key NISSAN TIIDA 2007 Service Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 172 of 5883

BCS

BCM (BODY CONTROL MODULE)

BCS-37

< ECU DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L B A

O

P N

I-KEY UNLOCK1UNLOCK button of Intelligent Key is not pressed OFF

UNLOCK button of Intelligent Key is pressed ON

KEY SW

2Mechanical key is removed from key cylinder OFF

Mechanical key is inserted to key cylinder ON

KEYLESS LOCK

2LOCK button of key fob is not pressed OFF

LOCK button of key fob is pressed ON

KEYLESS UNLOCK

2UNLOCK button of key fob is not pressed OFF

UNLOCK button of key fob is pressed ON

LIT-SEN FAILLight & rain sensor is in normal condition OK

Light & rain sensor is with internal error NOTOK

OIL PRESS SW Ignition switch OFF or ACC

Engine runningOFF

Ignition switch ON ON

OUT SIDE TEMP

NOTE:

Diesel engine modelsIgnition switch ONApproximately the same as outside

air temperature

PASSING SWOther than lighting switch PASS OFF

Lighting switch PASS ON

PUSH SW

1Return to ignition switch to LOCK position OFF

Press ignition switch ON

REAR DEF SWRear window defogger switch OFF OFF

Rear window defogger switch ON ON

RKE LOCK AND

UNLOCK

2NOTE:

The item is indicated, but not monitoredOFF

ON

RR FOG SWRear fog lamp switch OFF OFF

Rear fog lamp switch ON ON

RR WASHER SW

3Rear washer switch OFF OFF

Rear washer switch ON ON

RR WIPER INT

3Rear wiper switch OFF OFF

Rear wiper switch INT ON

RR WIPER ON

3 Rear wiper switch OFF OFF

Rear wiper switch ON ON

RR WIPER STOP

3Rear wiper stop position OFF

Other than rear wiper stop position ON

TAIL LAMP SWLighting switch OFF OFF

Lighting switch 1ST ON

TRNK OPNR SWWhen back door opener switch is not pressed OFF

When back door opener switch is pressed ON

TURN SIGNAL LTurn signal switch OFF OFF

Turn signal switch LH ON

TURN SIGNAL RTurn signal switch OFF OFF

Turn signal switch RH ON

UNLOCK WITH DRNOTE:

The item is indicated, but not monitoredOFF

ON

VEHICLE SPEED While driving Equivalent to speedometer reading Monitor Item Condition Value/Status

Page 173 of 5883

BCS-38

< ECU DIAGNOSIS >

BCM (BODY CONTROL MODULE)

