Ext NISSAN TIIDA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 3110 of 5883

EXT-6

< ON-VEHICLE MAINTENANCE >

SQUEAK AND RATTLE TROUBLE DIAGNOSIS

UHMW (TEFLON) TAPE

Insulates where slight movement is present. Ideal for instrument panel applications.

SILICONE GREASE

Used in place of UHMW tape that will be visible or not fit.

Note: Will only last a few months.

SILICONE SPRAY

Use when grease cannot be applied.

DUCT TAPE

Use to eliminate movement.

CONFIRM THE REPAIR

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Generic Squeak and Rattle TroubleshootingINFOID:0000000001568922

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. The cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicone spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or rattle. If you saturate the area with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation procedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the areas with felt cloth tape or insulator foam blocks from

the Squeak and Rattle Kit to repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid bumpers out of adjustment

2. Trunk lid striker out of adjustment

3. The trunk lid torsion bars knocking together

Page 3111 of 5883

SQUEAK AND RATTLE TROUBLE DIAGNOSIS

EXT-7

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

L

MA

B

EXT

N

O

P

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sun visor shaft shaking in the holder

3. Front or rear windshield touching headliner and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

OVERHEAD CONSOLE (FRONT AND REAR)

Overhead console noises are often caused by the console panel clips not being engaged correctly. Most of

these incidents are repaired by pushing up on the console at the clip locations until the clips engage.

In addition look for:

1. Loose harness or harness connectors.

2. Front console map/reading lamp lens loose.

3. Loose screws at console attachment points.

SEATS

When isolating seat noise it's important to note the position the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of these incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component installed on the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Page 3112 of 5883

