turn signal NISSAN TIIDA 2007 Service Owners Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 382 of 5883

![NISSAN TIIDA 2007 Service Owners Manual C1160 DECEL G SEN SET

BRC-149

< COMPONENT DIAGNOSIS >[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

C1160 DECEL G SEN SET

DescriptionINFOID:0000000001731155

The yaw rate/side/decel G sensor detects th NISSAN TIIDA 2007 Service Owners Manual C1160 DECEL G SEN SET

BRC-149

< COMPONENT DIAGNOSIS >[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

C1160 DECEL G SEN SET

DescriptionINFOID:0000000001731155

The yaw rate/side/decel G sensor detects th](/img/5/57395/w960_57395-381.png)

C1160 DECEL G SEN SET

BRC-149

< COMPONENT DIAGNOSIS >[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

C1160 DECEL G SEN SET

DescriptionINFOID:0000000001731155

The yaw rate/side/decel G sensor detects the yaw rate/side/decel G affecting the vehicle, and transmits the

data to the ABS actuator and electric unit (control unit) as an analog voltage signal.

DTC LogicINFOID:0000000001731156

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAGNOSIS RESULTS

Check the self-diagnosis results.

Is above displayed on the self-diagnosis display?

YES >> Proceed to diagnosis procedure. Refer to BRC-149, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000001731157

INSPECTION PROCEDURE

1.PERFORM SELF-DIAGNOSIS

Perform ABS actuator and electric unit (control unit) self-diagnosis.

Do self-diagnosis results indicate anything other than shown above?

YES >> Perform repair or replacement for the item indicated.

NO >> Perform calibration of decel G sensor. Refer to BRC-91, "

CALIBRATION OF DECEL G SENSOR

: Description". GO TO 2

2.PERFORM SELF-DIAGNOSIS AGAIN

1. Turn the ignition switch to OFF and then to ON and erase self-diagnosis results.

2. Perform ABS actuator and electric unit (control unit) self-diagnosis again.

Are any self-diagnosis results displayed?

YES >> Replace yaw rate/side/decel G sensor. Refer to BRC-185, "Removal and Installation".

NO >> INSPECTION END

DTC Display item Malfunction detected condition Possible cause

C1160 DECEL G SEN SET ABS decel G sensor adjustment is incomplete. Decel G sensor calibration

Yaw rate/side/decel G sensor

ABS actuator and electric unit

(control unit)

Self-diagnosis results

DECEL G SEN SET

Self-diagnosis results

DECEL G SEN SET

Page 384 of 5883

![NISSAN TIIDA 2007 Service Owners Manual C1179 ABS DELTA S SEN NG

BRC-151

< COMPONENT DIAGNOSIS >[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

C1179 ABS DELTA S SEN NG

DescriptionINFOID:0000000001731171

The active brake booster consists of NISSAN TIIDA 2007 Service Owners Manual C1179 ABS DELTA S SEN NG

BRC-151

< COMPONENT DIAGNOSIS >[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

C1179 ABS DELTA S SEN NG

DescriptionINFOID:0000000001731171

The active brake booster consists of](/img/5/57395/w960_57395-383.png)

C1179 ABS DELTA S SEN NG

BRC-151

< COMPONENT DIAGNOSIS >[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

C1179 ABS DELTA S SEN NG

DescriptionINFOID:0000000001731171

The active brake booster consists of a vacuum booster, an active booster control group and a delta stroke

sensor. If a brake booster system malfunction occurs due to loss of vacuum, the delta stroke sensor will signal

the ABS actuator and electric unit (control unit) that a booster malfunction has occurred. The active booster

then applies supplemental force to the master cylinder relative to the amount of force exerted on the brake

pedal.

DTC LogicINFOID:0000000001731172

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAGNOSIS RESULTS

Check the self-diagnosis results.

Is above displayed on the self-diagnosis display?

