Ignition NISSAN TERRANO 2004 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 581 of 1833

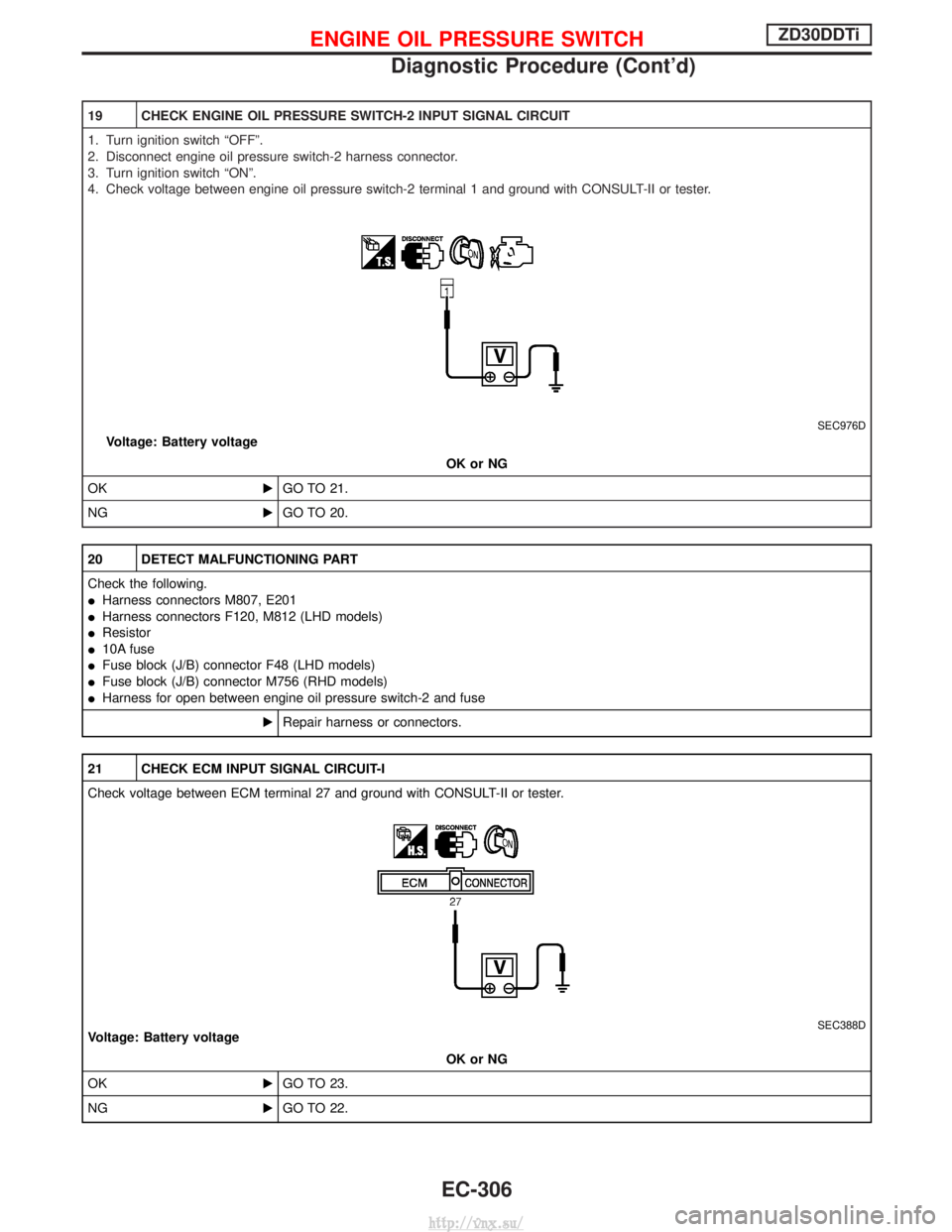

19 CHECK ENGINE OIL PRESSURE SWITCH-2 INPUT SIGNAL CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect engine oil pressure switch-2 harness connector.

3. Turn ignition switch ªONº.

4. Check voltage between engine oil pressure switch-2 terminal 1 and ground with CONSULT-II or tester.

SEC976D

Voltage: Battery voltageOK or NG

OK EGO TO 21.

NG EGO TO 20.

20 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors M807, E201

I Harness connectors F120, M812 (LHD models)

I Resistor

I 10A fuse

I Fuse block (J/B) connector F48 (LHD models)

I Fuse block (J/B) connector M756 (RHD models)

I Harness for open between engine oil pressure switch-2 and fuse

ERepair harness or connectors.