1: With Intelligent Key

2: With remote keyless entry system

3: Hatchback

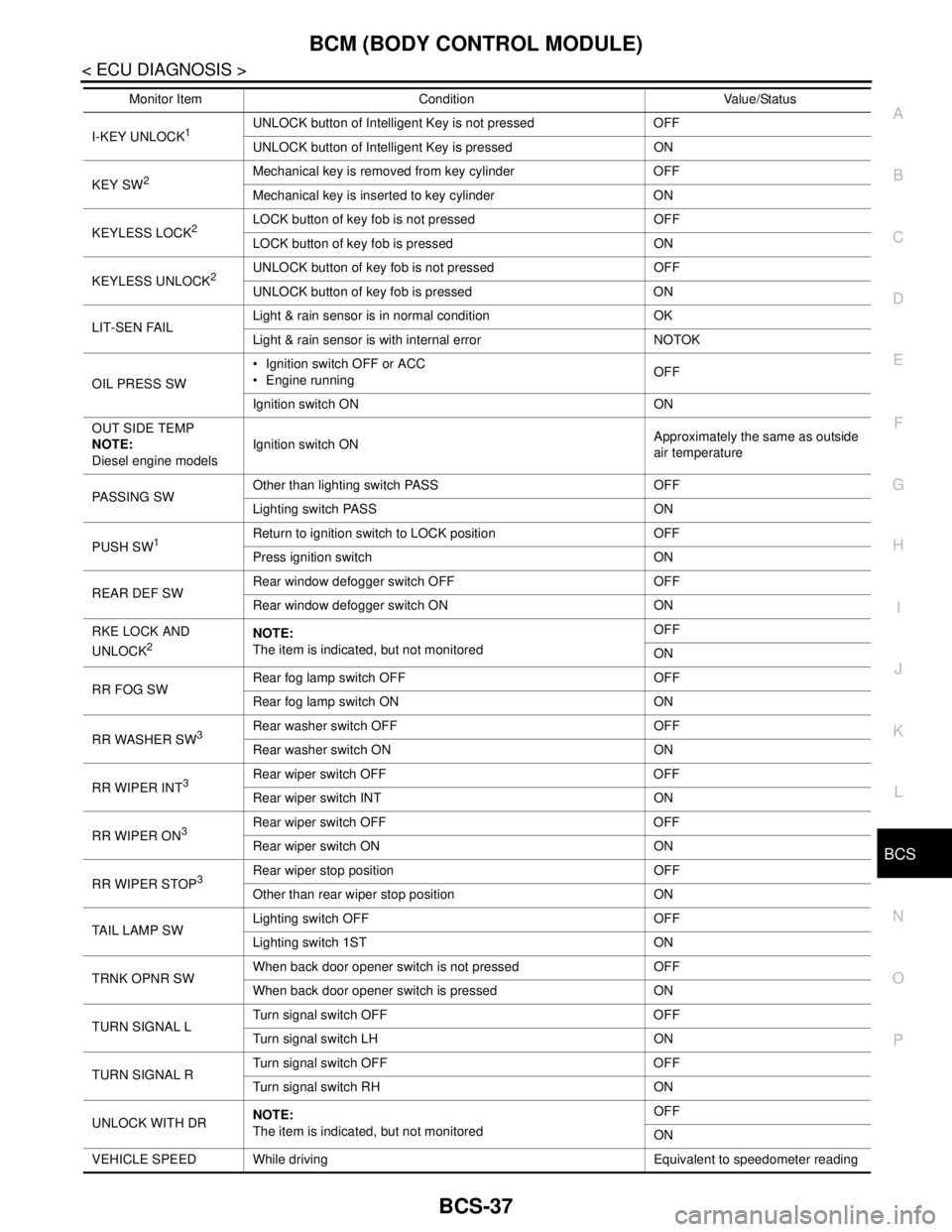

Terminal LayoutINFOID:0000000001538883

TERMINAL LAYOUT

ALMIA0185ZZ

Page 174 of 5883

BCS

BCM (BODY CONTROL MODULE)

