engine coolant NISSAN TIIDA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 4978 of 5883

![NISSAN TIIDA 2007 Service Repair Manual TM-32

< FUNCTION DIAGNOSIS >[TYPE 1 (4AT: RE4F03B)]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

ON BOARD DIAGNOSTIC (OBD) SYSTEM

IntroductionINFOID:0000000001694433

A/T system has two self-diagnostic systems.

Th NISSAN TIIDA 2007 Service Repair Manual TM-32

< FUNCTION DIAGNOSIS >[TYPE 1 (4AT: RE4F03B)]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

ON BOARD DIAGNOSTIC (OBD) SYSTEM

IntroductionINFOID:0000000001694433

A/T system has two self-diagnostic systems.

Th](/img/5/57395/w960_57395-4977.png)

TM-32

< FUNCTION DIAGNOSIS >[TYPE 1 (4AT: RE4F03B)]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

ON BOARD DIAGNOSTIC (OBD) SYSTEM

IntroductionINFOID:0000000001694433

A/T system has two self-diagnostic systems.

The first is emission-related on board diagnostic system (OBD) performed by the TCM in combination with the

ECM. The malfunction is indicated by the MIL (malfunction indicator lamp) and is stored as a DTC in the ECM

memory but not the TCM memory.

The second is the TCM original self-diagnosis indicated by the OD OFF indicator lamp. The malfunction is

stored in the TCM memory. The detected items are overlapped with OBD self-diagnostic items. For detail,

refer to TM-35, "

CONSULT-III Function (TRANSMISSION)".

OBD Function for A/T SystemINFOID:0000000001694434

The ECM provides emission-related on board diagnostic (OBD) functions for the A/T system. One function is

to receive a signal from the TCM used with OBD-related parts of the A/T system. The signal is sent to the ECM

when a malfunction occurs in the corresponding OBD-related part. The other function is to indicate a diagnos-

tic result by means of the MIL (malfunction indicator lamp) on the instrument panel. Sensors, switches and

solenoid valves are used as sensing elements.

The MIL automatically illuminates in One or Two Trip Detection Logic when a malfunction is sensed in relation

to A/T system parts.

One or Two Trip Detection Logic of OBDINFOID:0000000001694435

ONE TRIP DETECTION LOGIC

If a malfunction is sensed during the first test drive, the MIL will illuminate and the malfunction will be stored in

the ECM memory as a DTC. The TCM is not provided with such a memory function.

TWO TRIP DETECTION LOGIC

When a malfunction is sensed during the first test drive, it is stored in the ECM memory as a 1st trip DTC

(diagnostic trouble code) or 1st trip freeze frame data. At this point, the MIL will not illuminate. — 1st trip

If the same malfunction as that experienced during the first test drive is sensed during the second test drive,

the MIL will illuminate. — 2nd trip

The “trip” in the “One or Two Trip Detection Logic” means a driving mode in which self-diagnosis is performed

during vehicle operation.

OBD Diagnostic Trouble Code (DTC)INFOID:0000000001694436

HOW TO READ DTC AND 1ST TRIP DTC

DTC and 1st trip DTC can be read by the following methods.

( with CONSULT-III or GST) CONSULT-III or GST (Generic Scan Tool) Examples: P0705, P0720 etc.

These DTC are prescribed by SAE J2012.

(CONSULT-III also displays the malfunctioning component or system.)

1st trip DTC No. is the same as DTC No.

Output of the diagnostic trouble code indicates that the indicated circuit has a malfunction. How-

ever, in case of the Mode II and GST, they do not indicate whether the malfunction is still occurring or

occurred in the past and returned to normal.

CONSULT-III can identify them as shown below, therefore, CONSULT-III (if available) is recom-

mended.

Freeze Frame Data and 1st Trip Freeze Frame Data

The ECM has a memory function, which stores the driving condition such as fuel system status, calculated

load value, engine coolant temperature, short term fuel trim, long term fuel trim, engine speed and vehicle

speed at the moment the ECM detects a malfunction.

Data which are stored in the ECM memory, along with the 1st trip DTC, are called 1st trip freeze frame data,

and the data, stored together with the DTC data, are called freeze frame data and displayed on CONSULT-III

or GST. The 1st trip freeze frame data can only be displayed on the CONSULT-III screen, not on the GST. For

detail, refer to EC-107, "

CONSULT-III Function".

