Ext NISSAN TIIDA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 2938 of 5883

![NISSAN TIIDA 2007 Service Repair Manual TIMING BELT

EM-291

< ON-VEHICLE REPAIR >[K9K]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

TIMING BELT

Exploded ViewINFOID:0000000001381499

Removal and InstallationINFOID:0000000001381500

CAUTION:

Apply new engi NISSAN TIIDA 2007 Service Repair Manual TIMING BELT

EM-291

< ON-VEHICLE REPAIR >[K9K]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

TIMING BELT

Exploded ViewINFOID:0000000001381499

Removal and InstallationINFOID:0000000001381500

CAUTION:

Apply new engi](/img/5/57395/w960_57395-2937.png)

TIMING BELT

EM-291

< ON-VEHICLE REPAIR >[K9K]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

TIMING BELT

Exploded ViewINFOID:0000000001381499

Removal and InstallationINFOID:0000000001381500

CAUTION:

Apply new engine oil to parts marked in illustration before installation.

Replace any belt that has been removed.

Never turn the engine in the direction opposite to that of normal operation.

When replacing the timing belt, be sure to replace the timing belt tensioner.

Do not run the engine without the drive belts to avoid damaging the crankshaft pulley.

REMOVAL

1. Remove front wheel RH. Refer to WT-6, "Rotation".

2. Remove fender protector RH. Refer to EXT-22, "

Removal and Installation".

3. Remove engine cover.

4. Remove drive belt. Refer to EM-291, "

Removal and Installation".

5. Support the engine using suitable tool.

6. Remove RH engine torque rod.

7. Remove RH engine mounting support bracket and RH engine mounting insulator.

1. Timing belt inner cover 2. Timing belt 3. Camshaft sprocket

4. Camshaft sprocket stud bolt 5. Timing belt tensioner 6. Timing belt cover

7. Cylinder head suspended bracket 8. Crankshaft pulley 9. Crankshaft sprocket (timing belt)

10. Oil seal 11. Crankshaft cover 12. Gasket

A. 30.0 N·m (3.1 kg-m, 22 ft-lb) and 86 degrees

B. 120.0 N·m (12 kg-m, 89 ft-lb) and 95 degrees

E1BIA0022GB

Page 2945 of 5883

![NISSAN TIIDA 2007 Service Repair Manual EM-298

< ON-VEHICLE REPAIR >[K9K]

CAMSHAFT

CAMSHAFT

Exploded ViewINFOID:0000000001381501

Removal and InstallationINFOID:0000000001381502

CAUTION:

Apply new engine oil to parts marked in illustration b NISSAN TIIDA 2007 Service Repair Manual EM-298

< ON-VEHICLE REPAIR >[K9K]

CAMSHAFT

CAMSHAFT

Exploded ViewINFOID:0000000001381501

Removal and InstallationINFOID:0000000001381502

CAUTION:

Apply new engine oil to parts marked in illustration b](/img/5/57395/w960_57395-2944.png)

EM-298

< ON-VEHICLE REPAIR >[K9K]

CAMSHAFT

CAMSHAFT

Exploded ViewINFOID:0000000001381501

Removal and InstallationINFOID:0000000001381502

CAUTION:

Apply new engine oil to parts marked in illustration before installation.

REMOVAL

1. Remove front wheel RH. Refer to WT-6, "Rotation".

2. Remove fender protector RH. Refer to EXT-22, "

Removal and Installation".

3. Remove rocker cover. Refer to EM-289, "

Removal and Installation".

4. Remove electronic throttle control actuator. Refer to EM-272, "

Exploded View".

5. Remove vacuum pump. Refer to EM-280, "

Removal and Installation".

6. Remove drive belt. Refer to EM-263, "

Removal and Installation".

7. Support the engine using suitable tool.

CAUTION:

Put a piece of wood or something similar as supporting surface to secure a completely stable con-

dition.

8. Remove timing belt. Refer to EM-291, "

Removal and Installation".