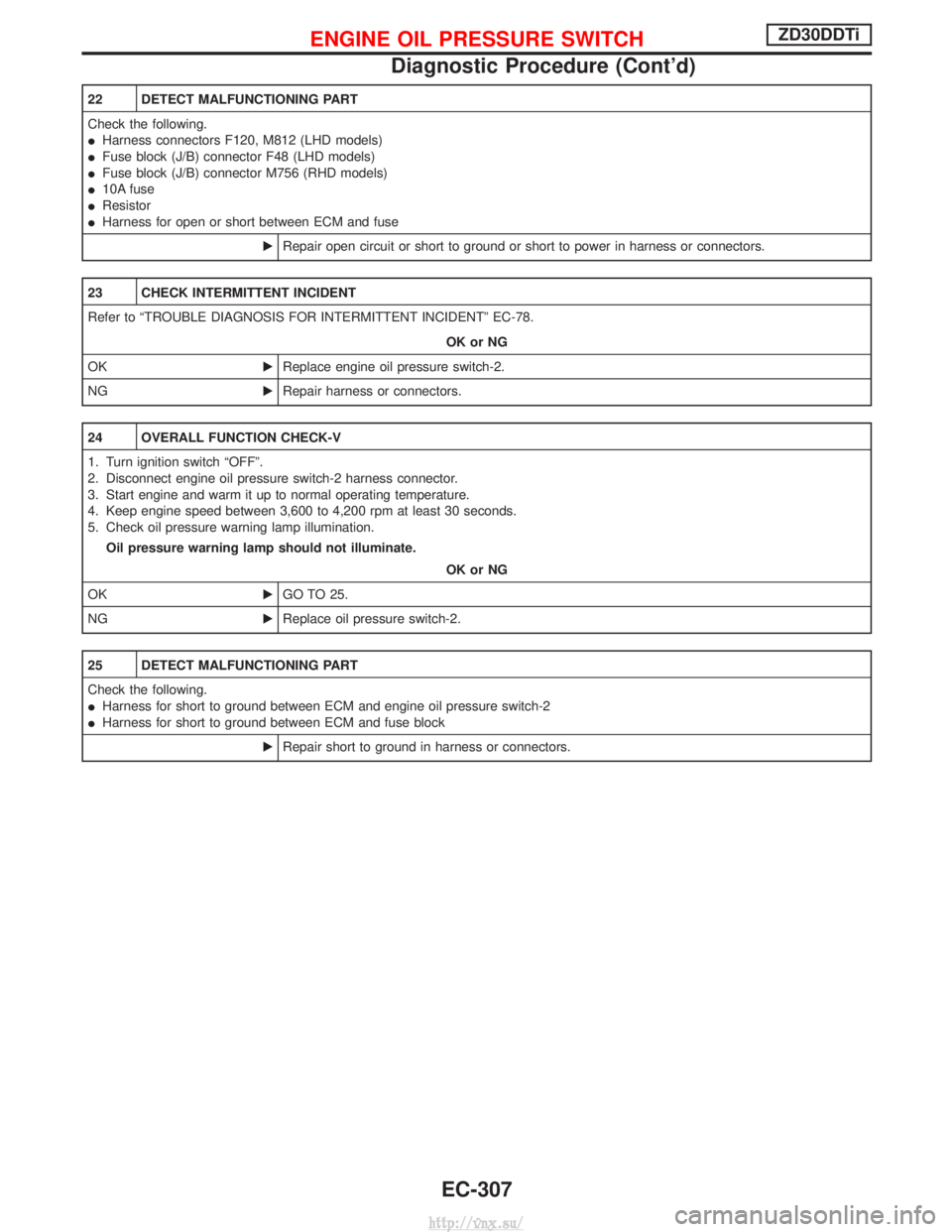

21 CHECK ECM INPUT SIGNAL CIRCUIT-I

Check voltage between ECM terminal 27 and ground with CONSULT-II or tester.

SEC388DVoltage: Battery voltage

OK or NG

OK EGO TO 23.

NG EGO TO 22.

ENGINE OIL PRESSURE SWITCHZD30DDTi

Diagnostic Procedure (Cont'd)

EC-306

http://vnx.su/

Page 582 of 1833

22 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors F120, M812 (LHD models)

I Fuse block (J/B) connector F48 (LHD models)

I Fuse block (J/B) connector M756 (RHD models)

I 10A fuse

I Resistor

I Harness for open or short between ECM and fuse

ERepair open circuit or short to ground or short to power in harness or connectors.

23 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº EC-78.

OK or NG

OK EReplace engine oil pressure switch-2.

NG ERepair harness or connectors.

24 OVERALL FUNCTION CHECK-V

1. Turn ignition switch ªOFFº.

2. Disconnect engine oil pressure switch-2 harness connector.

3. Start engine and warm it up to normal operating temperature.

4. Keep engine speed between 3,600 to 4,200 rpm at least 30 seconds.

5. Check oil pressure warning lamp illumination.

Oil pressure warning lamp should not illuminate.

OK or NG

OK EGO TO 25.

NG EReplace oil pressure switch-2.

25 DETECT MALFUNCTIONING PART

Check the following.

IHarness for short to ground between ECM and engine oil pressure switch-2

I Harness for short to ground between ECM and fuse block

ERepair short to ground in harness or connectors.

ENGINE OIL PRESSURE SWITCHZD30DDTi

Diagnostic Procedure (Cont'd)

EC-307

http://vnx.su/

Page 590 of 1833

Precautions

SUPPLEMENTAL RESTRAINT SYSTEM (SRS) ªAIR BAGº AND ªSEAT BELT

PRE-TENSIONERº

The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS composition which is available to NISSAN MODEL R20 is as follows (The composition

varies according to the destination and optional equipment.):

IFor a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steer-

ing wheel), front passenger air bag module (located on the instrument panel on passenger side), front seat

belt pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

I For a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of front

seat), side air bag (satellite) sensor, diagnosis sensor unit (one of components of air bags for a frontal

collision), wiring harness, warning lamp (one of components of air bags for a frontal collision).

WARNING:

I To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be per-

formed by an authorized NISSAN dealer.

I Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system.

I Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation tape either just

before the harness connectors or for the complete harness are related to the SRS.

PRECAUTIONS

IBefore connecting or disconnecting the ECM harness

connector, turn ignition switch OFF and disconnect nega-

tive battery terminal. Failure to do so may damage the ECM

because battery voltage is applied to ECM even if ignition

switch is turned off.

