ECM if oil pressure drops

lower than specified value when engine is running at high speed or

under high loading. Then the ECM turns oil pressure warning lamp

ON.

System Description

Malfunction is detected when...ConditionOil pressure

warning lamp

Engine oil pressure switch-1 Engine oil amount is too low.

IEngine is running. ON

Except above condition OFF

Engine oil pressure switch-2 An excessively high voltage is sent

to the ECM.

I

Ignition switch: ON

(Engine stopped)

I Engine is running ON

Engine oil amount is below low level

for running engine at high speed. More than 5 seconds when the fol-

lowing conditions are met

I

Engine: After warming-up [Below

95ÉC (203ÉF)]

I Engine speed: 3,600 - 4,200 rpm

I Engine oil pressure switch-2: ON ON

Except above condition OFF

NOTE:

Oil pressure warning lamp is not turned OFF until ignition switch is turned OFF when turning ON during engine run-

ning.

If the test is performed again, always perform the test after turning ignition switch OFF.

SEC382D

ENGINE OIL PRESSURE SWITCHZD30DDTi

EC-297

http://vnx.su/

Page 573 of 1833

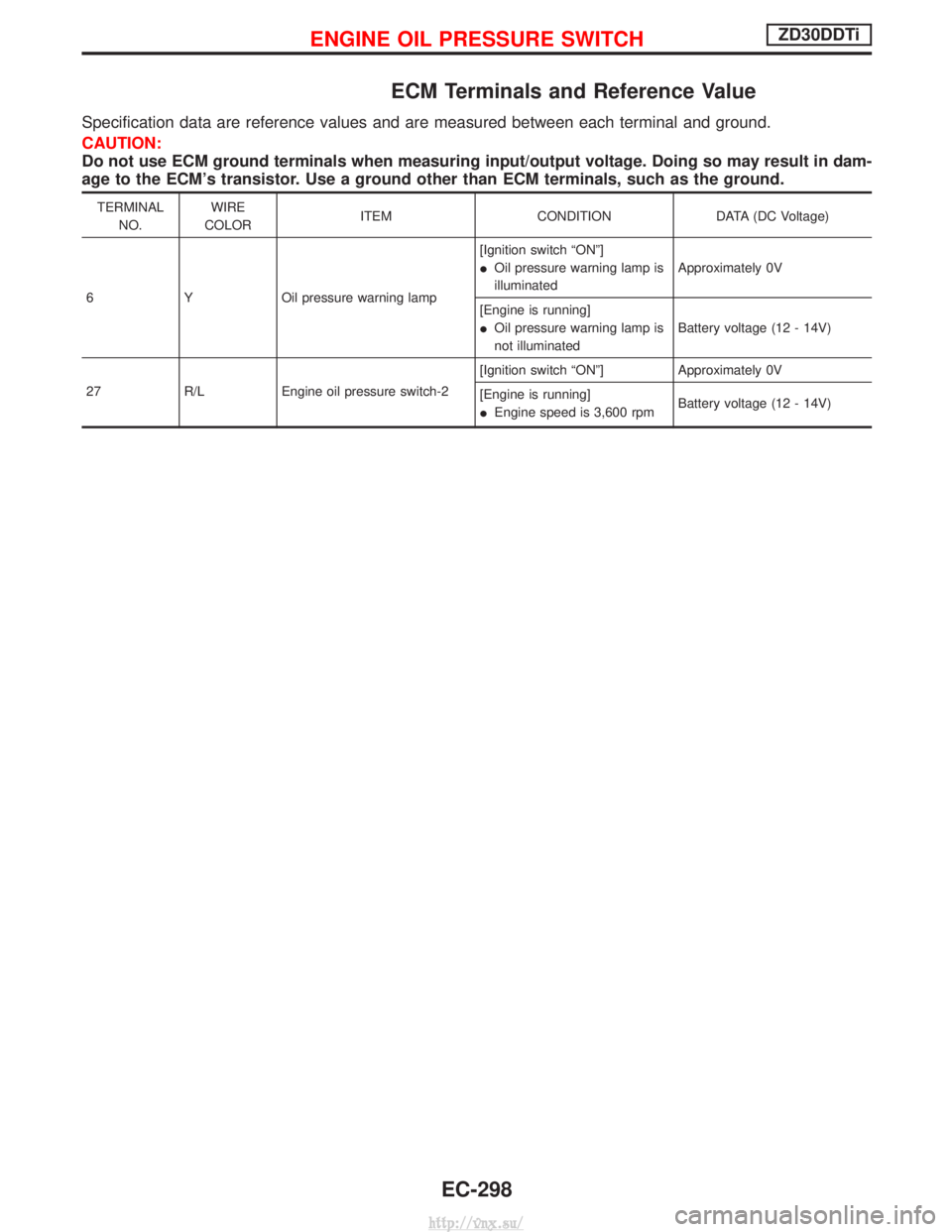

ECM Terminals and Reference Value

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMINALNO. WIRE

COLOR ITEM CONDITION DATA (DC Voltage)