EXT-8

< ON-VEHICLE MAINTENANCE >

SQUEAK AND RATTLE TROUBLE DIAGNOSIS

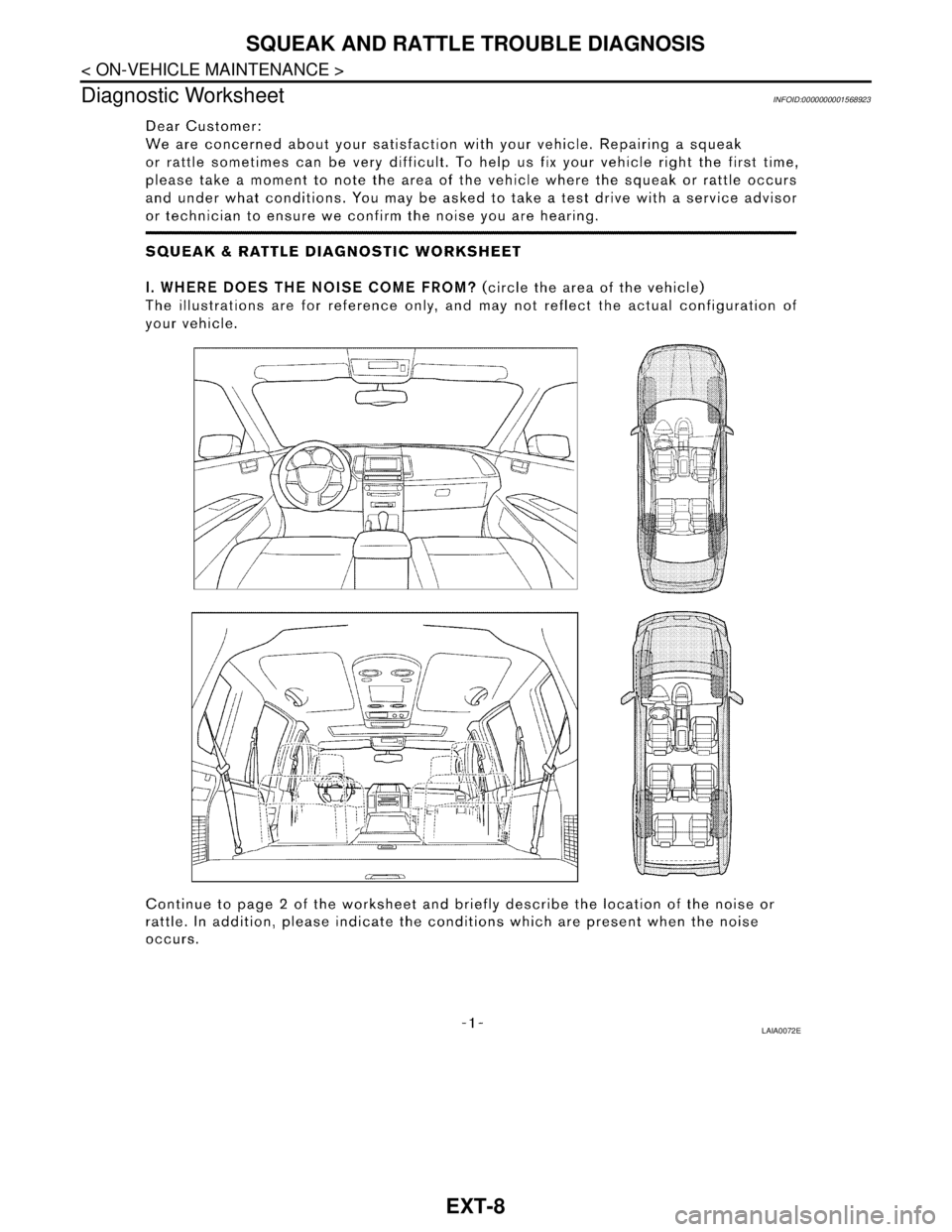

Diagnostic Worksheet

INFOID:0000000001568923

LAIA0072E

Page 3113 of 5883

SQUEAK AND RATTLE TROUBLE DIAGNOSIS

EXT-9

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

L

MA

B

EXT

N

O

P