YES >> Proceed to diagnosis procedure. Refer to BRC-151, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000001731173

INSPECTION PROCEDURE

1.CONNECTOR INSPECTION

1. Turn the ignition switch OFF.

2. Disconnect the delta stroke sensor connector E114 and ABS actuator and electric unit (control unit) con-

nector E125 and inspect the terminals for deformation, disconnection, looseness, or damage.

Is the inspection result normal?

YES >> GO TO 2

NO >> Repair connector.

2.DELTA STROKE SENSOR CIRCUIT INSPECTION

1. Measure the continuity between ABS actuator and electric unit

(control unit) harness connector E125 (A) and delta stroke sen-

sor harness connector E114 (B).

2. Measure the continuity between ABS actuator and electric unit (control unit) harness connector E125 (A)

and body ground.

DTC Display item Malfunction detected condition Possible cause

C1179 ABS DELTA S SEN NGDelta stroke sensor is malfunctioning, or signal line of

delta stroke sensor is open or shorted. Harness or connector

Delta stroke sensor

ABS actuator and electric unit

(control unit)

Self-diagnosis results

ABS DELTA S SEN NG

ABS actuator and electric unit

(control unit)Delta stroke sensor

Continuity

Connector Terminal Connector Terminal

A: E12526

B: E1141

Ye s 39 3

40 5

AWFIA0029ZZ

Page 386 of 5883

![NISSAN TIIDA 2007 Service Owners Manual U1000 CAN COMM CIRCUIT

BRC-153

< COMPONENT DIAGNOSIS >[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

U1000 CAN COMM CIRCUIT

DescriptionINFOID:0000000001731176

CAN (Controller Area Network) is a serial NISSAN TIIDA 2007 Service Owners Manual U1000 CAN COMM CIRCUIT

BRC-153

< COMPONENT DIAGNOSIS >[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

U1000 CAN COMM CIRCUIT

DescriptionINFOID:0000000001731176

CAN (Controller Area Network) is a serial](/img/5/57395/w960_57395-385.png)

U1000 CAN COMM CIRCUIT

BRC-153

< COMPONENT DIAGNOSIS >[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

U1000 CAN COMM CIRCUIT

DescriptionINFOID:0000000001731176

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

DTC LogicINFOID:0000000001731177

DTC DETECTION LOGIC

Diagnosis ProcedureINFOID:0000000001731178

INSPECTION PROCEDURE

1.CHECK CONNECTOR

1. Turn ignition switch OFF, disconnect the ABS actuator and electric unit (control unit) connector, and check

the terminals for deformation, disconnection, looseness, and so on. If there is a malfunction, repair or

replace the terminal.

2. Reconnect connector and perform self-diagnosis.

Is

“CAN COMM CIRCUIT” displayed in self-diagnosis display items?

YES >> Print out the self-diagnostic results, and refer to BRC-86, "Work Flow".

NO >> Connector terminal is loose, damaged, open, or shorted.

Special Repair RequirementINFOID:0000000001731179

1.ADJUSTMENT OF STEERING ANGLE SENSOR NEUTRAL POSITION

Always perform neutral position adjustment for the steering angle sensor when replacing the ABS actuator

and electric unit (control unit). Refer to BRC-90, "

ADJUSTMENT OF STEERING ANGLE SENSOR NEUTRAL

POSITION : Description".

>> GO TO 2

2.CALIBRATION OF DECEL G SENSOR

Always perform calibration of decel G sensor when replacing the ABS actuator and electric unit (control unit).

Refer to BRC-91, "

CALIBRATION OF DECEL G SENSOR : Description".

