sensor NISSAN TIIDA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 3334 of 5883

HAC-1

VENTILATION, HEATER & AIR CONDITIONER

C

D

E

F

G

H

J

K

L

M

SECTION HAC

A

B

HAC

N

O

P

CONTENTS

HEATER & AIR CONDITIONING CONTROL SYSTEM

MANUAL AIR CONDITIONER

BASIC INSPECTION ....................................

5

DIAGNOSIS AND REPAIR WORKFLOW ..........5

How to Perform Trouble Diagnosis For Quick and

Accurate Repair ........................................................

5

INSPECTION AND ADJUSTMENT .....................6

Operational Check ....................................................6

FUNCTION DIAGNOSIS ...............................8

FUNCTION INFORMATION ................................8

Component Part Location .........................................8

REFRIGERATION SYSTEM ..............................10

Refrigerant Cycle ....................................................10

Refrigerant System Protection ................................10

AIR CONDITIONER CONTROL .........................11

System Diagram ......................................................11

System Description .................................................11

Discharge Air Flow ..................................................11

Switches And Their Control Function ......................12

Component Description ...........................................13

CAN COMMUNICATION SYSTEM ....................14

System Description .................................................14

DIAGNOSIS SYSTEM (BCM) ............................15

CONSULT-III Function (BCM) .................................15

COMPONENT DIAGNOSIS .........................16

MODE DOOR .....................................................16

Mode Door Diagnostic Procedure ...........................16

AIR MIX DOOR ...................................................17

Air Mix Door Diagnostic Procedure .........................17

INTAKE DOOR ...................................................18

Intake Door Diagnostic Procedure ..........................18

BLOWER MOTOR ............................................19

Front Blower Motor Component Function Check ....19

Front Blower Motor Diagnosis Procedure ................19

MAGNET CLUTCH ...........................................23

System Description ..................................................23

Magnet Clutch Component Function Check ............23

Magnet Clutch Diagnosis Procedure .......................24

INTAKE SENSOR .............................................30

Component Inspection .............................................30

Intake Sensor Diagnosis Procedure ........................30

Intake Sensor Component Inspection .....................31

PTC HEATER CONTROL SYSTEM .................33

PTC HEATER (300 WATT) ........................................33

PTC HEATER (300 WATT) : PTC Heater System

Description ...............................................................

33

PTC HEATER (300 WATT) : PTC Heater Compo-

nent Description .......................................................

34

PTC HEATER (300 WATT) : PTC Heater (300

Watt) Diagnosis Procedure ......................................

35

PTC HEATER (300 WATT) : PTC Heater (300

Watt) Component Inspection ...................................

41

PTC HEATER (1500 WATT) ......................................43

PTC HEATER (1500 WATT) : System Description ....43

PTC HEATER (1500 WATT) : Component De-

scription ...................................................................

44

PTC HEATER (1500 WATT) : PTC Heater (1500

Watt) Diagnosis Procedure ......................................

45

PTC HEATER (1500 WATT) : PTC Heater (1500

Watt) Component Inspection ...................................

50

ECU DIAGNOSIS .........................................53

AIR CONDITIONER CONTROL ........................53

Reference Value ......................................................53

Wiring Diagram - Heater Control (without A/C) - .....54

Wiring Diagram - Air Conditioner Control - ..............56

Page 3335 of 5883

HAC-2

PTC HEATER CONTROL SYSTEM ..................63

PTC HEATER (300 WATT) .......................................63

PTC HEATER (300 WATT) : Wiring Diagram -

PTC Heater (300 Watt) - .........................................

63

PTC HEATER (1500 WATT) .....................................67

PTC HEATER (1500 WATT) : Wiring Diagram -

PTC Heater (1500 Watt) - .......................................

68

SYMPTOM DIAGNOSIS .............................72

AIR CONDITIONER CONTROL ........................72

Symptom Matrix Chart ..........................................72

INSUFFICIENT COOLING .................................73

Component Function Check ...................................73

Performance Test Diagnoses .................................74

Performance Chart .................................................75

Test Reading ..........................................................76

Trouble Diagnoses for Unusual Pressure ...............77

INSUFFICIENT HEATING .................................81

Component Function Check ...................................81

NOISE ................................................................83

Component Function Check ...................................83

PRECAUTION .............................................84

PRECAUTIONS .................................................84

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .................................................................

84

Precaution for Procedures Without Cowl Top Cov-

er ............................................................................

84

Working with HFC-134a (R-134a) ..........................84

Precaution for Service Equipment ..........................85

AUTO AIR CONDITIONER (W/O NAVI)

BASIC INSPECTION ...................................

86

DIAGNOSIS AND REPAIR WORKFLOW .........86

How to Perform Trouble Diagnosis For Quick And

Accurate Repair ......................................................

