Ext NISSAN TIIDA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 3524 of 5883

![NISSAN TIIDA 2007 Service Repair Manual INSUFFICIENT COOLING

HAC-191

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/O NAVI)]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P Both High- and Low-pressure Sides are Too Low

Low-pressure Side Sometimes Becomes N NISSAN TIIDA 2007 Service Repair Manual INSUFFICIENT COOLING

HAC-191

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/O NAVI)]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P Both High- and Low-pressure Sides are Too Low

Low-pressure Side Sometimes Becomes N](/img/5/57395/w960_57395-3523.png)

INSUFFICIENT COOLING

HAC-191

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/O NAVI)]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P Both High- and Low-pressure Sides are Too Low

Low-pressure Side Sometimes Becomes Negative

Gauge indication Refrigerant cycle Probable cause Corrective action

High-pressure side is too low

and low-pressure side is too

high.High- and low-pressure sides

become equal soon after com-

pressor operation stops.Compressor pressure operation

is improper.

↓

Damaged inside compressor

packings.Replace compressor.

No temperature difference be-

tween high- and low-pressure

sides.Compressor pressure operation

is improper.

↓

Damaged inside compressor

packings.Replace compressor.

AC356A

Gauge indication Refrigerant cycle Probable cause Corrective action

Both high- and low-pressure

sides are too low. There is a big temperature dif-

ference between liquid tank

outlet and inlet. Outlet tem-

perature is extremely low.

Liquid tank inlet and expan-

sion valve are frosted.Liquid tank inside is slightly

clogged. Replace liquid tank.

Check oil for contamination.

Temperature of expansion

valve inlet is extremely low as

compared with areas near liq-

uid tank.

Expansion valve inlet may be

frosted.

Temperature difference oc-

curs somewhere in high-pres-

sure side.High-pressure pipe located be-

tween liquid tank and expansion

valve is clogged. Check and repair malfunc-

tioning parts.

Check oil for contamination.

Expansion valve and liquid tank

are warm or only cool when

touched.Low refrigerant charge.

↓

Leaking fittings or componentsCheck refrigerant for leaks.

Refer to XXXX CHECKING OF

REFRIG LEAKS .

There is a big temperature dif-

ference between expansion

valve inlet and outlet while the

valve itself is frosted.Expansion valve closes a little

compared with the specification.

↓

1. Improper expansion valve

adjustment.

2. Malfunctioning expansion

valve.

3. Outlet and inlet may be

clogged. Remove foreign particles by

using compressed air.

Replace expansion valve.

Check oil for contamination.

An area of the low-pressure pipe

is colder than areas near the

evaporator outlet.Low-pressure pipe is clogged or

crushed. Check and repair malfunc-

tioning parts.

Check oil for contamination.

Air flow volume is not enough or

is too low.Evaporator is frozen. Check intake sensor circuit.

Refer to XXXX INTAKE

SENSOR CIR .

Replace compressor.

Repair evaporator fins.

Replace evaporator.

Refer to XXXX BLOWER

MOTOR CIR..

AC353A

Page 3535 of 5883

![NISSAN TIIDA 2007 Service Repair Manual HAC-202

< BASIC INSPECTION >[AUTO AIR CONDITIONER (W/NAVI)]

INSPECTION AND ADJUSTMENT

INSPECTION AND ADJUSTMENT

Operational CheckINFOID:0000000001547306

The purpose of the operational check is to conf NISSAN TIIDA 2007 Service Repair Manual HAC-202

< BASIC INSPECTION >[AUTO AIR CONDITIONER (W/NAVI)]

INSPECTION AND ADJUSTMENT

INSPECTION AND ADJUSTMENT

Operational CheckINFOID:0000000001547306

The purpose of the operational check is to conf](/img/5/57395/w960_57395-3534.png)

HAC-202

< BASIC INSPECTION >[AUTO AIR CONDITIONER (W/NAVI)]

INSPECTION AND ADJUSTMENT

INSPECTION AND ADJUSTMENT

Operational CheckINFOID:0000000001547306

The purpose of the operational check is to confirm that the system operates properly.

CHECKING BLOWER

1. Turn blower control dial to 1st speed. Blower should operate on low speed.

2. Turn blower control dial to 2nd speed, and continue checking blower motor until all speed are checked.

3. Leave blower on max. speed.

If NG, go to trouble diagnosis procedure for HAC-234, "

Front Blower Motor Diagnosis Procedure".