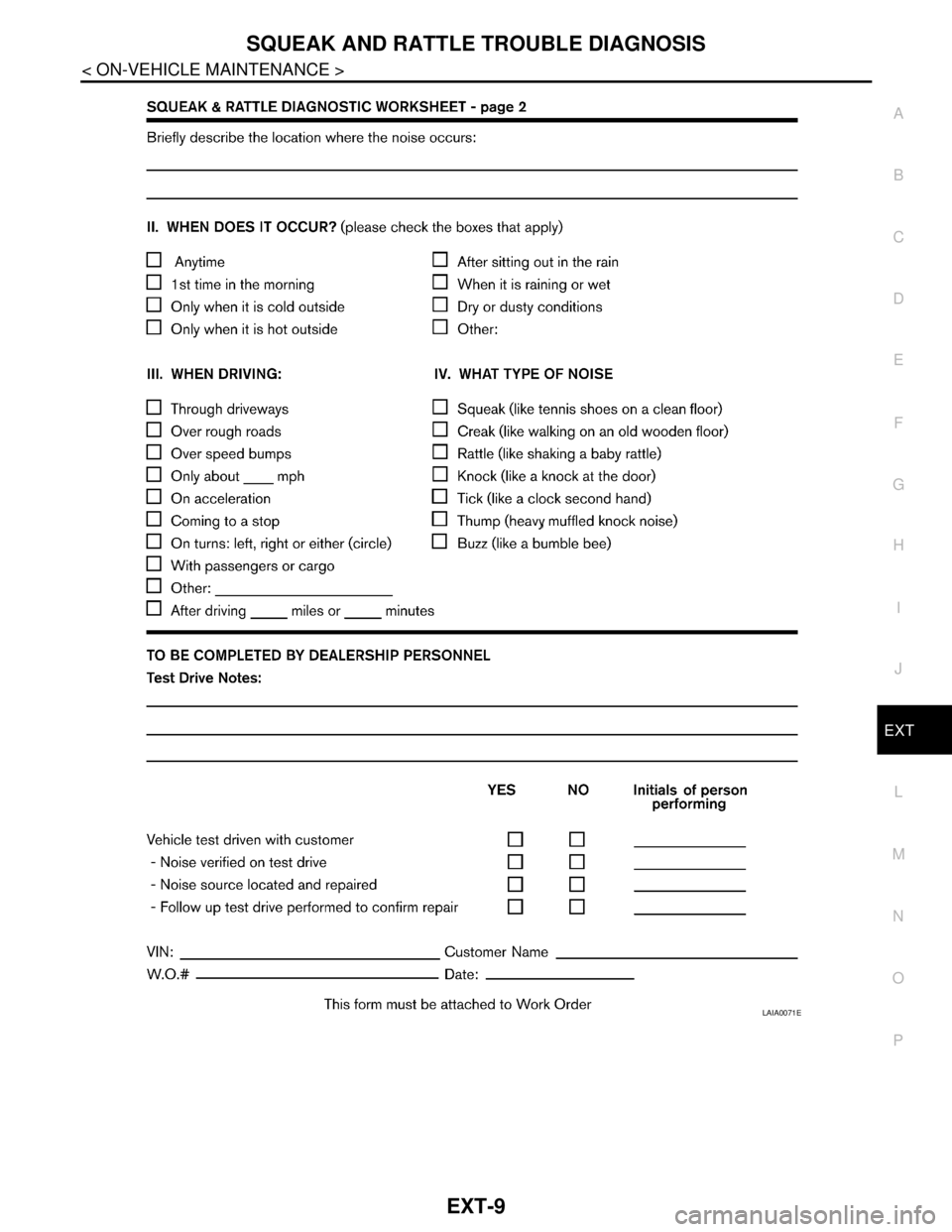

LAIA0071E

Page 3114 of 5883

EXT-10

< ON-VEHICLE REPAIR >

CLIP AND FASTENER

ON-VEHICLE REPAIR

CLIP AND FASTENER

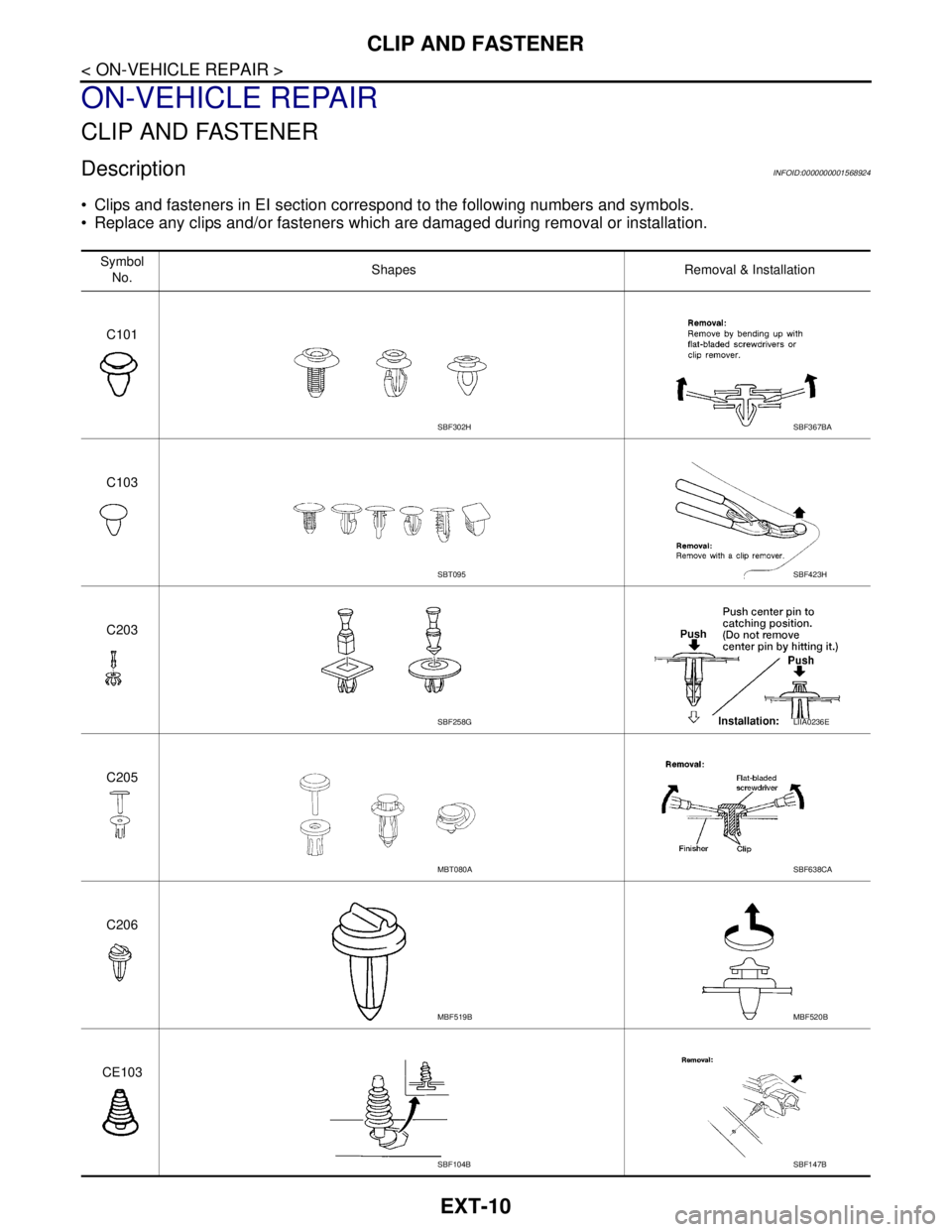

DescriptionINFOID:0000000001568924

Clips and fasteners in EI section correspond to the following numbers and symbols.