9. Remove camshaft brackets.

10. Remove camshaft.

11. Remove valve lifter.

INSTALLATION

1. Camshaft sprocket stud bolt 2. Camshaft sprocket 3. Oil seal

4. Camshaft bracket 5. Camshaft 6. Cylinder head suspended bracket

7. Valve lifter 8. Cap 9. Cylinder head

A. 30.0 N·m (3.1 kg-m, 22 ft-lb) and 86 degrees

E1BIA0023GB

Page 2950 of 5883

![NISSAN TIIDA 2007 Service Repair Manual ENGINE ASSEMBLY

EM-303

< REMOVAL AND INSTALLATION >[K9K]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

Remove engine and transaxle assembly from vehicle down ward. Separate engine and transaxle.

Preparation

Remove NISSAN TIIDA 2007 Service Repair Manual ENGINE ASSEMBLY

EM-303

< REMOVAL AND INSTALLATION >[K9K]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

Remove engine and transaxle assembly from vehicle down ward. Separate engine and transaxle.

Preparation

Remove](/img/5/57395/w960_57395-2949.png)

ENGINE ASSEMBLY

EM-303

< REMOVAL AND INSTALLATION >[K9K]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

Remove engine and transaxle assembly from vehicle down ward. Separate engine and transaxle.

Preparation

Remove the following parts.

Battery ground cable.

Engine undercover.

LH and RH front wheels. Refer to WT-6, "

Rotation".

LH and RH fender protectors. Refer to EXT-22, "

Removal and Installation".

Engine Room

1. Drain engine coolant. Refer to CO-58, "Draining".

CAUTION:

Perform when engine is cold.

2. Remove lower radiator hose. Refer to CO-62, "

Exploded View".

3. Drain transaxle fluid. Refer to TM-672, "

Draining".

4. Disconnect clutch tube at clutch housing and drain clutch fluid.

NOTE:

Cover clutch tube ends to prevent contamination.

5. Remove hood. Refer to DLK-214, "

Removal and Installation".

6. Remove cowl top cover and cowl top extension assembly. Refer to EXT-20, "

Removal and Installation".

7. Remove battery and battery trap. Refer to PG-6, "

Removal and Installation".

8. Disconnect engine room harness from the engine side and position aside.

9. Remove the air duct (inlet). Refer to EM-269, "

Exploded View".

10. Remove engine cover.

11. Remove blow-by hose.

12. Remove air cleaner case and air duct (suction). Refer to EM-269, "

Removal and Installation".

13. Remove reservoir tank and hoses. Refer to CO-62, "

Exploded View".

14. Remove charge air cooler hoses and tubes. Refer to EM-270, "

Exploded View".

15. Remove vacuum hose. Refer to EM-280, "

Removal and Installation".

16. Disconnect fuel feed and return hoses, and plug it to prevent fuel from draining.

17. Remove radiator upper hose. Refer to CO-62, "

Exploded View".

18. Disconnect heater hoses.

19. Disconnect transaxle side harness.

20. Disconnect breather hose transaxle side.

21. Disconnect shift cable and select cable. Refer to TM-674, "

Exploded View".

22. Remove cooling fan. Refer to CO-64, "

Removal and Installation".

23. Remove radiator. Refer to CO-62, "

Exploded View".

24. Disconnect all the body-side vacuum hoses and air hoses at engine side.

Vehicle Underbody

1. Remove drive shaft assembly RH and LH. Refer to Removal and Installation.

2. Remove exhaust front tube. Refer to EX-14, "

Component".

3. Remove drive belt. Refer to EM-263, "

Removal and Installation".

4. Remove A/C compressor and position aside.

NOTE:

Secure it to body with a rope to avoid putting load on A/C lines.

5. Remove lower torque rod. Refer to EM-302, "

Exploded View".

