Ext NISSAN TIIDA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 3130 of 5883

EXT-26

< ON-VEHICLE REPAIR >

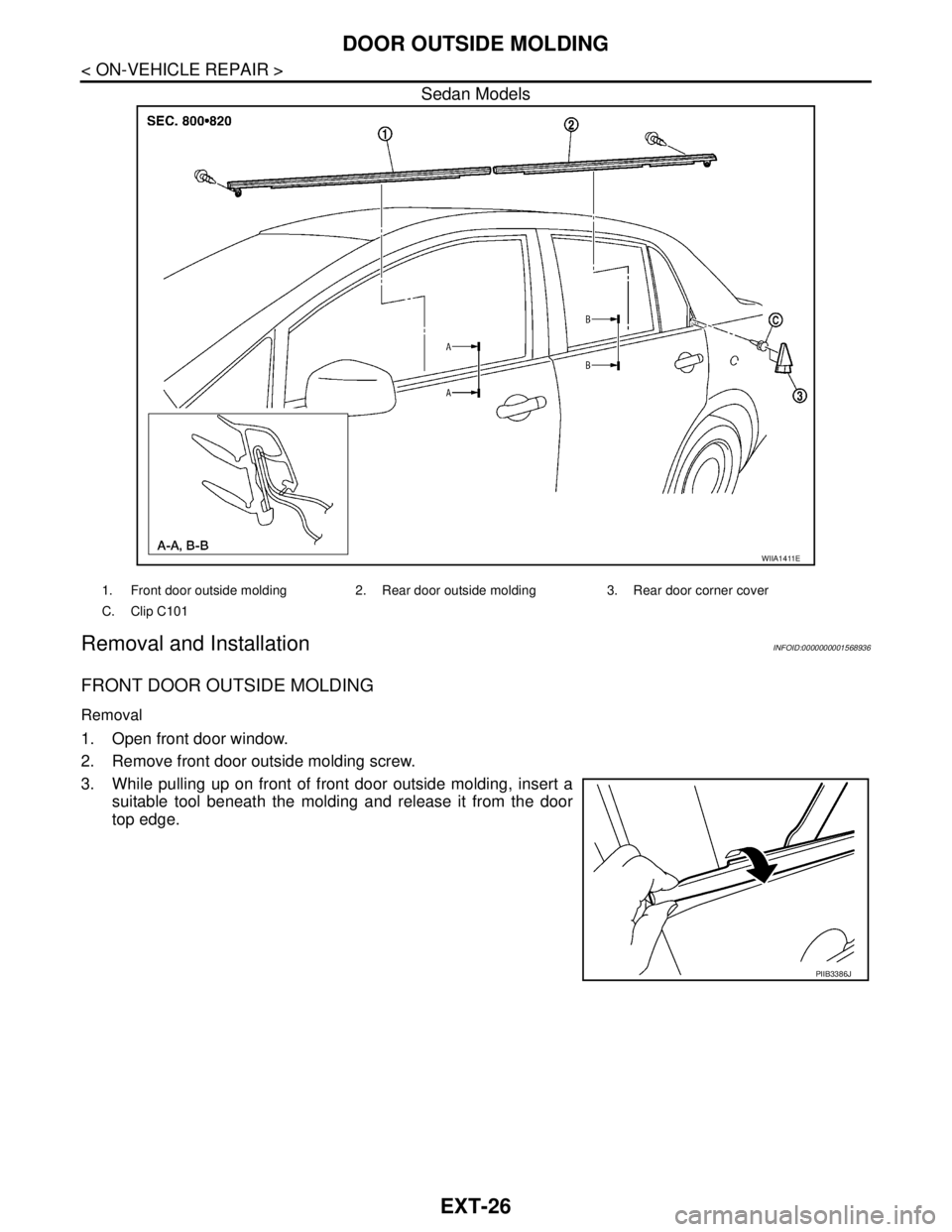

DOOR OUTSIDE MOLDING

Sedan Models

Removal and InstallationINFOID:0000000001568936

FRONT DOOR OUTSIDE MOLDING

Removal

1. Open front door window.

2. Remove front door outside molding screw.

3. While pulling up on front of front door outside molding, insert a

suitable tool beneath the molding and release it from the door

top edge.