>> END

DTC Display item Malfunction detected condition Possible cause

U1000 CAN COMM CIRCUITWhen ABS actuator and electric unit (control unit) is not

transmitting or receiving CAN communication signal for 2

seconds or more. CAN communication line

ABS actuator and electric unit

(control unit)

Page 393 of 5883

![NISSAN TIIDA 2007 Service Owners Manual BRC-160

< ECU DIAGNOSIS >[ESP/TCS/ABS]

ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

ECU DIAGNOSIS

ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

Reference ValueINFOID:0000000001731196

VALUES ON THE DI NISSAN TIIDA 2007 Service Owners Manual BRC-160

< ECU DIAGNOSIS >[ESP/TCS/ABS]

ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

ECU DIAGNOSIS

ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

Reference ValueINFOID:0000000001731196

VALUES ON THE DI](/img/5/57395/w960_57395-392.png)

BRC-160

< ECU DIAGNOSIS >[ESP/TCS/ABS]

ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

ECU DIAGNOSIS

ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

Reference ValueINFOID:0000000001731196

VALUES ON THE DIAGNOSIS TOOL

CAUTION:

The display shows the control unit calculation data, so a normal value might be displayed even in the

event the output circuit (harness) is open or short-circuited.

CONSULT-III MONITOR ITEM

Monitor item Display contentData monitor

ConditionReference value in

normal operation

FR LH SENSOR Wheel speed0 [km/h (MPH)] Vehicle stopped

Nearly matches the speed meter display

(± 10% or less)Vehicle running

(Note 1)

FR RH SENSOR Wheel speed0 [km/h (MPH)] Vehicle stopped

Nearly matches the speed meter display

(± 10% or less)Vehicle running

(Note 1)

RR LH SENSOR Wheel speed0 [km/h (MPH)] Vehicle stopped

Nearly matches the speed meter display

(± 10% or less)Vehicle running

(Note 1)

RR RH SENSOR Wheel speed0 [km/h (MPH)] Vehicle stopped

Nearly matches the speed meter display

(± 10% or less)Vehicle running

(Note 1)

STOP LAMP SW Stop lamp switch signal statusWhen brake pedal is depressed ON

When brake pedal is released OFF

BATTERY VOLTBattery voltage supplied to the ABS actuator

and electric unit (control unit)Ignition switch ON 10 – 16 V

GEAR Gear position determined by TCM1st gear

2nd gear

3rd gear

4th gear

5th gear1

2

3

4

5

SLCT LVR POSI A/T selector lever positionP position

R position

N position

D positionP

R

N

D

OFF SW VDC OFF switch ON/OFFVDC OFF switch ON

(When VDC OFF indicator lamp is ON)ON

VDC OFF switch OFF

(When VDC OFF indicator lamp is OFF)OFF

YAW R AT E S E NYaw rate detected by yaw rate/side/decel G

sensorWhen vehicle is stopped Approx. 0 d/s

When vehicle turning−75 to 75 d/s

ACCEL POS SIG Throttle actuator opening/closing is dis-

played (linked with accelerator pedal)Accelerator pedal not depressed (ignition

switch is ON)0 %

Accelerator pedal depressed (ignition

switch is ON)0 - 100 %

Page 394 of 5883

![NISSAN TIIDA 2007 Service Owners Manual ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

BRC-161

< ECU DIAGNOSIS >[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

SIDE G-SENSOR Transverse G detected by side G sensorVehicle stopped

Approx. 0 m/s

NISSAN TIIDA 2007 Service Owners Manual ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

BRC-161

< ECU DIAGNOSIS >[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

SIDE G-SENSOR Transverse G detected by side G sensorVehicle stopped

Approx. 0 m/s](/img/5/57395/w960_57395-393.png)

ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

BRC-161

< ECU DIAGNOSIS >[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

SIDE G-SENSOR Transverse G detected by side G sensorVehicle stopped

Approx. 0 m/s

2

Vehicle turning rightNegative value

(m/s2)

Vehicle turning leftPositive value

(m/s

2)

STR ANGLE SIGSteering angle detected by steering angle

sensorStraight-ahead Approx. 0°

Steering wheel turned –720 to 720°

PRESS SENSORBrake fluid pressure detected by front pres-

sure sensorWith ignition switch turned ON and brake

pedal releasedApprox. 0 bar

With ignition switch turned ON and brake

pedal depressed–40 to 300 bar

ENGINE SPEED With engine runningWith engine stopped 0 rpm

Engine runningAlmost in accor-

dance with tachome-

ter display

FLUID LEV SW Brake fluid level switch signal statusWhen brake fluid level switch ON ON

