stop start NISSAN TIIDA 2007 Service Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 793 of 5883

![NISSAN TIIDA 2007 Service Owners Manual DLK-204

< SYMPTOM DIAGNOSIS >[WITH I-KEY, WITHOUT SUPER LOCK]

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under t NISSAN TIIDA 2007 Service Owners Manual DLK-204

< SYMPTOM DIAGNOSIS >[WITH I-KEY, WITHOUT SUPER LOCK]

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under t](/img/5/57395/w960_57395-792.png)

DLK-204

< SYMPTOM DIAGNOSIS >[WITH I-KEY, WITHOUT SUPER LOCK]

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Inspection ProcedureINFOID:0000000001396664

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. Cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicon spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or rattle. If you saturate the area with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation procedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the areas with felt cloth tape or insulator foam blocks to

repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid dumpers out of adjustment

2. Trunk lid striker out of adjustment

3. Trunk lid torsion bars knocking together

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sunvisor shaft shaking in the holder

3. Front or rear windshield touching headlining and squeaking

Page 868 of 5883

![NISSAN TIIDA 2007 Service Owners Manual DIAGNOSIS SYSTEM (INTELLIGENT KEY UNIT)

DLK-279

< FUNCTION DIAGNOSIS >[WITH I-KEY & SUPER LOCK]

C

D

E

F

G

H

I

J

L

MA

B

DLK

N

O

P

ACTIVE TEST

Monitor Item Condition

PUSH SW Indicates [ON (pressed)/OFF NISSAN TIIDA 2007 Service Owners Manual DIAGNOSIS SYSTEM (INTELLIGENT KEY UNIT)

DLK-279

< FUNCTION DIAGNOSIS >[WITH I-KEY & SUPER LOCK]

C

D

E

F

G

H

I

J

L

MA

B

DLK

N

O

P

ACTIVE TEST

Monitor Item Condition

PUSH SW Indicates [ON (pressed)/OFF](/img/5/57395/w960_57395-867.png)

DIAGNOSIS SYSTEM (INTELLIGENT KEY UNIT)

DLK-279

< FUNCTION DIAGNOSIS >[WITH I-KEY & SUPER LOCK]

C

D

E

F

G

H

I

J

L

MA

B

DLK

N

O

P

ACTIVE TEST

Monitor Item Condition

PUSH SW Indicates [ON (pressed)/OFF (released)] condition of ignition knob switch.

KEY SW Indicates [ON (inserted)/OFF (removed)] condition of key switch.

DR REQ SW Indicates [ON (pressed)/OFF (released)] condition of door request switch (driver side).

AS REQ SWIndicates [ON (pressed)/OFF (released)] condition of door request switch (passenger

side).

BD/TR REQ SW Indicates [ON (pressed)/OFF (released)] condition of back door/trunk request switch.

IGN SWIndicates [ON (ON or START position)/OFF (other than ON and START position)] con-

dition of ignition switch ON position.

ACC SW Indicates [ON/OFF] condition of ignition switch ACC position.

STOP LAMP SW Indicates [ON/OFF] condition of stop lamp switch.

DOOR LOCK SIG Indicates [ON/OFF] condition of LOCK signal from Intelligent Key.

DOOR UNLOCK SIG Indicates [ON/OFF] condition of UNLOCK signal from Intelligent Key.

DOOR SW DRIndicates [OPEN/CLOSE] condition of front door switch (driver side) from BCM via CAN

communication.

DOOR SW ASIndicates [OPEN/CLOSE] condition of front door switch (passenger side) from BCM via

CAN communication.

DOOR SW RRIndicates [OPEN/CLOSE] condition of rear door switch (RH) from BCM via CAN com-

munication.

DOOR SW RLIndicates [OPEN/CLOSE] condition of rear door switch (LH) from BCM via CAN com-

munication.

DOOR BK SWIndicates [OPEN/CLOSE] condition of back door switch from BCM via CAN communi-

cation.

VEHICLE SPEEDDisplays the vehicle speed signal received from combination meter by numerical value

[km/h].

Test item Description

DOOR LOCK/UNLOCKThis test is able to check door lock/unlock operation.

ALL UNLK: All door lock actuators are unlocked.

DR UNLK: Door lock actuator (driver side) is unlocked.

AS UNLK: Door lock actuator (passenger side) is unlocked.