BCS-39

< ECU DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L B A

O

P N

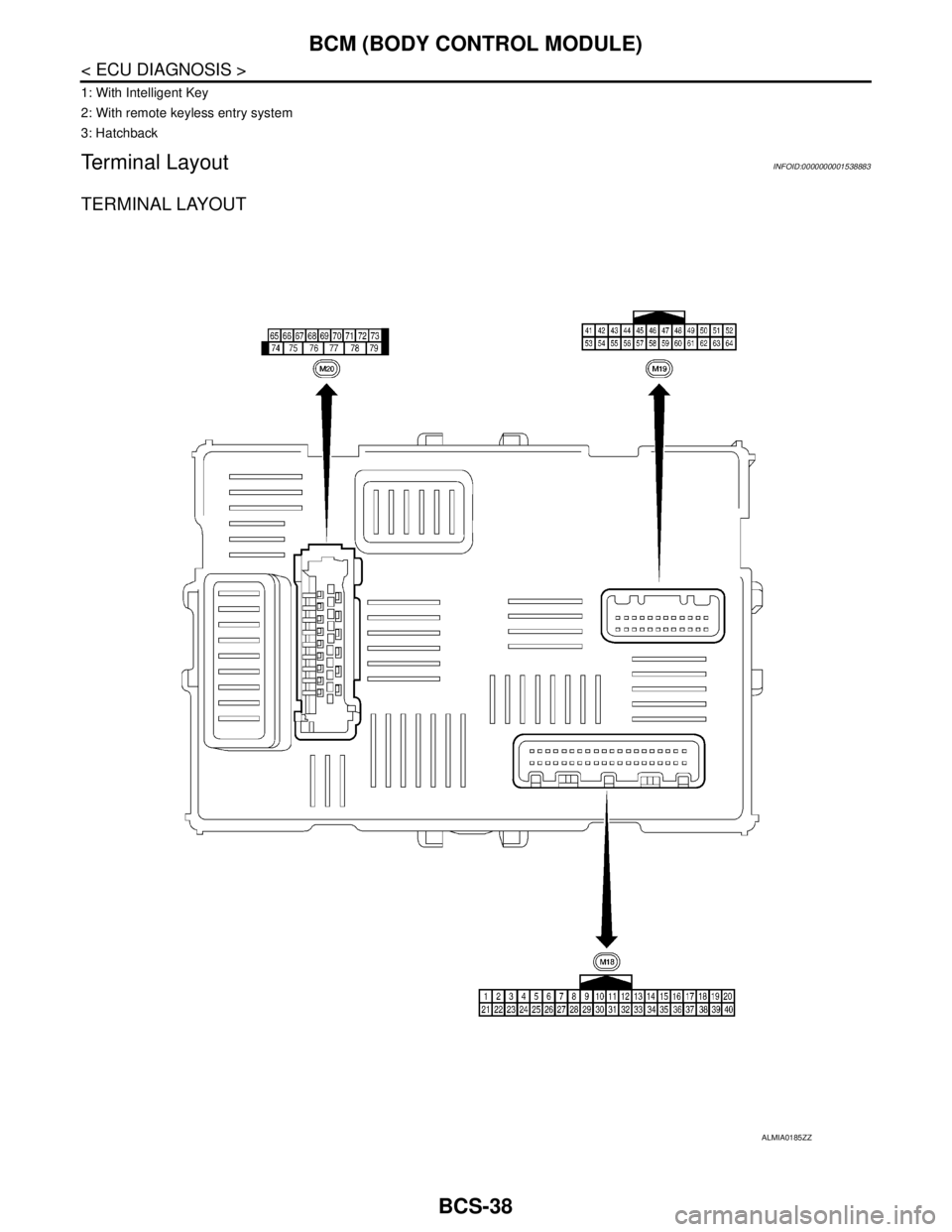

Physical ValuesINFOID:0000000001538886

PHYSICAL VALUES

CAUTION:

Check combination switch system terminal waveform under the loaded condition with lighting

switch, turn signal switch and wiper switch OFF is not to be fluctuated by being overloaded.

Turn wiper intermittent dial position to 4 except when checking waveform or voltage of wiper inter-

mittent dial position. Wiper intermittent dial position can be confirmed on CONSULT -III. Refer to

BCS-24, "

COMB SW : CONSULT-III Function (BCM - COMB SW)".

BCM reads the status of the combination switch at 10 ms internal normally. Refer to BCS-7, "

System

Description".

Terminal No.

(Wire color)Description

ConditionReference Value

(Approx.)

Signal nameInput/

Output +−

2

(B)Ground Ground — — 0V

3

(G)Ground Key switch OutputInsert mechanical key into ignition key cylin-

derBattery voltage

Remove mechanical key from ignition key

cylinder0V

4

(W)GroundRear window defog-

ger switchOutputRear window

defogger switchNot pressed 5V

While pressing 0V

5

1

(V)GroundBack door opener

switchOutputBack door

opener switchNot pressed Battery voltage

Pressed 0V

5

2

(V)Ground Trunk opener switch OutputTrunk opener

switchNot pressed Battery voltage

Pressed 0V

6

(GR)GroundDoor lock/unlock

switch (Lock) OutputDoor lock/un-

lock switchNot pressed 5V

Pressed to the lock side 0V

Page 182 of 5883

BCS

BCM (BODY CONTROL MODULE)

BCS-47

< ECU DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L B A

O

P N

324

(LG)GroundDoor lock status indi-

catorOutputDoor lock status

indicatorON Battery voltage

OFF 0V

33

(G)GroundCombination switch

OUTPUT 2OutputCombination

switchAll switch OFF

(Wiper intermittent dial 4)0V

Front washer switch ON

(Wiper intermittent dial 4)

Rear wiper switch ON

(Wiper intermittent dial 4)