Only one set of freeze frame data (either 1st trip freeze frame data of freeze frame data) can be stored in the

ECM. 1st trip freeze frame data is stored in the ECM memory along with the 1st trip DTC. There is no priority

for 1st trip freeze frame data and it is updated each time a different 1st trip DTC is detected. However, once

freeze frame data (2nd trip detection/MIL on) is stored in the ECM memory, 1st trip freeze frame data is no

Page 5111 of 5883

![NISSAN TIIDA 2007 Service Repair Manual PRECAUTIONS

TM-165

< PRECAUTION >[TYPE 1 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

Before assembly, apply a coat of recommended ATF to all parts. Apply petroleum jelly to protect O-rings and

s NISSAN TIIDA 2007 Service Repair Manual PRECAUTIONS

TM-165

< PRECAUTION >[TYPE 1 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

Before assembly, apply a coat of recommended ATF to all parts. Apply petroleum jelly to protect O-rings and

s](/img/5/57395/w960_57395-5110.png)

PRECAUTIONS

TM-165

< PRECAUTION >[TYPE 1 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

Before assembly, apply a coat of recommended ATF to all parts. Apply petroleum jelly to protect O-rings and

seals, or hold bearings and washers in place during assembly. Do not use grease.

Extreme care should be taken to avoid damage to O-rings, seals and gaskets when assembling.

After overhaul, refill the A/T with new ATF.

When the A/T drain plug is removed, only some of the fluid is drained. Old A/T fluid will remain in torque con-

verter and ATF cooling system.

Always follow the procedures under “Changing A/T Fluid” in the AT section when changing A/T fluid. Refer to

XX-XX, "*****"

, XX-XX, "*****".

Service Notice or PrecautionINFOID:0000000001696268

TORQUE CONVERTER SERVICE

The torque converter should be replaced under any of the following conditions:

External leaks in the hub weld area.

Converter hub is scored or damaged.

Converter pilot is broken, damaged or fits poorly into crankshaft.

Steel particles are found after flushing the cooler and cooler lines.

Pump is damaged or steel particles are found in the converter.

Vehicle has TCC shudder and/or no TCC apply. Replace only after all hydraulic and electrical diagnoses

have been made. (Converter clutch material may be glazed.)

Converter is contaminated with engine coolant containing antifreeze.

Internal malfunction of stator roller clutch.

Heavy clutch debris due to overheating (blue converter).

Steel particles or clutch lining material found in fluid filter or on magnet when no internal parts in unit are

worn or damaged — indicates that lining material came from converter.

The torque converter should not be replaced if:

The fluid has an odor, is discolored, and there is no evidence of metal or clutch facing particles.

The threads in one or more of the converter bolt holes are damaged.

A/T malfunction did not display evidence of damaged or worn internal parts, steel particles or clutch plate lin-

ing material in unit and inside the fluid filter.

Vehicle has been exposed to high mileage (only). The exception may be where the torque converter clutch

dampener plate lining has seen excess wear by vehicles operated in heavy and/or constant traffic, such as

taxi, delivery or police use.

OBD SELF-DIAGNOSIS (FOR TYPE 1 ONLY)

A/T self-diagnosis is performed by the TCM in combination with the ECM. The results can be read through

the blinking pattern of the OD OFF indicator lamp or the malfunction indicator lamp (MIL). Refer to the table

on XX-XX, "*****"

for the indicator used to display each self-diagnostic result.

The self-diagnostic results indicated by the MIL are automatically stored in both the ECM and TCM memo-

ries.

Always perform the procedure “HOW TO ERASE DTC” on XX-XX, "*****"

to complete the repair and

avoid unnecessary blinking of the MIL.

The following self-diagnostic items can be detected using ECM self-diagnostic results mode* only when the

OD OFF indicator lamp does not indicate any malfunctions.

-PNP switch

- A/T 1st, 2nd, 3rd, or 4th gear function

*: For details of OBD, refer to XX-XX, "*****"

.

Wiring Diagram and Trouble DiagnosisINFOID:0000000001696269

When reading wiring diagrams, refer to the following:

XX-XX, "*****"

XX-XX, "*****"

When performing trouble diagnosis, refer to the following:

XX-XX, "*****"

XX-XX, "*****"

Page 5413 of 5883

![NISSAN TIIDA 2007 Service Repair Manual PRECAUTIONS

TM-467

< PRECAUTION >[TYPE 2 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

Before assembly, apply a coat of recommended ATF to all parts. Apply petroleum jelly to protect O-rings and

s NISSAN TIIDA 2007 Service Repair Manual PRECAUTIONS

TM-467

< PRECAUTION >[TYPE 2 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

Before assembly, apply a coat of recommended ATF to all parts. Apply petroleum jelly to protect O-rings and

s](/img/5/57395/w960_57395-5412.png)

PRECAUTIONS

TM-467

< PRECAUTION >[TYPE 2 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

Before assembly, apply a coat of recommended ATF to all parts. Apply petroleum jelly to protect O-rings and

seals, or hold bearings and washers in place during assembly. Do not use grease.