When brake fluid level switch OFF OFF

FR RH IN SOL Operation status of each solenoid valve Actuator (solenoid valve) is active (“AC-

TIVE TEST” with CONSULT-III) or actua-

tor relay is inactive (in fail-safe mode)ON

When the actuator (solenoid valve) is not

active and actuator relay is active (igni-

tion switch ON)OFF

FR RH OUT SOL Operation status of each solenoid valve Actuator (solenoid valve) is active (“AC-

TIVE TEST” with CONSULT-III) or actua-

tor relay is inactive (in fail-safe mode)ON

When the actuator (solenoid valve) is not

active and actuator relay is active (igni-

tion switch ON)OFF

FR LH IN SOL Operation status of each solenoid valve Actuator (solenoid valve) is active (“AC-

TIVE TEST” with CONSULT-III) or actua-

tor relay is inactive (in fail-safe mode)ON

When the actuator (solenoid valve) is not

active and actuator relay is active (igni-

tion switch ON)OFF

FR LH OUT SOL Operation status of each solenoid valve Actuator (solenoid valve) is active (“AC-

TIVE TEST” with CONSULT-III) or actua-

tor relay is inactive (in fail-safe mode)ON

When the actuator (solenoid valve) is not

active and actuator relay is active (igni-

tion switch ON)OFF

RR RH IN SOL Operation status of each solenoid valve Actuator (solenoid valve) is active (“AC-

TIVE TEST” with CONSULT-III) or actua-

tor relay is inactive (in fail-safe mode)ON

When the actuator (solenoid valve) is not

active and actuator relay is active (igni-

tion switch ON)OFF Monitor item Display contentData monitor

ConditionReference value in

normal operation

Page 396 of 5883

![NISSAN TIIDA 2007 Service Owners Manual ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

BRC-163

< ECU DIAGNOSIS >[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

TCS FAIL SIG TCS fail-safe signalIn TCS fail-safe ON

TCS is normal OFF

VDC FAIL SI NISSAN TIIDA 2007 Service Owners Manual ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

BRC-163

< ECU DIAGNOSIS >[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

TCS FAIL SIG TCS fail-safe signalIn TCS fail-safe ON

TCS is normal OFF

VDC FAIL SI](/img/5/57395/w960_57395-395.png)

ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

BRC-163

< ECU DIAGNOSIS >[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

TCS FAIL SIG TCS fail-safe signalIn TCS fail-safe ON

TCS is normal OFF

VDC FAIL SIG VDC fail-safe signalIn VDC fail-safe ON

VDC is normal OFF

CRANKING SIG Crank operationCrank is active ON

Crank is inactive OFF

CV1 VDC switch-over valveWhen actuator (switch-over valve) is ac-

tive (“ACTIVE TEST” with CONSULT-III)

or actuator relay is inactive (when in fail-

safe mode)ON

When actuator (switch-over valve) is not

active and actuator relay is active (igni-

tion switch ON)OFF

CV2 VDC switch-over valveWhen actuator (switch-over valve) is ac-

tive (“ACTIVE TEST” with CONSULT-III)

or actuator relay is inactive (when in fail-

safe mode)ON

When actuator (switch-over valve) is not

active and actuator relay is active (igni-

tion switch ON)OFF

SV1 VDC switch-over valveWhen actuator (switch-over valve) is ac-

tive (“ACTIVE TEST” with CONSULT-III)

or actuator relay is inactive (when in fail-

safe mode)ON

When actuator (switch-over valve) is not

active and actuator relay is active (igni-

tion switch ON)OFF

SV2 VDC switch-over valveWhen actuator (switch-over valve) is ac-

tive (“ACTIVE TEST” with CONSULT-III)