Replace any clips and/or fasteners which are damaged during removal or installation.

Symbol

No.Shapes Removal & Installation

C101

C103

C203

C205

C206

CE103

SBF302HSBF367BA

SBT095SBF423H

SBF258GLIIA0236E

MBT080ASBF638CA

MBF519BMBF520B

SBF104BSBF147B

Page 3115 of 5883

CLIP AND FASTENER

EXT-11

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

L

MA

B

EXT

N

O

P

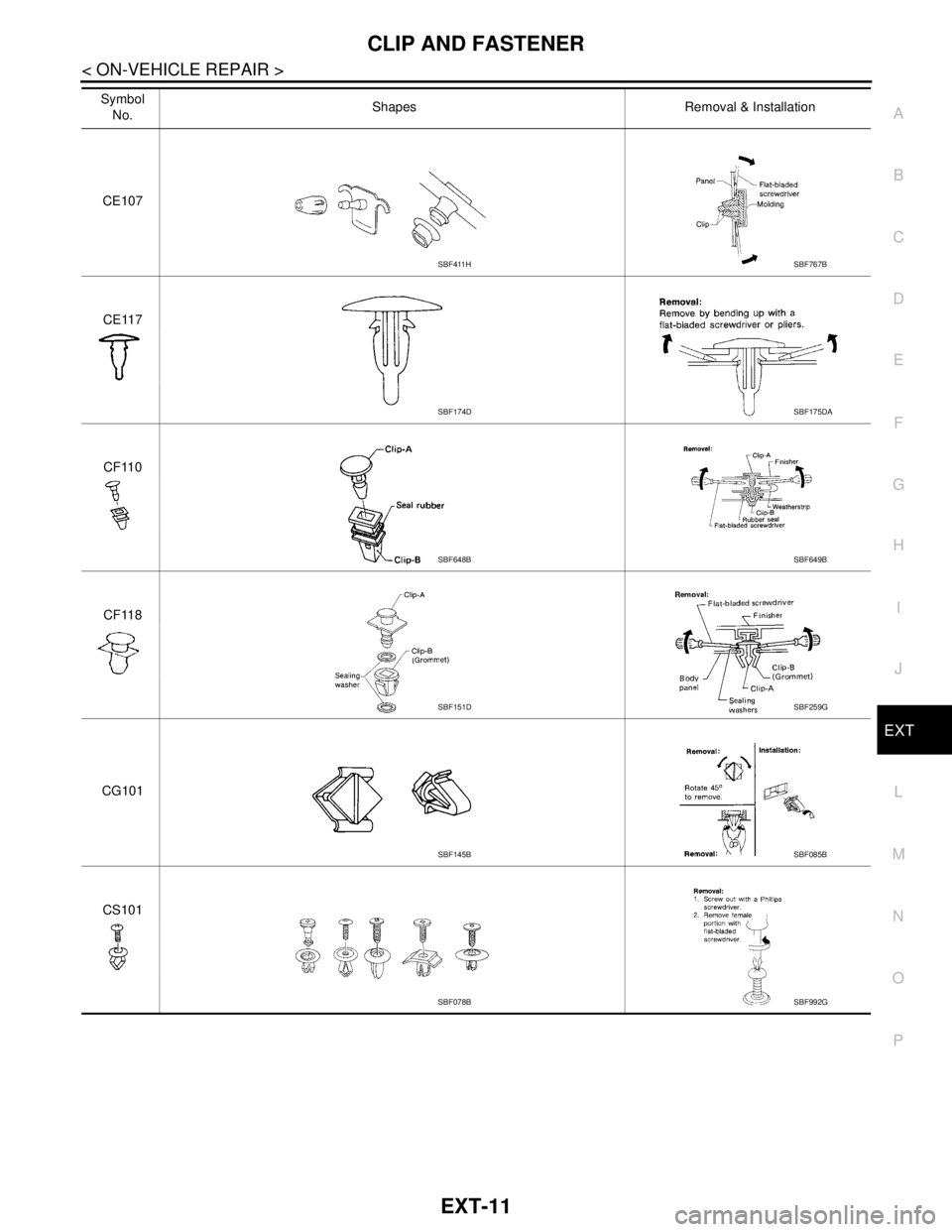

CE107

CE117

CF110

CF118

CG101

CS101 Symbol

No.Shapes Removal & Installation

SBF411HSBF767B

SBF174DSBF175DA

SBF648BSBF649B

SBF151DSBF259G

SBF145BSBF085B

SBF078BSBF992G

Page 3116 of 5883

EXT-12