86

INSPECTION AND ADJUSTMENT ...................87

Operational Check ..................................................87

FUNCTION DIAGNOSIS .............................89

FUNCTION INFORMATION ..............................89

Component Part Location .......................................89

REFRIGERATION SYSTEM ..............................91

Refrigerant Cycle ....................................................91

Refrigerant System Protection ................................91

AUTOMATIC AIR CONDITIONER SYSTEM .....92

Control System Diagram ........................................92

Control System Description ....................................92

Discharge Air Flow .................................................94

Switches And Their Control Function ......................95

CAN COMMUNICATION SYSTEM ...................96

System Description .................................................96

DIAGNOSIS SYSTEM (BCM) ............................97

CONSULT-III Function (BCM) ................................97

SELF-DIAGNOSIS FUNCTION .........................98

Front Air Control Self-Diagnosis .............................98

A/C System Self-Diagnosis Code Chart ...............104

COMPONENT DIAGNOSIS ......................106

MODE DOOR MOTOR .....................................106

System Description ...............................................106

Mode Door Motor Component Function Check ....107

Mode Door Motor Diagnosis Procedure ................109

AIR MIX DOOR MOTOR ..................................110

System Description ...............................................110

Air Mix Door Motor Component Function Check ..111

Air Mix Door Motor Diagnosis Procedure ..............112

INTAKE DOOR MOTOR ...................................114

System Description ...............................................114

Intake Door Motor Component Function Check ....115

Intake Door Motor Diagnosis Procedure ...............116

BLOWER MOTOR CONTROL SYSTEM .........118

System Description ...............................................118

Front Blower Motor Component Function Check ..119

Front Blower Motor Diagnosis Procedure .............120

Front Blower Motor Component Inspection ..........123

MAGNET CLUTCH ...........................................124

System Description ...............................................124

Magnet Clutch Component Function Check .........124

Magnet Clutch Diagnosis Procedure ....................125

AMBIENT SENSOR ..........................................130

Component Description ........................................130

Ambient Sensor Diagnosis Procedure ..................130

Ambient Sensor Component Inspection ...............131

IN-VEHICLE SENSOR ......................................133

Component Description ........................................133

In-Vehicle Sensor Diagnosis Procedure ...............133

In-Vehicle Sensor Component Inspection .............135

SUNLOAD SENSOR ........................................136

System Description ...............................................136

Sunload Sensor Diagnosis Procedure ..................136

Sunload Component Inspection ............................137

INTAKE SENSOR .............................................139

Component Inspection ..........................................139

Intake Sensor Diagnosis Procedure .....................139

Intake Sensor Component Inspection ...................140

PTC HEATER CONTROL SYSTEM .................142

Page 3337 of 5883

HAC-4

INTAKE DOOR MOTOR ..................................228

System Description ................................................228

Intake Door Motor Component Function Check ....229

Intake Door Motor Diagnosis Procedure ...............230

BLOWER MOTOR CONTROL SYSTEM ........232

System Description ................................................232

Front Blower Motor Component Function Check ...233

Front Blower Motor Diagnosis Procedure ..............234

Front Blower Motor Component Inspection ...........236

MAGNET CLUTCH ..........................................238

System Description ................................................238

Magnet Clutch Component Function Check ..........238

Magnet Clutch Diagnosis Procedure .....................239

AMBIENT SENSOR .........................................244

Component Description .........................................244

Ambient Sensor Diagnosis Procedure ...................244

Ambient Sensor Component Inspection ................245

IN-VEHICLE SENSOR .....................................247

Component Description .........................................247

In-Vehicle Sensor Diagnosis Procedure ................247

In-Vehicle Sensor Component Inspection .............249

SUNLOAD SENSOR .......................................250

Component Description .........................................250

Sunload Sensor Diagnosis Procedure ...................250

Sunload Sensor Component Inspection ................251

INTAKE SENSOR ............................................253

System Description ................................................253

Intake Sensor Diagnosis Procedure ......................253

Intake Sensor Component Inspection ...................254

PTC HEATER CONTROL SYSTEM ................256

PTC HEATER (300 WATT) ......................................256

PTC HEATER (300 WATT) : PTC Heater System

Description .............................................................

256

PTC HEATER (300 WATT) : PTC Heater Compo-

nent Description .....................................................

257

PTC HEATER (300 WATT) : PTC Heater (300

Watt) Diagnosis Procedure ....................................

258

PTC HEATER (300 WATT) : PTC Heater (300

Watt) Component Inspection .................................

265

PTC HEATER (1500 WATT) ....................................267

PTC HEATER (1500 WATT) : System Description ..267

PTC HEATER (1500 WATT) : Component De-

scription .................................................................

268

PTC HEATER (1500 WATT) : PTC Heater (1500

Watt) Diagnosis Procedure ....................................

