engine NISSAN TIIDA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 4387 of 5883

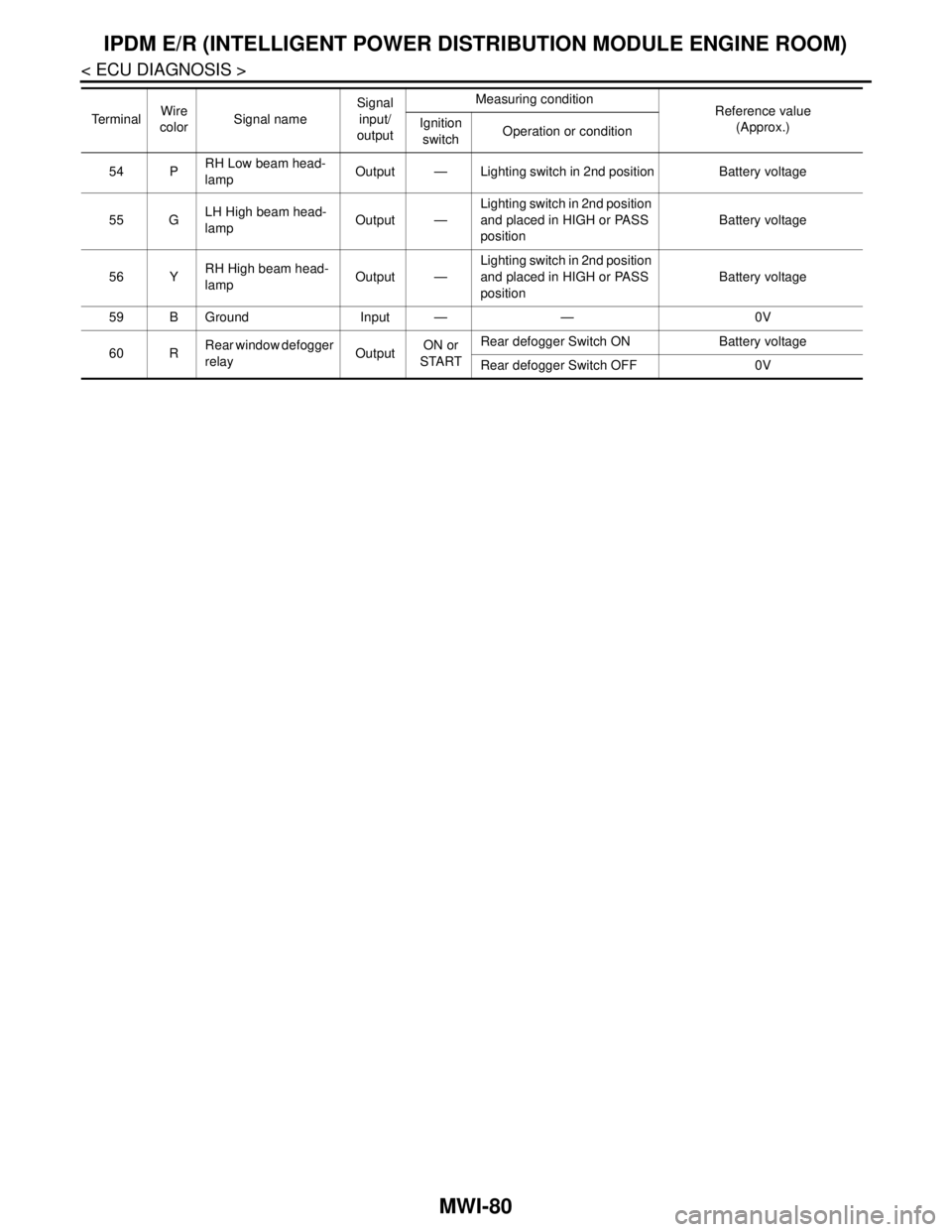

MWI-80

< ECU DIAGNOSIS >

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

54 PRH Low beam head-

lampOutput — Lighting switch in 2nd position Battery voltage

55 GLH High beam head-

lampOutput —Lighting switch in 2nd position

and placed in HIGH or PASS

positionBattery voltage

56 YRH High beam head-

