Ext NISSAN TIIDA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 3323 of 5883

HIGH-PRESSURE FLEXIBLE HOSE

HA-41

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

J

K

L

MA

B

HA

N

O

P

HIGH-PRESSURE FLEXIBLE HOSE

Removal and Installation of High-Pressure Flexible Hose - MR18DE, HR16DE

INFOID:0000000001404151

REMOVAL

1. Use the recovery/recycling equipment to evacuate the refrigerant. Refer to HA-21, "HFC-134a (R-134a)

Service Procedure".

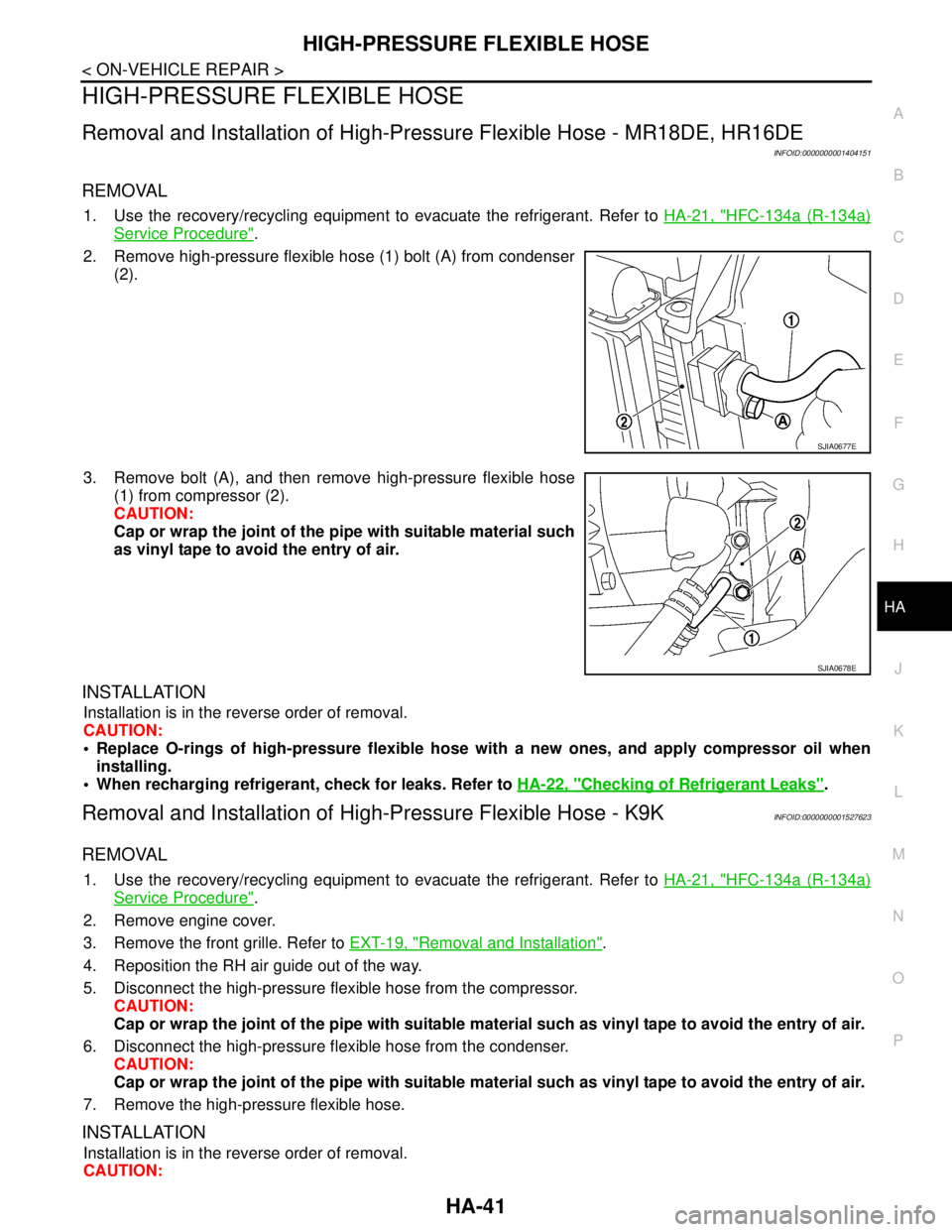

2. Remove high-pressure flexible hose (1) bolt (A) from condenser

(2).

3. Remove bolt (A), and then remove high-pressure flexible hose

(1) from compressor (2).

CAUTION:

Cap or wrap the joint of the pipe with suitable material such

as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Replace O-rings of high-pressure flexible hose with a new ones, and apply compressor oil when

installing.

When recharging refrigerant, check for leaks. Refer to HA-22, "

Checking of Refrigerant Leaks".

Removal and Installation of High-Pressure Flexible Hose - K9KINFOID:0000000001527623

REMOVAL

1. Use the recovery/recycling equipment to evacuate the refrigerant. Refer to HA-21, "HFC-134a (R-134a)

Service Procedure".

2. Remove engine cover.

3. Remove the front grille. Refer to EXT-19, "

Removal and Installation".

4. Reposition the RH air guide out of the way.

5. Disconnect the high-pressure flexible hose from the compressor.

CAUTION:

Cap or wrap the joint of the pipe with suitable material such as vinyl tape to avoid the entry of air.