Rear washer switch ON

(Wiper intermittent dial 4)

Any of the condition below

with all switch OFF

Wiper intermittent dial 1

Wiper intermittent dial 5

Wiper intermittent dial 6

34

(GR)GroundCombination switch

OUTPUT 4OutputCombination

switch

(Wiper intermit-

tent dial 4)All switch OFF 0V

Lighting switch 2ND

Lighting switch PASS

Front fog lamp switch ON

Turn signal switch LH

35

3, 7

(BR)Ground Sensor ground Output Ignition switchON 0V → 5V

OFF 0V

36

7

(V)GroundAmbient sensor sig-

nalInput Ignition switchON 0V → 5V

OFF 0V

38

5

(V)Ground NATS antenna amp.Input/

OutputInsert mechanical key into ignition key cylin-

derJust after Insert mechanical key

into ignition key cylinder. Pointer

of tester should move

39

(P)—CAN-LInput/

Output——

45

3

(GR)Ground Intake sensor Input Ignition switchON 0V

OFF Battery voltage

47

5

(GR)Ground Security indicator OutputSecurity indica-

torON 0V

Blinking

(every 2.4 seconds)Battery voltage → 0V

OFF Battery voltage

48

(W)Ground Start power supply InputIgnition switch START Battery voltage

Other than above 0V

49

(R)GroundFront demist vent

switchInputFront demist

vent switchON 0V → 5V

OFF 0V

50

(P)Ground Fan switch Output Fan switchNot pressed Battery voltage

Pressed 0

51

7

(L)Ground PTC relay 3 control Output Ignition ONPTC heater 3 ON 0V

PTC heater 3 OFF Battery voltage Terminal No.

(Wire color)Description

ConditionReference Value

(Approx.)

Signal nameInput/

Output +−

SKIA2167J

SKIA2167J

Page 184 of 5883

BCS

BCM (BODY CONTROL MODULE)

