engine NISSAN TIIDA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 4440 of 5883

![NISSAN TIIDA 2007 Service Repair Manual PCS-26

< ECU DIAGNOSIS >[IPDM E/R]

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

Fail Safe

INFOID:0000000001697599

CAN COMMUNICATION CONTROL

When CAN communication with ECM and BCM is i NISSAN TIIDA 2007 Service Repair Manual PCS-26

< ECU DIAGNOSIS >[IPDM E/R]

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

Fail Safe

INFOID:0000000001697599

CAN COMMUNICATION CONTROL

When CAN communication with ECM and BCM is i](/img/5/57395/w960_57395-4439.png)

PCS-26

< ECU DIAGNOSIS >[IPDM E/R]

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

Fail Safe

INFOID:0000000001697599

CAN COMMUNICATION CONTROL

When CAN communication with ECM and BCM is impossible, IPDM E/R performs fail-safe control. After CAN

communication recovers normally, it also returns to normal control.

If No CAN Communication Is Available With ECM

ALMIA0252GB

Page 4441 of 5883

![NISSAN TIIDA 2007 Service Repair Manual PCS

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PCS-27

< ECU DIAGNOSIS >[IPDM E/R]

C

D

E

F

G

H

I

J

K

L B A

O

P N If No CAN Communication Is Available With BCM

IGNITION RELAY MALFUNCTI NISSAN TIIDA 2007 Service Repair Manual PCS

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PCS-27

< ECU DIAGNOSIS >[IPDM E/R]

C

D

E

F

G

H

I

J

K

L B A

O

P N If No CAN Communication Is Available With BCM

IGNITION RELAY MALFUNCTI](/img/5/57395/w960_57395-4440.png)

PCS

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PCS-27

< ECU DIAGNOSIS >[IPDM E/R]

C

D

E

F

G

H

I

J

K

L B A

O

P N If No CAN Communication Is Available With BCM

IGNITION RELAY MALFUNCTION DETECTION FUNCTION

IPDM E/R monitors the voltage at the contact circuit and excitation coil circuit of the ignition relay inside it.

IPDM E/R judges the ignition relay error if the voltage differs between the contact circuit and the excitation

coil circuit.

If the ignition relay cannot turn OFF due to contact seizure, it activates the tail lamp relay for 10 minutes to

alert the user to the ignition relay malfunction when the ignition switch is turned OFF.

NOTE:

The tail lamp turns OFF when the ignition switch is turned ON.

FRONT WIPER CONTROL

IPDM E/R detects front wiper stop position by a front wiper auto stop signal.

When a front wiper auto stop signal is in the conditions listed below, IPDM E/R stops power supply to wiper

after repeating a front wiper 10 second activation and 20 second stop five times.

NOTE:

This operation status can be confirmed on the IPDM E/R “DATA MONITOR” that displays “Block” for the item

“WIP PROT” while the wiper is stopped.

STARTER MOTOR PROTECTION FUNCTION

IPDM E/R turns OFF the starter control relay to protect the starter motor when the starter control relay remains

active for 90 seconds.

Control part Fail-safe in operation

Cooling fan Turns ON the cooling fan relay when the ignition switch is turned ON

Turns OFF the cooling fan relay when the ignition switch is turned OFF

Control part Fail-safe in operation

Headlamp Turns ON the headlamp low relay when the ignition switch is turned ON

Turns OFF the headlamp low relay when the ignition switch is turned OFF

Headlamp high relay OFF

Parking lamps

License plate lamps

Tail lamps Turns ON the tail lamp relay when the ignition switch is turned ON

Turns OFF the tail lamp relay when the ignition switch is turned OFF

Front wiper The status just before activation of fail-safe control is maintained until the ignition

switch is turned OFF while the front wiper is operating at LO or HI speed.

The wiper is operated at LO speed until the ignition switch is turned OFF if the fail-

safe control is activated while the front wiper is set in the INT mode and the front wiper

motor is operating.