6 Y Oil pressure warning lamp [Ignition switch ªONº]

I

Oil pressure warning lamp is

illuminated Approximately 0V

[Engine is running]

I Oil pressure warning lamp is

not illuminated Battery voltage (12 - 14V)

27 R/L Engine oil pressure switch-2 [Ignition switch ªONº] Approximately 0V

[Engine is running]

I

Engine speed is 3,600 rpm Battery voltage (12 - 14V)

ENGINE OIL PRESSURE SWITCHZD30DDTi

EC-298

http://vnx.su/

Page 576 of 1833

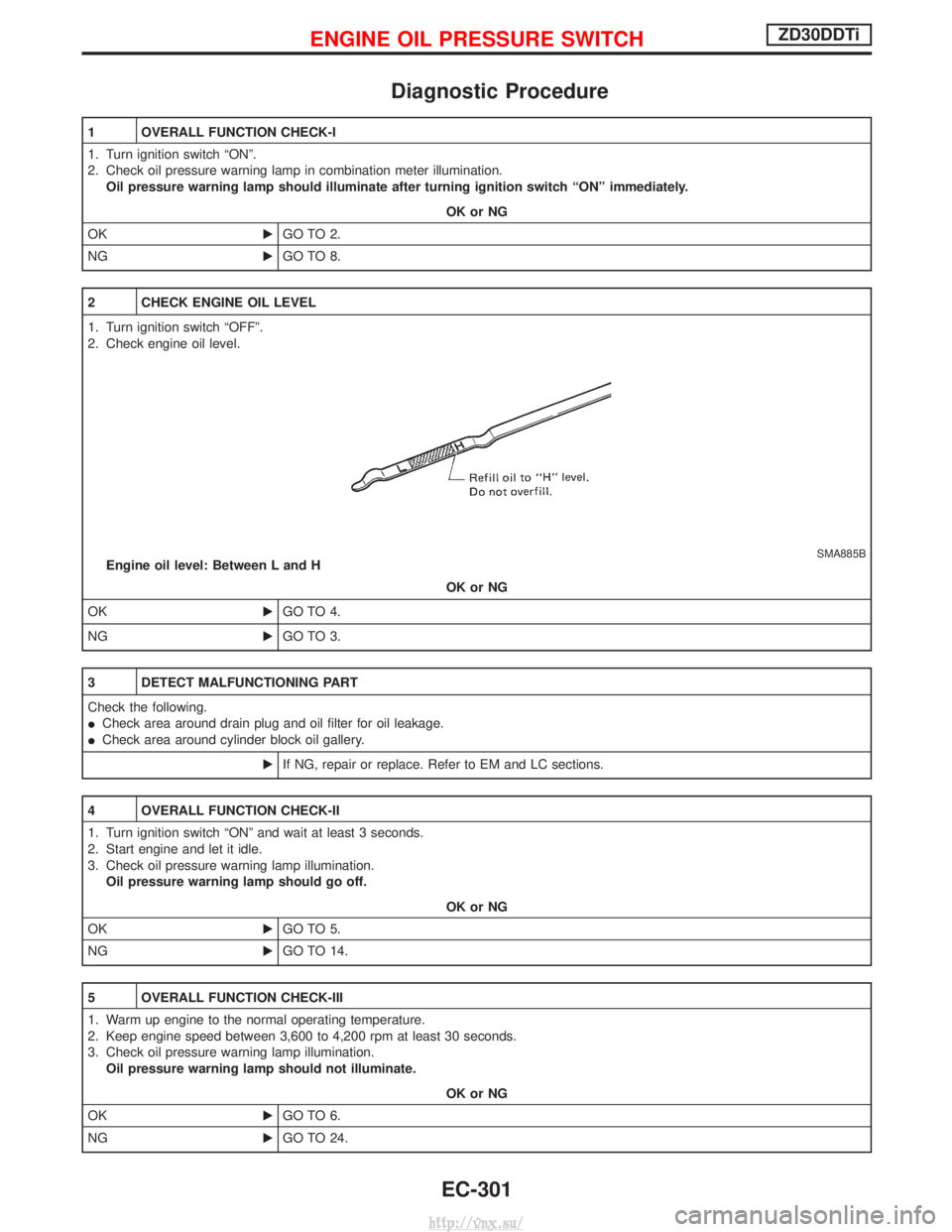

Diagnostic Procedure

1 OVERALL FUNCTION CHECK-I

1. Turn ignition switch ªONº.

2. Check oil pressure warning lamp in combination meter illumination.Oil pressure warning lamp should illuminate after turning ignition switch ªONº immediately.

OK or NG

OK EGO TO 2.

NG EGO TO 8.

2 CHECK ENGINE OIL LEVEL

1. Turn ignition switch ªOFFº.

2. Check engine oil level.

SMA885BEngine oil level: Between L and H

OK or NG

OK EGO TO 4.

NG EGO TO 3.

3 DETECT MALFUNCTIONING PART

Check the following.

ICheck area around drain plug and oil filter for oil leakage.

I Check area around cylinder block oil gallery.

EIf NG, repair or replace. Refer to EM and LC sections.

4 OVERALL FUNCTION CHECK-II

1. Turn ignition switch ªONº and wait at least 3 seconds.

2. Start engine and let it idle.

3. Check oil pressure warning lamp illumination.

Oil pressure warning lamp should go off.

OK or NG

OK EGO TO 5.

NG EGO TO 14.

5 OVERALL FUNCTION CHECK-III

1. Warm up engine to the normal operating temperature.

2. Keep engine speed between 3,600 to 4,200 rpm at least 30 seconds.

3. Check oil pressure warning lamp illumination.

Oil pressure warning lamp should not illuminate.

OK or NG

OK EGO TO 6.

NG EGO TO 24.