If OK, continue the check.

CHECKING DISCHARGE AIR

1. Turn mode control dial to each position.

2. Confirm that discharge air comes out according to the air distribution table. Refer to HAC-208, "

Discharge

Air Flow".

Intake door position is checked in the next step.

If NG, go to trouble diagnosis procedure for HAC-222, "

Mode Door Motor Diagnosis Procedure".

If OK, continue the check.

NOTE:

Confirm that the compressor clutch is engaged (sound or visual inspection) and intake door position is at

FRESH when the DEF is selected.

CHECKING INTAKE DOOR

1. Press intake switch. Recirculation indicator should illuminate.

2. Press intake switch again. Fresh indicator should illuminate.

3. Listen for intake door position change (you should hear blower sound change slightly).

If NG, go to trouble diagnosis procedure for HAC-230, "

Intake Door Motor Diagnosis Procedure".

If OK, continue the check.

CHECKING TEMPERATURE DECREASE

1. Turn temperature control dial counterclockwise until 18°C (64°F).

2. Check for cold air at discharge air outlets.

If NG, go to trouble diagnosis procedure for HAC-299, "

Component Function Check".

If OK, continue the check.

CHECKING TEMPERATURE INCREASE

1. Turn temperature control dial clockwise until 32°C (90°F).

2. Check for hot air at discharge air outlets.

If NG, go to trouble diagnosis procedure for HAC-307, "

Component Function Check".

If OK, continue the check.

CHECKING A/C SWITCH

1. Turn blower control dial to ON.

2. Press A/C switch.

3. A/C switch indicator will turn ON.

Confirm that the compressor clutch engages (sound or visual inspection).

If NG, go to trouble diagnosis procedure for HAC-239, "

Magnet Clutch Diagnosis Procedure".

If OK, continue the check.

CHECKING AUTO MODE

1. Set mode control dial and blower control dial to AUTO position.

2. Press A/C switch.Conditions : Engine running at usual operating temperature

Page 3549 of 5883

![NISSAN TIIDA 2007 Service Repair Manual HAC-216

< FUNCTION DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

SELF-DIAGNOSIS FUNCTION

Go to Magnet Clutch Circuit. Refer to HAC-239, "Magnet Clutch Diagnosis Procedure".

9.CHECK MALFUNCTION SENSOR

Ref NISSAN TIIDA 2007 Service Repair Manual HAC-216

< FUNCTION DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

SELF-DIAGNOSIS FUNCTION

Go to Magnet Clutch Circuit. Refer to HAC-239, "Magnet Clutch Diagnosis Procedure".

9.CHECK MALFUNCTION SENSOR

Ref](/img/5/57395/w960_57395-3548.png)

HAC-216

< FUNCTION DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

SELF-DIAGNOSIS FUNCTION

Go to Magnet Clutch Circuit. Refer to HAC-239, "Magnet Clutch Diagnosis Procedure".

9.CHECK MALFUNCTION SENSOR

Refer to the following chart.

*1: Perform self-diagnosis STEP-2 under sunshine.

When performing indoors, aim a light (more than 60W) at sunload

sensor, otherwise LED of rear window defogger switch will illuminate

despite that sunload sensor is functioning properly.

*2: HAC-244, "

Ambient Sensor Diagnosis Procedure".

*3: HAC-247, "

In-Vehicle Sensor Diagnosis Procedure".

*4: HAC-253, "

Intake Sensor Diagnosis Procedure".

*5: HAC-250, "

Sunload Sensor Diagnosis Procedure".

*6: HAC-226, "

Air Mix Door Motor Diagnosis Procedure".

*7: HAC-222, "

Mode Door Motor Diagnosis Procedure".

*8: HAC-230, "

Intake Door Motor Diagnosis Procedure".

In case of a break in the ambient sensor, front air control regards ambient temperature as extreme cold

(approximately –42°C or less) and then start warming.

>> INSPECTION END

10.CHECK MALFUNCTION DOOR MOTOR POSITION SWITCH

Usual: LED for A/C switch and intake switch turn ON.

Unusual: LED for malfunctioning door motor blinks. If unusual condi-

tions are detected in multiple door motor-positions, appropriate

switch LED blink twice respectively.