Rear window defogger Rear window defogger relay OFF

A/C compressor A/C relay OFF

Front fog lamps Front fog lamp relay OFF

Ignition switch Ignition relay Tail lamp relay

ON ON —

OFF OFF —

Ignition switch Front wiper switch Auto stop signal

ONOFFFront wiper stop position signal cannot be

input 10 seconds.

ON The signal does not change for 10 seconds.

Page 4442 of 5883

![NISSAN TIIDA 2007 Service Repair Manual PCS-28

< ECU DIAGNOSIS >[IPDM E/R]

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

DTC Index

INFOID:0000000001697600

NOTE:

The details of TIME display are as follows.

CRNT: The malfunct NISSAN TIIDA 2007 Service Repair Manual PCS-28

< ECU DIAGNOSIS >[IPDM E/R]

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

DTC Index

INFOID:0000000001697600

NOTE:

The details of TIME display are as follows.

CRNT: The malfunct](/img/5/57395/w960_57395-4441.png)

PCS-28

< ECU DIAGNOSIS >[IPDM E/R]

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

DTC Index

INFOID:0000000001697600

NOTE:

The details of TIME display are as follows.

CRNT: The malfunctions that are detected now

1 - 39: The number is indicated when it is normal at present and a malfunction was detected in the past. It

increases like 0 → 1 → 2 ··· 38 → 39 after returning to the normal condition whenever IGN OFF → ON. It is

fixed to 39 until the self-diagnosis results are erased if it is over 39. It returns to 0 when a malfunction is

detected again in the process.

CONSULT-III display Fail-safe

TIMENOTERefer to

No DTC is detected.

further testing

may be required.————

U1000: CAN COMM CIRCUIT×CRNT 1 – 39PCS-15

Page 4444 of 5883

![NISSAN TIIDA 2007 Service Repair Manual PCS-30

< REMOVAL AND INSTALLATION >[IPDM E/R]

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

REMOVAL AND INSTALLATION

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE

ROOM)

Removal NISSAN TIIDA 2007 Service Repair Manual PCS-30

< REMOVAL AND INSTALLATION >[IPDM E/R]

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

REMOVAL AND INSTALLATION

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE

ROOM)

Removal](/img/5/57395/w960_57395-4443.png)

PCS-30

< REMOVAL AND INSTALLATION >[IPDM E/R]

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

REMOVAL AND INSTALLATION

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE

ROOM)

Removal and Installation of IPDM E/RINFOID:0000000001697602

REMOVAL

1. Disconnect negative battery cable.

2. Remove IPDM E/R upper cover.

3. Release 2 clips and pull IPDM E/R up from case.

4. Disconnect IPDM E/R connectors and remove the IPDM E/R.

INSTALLATION

Installation is in the reverse order of removal.

WKIA1454E

WKIA1696E

Page 4451 of 5883

![NISSAN TIIDA 2007 Service Repair Manual PCS

POWER SUPPLY AND GROUND CIRCUIT

PCS-37

< COMPONENT DIAGNOSIS >[POWER DISTRIBUTION SYSTEM]

C

D

E

F

G

H

I

J

K

L B A

O

P N

POWER SUPPLY AND GROUND CIRCUIT

BCM

BCM : Diagnosis ProcedureINFOID:00000000 NISSAN TIIDA 2007 Service Repair Manual PCS

POWER SUPPLY AND GROUND CIRCUIT

PCS-37

< COMPONENT DIAGNOSIS >[POWER DISTRIBUTION SYSTEM]

C

D

E

F

G

H

I

J

K

L B A

O

P N

POWER SUPPLY AND GROUND CIRCUIT

BCM

BCM : Diagnosis ProcedureINFOID:00000000](/img/5/57395/w960_57395-4450.png)

PCS

POWER SUPPLY AND GROUND CIRCUIT

PCS-37

< COMPONENT DIAGNOSIS >[POWER DISTRIBUTION SYSTEM]

C

D

E

F

G

H

I

J

K

L B A

O

P N

POWER SUPPLY AND GROUND CIRCUIT

BCM

BCM : Diagnosis ProcedureINFOID:0000000001697613

Refer to BCS-30, "Diagnosis Procedure".