I Do not disassemble ECM.

SEF289H

PRECAUTIONS AND PREPARATIONTD27Ti

EC-315

http://vnx.su/

Page 596 of 1833

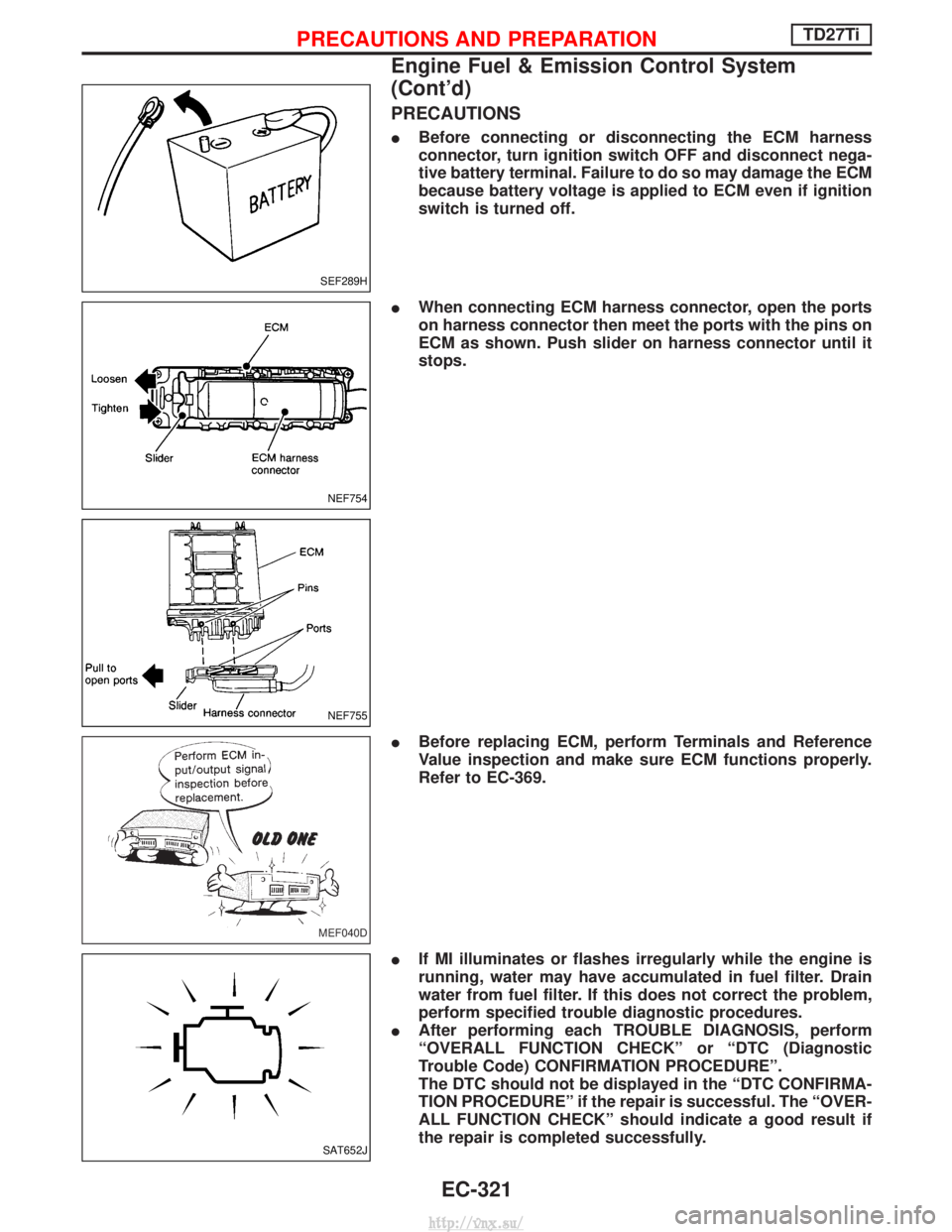

PRECAUTIONS

IBefore connecting or disconnecting the ECM harness

connector, turn ignition switch OFF and disconnect nega-

tive battery terminal. Failure to do so may damage the ECM

because battery voltage is applied to ECM even if ignition

switch is turned off.

I When connecting ECM harness connector, open the ports

on harness connector then meet the ports with the pins on

ECM as shown. Push slider on harness connector until it

stops.

I Before replacing ECM, perform Terminals and Reference

Value inspection and make sure ECM functions properly.

Refer to EC-369.

I If MI illuminates or flashes irregularly while the engine is

running, water may have accumulated in fuel filter. Drain

water from fuel filter. If this does not correct the problem,

perform specified trouble diagnostic procedures.

I After performing each TROUBLE DIAGNOSIS, perform

ªOVERALL FUNCTION CHECKº or ªDTC (Diagnostic

Trouble Code) CONFIRMATION PROCEDUREº.

The DTC should not be displayed in the ªDTC CONFIRMA-

TION PROCEDUREº if the repair is successful. The ªOVER-

ALL FUNCTION CHECKº should indicate a good result if

the repair is completed successfully.