Removal

Page 2992 of 5883

![NISSAN TIIDA 2007 Service Repair Manual EX-6

< ON-VEHICLE REPAIR >[HR16DE]

EXHAUST SYSTEM

2. Disconnect each joint and mounting rubber.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Always replace exhaust gaskets NISSAN TIIDA 2007 Service Repair Manual EX-6

< ON-VEHICLE REPAIR >[HR16DE]

EXHAUST SYSTEM

2. Disconnect each joint and mounting rubber.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Always replace exhaust gaskets](/img/5/57395/w960_57395-2991.png)

EX-6

< ON-VEHICLE REPAIR >[HR16DE]

EXHAUST SYSTEM

2. Disconnect each joint and mounting rubber.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Always replace exhaust gaskets and seal bearings with new ones when installing.

Discard any heated oxygen sensor 2 which has been dropped from a height of more than 0.5 m (19.7

in) onto a hard surface such as a concrete floor; use a new one.

Before installing a new heated oxygen sensor 2, clean exhaust system threads using the heated oxy-

gen sensor thread cleaner and apply anti-seize lubricant (commercial service tool).

Do not over tighten heated oxygen sensor 2. Doing so may cause damage to the heated oxygen sen-

sor 2, resulting in the “MIL” coming on.

Remove deposits from the sealing surface of each connection. Connect them securely to avoid

exhaust leakage.

Temporarily tighten nuts on the exhaust manifold side and bolts on the vehicle side. Check each part

for unusual interference, and then tighten them to the specified torque.

When installing each mounting rubber, avoid twisting or unusual extension in up/down and right/left

directions.

Exhaust Manifold to Exhaust Front Tube

1. Securely insert seal bearing (2) into exhaust manifold (1) side in

the direction shown.

Exhaust front tube (5)

CAUTION:

Be careful not to damage seal bearing surface when install-

ing.

2. Install spring (3), tighten nut (4).

Be careful that the stud bolt nut does not interfere with the

flanged area ( ).

Make sure the spring (3) sits properly on the flange surface by

aligning it to the locator dimples.

Exhaust Front Tube to Center Muffler

1. Securely insert seal bearing (2) into exhaust front tube (1) side

in the direction shown.

Center muffler (5)

CAUTION:

Be careful not to damage seal bearing surface when install-

ing.

2. With spring (3), tighten bolt (4).

Be careful that the stud bolt does not interfere with the flanged

area ( ).

Make sure the spring (3) sits properly on the flange surface by

aligning it to the locator dimples.

InspectionINFOID:0000000001700348

INSPECTION AFTER INSTALLATION

With the engine running, check exhaust tube joints for exhaust leakage and unusual noise.

Check to ensure that brackets and mounting rubbers are installed properly and free from undue stress.

Improper installation could result in excessive noise and vibration.

PBIC3797E

PBIC3798E

Page 2997 of 5883

![NISSAN TIIDA 2007 Service Repair Manual EXHAUST SYSTEM

EX-11

< ON-VEHICLE REPAIR >[MR18DE]

C

D

E

F

G

H

I

J

K

L

MA

EX

N

P O

2. Disconnect each joint and mounting rubber.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION: NISSAN TIIDA 2007 Service Repair Manual EXHAUST SYSTEM

EX-11

< ON-VEHICLE REPAIR >[MR18DE]

C

D

E

F

G

H

I

J

K

L

MA

EX

N

P O

2. Disconnect each joint and mounting rubber.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:](/img/5/57395/w960_57395-2996.png)

EXHAUST SYSTEM

EX-11

< ON-VEHICLE REPAIR >[MR18DE]

C

D

E

F

G

H

I

J

K

L

MA

EX

N

P O

2. Disconnect each joint and mounting rubber.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Always replace exhaust gaskets and seal bearings with new ones when installing.

Discard any heated oxygen sensor 2 which has been dropped from a height of more than 0.5 m (19.7

in) onto a hard surface such as a concrete floor; use a new one.

Before installing a new heated oxygen sensor 2, clean exhaust system threads using the heated oxy-

gen sensor thread cleaner and apply anti-seize lubricant (commercial service tool).