BCM : Special Repair RequirementINFOID:0000000001697614

1.REQUIRED WORK WHEN REPLACING BCM

Initialize control unit. Refer to CONSULT-III Operation Manual.

>> Work end.

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM) : Di-

agnosis Procedure

INFOID:0000000001697615

Refer to PCS-16, "Diagnosis Procedure".

Page 4453 of 5883

![NISSAN TIIDA 2007 Service Repair Manual PCS

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PCS-39

< ECU DIAGNOSIS >[POWER DISTRIBUTION SYSTEM]

C

D

E

F

G

H

I

J

K

L B A

O

P N

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGIN NISSAN TIIDA 2007 Service Repair Manual PCS

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PCS-39

< ECU DIAGNOSIS >[POWER DISTRIBUTION SYSTEM]

C

D

E

F

G

H

I

J

K

L B A

O

P N

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGIN](/img/5/57395/w960_57395-4452.png)

PCS

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PCS-39

< ECU DIAGNOSIS >[POWER DISTRIBUTION SYSTEM]

C

D

E

F

G

H

I

J

K

L B A

O

P N

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE

ROOM)

Reference ValueINFOID:0000000001697622

Refer to PCS-17, "Reference Value".

Terminal LayoutINFOID:0000000001697623

Refer to PCS-19, "Terminal Layout".

Physical ValuesINFOID:0000000001697624

Refer to PCS-19, "Physical Values".

Wiring DiagramINFOID:0000000001697625

Refer to PCS-23, "Wiring Diagram".

Fail SafeINFOID:0000000001697626

Refer to PCS-26, "FailSafe".

DTC IndexINFOID:0000000001697627

Refer to PCS-28, "DTCIndex".

Page 4454 of 5883

![NISSAN TIIDA 2007 Service Repair Manual PCS-40

< ON-VEHICLE MAINTENANCE >[POWER DISTRIBUTION SYSTEM]

PRE-INSPECTION FOR DIAGNOSTIC

ON-VEHICLE MAINTENANCE

PRE-INSPECTION FOR DIAGNOSTIC

Basic InspectionINFOID:0000000001697628

The engine start NISSAN TIIDA 2007 Service Repair Manual PCS-40

< ON-VEHICLE MAINTENANCE >[POWER DISTRIBUTION SYSTEM]

PRE-INSPECTION FOR DIAGNOSTIC

ON-VEHICLE MAINTENANCE

PRE-INSPECTION FOR DIAGNOSTIC

Basic InspectionINFOID:0000000001697628

The engine start](/img/5/57395/w960_57395-4453.png)

PCS-40

< ON-VEHICLE MAINTENANCE >[POWER DISTRIBUTION SYSTEM]

PRE-INSPECTION FOR DIAGNOSTIC

ON-VEHICLE MAINTENANCE

PRE-INSPECTION FOR DIAGNOSTIC

Basic InspectionINFOID:0000000001697628

The engine start function, door lock function, power distribution system and NATS-NVIS system are closely

related to each other regarding control. Narrow down the functional area in question by performing basic

inspection to identify which function is malfunctioning. The vehicle security function can operate only when the

door lock and power distribution system are operating normally. Therefore, it is easy to identify any factor

unique to the vehicle security system by performing the vehicle security operation check after basic inspection.

1. CHECK DOOR LOCK OPERATION

1. Check the door lock for normal operation with the keyfob or Intelligent Key (if equipped) and door request

switch.

Successful door lock operation with the keyfob or Intelligent Key (if equipped) and request SW indicates

that the remote keyless entry receiver and inside key antenna (with Intelligent Key) required for engine

start are functioning normally.

Identify the malfunctioning point by referring to the DLK section if the door cannot be unlocked.