lampOutput —Lighting switch in 2nd position

and placed in HIGH or PASS

positionBattery voltage

59 B Ground Input — — 0V

60 RRear window defogger

relayOutputON or

STARTRear defogger Switch ON Battery voltage

Rear defogger Switch OFF 0V Te r m i n a lWire

colorSignal nameSignal

input/

outputMeasuring condition

Reference value

(Approx.) Ignition

switchOperation or condition

Page 4388 of 5883

MWI

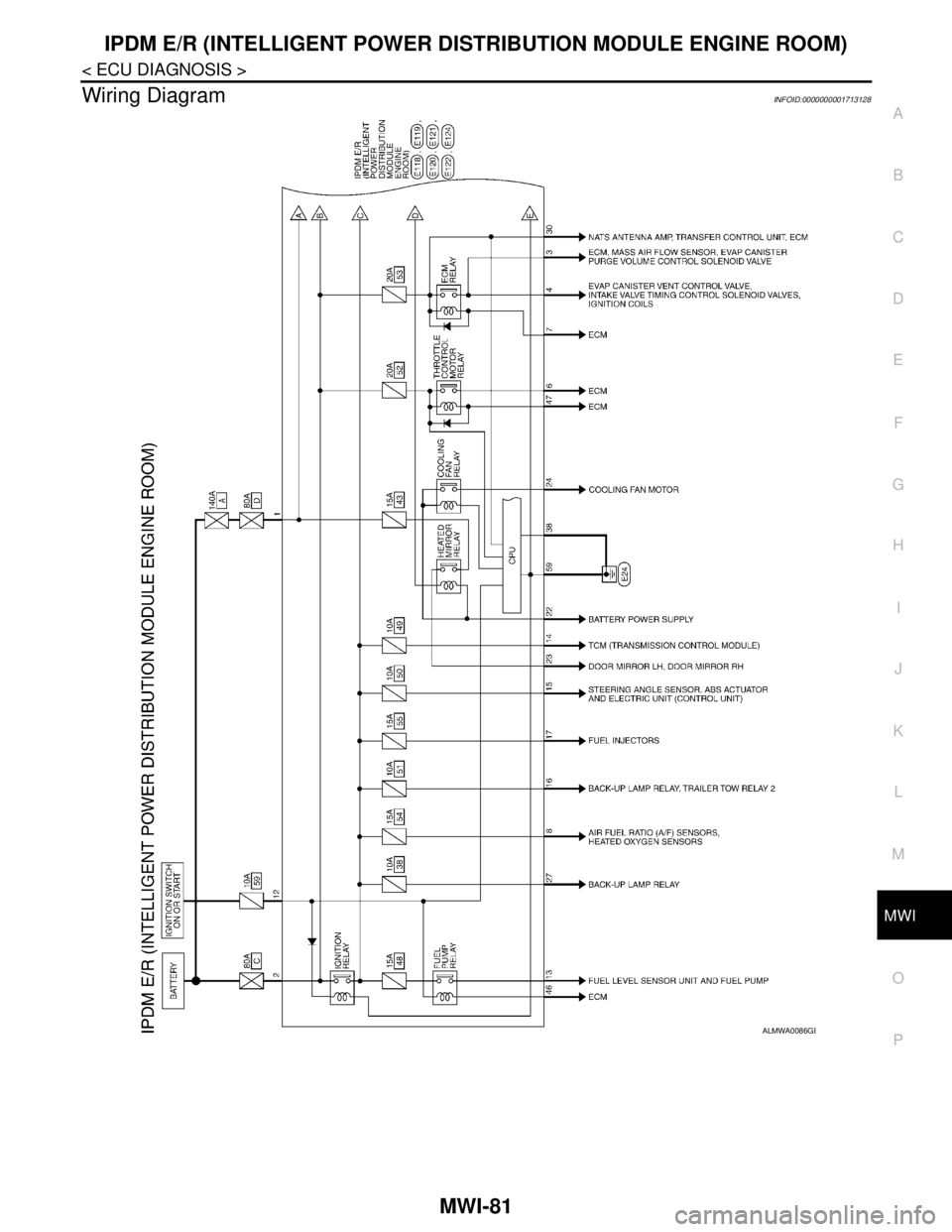

