mirror NISSAN TIIDA 2007 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 580 of 5883

REAR WINDOW DEFOGGER AND DOOR MIRROR DEFOGGER DO NOT OPER-

ATE.

DEF-29

< SYMPTOM DIAGNOSIS >

C

D

E

F

G

H

I

J

K

MA

B

DEF

N

O

P

SYMPTOM DIAGNOSIS

REAR WINDOW DEFOGGER AND DOOR MIRROR DEFOGGER DO NOT

OPERATE.

Diagnosis ProcedureINFOID:0000000001697569

1. CHECK REAR WINDOW DEFOGGER SWITCH

Check rear window defogger switch.

Refer to DEF-14, "

Component Function Check".

Is the inspection result normal?

YES >> GO TO 2

NO >> Repair or replace the malfunctioning parts.

2. CHECK REAR WINDOW DEFOGGER RELAY

Check rear window defogger relay.

Refer to DEF-12, "

Component Function Check".

Is the inspection result normal?

YES >> Refer to XX-XX, "*****".

NO >> Repair or replace the malfunctioning parts.

Page 581 of 5883

DEF-30

< SYMPTOM DIAGNOSIS >

REAR WINDOW DEFOGGER DOES NOT OPERATE BUT BOTH OF DOOR MIR-

ROR DEFOGGER OPERATE.

REAR WINDOW DEFOGGER DOES NOT OPERATE BUT BOTH OF DOOR

MIRROR DEFOGGER OPERATE.

Diagnosis ProcedureINFOID:0000000001697570

1. CHECK REAR WINDOW DEFOGGER POWER SUPPLY AND GROUND CIRCUIT

Check rear window defogger power supply and ground circuit.

Refer to DEF-14, "

Component Function Check".

Is the inspection result normal?

YES >> Refer to XX-XX, "*****".

NO >> Repair or replace the malfunctioning parts.

Page 582 of 5883

BOTH DOORS MIRROR DEFOGGER DON’T OPERATE BUT REAR WINDOW

DEFOGGER OPERATES

DEF-31

< SYMPTOM DIAGNOSIS >

C

D

E

F

G

H

I

J

K

MA

B

DEF

N

O

P

BOTH DOORS MIRROR DEFOGGER DON’T OPERATE BUT REAR WIN-

DOW DEFOGGER OPERATES

Diagnosis ProcedureINFOID:0000000001697571

1. CHECK INTERMITTENT INCIDENT

Check intermittent incident.

Refer to XX-XX, "*****"

.

Is the inspection result normal?

YES >> Check the following.

Battery power supply circuit.

Fuse block (J/B).

NO >> Repair or replace the malfunctioning parts.

Page 583 of 5883

DEF-32

< SYMPTOM DIAGNOSIS >

DRIVER SIDE DOOR MIRROR DEFOGGER DOES NOT OPERATE.

DRIVER SIDE DOOR MIRROR DEFOGGER DOES NOT OPERATE.

Diagnosis ProcedureINFOID:0000000001697572

1. CHECK DOOR MIRROR DEFOGGER LH

Check door mirror defogger LH.

Refer to DEF-16, "

Component Function Check".

Is the inspection result normal?

YES >> Refer to XX-XX, "*****".

NO >> Repair or replace the malfunctioning parts.

Page 584 of 5883

PASSENGER SIDE DOOR MIRROR DEFOGGER DOES NOT OPERATE.

DEF-33

< SYMPTOM DIAGNOSIS >

C

D

E

F

G

H

I

J

K

MA

B

DEF

N

O

P

PASSENGER SIDE DOOR MIRROR DEFOGGER DOES NOT OPERATE.

Diagnosis ProcedureINFOID:0000000001697573

1. CHECK DOOR MIRROR DEFOGGER RH

Check door mirror defogger RH.

Refer to DEF-18, "

Component Function Check".

Is the inspection result normal?

YES >> Refer to XX-XX, "*****".

NO >> Repair or replace the malfunctioning parts.

