wiring NISSAN TIIDA 2007 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 191 of 5883

BCS-56

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001523305

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

Page 195 of 5883

PRECAUTIONS

BR-3

< PRECAUTION >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001716907

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

Precaution for Brake SystemINFOID:0000000001716908

Refill using recommended brake fluid. Refer to MA-19, "Fluids and Lubricants".

Never reuse drained brake fluid.

Be careful not to splash brake fluid on painted surface of body. If brake fluid is splashed on painted surfaces

of body immediately wipe it off with cloth and then wash it away with water.

To clean or wash all parts of master cylinder, disc brake caliper and wheel cylinder, use new brake fluid.

Never use mineral oils such as gasoline or kerosene. They will ruin rubber parts of the hydraulic system.

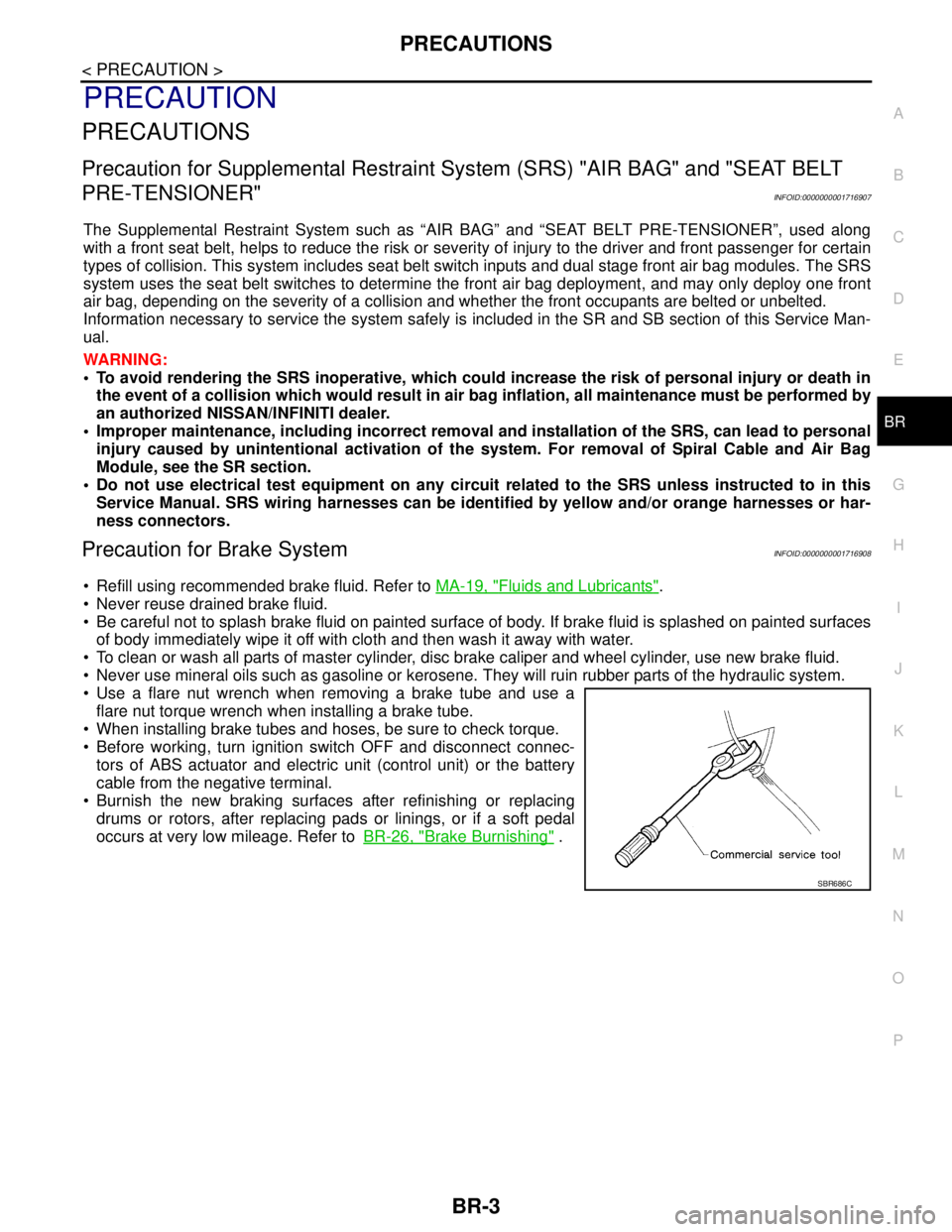

Use a flare nut wrench when removing a brake tube and use a

flare nut torque wrench when installing a brake tube.