269

PTC HEATER (1500 WATT) : PTC Heater (1500

Watt) Component Inspection .................................

274

POWER SUPPLY AND GROUND CIRCUIT

FOR CONTROLLER .........................................

277

Component Description ........................................277

A/C Auto Amp. Component Function Check .........277

A/C Auto Amp Power and Ground Diagnosis Pro-

cedure ...................................................................

278

ECU DIAGNOSIS ......................................279

AIR CONDITIONER CONTROL .......................279

Front Air Control Terminals Reference Values .....279

Wiring Diagram - Air Conditioner Control - ...........281

PTC HEATER CONTROL SYSTEM .................289

PTC HEATER (300 WATT) .....................................289

PTC HEATER (300 WATT) : Wiring Diagram -

PTC Heater (300 Watt) - .......................................

289

PTC HEATER (1500 WATT) ...................................293

PTC HEATER (1500 WATT) : Wiring Diagram -

PTC Heater (1500 Watt) - .....................................

294

SYMPTOM DIAGNOSIS ...........................298

AIR CONDITIONER CONTROL .......................298

Symptom Matrix Chart .........................................298

INSUFFICIENT COOLING ................................299

Component Function Check .................................299

Performance Test Diagnoses ...............................300

Performance Chart ................................................302

Test Reading .........................................................303

Trouble Diagnoses for Unusual Pressure .............303

INSUFFICIENT HEATING ................................307

Component Function Check .................................307

NOISE ...............................................................309

Component Function Check .................................309

SELF-DIAGNOSIS CANNOT BE PER-

FORMED ...........................................................

311

Self-Diagnosis .......................................................311

MEMORY FUNCTION DOES NOT OPERATE ..312

Memory Function Check .......................................312

PRECAUTION ...........................................313

PRECAUTIONS ................................................313

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...............................................................

313

Precaution for Procedures Without Cowl Top Cov-

er ...........................................................................

313

Working with HFC-134a (R-134a) .........................313

Precaution for Service Equipment ........................314

Page 3341 of 5883

![NISSAN TIIDA 2007 Service Repair Manual HAC-8

< FUNCTION DIAGNOSIS >[MANUAL AIR CONDITIONER]