Do not over tighten heated oxygen sensor 2. Doing so may cause damage to the heated oxygen sen-

sor 2, resulting in the “MIL” coming on.

Remove deposits from the sealing surface of each connection. Connect them securely to avoid

exhaust leakage.

Temporarily tighten nuts on the exhaust manifold side and bolts on the vehicle side. Check each part

for unusual interference, and then tighten them to the specified torque.

When installing each mounting rubber, avoid twisting or unusual extension in up/down and right/left

directions.

Exhaust Manifold to Exhaust Front Tube

1. Securely insert seal bearing (2) into exhaust manifold (1) side in

the direction shown.

Exhaust front tube (5)

CAUTION:

Be careful not to damage seal bearing surface when install-

ing.

2. Install spring (3), tighten nut (4).

Be careful that the stud bolt nut does not interfere with the

flanged area ( ).

Make sure the spring (3) sits properly on the flange surface by

aligning it to the locator dimples.

Exhaust Front Tube to Center Muffler

1. Securely insert seal bearing (2) into exhaust front tube (1) side

in the direction shown.

Center muffler (5)

CAUTION:

Be careful not to damage seal bearing surface when install-

ing.

2. With spring (3), tighten bolt (4).

Be careful that the stud bolt does not interfere with the flanged

area ( ).

Make sure the spring (3) sits properly on the flange surface by

aligning it to the locator dimples.

INSPECTION AFTER INSTALLATION

With the engine running, check exhaust tube joints for exhaust leakage and unusual noise.

Check to ensure that brackets and mounting rubbers are installed properly and free from undue stress.

Improper installation could result in excessive noise and vibration.

InspectionINFOID:0000000001696389

INSPECTION AFTER INSTALLATION

Make sure clearance between tail tube and rear bumper is even.

With engine running, check exhaust tube joints for gas leakage and unusual noises.

Check to ensure that mounting brackets and mounting rubbers are installed properly and free from undue

stress. Improper installation could result in excessive noise and vibration.

PBIC3797E

PBIC3798E

Page 3001 of 5883

![NISSAN TIIDA 2007 Service Repair Manual EXHAUST SYSTEM

EX-15

< ON-VEHICLE REPAIR >[K9K]

C

D

E

F

G

H

I

J

K

L

MA

EX

N

P O

When installing each mounting rubbers, avoid twisting or unusual extension in up/down and right/

left directions.

Exha NISSAN TIIDA 2007 Service Repair Manual EXHAUST SYSTEM

EX-15

< ON-VEHICLE REPAIR >[K9K]

C

D

E

F

G

H

I

J

K

L

MA

EX

N

P O

When installing each mounting rubbers, avoid twisting or unusual extension in up/down and right/

left directions.

Exha](/img/5/57395/w960_57395-3000.png)

EXHAUST SYSTEM

EX-15

< ON-VEHICLE REPAIR >[K9K]

C

D

E

F

G

H

I

J

K

L

MA

EX

N

P O

When installing each mounting rubbers, avoid twisting or unusual extension in up/down and right/

left directions.

Exhaust Manifold to Exhaust Front Tube

1. Securely insert seal bearing (2) into catalyst (1) side in the direc-

tion shown.

Exhaust front tube (5)

CAUTION:

Be careful not to damage seal bearing surface when install-

ing.

2. Install spring (3), tighten nut (4).

Be careful that the stud bolt nut does not interfere with the

flanged area ( ).

Make sure the spring (3) sits properly on the flange surface by

aligning it to the locator dimples.

Exhaust Front Tube to Center Muffler

1. Securely insert seal bearing (2) into exhaust front tube (1) side

in the direction shown.

Center muffler (5)

CAUTION:

Be careful not to damage seal bearing surface when install-

ing.

2. With spring (3), tighten bolt (4).

Be careful that the stud bolt does not interfere with the flanged

area ( ).

Make sure the spring (3) sits properly on the flange surface by

aligning it to the locator dimples.