< ON-VEHICLE REPAIR >

CLIP AND FASTENER

CR103

Metal ClipSymbol

No.Shapes Removal & Installation

SBF768BSBF770B

WBT072WBT073

Page 3117 of 5883

FRONT BUMPER

EXT-13

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

L

MA

B

EXT

N

O

P

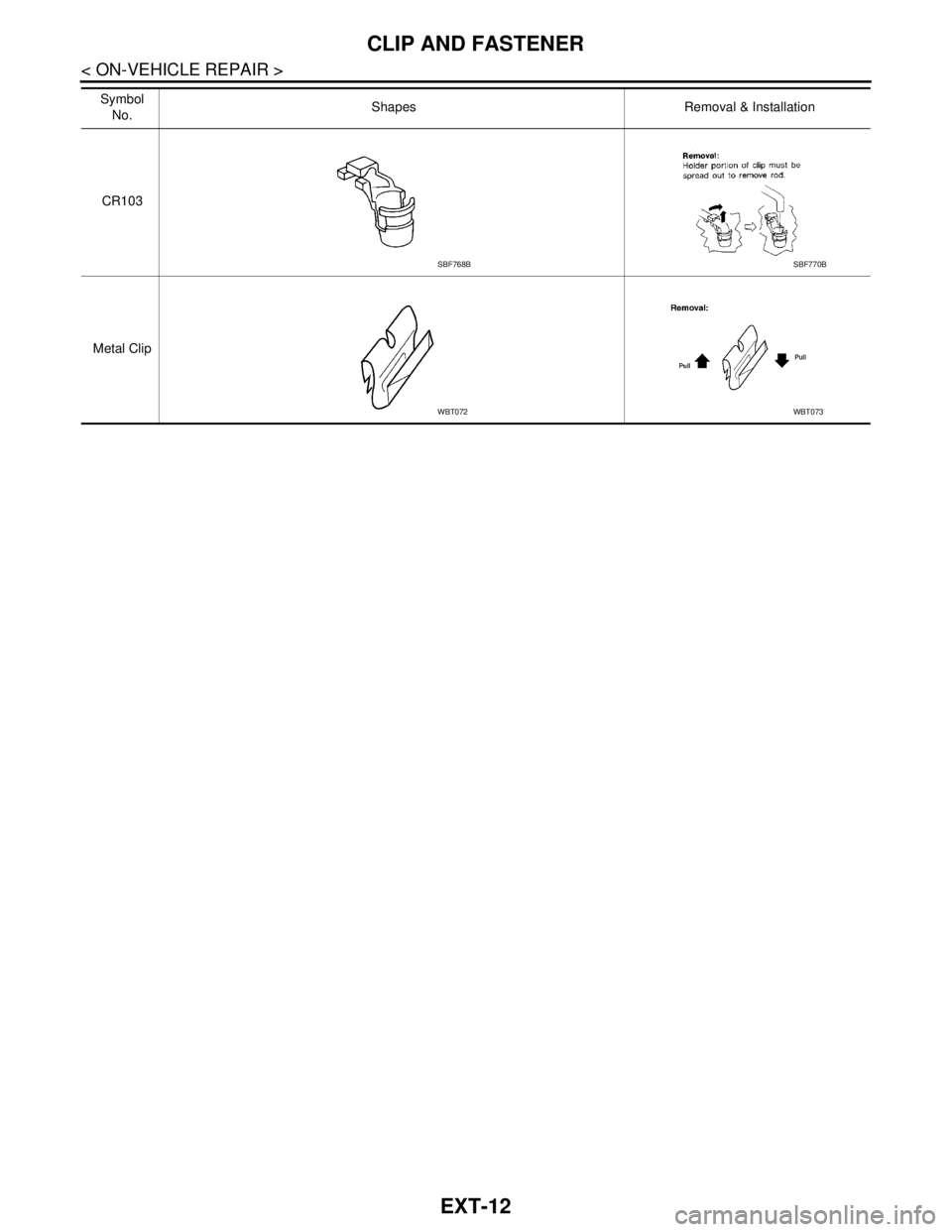

FRONT BUMPER

Removal and InstallationINFOID:0000000001568925

1. Upper bumper reinforcement 2. Upper bumper energy absorber 3. Lower bumper reinforcement

4. Lower bumper energy absorber 5. Engine undercover 6. Front bumper fascia

7. Access cover 8. Fog lamp opening finisher (without

fog lamps)9. Fog lamp opening finisher (with fog

lamps)