FUNCTION INFORMATION

FUNCTION DIAGNOSIS

FUNCTION INFORMATION

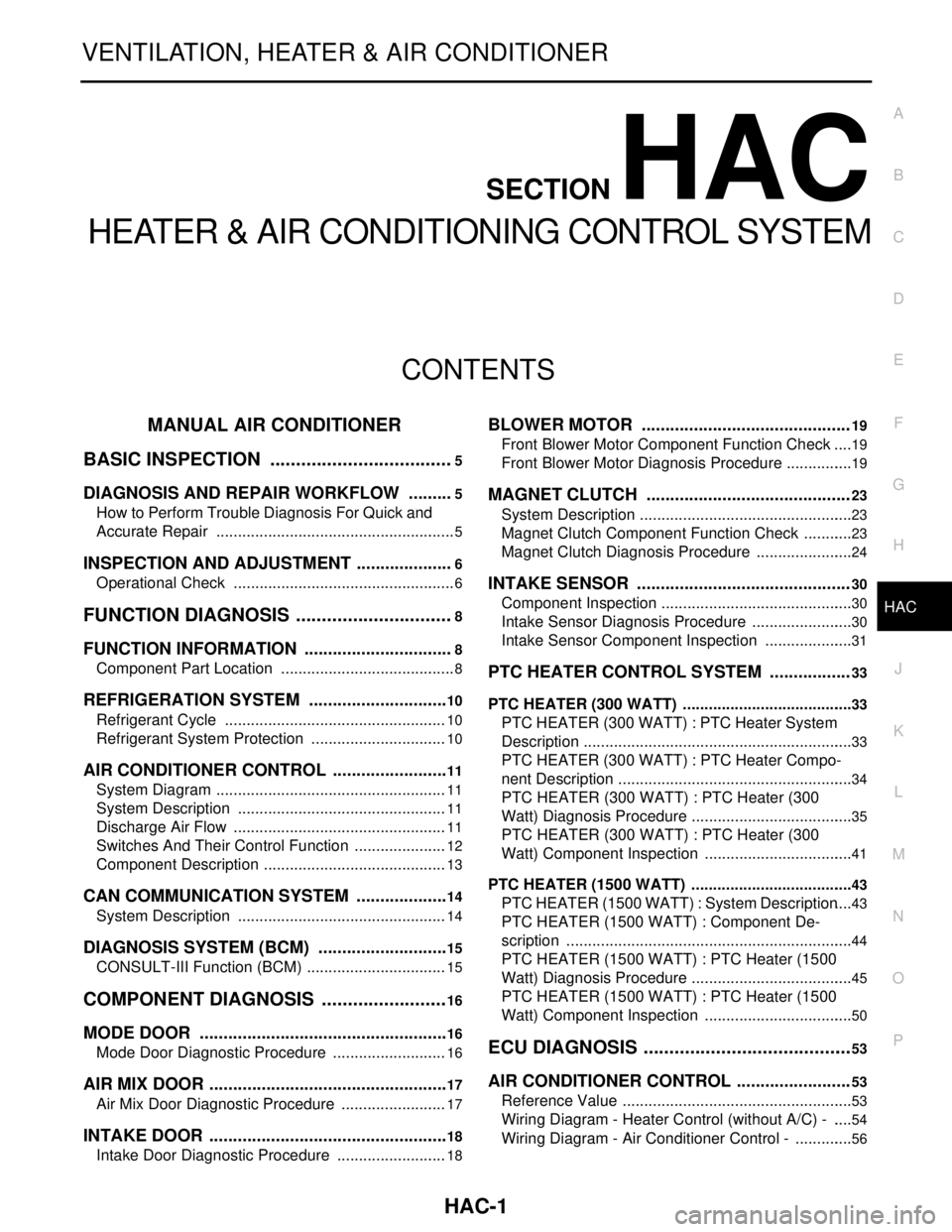

Component Part LocationINFOID:0000000001203053

ENGINE COMPARTMENT

PASSENGER COMPARTMEN NISSAN TIIDA 2007 Service Repair Manual HAC-8

< FUNCTION DIAGNOSIS >[MANUAL AIR CONDITIONER]

FUNCTION INFORMATION

FUNCTION DIAGNOSIS

FUNCTION INFORMATION

Component Part LocationINFOID:0000000001203053

ENGINE COMPARTMENT

PASSENGER COMPARTMEN](/img/5/57395/w960_57395-3340.png)

HAC-8

< FUNCTION DIAGNOSIS >[MANUAL AIR CONDITIONER]

FUNCTION INFORMATION

FUNCTION DIAGNOSIS

FUNCTION INFORMATION

Component Part LocationINFOID:0000000001203053

ENGINE COMPARTMENT

PASSENGER COMPARTMENT

WJIA2235E

1. Refrigerant pressure sensor E17 (if

equipped)2. A/C compressor F3 (if equipped)