BK UNLK: This item is indicated, but inactive.

LOCK: All door lock actuator is locked.

ANTENNAThis test is able to check Intelligent Key antenna operation.

When the following condition are met, hazard warning lamps flash.

ROOM ANT1: Inside key antenna (console) detects Intelligent Key, when “ROOM

ANT1” is selected.

ROOM ANT2: Inside key antenna (instrument center/rear seat) detects Intelligent

Key, when “ROOM ANT2”is selected.

DRIVER ANT: Outside key antenna (driver side) detects Intelligent Key, when “DRIV-

ER ANT” is selected.

ASSIST ANT: Outside key antenna (passenger side) detects Intelligent Key, when

“ASSIST ANT” is selected.

BK DOOR ANT: Outside key antenna (rear bumper) detects Intelligent Key, when “BK

DOOR ANT” is selected.

OUTSIDE BUZZERThis test is able to check Intelligent Key warning buzzer(s) operation.

ON

OFF

INSIDE BUZZERThis test is able to check warning chime in combination meter operation.

TAKE OUT: Take away warning chime sounds.

KNOB: Ignition knob switch warning chime sounds.

KEY: Key warning chime sounds.

OFF

Page 1017 of 5883

![NISSAN TIIDA 2007 Service Owners Manual DLK-428

< SYMPTOM DIAGNOSIS >[WITH I-KEY & SUPER LOCK]

WARNING FUNCTION SYMPTOMS

Intelligent Key is registered.

Key is not inserted in ignition switch.

One or more registered Intelligent Keys ar NISSAN TIIDA 2007 Service Owners Manual DLK-428

< SYMPTOM DIAGNOSIS >[WITH I-KEY & SUPER LOCK]

WARNING FUNCTION SYMPTOMS

Intelligent Key is registered.

Key is not inserted in ignition switch.

One or more registered Intelligent Keys ar](/img/5/57395/w960_57395-1016.png)

DLK-428

< SYMPTOM DIAGNOSIS >[WITH I-KEY & SUPER LOCK]

WARNING FUNCTION SYMPTOMS

Intelligent Key is registered.

Key is not inserted in ignition switch.

One or more registered Intelligent Keys are in the vehicle.

KEY WARNING LAMP DOES NOT ILLUMINATE

Conditions of Vehicle (Operating Conditions)

Intelligent Key is registered.

Mechanical key is out of ignition switch.

One or more registered Intelligent Keys are in the vehicle.

ENGINE START CONDITION CHECK (LOCKED IGNITION KNOB)

NOTE:

Before performing the diagnosis in the following table, check “Trouble Diagnosis Procedure”. Refer to DLK-

16, "Work Flow".

If the following “symptoms” are detected, check systems shown in the ”Diagnoses/service procedure” col-

umn in this order.

WARNING LAMP

WARNING LAMP : Symptom TableINFOID:0000000001530567

WARNING LAMP OPERATION MALFUNCTION

NOTE:

Before performing the diagnosis in the following table, check “Work Flow”. Refer to DLK-16, "

Work Flow".

Check that vehicle is under the condition shown in “Conditions of vehicle” before starting diagnosis, and

check each symptom.

If the following symptoms are detected, check systems shown in the “Diagnosis/service procedure” column

in this order.

Conditions of Vehicle (Operating Conditions)

Symptom Diagnosis/service procedure Reference page

Ignition switch does not turn on with Intelligent Key.

[KEY warning lamp (red) illuminates].1a. Check instrument panel inside key antenna.DLK-120

1b. Check front console inside key antenna.DLK-123

1c. Check rear floor inside key antenna.DLK-127

2. Replace Intelligent Key unit.SEC-79

Symptom Diagnosis/service procedure Reference page

Ignition switch does not turn on with Intelligent Key.