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

MWI-81

< ECU DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

MB A

O

P

Wiring DiagramINFOID:0000000001713128

ALMWA0086GB

Page 4389 of 5883

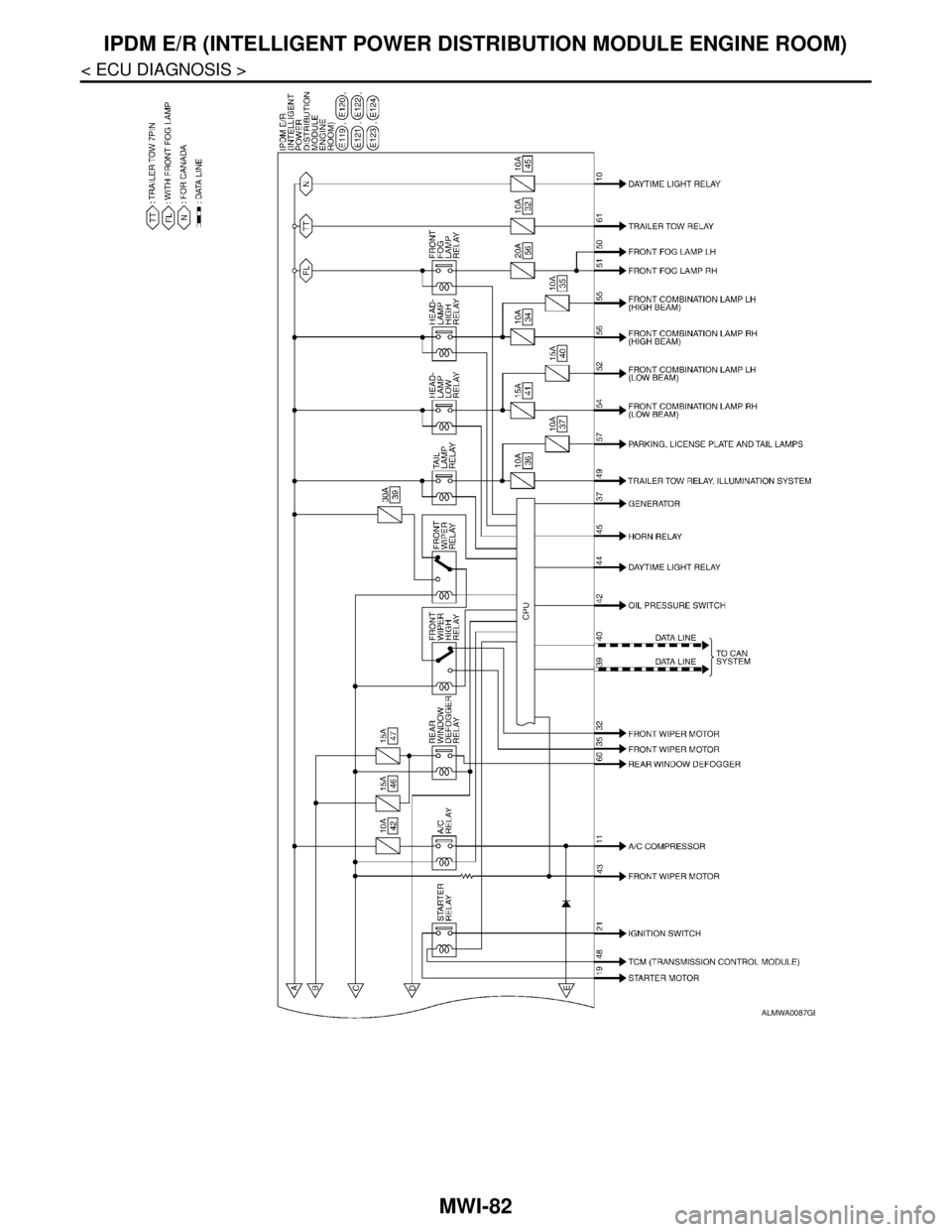

MWI-82

< ECU DIAGNOSIS >

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

ALMWA0087GB

Page 4390 of 5883

MWI

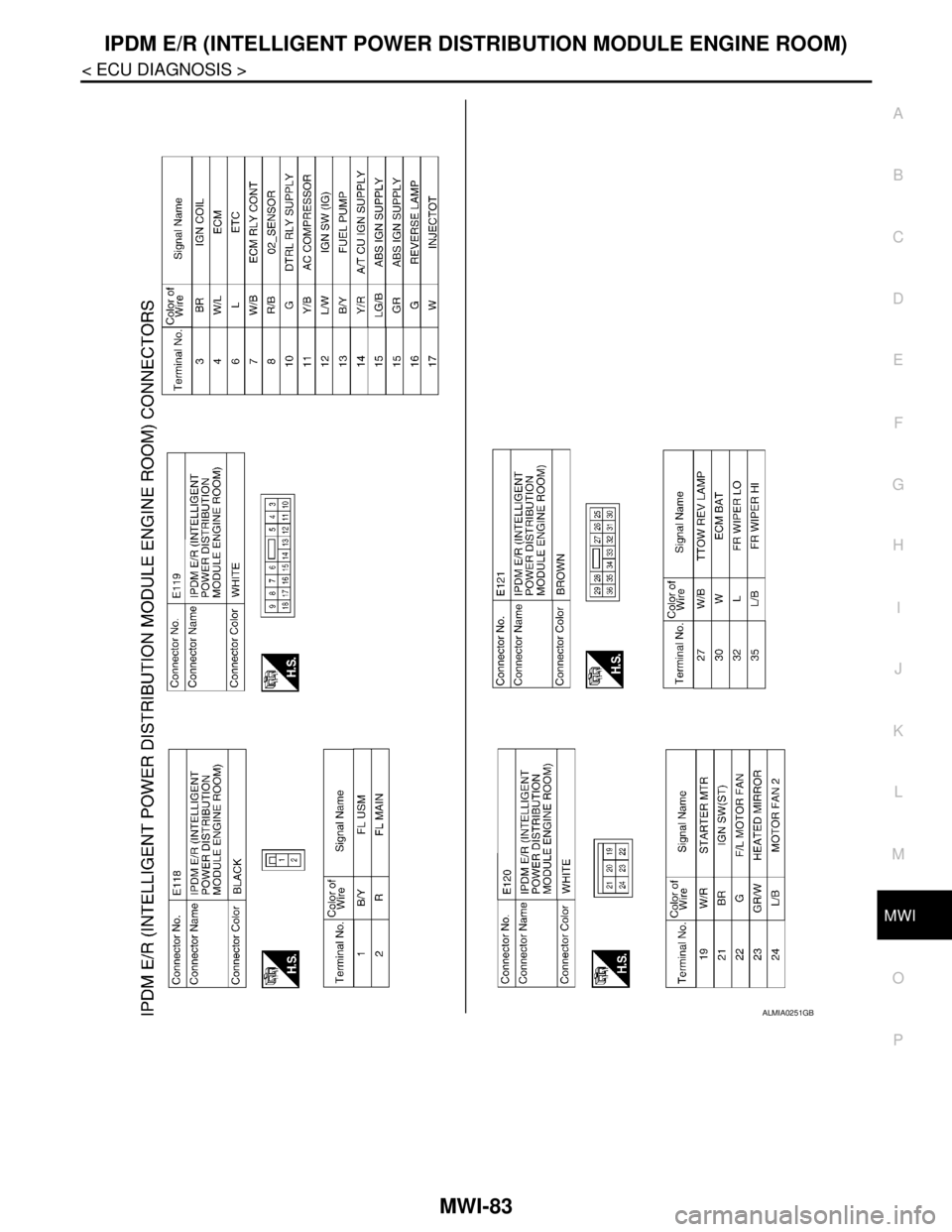

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

MWI-83