Extreme care should be taken to avoid damage to O-rings, seals and gaskets when assembling.

After overhaul, refill the A/T with new ATF.

When the A/T drain plug is removed, only some of the fluid is drained. Old A/T fluid will remain in torque con-

verter and ATF cooling system.

Always follow the procedures under “Changing A/T Fluid” in the AT section when changing A/T fluid. Refer to

XX-XX, "*****"

, XX-XX, "*****".

Service Notice or PrecautionINFOID:0000000001723048

TORQUE CONVERTER SERVICE

The torque converter should be replaced under any of the following conditions:

External leaks in the hub weld area.

Converter hub is scored or damaged.

Converter pilot is broken, damaged or fits poorly into crankshaft.

Steel particles are found after flushing the cooler and cooler lines.

Pump is damaged or steel particles are found in the converter.

Vehicle has TCC shudder and/or no TCC apply. Replace only after all hydraulic and electrical diagnoses

have been made. (Converter clutch material may be glazed.)

Converter is contaminated with engine coolant containing antifreeze.

Internal malfunction of stator roller clutch.

Heavy clutch debris due to overheating (blue converter).

Steel particles or clutch lining material found in fluid filter or on magnet when no internal parts in unit are

worn or damaged — indicates that lining material came from converter.

The torque converter should not be replaced if:

The fluid has an odor, is discolored, and there is no evidence of metal or clutch facing particles.

The threads in one or more of the converter bolt holes are damaged.

A/T malfunction did not display evidence of damaged or worn internal parts, steel particles or clutch plate lin-

ing material in unit and inside the fluid filter.

Vehicle has been exposed to high mileage (only). The exception may be where the torque converter clutch

dampener plate lining has seen excess wear by vehicles operated in heavy and/or constant traffic, such as

taxi, delivery or police use.

OBD SELF-DIAGNOSIS (FOR TYPE 1 ONLY)

A/T self-diagnosis is performed by the TCM in combination with the ECM. The results can be read through

the blinking pattern of the OD OFF indicator lamp or the malfunction indicator lamp (MIL). Refer to the table

on XX-XX, "*****"

for the indicator used to display each self-diagnostic result.

The self-diagnostic results indicated by the MIL are automatically stored in both the ECM and TCM memo-

ries.

Always perform the procedure “HOW TO ERASE DTC” on XX-XX, "*****"

to complete the repair and

avoid unnecessary blinking of the MIL.

The following self-diagnostic items can be detected using ECM self-diagnostic results mode* only when the

OD OFF indicator lamp does not indicate any malfunctions.

-PNP switch

- A/T 1st, 2nd, 3rd, or 4th gear function

*: For details of OBD, refer to XX-XX, "*****"

.

Wiring Diagram and Trouble DiagnosisINFOID:0000000001723049

When reading wiring diagrams, refer to the following:

XX-XX, "*****"

XX-XX, "*****"

When performing trouble diagnosis, refer to the following:

XX-XX, "*****"

XX-XX, "*****"

Page 5673 of 5883

![NISSAN TIIDA 2007 Service Repair Manual VTL-12

< ON-VEHICLE REPAIR >[AUTOMATIC AIR CONDITIONER]

A/C UNIT ASSEMBLY

A/C UNIT ASSEMBLY

Removal and InstallationINFOID:0000000001696285

NOTE:

A LHD model shown, RHD model similar.

REMOVAL

1. Use t NISSAN TIIDA 2007 Service Repair Manual VTL-12

< ON-VEHICLE REPAIR >[AUTOMATIC AIR CONDITIONER]

A/C UNIT ASSEMBLY

A/C UNIT ASSEMBLY

Removal and InstallationINFOID:0000000001696285

NOTE:

A LHD model shown, RHD model similar.

REMOVAL

1. Use t](/img/5/57395/w960_57395-5672.png)

VTL-12

< ON-VEHICLE REPAIR >[AUTOMATIC AIR CONDITIONER]

A/C UNIT ASSEMBLY

A/C UNIT ASSEMBLY

Removal and InstallationINFOID:0000000001696285

NOTE:

A LHD model shown, RHD model similar.