[GREEN key warning lamp does not illuminate].1. Check Intelligent Key unit power supply and ground cir-

cuit.DLK-59

2. Check ignition knob switch.DLK-80

3. Check key switch.DLK-77

4. Check "KEY" warning lamp (GREEN).DLK-146

5. Replace Intelligent Key unit.SEC-79

RED key warning lamp does not illuminate

[Without Intelligent Key].1. Check "KEY" warning lamp (RED).DLK-146

2. Replace Intelligent Key unit.SEC-79

Symptom Diagnosis/service procedure Reference page

Engine start condition check1. Check park/neutral position switch in combination meter (A/T)MWI-3

2. Check key interlock solenoid (M/T)DLK-137

3. Check stop lamp switch (A/T)DLK-138

4. Check stop lamp switch (M/T)DLK-140

Page 1022 of 5883

![NISSAN TIIDA 2007 Service Owners Manual SQUEAK AND RATTLE TROUBLE DIAGNOSES

DLK-433

< SYMPTOM DIAGNOSIS >[WITH I-KEY & SUPER LOCK]

C

D

E

F

G

H

I

J

L

MA

B

DLK

N

O

P

Confirm that the cause of a noise is repaired by test driving the vehicle. O NISSAN TIIDA 2007 Service Owners Manual SQUEAK AND RATTLE TROUBLE DIAGNOSES

DLK-433

< SYMPTOM DIAGNOSIS >[WITH I-KEY & SUPER LOCK]

C

D

E

F

G

H

I

J

L

MA

B

DLK

N

O

P

Confirm that the cause of a noise is repaired by test driving the vehicle. O](/img/5/57395/w960_57395-1021.png)

SQUEAK AND RATTLE TROUBLE DIAGNOSES

DLK-433

< SYMPTOM DIAGNOSIS >[WITH I-KEY & SUPER LOCK]

C

D

E

F

G

H

I

J

L

MA

B

DLK

N

O

P

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Inspection ProcedureINFOID:0000000001396892

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. Cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicon spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or rattle. If you saturate the area with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation procedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the areas with felt cloth tape or insulator foam blocks to

repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid dumpers out of adjustment

2. Trunk lid striker out of adjustment

3. Trunk lid torsion bars knocking together

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sunvisor shaft shaking in the holder

3. Front or rear windshield touching headlining and squeaking

Page 1164 of 5883

![NISSAN TIIDA 2007 Service Owners Manual SQUEAK AND RATTLE TROUBLE DIAGNOSES

DLK-575

< SYMPTOM DIAGNOSIS >[WITHOUT I-KEY & SUPER LOCK]

C

D

E

F

G

H

I

J

L

MA

B

DLK

N

O

P

Confirm that the cause of a noise is repaired by test driving the vehicle NISSAN TIIDA 2007 Service Owners Manual SQUEAK AND RATTLE TROUBLE DIAGNOSES

DLK-575

< SYMPTOM DIAGNOSIS >[WITHOUT I-KEY & SUPER LOCK]

C

D

E

F

G

H

I

J

L

MA

B

DLK

N

O

P

Confirm that the cause of a noise is repaired by test driving the vehicle](/img/5/57395/w960_57395-1163.png)

SQUEAK AND RATTLE TROUBLE DIAGNOSES

DLK-575

< SYMPTOM DIAGNOSIS >[WITHOUT I-KEY & SUPER LOCK]

C

D

E

F

G

H

I

J

L

MA

B

DLK

N

O

P

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Inspection ProcedureINFOID:0000000001397115

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. Cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicon spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or rattle. If you saturate the area with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation procedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the areas with felt cloth tape or insulator foam blocks to

repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid dumpers out of adjustment

2. Trunk lid striker out of adjustment

3. Trunk lid torsion bars knocking together

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sunvisor shaft shaking in the holder

3. Front or rear windshield touching headlining and squeaking

Page 1315 of 5883

![NISSAN TIIDA 2007 Service Owners Manual DLK-726

< SYMPTOM DIAGNOSIS >[WITHOUT I-KEY, WITH SUPER LOCK]

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under t NISSAN TIIDA 2007 Service Owners Manual DLK-726

< SYMPTOM DIAGNOSIS >[WITHOUT I-KEY, WITH SUPER LOCK]

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under t](/img/5/57395/w960_57395-1314.png)

DLK-726

< SYMPTOM DIAGNOSIS >[WITHOUT I-KEY, WITH SUPER LOCK]

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Inspection ProcedureINFOID:0000000001397340

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. Cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicon spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or rattle. If you saturate the area with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation procedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the areas with felt cloth tape or insulator foam blocks to

repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid dumpers out of adjustment

2. Trunk lid striker out of adjustment

3. Trunk lid torsion bars knocking together

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sunvisor shaft shaking in the holder

