engine NISSAN TIIDA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 4292 of 5883

MA-52

< ON-VEHICLE MAINTENANCE >

CHASSIS AND BODY MAINTENANCE

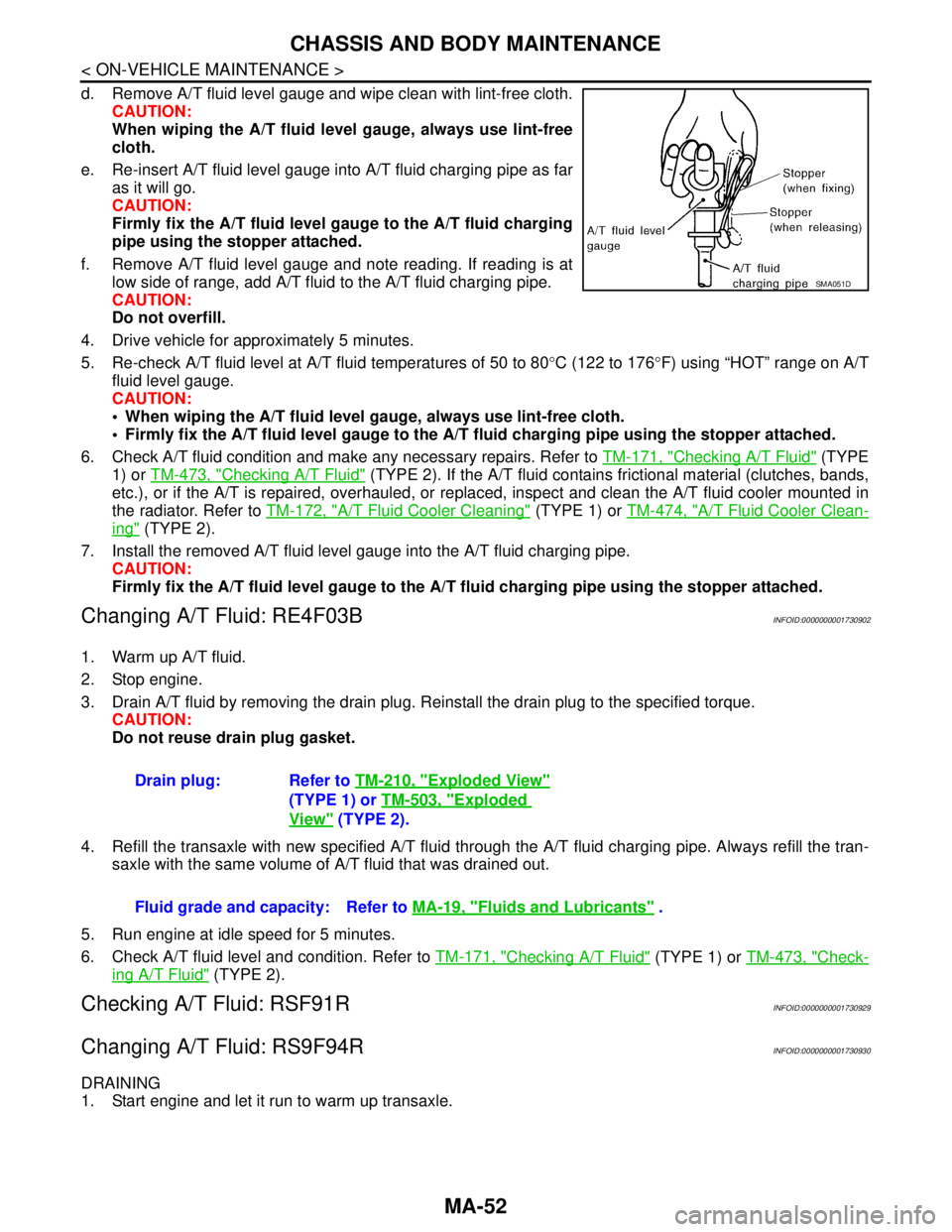

d. Remove A/T fluid level gauge and wipe clean with lint-free cloth.

CAUTION:

When wiping the A/T fluid level gauge, always use lint-free

cloth.

e. Re-insert A/T fluid level gauge into A/T fluid charging pipe as far

as it will go.

CAUTION:

Firmly fix the A/T fluid level gauge to the A/T fluid charging

pipe using the stopper attached.

f. Remove A/T fluid level gauge and note reading. If reading is at

low side of range, add A/T fluid to the A/T fluid charging pipe.

CAUTION:

Do not overfill.

4. Drive vehicle for approximately 5 minutes.

5. Re-check A/T fluid level at A/T fluid temperatures of 50 to 80°C (122 to 176°F) using “HOT” range on A/T

fluid level gauge.

CAUTION:

When wiping the A/T fluid level gauge, always use lint-free cloth.

Firmly fix the A/T fluid level gauge to the A/T fluid charging pipe using the stopper attached.

6. Check A/T fluid condition and make any necessary repairs. Refer to TM-171, "

Checking A/T Fluid" (TYPE

1) or TM-473, "

Checking A/T Fluid" (TYPE 2). If the A/T fluid contains frictional material (clutches, bands,

etc.), or if the A/T is repaired, overhauled, or replaced, inspect and clean the A/T fluid cooler mounted in

the radiator. Refer to TM-172, "

A/T Fluid Cooler Cleaning" (TYPE 1) or TM-474, "A/T Fluid Cooler Clean-

ing" (TYPE 2).

7. Install the removed A/T fluid level gauge into the A/T fluid charging pipe.

CAUTION:

Firmly fix the A/T fluid level gauge to the A/T fluid charging pipe using the stopper attached.

Changing A/T Fluid: RE4F03BINFOID:0000000001730902

1. Warm up A/T fluid.

2. Stop engine.

3. Drain A/T fluid by removing the drain plug. Reinstall the drain plug to the specified torque.

CAUTION:

Do not reuse drain plug gasket.