WIIA1411E

1. Front door outside molding 2. Rear door outside molding 3. Rear door corner cover

C. Clip C101

PIIB3386J

Page 3131 of 5883

DOOR OUTSIDE MOLDING

EXT-27

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

L

MA

B

EXT

N

O

P

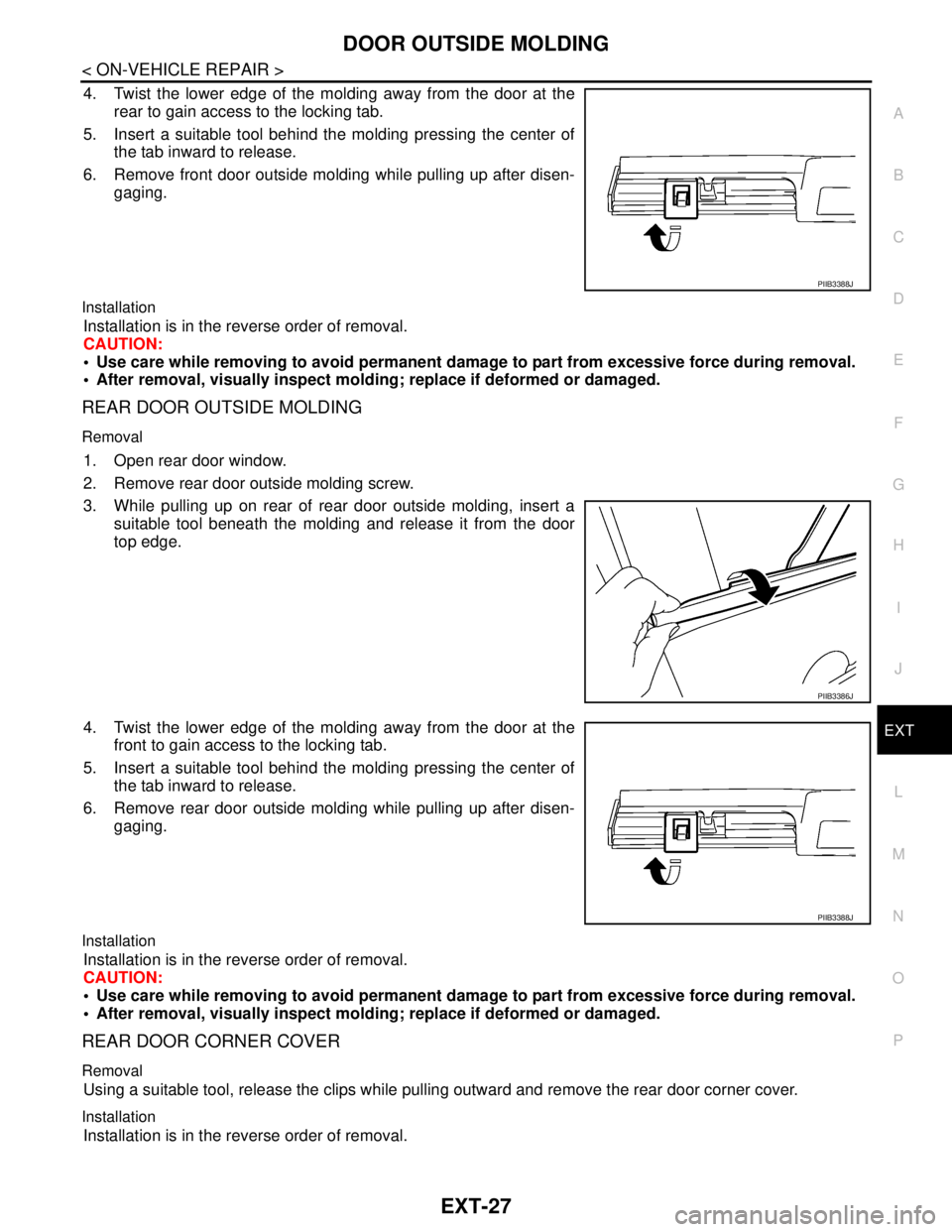

4. Twist the lower edge of the molding away from the door at the

rear to gain access to the locking tab.

5. Insert a suitable tool behind the molding pressing the center of

the tab inward to release.

6. Remove front door outside molding while pulling up after disen-

gaging.

Installation

Installation is in the reverse order of removal.

CAUTION:

Use care while removing to avoid permanent damage to part from excessive force during removal.

After removal, visually inspect molding; replace if deformed or damaged.

REAR DOOR OUTSIDE MOLDING

Removal

1. Open rear door window.

2. Remove rear door outside molding screw.

3. While pulling up on rear of rear door outside molding, insert a

suitable tool beneath the molding and release it from the door

top edge.

4. Twist the lower edge of the molding away from the door at the

front to gain access to the locking tab.

5. Insert a suitable tool behind the molding pressing the center of

the tab inward to release.

6. Remove rear door outside molding while pulling up after disen-

gaging.

Installation

Installation is in the reverse order of removal.

CAUTION:

Use care while removing to avoid permanent damage to part from excessive force during removal.

After removal, visually inspect molding; replace if deformed or damaged.

REAR DOOR CORNER COVER

Removal

Using a suitable tool, release the clips while pulling outward and remove the rear door corner cover.

Installation

Installation is in the reverse order of removal.