INSPECTION AFTER INSTALLATION

With the engine running, check exhaust tube joints for exhaust leakage and unusual noise.

Check to ensure that brackets and mounting rubbers are installed properly and free from undue stress.

Improper installation could result in excessive noise and vibration.

InspectionINFOID:0000000001696394

INSPECTION AFTER INSTALLATION

With the engine running, check exhaust tube joints for gas leakage and unusual noises.

Check to ensure that mounting brackets and mounting rubbers are installed properly and free from undue

stress. Improper installation could result in excessive noise and vibration.

PBIC3797E

PBIC3798E

Page 3002 of 5883

EXL-1

DRIVER CONTROLS

C

D

E

F

G

H

I

J

K

M

SECTION EXL

A

B

EXL

N

O

P

CONTENTS

EXTERIOR LIGHTING SYSTEM

BASIC INSPECTION ....................................5

DIAGNOSIS AND REPAIR WORKFLOW ..........5

Work Flow .................................................................5

FUNCTION DIAGNOSIS ...............................8

HEADLAMP (HALOGEN) ...................................8

System Diagram ........................................................8

System Description ...................................................8

Component Parts Location ........................................8

Component Description .............................................8

HEADLAMP (XENON) .......................................10

System Diagram ......................................................10

System Description .................................................10

Component Parts Location ......................................10

Component Description ..........................................11

AUTO LIGHT SYSTEM ......................................12

System Diagram ......................................................12

System Description .................................................12

Component Parts Location ......................................12

Component Description ...........................................13

HEADLAMP AIMING SYSTEM (MANUAL) .......14

System Diagram ......................................................14

System Description .................................................14

Component Parts Location ......................................14

Component Description ...........................................14

HEADLAMP AIMING SYSTEM (AUTOMAT-

IC) .......................................................................

15

System Diagram ......................................................15

System Description .................................................15

Component Parts Location ......................................15

Component Description ...........................................15

DAYTIME LIGHT SYSTEM ................................17

System Diagram ......................................................17

System Description .................................................17

Component Parts Location ......................................17

Component Description ..........................................18

FRONT FOG LAMP ..........................................19

System Diagram ......................................................19

System Description ..................................................19

Component Parts Location ......................................19

Component Description ...........................................20

REAR FOG LAMP .............................................21

System Diagram ......................................................21

System Description ..................................................21

Component Parts Location ......................................21

Component Description ..........................................21

TURN SIGNAL AND HAZARD WARNING

LAMPS ..............................................................

22

System Diagram ......................................................22

System Description ..................................................22

Component Parts Location ......................................22

Component Description ...........................................23

PARKING, LICENSE PLATE AND TAIL

LAMPS ..............................................................

24

System Diagram ......................................................24

System Description ..................................................24

Component Parts Location ......................................25

Component Description ...........................................25

DIAGNOSIS SYSTEM (BCM) ...........................26

COMMON ITEM .........................................................26

COMMON ITEM : CONSULT-III Function (BCM -

COMMON ITEM) .....................................................

26

BCM ...........................................................................26

BCM : CONSULT-III Function (BCM - BCM) ...........26

HEADLAMP ...............................................................26

HEADLAMP : CONSULT-III Function (BCM -

HEAD LAMP) ...........................................................

26

FLASHER ...................................................................27

Page 3004 of 5883

EXL-3

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

TURN SIGNAL AND HAZARD WARNING

LAMPS ...............................................................

66

Wiring Diagram .......................................................66

PARKING, LICENSE PLATE AND TAIL

LAMPS ...............................................................

67

WITH DAYTIME LIGHT SYSTEM .............................67

WITH DAYTIME LIGHT SYSTEM : Wiring Dia-

gram ........................................................................

67

WITHOUT DAYTIME LIGHT SYSTEM ......................67

WITHOUT DAYTIME LIGHT SYSTEM : Wiring Di-

agram ......................................................................