4. Refill the transaxle with new specified A/T fluid through the A/T fluid charging pipe. Always refill the tran-

saxle with the same volume of A/T fluid that was drained out.

5. Run engine at idle speed for 5 minutes.

6. Check A/T fluid level and condition. Refer to TM-171, "

Checking A/T Fluid" (TYPE 1) or TM-473, "Check-

ing A/T Fluid" (TYPE 2).

Checking A/T Fluid: RSF91RINFOID:0000000001730929

Changing A/T Fluid: RS9F94RINFOID:0000000001730930

DRAINING

1. Start engine and let it run to warm up transaxle.

SMA051D

Drain plug: Refer to TM-210, "Exploded View"

(TYPE 1) or TM-503, "

Exploded

View" (TYPE 2).

Fluid grade and capacity: Refer to MA-19, "

Fluids and Lubricants" .

Page 4293 of 5883

CHASSIS AND BODY MAINTENANCE

MA-53

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

MB

MAN

OA

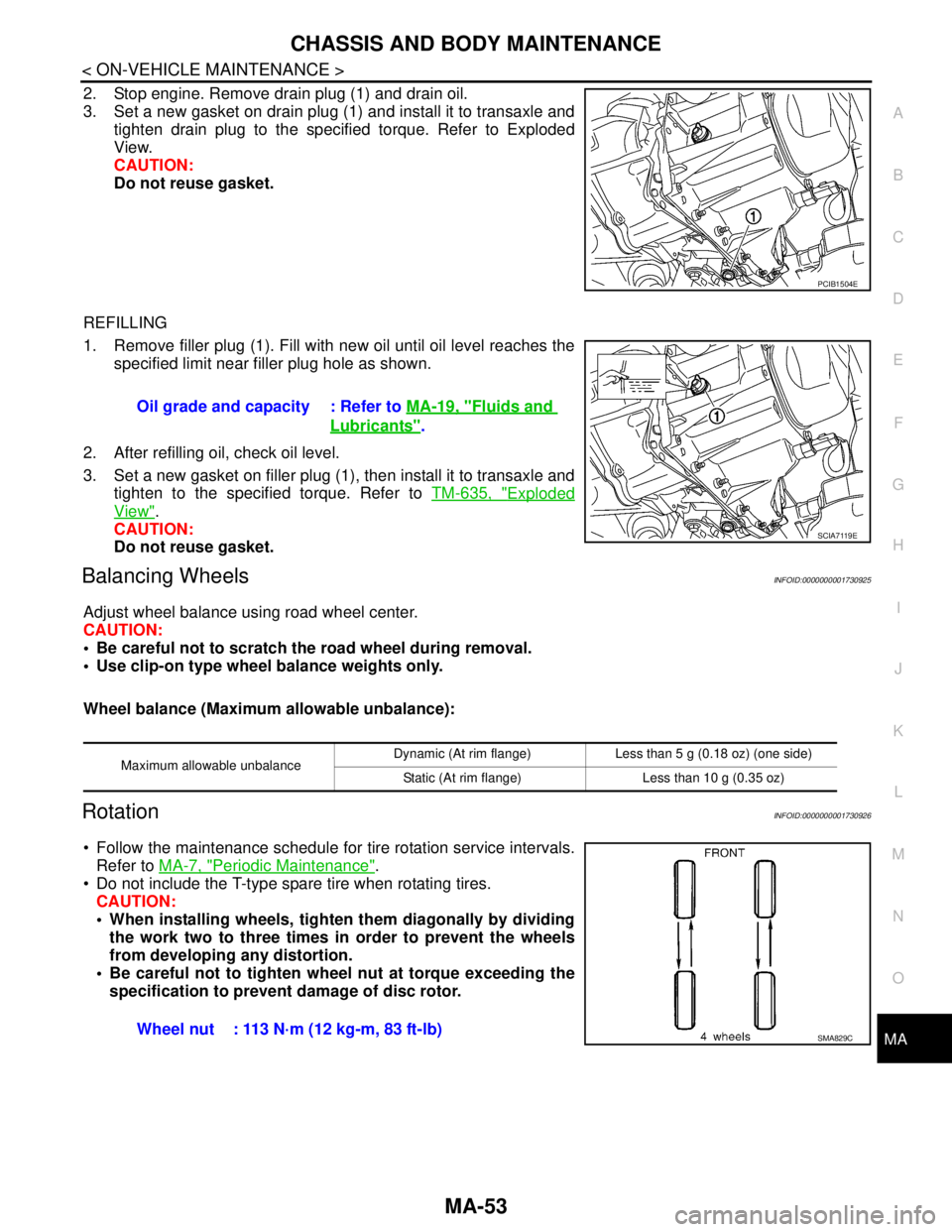

2. Stop engine. Remove drain plug (1) and drain oil.

3. Set a new gasket on drain plug (1) and install it to transaxle and

tighten drain plug to the specified torque. Refer to Exploded

View.

CAUTION:

Do not reuse gasket.

REFILLING

1. Remove filler plug (1). Fill with new oil until oil level reaches the

specified limit near filler plug hole as shown.

2. After refilling oil, check oil level.

3. Set a new gasket on filler plug (1), then install it to transaxle and

tighten to the specified torque. Refer to TM-635, "

Exploded

View".

CAUTION:

Do not reuse gasket.

Balancing WheelsINFOID:0000000001730925

Adjust wheel balance using road wheel center.

CAUTION:

Be careful not to scratch the road wheel during removal.

Use clip-on type wheel balance weights only.

Wheel balance (Maximum allowable unbalance):

RotationINFOID:0000000001730926

Follow the maintenance schedule for tire rotation service intervals.

Refer to MA-7, "

Periodic Maintenance".

Do not include the T-type spare tire when rotating tires.

CAUTION:

When installing wheels, tighten them diagonally by dividing

the work two to three times in order to prevent the wheels

from developing any distortion.

Be careful not to tighten wheel nut at torque exceeding the

specification to prevent damage of disc rotor.