Page 2686 of 5883

![NISSAN TIIDA 2007 Service User Guide FUEL INJECTOR AND FUEL TUBE

EM-39

< ON-VEHICLE REPAIR >[HR16DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

c. Align center to insert quick connector straightly into fuel tube.

Insert quick connector to fuel tu NISSAN TIIDA 2007 Service User Guide FUEL INJECTOR AND FUEL TUBE

EM-39

< ON-VEHICLE REPAIR >[HR16DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

c. Align center to insert quick connector straightly into fuel tube.

Insert quick connector to fuel tu](/img/5/57395/w960_57395-2685.png)

FUEL INJECTOR AND FUEL TUBE

EM-39

< ON-VEHICLE REPAIR >[HR16DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

c. Align center to insert quick connector straightly into fuel tube.

Insert quick connector to fuel tube until the top spool on fuel

tube is inserted completely and the 2nd level spool is posi-

tioned slightly below quick connector bottom end.

CAUTION:

Hold “A” position shown when inserting fuel tube into

quick connector.

Carefully align center to avoid inclined insertion to pre-

vent damage to O-ring inside quick connector.

Insert until you hear a “click” sound and actually feel

the engagement.

To avoid misidentification of engagement with a similar

sound, be sure to perform the next step.

d. Before clamping fuel feed hose with hose clamp, pull quick connector hard by hand holding “A” position.

Make sure it is completely engaged (connected) so that it does not come out from fuel tube.

e. Install quick connector cap (1) to quick connector connection.

Install quick connector cap with the side arrow facing quick

connector side (fuel feed hose side).

CAUTION:

Make sure that the quick connector and fuel tube are

securely engaged with the quick connector cap mount-

ing groove.

Quick connector may not be connected correctly if

quick connector cap cannot be installed easily. Remove

the quick connector cap, and then check the connection

of quick connector again.

f. Install fuel feed hose to hose clamp.

7. Installation is in the reverse order of removal, for the remaining parts.

InspectionINFOID:0000000001381405

INSPECTION AFTER INSTALLATION

Check on Fuel Leakage

1. Turn ignition switch “ON” (with the engine stopped). With fuel pressure applied to fuel piping, make sure

there are no fuel leaks at connection points.

NOTE:

Use mirrors for checking at points out of clear sight.

2. Start the engine. With engine speed increased, make sure again that there are no fuel leaks at connection

points.

CAUTION:

Never touch the engine immediately after stopped, as the engine becomes extremely hot.