AWIIA0330ZZ

AWIIA0331GB

SJIA0862E

Page 3552 of 5883

![NISSAN TIIDA 2007 Service Repair Manual MODE DOOR MOTOR

HAC-219

< COMPONENT DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

COMPONENT DIAGNOSIS

MODE DOOR MOTOR

System DescriptionINFOID:0000000001547326

SYSTEM DES NISSAN TIIDA 2007 Service Repair Manual MODE DOOR MOTOR

HAC-219

< COMPONENT DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

COMPONENT DIAGNOSIS

MODE DOOR MOTOR

System DescriptionINFOID:0000000001547326

SYSTEM DES](/img/5/57395/w960_57395-3551.png)

MODE DOOR MOTOR

HAC-219

< COMPONENT DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

COMPONENT DIAGNOSIS

MODE DOOR MOTOR

System DescriptionINFOID:0000000001547326

SYSTEM DESCRIPTION

Component Parts

Mode door control system components are:

Front air control

Mode door motor

In-vehicle sensor

Ambient sensor

Sunload sensor

System Operation

The front air control receives data from each of the sensors. When a drive signal is input from front air control

to door motor, a step motor built into the door motor rotates according to the drive signal, and then stops at the

position of target door.

Mode door changes to manual select mode by turning mode control dial of the controller. That allows mode

door to be fixed.

Pressing AUTO switch allows automatic control by front air control, and mode door is fixed in the FOOT posi-

tion by pressing OFF switch.

During automatic operation of mode door, mode door position (VENT, B/L, FOOT) is selected according to the

temperature of blow-off wind calculated by front air control based on the target opening angle of air mix door

and the amount of solar radiation. And only when ambient temperature is extremely low with the mode door in

the FOOT position, D/F is selected and prevents windshield fogging.

AWIIA0333GB

Page 3565 of 5883

![NISSAN TIIDA 2007 Service Repair Manual HAC-232

< COMPONENT DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

BLOWER MOTOR CONTROL SYSTEM

BLOWER MOTOR CONTROL SYSTEM

System DescriptionINFOID:0000000001547339

SYSTEM DESCRIPTION

Component Parts

Blow NISSAN TIIDA 2007 Service Repair Manual HAC-232

< COMPONENT DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

BLOWER MOTOR CONTROL SYSTEM

BLOWER MOTOR CONTROL SYSTEM

System DescriptionINFOID:0000000001547339

SYSTEM DESCRIPTION

Component Parts

Blow](/img/5/57395/w960_57395-3564.png)

HAC-232

< COMPONENT DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

BLOWER MOTOR CONTROL SYSTEM

BLOWER MOTOR CONTROL SYSTEM

System DescriptionINFOID:0000000001547339

SYSTEM DESCRIPTION

Component Parts

Blower motor speed control system components are: Front air control

In-vehicle sensor

Ambient sensor

Sunload sensor

Intake sensor

System Operation

Automatic Mode

In the automatic mode, the blower motor speed is calculated by the front air control based on input from in-

vehicle sensor, sunload sensor, intake sensor and ambient sensor.

The blower motor is applied voltage ranges from approximately 3.0 volts (lowest speed) to 12 volts (highest

speed).

The control blower speed (in the range of 3.0 to 12V), front air control supplies a gate voltage to the power

transistor. Based on this voltage, front air control controls voltage supplied to the blower motor.

Starting Blower Motor Speed Control

Start up from COLD SOAK Condition (Automatic mode)

In a cold start up condition where the engine coolant temperature is below 56°C, the blower will not operate for

a short period of time (up to 150 seconds). The exact start delay time varies depending on the ambient and

engine coolant temperature.

In the most extreme case (very low ambient) the blower starting delay will be 150 seconds as described

above. After this delay, the blower will operate at low speed until the engine coolant temperature rises above

56°C, at which time the blower speed will increase to the objective speed.

Start up from usual or HOT SOAK Condition (Automatic mode)

The blower will begin operation momentarily after the A/C switch is pushed. The blower speed will gradually

rise to the objective speed over a time period of 3 seconds or less (actual time depends on the objective

blower speed).