PCIB1504E

Oil grade and capacity : Refer to MA-19, "Fluids and

Lubricants".

SCIA7119E

Maximum allowable unbalanceDynamic (At rim flange) Less than 5 g (0.18 oz) (one side)

Static (At rim flange) Less than 10 g (0.35 oz)

Wheel nut : 113 N·m (12 kg-m, 83 ft-lb)SMA829C

Page 4308 of 5883

MWI

MWI-1

DRIVER INFORMATION & MULTIMEDIA

C

D

E

F

G

H

I

J

K

L

MB

SECTION MWI

A

O

P

CONTENTS

METER, WARNING LAMP & INDICATOR

BASIC INSPECTION ....................................3

DIAGNOSIS AND REPAIR WORKFLOW ..........3

Work Flow .................................................................3

FUNCTION DIAGNOSIS ...............................4

METER SYSTEM .................................................4

METER SYSTEM .........................................................4

METER SYSTEM : System Diagram ........................4

METER SYSTEM : System Description ....................4

METER SYSTEM : Arrangement of Combination

Meter .........................................................................

5

METER SYSTEM : Component Parts Location ........6

METER SYSTEM : Component Description .............7

SPEEDOMETER ..........................................................7

SPEEDOMETER : System Diagram .........................7

SPEEDOMETER : System Description .....................7

SPEEDOMETER : Component Parts Location .........8

SPEEDOMETER : Component Description ..............9

TACHOMETER ............................................................9

TACHOMETER : System Diagram ...........................9

TACHOMETER : System Description .......................9

TACHOMETER : Component Parts Location .........10

TACHOMETER : Component Description ..............11

FUEL GAUGE ............................................................11

FUEL GAUGE : System Diagram ...........................11

FUEL GAUGE : System Description .......................11

FUEL GAUGE : Component Parts Location ...........12

FUEL GAUGE : Component Description ................13

ODO/TRIP METER ....................................................13

ODO/TRIP METER : System Diagram ....................13

ODO/TRIP METER : System Description ...............13

ODO/TRIP METER : Component Parts Location ....14

ODO/TRIP METER : Component Description .........15

WARNING LAMPS/INDICATOR LAMPS ..................15

WARNING LAMPS/INDICATOR LAMPS : System

Diagram ...................................................................

15

WARNING LAMPS/INDICATOR LAMPS : System

Description ...............................................................

15

WARNING LAMPS/INDICATOR LAMPS : Com-

ponent Parts Location ..............................................

16

WARNING LAMPS/INDICATOR LAMPS : Com-

ponent Description ...................................................

17

INFORMATION DISPLAY ..........................................17

INFORMATION DISPLAY : System Diagram ..........17

INFORMATION DISPLAY : System Description .....17

INFORMATION DISPLAY : Component Parts Lo-

cation .......................................................................

19

INFORMATION DISPLAY : Component Descrip-

tion ...........................................................................

19

DIAGNOSIS SYSTEM (METER) .......................21

Diagnosis Description ..............................................21

CONSULT-III Function (METER/M&A) ....................22

COMPONENT DIAGNOSIS .........................24

DTC U1000 CAN COMMUNICATION ...............24

DTC Logic ................................................................24

Diagnosis Procedure ..............................................24

DTC B2205 VEHICLE SPEED CIRCUIT ..........25

Description ...............................................................25

DTC Logic ................................................................25

Diagnosis Procedure ..............................................25

POWER SUPPLY AND GROUND CIRCUIT ....26

COMBINATION METER ............................................26

COMBINATION METER : Diagnosis Procedure .....26

BCM (BODY CONTROL MODULE) ..........................26

BCM (BODY CONTROL MODULE) : Diagnosis

Procedure ................................................................

26

IPDM E/R (INTELLIGENT POWER DISTRIBU-

TION MODULE ENGINE ROOM) ..........................

Page 4309 of 5883

MWI-2

IPDM E/R (INTELLIGENT POWER DISTRIBU-

TION MODULE ENGINE ROOM) : Diagnosis Pro-

cedure .....................................................................

27

FUEL LEVEL SENSOR SIGNAL CIRCUIT .......29

Description ..............................................................29

Component Function Check ...................................29

Diagnosis Procedure .............................................29

Component Inspection ............................................30

OIL PRESSURE SWITCH SIGNAL CIRCUIT ...31

Description ..............................................................31

Component Function Check ...................................31

Diagnosis Procedure ..............................................31

Component Inspection ............................................31

OIL LEVEL SENSOR SIGNAL CIRCUIT ..........32

Description ..............................................................32

Diagnosis Procedure (With Diesel) .........................32

Diagnosis Procedure (Without Diesel) ....................32

Component Inspection (With Diesel) ......................32

Component Inspection (Without Diesel) .................33

AMBIENT SENSOR SIGNAL CIRCUIT .............34

Description ..............................................................34

Diagnosis Procedure ..............................................34

Component Inspection ............................................35

ECU DIAGNOSIS ........................................36

COMBINATION METER ....................................36

Reference Value .....................................................36

Wiring Diagram .......................................................39

Fail Safe .................................................................53

DTC Index ..............................................................54

BCM (BODY CONTROL MODULE) ..................55

Reference Value .....................................................55

Terminal Layout ......................................................58

Physical Values ......................................................58

Wiring Diagram .......................................................70

DTC Inspection Priority Chart ..............................73

DTC Index ..............................................................74

IPDM E/R (INTELLIGENT POWER DISTRI-

BUTION MODULE ENGINE ROOM) .................

75

Reference Value .....................................................75

Terminal Layout ......................................................77

Physical Values ......................................................77

Wiring Diagram .......................................................81

Fail Safe .................................................................84

DTC Index ..............................................................86

SYMPTOM DIAGNOSIS ............................87

THE FUEL GAUGE POINTER DOES NOT

MOVE .................................................................

87

Description ..............................................................87

Diagnosis Procedure ...............................................87

THE FUEL GAUGE POINTER DOES NOT

MOVE TO "F" WHEN REFUELING ..................