KBIA0272E

PBIC3664E

Page 3075 of 5883

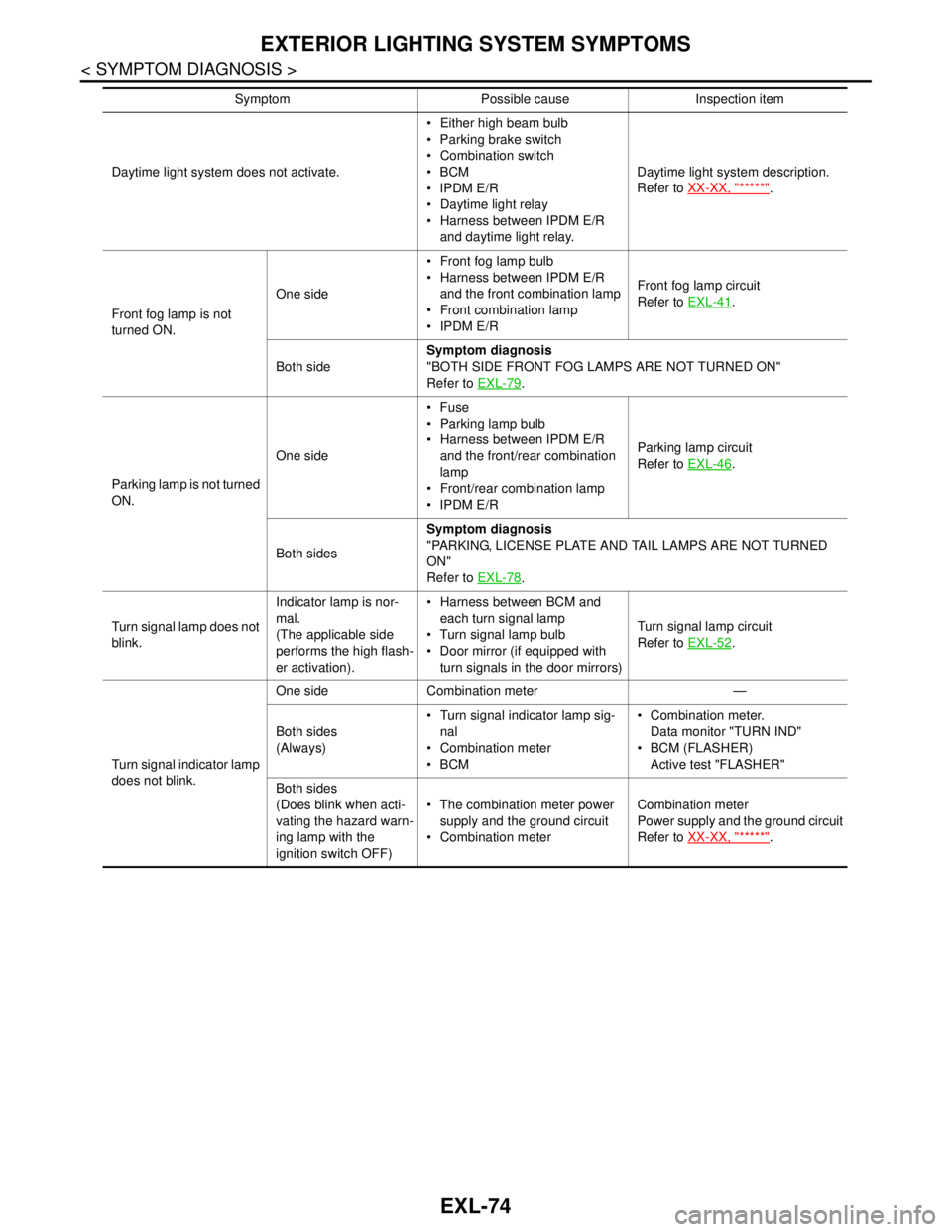

EXL-74

< SYMPTOM DIAGNOSIS >

EXTERIOR LIGHTING SYSTEM SYMPTOMS

Daytime light system does not activate. Either high beam bulb

Parking brake switch

Combination switch

BCM

IPDM E/R

Daytime light relay

Harness between IPDM E/R

and daytime light relay.Daytime light system description.

Refer to XX-XX, "*****"

.

Front fog lamp is not

turned ON.One side Front fog lamp bulb

Harness between IPDM E/R

and the front combination lamp

Front combination lamp

IPDM E/RFront fog lamp circuit

Refer to EXL-41

.

Both sideSymptom diagnosis

"BOTH SIDE FRONT FOG LAMPS ARE NOT TURNED ON"

Refer to EXL-79

.

Parking lamp is not turned

ON.One sideFuse

Parking lamp bulb

Harness between IPDM E/R

and the front/rear combination

lamp

Front/rear combination lamp

IPDM E/RParking lamp circuit

Refer to EXL-46

.

Both sidesSymptom diagnosis

"PARKING, LICENSE PLATE AND TAIL LAMPS ARE NOT TURNED

ON"

Refer to EXL-78

.

Turn signal lamp does not

blink.Indicator lamp is nor-

mal.

(The applicable side

performs the high flash-

er activation). Harness between BCM and

each turn signal lamp

Turn signal lamp bulb

Door mirror (if equipped with

turn signals in the door mirrors)Turn signal lamp circuit

Refer to EXL-52

.