10. Fog lamp assembly 11. Bumper molding 12. Bumper side retainer

A. Clip C205

ALIIA0108GB

Page 3118 of 5883

EXT-14

< ON-VEHICLE REPAIR >

FRONT BUMPER

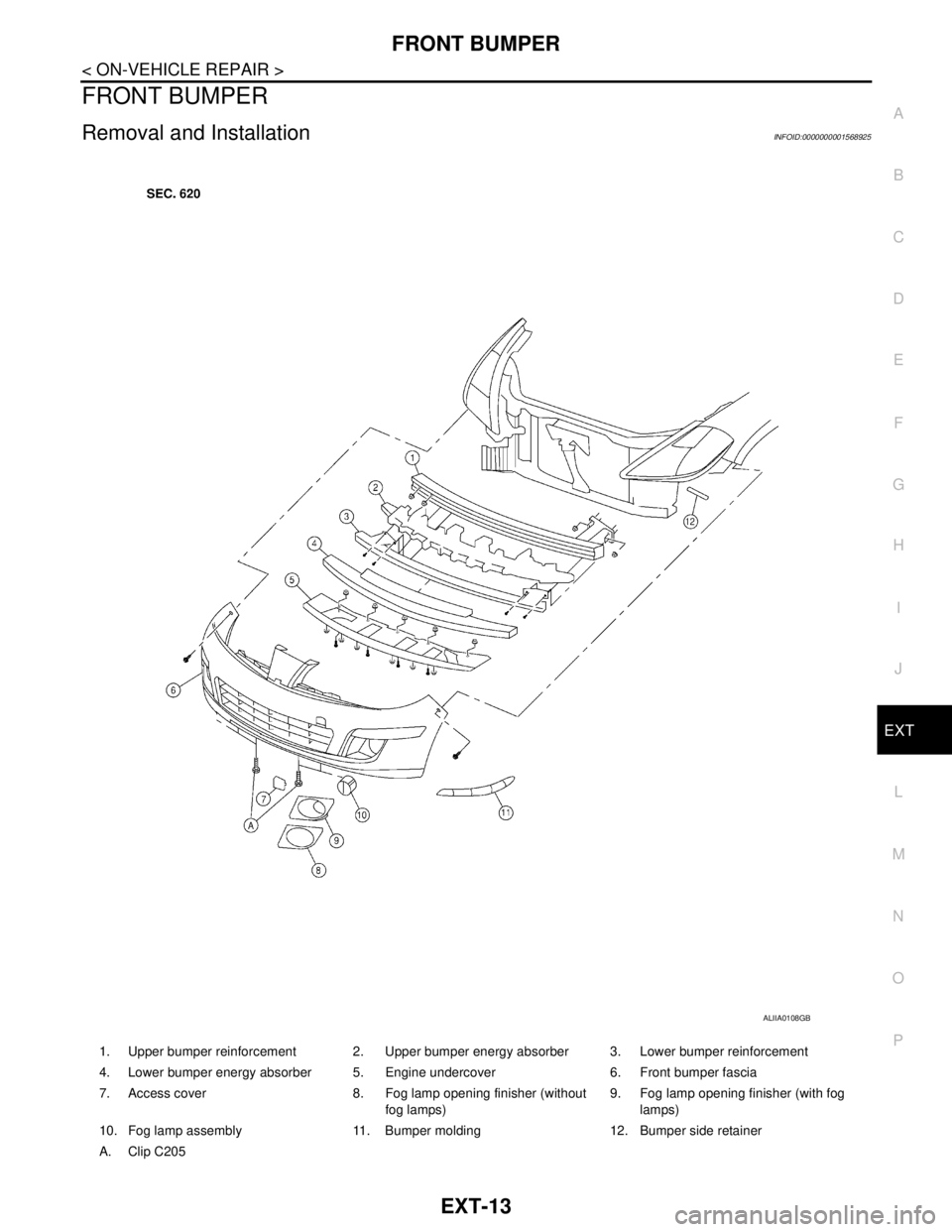

CAUTION:

Bumper fascia is made of resin. Do not apply strong force to it, and be careful to prevent contact with

oil.