6. Disconnect the high-pressure flexible hose from the condenser.

CAUTION:

Cap or wrap the joint of the pipe with suitable material such as vinyl tape to avoid the entry of air.

7. Remove the high-pressure flexible hose.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

SJIA0677E

SJIA0678E

Page 3325 of 5883

HIGH-PRESSURE PIPE

HA-43

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

J

K

L

MA

B

HA

N

O

P

HIGH-PRESSURE PIPE

Removal and Installation of High-Pressure Pipe - MR18DE, HR16DEINFOID:0000000001404219

REMOVAL

1. Remove low-pressure flexible hose. Refer to HA-38, "Removal and Installation of Low-Pressure Flexible

Hose - MR18DE, HR16DE".

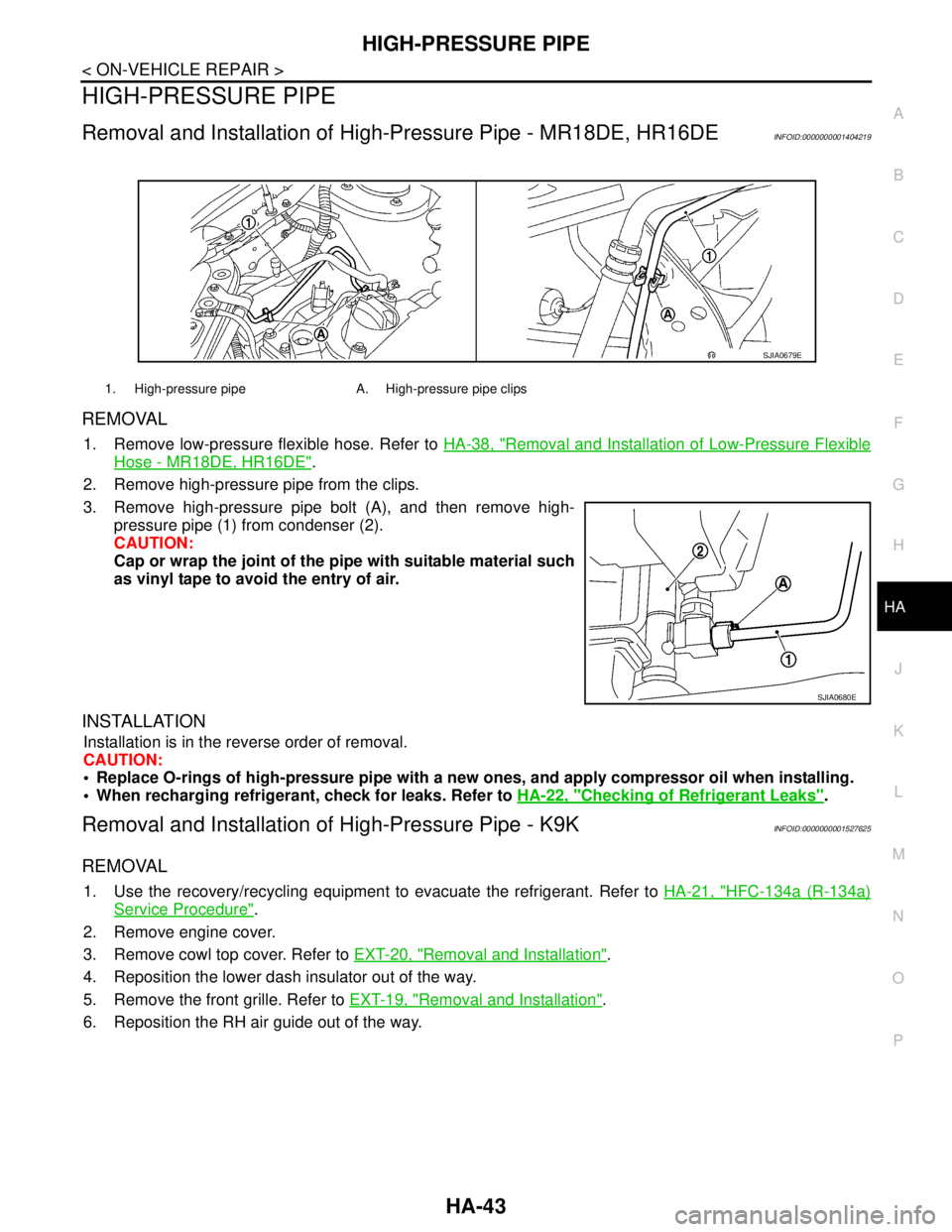

2. Remove high-pressure pipe from the clips.

3. Remove high-pressure pipe bolt (A), and then remove high-

pressure pipe (1) from condenser (2).

CAUTION:

Cap or wrap the joint of the pipe with suitable material such

as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Replace O-rings of high-pressure pipe with a new ones, and apply compressor oil when installing.

When recharging refrigerant, check for leaks. Refer to HA-22, "

Checking of Refrigerant Leaks".

Removal and Installation of High-Pressure Pipe - K9KINFOID:0000000001527625

REMOVAL

1. Use the recovery/recycling equipment to evacuate the refrigerant. Refer to HA-21, "HFC-134a (R-134a)

Service Procedure".

2. Remove engine cover.

3. Remove cowl top cover. Refer to EXT-20, "

Removal and Installation".

4. Reposition the lower dash insulator out of the way.

5. Remove the front grille. Refer to EXT-19, "

Removal and Installation".