Page 3342 of 5883

![NISSAN TIIDA 2007 Service Repair Manual FUNCTION INFORMATION

HAC-9

< FUNCTION DIAGNOSIS >[MANUAL AIR CONDITIONER]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

1. Front air control M33, M49 2. Fuse Block (J/B) 3. Blower relay J-1

4. Front blower motor r NISSAN TIIDA 2007 Service Repair Manual FUNCTION INFORMATION

HAC-9

< FUNCTION DIAGNOSIS >[MANUAL AIR CONDITIONER]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

1. Front air control M33, M49 2. Fuse Block (J/B) 3. Blower relay J-1

4. Front blower motor r](/img/5/57395/w960_57395-3341.png)

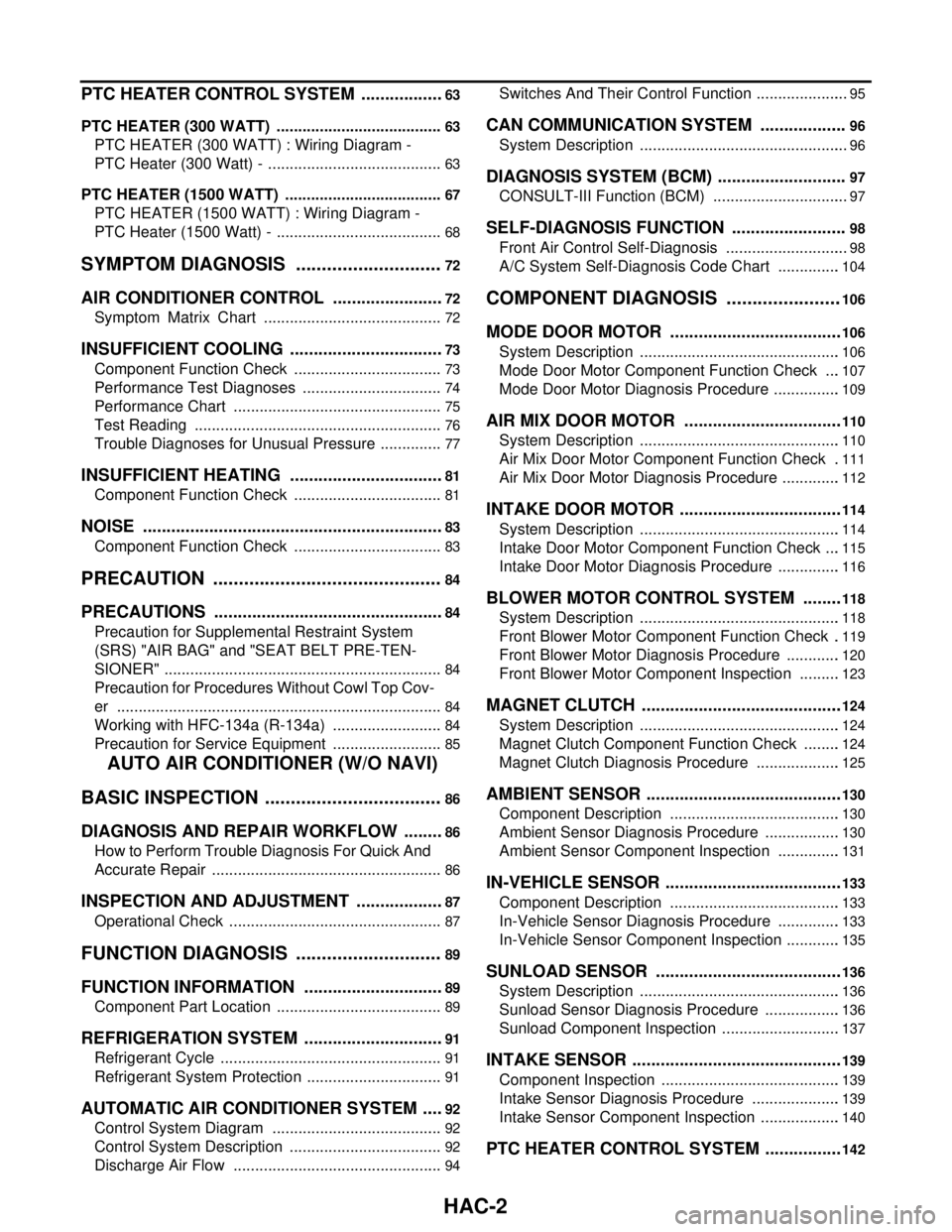

FUNCTION INFORMATION

HAC-9

< FUNCTION DIAGNOSIS >[MANUAL AIR CONDITIONER]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

1. Front air control M33, M49 2. Fuse Block (J/B) 3. Blower relay J-1

4. Front blower motor resistor M95 5. Intake sensor M42 6. Front blower motor M62

7. Defrost A/C switch M49

WJIA2258E

Page 3356 of 5883

![NISSAN TIIDA 2007 Service Repair Manual MAGNET CLUTCH

HAC-23

< COMPONENT DIAGNOSIS >[MANUAL AIR CONDITIONER]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

MAGNET CLUTCH

System DescriptionINFOID:0000000001547069

SYSTEM DESCRIPTION

Intake sensor controls NISSAN TIIDA 2007 Service Repair Manual MAGNET CLUTCH

HAC-23

< COMPONENT DIAGNOSIS >[MANUAL AIR CONDITIONER]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

MAGNET CLUTCH

System DescriptionINFOID:0000000001547069

SYSTEM DESCRIPTION

Intake sensor controls](/img/5/57395/w960_57395-3355.png)

MAGNET CLUTCH

HAC-23

< COMPONENT DIAGNOSIS >[MANUAL AIR CONDITIONER]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

MAGNET CLUTCH

System DescriptionINFOID:0000000001547069

SYSTEM DESCRIPTION

Intake sensor controls A/C compressor operation by intake air temperature and signal from ECM.

The defrost A/C switch controls A/C compressor operation by the BCM when the mode switch is turned to the

(DEF) position.

Low Temperature Protection Control

When intake air temperatures are higher than 4°C (39°F), the com-

pressor turns ON. The compressor turns OFF when intake air tem-

peratures are lower than 2°C (36°F).

Magnet Clutch Component Function CheckINFOID:0000000001547070

SYMPTOM: Magnet clutch does not engage.

INSPECTION FLOW

1.CONFIRM SYMPTOM BY PERFORMING OPERATIONAL CHECK - MAGNET CLUTCH

1. Turn ignition switch ON.

2. Turn blower control dial to the desired (1 to 4 speed) position.

3. Press the A/C switch. A/C indicator will turn on.

4. Confirm that the compressor clutch engages (sound or visual inspection).

Can the symptom be duplicated?

YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK FOR ANY SYMPTOMS

Perform a complete operational check for any symptoms. Refer to HAC-6, "

Operational Check".

Does another symptom exist?

YES >> Refer to HAC-5, "How to Perform Trouble Diagnosis For Quick and Accurate Repair".

NO >> System OK.

3.CHECK FOR SERVICE BULLETINS

Check for any service bulletins.

>> GO TO 4.

4.CHECK COMPRESSOR BELT TENSION

Check compressor belt tension. Refer to EM-15, "

Checking" (HR16DE) or EM-142, "Checking Drive Belts"

(MR18DE) or EM-263, "Inspection and Adjustment" (K9K).