SEF289H

NEF754

NEF755

MEF040D

SAT652J

PRECAUTIONS AND PREPARATIONTD27Ti

Engine Fuel & Emission Control System

(Cont'd)

EC-321

http://vnx.su/

Page 603 of 1833

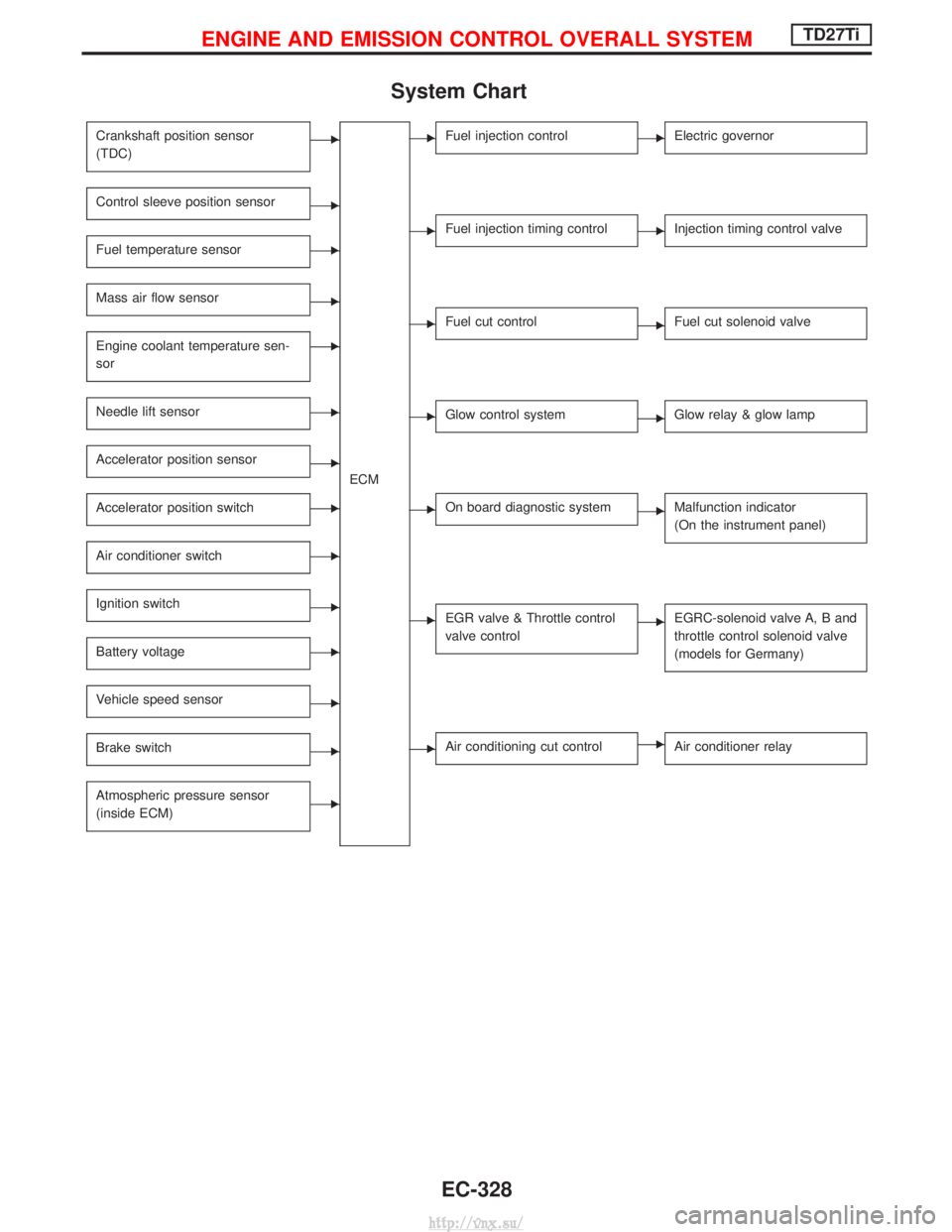

System Chart

Crankshaft position sensor

(TDC)E

ECM

Control sleeve position sensorE

Fuel temperature sensorE

Mass air flow sensorE

Engine coolant temperature sen-

sorE

Needle lift sensorE

Accelerator position sensorE

Accelerator position switchE

Air conditioner switchE

Ignition switchE

Battery voltageE

Vehicle speed sensorE

Brake switchE

Atmospheric pressure sensor

(inside ECM)E

EFuel injection controlEElectric governor

EFuel injection timing controlEInjection timing control valve

EFuel cut controlEFuel cut solenoid valve

EGlow control systemEGlow relay & glow lamp

EOn board diagnostic systemEMalfunction indicator

(On the instrument panel)

EEGR valve & Throttle control

valve controlEEGRC-solenoid valve A, B and

throttle control solenoid valve

(models for Germany)