68

STOP LAMP .......................................................69

Wiring Diagram .......................................................69

BACK-UP LAMP ................................................70

Wiring Diagram .......................................................70

ECU DIAGNOSIS .........................................71

BCM (BODY CONTROL MODULE) ...................71

Description ..............................................................71

IPDM E/R (INTELLIGENT POWER DISTRI-

BUTION MODULE ENGINE ROOM) .................

72

Description ..............................................................72

SYMPTOM DIAGNOSIS ..............................73

EXTERIOR LIGHTING SYSTEM SYMPTOMS ....73

Symptom Table .......................................................73

NORMAL OPERATING CONDITION .................75

Description ..............................................................75

BOTH SIDE HEADLAMPS DO NOT SWITCH

TO HIGH BEAM .................................................

76

Description ..............................................................76

Diagnosis Procedure ...............................................76

BOTH SIDE HEADLAMPS (LO) ARE NOT

TURNED ON .......................................................

77

Description ..............................................................77

Diagnosis Procedure ...............................................77

PARKING, LICENSE PLATE AND TAIL

LAMPS ARE NOT TURNED ON ........................

78

Description ..............................................................78

Diagnosis Procedure ...............................................78

BOTH SIDE FRONT FOG LAMPS ARE NOT

TURNED ON .......................................................

79

Description ..............................................................79

Diagnosis Procedure ...............................................79

PRECAUTION ..............................................80

PRECAUTIONS ..................................................80

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .................................................................

80

ON-VEHICLE MAINTENANCE ....................81

HEADLAMP ......................................................81

Aiming Adjustment ...................................................81

FRONT FOG LAMP ..........................................83

Aiming Adjustment ...................................................83

ON-VEHICLE REPAIR .................................84

HEADLAMP ......................................................84

Bulb Replacement ...................................................84

Removal and Installation .........................................84

Disassembly and Assembly - Halogen ....................85

Disassembly and Assembly - Xenon .......................86

FRONT FOG LAMP ..........................................87

Bulb Replacement ...................................................87

Removal and Installation .........................................87

HEADLAMP AIMING CONTROL ......................88

Removal and Installation of Headlamp Aiming

Switch ......................................................................

88

Removal and Installation of Height Sensor .............89

AUTO LIGHT SYSTEM .....................................91

Removal and Installation of Light and Rain Sensor

....

91

SIDE TURN SIGNAL LAMP ..............................92

Bulb Replacement ...................................................92

Removal and Installation .........................................92

REAR COMBINATION LAMP ...........................93

Bulb Replacement ...................................................93

Removal and Installation .........................................93

Disassembly and Assembly .....................................93

HIGH-MOUNTED STOP LAMP ........................96

Bulb Replacement ...................................................96

Removal and Installation .........................................96

LICENSE PLATE LAMP ...................................98

Bulb Replacement ...................................................98

Removal and Installation .........................................98

REAR FOG LAMP ...........................................100

Bulb Replacement .................................................100

Removal and Installation .......................................100

LIGHTING & TURN SIGNAL SWITCH ...........101

Removal and Installation .......................................101

HAZARD SWITCH ..........................................102

Removal and Installation .......................................102

SERVICE DATA AND SPECIFICATIONS

(SDS) ..........................................................