6. Reposition the RH air guide out of the way.

1. High-pressure pipe A. High-pressure pipe clips

SJIA0679E

SJIA0680E

Page 3327 of 5883

CONDENSER

HA-45

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

J

K

L

MA

B

HA

N

O

P

CONDENSER

Removal and Installation of Condenser - MR18DE, HR16DEINFOID:0000000001527646

REMOVAL

1. Use the recovery/recycling equipment to evacuate the refrigerant. Refer to HA-21, "HFC-134a (R-134a)

Service Procedure".

2. Remove the three upper headlamp bolts to reposition the headlamps out of the way

3. Remove the radiator core support upper.

4. Disconnect the high-pressure flexible hose and high-pressure pipe from condenser.

CAUTION:

Cap or wrap the joint of the pipe with suitable material such as vinyl tape to avoid the entry of air.

5. Disconnect refrigerant pressure sensor connector.

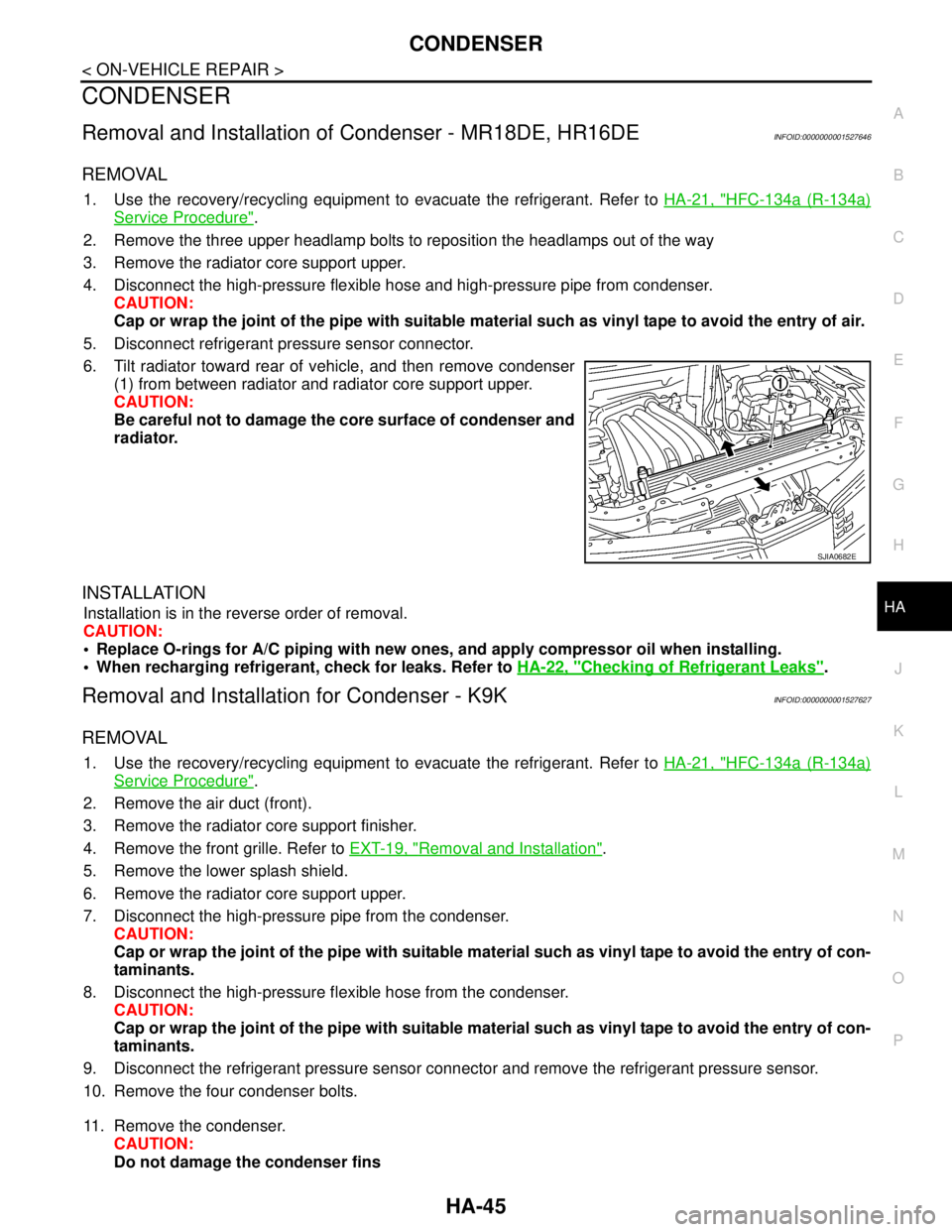

6. Tilt radiator toward rear of vehicle, and then remove condenser

(1) from between radiator and radiator core support upper.

CAUTION:

Be careful not to damage the core surface of condenser and

radiator.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Replace O-rings for A/C piping with new ones, and apply compressor oil when installing.

When recharging refrigerant, check for leaks. Refer to HA-22, "

Checking of Refrigerant Leaks".

Removal and Installation for Condenser - K9KINFOID:0000000001527627

REMOVAL

1. Use the recovery/recycling equipment to evacuate the refrigerant. Refer to HA-21, "HFC-134a (R-134a)

Service Procedure".

2. Remove the air duct (front).

3. Remove the radiator core support finisher.

4. Remove the front grille. Refer to EXT-19, "

Removal and Installation".