EAir conditioning cut controlEAir conditioner relay

ENGINE AND EMISSION CONTROL OVERALL SYSTEMTD27Ti

EC-328

http://vnx.su/

Page 604 of 1833

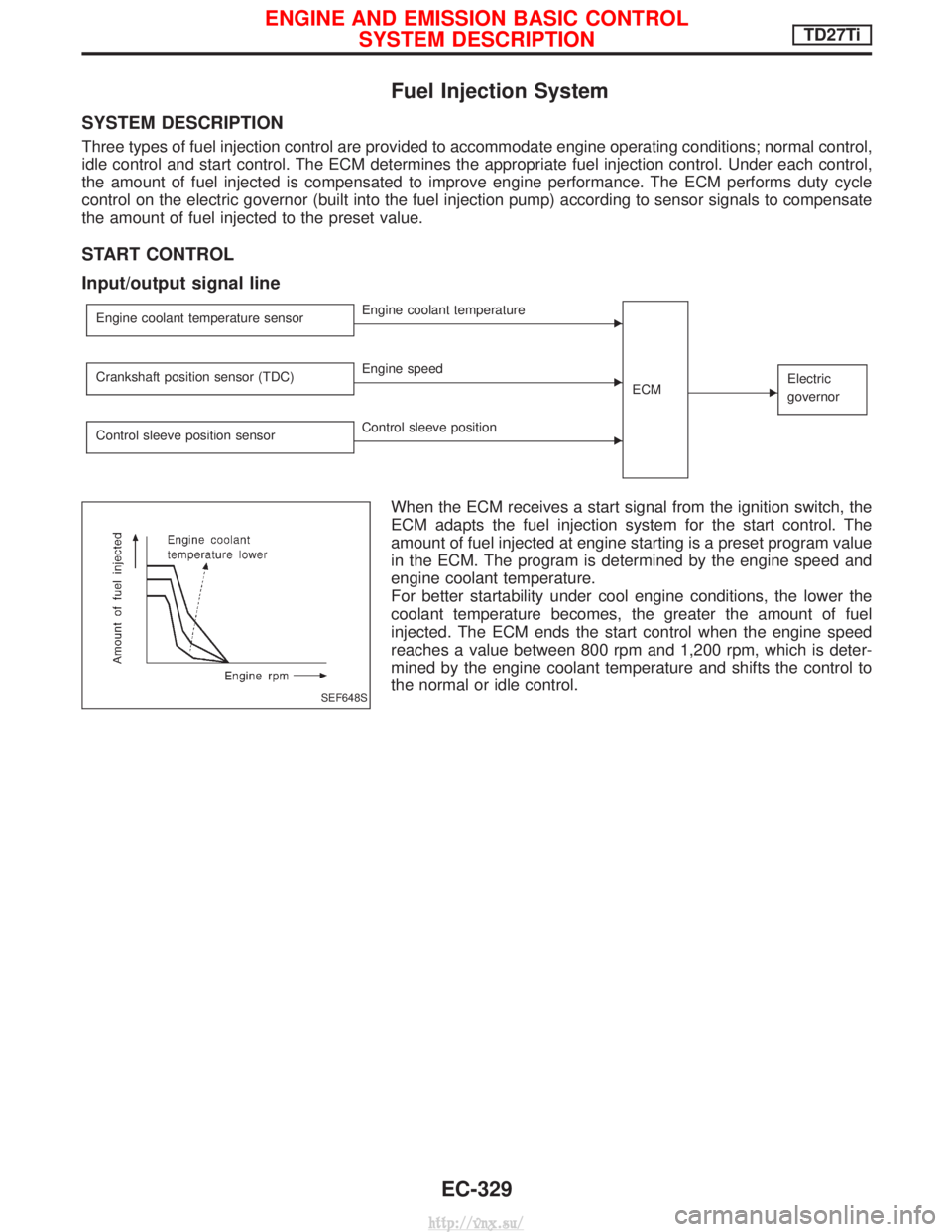

Fuel Injection System

SYSTEM DESCRIPTION

Three types of fuel injection control are provided to accommodate engine operating conditions; normal control,

idle control and start control. The ECM determines the appropriate fuel injection control. Under each control,

the amount of fuel injected is compensated to improve engine performance. The ECM performs duty cycle

control on the electric governor (built into the fuel injection pump) according to sensor signals to compensate

the amount of fuel injected to the preset value.

START CONTROL

Input/output signal line

Engine coolant temperature sensorEEngine coolant temperatureECM

EElectric

governorCrankshaft position sensor (TDC)EEngine speed

Control sleeve position sensor

EControl sleeve position

When the ECM receives a start signal from the ignition switch, the

ECM adapts the fuel injection system for the start control. The

amount of fuel injected at engine starting is a preset program value

in the ECM. The program is determined by the engine speed and

engine coolant temperature.

For better startability under cool engine conditions, the lower the

coolant temperature becomes, the greater the amount of fuel

injected. The ECM ends the start control when the engine speed

reaches a value between 800 rpm and 1,200 rpm, which is deter-

mined by the engine coolant temperature and shifts the control to

the normal or idle control.