BCS-49

< ECU DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L B A

O

P N

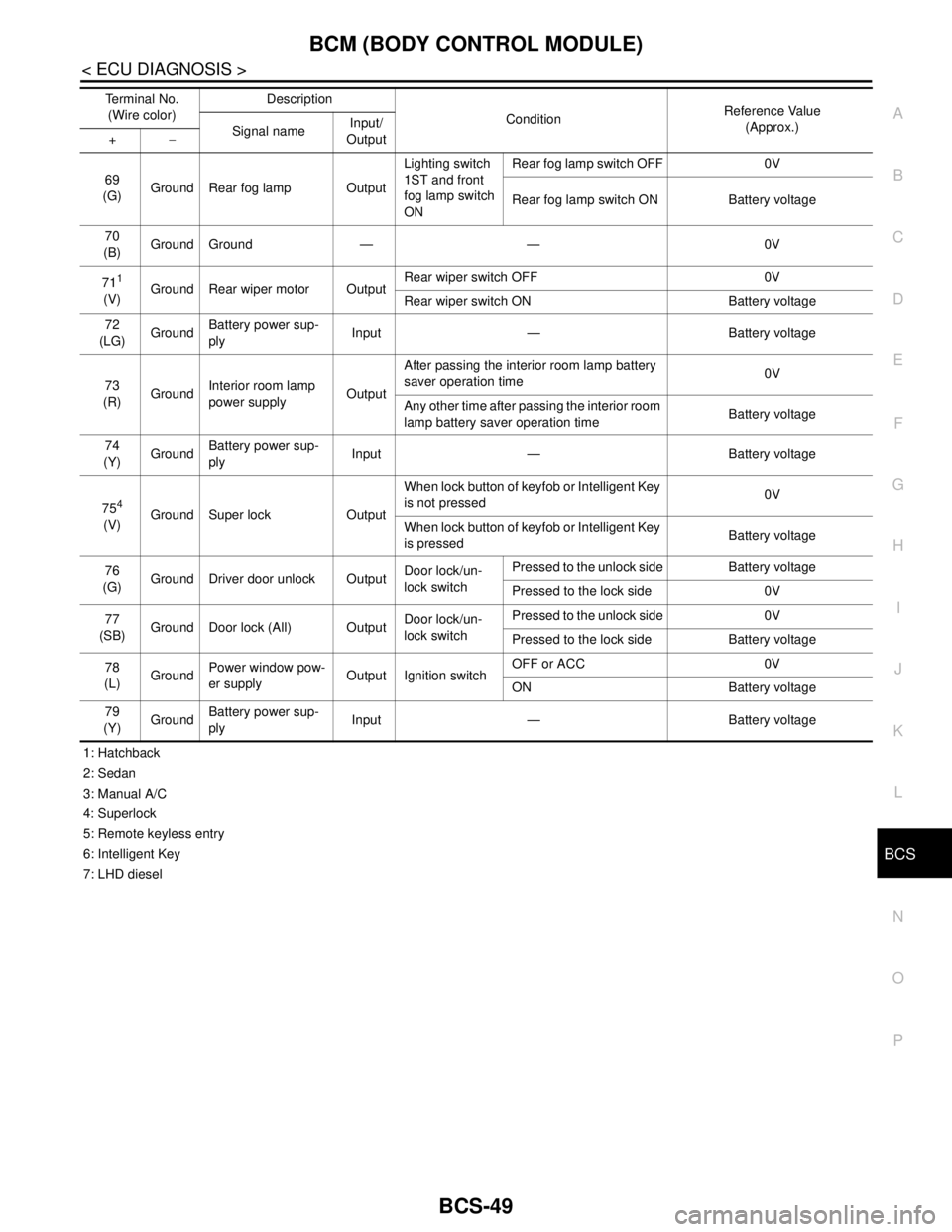

1: Hatchback

2: Sedan

3: Manual A/C

4: Superlock

5: Remote keyless entry

6: Intelligent Key

7: LHD diesel69

(G)Ground Rear fog lamp OutputLighting switch

1ST and front

fog lamp switch

ONRear fog lamp switch OFF 0V

Rear fog lamp switch ON Battery voltage

70

(B)Ground Ground — — 0V

71

1

(V)Ground Rear wiper motor OutputRear wiper switch OFF 0V

Rear wiper switch ON Battery voltage

72

(LG)GroundBattery power sup-

plyInput — Battery voltage

73

(R)GroundInterior room lamp

power supplyOutputAfter passing the interior room lamp battery

saver operation time0V

Any other time after passing the interior room

lamp battery saver operation timeBattery voltage

74

(Y)GroundBattery power sup-

plyInput — Battery voltage

75

4

(V)Ground Super lock OutputWhen lock button of keyfob or Intelligent Key

is not pressed 0V

When lock button of keyfob or Intelligent Key

is pressed Battery voltage

76

(G)Ground Driver door unlock OutputDoor lock/un-

lock switchPressed to the unlock side Battery voltage

Pressed to the lock side 0V

77

(SB)Ground Door lock (All) OutputDoor lock/un-

lock switchPressed to the unlock side 0V

Pressed to the lock side Battery voltage

78

(L)GroundPower window pow-

er supplyOutput Ignition switchOFF or ACC 0V

ON Battery voltage

79

(Y)GroundBattery power sup-

plyInput — Battery voltage Terminal No.

(Wire color)Description

ConditionReference Value

(Approx.)

Signal nameInput/

Output +−

Page 192 of 5883

BCS

BCM (BODY CONTROL MODULE)

BCS-57

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

K

L B A

O

P N

ON-VEHICLE REPAIR

BCM (BODY CONTROL MODULE)