88

Description ..............................................................88

Diagnosis Procedure ...............................................88

THE OIL PRESSURE WARNING LAMP

DOES NOT TURN ON .......................................

89

Description ..............................................................89

Diagnosis Procedure ...............................................89

THE OIL PRESSURE WARNING LAMP

DOES NOT TURN OFF .....................................

90

Description ..............................................................90

Diagnosis Procedure ...............................................90

THE AMBIENT TEMPERATURE DISPLAY IS

INCORRECT ......................................................

91

Description ..............................................................91

Diagnosis Procedure ...............................................91

NORMAL OPERATING CONDITION ................92

INFORMATION DISPLAY .........................................92

INFORMATION DISPLAY : Description ..................92

PRECAUTION ............................................93

PRECAUTIONS .................................................93

Supplemental Restraint System (SRS) "AIR BAG"

and "SEAT BELT PRE-TENSIONER" ....................

93

ON-VEHICLE REPAIR ...............................94

COMBINATION METER ....................................94

Removal and Installation .........................................94

DISASSEMBLY AND ASSEMBLY ............97

COMBINATION METER ....................................97

Disassembly and Assembly ....................................97

Page 4313 of 5883

MWI-6

< FUNCTION DIAGNOSIS >

METER SYSTEM

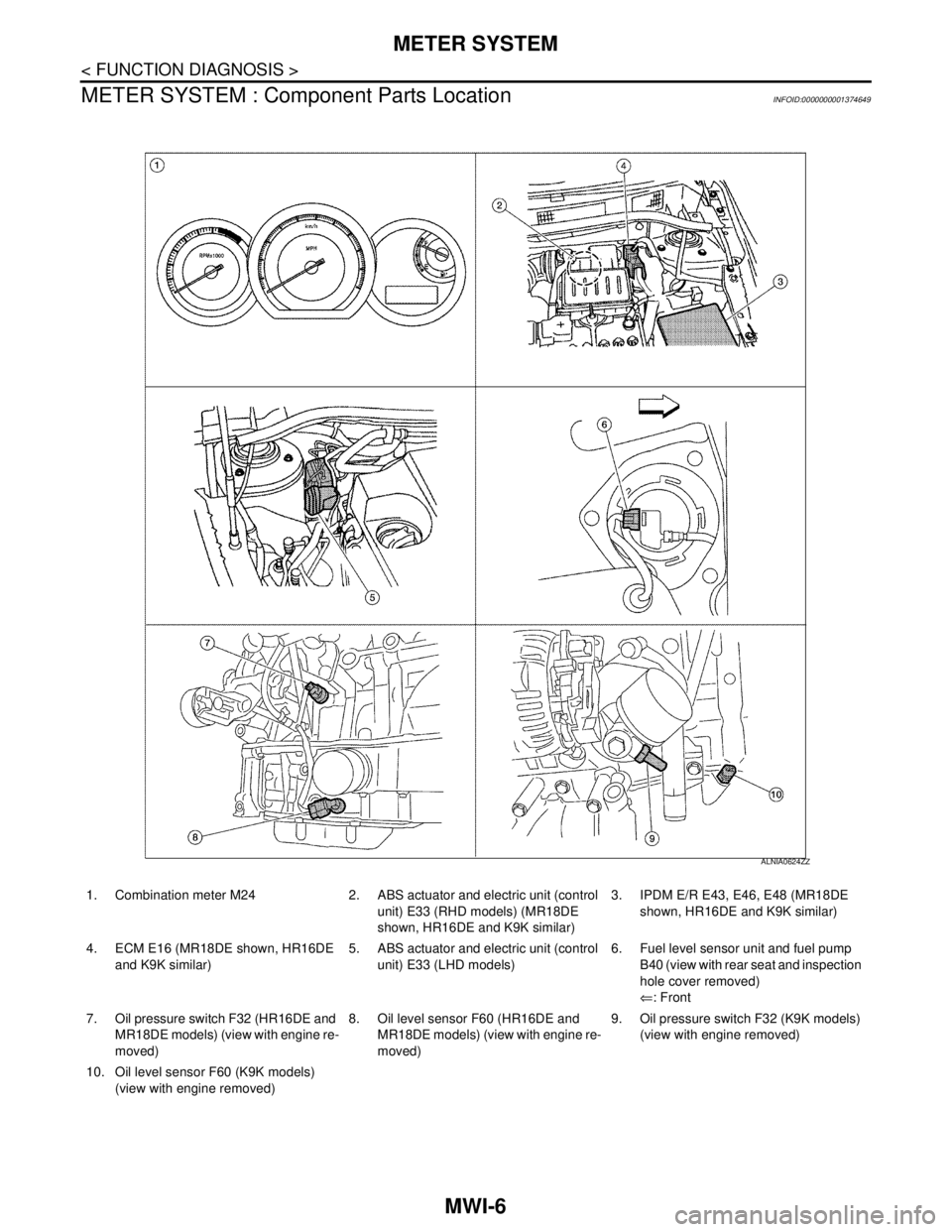

METER SYSTEM : Component Parts Location

INFOID:0000000001374649

1. Combination meter M24 2. ABS actuator and electric unit (control

unit) E33 (RHD models) (MR18DE

shown, HR16DE and K9K similar)3. IPDM E/R E43, E46, E48 (MR18DE

shown, HR16DE and K9K similar)

4. ECM E16 (MR18DE shown, HR16DE

and K9K similar)5. ABS actuator and electric unit (control

unit) E33 (LHD models)6. Fuel level sensor unit and fuel pump

B40 (view with rear seat and inspection

hole cover removed)

⇐: Front

7. Oil pressure switch F32 (HR16DE and

MR18DE models) (view with engine re-

moved)8. Oil level sensor F60 (HR16DE and

MR18DE models) (view with engine re-

moved)9. Oil pressure switch F32 (K9K models)

(view with engine removed)

10. Oil level sensor F60 (K9K models)

(view with engine removed)