Turn signal indicator lamp

does not blink.One side Combination meter —

Both sides

(Always) Turn signal indicator lamp sig-

nal

Combination meter

BCM Combination meter.

Data monitor "TURN IND"

BCM (FLASHER)

Active test "FLASHER"

Both sides

(Does blink when acti-

vating the hazard warn-

ing lamp with the

ignition switch OFF) The combination meter power

supply and the ground circuit

Combination meterCombination meter

Power supply and the ground circuit

Refer to XX-XX, "*****"

. Symptom Possible cause Inspection item

Page 3092 of 5883

AUTO LIGHT SYSTEM

EXL-91

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

AUTO LIGHT SYSTEM

Removal and Installation of Light and Rain SensorINFOID:0000000001530408

REMOVAL

1. Remove the rear view mirror. Refer to MIR-9, "Removal and Installation".

2. Disconnect the light and rain sensor connector.

3. Remove the light and rain sensor.

INSTALLATION

Installation is in the reverse order of removal.

Page 3221 of 5883

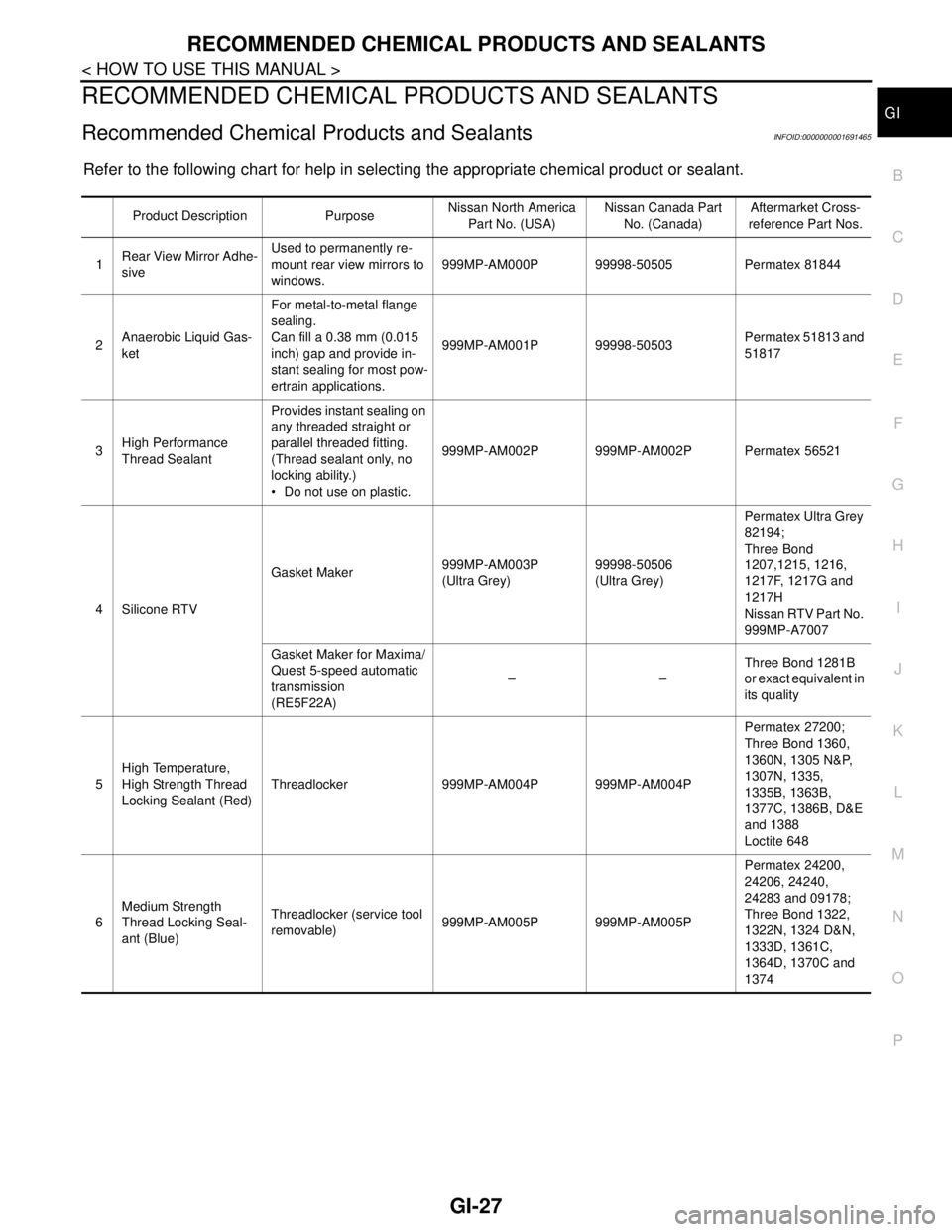

RECOMMENDED CHEMICAL PRODUCTS AND SEALANTS

GI-27

< HOW TO USE THIS MANUAL >

C

D

E

F

G

H

I

J

K

L

MB

GI

N

O

PRECOMMENDED CHEMICAL PRODUCTS AND SEALANTS

Recommended Chemical Products and SealantsINFOID:0000000001691465

Refer to the following chart for help in selecting the appropriate chemical product or sealant.

Product Description PurposeNissan North America