ENGINE OIL PRESSURE SWITCHZD30DDTi

EC-301

http://vnx.su/

Page 577 of 1833

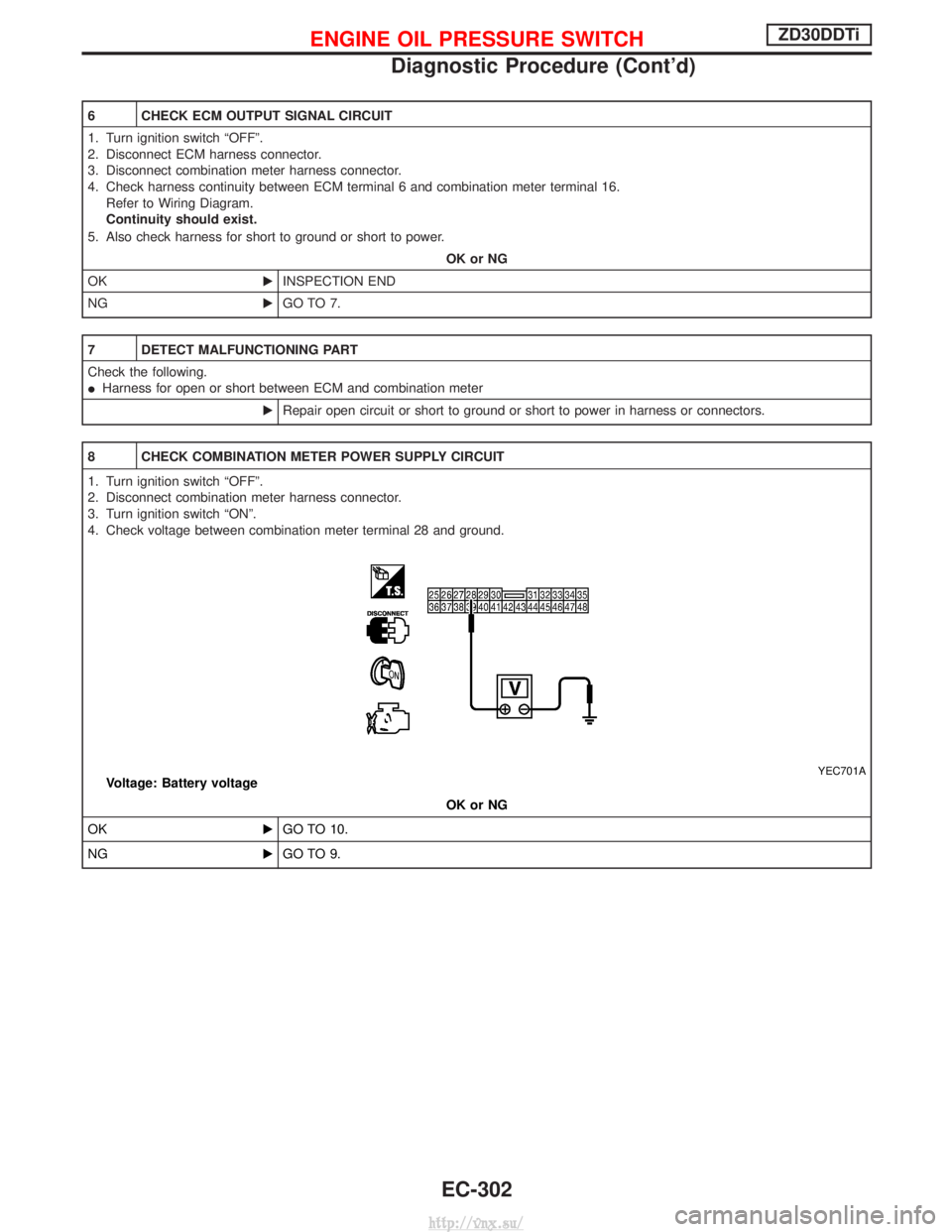

6 CHECK ECM OUTPUT SIGNAL CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Disconnect combination meter harness connector.

4. Check harness continuity between ECM terminal 6 and combination meter terminal 16.Refer to Wiring Diagram.

Continuity should exist.

5. Also check harness for short to ground or short to power.

OK or NG

OK EINSPECTION END

NG EGO TO 7.

7 DETECT MALFUNCTIONING PART

Check the following.

IHarness for open or short between ECM and combination meter

ERepair open circuit or short to ground or short to power in harness or connectors.

8 CHECK COMBINATION METER POWER SUPPLY CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect combination meter harness connector.

3. Turn ignition switch ªONº.

4. Check voltage between combination meter terminal 28 and ground.

YEC701AVoltage: Battery voltage

OK or NG

OK EGO TO 10.

NG EGO TO 9.

ENGINE OIL PRESSURE SWITCHZD30DDTi

Diagnostic Procedure (Cont'd)

EC-302

http://vnx.su/

Page 578 of 1833

9 DETECT MALFUNCTIONING PART

Check the following.

I10A fuse

I Fuse block (J/B) connector F48 (LHD models)

I Fuse block (J/B) connector M756 (RHD models)

I Harness for open or short between combination meter and fuse block

ERepair open circuit or short to ground or short to power in harness or connectors.

10 CHECK ENGINE OIL PRESSURE SWITCH-1 INPUT SIGNAL CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect engine oil pressure switch-1 harness connector.

3. Check harness continuity between combination meter terminal 16 and engine oil pressure switch-1 terminal 1.

Refer to Wiring Diagram.

Continuity should exist.

4. Also check harness for short to power.

OK or NG

OK EGO TO 12.

NG EGO TO 11.

11 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors F108, E225

I Harness connectors M842, F135 (RHD models)

I Harness for open or short between combination meter and engine oil pressure switch-1

ERepair open circuit or short to power in harness or connectors.

ENGINE OIL PRESSURE SWITCHZD30DDTi

Diagnostic Procedure (Cont'd)