ALNIA0624ZZ

Page 4314 of 5883

MWI

METER SYSTEM

MWI-7

< FUNCTION DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

MB A

O

P

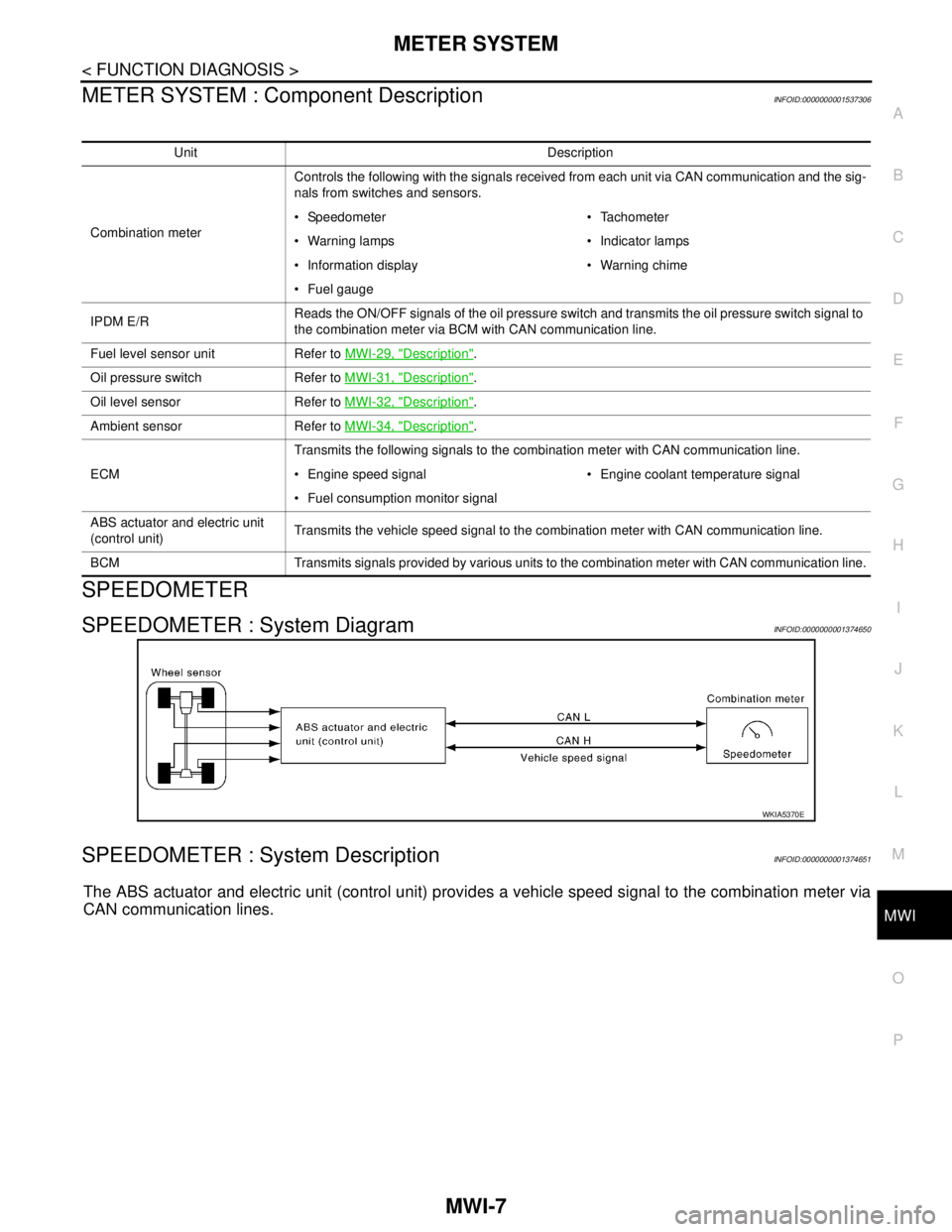

METER SYSTEM : Component DescriptionINFOID:0000000001537306

SPEEDOMETER

SPEEDOMETER : System DiagramINFOID:0000000001374650

SPEEDOMETER : System DescriptionINFOID:0000000001374651

The ABS actuator and electric unit (control unit) provides a vehicle speed signal to the combination meter via

CAN communication lines.

Unit Description

Combination meterControls the following with the signals received from each unit via CAN communication and the sig-

nals from switches and sensors.

Speedometer Tachometer

Warning lamps Indicator lamps

Information display Warning chime

Fuel gauge

IPDM E/RReads the ON/OFF signals of the oil pressure switch and transmits the oil pressure switch signal to

the combination meter via BCM with CAN communication line.

Fuel level sensor unit Refer to MWI-29, "

Description".

Oil pressure switch Refer to MWI-31, "

Description".

Oil level sensor Refer to MWI-32, "

Description".

Ambient sensor Refer to MWI-34, "

Description".

ECMTransmits the following signals to the combination meter with CAN communication line.

Engine speed signal Engine coolant temperature signal

Fuel consumption monitor signal

ABS actuator and electric unit

(control unit)Transmits the vehicle speed signal to the combination meter with CAN communication line.

BCM Transmits signals provided by various units to the combination meter with CAN communication line.