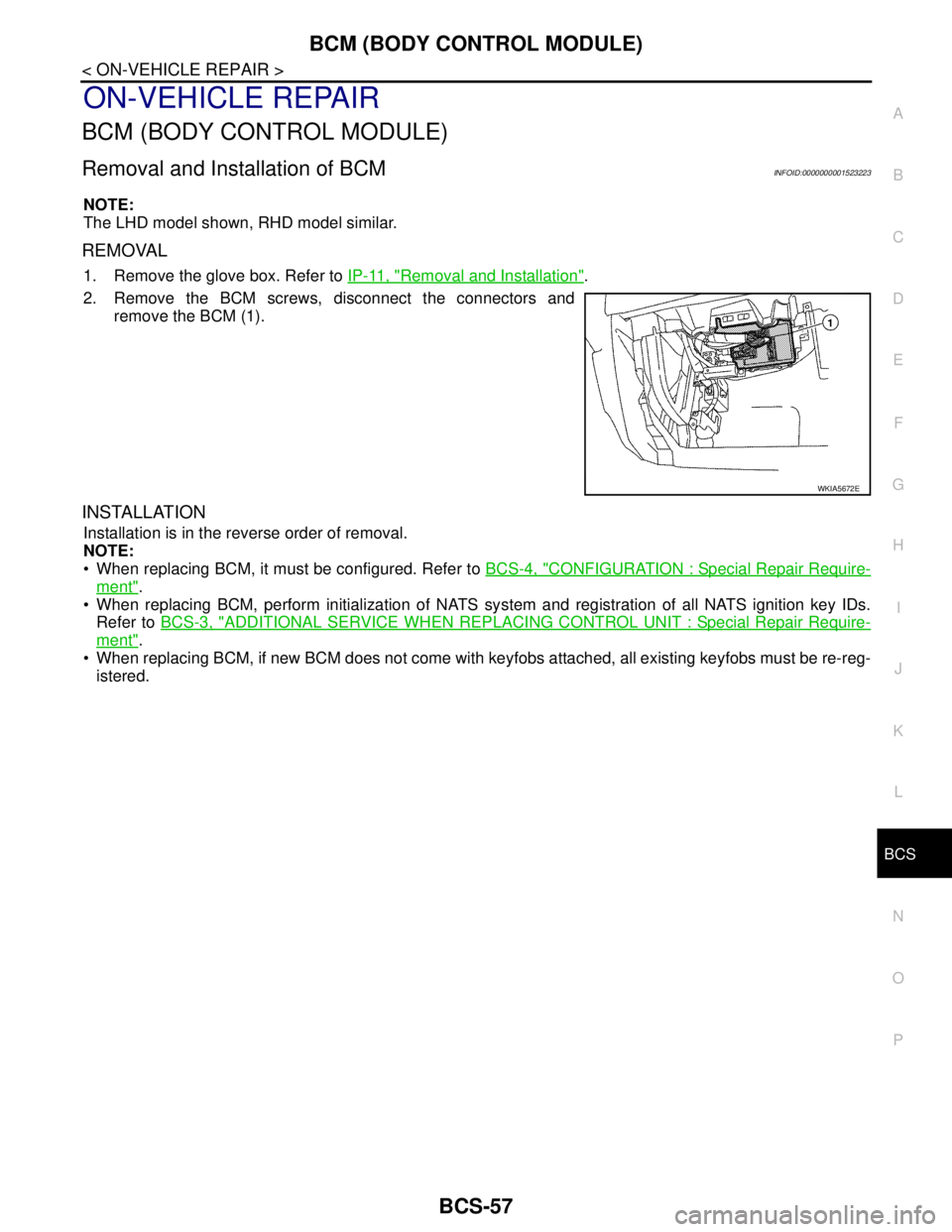

Removal and Installation of BCMINFOID:0000000001523223

NOTE:

The LHD model shown, RHD model similar.

REMOVAL

1. Remove the glove box. Refer to IP-11, "Removal and Installation".

2. Remove the BCM screws, disconnect the connectors and

remove the BCM (1).

INSTALLATION

Installation is in the reverse order of removal.

NOTE:

When replacing BCM, it must be configured. Refer to BCS-4, "

CONFIGURATION : Special Repair Require-

ment".

When replacing BCM, perform initialization of NATS system and registration of all NATS ignition key IDs.

Refer to BCS-3, "

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT : Special Repair Require-

ment".

When replacing BCM, if new BCM does not come with keyfobs attached, all existing keyfobs must be re-reg-

istered.