When installing brake tubes and hoses, be sure to check torque.

Before working, turn ignition switch OFF and disconnect connec-

tors of ABS actuator and electric unit (control unit) or the battery

cable from the negative terminal.

Burnish the new braking surfaces after refinishing or replacing

drums or rotors, after replacing pads or linings, or if a soft pedal

occurs at very low mileage. Refer toBR-26, "

Brake Burnishing" .

SBR686C

Page 235 of 5883

BRC-2

C1110, C1170 ABS ACTUATOR AND ELEC-

TRIC UNIT (CONTROL UNIT) ...........................

38

DTC Logic ...............................................................38

Diagnosis Procedure ..............................................38

Special Repair Requirement ...................................38

C1111 ABS MOTOR, MOTOR RELAY SYS-

TEM ....................................................................

39

Description ..............................................................39

DTC Logic ...............................................................39

Diagnosis Procedure ..............................................39

Component Inspection ............................................40

Special Repair Requirement ...................................40

C1115 WHEEL SENSOR ...................................41

Description ..............................................................41

DTC Logic ...............................................................41

Diagnosis Procedure ..............................................41

Component Inspection ............................................42

Special Repair Requirement ...................................43

C1116 STOP LAMP SWITCH ............................44

Description ..............................................................44

DTC Logic ...............................................................44

Diagnosis Procedure ..............................................44

Special Repair Requirement ...................................45

C1120, C1122, C1124, C1126 IN ABS SOL .....46

Description ..............................................................46

DTC Logic ...............................................................46

Diagnosis Procedure ..............................................46

Component Inspection ............................................47

Special Repair Requirement ...................................48

C1121, C1123, C1125, C1127 OUT ABS SOL ...49

Description ..............................................................49

DTC Logic ...............................................................49

Diagnosis Procedure ..............................................49

Component Inspection ............................................50

Special Repair Requirement ...................................51

C1130, C1131, C1132, C1133, C1136 EN-

GINE SIGNAL ....................................................

52

Description ..............................................................52

DTC Logic ...............................................................52

Diagnosis Procedure ..............................................52

Special Repair Requirement ...................................52

C1140 ACTUATOR RLY ...................................54

Description ..............................................................54

DTC Logic ...............................................................54

Diagnosis Procedure ..............................................54

Component Inspection ............................................55

Special Repair Requirement ...................................55

C1155 BRAKE FLUID LEVEL SWITCH ............56

Description ..............................................................56

DTC Logic ...............................................................56

Diagnosis Procedure ..............................................56

Component Inspection ............................................57

Special Repair Requirement ...................................57

U1000 CAN COMM CIRCUIT ............................59

Description ..............................................................59

DTC Logic ...............................................................59

Diagnosis Procedure ...............................................59

Special Repair Requirement ...................................59

ABS WARNING LAMP ......................................60

Description ..............................................................60

Component Function Check ...................................60

Diagnosis Procedure ...............................................60

BRAKE WARNING LAMP .................................61

Description ..............................................................61

Component Function Check ...................................61

Diagnosis Procedure ...............................................61

ECU DIAGNOSIS .......................................62

ABS ACTUATOR AND ELECTRIC UNIT

(CONTROL UNIT) ..............................................

62

Reference Value .....................................................62

Wiring Diagram - LHD .............................................67

Wiring Diagram - RHD ............................................69

Fail-Safe ..................................................................70

DTC No. Index ........................................................71

SYMPTOM DIAGNOSIS ............................73

ABS ....................................................................73

Symptom Table .......................................................73

EXCESSIVE ABS FUNCTION OPERATION

FREQUENCY .....................................................

74

Diagnosis Procedure ...............................................74

UNEXPECTED PEDAL REACTION ..................75

Diagnosis Procedure ...............................................75

THE BRAKING DISTANCE IS LONG ...............76

Diagnosis Procedure ...............................................76

ABS FUNCTION DOES NOT OPERATE ..........77

Diagnosis Procedure ...............................................77

PEDAL VIBRATION OR ABS OPERATION

SOUND OCCURS ..............................................