< ECU DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

MB A

O

P

ALMIA0251GB

Page 4391 of 5883

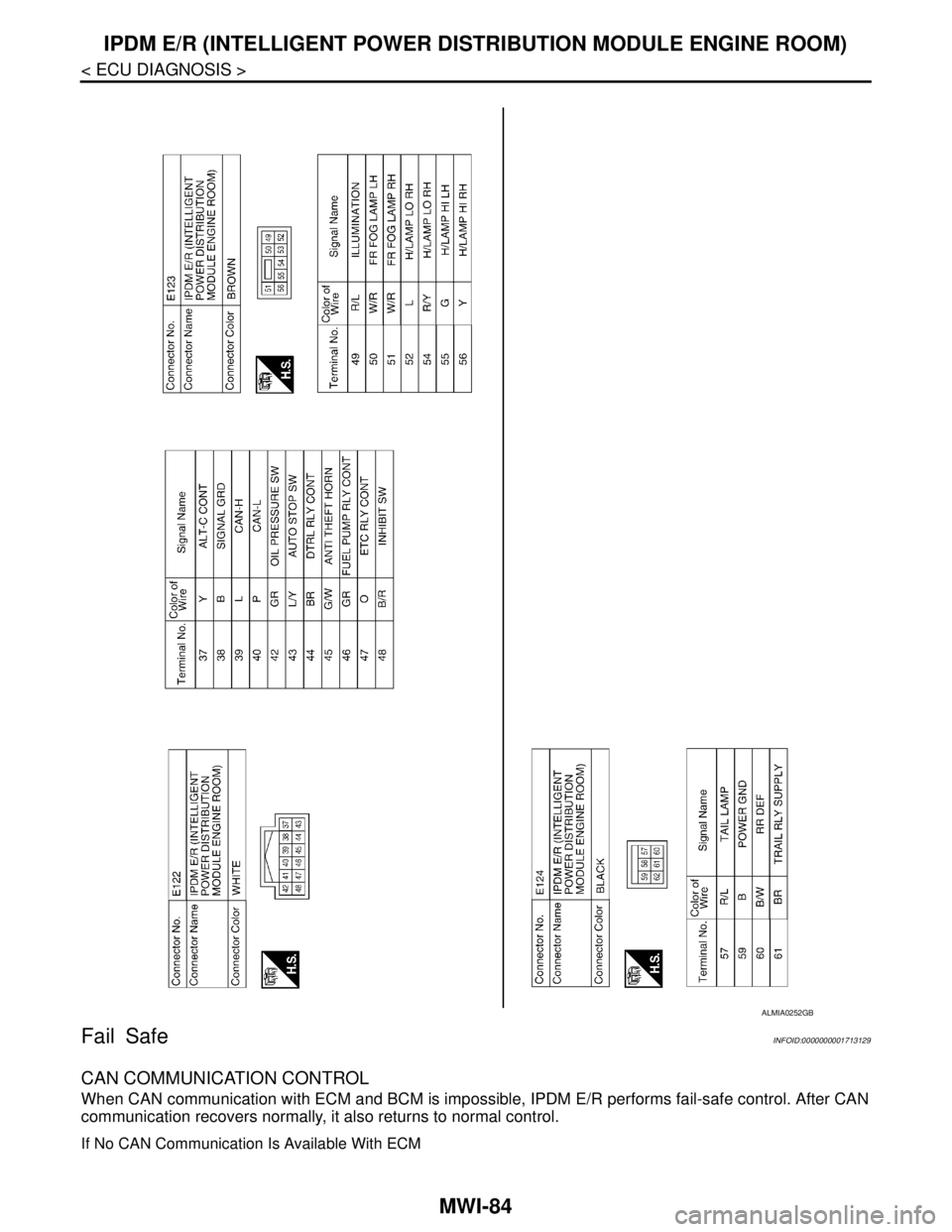

MWI-84

< ECU DIAGNOSIS >

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

Fail Safe

INFOID:0000000001713129

CAN COMMUNICATION CONTROL

When CAN communication with ECM and BCM is impossible, IPDM E/R performs fail-safe control. After CAN

communication recovers normally, it also returns to normal control.