WKIA5370E

Page 4315 of 5883

MWI-8

< FUNCTION DIAGNOSIS >

METER SYSTEM

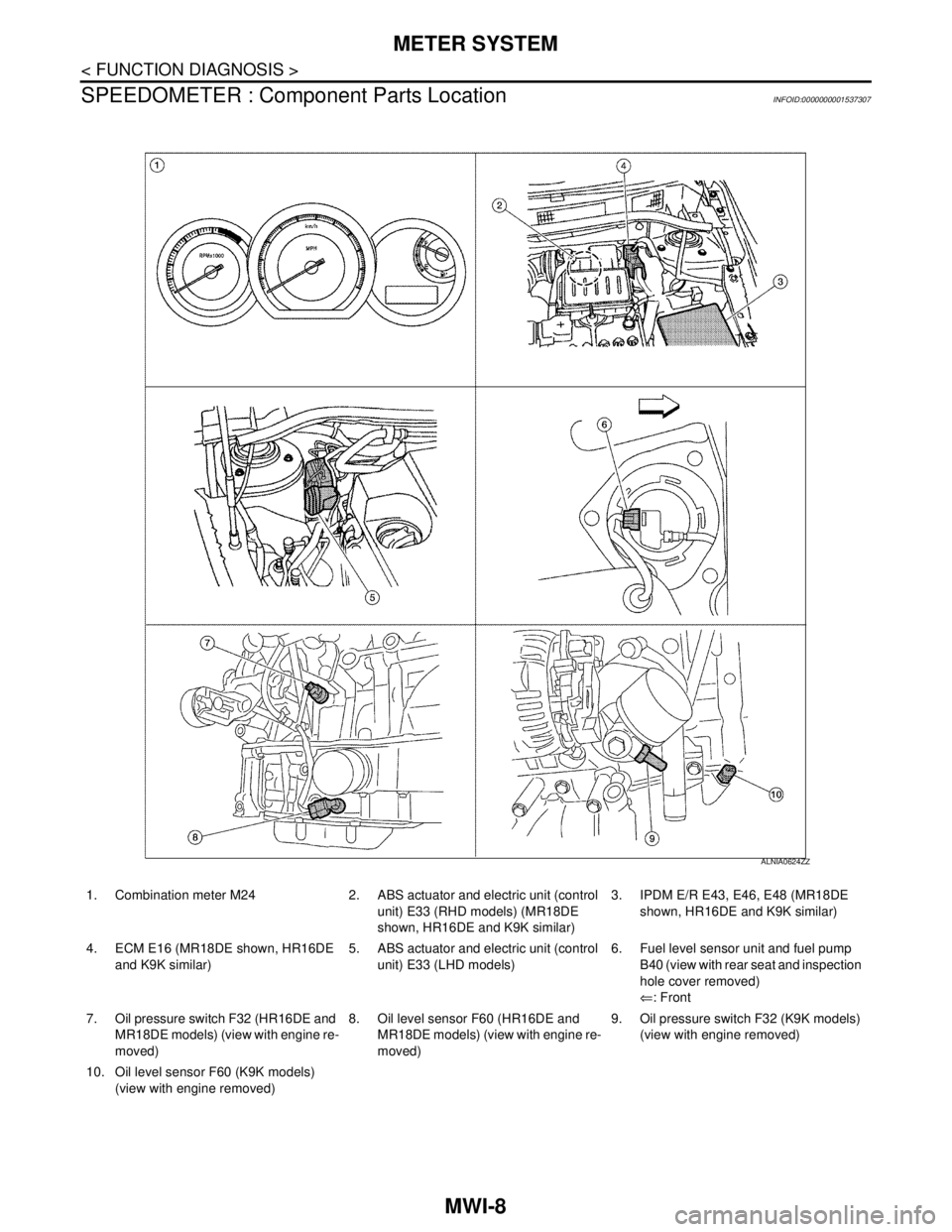

SPEEDOMETER : Component Parts Location

INFOID:0000000001537307

1. Combination meter M24 2. ABS actuator and electric unit (control

unit) E33 (RHD models) (MR18DE

shown, HR16DE and K9K similar)3. IPDM E/R E43, E46, E48 (MR18DE

shown, HR16DE and K9K similar)

4. ECM E16 (MR18DE shown, HR16DE

and K9K similar)5. ABS actuator and electric unit (control

unit) E33 (LHD models)6. Fuel level sensor unit and fuel pump

B40 (view with rear seat and inspection

hole cover removed)

⇐: Front

7. Oil pressure switch F32 (HR16DE and

MR18DE models) (view with engine re-

moved)8. Oil level sensor F60 (HR16DE and

MR18DE models) (view with engine re-

moved)9. Oil pressure switch F32 (K9K models)

(view with engine removed)

10. Oil level sensor F60 (K9K models)

(view with engine removed)