REMOVAL

1. Use the recovery/recycling equipment (for HFC-134a) to discharge the refrigerant. Refer to HA-29, "HFC-

134a (R-134a) Service Procedure".

2. Drain the coolant from the cooling system. Refer to CO-11, "

Changing Engine Coolant" (HR16DE), CO-

35, "Changing Engine Coolant" (MR18DE), CO-58, "Draining" (K9K).

3. Remove cowl top cover. Refer to EXT-20, "

Removal and Installation".

4. Remove lower dash insulator.

5. Remove bolt (A), and then disconnect low-pressure flexible

hose (1) and high-pressure pipe (2) from evaporator.

CAUTION:

Cap or wrap the joint of the pipe with suitable material such

as vinyl tape to avoid the entry of air.

6. Remove clamps (A), and then disconnect heater hoses (1) from

heater core.

SJIA0648E

A. A/C unit assembly bolts B. Steering member bolts C. Steering column nuts

SJIA0644E

SJIA0645E

Page 5674 of 5883

![NISSAN TIIDA 2007 Service Repair Manual A/C UNIT ASSEMBLY

VTL-13

< ON-VEHICLE REPAIR >[AUTOMATIC AIR CONDITIONER]

C

D

E

F

G

H

J

K

L

MA

B

VTL

N

O

P

7. Remove console box assembly. Refer to IP-11, "Removal and Installation"

8. Remove the inst NISSAN TIIDA 2007 Service Repair Manual A/C UNIT ASSEMBLY

VTL-13

< ON-VEHICLE REPAIR >[AUTOMATIC AIR CONDITIONER]

C

D

E

F

G

H

J

K

L

MA

B

VTL

N

O

P

7. Remove console box assembly. Refer to IP-11, "Removal and Installation"

8. Remove the inst](/img/5/57395/w960_57395-5673.png)

A/C UNIT ASSEMBLY

VTL-13

< ON-VEHICLE REPAIR >[AUTOMATIC AIR CONDITIONER]

C

D

E

F

G

H

J

K

L

MA

B

VTL

N

O

P

7. Remove console box assembly. Refer to IP-11, "Removal and Installation"

8. Remove the instrument stay nuts (A) and harness clamps (B),

and then remove instrument stay (1).

9. Disconnect intake sensor connector (1).

10. Remove instrument panel and pad. Refer to IP-11, "

Removal and Installation".

11. Remove side ventilator ducts. Refer to VTL-23, "

Removal and Installation".

12. Remove center ventilator ducts. Refer to VTL-23, "

Removal and Installation".

13. Remove the side kicking plates. Refer to INT-20, "

Removal and Installation".

14. Disconnect the fuel filler door cable and the rear hatch door cable (if equipped).

15. Remove A/C unit assembly bolts, steering member bolts, steering column nuts and harness clips.

16. Remove steering member, and then remove A/C unit assembly.

INSTALLATION

Installation is in the reverse order of removal.

Fill the cooling system with coolant. Refer to CO-11, "

Changing Engine Coolant" (HR16DE), CO-35, "Chang-

ing Engine Coolant" (MR18DE), CO-58, "Refilling" (K9K).

Recharge the refrigerant. Refer to HA-29, "

HFC-134a (R-134a) Service Procedure".

CAUTION:

Replace O-rings for A/C piping with new ones, and then apply compressor oil to it when installing it.

When recharging refrigerant, check for leaks.

SJIA0646E

SJIA0690E

A/C unit assembly bolt : 6.9 N·m (0.7 kg-m, 61 in-lb)

Steering member bolt : 12 N·m (1.25 kg-m, 9 ft-lb)

Steering column nut : -Refer to ST-9, "

Removal and Installation".

Page 5698 of 5883

![NISSAN TIIDA 2007 Service Repair Manual A/C UNIT ASSEMBLY

VTL-37

< ON-VEHICLE REPAIR >[MANUAL AIR CONDITIONER]

C

D

E

F

G

H

J

K

L

MA

B

VTL

N

O

P

A/C UNIT ASSEMBLY

Removal and InstallationINFOID:0000000001696531

NOTE:

A LHD model shown, RHD m NISSAN TIIDA 2007 Service Repair Manual A/C UNIT ASSEMBLY

VTL-37

< ON-VEHICLE REPAIR >[MANUAL AIR CONDITIONER]

C

D

E

F

G

H

J

K

L

MA

B

VTL

N

O

P

A/C UNIT ASSEMBLY

Removal and InstallationINFOID:0000000001696531

NOTE:

A LHD model shown, RHD m](/img/5/57395/w960_57395-5697.png)

A/C UNIT ASSEMBLY

VTL-37

< ON-VEHICLE REPAIR >[MANUAL AIR CONDITIONER]

C

D

E

F

G

H

J

K

L

MA

B

VTL

N

O

P

A/C UNIT ASSEMBLY

Removal and InstallationINFOID:0000000001696531

NOTE:

A LHD model shown, RHD model similar.