or actuator relay is inactive (when in fail-

safe mode)ON

When actuator (switch-over valve) is not

active and actuator relay is active (igni-

tion switch ON)OFF

DECEL G-SENLongitudinal acceleration detected by Decel

G-SensorVehicle stopped Approx. 0 G

Vehicle running -1.7 to 1.7 G

EBD WARN LAMPEBD warning lamp

(Note 3)When EBD warning lamp is ON ON

When EBD warning lamp is OFF OFF

N POSI SIG PNP switch signal ON/OFF conditionA/T shift position = N position ON

A/T shift position = other than N position OFF

P POSI SIG PNP switch signal ON/OFF conditionA/T shift position = P position ON

A/T shift position = other than P position OFF

R POSI SIG PNP switch signal ON/OFF conditionA/T shift position = R position ON

A/T shift position = other than R position OFF

2WD/4WD Drive axle2WD model 2WD

4WD model 4WD

PRESS SEN2Brake fluid pressure detected by rear pres-

sure sensorWith ignition switch turned ON and brake

pedal releasedApprox. 0 bar

With ignition switch turned ON and brake

pedal depressed–40 to 300 bar Monitor item Display contentData monitor

ConditionReference value in

normal operation

Page 402 of 5883

![NISSAN TIIDA 2007 Service Owners Manual ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

BRC-169

< ECU DIAGNOSIS >[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

In case of an electrical malfunction with the ABS, the ABS warning lamp, VDC OFF i NISSAN TIIDA 2007 Service Owners Manual ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

BRC-169

< ECU DIAGNOSIS >[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

In case of an electrical malfunction with the ABS, the ABS warning lamp, VDC OFF i](/img/5/57395/w960_57395-401.png)

ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

BRC-169

< ECU DIAGNOSIS >[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

In case of an electrical malfunction with the ABS, the ABS warning lamp, VDC OFF indicator lamp and SLIP

indicator lamp will turn on. In case of an electrical malfunction with the EBD system, the BRAKE warning lamp,

ABS warning lamp, VDC OFF indicator lamp and SLIP indicator lamp will turn on.

The system will revert to one of the following conditions of the Fail-Safe function.

1. For ABS malfunction, only the EBD is operative and the condition of the vehicle is the same condition of

vehicles without ABS/TCS/VDC system.

2. For EBD malfunction, the EBD and ABS become inoperative, and the condition of the vehicle is the same

as the condition of vehicles without ABS/TCS/VDC or EBD system.

VDC/TCS SYSTEM

In case of TCS/VDC system malfunction, the VDC OFF indicator lamp and SLIP indicator lamp are turned on

and the condition of the vehicle is the same as the condition of vehicles without TCS/VDC system. In case of

an electrical malfunction with the TCS/VDC system, the ABS control continues to operate normally without

TCS/VDC control.

DTC No. IndexINFOID:0000000001731199

DTC Items (CONSULT screen terms) Reference

C1101 RR RH SENSOR-1

BRC-30, "

Description"C1102 RR LH SENSOR-1

C1103 FR RH SENSOR-1

C1104 FR LH SENSOR-1

C1105 RR RH SENSOR-2

BRC-33, "

Description"C1106 RR LH SENSOR-2

C1107 FR RH SENSOR-2

C1108 FR LH SENSOR-2

C1109 BATTERY VOLTAGE [ABNORMAL]BRC-36, "

Description"

C1110 CONTROLLER FAILUREBRC-38, "DTC Logic"

C 1111 P U M P M O T O RBRC-39, "Description"

C1113 G-SENSORXX-XX, "*****"

C1115 ABS SENSOR [ABNORMAL SIGNAL]BRC-41, "Description"

C1116 STOP LAMP SWBRC-44, "Description"

C1120 FR LH IN ABS SOLBRC-46, "Description"

C1121 FR LH OUT ABS SOLBRC-49, "Description"

C1122 FR RH IN ABS SOLBRC-46, "Description"

C1123 FR RH OUT ABS SOLBRC-49, "Description"

C1124 RR LH IN ABS SOLBRC-46, "Description"

C1125 RR LH OUT ABS SOLBRC-49, "Description"

C1126 RR RH IN ABS SOLBRC-46, "Description"

C1127 RR RH OUT ABS SOLBRC-49, "Description"