SEF648S

ENGINE AND EMISSION BASIC CONTROL SYSTEM DESCRIPTIONTD27Ti

EC-329

http://vnx.su/

Page 608 of 1833

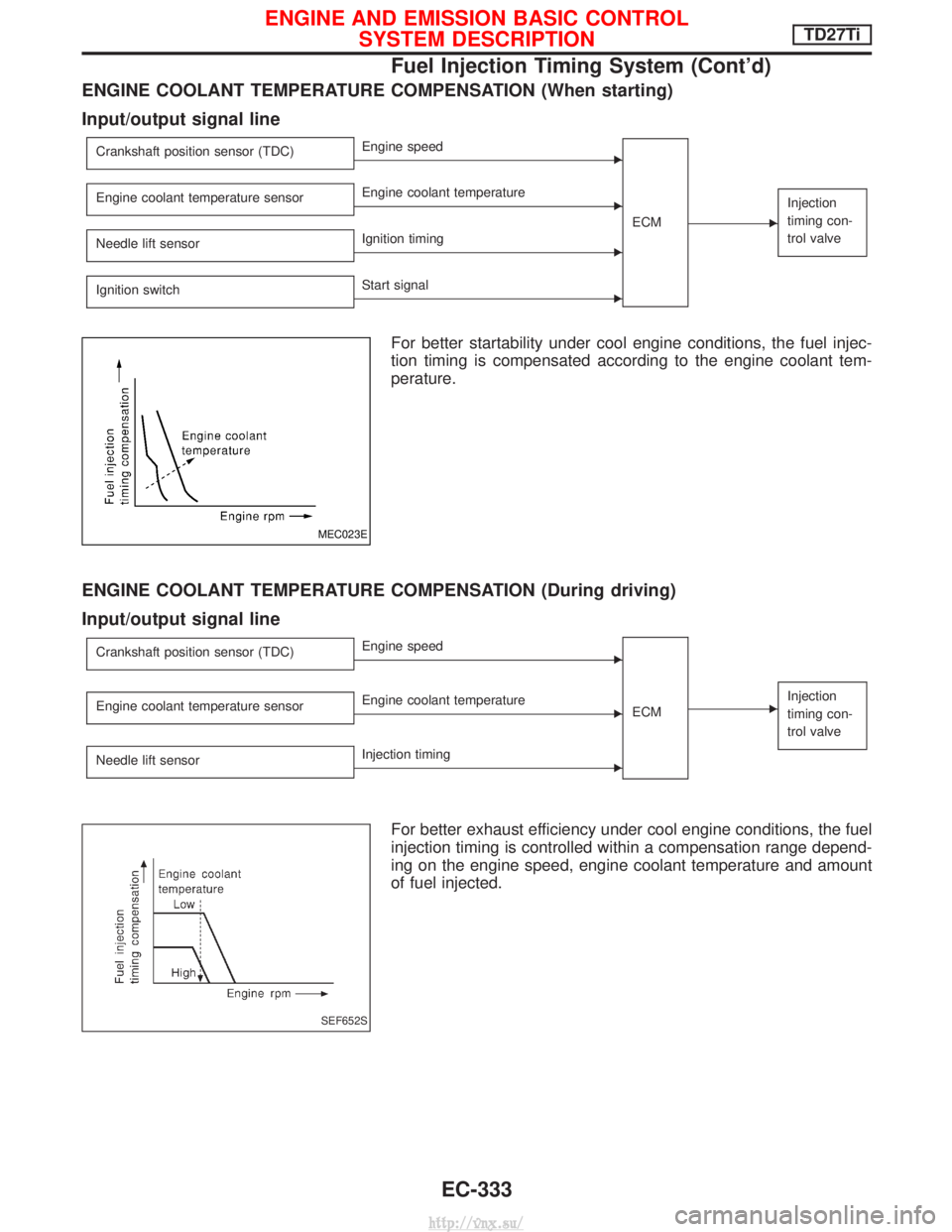

ENGINE COOLANT TEMPERATURE COMPENSATION (When starting)

Input/output signal line

Crankshaft position sensor (TDC)EEngine speedECM

E

Injection

timing con-

trol valveEngine coolant temperature sensorEEngine coolant temperature

Needle lift sensor

EIgnition timing

Ignition switch

EStart signal

For better startability under cool engine conditions, the fuel injec-

tion timing is compensated according to the engine coolant tem-

perature.

ENGINE COOLANT TEMPERATURE COMPENSATION (During driving)

Input/output signal line

Crankshaft position sensor (TDC)EEngine speed

ECM

EInjection

timing con-

trol valveEngine coolant temperature sensorEEngine coolant temperature

Needle lift sensor

EInjection timing

For better exhaust efficiency under cool engine conditions, the fuel

injection timing is controlled within a compensation range depend-

ing on the engine speed, engine coolant temperature and amount

of fuel injected.

MEC023E

SEF652S

ENGINE AND EMISSION BASIC CONTROL SYSTEM DESCRIPTIONTD27Ti

Fuel Injection Timing System (Cont'd)