ALNIA0624ZZ

Page 4316 of 5883

MWI

METER SYSTEM

MWI-9

< FUNCTION DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

MB A

O

P

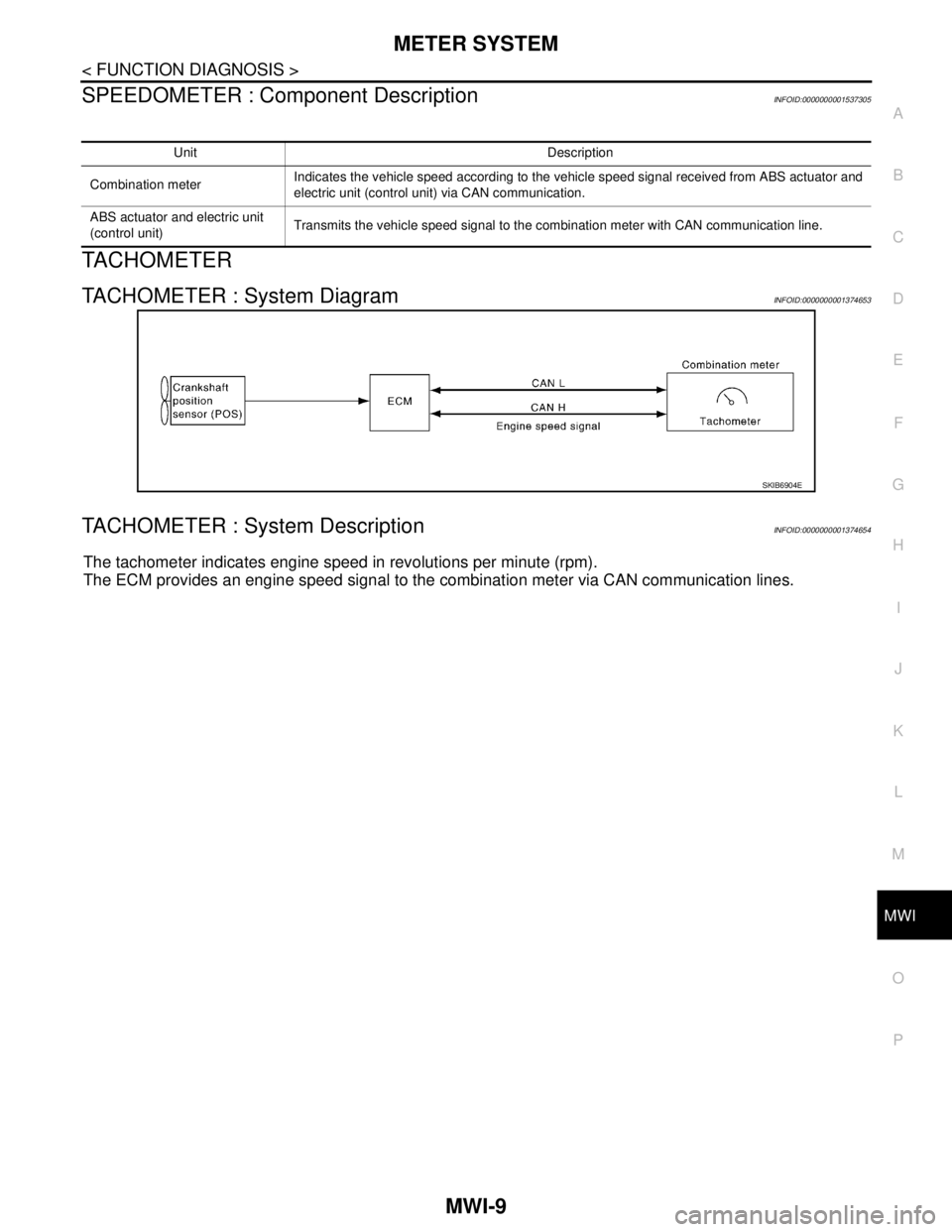

SPEEDOMETER : Component DescriptionINFOID:0000000001537305

TACHOMETER

TACHOMETER : System DiagramINFOID:0000000001374653

TACHOMETER : System DescriptionINFOID:0000000001374654

The tachometer indicates engine speed in revolutions per minute (rpm).

The ECM provides an engine speed signal to the combination meter via CAN communication lines.

Unit Description

Combination meterIndicates the vehicle speed according to the vehicle speed signal received from ABS actuator and

electric unit (control unit) via CAN communication.

ABS actuator and electric unit

(control unit)Transmits the vehicle speed signal to the combination meter with CAN communication line.

SKIB6904E

Page 4317 of 5883

MWI-10

< FUNCTION DIAGNOSIS >

METER SYSTEM

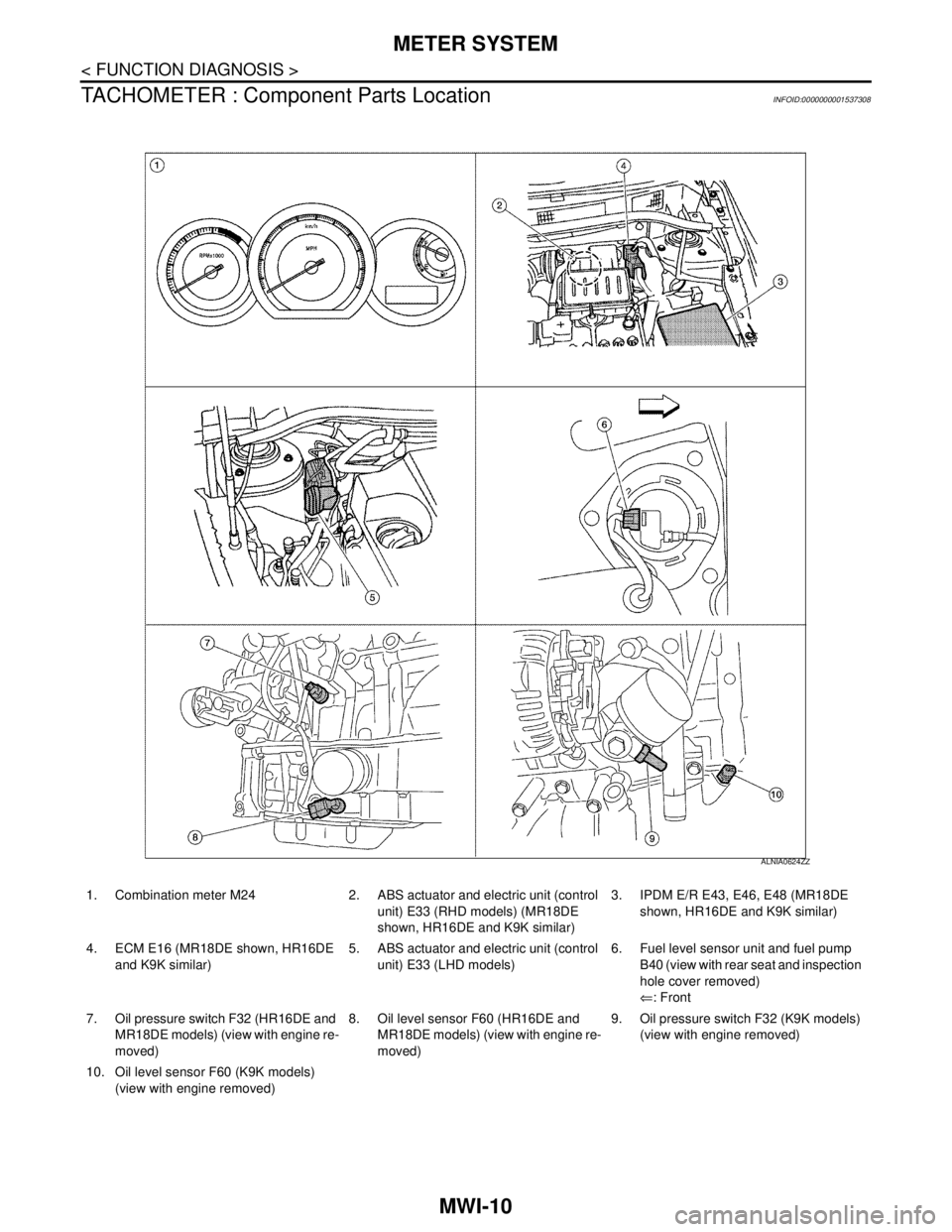

TACHOMETER : Component Parts Location

INFOID:0000000001537308

1. Combination meter M24 2. ABS actuator and electric unit (control

unit) E33 (RHD models) (MR18DE

shown, HR16DE and K9K similar)3. IPDM E/R E43, E46, E48 (MR18DE

shown, HR16DE and K9K similar)