5. Remove the lower splash shield.

6. Remove the radiator core support upper.

7. Disconnect the high-pressure pipe from the condenser.

CAUTION:

Cap or wrap the joint of the pipe with suitable material such as vinyl tape to avoid the entry of con-

taminants.

8. Disconnect the high-pressure flexible hose from the condenser.

CAUTION:

Cap or wrap the joint of the pipe with suitable material such as vinyl tape to avoid the entry of con-

taminants.

9. Disconnect the refrigerant pressure sensor connector and remove the refrigerant pressure sensor.

10. Remove the four condenser bolts.

11. Remove the condenser.

CAUTION:

Do not damage the condenser fins

SJIA0682E

Page 3329 of 5883

AMBIENT SENSOR

HA-47

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

J

K

L

MA

B

HA

N

O

P

AMBIENT SENSOR

Removal and Installation of Ambient Sensor - MR18DE, HR16DE and K9KINFOID:0000000001696506

NOTE:

Vehicles with automatic A/C systems and manual A/C system with a PTC heater are equipped with a ambient

sensor.

REMOVAL

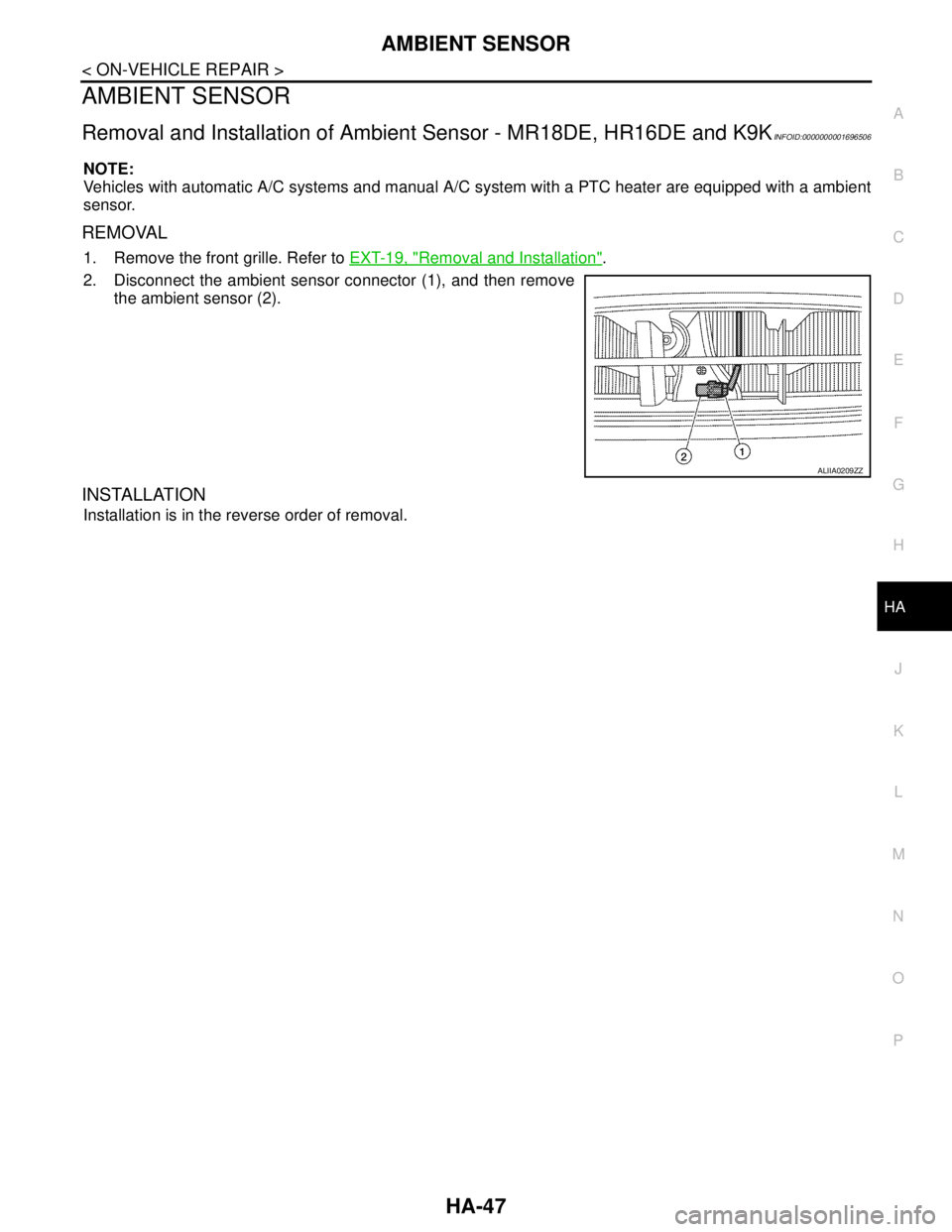

1. Remove the front grille. Refer to EXT-19, "Removal and Installation".

2. Disconnect the ambient sensor connector (1), and then remove

the ambient sensor (2).

INSTALLATION

Installation is in the reverse order of removal.