PIIB3388J

PIIB3386J

PIIB3388J

Page 3132 of 5883

EXT-28

< ON-VEHICLE REPAIR >

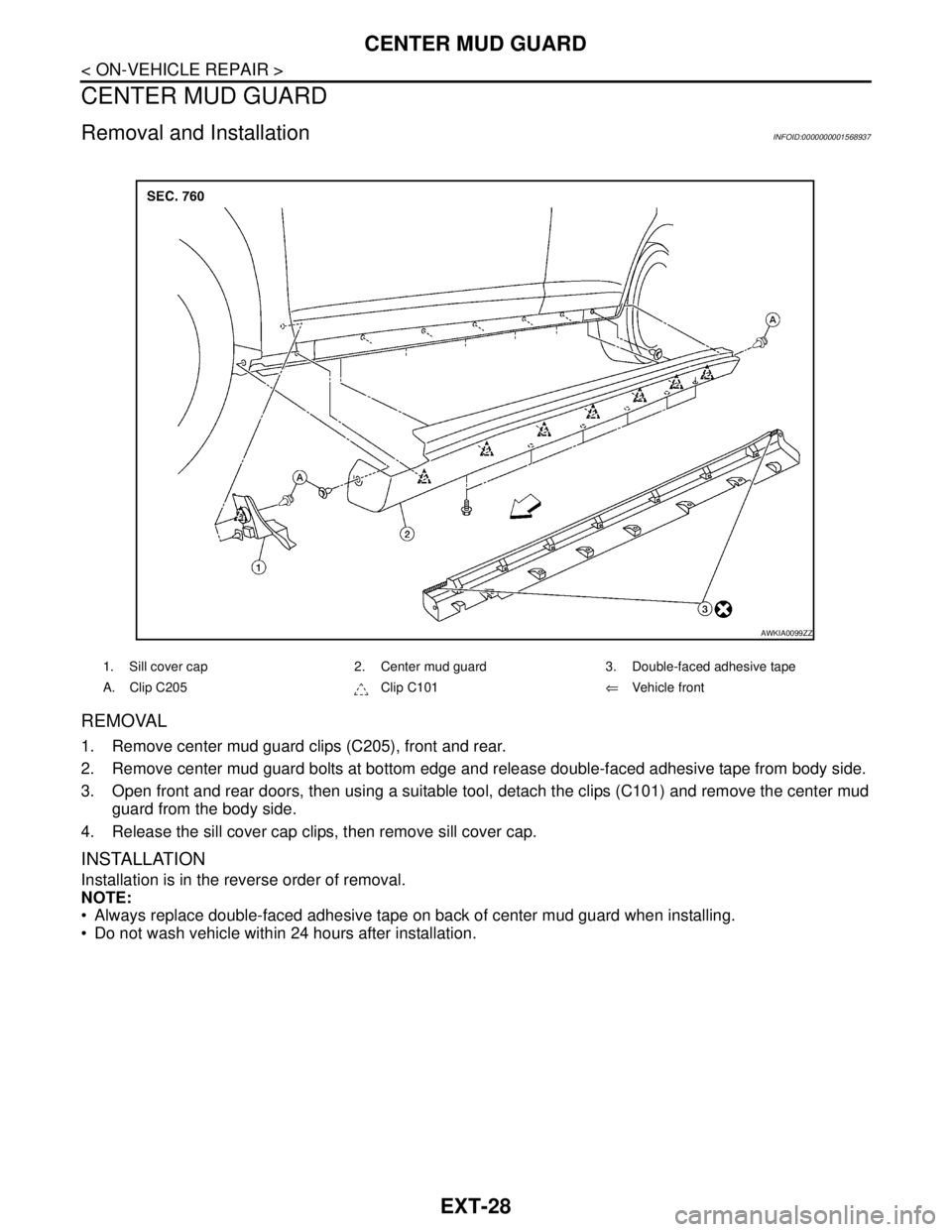

CENTER MUD GUARD

CENTER MUD GUARD

Removal and InstallationINFOID:0000000001568937

REMOVAL

1. Remove center mud guard clips (C205), front and rear.

2. Remove center mud guard bolts at bottom edge and release double-faced adhesive tape from body side.

3. Open front and rear doors, then using a suitable tool, detach the clips (C101) and remove the center mud

guard from the body side.

4. Release the sill cover cap clips, then remove sill cover cap.

INSTALLATION

Installation is in the reverse order of removal.

NOTE:

Always replace double-faced adhesive tape on back of center mud guard when installing.

Do not wash vehicle within 24 hours after installation.

1. Sill cover cap 2. Center mud guard 3. Double-faced adhesive tape

A. Clip C205 Clip C101⇐Vehicle front

AWKIA0099ZZ

Page 3133 of 5883

TRUNK LID FINISHER

EXT-29

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

L

MA

B

EXT

N

O

P

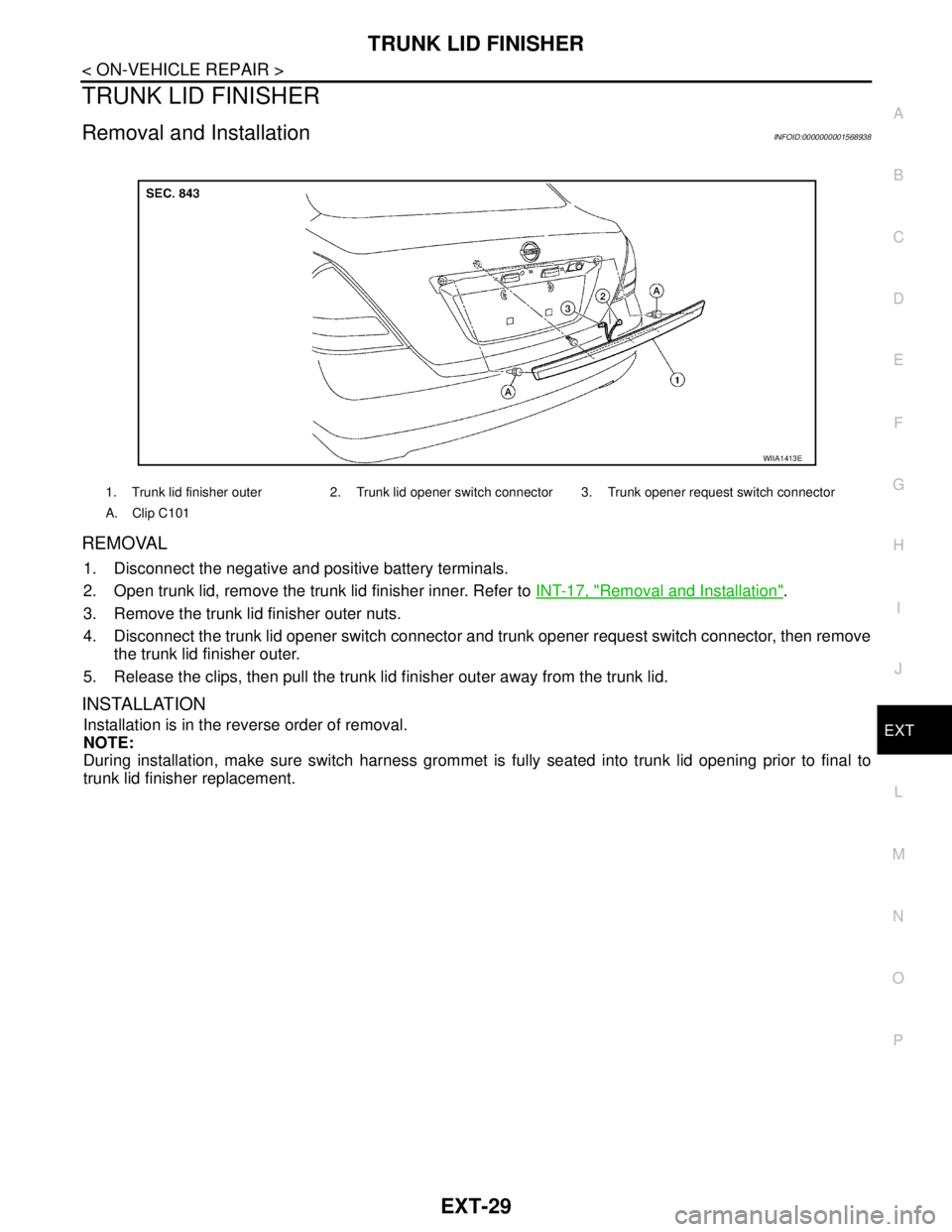

TRUNK LID FINISHER

Removal and InstallationINFOID:0000000001568938

REMOVAL

1. Disconnect the negative and positive battery terminals.

2. Open trunk lid, remove the trunk lid finisher inner. Refer to INT-17, "

Removal and Installation".