C1130 ENGINE SIGNAL 1

BRC-52, "

Description"

C1131 ENGINE SIGNAL 2

C1132 ENGINE SIGNAL 3

C1133 ENGINE SIGNAL 4

C1136 ENGINE SIGNAL 6

C1140 ACTUATOR RLYBRC-54, "

Description"

C1142 PRESS SEN CIRCUITXX-XX, "*****"

C1143 ST ANG SEN CIRCUIT

XX-XX, "*****"

C1144 ST ANG SEN SIGNAL

Page 557 of 5883

DEF-6

< FUNCTION DIAGNOSIS >

REAR WINDOW DEFOGGER SYSTEM

FUNCTION DIAGNOSIS

REAR WINDOW DEFOGGER SYSTEM

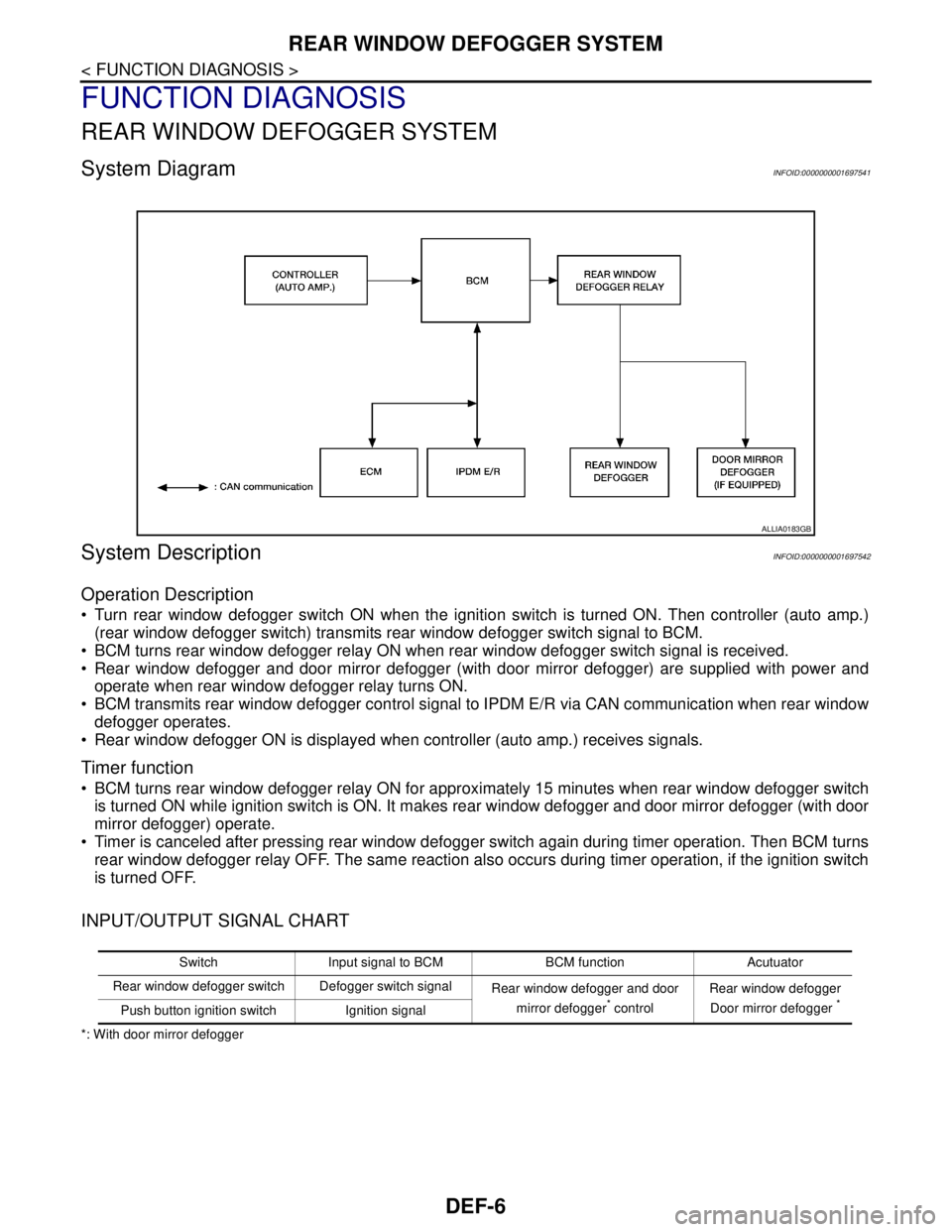

System DiagramINFOID:0000000001697541

System DescriptionINFOID:0000000001697542

Operation Description

Turn rear window defogger switch ON when the ignition switch is turned ON. Then controller (auto amp.)

(rear window defogger switch) transmits rear window defogger switch signal to BCM.

BCM turns rear window defogger relay ON when rear window defogger switch signal is received.

Rear window defogger and door mirror defogger (with door mirror defogger) are supplied with power and

operate when rear window defogger relay turns ON.

BCM transmits rear window defogger control signal to IPDM E/R via CAN communication when rear window

defogger operates.

Rear window defogger ON is displayed when controller (auto amp.) receives signals.

Timer function

BCM turns rear window defogger relay ON for approximately 15 minutes when rear window defogger switch

is turned ON while ignition switch is ON. It makes rear window defogger and door mirror defogger (with door

mirror defogger) operate.

Timer is canceled after pressing rear window defogger switch again during timer operation. Then BCM turns

rear window defogger relay OFF. The same reaction also occurs during timer operation, if the ignition switch

is turned OFF.

INPUT/OUTPUT SIGNAL CHART

*: With door mirror defogger

ALLIA0183GB

Switch Input signal to BCM BCM function Acutuator

Rear window defogger switch Defogger switch signal

Rear window defogger and door

mirror defogger

* controlRear window defogger

Door mirror defogger *Push button ignition switch Ignition signal

Page 597 of 5883

DLK-8

Component Function Check ................................376

Diagnosis Procedure .............................................376

LOCK WARNING LAMP .................................377

Description .............................................................377

Component Function Check ................................377

Diagnosis Procedure .............................................377