WKIA5672E

Page 260 of 5883

![NISSAN TIIDA 2007 Service Owners Manual DIAGNOSIS SYSTEM [ABS ACTUATOR AND ELECTRIC UNIT (CONTROL

UNIT)]

BRC-27

< FUNCTION DIAGNOSIS >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

CV1

(ON/OFF)––×Front side switch-over solenoid

valve (cut va NISSAN TIIDA 2007 Service Owners Manual DIAGNOSIS SYSTEM [ABS ACTUATOR AND ELECTRIC UNIT (CONTROL

UNIT)]

BRC-27

< FUNCTION DIAGNOSIS >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

CV1

(ON/OFF)––×Front side switch-over solenoid

valve (cut va](/img/5/57395/w960_57395-259.png)

DIAGNOSIS SYSTEM [ABS ACTUATOR AND ELECTRIC UNIT (CONTROL

UNIT)]

BRC-27

< FUNCTION DIAGNOSIS >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

CV1

(ON/OFF)––×Front side switch-over solenoid

valve (cut valve) (ON/OFF) status is

displayed.

CV2

(ON/OFF)––×Rear side switch-over solenoid

valve (cut-valve) (ON/OFF) status is

displayed.

SV1

(ON/OFF)––×Front side switch-over solenoid

valve (suction valve) (ON/OFF) sta-

tus is displayed.

SV2

(ON/OFF)––×Rear side switch-over solenoid

valve (suction valve) (ON/OFF) sta-

tus is displayed.

VDC FAIL SIG

(ON/OFF)––×VDC fail signal (ON/OFF) status is

displayed.

TCS FAIL SIG

(ON/OFF)––×TCS fail signal (ON/OFF) status is

displayed.

ABS FAIL SIG

(ON/OFF)––×ABS fail signal (ON/OFF) status is

displayed.

EBD FAIL SIG

(ON/OFF)––×EBD fail signal (ON/OFF) status is

displayed.

FLUID LEV SW

(ON/OFF)×–×Brake fluid level switch (ON/OFF)

status is displayed.

EBD SIGNAL

(ON/OFF)––×EBD operation (ON/OFF) status is

displayed.

ABS SIGNAL

(ON/OFF)––×ABS operation (ON/OFF) status is

displayed.

TCS SIGNAL

(ON/OFF)––×TCS operation (ON/OFF) status is

displayed.

VDC SIGNAL

(ON/OFF)––×VDC operation (ON/OFF) status is

displayed.

EBD WARN LAMP – –×Brake warning lamp (ON/OFF) sta-

tus is displayed.

SLCT LVR POSI×××Shift position judged by PNP switch

signal.

R POSI SIG – –×Shift position judged by PNP switch

signal.

2WD/4WD – –×It recognizes on software whether it

is 2WD and whether it is in 4WD

state.

BST OPER SIG – –×

Active booster operation (ON/OFF)

status is displayed.

PRESS SENSOR×–×Brake pressure detected by pres-

sure sensor is displayed.

CRANKING SIG – –×The input state of the key SW

START position signal is displayed.

PRESS SEN 2 – –×Brake pressure detected by pres-

sure sensor is displayed.

DELTA S SEN – –×The amount of stroke sensor move-

ments in the active booster detected

by DELTA S SEN is displayed. Item

(Unit)Data monitor item selection

Remarks

ECU INPUT

SIGNALSMAIN

SIGNALSSELECTION

FROM MENU

Page 340 of 5883

![NISSAN TIIDA 2007 Service Owners Manual DIAGNOSIS SYSTEM [ABS ACTUATOR AND ELECTRIC UNIT (CONTROL

UNIT)]

BRC-107

< FUNCTION DIAGNOSIS >[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

CV1

(ON/OFF)––×Front side switch-over solenoid

valv NISSAN TIIDA 2007 Service Owners Manual DIAGNOSIS SYSTEM [ABS ACTUATOR AND ELECTRIC UNIT (CONTROL

UNIT)]

BRC-107

< FUNCTION DIAGNOSIS >[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

CV1

(ON/OFF)––×Front side switch-over solenoid

valv](/img/5/57395/w960_57395-339.png)

DIAGNOSIS SYSTEM [ABS ACTUATOR AND ELECTRIC UNIT (CONTROL

UNIT)]

BRC-107

< FUNCTION DIAGNOSIS >[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

CV1

(ON/OFF)––×Front side switch-over solenoid

valve (cut valve) (ON/OFF) status is

displayed.

CV2

(ON/OFF)––×Rear side switch-over solenoid

valve (cut-valve) (ON/OFF) status is

displayed.