3. Remove the trunk lid finisher outer nuts.

4. Disconnect the trunk lid opener switch connector and trunk opener request switch connector, then remove

the trunk lid finisher outer.

5. Release the clips, then pull the trunk lid finisher outer away from the trunk lid.

INSTALLATION

Installation is in the reverse order of removal.

NOTE:

During installation, make sure switch harness grommet is fully seated into trunk lid opening prior to final to

trunk lid finisher replacement.

1. Trunk lid finisher outer 2. Trunk lid opener switch connector 3. Trunk opener request switch connector

A. Clip C101

WIIA1413E

Page 3134 of 5883

EXT-30

< ON-VEHICLE REPAIR >

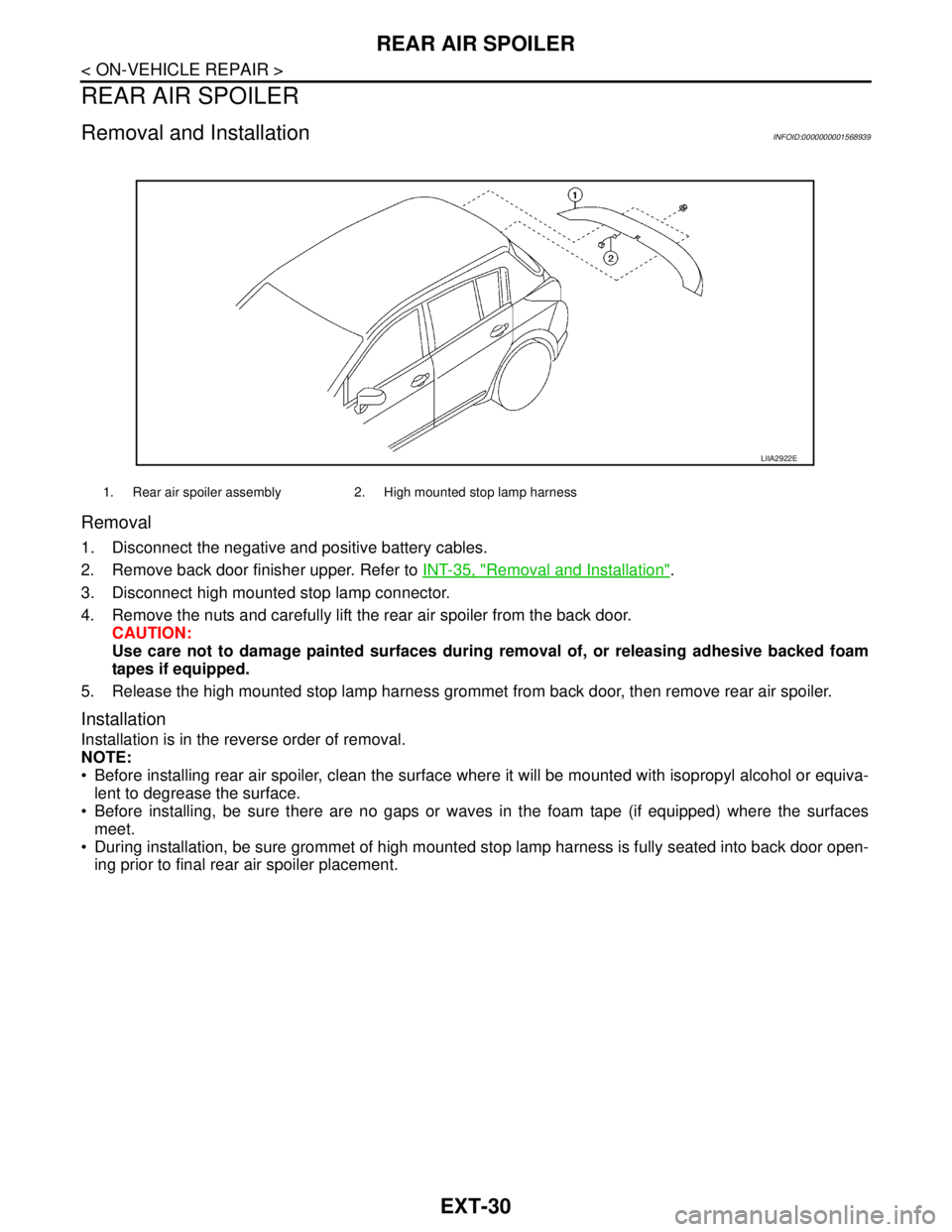

REAR AIR SPOILER

REAR AIR SPOILER

Removal and InstallationINFOID:0000000001568939

Removal

1. Disconnect the negative and positive battery cables.

2. Remove back door finisher upper. Refer to INT-35, "

Removal and Installation".

3. Disconnect high mounted stop lamp connector.

4. Remove the nuts and carefully lift the rear air spoiler from the back door.

CAUTION:

Use care not to damage painted surfaces during removal of, or releasing adhesive backed foam

tapes if equipped.

5. Release the high mounted stop lamp harness grommet from back door, then remove rear air spoiler.

Installation

Installation is in the reverse order of removal.

NOTE:

Before installing rear air spoiler, clean the surface where it will be mounted with isopropyl alcohol or equiva-

lent to degrease the surface.

Before installing, be sure there are no gaps or waves in the foam tape (if equipped) where the surfaces

meet.

During installation, be sure grommet of high mounted stop lamp harness is fully seated into back door open-

ing prior to final rear air spoiler placement.