HAZARD WARNING LAMPS ..........................378

Description .............................................................378

Component Function Check ................................378

Diagnosis Procedure .............................................378

VEHICLE SPEED SIGNAL CIRCUIT ..............379

Description .............................................................379

Component Function Check ................................379

Diagnosis Procedure .............................................379

INTELLIGENT KEY BATTERY AND FUNC-

TION .................................................................

380

Description .............................................................380

Component Function Check ................................380

Diagnosis Procedure .............................................380

Component Inspection ...........................................380

Special Repair Requirement ..................................380

ECU DIAGNOSIS .......................................381

INTELLIGENT KEY UNIT ................................381

Reference Value ....................................................381

Wiring Diagram - INTELLIGENT KEY SYSTEM - ..388

Fail Safe ................................................................400

DTC Inspection Priority Chart .............................400

DTC Index .............................................................400

BCM (BODY CONTROL MODULE) ................401

Reference Value ....................................................401

Wiring Diagram - POWER DOOR LOCK SYSTEM

- .............................................................................

401

Wiring Diagram - BACK DOOR OPENER SYS-

TEM - .....................................................................

411

Wiring Diagram - TRUNK LID OPENER SYSTEM

- .............................................................................

415

Fail Safe ................................................................417

DTC Inspection Priority Chart .............................418

DTC Index .............................................................418

SYMPTOM DIAGNOSIS ............................420

DOOR LOCK FUNCTION SYMPTOMS ..........420

DOOR LOCK AND UNLOCK SWITCH ...................420

DOOR LOCK AND UNLOCK SWITCH : Symptom

Table ......................................................................