3. Front or rear windshield touching headlining and squeaking

Page 1365 of 5883

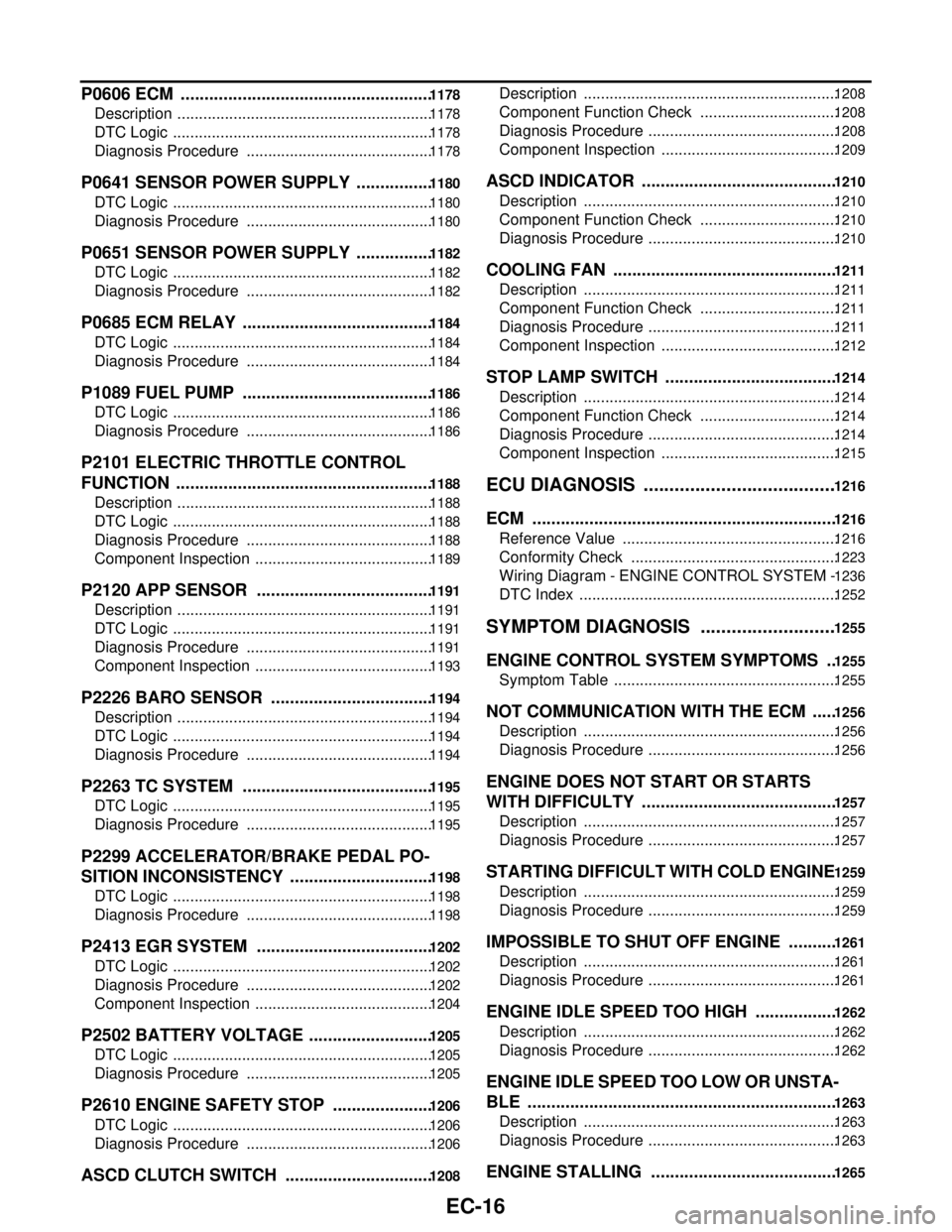

EC-16

P0606 ECM .....................................................1178

Description ...........................................................1178

DTC Logic ............................................................1178

Diagnosis Procedure ...........................................1178

P0641 SENSOR POWER SUPPLY ................1180

DTC Logic ............................................................1180

Diagnosis Procedure ...........................................1180

P0651 SENSOR POWER SUPPLY ................1182

DTC Logic ............................................................1182

Diagnosis Procedure ...........................................1182

P0685 ECM RELAY ........................................1184

DTC Logic ............................................................1184

Diagnosis Procedure ...........................................1184

P1089 FUEL PUMP ........................................1186

DTC Logic ............................................................1186

Diagnosis Procedure ...........................................1186

P2101 ELECTRIC THROTTLE CONTROL

FUNCTION ......................................................