ALIIA0209ZZ

Page 3330 of 5883

HA-48

< ON-VEHICLE REPAIR >

REFRIGERANT PRESSURE SENSOR

REFRIGERANT PRESSURE SENSOR

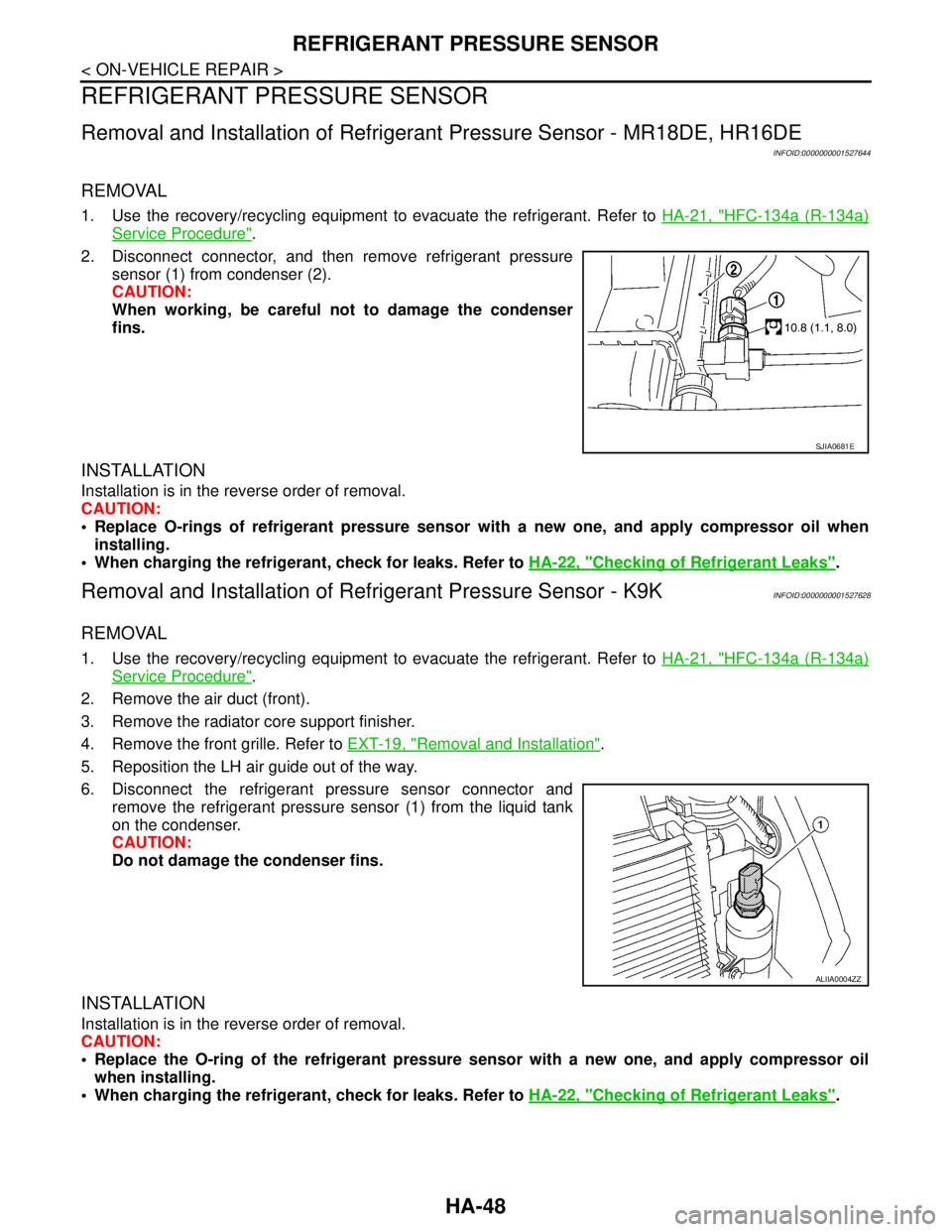

Removal and Installation of Refrigerant Pressure Sensor - MR18DE, HR16DE

INFOID:0000000001527644

REMOVAL

1. Use the recovery/recycling equipment to evacuate the refrigerant. Refer to HA-21, "HFC-134a (R-134a)

Service Procedure".

2. Disconnect connector, and then remove refrigerant pressure

sensor (1) from condenser (2).

CAUTION:

When working, be careful not to damage the condenser

fins.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Replace O-rings of refrigerant pressure sensor with a new one, and apply compressor oil when

installing.

When charging the refrigerant, check for leaks. Refer to HA-22, "

Checking of Refrigerant Leaks".

Removal and Installation of Refrigerant Pressure Sensor - K9KINFOID:0000000001527628

REMOVAL

1. Use the recovery/recycling equipment to evacuate the refrigerant. Refer to HA-21, "HFC-134a (R-134a)

Service Procedure".

2. Remove the air duct (front).

3. Remove the radiator core support finisher.

4. Remove the front grille. Refer to EXT-19, "

Removal and Installation".

5. Reposition the LH air guide out of the way.

6. Disconnect the refrigerant pressure sensor connector and

remove the refrigerant pressure sensor (1) from the liquid tank

on the condenser.

CAUTION:

Do not damage the condenser fins.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Replace the O-ring of the refrigerant pressure sensor with a new one, and apply compressor oil

when installing.

When charging the refrigerant, check for leaks. Refer to HA-22, "

Checking of Refrigerant Leaks".