EC-303

http://vnx.su/

Page 579 of 1833

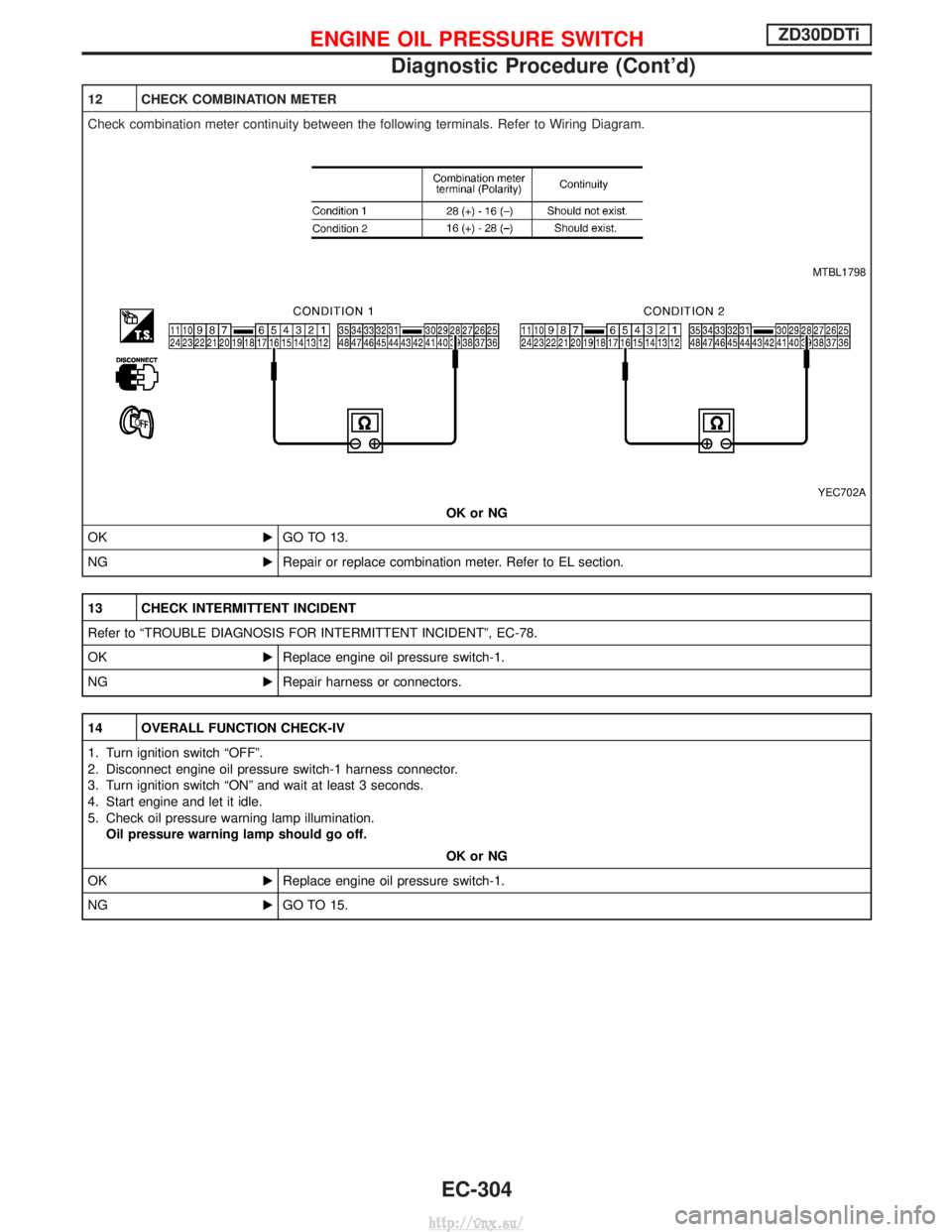

12 CHECK COMBINATION METER

Check combination meter continuity between the following terminals. Refer to Wiring Diagram.

MTBL1798

YEC702A

OK or NG

OK EGO TO 13.

NG ERepair or replace combination meter. Refer to EL section.

13 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-78.

OK EReplace engine oil pressure switch-1.

NG ERepair harness or connectors.

14 OVERALL FUNCTION CHECK-IV

1. Turn ignition switch ªOFFº.

2. Disconnect engine oil pressure switch-1 harness connector.

3. Turn ignition switch ªONº and wait at least 3 seconds.

4. Start engine and let it idle.

5. Check oil pressure warning lamp illumination.

Oil pressure warning lamp should go off.

OK or NG

OK EReplace engine oil pressure switch-1.

NG EGO TO 15.

ENGINE OIL PRESSURE SWITCHZD30DDTi

Diagnostic Procedure (Cont'd)