78

Diagnosis Procedure ...............................................78

NORMAL OPERATING CONDITION ................79

Description ..............................................................79

PRECAUTION ............................................80

PRECAUTIONS .................................................80

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .................................................................

80

Precaution for Brake System ..................................80

Precaution for Brake Control ...................................80

Precaution for Harness Repair ................................81

Page 237 of 5883

BRC-4

C1115 WHEEL SENSOR .................................124

Description .............................................................124

DTC Logic ..............................................................124

Diagnosis Procedure .............................................124

Component Inspection ...........................................125

Special Repair Requirement ..................................126

C1116 STOP LAMP SWITCH ..........................127

Description .............................................................127

DTC Logic ..............................................................127

Diagnosis Procedure .............................................127

Special Repair Requirement ..................................128

C1120, C1122, C1124, C1126 IN ABS SOL ...129

Description .............................................................129

DTC Logic ..............................................................129

Diagnosis Procedure .............................................129

Component Inspection ...........................................130

Special Repair Requirement ..................................131

C1121, C1123, C1125, C1127 OUT ABS SOL .132

Description .............................................................132

DTC Logic ..............................................................132

Diagnosis Procedure .............................................132

Component Inspection ...........................................133

Special Repair Requirement ..................................134

C1130, C1131, C1132, C1133, C1136 EN-

GINE SIGNAL ..................................................

135

Description .............................................................135

DTC Logic ..............................................................135

Diagnosis Procedure .............................................135

Special Repair Requirement ..................................135

C1140 ACTUATOR RLY .................................137

Description .............................................................137

DTC Logic ..............................................................137

Diagnosis Procedure .............................................137

Component Inspection ...........................................138

Special Repair Requirement ..................................138

C1142 PRESS SENSOR .................................139

Description .............................................................139

DTC Logic ..............................................................139

Diagnosis Procedure .............................................139

Component Inspection ...........................................141

Special Repair Requirement ..................................141

C1143, C1144 STEERING ANGLE SENSOR .142

Description .............................................................142

DTC Logic ..............................................................142

Diagnosis Procedure .............................................142

Component Inspection ...........................................143

Special Repair Requirement ..................................143

C1155 BRAKE FLUID LEVEL SWITCH ..........145

Description .............................................................145

DTC Logic ..............................................................145

Diagnosis Procedure .............................................145

Component Inspection ...........................................146

Special Repair Requirement ..................................146

C1156 ST ANG SEN COM CIR ........................148

Description ............................................................148

DTC Logic .............................................................148

Diagnosis Procedure .............................................148

C1160 DECEL G SEN SET ..............................149

Description ............................................................149

DTC Logic .............................................................149

Diagnosis Procedure .............................................149

C1163 ST ANGLE SEN SAFE .........................150

Description ............................................................150

DTC Logic .............................................................150

Diagnosis Procedure .............................................150

C1179 ABS DELTA S SEN NG ........................151

Description ............................................................151

DTC Logic .............................................................151

Diagnosis Procedure .............................................151

Component Inspection ..........................................152

Special Repair Requirement .................................152

U1000 CAN COMM CIRCUIT ...........................153

Description ............................................................153

DTC Logic .............................................................153

Diagnosis Procedure .............................................153

Special Repair Requirement .................................153

VDC OFF SWITCH ...........................................154

Description ............................................................154

Component Function Check .................................154

Diagnosis Procedure .............................................154

Component Inspection ..........................................155

ABS WARNING LAMP .....................................156

Description ............................................................156

Component Function Check .................................156

Diagnosis Procedure .............................................156

BRAKE WARNING LAMP ................................157

Description ............................................................157

Component Function Check .................................157

Diagnosis Procedure .............................................157

VDC OFF INDICATOR LAMP ..........................158

Description ............................................................158

Component Function Check .................................158

Diagnosis Procedure .............................................158

SLIP INDICATOR LAMP ..................................159

Description ............................................................159

Component Function Check .................................159

Diagnosis Procedure .............................................159

ECU DIAGNOSIS ......................................160

ABS ACTUATOR AND ELECTRIC UNIT

(CONTROL UNIT) .............................................