EC-333

http://vnx.su/

Page 609 of 1833

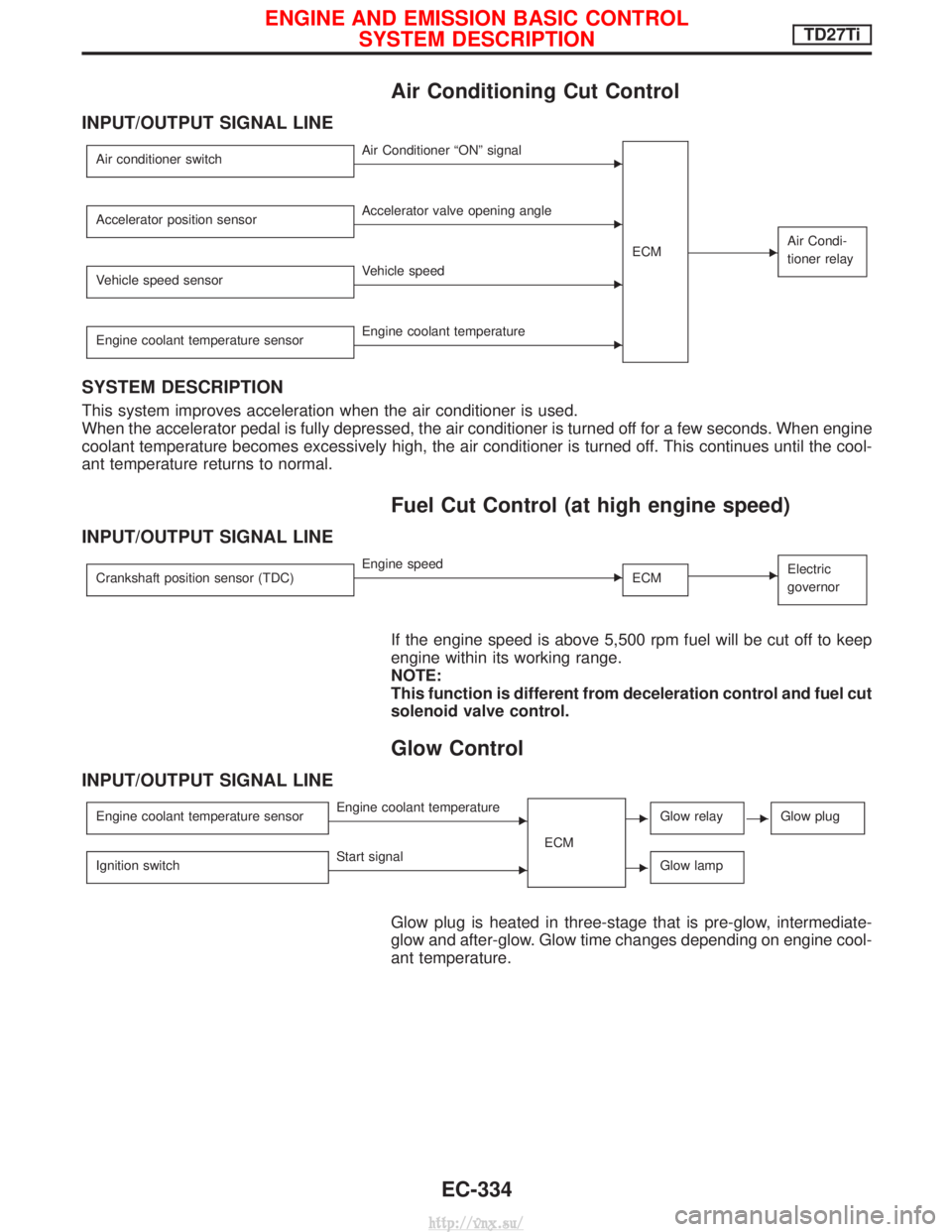

Air Conditioning Cut Control

INPUT/OUTPUT SIGNAL LINE

Air conditioner switchEAir Conditioner ªONº signalECM

EAir Condi-

tioner relay

Accelerator position sensorEAccelerator valve opening angle

Vehicle speed sensor

EVehicle speed

Engine coolant temperature sensor

EEngine coolant temperature

SYSTEM DESCRIPTION

This system improves acceleration when the air conditioner is used.

When the accelerator pedal is fully depressed, the air conditioner is turned off for a few seconds. When engine

coolant temperature becomes excessively high, the air conditioner is turned off. This continues until the cool-

ant temperature returns to normal.

Fuel Cut Control (at high engine speed)

INPUT/OUTPUT SIGNAL LINE

Crankshaft position sensor (TDC)EEngine speed ECMEElectric

governor

If the engine speed is above 5,500 rpm fuel will be cut off to keep

engine within its working range.

NOTE:

This function is different from deceleration control and fuel cut

solenoid valve control.

Glow Control

INPUT/OUTPUT SIGNAL LINE

Engine coolant temperature sensorEEngine coolant temperature

ECMEGlow relayEGlow plug

Ignition switchEStart signalEGlow lamp

Glow plug is heated in three-stage that is pre-glow, intermediate-

glow and after-glow. Glow time changes depending on engine cool-

ant temperature.

ENGINE AND EMISSION BASIC CONTROLSYSTEM DESCRIPTIONTD27Ti

EC-334

http://vnx.su/

Page 619 of 1833

DTC and MI Detection Logic

When a malfunction is detected for the first time, the malfunction (DTC) is stored in the ECM memory.

The MI will light up each time the ECM detects a malfunction. However, if the same malfunction is experienced

in two consecutive driving patterns and the engine is still running, the MI will stay lit up. For a description of

diagnostic items causing the MI to light up, refer to ªTROUBLE DIAGNOSIS Ð INDEXº, EC-313.

Diagnostic Trouble Code (DTC)

HOW TO READ DTC

The DTC can be read by the following methods.

Without CONSULT-II

ECM displays the DTC by a set of four digit numbers with MI illumination in the diagnostic test mode II (Self-

diagnostic results). Example: 0102, 0103, 0104, etc.

With CONSULT-II

CONSULT-II displays the DTC in ªSELF-DIAG RESULTSº mode. Examples: P0100, P0115, P0500, etc.

These DTCs are prescribed by ISO15031-6.

(CONSULT-II also displays the malfunctioning component or system.)

IOutput of the trouble code means that the indicated circuit has a malfunction. However, in the Mode

II it does not indicate whether the malfunction is still occurring or occurred in the past and returned

to normal.

CONSULT-II can identify them. Therefore, using CONSULT-II (if available) is recommended.