1188

Description ...........................................................1188

DTC Logic ............................................................1188

Diagnosis Procedure ...........................................1188

Component Inspection .........................................1189

P2120 APP SENSOR .....................................1191

Description ...........................................................1191

DTC Logic ............................................................1191

Diagnosis Procedure ...........................................1191

Component Inspection .........................................1193

P2226 BARO SENSOR ..................................1194

Description ...........................................................1194

DTC Logic ............................................................1194

Diagnosis Procedure ...........................................1194

P2263 TC SYSTEM ........................................1195

DTC Logic ............................................................1195

Diagnosis Procedure ...........................................1195

P2299 ACCELERATOR/BRAKE PEDAL PO-

SITION INCONSISTENCY ..............................

1198

DTC Logic ............................................................1198

Diagnosis Procedure ...........................................1198

P2413 EGR SYSTEM .....................................1202

DTC Logic ............................................................1202

Diagnosis Procedure ...........................................1202

Component Inspection .........................................1204

P2502 BATTERY VOLTAGE ..........................1205

DTC Logic ............................................................1205

Diagnosis Procedure ...........................................1205

P2610 ENGINE SAFETY STOP .....................1206

DTC Logic ............................................................1206

Diagnosis Procedure ...........................................1206

ASCD CLUTCH SWITCH ...............................1208

Description ...........................................................1208

Component Function Check ................................1208

Diagnosis Procedure ............................................1208

Component Inspection .........................................1209

ASCD INDICATOR .........................................1210

Description ...........................................................1210

Component Function Check ................................1210

Diagnosis Procedure ............................................1210

COOLING FAN ...............................................1211

Description ...........................................................1211

Component Function Check ................................1211

Diagnosis Procedure ............................................1211

Component Inspection .........................................1212

STOP LAMP SWITCH ....................................1214

Description ...........................................................1214

Component Function Check ................................1214

Diagnosis Procedure ............................................1214

Component Inspection .........................................1215

ECU DIAGNOSIS .....................................1216

ECM ................................................................1216

Reference Value ..................................................1216

Conformity Check ................................................1223

Wiring Diagram - ENGINE CONTROL SYSTEM - 1236

DTC Index ............................................................1252

SYMPTOM DIAGNOSIS ..........................1255

ENGINE CONTROL SYSTEM SYMPTOMS ..1255

Symptom Table ....................................................1255

NOT COMMUNICATION WITH THE ECM .....1256

Description ...........................................................1256

Diagnosis Procedure ............................................1256

ENGINE DOES NOT START OR STARTS

WITH DIFFICULTY .........................................

1257

Description ...........................................................1257

Diagnosis Procedure ............................................1257

STARTING DIFFICULT WITH COLD ENGINE 1259

Description ...........................................................1259

Diagnosis Procedure ............................................1259

IMPOSSIBLE TO SHUT OFF ENGINE ..........1261

Description ...........................................................1261

Diagnosis Procedure ............................................1261

ENGINE IDLE SPEED TOO HIGH .................1262

Description ...........................................................1262

Diagnosis Procedure ............................................1262

ENGINE IDLE SPEED TOO LOW OR UNSTA-

BLE .................................................................

1263

Description ...........................................................1263

Diagnosis Procedure ............................................1263

ENGINE STALLING .......................................1265

Page 1372 of 5883

![NISSAN TIIDA 2007 Service Owners Manual INSPECTION AND ADJUSTMENT

EC-23

< BASIC INSPECTION >[HR16DE (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

2. Rev engine (2,000 to 3,000 rpm) two or three times under no

load, then run engine at idl NISSAN TIIDA 2007 Service Owners Manual INSPECTION AND ADJUSTMENT

EC-23

< BASIC INSPECTION >[HR16DE (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

2. Rev engine (2,000 to 3,000 rpm) two or three times under no

load, then run engine at idl](/img/5/57395/w960_57395-1371.png)

INSPECTION AND ADJUSTMENT

EC-23

< BASIC INSPECTION >[HR16DE (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

2. Rev engine (2,000 to 3,000 rpm) two or three times under no

load, then run engine at idle speed for about 1 minute.