Can the door be locked with the Intelligent Key and door request switch?

YES >> GO TO 2

NO >> Refer to DLK-191, "

DOOR LOCK AND UNLOCK SWITCH : Symptom Table" (with Intelligent Key

without super lock), DLK-420, "

DOOR LOCK AND UNLOCK SWITCH : Symptom Table" (with

Intelligent Key and super lock), DLK-567, "

DOOR LOCK AND UNLOCK SWITCH : Symptom

Table" (without Intelligent Key without super lock) or DLK-718, "DOOR LOCK AND UNLOCK

SWITCH : Symptom Table" (without Intelligent Key with super lock).

2. CHECK ENGINE STARTING

1. Checks that the engine starts.

Does the engine start?

YES >> GO TO 3

NO >> Refer to SEC-76, "

Symptom Table" (with Intelligent Key) or SEC-117, "Symptom Table" (without

Intelligent Key).

3. CHECK STEERING LOCKING (MODELS WITH INTELLIGENT KEY)

1. Does the steering lock when operating door switch after switching the power supply from ON position (or

ACC position) to LOCK position?

If door switch is malfunctioning, BCM cannot lock the steering. If BCM does not detect DTC, steering lock

unit is normal.

Does steering lock?

YES >> GO TO 4

NO >> Refer to STC-29, "

Symptom Chart".

4. CHECK VEHICLE SECURITY SYSTEM

1. Check the vehicle security system for normal operation.

The vehicle security function can operate only when the door lock and power distribution functions are

operating normally.

Therefore, it is easy to identify any factor unique to the vehicle security by performing the vehicle security

operation check after this basic inspection.

>> Refer to SEC-75, "

Symptom Table" (with Intelligent Key) or SEC-116, "Symptom Table" (without

Intelligent Key).

Page 4458 of 5883

PG

BATTERY

PG-3

< BASIC INSPECTION >

C

D

E

F

G

H

I

J

K

L B A

O

P N

BASIC INSPECTION

BATTERY

How to Handle BatteryINFOID:0000000001723097

CAUTION:

If it becomes necessary to start the engine with a booster battery and jumper cables, use a 12-volt

booster battery.

After connecting battery cables, ensure that they are tightly clamped to battery terminals for good

contact.

Never add distilled water through the hole used to check specific gravity.