OK or NG

OK >> GO TO 5.

NG >> Adjust or replace A/C compressor belt.

5.CHECK REFRIGERANT PRESSURE

Check refrigerant pressure with manifold gauge connected. Refer to HAC-73, "

Component Function Check".

OK or NG

OK >> GO TO 6.

SJIA0741E

Page 3358 of 5883

![NISSAN TIIDA 2007 Service Repair Manual MAGNET CLUTCH

HAC-25

< COMPONENT DIAGNOSIS >[MANUAL AIR CONDITIONER]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

1. Disconnect A/C compressor connector.

2. Start the engine.

3. Turn blower control dial and A/C s NISSAN TIIDA 2007 Service Repair Manual MAGNET CLUTCH

HAC-25

< COMPONENT DIAGNOSIS >[MANUAL AIR CONDITIONER]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

1. Disconnect A/C compressor connector.

2. Start the engine.

3. Turn blower control dial and A/C s](/img/5/57395/w960_57395-3357.png)

MAGNET CLUTCH

HAC-25

< COMPONENT DIAGNOSIS >[MANUAL AIR CONDITIONER]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

1. Disconnect A/C compressor connector.

2. Start the engine.

3. Turn blower control dial and A/C switch ON.

4. Check voltage between A/C compressor harness connector F3

terminal 1 and ground.

OK or NG

OK >> Replace magnet clutch. Refer to XX.

NG >> GO TO 4.

4.CHECK CIRCUIT CONTINUITY BETWEEN IPDM E/R AND COMPRESSOR

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector.

3. Check continuity between A/C compressor harness connector

F3 (A) terminal 1 and IPDM E/R harness connector E43 (B) ter-

minal 11.

OK or NG

OK >> Replace IPDM E/R. Refer to XX.

NG >> Repair harness or connector.

5.CHECK DEFROST A/C SWITCH

1. Start the engine.

2. Turn the mode control dial to (DEF) position.

Does the magnet clutch operate

OK >> GO TO 6.

NG >> GO TO 19.

6.CHECK BCM INPUT (COMPRESSOR ON) SIGNAL

1. Turn ignition switch OFF.

2. Check compressor ON/OFF signal. Refer to HAC-15, "

CONSULT-III Function (BCM)".

OK or NG

OK >> GO TO 8.

NG >> GO TO 7.

7.CHECK CIRCUIT CONTINUITY BETWEEN FRONT AIR CONTROL AND BCM

1. Turn ignition switch OFF.

2. Disconnect front air control and BCM connector.

3. Check continuity between front air control harness connector

M33 (A) terminal 1and BCM harness connector M19 (B) termi-

nal 61.

OK or NG

OK >> GO TO 8.

NG >> Repair harness or connector.

8.CHECK REFRIGERANT PRESSURE SENSOR

1. Reconnect front air control connector and BCM connector.1 - Ground :Battery voltage

SJIA0743E

1 - 11 :Continuity should exist

WJIA2233E

A/C SW ON : AIR COND SW ON

A/C SW OFF : AIR COND SW OFF

1 - 61 :Continuity should exist

AWIIA0448ZZ

Page 3359 of 5883

![NISSAN TIIDA 2007 Service Repair Manual HAC-26

< COMPONENT DIAGNOSIS >[MANUAL AIR CONDITIONER]

MAGNET CLUTCH

2. Check refrigerant pressure sensor. Refer to EC-326, "Component Function Check" (HR16DE with EURO-

OBD), XX-XX, "*****"

(HR16DE NISSAN TIIDA 2007 Service Repair Manual HAC-26

< COMPONENT DIAGNOSIS >[MANUAL AIR CONDITIONER]

MAGNET CLUTCH

2. Check refrigerant pressure sensor. Refer to EC-326, "Component Function Check" (HR16DE with EURO-

OBD), XX-XX, "*****"

(HR16DE](/img/5/57395/w960_57395-3358.png)

HAC-26

< COMPONENT DIAGNOSIS >[MANUAL AIR CONDITIONER]

MAGNET CLUTCH

2. Check refrigerant pressure sensor. Refer to EC-326, "Component Function Check" (HR16DE with EURO-

OBD), XX-XX, "*****"

(HR16DE without EURO-OBD), EC-988, "Component Function Check" (MR18DE)

or EC-1166, "

Diagnosis Procedure" (K9K).

.OK or NG

OK >> WITH CONSULT-III

GO TO 9.

WITHOUT CONSULT-III

GO TO 10.

NG >> Replace as necessary.

9.CHECK BCM INPUT (FAN ON) SIGNAL

Check FAN ON/OFF signal. Refer to XX.

OK or NG

OK >> GO TO 12.

NG >> GO TO 10.