SV1

(ON/OFF)––×Front side switch-over solenoid

valve (suction valve) (ON/OFF) sta-

tus is displayed.

SV2

(ON/OFF)––×Rear side switch-over solenoid

valve (suction valve) (ON/OFF) sta-

tus is displayed.

VDC FAIL SIG

(ON/OFF)––×VDC fail signal (ON/OFF) status is

displayed.

TCS FAIL SIG

(ON/OFF)––×TCS fail signal (ON/OFF) status is

displayed.

ABS FAIL SIG

(ON/OFF)––×ABS fail signal (ON/OFF) status is

displayed.

EBD FAIL SIG

(ON/OFF)––×EBD fail signal (ON/OFF) status is

displayed.

FLUID LEV SW

(ON/OFF)×–×Brake fluid level switch (ON/OFF)

status is displayed.

EBD SIGNAL

(ON/OFF)––×EBD operation (ON/OFF) status is

displayed.

ABS SIGNAL

(ON/OFF)––×ABS operation (ON/OFF) status is

displayed.

TCS SIGNAL

(ON/OFF)––×TCS operation (ON/OFF) status is

displayed.

VDC SIGNAL

(ON/OFF)––×VDC operation (ON/OFF) status is

displayed.

EBD WARN LAMP – –×Brake warning lamp (ON/OFF) sta-

tus is displayed.

SLCT LVR POSI×××Shift position judged by PNP switch

signal.

R POSI SIG – –×Shift position judged by PNP switch

signal.

2WD/4WD – –×It recognizes on software whether it

is 2WD and whether it is in 4WD

state.

BST OPER SIG – –×

Active booster operation (ON/OFF)

status is displayed.

PRESS SENSOR×–×Brake pressure detected by pres-

sure sensor is displayed.

CRANKING SIG – –×The input state of the key SW

START position signal is displayed.

PRESS SEN 2 – –×Brake pressure detected by pres-

sure sensor is displayed.

DELTA S SEN – –×The amount of stroke sensor move-

ments in the active booster detected

by DELTA S SEN is displayed. Item

(Unit)Data monitor item selection

Remarks

ECU INPUT

SIGNALSMAIN

SIGNALSSELECTION

FROM MENU

Page 489 of 5883

![NISSAN TIIDA 2007 Service Owners Manual CO-8

< PRECAUTION >[HR16DE]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001534589

The Supplemental Rest NISSAN TIIDA 2007 Service Owners Manual CO-8

< PRECAUTION >[HR16DE]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001534589

The Supplemental Rest](/img/5/57395/w960_57395-488.png)

CO-8

< PRECAUTION >[HR16DE]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001534589

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

Precaution Necessary for Steering Wheel Rotation After Battery Disconnect

INFOID:0000000001534590

NOTE:

This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK″ position.

Always use CONSULT-II to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery power is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables.

NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

5. When the repair work is completed, return the ignition switch to the ″LOCK″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of all control units using CONSULT-II.

Precaution for Liquid GasketINFOID:0000000001534591

REMOVAL OF LIQUID GASKET SEALING

After removing nuts and bolts, separate the mating surface, using Tool and remove old liquid gasket sealing.

Page 513 of 5883

![NISSAN TIIDA 2007 Service Owners Manual CO-32

< PRECAUTION >[MR18DE]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001516585

The Supplemental Res NISSAN TIIDA 2007 Service Owners Manual CO-32

< PRECAUTION >[MR18DE]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001516585

The Supplemental Res](/img/5/57395/w960_57395-512.png)

CO-32

< PRECAUTION >[MR18DE]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001516585

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

Precaution Necessary for Steering Wheel Rotation After Battery Disconnect

INFOID:0000000001337832

NOTE:

This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK″ position.

Always use CONSULT-II to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery power is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables.

NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

5. When the repair work is completed, return the ignition switch to the ″LOCK″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of all control units using CONSULT-II.

Precaution for Liquid GasketINFOID:0000000001337833

REMOVAL OF LIQUID GASKET SEALING

After removing nuts and bolts, separate the mating surface, using Tool and remove old liquid gasket sealing.