SJIA0681E

ALIIA0004ZZ

Page 3331 of 5883

EXPANSION VALVE

HA-49

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

J

K

L

MA

B

HA

N

O

P

EXPANSION VALVE

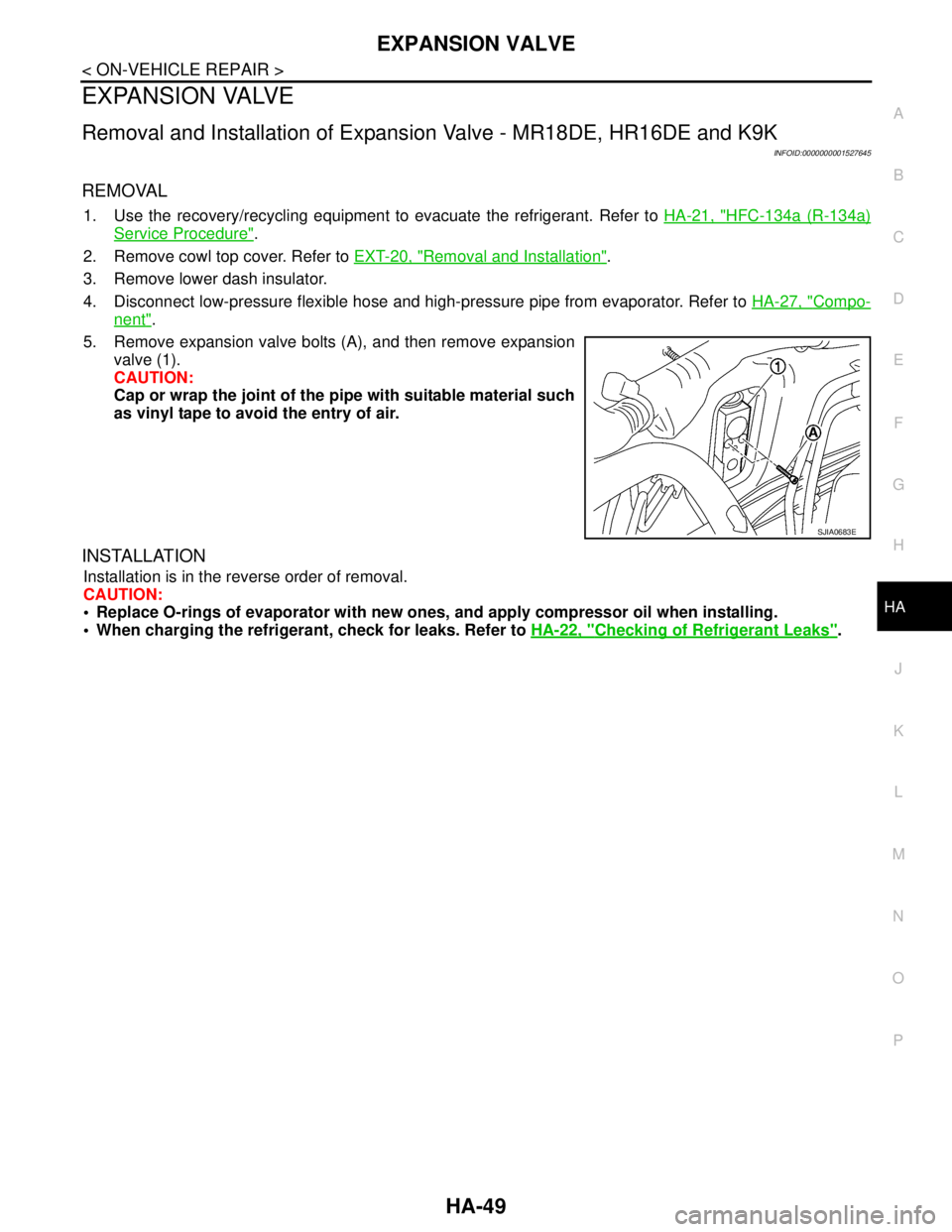

Removal and Installation of Expansion Valve - MR18DE, HR16DE and K9K

INFOID:0000000001527645

REMOVAL

1. Use the recovery/recycling equipment to evacuate the refrigerant. Refer to HA-21, "HFC-134a (R-134a)

Service Procedure".

2. Remove cowl top cover. Refer to EXT-20, "

Removal and Installation".

3. Remove lower dash insulator.

4. Disconnect low-pressure flexible hose and high-pressure pipe from evaporator. Refer to HA-27, "

Compo-

nent".

5. Remove expansion valve bolts (A), and then remove expansion

valve (1).

CAUTION:

Cap or wrap the joint of the pipe with suitable material such

as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Replace O-rings of evaporator with new ones, and apply compressor oil when installing.

When charging the refrigerant, check for leaks. Refer to HA-22, "

Checking of Refrigerant Leaks".

SJIA0683E

Page 3412 of 5883

![NISSAN TIIDA 2007 Service Repair Manual INSUFFICIENT COOLING

HAC-79

< SYMPTOM DIAGNOSIS >[MANUAL AIR CONDITIONER]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P Low-pressure Side Sometimes Becomes Negative

Low-pressure Side Becomes Negative

Gauge indicat NISSAN TIIDA 2007 Service Repair Manual INSUFFICIENT COOLING

HAC-79

< SYMPTOM DIAGNOSIS >[MANUAL AIR CONDITIONER]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P Low-pressure Side Sometimes Becomes Negative

Low-pressure Side Becomes Negative

Gauge indicat](/img/5/57395/w960_57395-3411.png)

INSUFFICIENT COOLING

HAC-79

< SYMPTOM DIAGNOSIS >[MANUAL AIR CONDITIONER]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P Low-pressure Side Sometimes Becomes Negative

Low-pressure Side Becomes Negative

Gauge indication Refrigerant cycle Probable cause Corrective action

Both high- and low-pressure

sides are too low. There is a big temperature dif-

ference between liquid tank

outlet and inlet. Outlet tem-

perature is extremely low.