If No CAN Communication Is Available With ECM

ALMIA0252GB

Page 4392 of 5883

MWI

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

MWI-85

< ECU DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

MB A

O

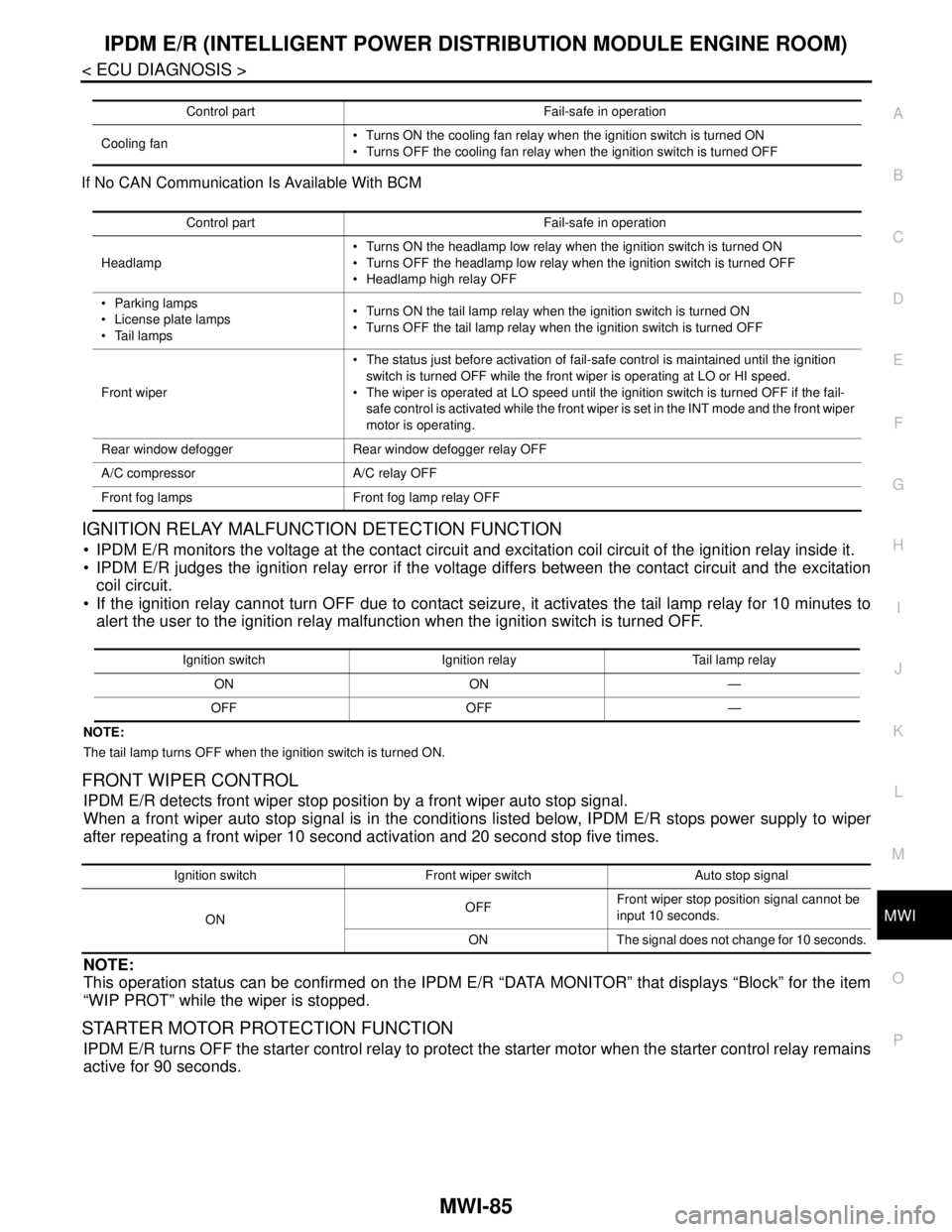

P If No CAN Communication Is Available With BCM

IGNITION RELAY MALFUNCTION DETECTION FUNCTION

IPDM E/R monitors the voltage at the contact circuit and excitation coil circuit of the ignition relay inside it.

IPDM E/R judges the ignition relay error if the voltage differs between the contact circuit and the excitation

coil circuit.

If the ignition relay cannot turn OFF due to contact seizure, it activates the tail lamp relay for 10 minutes to

alert the user to the ignition relay malfunction when the ignition switch is turned OFF.

NOTE:

The tail lamp turns OFF when the ignition switch is turned ON.

FRONT WIPER CONTROL

IPDM E/R detects front wiper stop position by a front wiper auto stop signal.

When a front wiper auto stop signal is in the conditions listed below, IPDM E/R stops power supply to wiper

after repeating a front wiper 10 second activation and 20 second stop five times.

NOTE:

This operation status can be confirmed on the IPDM E/R “DATA MONITOR” that displays “Block” for the item

“WIP PROT” while the wiper is stopped.

STARTER MOTOR PROTECTION FUNCTION

IPDM E/R turns OFF the starter control relay to protect the starter motor when the starter control relay remains

active for 90 seconds.