REMOVAL

1. Use a recovery/recycling equipment (for HFC-134a) to discharge refrigerant. Refer to HA-29, "HFC-134a

(R-134a) Service Procedure".

2. Drain coolant from cooling system. Refer to CO-11, "

Changing Engine Coolant" (HR16DE), CO-35,

"Changing Engine Coolant" (MR18DE), CO-58, "Draining" (K9K).

3. Remove cowl top cover. Refer to EXT-20, "

Removal and Installation".

4. Remove lower dash insulator.

5. Remove bolt (A), and then disconnect low-pressure flexible

hose (1) and high-pressure pipe (2) from evaporator.

CAUTION:

Cap or wrap the joint of the pipe with suitable material such

as vinyl tape to avoid the entry of air.

6. Remove clamps (A), and then disconnect heater hoses (1) from

heater core.

A. A/C unit assembly bolts B. Steering member bolts C. Steering column nuts

SJIA0648E

SJIA0644E

SJIA0645E

Page 5699 of 5883

![NISSAN TIIDA 2007 Service Repair Manual VTL-38

< ON-VEHICLE REPAIR >[MANUAL AIR CONDITIONER]

A/C UNIT ASSEMBLY

7. Remove console box assembly. Refer to IP-11, "Removal and Installation" .

8. Remove instrument stay nuts (A) and harness clamp NISSAN TIIDA 2007 Service Repair Manual VTL-38

< ON-VEHICLE REPAIR >[MANUAL AIR CONDITIONER]

A/C UNIT ASSEMBLY

7. Remove console box assembly. Refer to IP-11, "Removal and Installation" .

8. Remove instrument stay nuts (A) and harness clamp](/img/5/57395/w960_57395-5698.png)

VTL-38

< ON-VEHICLE REPAIR >[MANUAL AIR CONDITIONER]

A/C UNIT ASSEMBLY

7. Remove console box assembly. Refer to IP-11, "Removal and Installation" .

8. Remove instrument stay nuts (A) and harness clamps (B), and

then remove instrument stay (1).

9. Disconnect thermo control amp. connector (1).

10. Remove instrument panel and pad. Refer to IP-11, "

Removal and Installation".

11. Remove side ventilator ducts. Refer to VTL-48, "

Removal and Installation".

12. Remove center ventilator ducts. Refer to VTL-48, "

Removal and Installation".

13. Remove side kicking plates. Refer to INT-20, "

Removal and Installation".

14. Disconnect the fuel filler door cable and the rear hatch door cable.

15. Remove A/C unit assembly bolts, steering member bolts, steering column nuts and harness clips.

16. Remove steering member, and then remove A/C unit assembly.

INSTALLATION

Installation is in the reverse order of removal.

Fill the cooling system. Refer to CO-11, "

Changing Engine Coolant" (HR16DE), CO-35, "Changing Engine

Coolant" (MR18DE), CO-58, "Refilling" (K9K).

Recharge the refrigerant.

CAUTION:

Replace O-rings for A/C piping with new ones, and apply compressor oil when installing.

When recharging refrigerant, check for leaks.

SJIA0646E

SJIA0647E

A/C unit assembly bolt : 6.9 N·m (0.7 kg-m, 61 in-lb)

Steering member bolt : 12 N·m (1.25 kg-m, 9 ft-lb)

Steering column nut : Refer to ST-9, "

Removal and Installation".