Liquid tank inlet and expan-

sion valve are frosted.Liquid tank inside is slightly

clogged. Replace liquid tank.

Check oil for contamination.

Temperature of expansion

valve inlet is extremely low as

compared with areas near liq-

uid tank.

Expansion valve inlet may be

frosted.

Temperature difference oc-

curs somewhere in high-pres-

sure side.High-pressure pipe located be-

tween liquid tank and expansion

valve is clogged. Check and repair malfunc-

tioning parts.

Check oil for contamination.

Expansion valve and liquid tank

are warm or only cool when

touched.Low refrigerant charge.

↓

Leaking fittings or componentsCheck refrigerant for leaks.

Refer to XXXX CHECKING OF

REFRIG LEAKS .

There is a big temperature dif-

ference between expansion

valve inlet and outlet while the

valve itself is frosted.Expansion valve closes a little

compared with the specification.

↓

1. Improper expansion valve

adjustment.

2. Malfunctioning expansion

valve.

3. Outlet and inlet may be

clogged. Remove foreign particles by

using compressed air.

Replace expansion valve.

Check oil for contamination.

An area of the low-pressure pipe

is colder than areas near the

evaporator outlet.Low-pressure pipe is clogged or

crushed. Check and repair malfunc-

tioning parts.

Check oil for contamination.

Air flow volume is not enough or

is too low.Evaporator is frozen. Check thermo control amp.

Refer to XXXX MAG

CLUTCH CIR..

Replace compressor.

Repair evaporator fins.

Replace evaporator.

Refer to XXXX BLOWER

MOTOR CIR. .

AC353A

Gauge indication Refrigerant cycle Probable cause Corrective action

Low-pressure side sometimes be-

comes negative. Air conditioning system does

not function and does not cy-

clically cool the compart-

ment air.

The system constantly func-

tions for a certain period of

time after compressor is

stopped and restarted.Refrigerant does not discharge

cyclically.

↓

Moisture is frozen at expan-

sion valve outlet and inlet.

↓

Water is mixed with refrigerant. Drain water from refrigerant

or replace refrigerant.

Replace liquid tank.

AC354A

Page 3420 of 5883

![NISSAN TIIDA 2007 Service Repair Manual INSPECTION AND ADJUSTMENT

HAC-87

< BASIC INSPECTION >[AUTO AIR CONDITIONER (W/O NAVI)]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

INSPECTION AND ADJUSTMENT

Operational CheckINFOID:0000000001547386

The purpose o NISSAN TIIDA 2007 Service Repair Manual INSPECTION AND ADJUSTMENT

HAC-87

< BASIC INSPECTION >[AUTO AIR CONDITIONER (W/O NAVI)]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

INSPECTION AND ADJUSTMENT

Operational CheckINFOID:0000000001547386

The purpose o](/img/5/57395/w960_57395-3419.png)

INSPECTION AND ADJUSTMENT

HAC-87

< BASIC INSPECTION >[AUTO AIR CONDITIONER (W/O NAVI)]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

INSPECTION AND ADJUSTMENT

Operational CheckINFOID:0000000001547386

The purpose of the operational check is to confirm that the system operates properly.

CHECKING MEMORY FUNCTION

1. Press temperature control switch (UP: ) until 32°C is displayed.

2. Press OFF switch.

3. Turn the ignition switch OFF.

4. Turn the ignition switch ON.

5. Press the AUTO switch.

6. Confirm that the set temperature remains at previous temperature.

7. Press OFF switch.

If NG, go to trouble diagnosis procedure for HAC-198, "

Memory Function Check".

If OK, continue the check.

CHECKING BLOWER

1. Press blower motor switch (UP: ). Blower should operate on low speed. The fan symbol should have one

blade lit.

2. Press blower motor switch (UP: ), and continue checking blower speed and fan symbol until all speeds

are checked.

3. Leave blower on max. speed.

If NG, go to trouble diagnosis procedure for HAC-120, "

Front Blower Motor Diagnosis Procedure".

If OK, continue the check.

CHECKING DISCHARGE AIR

1. Press MODE switch and DEF switch.

2. Each position indicator should change shape.

3. Confirm that discharge air comes out according to the air distribution table. Refer to HAC-94, "

Discharge

Air Flow".

Intake door position is checked in the next step.

If NG, go to trouble diagnosis procedure for HAC-109, "

Mode Door Motor Diagnosis Procedure".

If OK, continue the check.

NOTE:

Confirm that the compressor clutch is engaged (sound or visual inspection) and intake door position is at

FRESH when the DEF is selected.

CHECKING RECIRCULATION

1. Press recirculation (REC) switch one time. Recirculation LED should illuminate.

2. Press fresh (FRE) switch one time. Fresh LED should illuminate.

3. Listen for intake door position change (you should hear blower sound change slightly).

If NG, go to trouble diagnosis procedure for HAC-116, "

Intake Door Motor Diagnosis Procedure".