1. Rear air spoiler assembly 2. High mounted stop lamp harness

LIIA2922E

Page 3142 of 5883

FAX-8

< REMOVAL AND INSTALLATION >

FRONT WHEEL HUB AND KNUCKLE

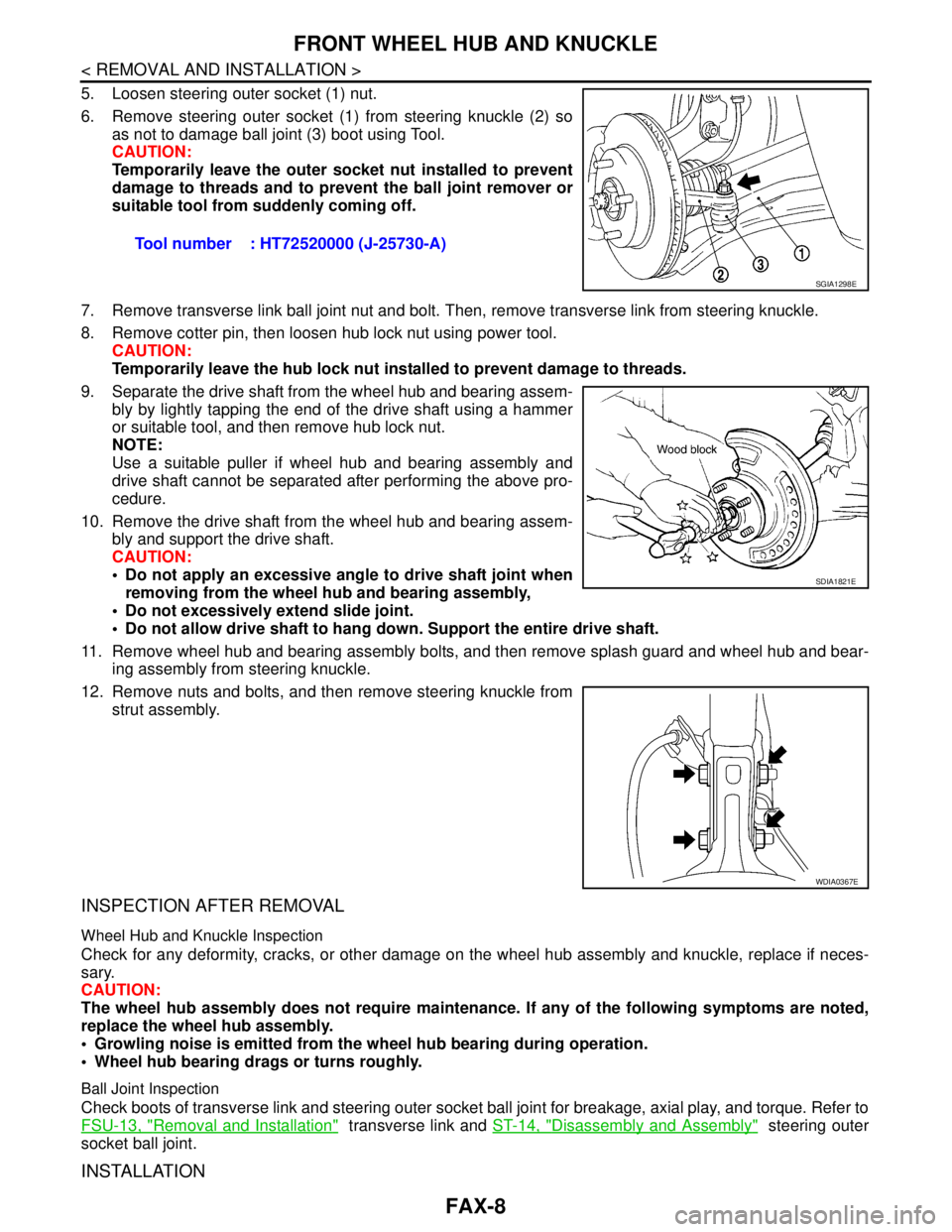

5. Loosen steering outer socket (1) nut.

6. Remove steering outer socket (1) from steering knuckle (2) so

as not to damage ball joint (3) boot using Tool.

CAUTION:

Temporarily leave the outer socket nut installed to prevent

damage to threads and to prevent the ball joint remover or

suitable tool from suddenly coming off.

7. Remove transverse link ball joint nut and bolt. Then, remove transverse link from steering knuckle.

8. Remove cotter pin, then loosen hub lock nut using power tool.

CAUTION:

Temporarily leave the hub lock nut installed to prevent damage to threads.

9. Separate the drive shaft from the wheel hub and bearing assem-

bly by lightly tapping the end of the drive shaft using a hammer

or suitable tool, and then remove hub lock nut.

NOTE:

Use a suitable puller if wheel hub and bearing assembly and

drive shaft cannot be separated after performing the above pro-

cedure.

10. Remove the drive shaft from the wheel hub and bearing assem-

bly and support the drive shaft.

CAUTION:

Do not apply an excessive angle to drive shaft joint when

removing from the wheel hub and bearing assembly,

Do not excessively extend slide joint.

Do not allow drive shaft to hang down. Support the entire drive shaft.

11. Remove wheel hub and bearing assembly bolts, and then remove splash guard and wheel hub and bear-

ing assembly from steering knuckle.

12. Remove nuts and bolts, and then remove steering knuckle from

strut assembly.

INSPECTION AFTER REMOVAL

Wheel Hub and Knuckle Inspection

Check for any deformity, cracks, or other damage on the wheel hub assembly and knuckle, replace if neces-

sary.

CAUTION:

The wheel hub assembly does not require maintenance. If any of the following symptoms are noted,

replace the wheel hub assembly.

Growling noise is emitted from the wheel hub bearing during operation.

Wheel hub bearing drags or turns roughly.

Ball Joint Inspection

Check boots of transverse link and steering outer socket ball joint for breakage, axial play, and torque. Refer to

FSU-13, "

Removal and Installation" transverse link and ST-14, "Disassembly and Assembly" steering outer

socket ball joint.