Blower Speed Compensation

Sunload

When the in-vehicle temperature and the set temperature are very close, the blower will be operating at low

speed. The low speed will vary depending on the sunload. During conditions of low or no sunload, the blower

AWIIA0341GB

Page 3638 of 5883

![NISSAN TIIDA 2007 Service Repair Manual INSUFFICIENT COOLING

HAC-305

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P Both High- and Low-pressure Sides are Too Low

Low-pressure Side Sometimes Becomes Neg NISSAN TIIDA 2007 Service Repair Manual INSUFFICIENT COOLING

HAC-305

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P Both High- and Low-pressure Sides are Too Low

Low-pressure Side Sometimes Becomes Neg](/img/5/57395/w960_57395-3637.png)

INSUFFICIENT COOLING

HAC-305

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P Both High- and Low-pressure Sides are Too Low

Low-pressure Side Sometimes Becomes Negative

Gauge indication Refrigerant cycle Probable cause Corrective action

High-pressure side is too low

and low-pressure side is too

high.High- and low-pressure sides

become equal soon after com-

pressor operation stops.Compressor pressure operation

is improper.

↓

Damaged inside compressor

packings.Replace compressor.

No temperature difference be-

tween high- and low-pressure

sides.Compressor pressure operation

is improper.

↓

Damaged inside compressor

packings.Replace compressor.

AC356A

Gauge indication Refrigerant cycle Probable cause Corrective action

Both high- and low-pressure

sides are too low. There is a big temperature dif-

ference between liquid tank

outlet and inlet. Outlet tem-

perature is extremely low.

Liquid tank inlet and expan-

sion valve are frosted.Liquid tank inside is slightly

clogged. Replace liquid tank.

Check oil for contamination.

Temperature of expansion

valve inlet is extremely low as

compared with areas near liq-

uid tank.

Expansion valve inlet may be

frosted.

Temperature difference oc-

curs somewhere in high-pres-

sure side.High-pressure pipe located be-

tween liquid tank and expansion

valve is clogged. Check and repair malfunc-

tioning parts.

Check oil for contamination.

Expansion valve and liquid tank

are warm or only cool when

touched.Low refrigerant charge.

↓

Leaking fittings or componentsCheck refrigerant for leaks.

Refer to HA-22, "

Checking of

Refrigerant Leaks".

There is a big temperature dif-

ference between expansion

valve inlet and outlet while the

valve itself is frosted.Expansion valve closes a little

compared with the specification.

↓

1. Improper expansion valve

adjustment.

2. Malfunctioning expansion

valve.

3. Outlet and inlet may be

clogged. Remove foreign particles by

using compressed air.

Replace expansion valve.

Check oil for contamination.

An area of the low-pressure pipe

is colder than areas near the

evaporator outlet.Low-pressure pipe is clogged or

crushed. Check and repair malfunc-

tioning parts.

Check oil for contamination.

Air flow volume is not enough or

is too low.Evaporator is frozen. Check intake sensor circuit.

Refer to HAC-229, "

Intake

Door Motor Component

Function Check".

Replace compressor.

Repair evaporator fins.

Replace evaporator.

Refer to HAC-233, "

Front

Blower Motor Component

Function Check".