EC-304

http://vnx.su/

Page 580 of 1833

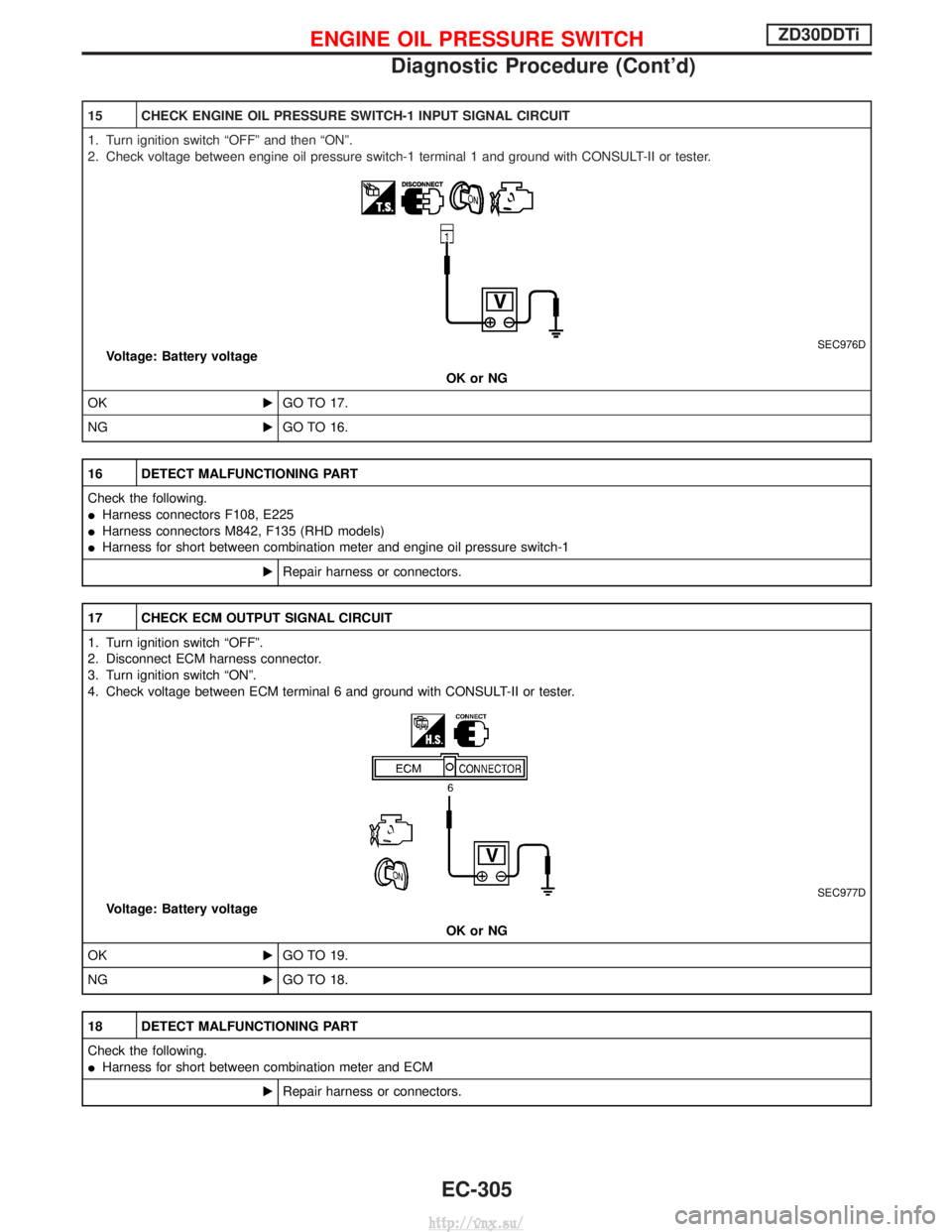

15 CHECK ENGINE OIL PRESSURE SWITCH-1 INPUT SIGNAL CIRCUIT

1. Turn ignition switch ªOFFº and then ªONº.

2. Check voltage between engine oil pressure switch-1 terminal 1 and ground with CONSULT-II or tester.

SEC976DVoltage: Battery voltageOK or NG

OK EGO TO 17.

NG EGO TO 16.

16 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors F108, E225

I Harness connectors M842, F135 (RHD models)

I Harness for short between combination meter and engine oil pressure switch-1

ERepair harness or connectors.

17 CHECK ECM OUTPUT SIGNAL CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Turn ignition switch ªONº.

4. Check voltage between ECM terminal 6 and ground with CONSULT-II or tester.

SEC977D

Voltage: Battery voltage

OK or NG

OK EGO TO 19.

NG EGO TO 18.

18 DETECT MALFUNCTIONING PART

Check the following.

IHarness for short between combination meter and ECM

ERepair harness or connectors.

ENGINE OIL PRESSURE SWITCHZD30DDTi

Diagnostic Procedure (Cont'd)

EC-305

http://vnx.su/