10.CHECK BCM INPUT (FAN ON) SIGNAL

1. Turn ignition switch ON.

2. Turn blower control dial to "1" position.

3. Confirm fan on signal between front air control harness connec-

tor M33 terminal 14 and ground using oscilloscope.

OK or NG

OK >> GO TO 12.

NG >> GO TO 11.

11 .CHECK CIRCUIT CONTINUITY BETWEEN BCM AND FRONT AIR CONTROL

1. Turn ignition switch OFF.

2. Disconnect front air control connector and BCM connector.

3. Check continuity between BCM harness connector M19 (A) ter-

minal 50 and front air control harness connector M33 (B) termi-

nal 14.

OK or NG

OK >> GO TO 12.

NG >> Repair harness or connector.

12.CHECK FAN SWITCH CIRCUIT

FAN CONTROL DIAL ON : FAN ON SIG ON

FAN CONTROL DIAL OFF : FAN ON SIG OFF

Te r m i n a l s

Voltag e

(Approx.) (+)

(-)

Connector Terminal

Front air con-

trol: M3314 Ground

SJIA0750E

ZJIA0583J

AB

Continuity

Connector Terminal Connector Terminal

BCM: M19 50Front air control:

M3314 Yes

AWIIA0449ZZ

Page 3361 of 5883

![NISSAN TIIDA 2007 Service Repair Manual HAC-28

< COMPONENT DIAGNOSIS >[MANUAL AIR CONDITIONER]

MAGNET CLUTCH

1. Turn ignition switch OFF.

2. Disconnect front air control connector.

3. While pressing the A/C switch, check continuity between NISSAN TIIDA 2007 Service Repair Manual HAC-28

< COMPONENT DIAGNOSIS >[MANUAL AIR CONDITIONER]

MAGNET CLUTCH

1. Turn ignition switch OFF.

2. Disconnect front air control connector.

3. While pressing the A/C switch, check continuity between](/img/5/57395/w960_57395-3360.png)

HAC-28

< COMPONENT DIAGNOSIS >[MANUAL AIR CONDITIONER]

MAGNET CLUTCH

1. Turn ignition switch OFF.

2. Disconnect front air control connector.

3. While pressing the A/C switch, check continuity between front

air control terminals 1 and 8.

OK or NG

OK >> GO TO 16.

NG >> Replace front air control. Refer to XX.

16.CHECK FRONT AIR CONTROL GROUND CIRCUIT

Check continuity between front air control harness connector M33

terminal 8 and ground.

OK or NG

OK >> GO TO 17.

NG >> Repair harness or connector.

17.CHECK INTAKE SENSOR

Refer to HAC-31, "

Intake Sensor Component Inspection".

OK or NG

OK >> GO TO 18.

NG >> Repair or replace as necessary.

18.CHECK CAN COMMUNICATION

Check CAN communication. Refer to LAN-22, "Trouble Diagnosis Flow Chart".

BCM – ECM

ECM – IPDM E/R

OK or NG

OK >> Replace BCM. Refer to BCS-57, "Removal and Installation of BCM".

NG >> Repair or replace malfunctioning part(s).

19.CHECK DEFROST A/C SWITCH CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connector.

3. Press the defrost A/C switch.

NOTE:

The defrost A/C switch is located on back side of the front air

control.

4. Check continuity between BCM harness connector M19 terminal

49 and ground.

OK or NG

OK >> Replace BCM. Refer to BCS-57, "Removal and Installation of BCM".

NG >> GO TO 20.

20.CHECK CIRCUIT CONTINUITY BETWEEN DEFROST A/C SWITCH AND BCM 1 - 8 :Continuity should exist

SJIA0756E

8 - Ground :Continuity should exist

SJIA0758E

49 - Ground :Continuity should exist

AWIIA0450ZZ

Page 3363 of 5883

![NISSAN TIIDA 2007 Service Repair Manual HAC-30

< COMPONENT DIAGNOSIS >[MANUAL AIR CONDITIONER]

INTAKE SENSOR

INTAKE SENSOR

Component InspectionINFOID:0000000001675415

COMPONENT DESCRIPTION

Intake Sensor

The intake sensor (1) is located on t NISSAN TIIDA 2007 Service Repair Manual HAC-30

< COMPONENT DIAGNOSIS >[MANUAL AIR CONDITIONER]

INTAKE SENSOR

INTAKE SENSOR

Component InspectionINFOID:0000000001675415

COMPONENT DESCRIPTION

Intake Sensor

The intake sensor (1) is located on t](/img/5/57395/w960_57395-3362.png)