Page 5733 of 5883

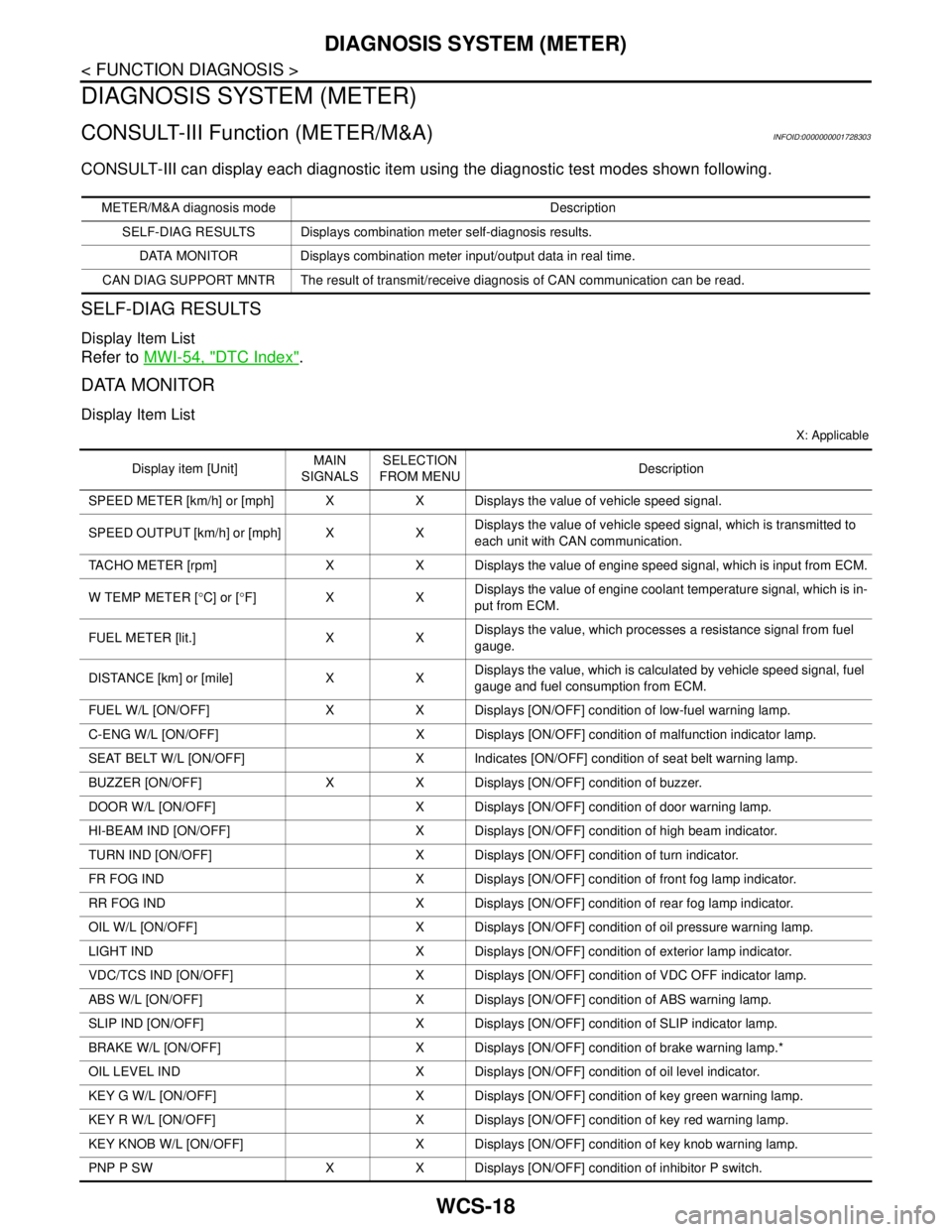

WCS-18

< FUNCTION DIAGNOSIS >

DIAGNOSIS SYSTEM (METER)

DIAGNOSIS SYSTEM (METER)

CONSULT-III Function (METER/M&A)INFOID:0000000001728303

CONSULT-III can display each diagnostic item using the diagnostic test modes shown following.

SELF-DIAG RESULTS

Display Item List

Refer to MWI-54, "DTC Index".

DATA MONITOR

Display Item List

X: Applicable

METER/M&A diagnosis mode Description

SELF-DIAG RESULTS Displays combination meter self-diagnosis results.

DATA MONITOR Displays combination meter input/output data in real time.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read.

Display item [Unit]MAIN

SIGNALSSELECTION

FROM MENUDescription

SPEED METER [km/h] or [mph] X X Displays the value of vehicle speed signal.

SPEED OUTPUT [km/h] or [mph] X XDisplays the value of vehicle speed signal, which is transmitted to

each unit with CAN communication.

TACHO METER [rpm] X X Displays the value of engine speed signal, which is input from ECM.

W TEMP METER [°C] or [°F] X XDisplays the value of engine coolant temperature signal, which is in-

put from ECM.

FUEL METER [lit.] X XDisplays the value, which processes a resistance signal from fuel

gauge.