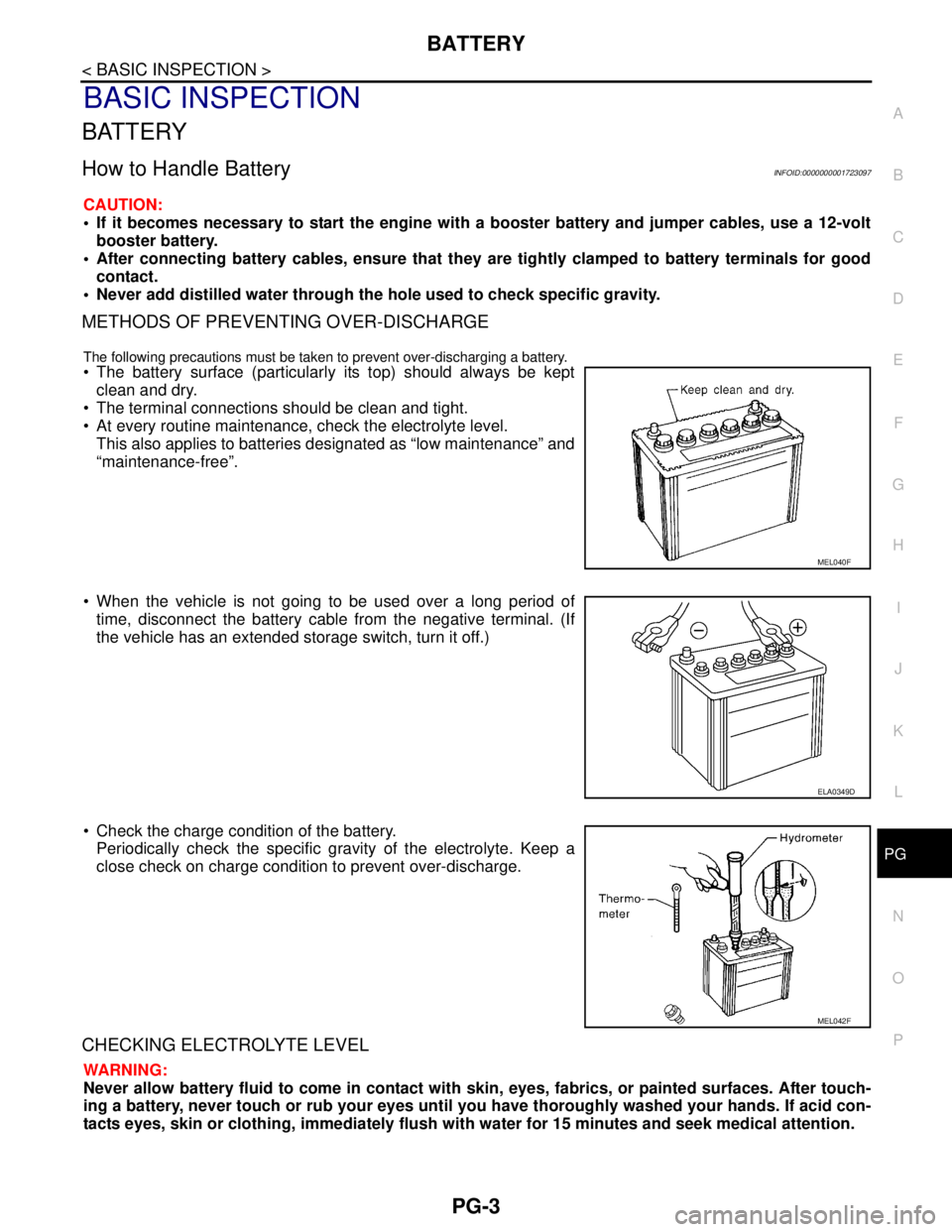

METHODS OF PREVENTING OVER-DISCHARGE

The following precautions must be taken to prevent over-discharging a battery.

The battery surface (particularly its top) should always be kept

clean and dry.

The terminal connections should be clean and tight.

At every routine maintenance, check the electrolyte level.

This also applies to batteries designated as “low maintenance” and

“maintenance-free”.

When the vehicle is not going to be used over a long period of

time, disconnect the battery cable from the negative terminal. (If

the vehicle has an extended storage switch, turn it off.)

Check the charge condition of the battery.

Periodically check the specific gravity of the electrolyte. Keep a

close check on charge condition to prevent over-discharge.

CHECKING ELECTROLYTE LEVEL

WARNING:

Never allow battery fluid to come in contact with skin, eyes, fabrics, or painted surfaces. After touch-

ing a battery, never touch or rub your eyes until you have thoroughly washed your hands. If acid con-

tacts eyes, skin or clothing, immediately flush with water for 15 minutes and seek medical attention.

MEL040F

ELA0349D

MEL042F

Page 4530 of 5883

PRECAUTIONS

RAX-3

< PRECAUTION >

C

E

F

G

H

I

J

K

L

MA

B

RAX

N

O

P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001724594

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PrecautionINFOID:0000000001724595

When installing each rubber part, final tightening must be car-

ried out under unladen condition* with tires on ground.

*: Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.

Use flare nut wrench when removing or installing brake tubes.

After installing removed suspension parts, check wheel align-

ment.

Do not jack up at the trailing arm and lateral link.

Always torque brake lines when installing.

SBR686C

Page 4538 of 5883

RF-4

< PREPARATION >

PREPARATION

PREPARATION

PREPARATION

Commercial Service ToolINFOID:0000000001724409

Tool name Description

Engine ear Locating the noise

SIIA0995E