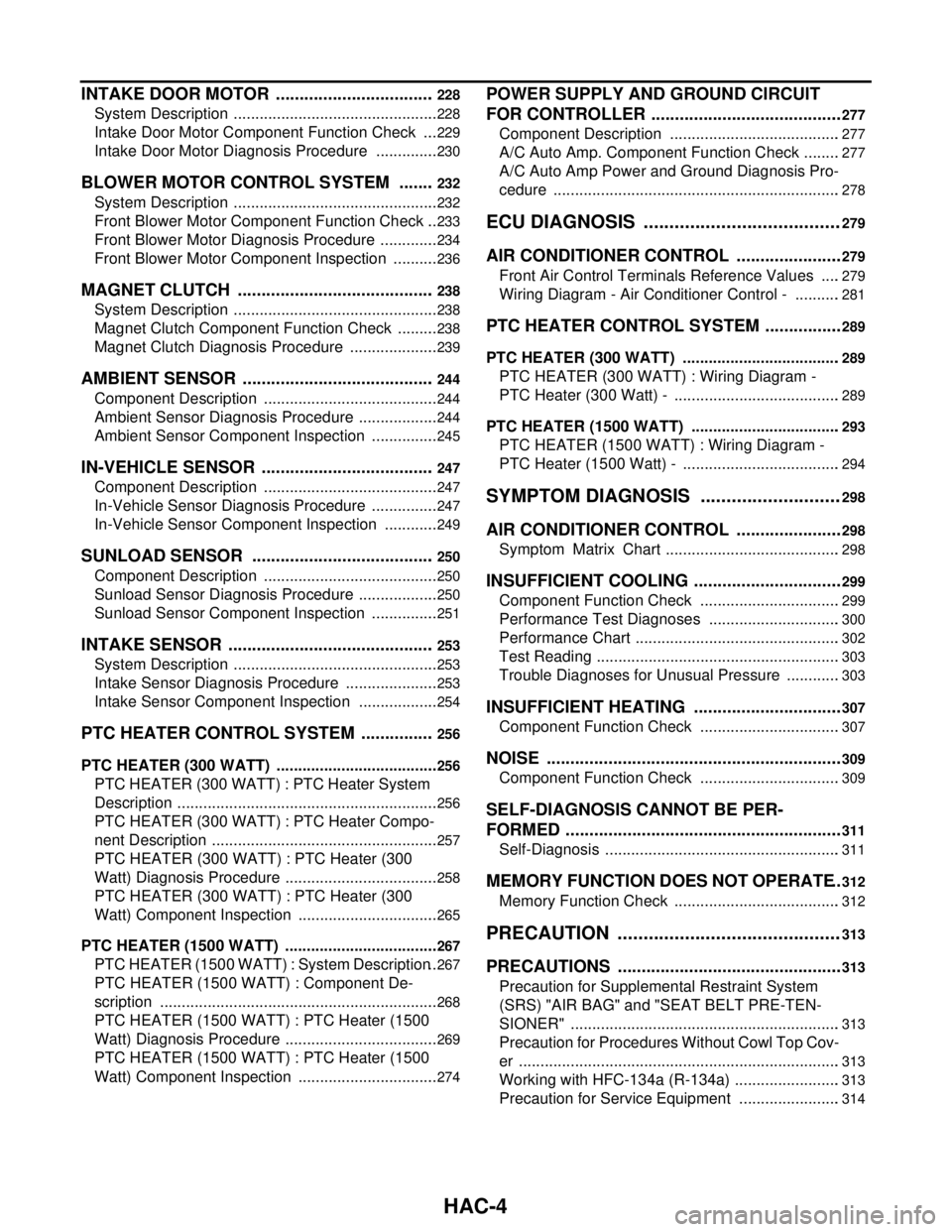

HAC-30

< COMPONENT DIAGNOSIS >[MANUAL AIR CONDITIONER]

INTAKE SENSOR

INTAKE SENSOR

Component InspectionINFOID:0000000001675415

COMPONENT DESCRIPTION

Intake Sensor

The intake sensor (1) is located on the A/C unit. It converts tempera-

ture of air after it passes through the evaporator (2) into a resistance

value which is then input to the BCM.

Intake Sensor Diagnosis ProcedureINFOID:0000000001675416

DIAGNOSTIC PROCEDURE FOR INTAKE SENSOR

SYMPTOM: Intake sensor circuit is open or shorted.

1.CHECK VOLTAGE BETWEEN INTAKE SENSOR AND GROUND

1. Turn ignition switch OFF.

2. Disconnect intake sensor connector.

3. Turn ignition switch ON.

4. Check voltage between intake sensor harness connector M42

terminal 1 and ground.

OK or NG

OK >> GO TO 2.

NG >> GO TO 4.

2.CHECK CIRCUIT CONTINUITY BETWEEN INTAKE SENSOR AND BCM

ZJIA0798J

AWIIA0452GB

Te r m i n a l s

Vo l ta g e

(Approx.) (+) (−)

Connector Terminal

Ground

Intake sensor: M42 1 5V

SJIA0825E