DISTANCE [km] or [mile] X XDisplays the value, which is calculated by vehicle speed signal, fuel

gauge and fuel consumption from ECM.

FUEL W/L [ON/OFF] X X Displays [ON/OFF] condition of low-fuel warning lamp.

C-ENG W/L [ON/OFF] X Displays [ON/OFF] condition of malfunction indicator lamp.

SEAT BELT W/L [ON/OFF] X Indicates [ON/OFF] condition of seat belt warning lamp.

BUZZER [ON/OFF] X X Displays [ON/OFF] condition of buzzer.

DOOR W/L [ON/OFF] X Displays [ON/OFF] condition of door warning lamp.

HI-BEAM IND [ON/OFF] X Displays [ON/OFF] condition of high beam indicator.

TURN IND [ON/OFF] X Displays [ON/OFF] condition of turn indicator.

FR FOG IND X Displays [ON/OFF] condition of front fog lamp indicator.

RR FOG IND X Displays [ON/OFF] condition of rear fog lamp indicator.

OIL W/L [ON/OFF] X Displays [ON/OFF] condition of oil pressure warning lamp.

LIGHT IND X Displays [ON/OFF] condition of exterior lamp indicator.

VDC/TCS IND [ON/OFF] X Displays [ON/OFF] condition of VDC OFF indicator lamp.

ABS W/L [ON/OFF] X Displays [ON/OFF] condition of ABS warning lamp.

SLIP IND [ON/OFF] X Displays [ON/OFF] condition of SLIP indicator lamp.

BRAKE W/L [ON/OFF] X Displays [ON/OFF] condition of brake warning lamp.*

OIL LEVEL IND X Displays [ON/OFF] condition of oil level indicator.

KEY G W/L [ON/OFF] X Displays [ON/OFF] condition of key green warning lamp.

KEY R W/L [ON/OFF] X Displays [ON/OFF] condition of key red warning lamp.

KEY KNOB W/L [ON/OFF] X Displays [ON/OFF] condition of key knob warning lamp.

PNP P SW X X Displays [ON/OFF] condition of inhibitor P switch.

Page 5753 of 5883

WCS-38

< ECU DIAGNOSIS >

COMBINATION METER

11 LG Brake fluid level switch ONBrake fluid level low 0

Brake fluid level normal Battery voltage

16 VSteering switch (trip comput-

er) signalONPress the steering switch (trip

computer)0

Other than the above 5

19 V Ambient sensor signal ON —

20 BR Ambient sensor ground ON — 0

21

BGround — — 0 22

23

24 V Fuel level sensor ground (-) ON — 0

25 RAuto A/C sense signal (with

auto A/C)ON — 5V

27 G Battery power supply OFF — Battery voltage

28 SB Ignition switch ON or START ON — Battery voltage

30 G Stop lamp switch ONBrake pedal depressed Battery voltage

Brake pedal released 0

31 V A/T N-range input (with A/T) ONTransmission gear selector lever

in N positionBattery voltage

Transmission gear selector lever

other than N position0

32 W A/T P-range input (with A/T) ONTransmission gear selector lever

in P positionBattery voltage

Transmission gear selector lever

other than P position0

33 Y A/T PN output (with A/T) ONTransmission gear selector lever

in P or N position0

Transmission gear selector lever

other than P or N positionBattery voltage

35 BREngine coolant temperature

signal outputONAt idle [after warming up, approx.

80°C (176°F)]

NOTE:

The waveforms vary depending

on engine coolant temperature. Te r -

mi-

nal

No.Wire

colorItemCondition

Reference value (V)