Control part Fail-safe in operation

Cooling fan Turns ON the cooling fan relay when the ignition switch is turned ON

Turns OFF the cooling fan relay when the ignition switch is turned OFF

Control part Fail-safe in operation

Headlamp Turns ON the headlamp low relay when the ignition switch is turned ON

Turns OFF the headlamp low relay when the ignition switch is turned OFF

Headlamp high relay OFF

Parking lamps

License plate lamps

Tail lamps Turns ON the tail lamp relay when the ignition switch is turned ON

Turns OFF the tail lamp relay when the ignition switch is turned OFF

Front wiper The status just before activation of fail-safe control is maintained until the ignition

switch is turned OFF while the front wiper is operating at LO or HI speed.

The wiper is operated at LO speed until the ignition switch is turned OFF if the fail-

safe control is activated while the front wiper is set in the INT mode and the front wiper

motor is operating.

Rear window defogger Rear window defogger relay OFF

A/C compressor A/C relay OFF

Front fog lamps Front fog lamp relay OFF

Ignition switch Ignition relay Tail lamp relay

ON ON —

OFF OFF —

Ignition switch Front wiper switch Auto stop signal

ONOFFFront wiper stop position signal cannot be

input 10 seconds.

ON The signal does not change for 10 seconds.

Page 4393 of 5883

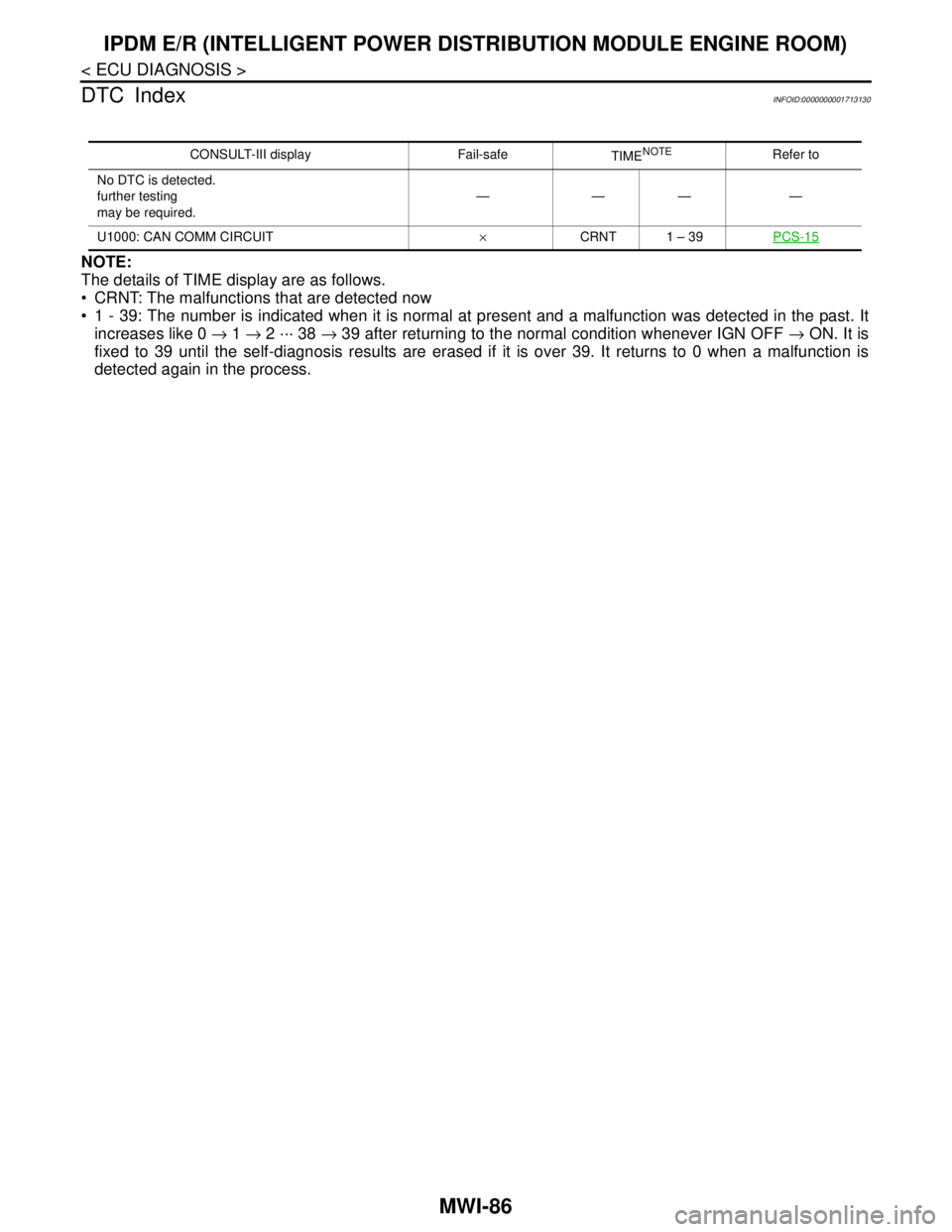

MWI-86

< ECU DIAGNOSIS >

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

DTC Index

INFOID:0000000001713130

NOTE:

The details of TIME display are as follows.

CRNT: The malfunctions that are detected now

1 - 39: The number is indicated when it is normal at present and a malfunction was detected in the past. It

increases like 0 → 1 → 2 ··· 38 → 39 after returning to the normal condition whenever IGN OFF → ON. It is

fixed to 39 until the self-diagnosis results are erased if it is over 39. It returns to 0 when a malfunction is

detected again in the process.