INSTALLATION

Tool number : HT72520000 (J-25730-A)

SGIA1298E

SDIA1821E

WDIA0367E

Page 3144 of 5883

FAX-10

< REMOVAL AND INSTALLATION >

FRONT DRIVE SHAFT

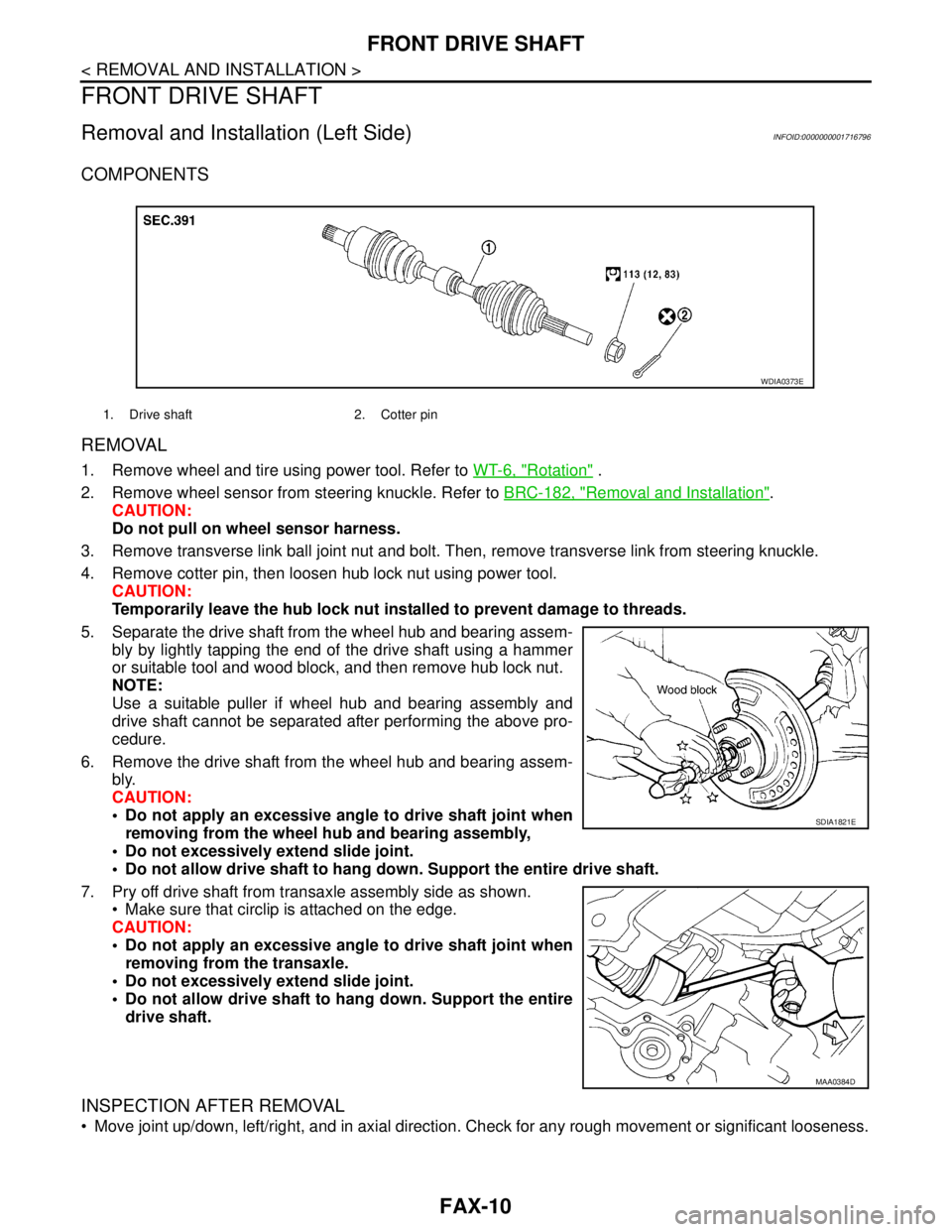

FRONT DRIVE SHAFT

Removal and Installation (Left Side)INFOID:0000000001716796

COMPONENTS

REMOVAL

1. Remove wheel and tire using power tool. Refer to WT-6, "Rotation" .

2. Remove wheel sensor from steering knuckle. Refer to BRC-182, "

Removal and Installation".

CAUTION:

Do not pull on wheel sensor harness.

3. Remove transverse link ball joint nut and bolt. Then, remove transverse link from steering knuckle.

4. Remove cotter pin, then loosen hub lock nut using power tool.

CAUTION:

Temporarily leave the hub lock nut installed to prevent damage to threads.

5. Separate the drive shaft from the wheel hub and bearing assem-

bly by lightly tapping the end of the drive shaft using a hammer

or suitable tool and wood block, and then remove hub lock nut.

NOTE:

Use a suitable puller if wheel hub and bearing assembly and

drive shaft cannot be separated after performing the above pro-

cedure.

6. Remove the drive shaft from the wheel hub and bearing assem-

bly.

CAUTION:

Do not apply an excessive angle to drive shaft joint when

removing from the wheel hub and bearing assembly,

Do not excessively extend slide joint.

Do not allow drive shaft to hang down. Support the entire drive shaft.

7. Pry off drive shaft from transaxle assembly side as shown.

Make sure that circlip is attached on the edge.

CAUTION:

Do not apply an excessive angle to drive shaft joint when

removing from the transaxle.

Do not excessively extend slide joint.

Do not allow drive shaft to hang down. Support the entire

drive shaft.

INSPECTION AFTER REMOVAL

Move joint up/down, left/right, and in axial direction. Check for any rough movement or significant looseness.