AC353A

Page 3651 of 5883

HRN-4

< ON-VEHICLE REPAIR >

HORN

ON-VEHICLE REPAIR

HORN

Removal and InstallationINFOID:0000000001728320

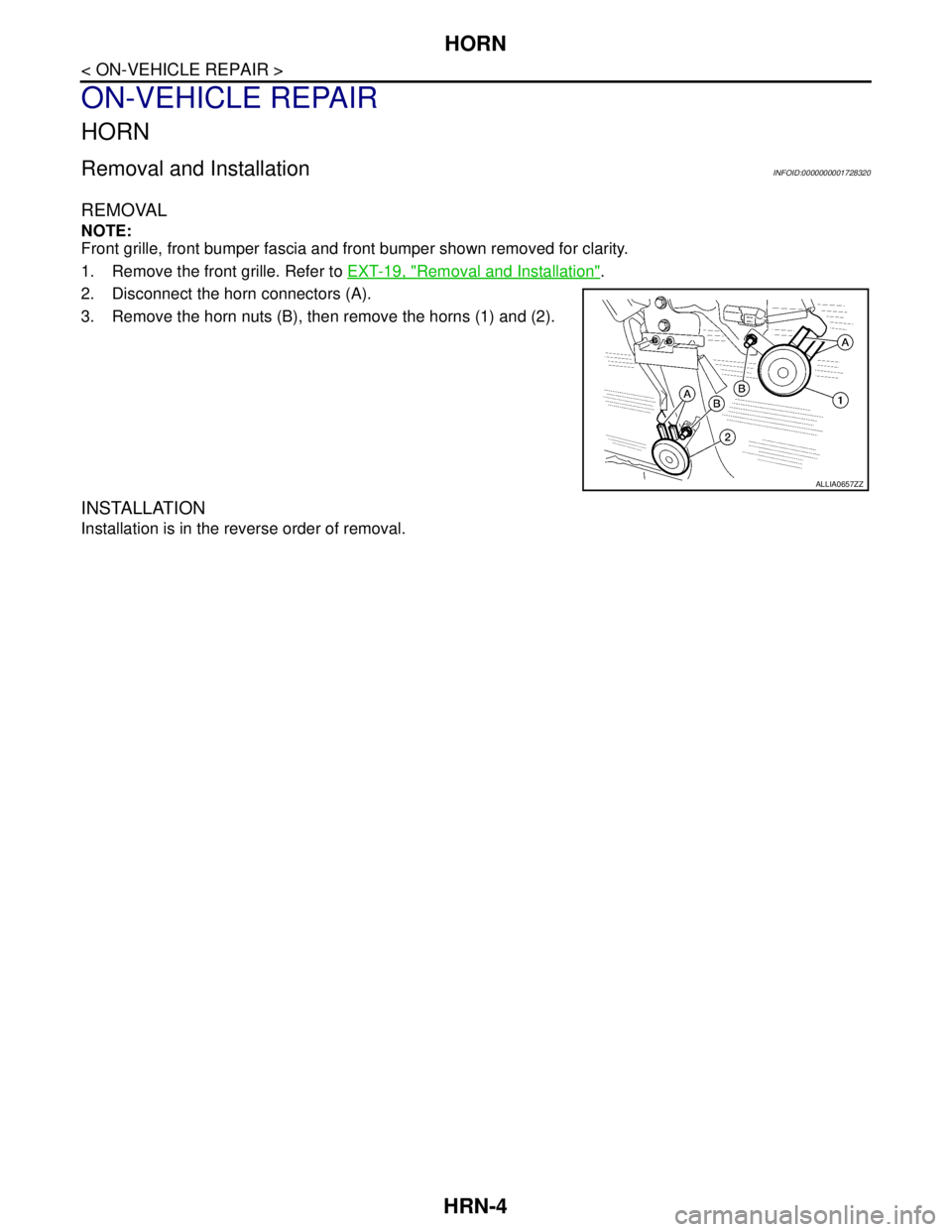

REMOVAL

NOTE:

Front grille, front bumper fascia and front bumper shown removed for clarity.

1. Remove the front grille. Refer to EXT-19, "

Removal and Installation".

2. Disconnect the horn connectors (A).

3. Remove the horn nuts (B), then remove the horns (1) and (2).

INSTALLATION

Installation is in the reverse order of removal.

ALLIA0657ZZ

Page 3681 of 5883

INT-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001530009

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PrecautionINFOID:0000000001329036

When removing or disassembling any part, be careful not to damage or deform it. Protect parts which may

get in the way with cloth.

When removing parts with a screwdriver or other tool, protect parts by wrapping them with vinyl or tape.

Keep removed parts protected with cloth.

If a clip is deformed or damaged, replace it.

If an unreusable part is removed, replace it with a new one.

Tighten bolts and nuts firmly to the specified torque.

After re-assembly has been completed, make sure each part functions correctly.

Remove stains in the following way.

- Water-soluble stains:

Dip a cloth in warm water, and squeeze tightly. After wiping the stain, wipe with a soft dry cloth.

- Oil stain:

Dissolve a synthetic detergent in warm water (density of 2 to 3% or less), dip the cloth, then clean off the

stain with the cloth. Next, dip the soft cloth in fresh water, and then squeeze it tightly. Then clean off the

detergent completely. Then wipe the area with a soft dry cloth.

Do not use any organic solvent, such as thinner or benzine.

When performing procedures that require removal of the cowl top,

cover the lower end of the windshield with a suitable protection

material.

PIIB3706J

Page 3717 of 5883

IP-2

< SERVICE INFORMATION >

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001523320

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PrecautionINFOID:0000000001523321

Disconnect both battery cables in advance.

Disconnect air bag system line in advance.