CONSULT-III display Fail-safe

TIMENOTERefer to

No DTC is detected.

further testing

may be required.————

U1000: CAN COMM CIRCUIT×CRNT 1 – 39PCS-15

Page 4397 of 5883

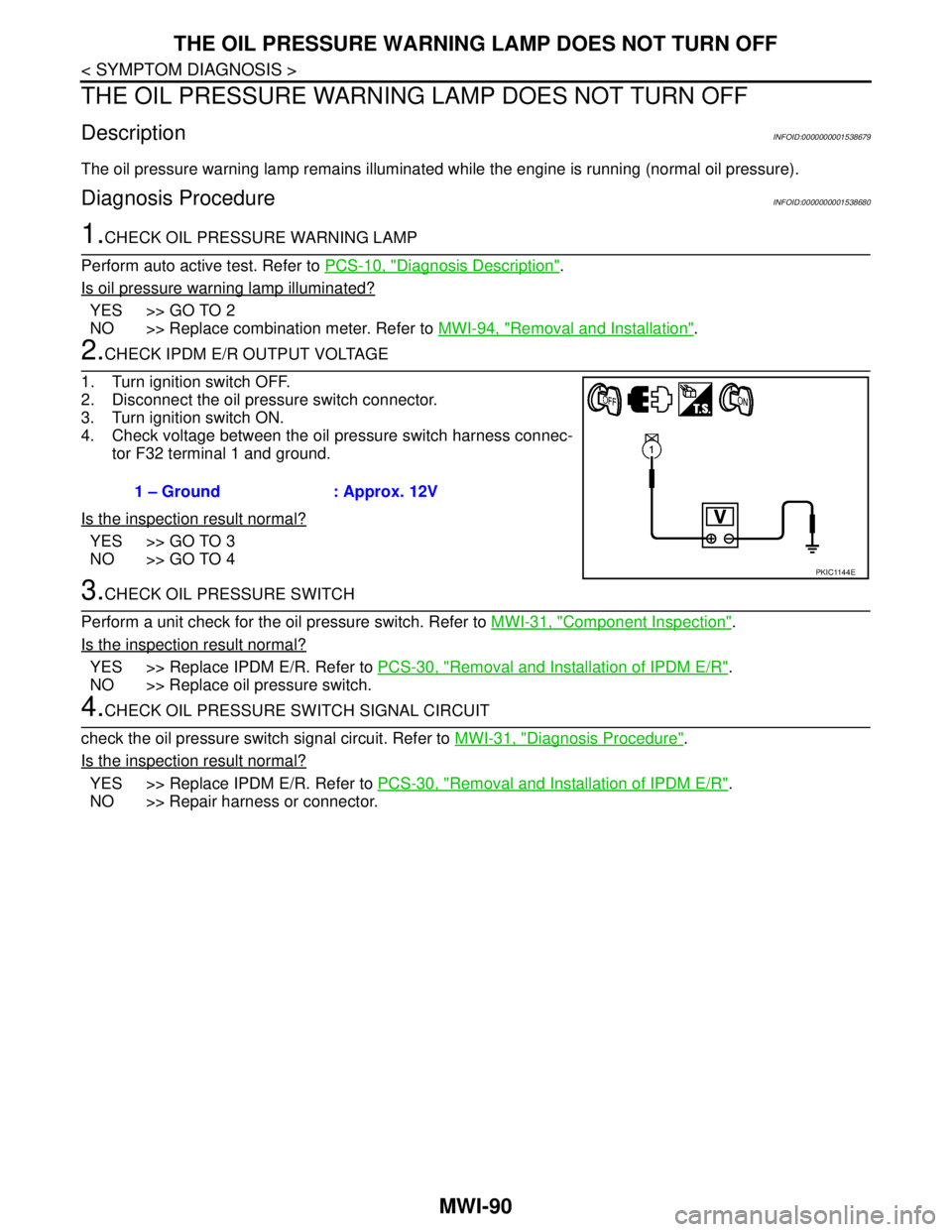

MWI-90

< SYMPTOM DIAGNOSIS >

THE OIL PRESSURE WARNING LAMP DOES NOT TURN OFF

THE OIL PRESSURE WARNING LAMP DOES NOT TURN OFF

DescriptionINFOID:0000000001538679

The oil pressure warning lamp remains illuminated while the engine is running (normal oil pressure).

Diagnosis ProcedureINFOID:0000000001538680

1.CHECK OIL PRESSURE WARNING LAMP

Perform auto active test. Refer to PCS-10, "

Diagnosis Description".

Is oil pressure warning lamp illuminated?

YES >> GO TO 2

NO >> Replace combination meter. Refer to MWI-94, "

Removal and Installation".

2.CHECK IPDM E/R OUTPUT VOLTAGE

1. Turn ignition switch OFF.

2. Disconnect the oil pressure switch connector.

3. Turn ignition switch ON.

4. Check voltage between the oil pressure switch harness connec-

tor F32 terminal 1 and ground.

Is the inspection result normal?