1. Drive shaft 2. Cotter pin

WDIA0373E

SDIA1821E

MAA0384D

Page 3146 of 5883

FAX-12

< REMOVAL AND INSTALLATION >

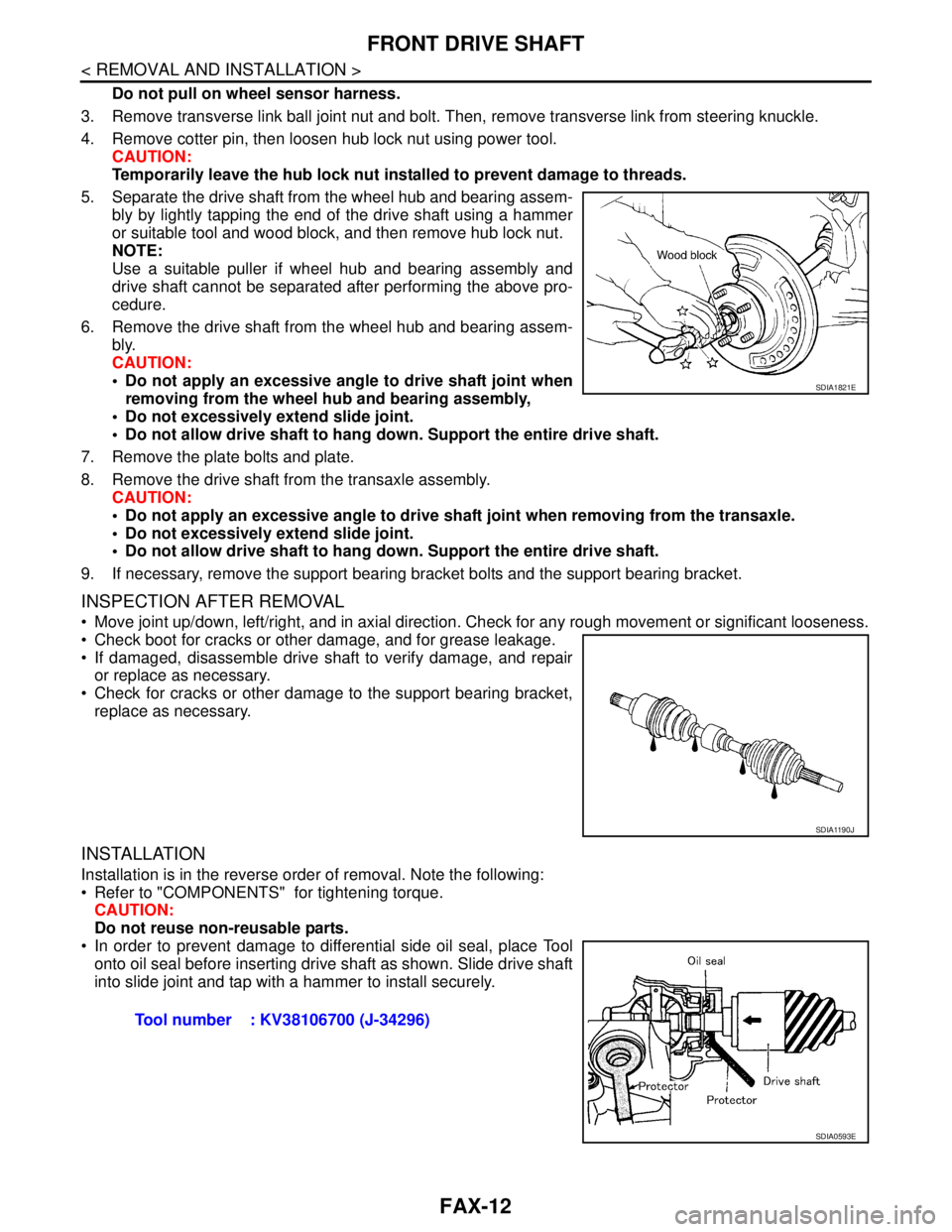

FRONT DRIVE SHAFT

Do not pull on wheel sensor harness.

3. Remove transverse link ball joint nut and bolt. Then, remove transverse link from steering knuckle.

4. Remove cotter pin, then loosen hub lock nut using power tool.

CAUTION:

Temporarily leave the hub lock nut installed to prevent damage to threads.

5. Separate the drive shaft from the wheel hub and bearing assem-

bly by lightly tapping the end of the drive shaft using a hammer

or suitable tool and wood block, and then remove hub lock nut.

NOTE:

Use a suitable puller if wheel hub and bearing assembly and

drive shaft cannot be separated after performing the above pro-

cedure.

6. Remove the drive shaft from the wheel hub and bearing assem-

bly.

CAUTION:

Do not apply an excessive angle to drive shaft joint when

removing from the wheel hub and bearing assembly,

Do not excessively extend slide joint.

Do not allow drive shaft to hang down. Support the entire drive shaft.

7. Remove the plate bolts and plate.

8. Remove the drive shaft from the transaxle assembly.

CAUTION:

Do not apply an excessive angle to drive shaft joint when removing from the transaxle.

Do not excessively extend slide joint.

Do not allow drive shaft to hang down. Support the entire drive shaft.

9. If necessary, remove the support bearing bracket bolts and the support bearing bracket.

INSPECTION AFTER REMOVAL

Move joint up/down, left/right, and in axial direction. Check for any rough movement or significant looseness.

Check boot for cracks or other damage, and for grease leakage.

If damaged, disassemble drive shaft to verify damage, and repair

or replace as necessary.

Check for cracks or other damage to the support bearing bracket,

replace as necessary.

INSTALLATION

Installation is in the reverse order of removal. Note the following:

Refer to "COMPONENTS" for tightening torque.

CAUTION:

Do not reuse non-reusable parts.

In order to prevent damage to differential side oil seal, place Tool

onto oil seal before inserting drive shaft as shown. Slide drive shaft

into slide joint and tap with a hammer to install securely.

SDIA1821E

SDIA1190J

Tool number : KV38106700 (J-34296)

SDIA0593E

Page 3164 of 5883

FL-4

< ON-VEHICLE MAINTENANCE >

FUEL SYSTEM

ON-VEHICLE MAINTENANCE

FUEL SYSTEM

Checking Fuel LineINFOID:0000000001722976

Inspect fuel lines, fuel filler cap and fuel tank for improper attach-

ment, leaks, cracks, damage, loose connections, chafing or deterio-

ration.

If necessary, repair or replace damaged parts.

General PrecautionINFOID:0000000001722977

WARNING:

When replacing fuel line parts, be sure to observe the following.

Put a “CAUTION: FLAMMABLE” sign in the work area.

Be sure to work in a well ventilated area and have a CO

2 fire extinguisher.

Do not smoke while working on the fuel system. Keep open flames and sparks away from the work

area.

Put drained fuel in an explosion-proof container and put the lid on securely. Keep the container in

safe area.

CAUTION:

Use gasoline required by the regulations for octane number. Refer to GI-45, "

Precaution for Fuel

(Unleaded Regular Gasoline Recommended)".

Before removing fuel line parts, perform the following procedures:

- Release fuel pressure from the fuel lines if necessary. Refer to EC-379, "

Inspection" (HR16DE with

Euro-OBD), EC-681, "

Inspection" (HR16DE without Euro-OBD), EC-1035, "Inspection" (MR18DE).

- Disconnect the battery ground cable.