Never tamper with or force air bag lid open, as this may adversely affect air bag performance.

Be careful not to scratch pad and other parts.

When removing or disassembling any part, be careful not to damage or deform it. Protect parts, which may

get in the way with cloth.

When removing parts with a screwdriver or other tool, protect parts by wrapping them with vinyl or tape.

Keep removed parts protected with cloth.

If a clip is deformed or damaged, replace it.

If an unreusable part is removed, replace it with a new one.

Tighten bolts and nuts firmly to the specified torque.

After re-assembly has been completed, make sure each part functions correctly.

Remove stains in the following way.

Water-soluble stains:

Dip a soft cloth in warm water, and then squeeze it tightly. After wiping the stain, wipe with a soft dry cloth.

Oil stain:

Dissolve a synthetic detergent in warm water (density of 2 to 3% or less), dip the cloth, then clean off the stain

with the cloth. Next, dip the cloth in fresh water and squeeze it tightly. Then clean off the detergent completely.

Then wipe the area with a soft dry cloth.

Do not use any organic solvent, such as thinner or benzine.

Page 3759 of 5883

![NISSAN TIIDA 2007 Service Repair Manual LAN

TROUBLE DIAGNOSIS

LAN-19

< FUNCTION DIAGNOSIS >[CAN FUNDAMENTAL]

C

D

E

F

G

H

I

J

K

L B A

O

P N

CAN Diagnosis with CONSULT-IIIINFOID:0000000001162760

CAN diagnosis on CONSULT-III extracts the root NISSAN TIIDA 2007 Service Repair Manual LAN

TROUBLE DIAGNOSIS

LAN-19

< FUNCTION DIAGNOSIS >[CAN FUNDAMENTAL]

C

D

E

F

G

H

I

J

K

L B A

O

P N

CAN Diagnosis with CONSULT-IIIINFOID:0000000001162760

CAN diagnosis on CONSULT-III extracts the root](/img/5/57395/w960_57395-3758.png)

LAN

TROUBLE DIAGNOSIS

LAN-19

< FUNCTION DIAGNOSIS >[CAN FUNDAMENTAL]

C

D

E

F

G

H

I

J

K

L B A

O

P N

CAN Diagnosis with CONSULT-IIIINFOID:0000000001162760

CAN diagnosis on CONSULT-III extracts the root cause by receiving the following information.

Response to the system call

Control unit diagnosis information

Self-diagnosis

CAN diagnostic support monitor

Self-DiagnosisINFOID:0000000001162761

CAN Diagnostic Support MonitorINFOID:0000000001162762

MONITOR ITEM (CONSULT-III)

Unit name Symptom

ECM Engine torque limiting is affected, and shift harshness increases.

Engine speed drops.

BCM Reverse warning chime does not sound.

The front wiper moves under continuous operation mode even though the front

wiper switch being in the intermittent position.

The room lamp does not turn ON.

The engine does not start (if an error or malfunction occurs while turning the igni-

tion switch OFF.)

The steering lock does not release (if an error or malfunction occurs while turning

the ignition switch OFF.)

EPS control unit The steering effort increases.

Combination meter The tachometer and the speedometer do not move.

Warning lamps turn ON.

Indicator lamps do not turn ON.

ABS actuator and electric unit (control unit) Normal operation.

TCM No impact on operation.

IPDM E/RWhen the ignition switch is ON,

The headlamps (Lo) turn ON.

The cooling fan continues to rotate.

DTCSelf-diagnosis item

(CONSULT-III indication)DTC detection condition Inspection/Action

U1000 CAN COMM CIRCUITWhen ECM is not transmitting or receiving CAN

communication signal of OBD (emission-related

diagnosis) for 2 seconds or more.

Start the inspection. Re-

fer to the applicable sec-

tion of the indicated

control unit. When a control unit (except for ECM) is not

transmitting or receiving CAN communication

signal for 2 seconds or more.

U1001 CAN COMM CIRCUITWhen ECM is not transmitting or receiving CAN

communication signal other than OBD (emis-

sion-related diagnosis) for 2 seconds or more.

U1002 SYSTEM COMMWhen a control unit is not transmitting or receiv-

ing CAN communication signal for 2 seconds or

less.

U1010 CONTROL UNIT [CAN]When an error is detected during the initial diag-

nosis for CAN controller of each control unit.Replace the control unit

indicating “U1010”.