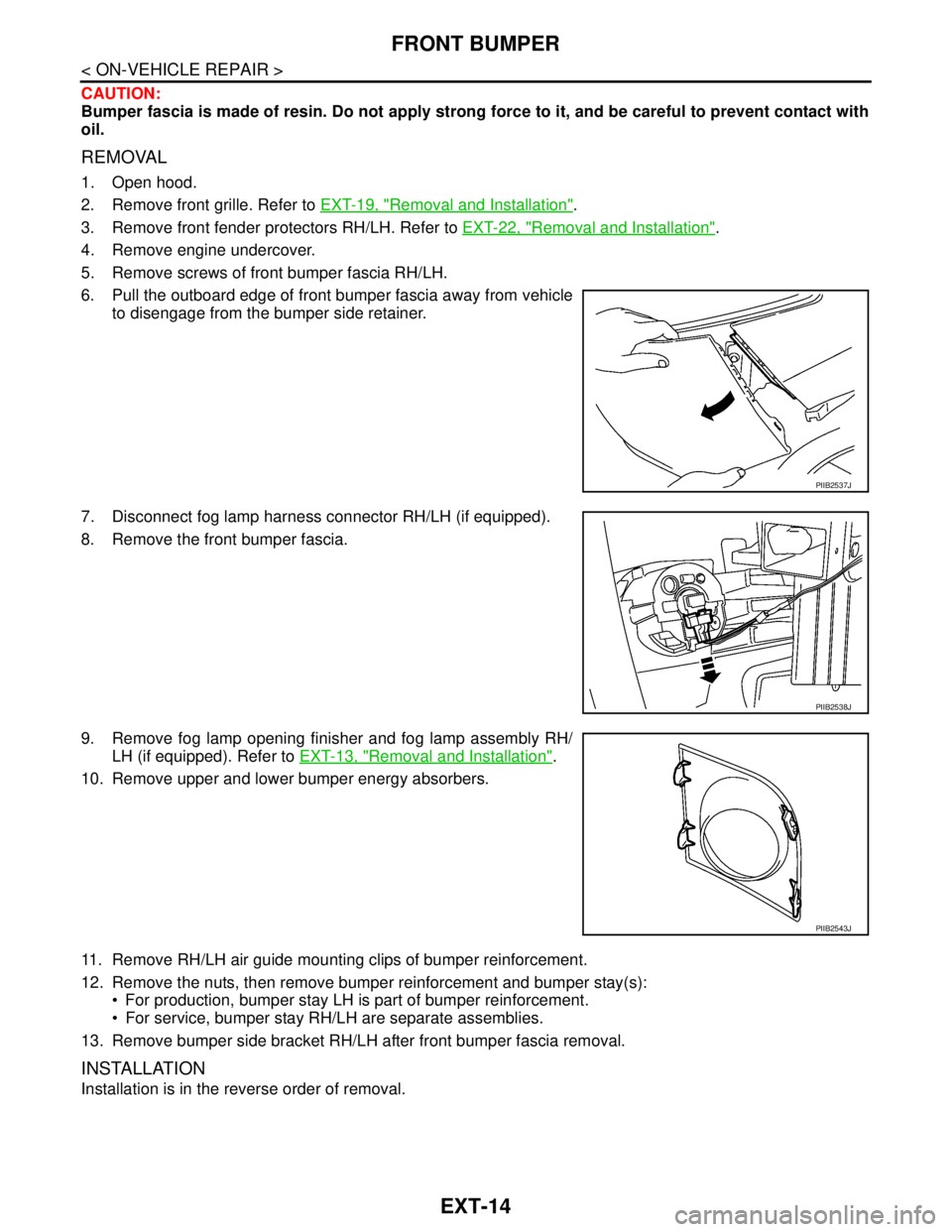

REMOVAL

1. Open hood.

2. Remove front grille. Refer to EXT-19, "

Removal and Installation".

3. Remove front fender protectors RH/LH. Refer to EXT-22, "

Removal and Installation".

4. Remove engine undercover.

5. Remove screws of front bumper fascia RH/LH.

6. Pull the outboard edge of front bumper fascia away from vehicle

to disengage from the bumper side retainer.

7. Disconnect fog lamp harness connector RH/LH (if equipped).

8. Remove the front bumper fascia.

9. Remove fog lamp opening finisher and fog lamp assembly RH/

LH (if equipped). Refer to EXT-13, "

Removal and Installation".

10. Remove upper and lower bumper energy absorbers.

11. Remove RH/LH air guide mounting clips of bumper reinforcement.

12. Remove the nuts, then remove bumper reinforcement and bumper stay(s):

For production, bumper stay LH is part of bumper reinforcement.

For service, bumper stay RH/LH are separate assemblies.

13. Remove bumper side bracket RH/LH after front bumper fascia removal.

INSTALLATION

Installation is in the reverse order of removal.