Always replace O-rings and clamps with new ones.

Do not kink or twist tubes when they are being installed.

Perform work on level surface.

Do not tighten hose clamps excessively to avoid damaging hoses.

After connecting fuel tube quick connectors, make sure quick connectors are secure.

Ensure that connector and resin tube do not contact any adjacent parts.

After installing tubes, make sure there is no fuel leakage at connections in the following steps.

- Apply fuel pressure to fuel lines by turning ignition switch ON (without starting the engine). Then

check for fuel leaks at the fuel tube connections.

- Start engine and rev it up and check for fuel leaks at connections.

Use only a genuine NISSAN fuel filler cap as a replacement. If an incorrect fuel filler cap is used, the

MIL may come on.

For servicing “Evaporative Emission System” parts, refer to EC-379, "

Inspection" (HR16DE with

Euro-OBD), EC-683, "

Inspection" (HR16DE without Euro-OBD), EC-1037, "Inspection" (MR18DE).

SMA803A

Page 3188 of 5883

FSU-12

< REMOVAL AND INSTALLATION >

COIL SPRING AND STRUT

COIL SPRING AND STRUT

Removal and InstallationINFOID:0000000001716888

REMOVAL

1. Remove cowl top panel. Refer to EXT-20, "Removal and Installation" .

2. Remove front tires using power tool.

3. Remove harness of wheel sensor from strut assembly. Refer to BRC-182, "

Removal and Installation" .

CAUTION:

Do not pull on wheel sensor harness.

4. Remove brake hose lock plate. Refer to BR-14, "

Front Brake Tube and Hose" .

5. Remove the nut on the upper side of stabilizer connecting rod using power tool, and then remove stabi-

lizer connecting rod from strut assembly.

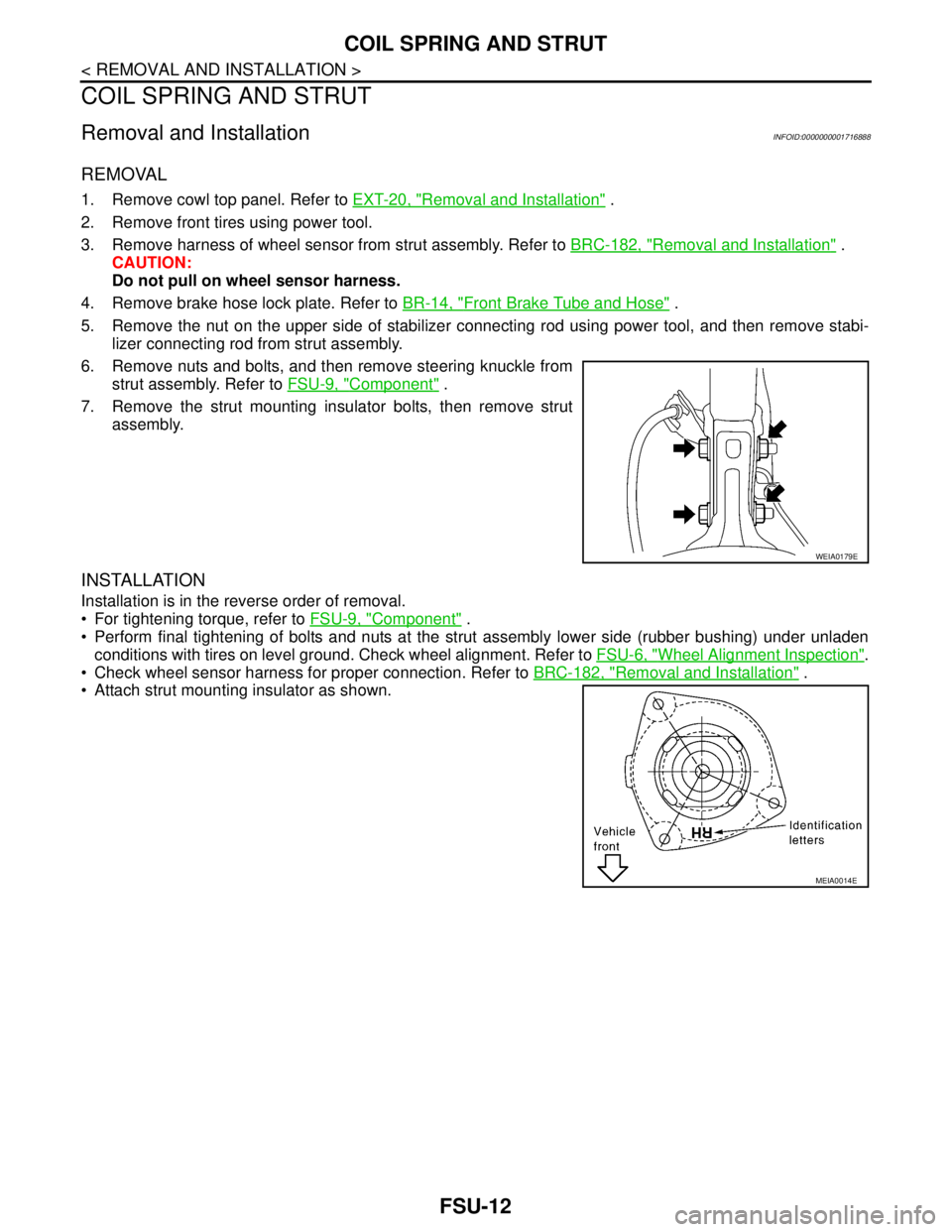

6. Remove nuts and bolts, and then remove steering knuckle from

strut assembly. Refer to FSU-9, "

Component" .

7. Remove the strut mounting insulator bolts, then remove strut

assembly.

INSTALLATION

Installation is in the reverse order of removal.

For tightening torque, refer to FSU-9, "

Component" .

Perform final tightening of bolts and nuts at the strut assembly lower side (rubber bushing) under unladen

conditions with tires on level ground. Check wheel alignment. Refer to FSU-6, "

Wheel Alignment Inspection".

Check wheel sensor harness for proper connection. Refer to BRC-182, "

Removal and Installation" .

Attach strut mounting insulator as shown.

WEIA0179E

MEIA0014E