3. Check idle speed.

For procedure, refer to EC-26, "

IDLE SPEED : Special Repair

Requirement".

For specification, refer to EC-380, "

Idle Speed".

Is the inspection result normal?

YES >> GO TO 10.

NO >> GO TO 4.

4.PERFORM ACCELERATOR PEDAL RELEASED POSITION LEARNING

1. Stop engine.

2. Perform EC-26, "

ACCELERATOR PEDAL RELEASED POSITION LEARNING : Special Repair Require-

ment".

>> GO TO 5.

5.PERFORM THROTTLE VALVE CLOSED POSITION LEARNING

Perform EC-27, "

THROTTLE VALVE CLOSED POSITION LEARNING : Special Repair Requirement".

>> GO TO 6.

6.PERFORM IDLE AIR VOLUME LEARNING

Perform EC-27, "

IDLE AIR VOLUME LEARNING : Special Repair Requirement".

Is Idle Air Volume Learning carried out successfully?

YES >> GO TO 7.

NO >> Follow the instruction of Idle Air Volume Learning. Then GO TO 4.

7.CHECK TARGET IDLE SPEED AGAIN

1. Start engine and warm it up to normal operating temperature.

2. Check idle speed.

For procedure, refer to EC-26, "

IDLE SPEED : Special Repair Requirement".

For specification, refer to EC-380, "

Idle Speed".

Is the inspection result normal?

YES >> GO TO 10.

NO >> GO TO 8.

8.DETECT MALFUNCTIONING PART

Check the Following.

Check camshaft position sensor (PHASE) and circuit. Refer to EC-202, "

Diagnosis Procedure".

Check crankshaft position sensor (POS) and circuit. Refer to EC-198, "

Diagnosis Procedure".

Is the inspection result normal?

YES >> GO TO 9.

NO >> Repair or replace. Then GO TO 4.

9.CHECK ECM FUNCTION

1. Substitute another known-good ECM to check ECM function. (ECM may be the cause of an incident, but

this is a rare case.)

2. Perform initialization of NATS system and registration of all NATS ignition key IDs. Refer to SEC-7, "

ECM

RE-COMMUNICATING FUNCTION : Special Repair Requirement" or SEC-83, "ECM RE-COMMUNICAT-

ING FUNCTION : Special Repair Requirement".

>> GO TO 4.

10.CHECK IGNITION TIMING

PBIA8513J

Page 1373 of 5883

![NISSAN TIIDA 2007 Service Owners Manual EC-24

< BASIC INSPECTION >[HR16DE (WITH EURO-OBD)]

INSPECTION AND ADJUSTMENT

1. Run engine at idle.

2. Check ignition timing with a timing light.

For procedure, refer to EC-26, "

IGNITION TIMING : Spe NISSAN TIIDA 2007 Service Owners Manual EC-24

< BASIC INSPECTION >[HR16DE (WITH EURO-OBD)]

INSPECTION AND ADJUSTMENT

1. Run engine at idle.

2. Check ignition timing with a timing light.

For procedure, refer to EC-26, "

IGNITION TIMING : Spe](/img/5/57395/w960_57395-1372.png)

EC-24

< BASIC INSPECTION >[HR16DE (WITH EURO-OBD)]

INSPECTION AND ADJUSTMENT

1. Run engine at idle.

2. Check ignition timing with a timing light.

For procedure, refer to EC-26, "

IGNITION TIMING : Special

Repair Requirement".

For specification, refer to EC-380, "

Ignition Timing".

Is the inspection result normal?

YES >> GO TO 19.

NO >> GO TO 11.

11 .PERFORM ACCELERATOR PEDAL RELEASED POSITION LEARNING

1. Stop engine.

2. Perform EC-26, "

ACCELERATOR PEDAL RELEASED POSITION LEARNING : Special Repair Require-

ment".

>> GO TO 12.

12.PERFORM THROTTLE VALVE CLOSED POSITION LEARNING

Perform EC-27, "

THROTTLE VALVE CLOSED POSITION LEARNING : Special Repair Requirement".

>> GO TO 13.

13.PERFORM IDLE AIR VOLUME LEARNING

Perform EC-27, "

IDLE AIR VOLUME LEARNING : Special Repair Requirement".