420

INTELLIGENT KEY ..................................................421

INTELLIGENT KEY : Symptom Table ...................421

DOOR REQUEST SWITCH .....................................422

DOOR REQUEST SWITCH : Symptom Table ......422

KEY REMINDER ......................................................422

KEY REMINDER : Symptom Table ......................423

AUTO RELOCK .......................................................423

AUTO RELOCK : Symptom Table ........................423

BACK DOOR OPEN FUNCTION SYMPTOMS

..

424

BACK DOOR OPENER SWITCH ...........................424

BACK DOOR OPENER SWITCH : Symptom Ta-

ble .........................................................................

424

TRUNK OPEN FUNCTION SYMPTOMS .........425

TRUNK LID OPENER SWITCH ..............................425

TRUNK LID OPENER SWITCH : Symptom Table .425

WARNING FUNCTION SYMPTOMS ...............426

BUZZER (COMBINATION METER) ........................426

BUZZER (COMBINATION METER) : Symptom

Table .....................................................................

426

INTELLIGENT KEY WARNING BUZZER ...............426

INTELLIGENT KEY WARNING BUZZER : Symp-

tom Table ..............................................................

426

IGNITION KNOB SWITCH DOES NOT TURN ON .427

IGNITION KNOB SWITCH DOES NOT TURN ON

: Symptom Table ...................................................

427

WARNING LAMP ....................................................428

WARNING LAMP : Symptom Table ......................428

BACK DOOR ...........................................................429

BACK DOOR : Symptom Table ............................429

HAZARD AND BUZZER REMINDER FUNC-

TION SYMPTOMS ............................................

430

HAZARD WARNING LAMP ....................................430

HAZARD WARNING LAMP : Symptom Table ......430

INTELLIGENT KEY WARNING BUZZER ...............430

INTELLIGENT KEY WARNING BUZZER : Symp-

tom Table ..............................................................

430

SQUEAK AND RATTLE TROUBLE DIAG-

NOSES ..............................................................

431

Work Flow .............................................................431

Inspection Procedure ............................................433

Diagnostic Worksheet ...........................................435

PRECAUTION ...........................................437

PRECAUTIONS ................................................437

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...............................................................

437

Procedure without Cowl Top Cover ...................437

Steering Wheel Rotation after Battery Disconn

ect .........................................................................

437

Work ......................................................................438

Page 633 of 5883

![NISSAN TIIDA 2007 Service Owners Manual DLK-44

< FUNCTION DIAGNOSIS >[WITH I-KEY, WITHOUT SUPER LOCK]

WARNING FUNCTION

Component Description

INFOID:0000000001396497

* : Sedan only

**: Hatchback onlyItem Function

BCM Controls the warning fun NISSAN TIIDA 2007 Service Owners Manual DLK-44

< FUNCTION DIAGNOSIS >[WITH I-KEY, WITHOUT SUPER LOCK]

WARNING FUNCTION

Component Description

INFOID:0000000001396497

* : Sedan only

**: Hatchback onlyItem Function

BCM Controls the warning fun](/img/5/57395/w960_57395-632.png)

DLK-44

< FUNCTION DIAGNOSIS >[WITH I-KEY, WITHOUT SUPER LOCK]

WARNING FUNCTION

Component Description

INFOID:0000000001396497

* : Sedan only

**: Hatchback onlyItem Function

BCM Controls the warning function with Intelligent Key unit.

Intelligent Key unit Controls the warning function with BCM.

Key switch Detects that mechanical key is inserted into ignition key cylinder.

Door switch Detects door state (open or closed).

Door lock and unlock switch Transmits door lock and unlock signal to BCM.

Intelligent Key unitRequests to turn ON hazard warning lamp to BCM and turn signal indicator to

combination meter.

Combination meterTurns ON the LOCK indicator, KEY indicator, turn signal indicator and buzzer

(built in combination meter) by the request from Intelligent Key unit via CAN com-

munication.

Intelligent Key warning buzzer (driver side) Sounds by the request from Intelligent Key unit.

Intelligent Key warning buzzer (trunk)

*Sounds by the request from Intelligent Key unit.

Back door opener switch

**Transmits back door open signal to BCM

Trunk lid opener switch

*Transmits trunk open signal to BCM