YES >> GO TO 3

NO >> GO TO 4

3.CHECK OIL PRESSURE SWITCH

Perform a unit check for the oil pressure switch. Refer to MWI-31, "

Component Inspection".

Is the inspection result normal?

YES >> Replace IPDM E/R. Refer to PCS-30, "Removal and Installation of IPDM E/R".

NO >> Replace oil pressure switch.

4.CHECK OIL PRESSURE SWITCH SIGNAL CIRCUIT

check the oil pressure switch signal circuit. Refer to MWI-31, "

Diagnosis Procedure".

Is the inspection result normal?

YES >> Replace IPDM E/R. Refer to PCS-30, "Removal and Installation of IPDM E/R".

NO >> Repair harness or connector.1 – Ground : Approx. 12V

PKIC1144E

Page 4415 of 5883

PCS

PCS-1

ELECTRICAL & POWER CONTROL

C

D

E

F

G

H

I

J

K

L B

SECTION PCS

A

O

P N

CONTENTS

POWER CONTROL SYSTEM

IPDM E/R

FUNCTION DIAGNOSIS ...............................

3

RELAY CONTROL SYSTEM ..............................3

System Diagram ........................................................3

System Description ...................................................4

Component Parts Location ........................................5

POWER CONTROL SYSTEM .............................6

System Diagram ........................................................6

System Description ...................................................6

SIGNAL BUFFER SYSTEM ................................7

System Diagram ........................................................7

System Description ...................................................7

POWER CONSUMPTION CONTROL SYS-

TEM .....................................................................

8

System Diagram ........................................................8

System Description ...................................................8

Component Parts Location ........................................9

DIAGNOSIS SYSTEM (IPDM E/R) .....................10

Diagnosis Description .............................................10

CONSULT - III Function (IPDM E/R) .......................13

COMPONENT DIAGNOSIS .........................15

U1000 CAN COMM CIRCUIT .............................15

Description ..............................................................15

DTC Logic ...............................................................15

Diagnosis Procedure ...............................................15

POWER SUPPLY AND GROUND CIRCUIT ......16

Diagnosis Procedure ...............................................16

ECU DIAGNOSIS .........................................17

IPDM E/R (INTELLIGENT POWER DISTRI-

BUTION MODULE ENGINE ROOM) .................

17

Reference Value .....................................................17

Terminal Layout ......................................................19

Physical Values .......................................................19

Wiring Diagram ........................................................23

Fail Safe ..................................................................26

DTC Index ...............................................................28

PRECAUTION ..............................................29

PRECAUTIONS .................................................29

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .................................................................

29

REMOVAL AND INSTALLATION ...............30

IPDM E/R (INTELLIGENT POWER DISTRI-

BUTION MODULE ENGINE ROOM) ................

30

Removal and Installation of IPDM E/R ....................30

POWER DISTRIBUTION SYSTEM

BASIC INSPECTION ...................................

31

DIAGNOSIS AND REPAIR WORKFLOW ........31

Work Flow ................................................................31

FUNCTION DIAGNOSIS ..............................34

POWER DISTRIBUTION SYSTEM ...................34

System Description ..................................................34

Component Parts Location ......................................34

Component Description ..........................................34

DIAGNOSIS SYSTEM (BCM) ...........................35

COMMON ITEM .........................................................35

COMMON ITEM : Diagnosis Description ................35

COMMON ITEM : CONSULT-III Function ...............35

INTELLIGENT KEY ....................................................35

INTELLIGENT KEY : CONSULT-III Function

(BCM - INTELLIGENT KEY) ....................................

35

COMPONENT DIAGNOSIS .........................36

Page 4416 of 5883

PCS-2

U1000 CAN COMM CIRCUIT ............................36

Description ..............................................................36

DTC Logic ...............................................................36

Diagnosis Procedure ..............................................36

POWER SUPPLY AND GROUND CIRCUIT .....37

BCM ...........................................................................37

BCM : Diagnosis Procedure ...................................37

BCM : Special Repair Requirement ........................37

IPDM E/R (INTELLIGENT POWER DISTRIBU-

TION MODULE ENGINE ROOM) .............................

37

IPDM E/R (INTELLIGENT POWER DISTRIBU-

TION MODULE ENGINE ROOM) : Diagnosis Pro-

cedure .....................................................................

37

ECU DIAGNOSIS ........................................38

BCM (BODY CONTROL MODULE) ..................38

Reference Value .....................................................38

Terminal Layout ......................................................38

Physical Values ......................................................38

Wiring Diagram .......................................................38

DTC Inspection Priority Chart ...............................38

DTC Index ..............................................................38

IPDM E/R (INTELLIGENT POWER DISTRI-

BUTION MODULE ENGINE ROOM) .................

39

Reference Value .....................................................39

Terminal Layout ......................................................39

Physical Values .......................................................39

Wiring Diagram .......................................................39

Fail Safe .................................................................39

DTC Index ..............................................................39

ON-VEHICLE MAINTENANCE ..................40

PRE-INSPECTION FOR DIAGNOSTIC ............40

Basic Inspection ......................................................40

ON-VEHICLE REPAIR ...............................41

BCM (BODY CONTROL MODULE) ..................41

Removal and Installation .........................................41