Is Idle Air Volume Learning carried out successfully?

YES >> GO TO 14.

NO >> Follow the instruction of Idle Air Volume Learning. Then GO TO 4.

14.CHECK TARGET IDLE SPEED AGAIN

1. Start engine and warm it up to normal operating temperature.

2. Check idle speed.

For procedure, refer to EC-26, "

IDLE SPEED : Special Repair Requirement".

For specification, refer to EC-380, "

Idle Speed".

Is the inspection result normal?

YES >> GO TO 15.

NO >> GO TO 17.

15.CHECK IGNITION TIMING AGAIN

1. Run engine at idle.

2. Check ignition timing with a timing light.

For procedure, refer to EC-26, "

IGNITION TIMING : Special

Repair Requirement".

For specification, refer to EC-380, "

Ignition Timing".

Is the inspection result normal?

YES >> GO TO 19.

NO >> GO TO 16.

16.CHECK TIMING CHAIN INSTALLATION

Check timing chain installation. Refer to EM-50, "

Removal and Installation".

Is the inspection result normal?

YES >> GO TO 17.

1 : Timing indicator

MBIB1331E

1 : Timing indicator

MBIB1331E

Page 1376 of 5883

![NISSAN TIIDA 2007 Service Owners Manual INSPECTION AND ADJUSTMENT

EC-27

< BASIC INSPECTION >[HR16DE (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

quirementINFOID:0000000001161131

1.START

1. Make sure that accelerator pedal is fully relea NISSAN TIIDA 2007 Service Owners Manual INSPECTION AND ADJUSTMENT

EC-27

< BASIC INSPECTION >[HR16DE (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

quirementINFOID:0000000001161131

1.START

1. Make sure that accelerator pedal is fully relea](/img/5/57395/w960_57395-1375.png)

INSPECTION AND ADJUSTMENT

EC-27

< BASIC INSPECTION >[HR16DE (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

quirementINFOID:0000000001161131

1.START

1. Make sure that accelerator pedal is fully released.

2. Turn ignition switch ON and wait at least 2 seconds.

3. Turn ignition switch OFF and wait at least 10 seconds.

4. Turn ignition switch ON and wait at least 2 seconds.

5. Turn ignition switch OFF and wait at least 10 seconds.

>> END

THROTTLE VALVE CLOSED POSITION LEARNING

THROTTLE VALVE CLOSED POSITION LEARNING : DescriptionINFOID:0000000001161132

Throttle Valve Closed Position Learning is a function of ECM to learn the fully closed position of the throttle

valve by monitoring the throttle position sensor output signal. It must be performed each time harness connec-

tor of electric throttle control actuator or ECM is disconnected.

THROTTLE VALVE CLOSED POSITION LEARNING : Special Repair Requirement

INFOID:0000000001161133

1.START

1. Make sure that accelerator pedal is fully released.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

Make sure that throttle valve moves during above 10 seconds by confirming the operating sound.

>> END

IDLE AIR VOLUME LEARNING

IDLE AIR VOLUME LEARNING : DescriptionINFOID:0000000001161134

Idle Air Volume Learning is a function of ECM to learn the idle air volume that keeps each engine idle speed

within the specific range. It must be performed under any of the following conditions:

Each time electric throttle control actuator or ECM is replaced.

Idle speed or ignition timing is out of specification.

IDLE AIR VOLUME LEARNING : Special Repair RequirementINFOID:0000000001161135

1.PRECONDITIONING

Make sure that all of the following conditions are satisfied.

Learning will be cancelled if any of the following conditions are missed for even a moment.

Battery voltage: More than 12.9V (At idle)

Engine coolant temperature: 70 - 100°C (158 - 212°F)

Park/neutral position switch: ON

Electric load switch: OFF

(Air conditioner, headlamp, rear window defogger)

On vehicles equipped with daytime light systems, set lighting switch to the 1st position to light only

small lamps.

Steering wheel: Neutral (Straight-ahead position)

Vehicle speed: Stopped

Transmission: Warmed-up

- For A/T models with CONSULT-III

Drive vehicle until “ATF TEMP SE 1” in “DATA MONITOR” mode of “A/T” system indicates less than 0.9V.

- For A/T models without CONSULT-III and M/T models.

Drive vehicle for 10 minutes

Do you have CONSULT-III?

YES >> GO TO 2.