160

Reference Value ...................................................160

Wiring Diagram - LHD ...........................................165

Wiring Diagram - RHD ..........................................167

Page 264 of 5883

![NISSAN TIIDA 2007 Service User Guide C1101, C1102, C1103, C1104 WHEEL SENSOR-1

BRC-31

< COMPONENT DIAGNOSIS >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

3. Spin the wheel of the vehicle by hand and observe the red SENSOR indicator on the ABS NISSAN TIIDA 2007 Service User Guide C1101, C1102, C1103, C1104 WHEEL SENSOR-1

BRC-31

< COMPONENT DIAGNOSIS >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

3. Spin the wheel of the vehicle by hand and observe the red SENSOR indicator on the ABS](/img/5/57395/w960_57395-263.png)

C1101, C1102, C1103, C1104 WHEEL SENSOR-1

BRC-31

< COMPONENT DIAGNOSIS >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

3. Spin the wheel of the vehicle by hand and observe the red SENSOR indicator on the ABS active wheel

sensor tester. The red SENSOR indicator should flash on and off to indicate an output signal.

NOTE:

If the red SENSOR indicator illuminates but does not flash, reverse the polarity of the tester leads and

retest.

Does the ABS active wheel sensor tester detect a signal?

YES >> GO TO 3

NO >> Replace the wheel sensor. Refer to BRC-83, "

Removal and Installation".

3.CHECK TIRES

Check for inflation pressure, wear and size of each tire.

Are tire pressure and size correct and is tire wear within specifications?

YES >> GO TO 4

NO >> Adjust tire pressure or replace tire(s).

4.CHECK WHEEL BEARINGS

Check wheel bearing axial end play. Refer to FA X - 6 , "

On-Vehicle Inspection and Service" (front) or RAX-5,

"On-Vehicle Inspection and Service" (rear).

Is the inspection result normal?

YES >> GO TO 5

NO >> Repair or replace as necessary. Refer to FAX-7, "

Removal and Installation" (front) or RAX-6,

"Removal and Installation" (rear).

5.CHECK WIRING HARNESS FOR SHORT CIRCUIT

1. Disconnect ABS actuator and electric unit (control unit) connec-

tor and wheel sensor connector of malfunction code No.

2. Check continuity between wheel sensor harness connector ter-

minals and ground.

Is the inspection result normal?

YES >> GO TO 6

NO >> Repair the circuit.

6.CHECK WIRING HARNESS FOR OPEN CIRCUIT

1. Check continuity between ABS actuator and electric unit (control unit) harness connector E125 and the

malfunctioning wheel sensor harness connector E18, E117, C10, or C11.

Is the inspection result normal?

YES >> Replace the ABS actuator and electric unit (control unit). Refer to BRC-85, "Removal and Installa-

tion".

NO >> Repair the circuit.Continuity should not exist.

WFIA0343E

Wheel sensorABS actuator and

electric unit (control unit)Wheel sensor

Continuity

Connector Terminal Connector Terminal

Front LH

E12545

E181

Ye s 46 2

Front RH34

E1171

33 2

Rear LH37

C112

36 1

Rear RH42

C102

43 1

Page 267 of 5883

![NISSAN TIIDA 2007 Service User Guide BRC-34

< COMPONENT DIAGNOSIS >[ABS]

C1105, C1106, C1107, C1108 WHEEL SENSOR-2

2.CHECK WHEEL SENSOR OUTPUT SIGNAL

1. Connect ABS active wheel sensor tester (J-45741) to wheel sensor using appropriate a NISSAN TIIDA 2007 Service User Guide BRC-34

< COMPONENT DIAGNOSIS >[ABS]

C1105, C1106, C1107, C1108 WHEEL SENSOR-2

2.CHECK WHEEL SENSOR OUTPUT SIGNAL

1. Connect ABS active wheel sensor tester (J-45741) to wheel sensor using appropriate a](/img/5/57395/w960_57395-266.png)

BRC-34

< COMPONENT DIAGNOSIS >[ABS]

C1105, C1106, C1107, C1108 WHEEL SENSOR-2

2.CHECK WHEEL SENSOR OUTPUT SIGNAL

1. Connect ABS active wheel sensor tester (J-45741) to wheel sensor using appropriate adapter.

2. Turn on the ABS active wheel sensor tester power switch.

NOTE:

The green POWER indicator should illuminate. If the POWER indicator does not illuminate, replace the

battery in the ABS active wheel sensor tester before proceeding.