PIIB2537J

PIIB2538J

PIIB2543J

Page 3119 of 5883

REAR BUMPER

EXT-15

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

L

MA

B

EXT

N

O

P

REAR BUMPER

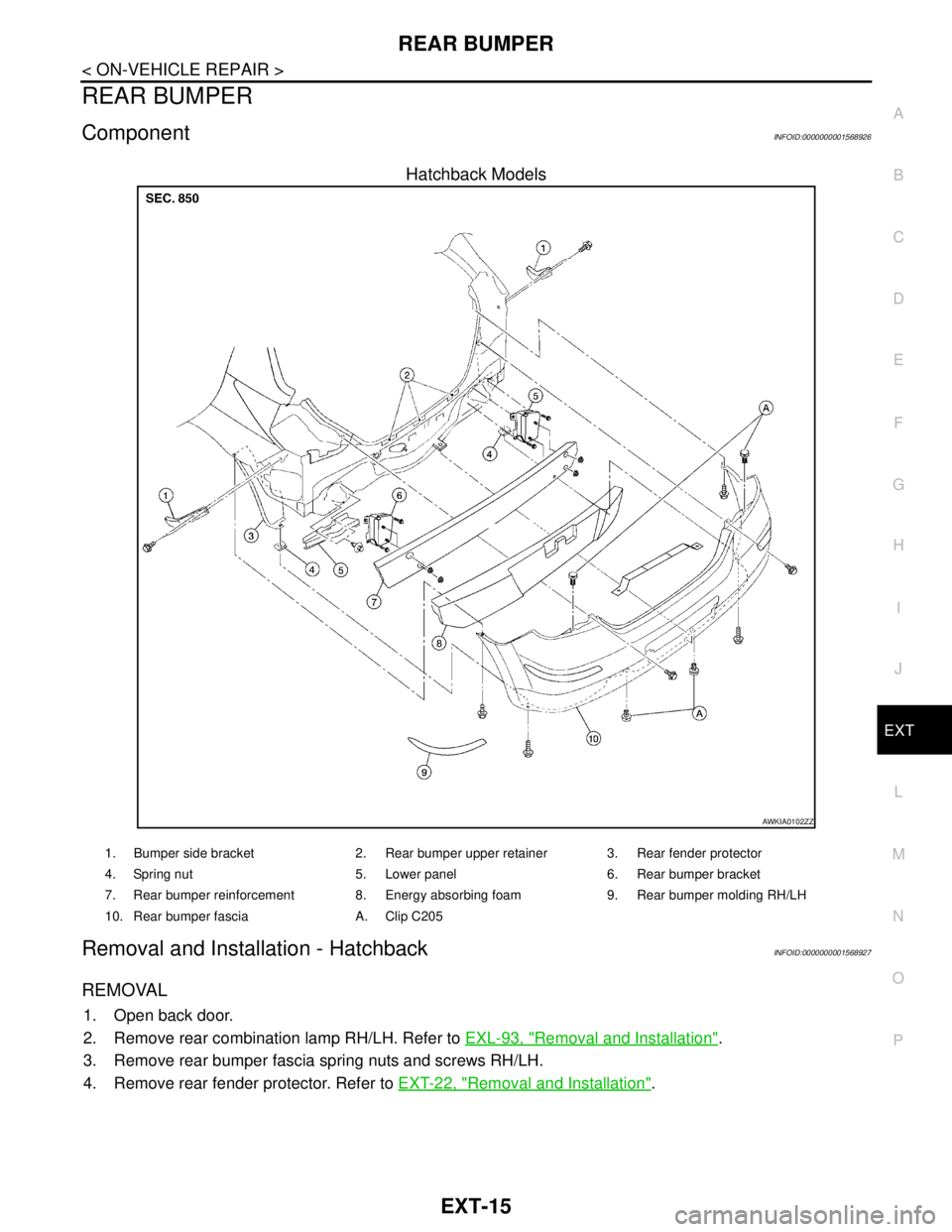

ComponentINFOID:0000000001568926

Hatchback Models

Removal and Installation - HatchbackINFOID:0000000001568927

REMOVAL

1. Open back door.

2. Remove rear combination lamp RH/LH. Refer to EXL-93, "

Removal and Installation".

3. Remove rear bumper fascia spring nuts and screws RH/LH.

4. Remove rear fender protector. Refer to EXT-22, "

Removal and Installation".

AWKIA0102ZZ

1. Bumper side bracket 2. Rear bumper upper retainer 3. Rear fender protector

4. Spring nut 5. Lower panel 6. Rear bumper bracket

7. Rear bumper reinforcement 8. Energy absorbing foam 9. Rear bumper molding RH/LH

10. Rear bumper fascia A. Clip C205