103

Page 3005 of 5883

EXL-4

BULB SPECIFICATIONS ................................103

Headlamp ..............................................................103

Exterior Lamp ........................................................103

Page 3013 of 5883

EXL-12

< FUNCTION DIAGNOSIS >

AUTO LIGHT SYSTEM

AUTO LIGHT SYSTEM

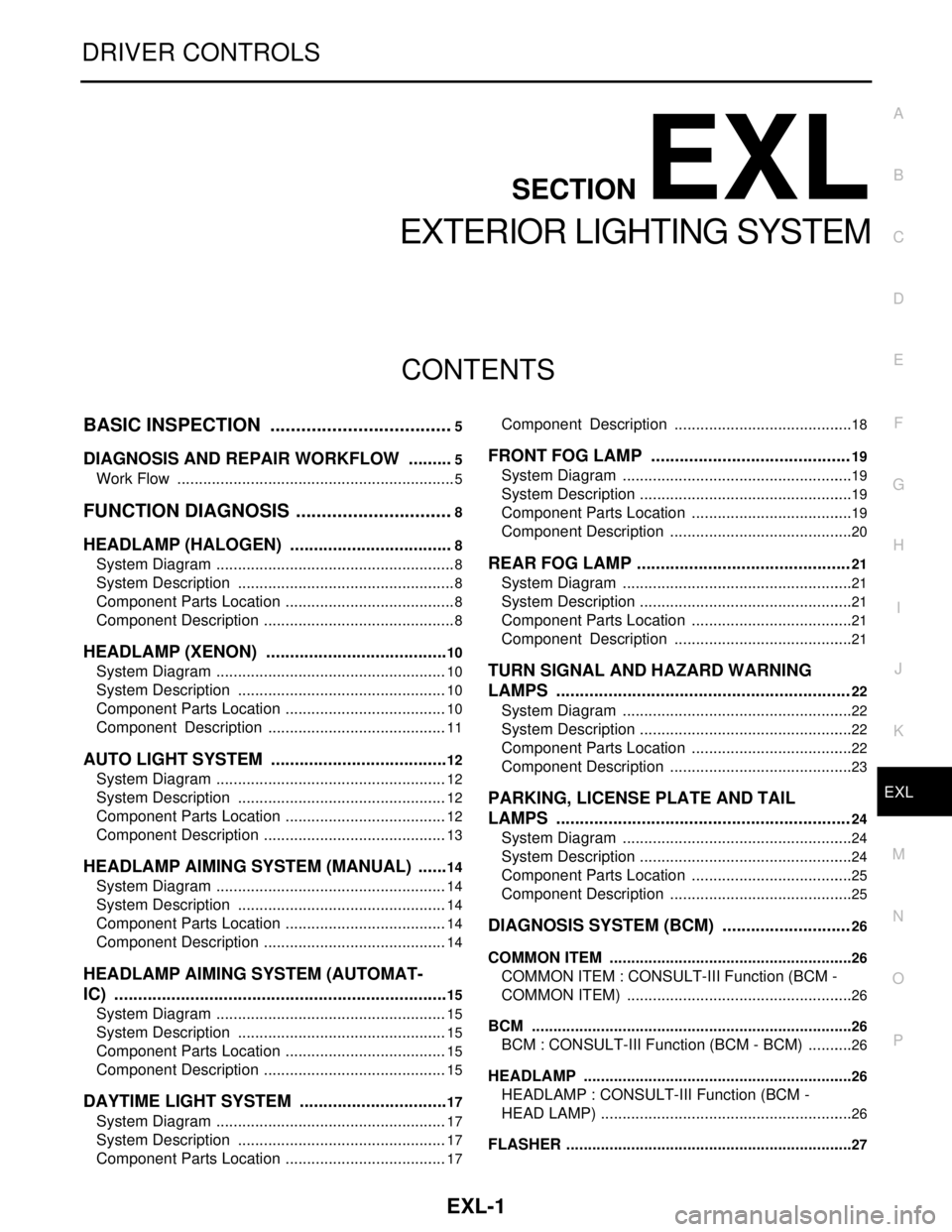

System DiagramINFOID:0000000001523233

System DescriptionINFOID:0000000001523234

When the lighting switch is in AUTO position, it automatically turns ON/OFF the exterior lamps in accordance

with the ambient light levels.

The light and rain sensor detects ambient brightness and converts light (lux) to voltage which is output to the

BCM. The BCM (Body Control Module) controls auto light operation according to the signal inputs from the

light and rain sensor, lighting switch and ignition switch. If conditions are met, the BCM sends a request (via

CAN communication lines) to the IPDM E/R (Intelligent Power Distribution Module Engine Room) to activate

the exterior lamps.