Part No. (USA)Nissan Canada Part

No. (Canada)Aftermarket Cross-

reference Part Nos.

1Rear View Mirror Adhe-

siveUsed to permanently re-

mount rear view mirrors to

windows.999MP-AM000P 99998-50505 Permatex 81844

2Anaerobic Liquid Gas-

ketFor metal-to-metal flange

sealing.

Can fill a 0.38 mm (0.015

inch) gap and provide in-

stant sealing for most pow-

ertrain applications.999MP-AM001P 99998-50503Permatex 51813 and

51817

3High Performance

Thread SealantProvides instant sealing on

any threaded straight or

parallel threaded fitting.

(Thread sealant only, no

locking ability.)

Do not use on plastic.999MP-AM002P 999MP-AM002P Permatex 56521

4 Silicone RTVGasket Maker999MP-AM003P

(Ultra Grey)99998-50506

(Ultra Grey)Permatex Ultra Grey

82194;

Three Bond

1207,1215, 1216,

1217F, 1217G and

1217H

Nissan RTV Part No.

999MP-A7007

Gasket Maker for Maxima/

Quest 5-speed automatic

transmission

(RE5F22A)––Three Bond 1281B

or exact equivalent in

its quality

5High Temperature,

High Strength Thread

Locking Sealant (Red)Threadlocker 999MP-AM004P 999MP-AM004PPermatex 27200;

Three Bond 1360,

1360N, 1305 N&P,

1307N, 1335,

1335B, 1363B,

1377C, 1386B, D&E

and 1388

Loctite 648

6Medium Strength

Thread Locking Seal-

ant (Blue)Threadlocker (service tool

removable)999MP-AM005P 999MP-AM005PPermatex 24200,

24206, 24240,

24283 and 09178;