3. Spin the wheel of the vehicle by hand and observe the red SENSOR indicator on the ABS active wheel

sensor tester. The red SENSOR indicator should flash on and off to indicate an output signal.

NOTE:

If the red SENSOR indicator illuminates but does not flash, reverse the polarity of the tester leads and

retest.

Does the ABS active wheel sensor tester detect a signal?

YES >> GO TO 3

NO >> Replace the wheel sensor. Refer to BRC-83, "

Removal and Installation".

3.CHECK TIRES

Check for inflation pressure, wear and size of each tire.

Are tire pressure and size correct and is tire wear within specifications?

YES >> GO TO 4

NO >> Adjust tire pressure or replace tire(s).

4.CHECK WHEEL BEARINGS

Check wheel bearing axial end play. Refer to FAX-5, "

On-Vehicle Inspection and Service" (front) or RAX-5,

"On-Vehicle Inspection and Service" (rear).

Is the inspection result normal?

YES >> GO TO 5

NO >> Repair or replace as necessary. Refer to FA X - 7 , "

Removal and Installation" (front) or RAX-6,

"Removal and Installation" (rear).

5.CHECK WIRING HARNESS FOR SHORT CIRCUIT

1. Disconnect ABS actuator and electric unit (control unit) connec-

tor and wheel sensor connector of malfunction code No.

2. Check continuity between wheel sensor harness connector ter-

minals and ground.

Is the inspection result normal?

YES >> GO TO 6

NO >> Repair the circuit.

6.CHECK WIRING HARNESS FOR OPEN CIRCUIT

1. Check continuity between ABS actuator and electric unit (control unit) harness connector E125 and the

malfunctioning wheel sensor harness connector E18, E117, C10, or C11. Continuity should not exist.

WFIA0343E

Page 275 of 5883

![NISSAN TIIDA 2007 Service User Guide BRC-42

< COMPONENT DIAGNOSIS >[ABS]

C1115 WHEEL SENSOR

Check for inflation pressure, wear and size of each tire.

Are tire pressure and size correct and is tire wear within specifications?

YES >> GO TO NISSAN TIIDA 2007 Service User Guide BRC-42

< COMPONENT DIAGNOSIS >[ABS]

C1115 WHEEL SENSOR

Check for inflation pressure, wear and size of each tire.

Are tire pressure and size correct and is tire wear within specifications?

YES >> GO TO](/img/5/57395/w960_57395-274.png)

BRC-42

< COMPONENT DIAGNOSIS >[ABS]

C1115 WHEEL SENSOR

Check for inflation pressure, wear and size of each tire.

Are tire pressure and size correct and is tire wear within specifications?

YES >> GO TO 4

NO >> Adjust tire pressure or replace tire(s).

4.CHECK WHEEL BEARINGS

Check wheel bearing axial end play. Refer to FAX-6, "

On-Vehicle Inspection and Service" (front) or RAX-5,

"On-Vehicle Inspection and Service" (rear).

Is the inspection result normal?

YES >> GO TO 5

NO >> Repair or replace as necessary. Refer to FA X - 7 , "

Removal and Installation" (front) or RAX-6,

"Removal and Installation" (rear).

5.CHECK WIRING HARNESS FOR SHORT CIRCUIT

1. Disconnect ABS actuator and electric unit (control unit) connec-

tor and wheel sensor connector of malfunction code No.

2. Check continuity between wheel sensor harness connector ter-

minals and ground.

Is the inspection result normal?

YES >> GO TO 6

NO >> Repair the circuit.

6.CHECK WIRING HARNESS FOR OPEN CIRCUIT

1. Check continuity between ABS actuator and electric unit (control unit) harness connector E125 and the

malfunctioning wheel sensor harness connector E18, E117, C10, or C11.

Is the inspection result normal?

YES >> Replace the ABS actuator and electric unit (control unit). Refer to BRC-85, "Removal and Installa-

tion".

NO >> Repair the circuit.

Component InspectionINFOID:0000000001731255

1.CHECK DATA MONITOR

On “DATA MONITOR”, select “FR LH SENSOR”, “FR RH SENSOR”, “RR LH SENSOR”, and “RR RH SEN-

SOR”, and check the vehicle speed.Continuity should not exist.