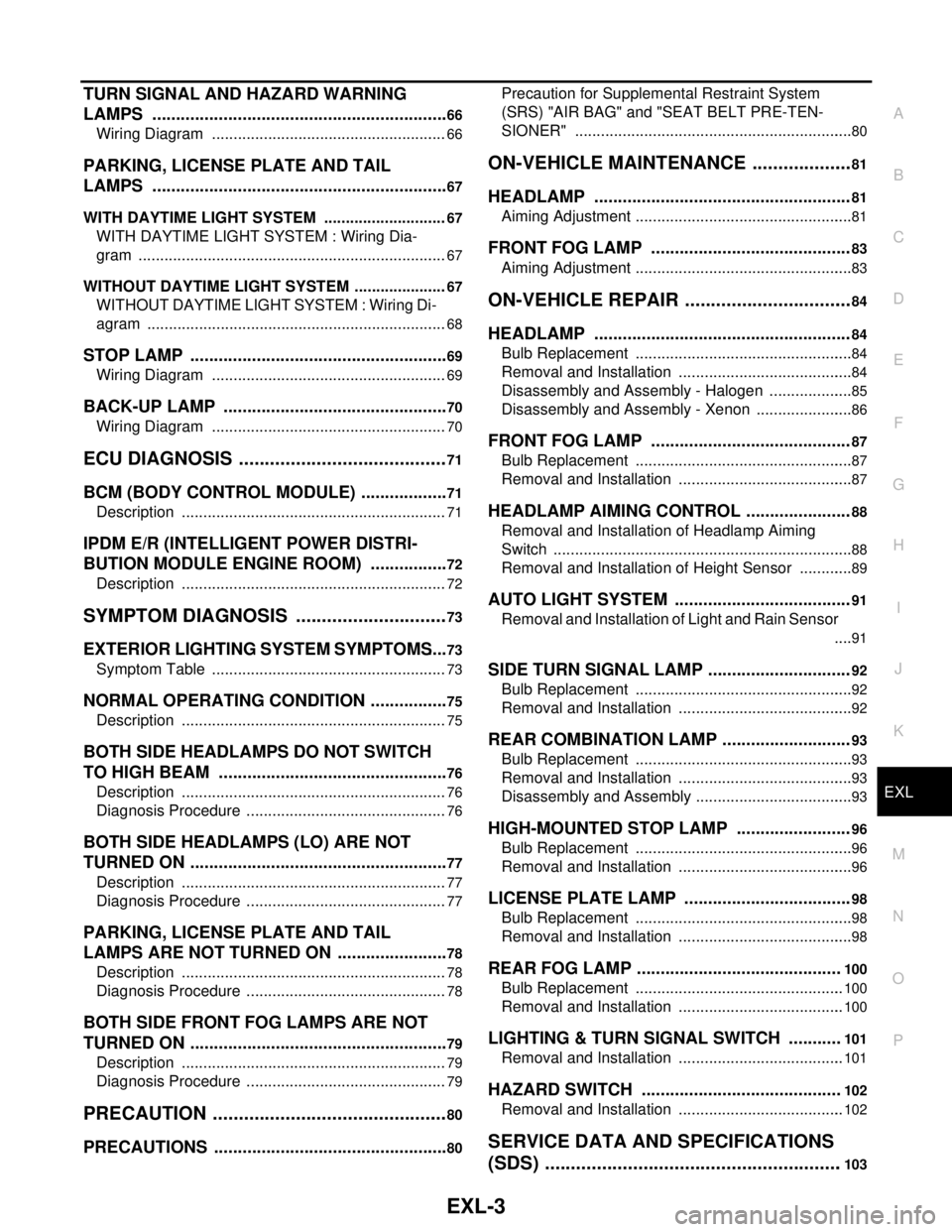

Component Parts LocationINFOID:0000000001523235

AWLIA0021GB

1. IPDM E/R E46, E47, E48 2. BCM M16, M17, M18, M19, M21 (view

with glove box removed)3. Combination switch M28

4. Light and rain sensor R11

AWLIA0022GB