If OK, continue the check.

CHECKING TEMPERATURE INCREASE

1. Press temperature control switch (UP: ) until 32°C is displayed.

2. Check for hot air at discharge air outlets.

If NG, go to trouble diagnosis procedure for HAC-193, "

Component Function Check".

If OK, continue the check.

CHECKING TEMPERATURE DECREASE

1. Press temperature control switch (DOWN: ) until 18°C is displayed. Conditions : Engine running at usual operating temperature

Page 3439 of 5883

![NISSAN TIIDA 2007 Service Repair Manual HAC-106

< COMPONENT DIAGNOSIS >[AUTO AIR CONDITIONER (W/O NAVI)]

MODE DOOR MOTOR

COMPONENT DIAGNOSIS

MODE DOOR MOTOR

System DescriptionINFOID:0000000001547404

SYSTEM DESCRIPTION

Component Parts

Mode d NISSAN TIIDA 2007 Service Repair Manual HAC-106

< COMPONENT DIAGNOSIS >[AUTO AIR CONDITIONER (W/O NAVI)]

MODE DOOR MOTOR

COMPONENT DIAGNOSIS

MODE DOOR MOTOR

System DescriptionINFOID:0000000001547404

SYSTEM DESCRIPTION

Component Parts

Mode d](/img/5/57395/w960_57395-3438.png)

HAC-106

< COMPONENT DIAGNOSIS >[AUTO AIR CONDITIONER (W/O NAVI)]

MODE DOOR MOTOR

COMPONENT DIAGNOSIS

MODE DOOR MOTOR

System DescriptionINFOID:0000000001547404

SYSTEM DESCRIPTION

Component Parts

Mode door control system components are:

Front air control

Mode door motor

In-vehicle sensor

Ambient sensor

Sunload sensor

System Operation

The front air control receives data from each of the sensors. When a drive signal is input from front air control

to door motor, a step motor built into the door motor rotates according to the drive signal, and then stops at the

position of target door.

Mode door changes to manual select mode by pressing MODE/DEF switch of the controller. That allows mode

door to be fixed.

Pressing AUTO switch allows automatic control by front air control, and mode door is fixed in the FOOT posi-

tion by pressing OFF switch.

During automatic operation of mode door, mode door position (VENT, B/L, FOOT) is selected according to the

temperature of discharge air calculated by front air control based on the target opening angle of air mix door

and the amount of sunload. And only when ambient temperature is extremely low with the mode door in the

FOOT position, D/F is selected and prevents windshield fogging.

AWIIA0290GB

Page 3451 of 5883

![NISSAN TIIDA 2007 Service Repair Manual HAC-118

< COMPONENT DIAGNOSIS >[AUTO AIR CONDITIONER (W/O NAVI)]

BLOWER MOTOR CONTROL SYSTEM

BLOWER MOTOR CONTROL SYSTEM

System DescriptionINFOID:0000000001547417

SYSTEM DESCRIPTION

Component Parts

Fa NISSAN TIIDA 2007 Service Repair Manual HAC-118

< COMPONENT DIAGNOSIS >[AUTO AIR CONDITIONER (W/O NAVI)]

BLOWER MOTOR CONTROL SYSTEM

BLOWER MOTOR CONTROL SYSTEM

System DescriptionINFOID:0000000001547417

SYSTEM DESCRIPTION

Component Parts

Fa](/img/5/57395/w960_57395-3450.png)

HAC-118

< COMPONENT DIAGNOSIS >[AUTO AIR CONDITIONER (W/O NAVI)]

BLOWER MOTOR CONTROL SYSTEM

BLOWER MOTOR CONTROL SYSTEM

System DescriptionINFOID:0000000001547417

SYSTEM DESCRIPTION

Component Parts

Fan speed control system components are: Front air control

In-vehicle sensor

Ambient sensor

Sunload sensor

Intake sensor

System Operation

Automatic Mode

In the automatic mode, the blower motor speed is calculated by the front air control based on input from in-

vehicle sensor, sunload sensor, intake sensor and ambient sensor.

The blower motor is applied voltage ranges from approximately 3.0 volts (lowest speed) to 12 volts (highest

speed).

The control blower speed (in the range of 3.0 to 12V), front air control supplies a gate voltage to the power

transistor. Based on this voltage, front air control controls voltage supplied to the blower motor.

Starting Fan Speed Control

Start up from COLD SOAK Condition (Automatic mode)

In a cold start up condition where the engine coolant temperature is below 56°C, the blower will not operate for

a short period of time (up to 150 seconds). The exact start delay time varies depending on the ambient and

engine coolant temperature.

In the most extreme case (very low ambient) the blower starting delay will be 150 seconds as described

above. After this delay, the blower will operate at low speed until the engine coolant temperature rises above

56°C, at which time the blower speed will increase to the objective speed.

Start up from usual or HOT SOAK Condition (Automatic mode)

The blower will begin operation momentarily after the A/C switch is pushed. The blower speed will gradually

rise to the objective speed over a time period of 3 seconds or less (actual time depends on the objective

blower speed).

Blower Speed Compensation

Sunload

When the in-vehicle temperature and the set temperature are very close, the blower will be operating at low

speed. The low speed will vary depending on the sunload. During conditions of low or no sunload, the blower

AWIIA0296GB