Three Bond 1322,

1322N, 1324 D&N,

1333D, 1361C,

1364D, 1370C and

1374

Page 3269 of 5883

GW-10

< ON-VEHICLE REPAIR >

WINDSHIELD GLASS

ON-VEHICLE REPAIR

WINDSHIELD GLASS

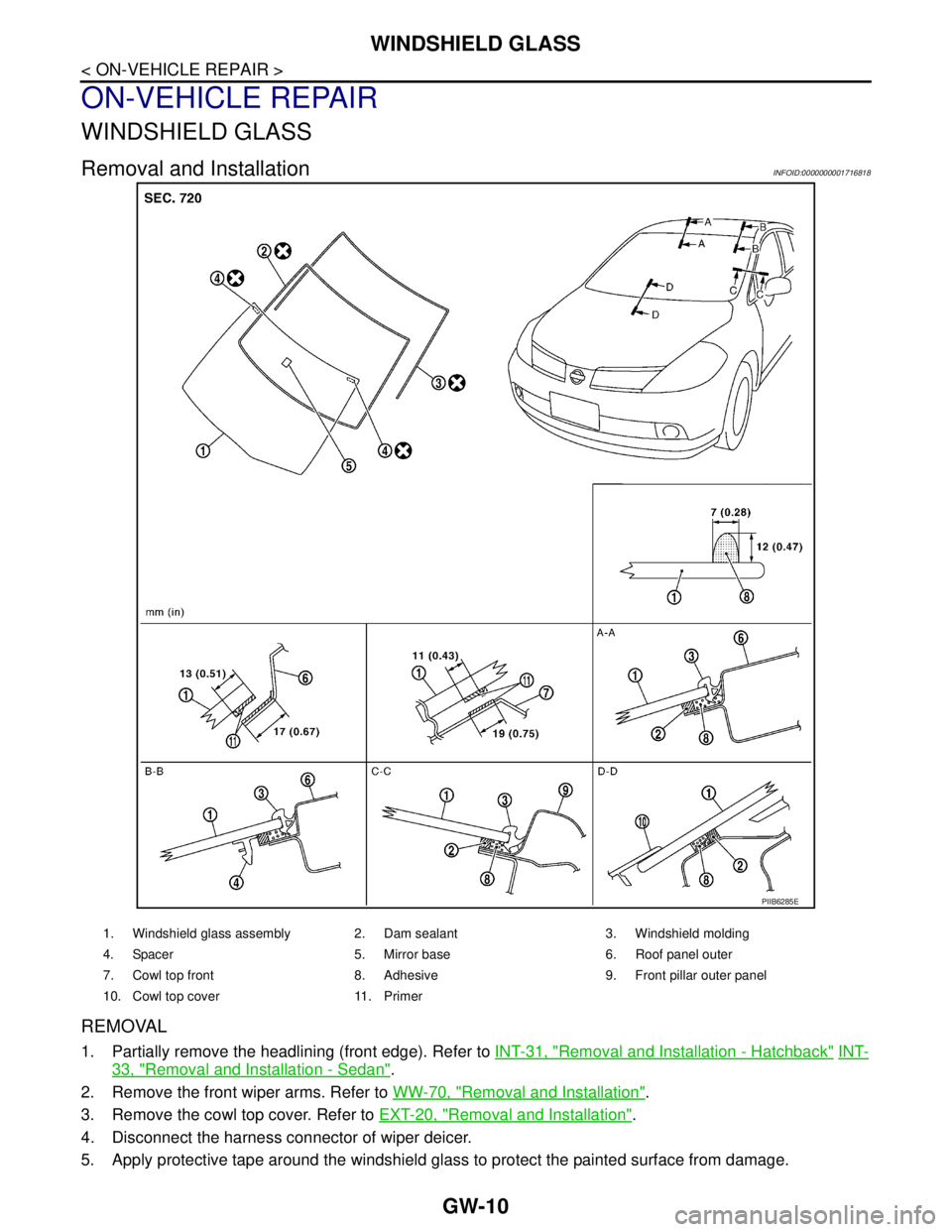

Removal and InstallationINFOID:0000000001716818

REMOVAL

1. Partially remove the headlining (front edge). Refer to INT-31, "Removal and Installation - Hatchback" INT-

33, "Removal and Installation - Sedan".

2. Remove the front wiper arms. Refer to WW-70, "

Removal and Installation".

3. Remove the cowl top cover. Refer to EXT-20, "

Removal and Installation".

4. Disconnect the harness connector of wiper deicer.

5. Apply protective tape around the windshield glass to protect the painted surface from damage.

PIIB6285E

1. Windshield glass assembly 2. Dam sealant 3. Windshield molding

4. Spacer 5. Mirror base 6. Roof panel outer

7. Cowl top front 8. Adhesive 9. Front pillar outer panel

10. Cowl top cover 11. Primer