HOW TO ERASE DTC

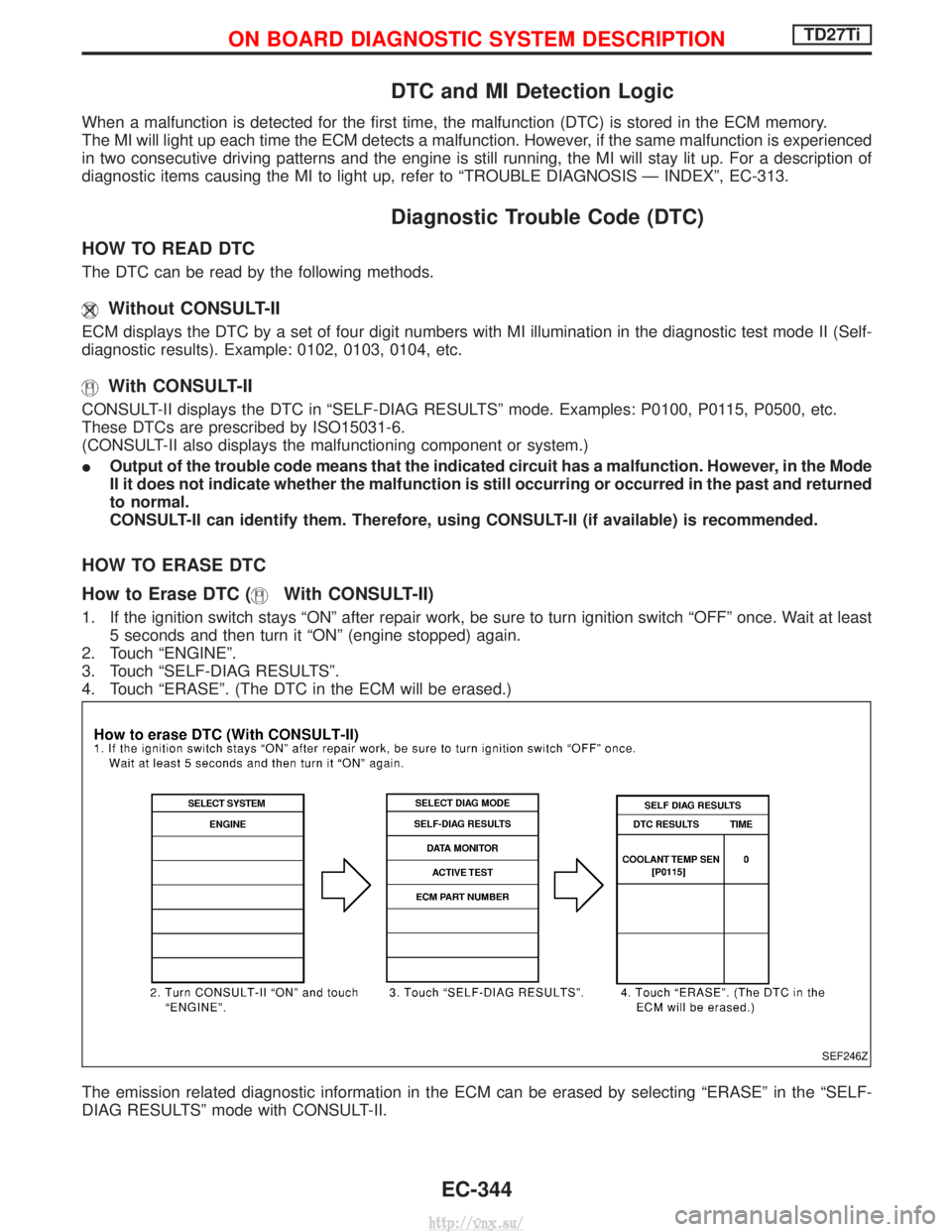

How to Erase DTC (

With CONSULT-II)

1. If the ignition switch stays ªONº after repair work, be sure to turn ignition switch ªOFFº once. Wait at least

5 seconds and then turn it ªONº (engine stopped) again.

2. Touch ªENGINEº.

3. Touch ªSELF-DIAG RESULTSº.

4. Touch ªERASEº. (The DTC in the ECM will be erased.)

The emission related diagnostic information in the ECM can be erased by selecting ªERASEº in the ªSELF-

DIAG RESULTSº mode with CONSULT-II.

SEF246Z

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONTD27Ti

EC-344

http://vnx.su/

Page 620 of 1833

How to Erase DTC (Without CONSULT-II)

1. If the ignition switch stays ªONº after repair work, be sure to turn ignition switch ªOFFº once. Wait at least5 seconds and then turn it ªONº (engine stopped) again.

2. Change the diagnostic test mode from Mode II to Mode I by using the data link connector. (See EC-346.)

The emission related diagnostic information in the ECM can be erased by changing the diagnostic test mode.

I If the battery is disconnected, the emission-related diagnostic information will be lost after approx.

24 hours.

I Erasing the emission-related diagnostic information using CONSULT-II is easier and quicker than

switching the diagnostic test mode using the data link connector.

Malfunction Indicator (MI)

1. The malfunction indicator will light up when the ignition switch

is turned ON without the engine running. This is a bulb check.

I If the malfunction indicator does not light up, refer to EL sec-

tion (ªWARNING LAMPS/WIRING DIAGRAMº) or see MI &

DATA LINK CONNECTORS.

2. When the engine is started, the malfunction indicator should go off.

If the lamp remains on, the on board diagnostic system has

detected an engine system malfunction.

If MI illuminates or flashes irregularly after starting engine,

water may have accumulated in fuel filter. Drain water from

fuel filter.

ON BOARD DIAGNOSTIC SYSTEM FUNCTION

The on board diagnostic system has the following three functions.

Diagnostic

Test Mode KEY and ENG.

Status Function Explanation of Function

Mode I Ignition switch in

ON position

Engine stoppedBULB CHECK

This function checks the MI bulb for damage (blown, open

circuit, etc.).

If the MI does not come on, check MI circuit. (See EC-475.)

Engine running

MALFUNCTION

WARNING This is a usual driving condition. When ECM detects a

malfunction, the MI will light up to inform the driver that a mal-

function has been detected.

Mode II Ignition switch in

ON position

Engine stopped

SELF-DIAGNOSTIC

RESULTS

This function allows DTCs to be read.

SAT652J

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONTD27Ti

Diagnostic Trouble Code (DTC) (Cont'd)

EC-345

http://vnx.su/