4. ECM E16 (MR18DE shown, HR16DE

and K9K similar)5. ABS actuator and electric unit (control

unit) E33 (LHD models)6. Fuel level sensor unit and fuel pump

B40 (view with rear seat and inspection

hole cover removed)

⇐: Front

7. Oil pressure switch F32 (HR16DE and

MR18DE models) (view with engine re-

moved)8. Oil level sensor F60 (HR16DE and

MR18DE models) (view with engine re-

moved)9. Oil pressure switch F32 (K9K models)

(view with engine removed)

10. Oil level sensor F60 (K9K models)

(view with engine removed)

ALNIA0624ZZ

Page 4318 of 5883

MWI

METER SYSTEM

MWI-11

< FUNCTION DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

MB A

O

P

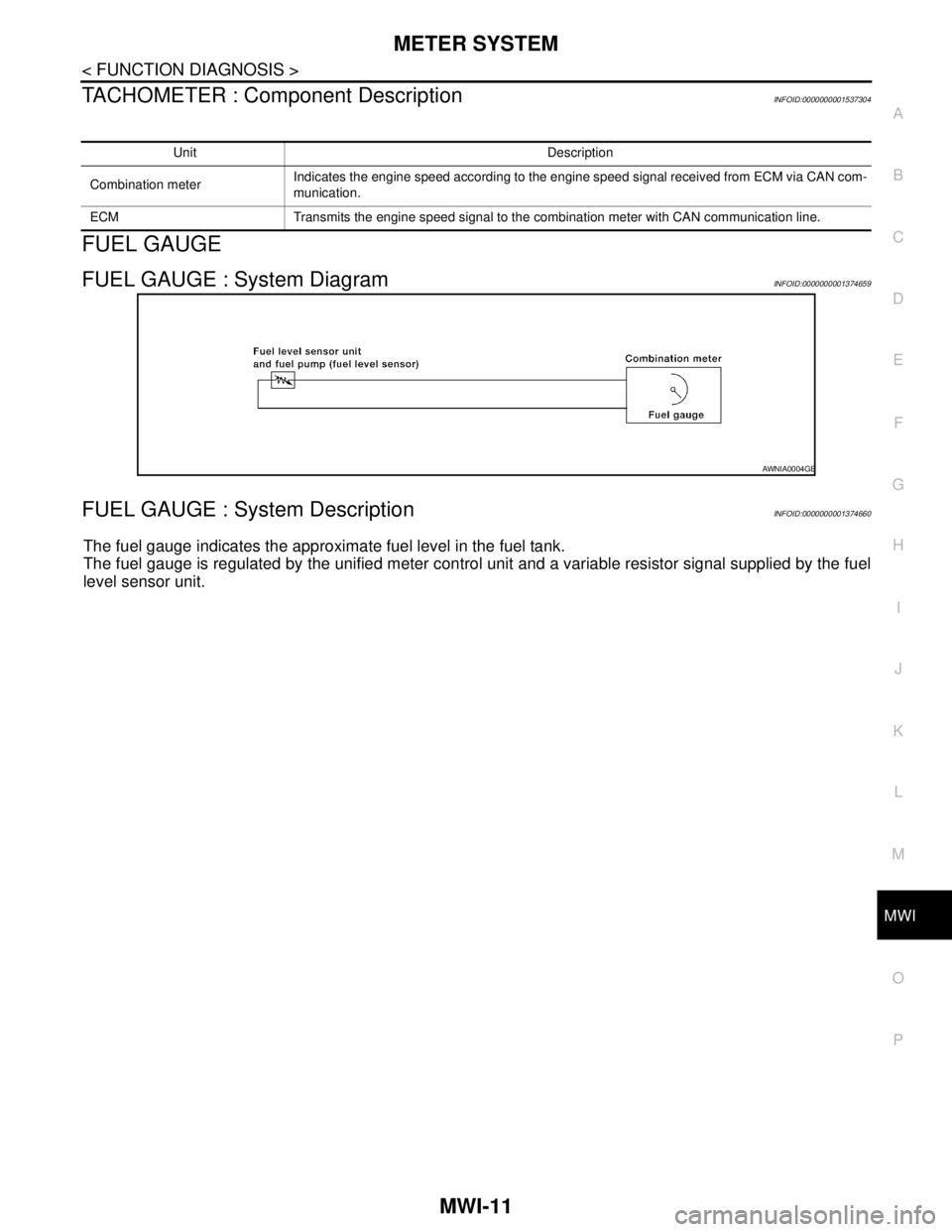

TACHOMETER : Component DescriptionINFOID:0000000001537304

FUEL GAUGE

FUEL GAUGE : System DiagramINFOID:0000000001374659

FUEL GAUGE : System DescriptionINFOID:0000000001374660

The fuel gauge indicates the approximate fuel level in the fuel tank.

The fuel gauge is regulated by the unified meter control unit and a variable resistor signal supplied by the fuel

level sensor unit.

Unit Description

Combination meterIndicates the engine speed according to the engine speed signal received from ECM via CAN com-

munication.

ECM Transmits the engine speed signal to the combination meter with CAN communication line.

AWNIA0004GB