WFIA0343E

Wheel sensorABS actuator and

electric unit (control unit)Wheel sensor

Continuity

Connector Terminal Connector Terminal

Front LH

E12545

E181

Ye s 46 2

Front RH34

E1171

33 2

Rear LH37

C112

36 1

Rear RH42

C102

43 1

Wheel sensor Vehicle speed (DATA MONITOR)

Page 292 of 5883

![NISSAN TIIDA 2007 Service User Guide U1000 CAN COMM CIRCUIT

BRC-59

< COMPONENT DIAGNOSIS >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

U1000 CAN COMM CIRCUIT

DescriptionINFOID:0000000001731319

CAN (Controller Area Network) is a serial communic NISSAN TIIDA 2007 Service User Guide U1000 CAN COMM CIRCUIT

BRC-59

< COMPONENT DIAGNOSIS >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

U1000 CAN COMM CIRCUIT

DescriptionINFOID:0000000001731319

CAN (Controller Area Network) is a serial communic](/img/5/57395/w960_57395-291.png)

U1000 CAN COMM CIRCUIT

BRC-59

< COMPONENT DIAGNOSIS >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

U1000 CAN COMM CIRCUIT

DescriptionINFOID:0000000001731319

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

DTC LogicINFOID:0000000001731320

DTC DETECTION LOGIC

Diagnosis ProcedureINFOID:0000000001731321

INSPECTION PROCEDURE

1.CHECK CONNECTOR

1. Turn ignition switch OFF, disconnect the ABS actuator and electric unit (control unit) connector, and check

the terminals for deformation, disconnection, looseness, and so on. If there is a malfunction, repair or

replace the terminal.

2. Reconnect connector and perform self-diagnosis.

Is

“CAN COMM CIRCUIT” displayed in self-diagnosis display items?

YES >> Print out the self-diagnostic results, and refer to LAN-22, "Trouble Diagnosis Flow Chart".

NO >> Connector terminal is loose, damaged, open, or shorted.

Special Repair RequirementINFOID:0000000001731322

1.ADJUSTMENT OF STEERING ANGLE SENSOR NEUTRAL POSITION

Always perform neutral position adjustment for the steering angle sensor when replacing the ABS actuator

and electric unit (control unit). Refer to BRC-90, "

ADJUSTMENT OF STEERING ANGLE SENSOR NEUTRAL

POSITION : Description".

>> GO TO 2

2.CALIBRATION OF DECEL G SENSOR

Always perform calibration of decel G sensor when replacing the ABS actuator and electric unit (control unit).

Refer to BRC-91, "

CALIBRATION OF DECEL G SENSOR : Description".

>> END

DTC Display item Malfunction detected condition Possible cause

U1000 CAN COMM CIRCUITWhen ABS actuator and electric unit (control unit) is not

transmitting or receiving CAN communication signal for 2

seconds or more. CAN communication line

ABS actuator and electric unit

(control unit)

Page 300 of 5883

![NISSAN TIIDA 2007 Service User Guide ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

BRC-67

< ECU DIAGNOSIS >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

Wiring Diagram - LHDINFOID:0000000001731340

AWFWA0012GB NISSAN TIIDA 2007 Service User Guide ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

BRC-67

< ECU DIAGNOSIS >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

Wiring Diagram - LHDINFOID:0000000001731340

AWFWA0012GB](/img/5/57395/w960_57395-299.png)

ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

BRC-67

< ECU DIAGNOSIS >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

Wiring Diagram - LHDINFOID:0000000001731340

AWFWA0012GB

Page 302 of 5883

![NISSAN TIIDA 2007 Service User Guide ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

BRC-69

< ECU DIAGNOSIS >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

Wiring Diagram - RHDINFOID:0000000001731382

AWFWA0013GB NISSAN TIIDA 2007 Service User Guide ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

BRC-69

< ECU DIAGNOSIS >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

Wiring Diagram - RHDINFOID:0000000001731382

AWFWA0013GB](/img/5/57395/w960_57395-301.png)

ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

BRC-69

< ECU DIAGNOSIS >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

Wiring Diagram - RHDINFOID:0000000001731382

AWFWA0013GB