(Approx.) Ignition

switchOperation or condition

JSNIA0014GB

SKIB3651J

Page 5771 of 5883

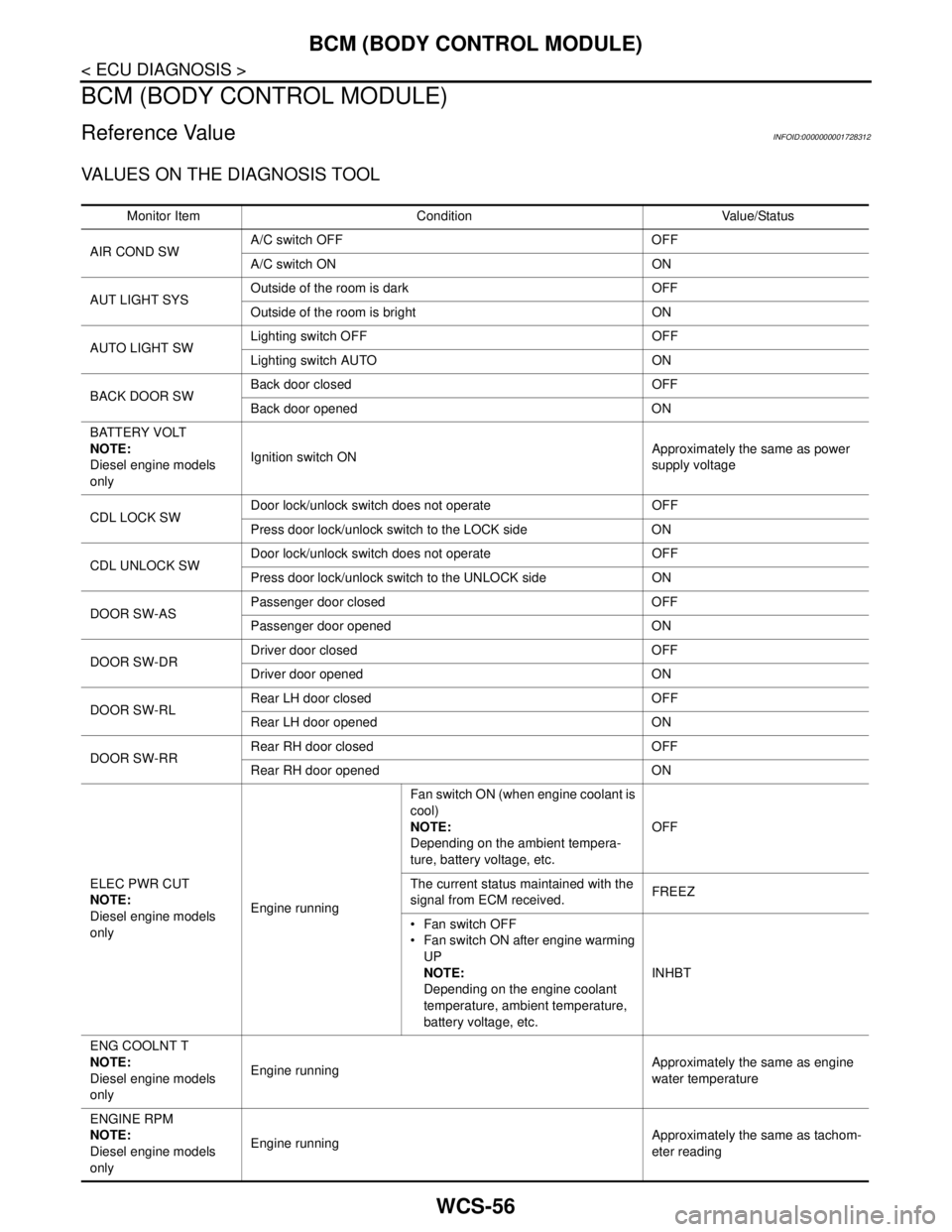

WCS-56

< ECU DIAGNOSIS >

BCM (BODY CONTROL MODULE)

BCM (BODY CONTROL MODULE)

Reference ValueINFOID:0000000001728312

VALUES ON THE DIAGNOSIS TOOL

Monitor Item Condition Value/Status

AIR COND SWA/C switch OFF OFF

A/C switch ON ON

AUT LIGHT SYSOutside of the room is dark OFF

Outside of the room is bright ON

AUTO LIGHT SWLighting switch OFF OFF

Lighting switch AUTO ON

BACK DOOR SWBack door closed OFF

Back door opened ON

BATTERY VOLT

NOTE:

Diesel engine models

onlyIgnition switch ONApproximately the same as power

supply voltage

CDL LOCK SWDoor lock/unlock switch does not operate OFF

Press door lock/unlock switch to the LOCK side ON

CDL UNLOCK SWDoor lock/unlock switch does not operate OFF

Press door lock/unlock switch to the UNLOCK side ON

DOOR SW-ASPassenger door closed OFF

Passenger door opened ON

DOOR SW-DRDriver door closed OFF

Driver door opened ON

DOOR SW-RLRear LH door closed OFF

Rear LH door opened ON

DOOR SW-RRRear RH door closed OFF

Rear RH door opened ON

ELEC PWR CUT

NOTE:

Diesel engine models

onlyEngine runningFan switch ON (when engine coolant is

cool)

NOTE:

Depending on the ambient tempera-

ture, battery voltage, etc.OFF

The current status maintained with the

signal from ECM received.FREEZ

Fan switch OFF

Fan switch ON after engine warming

UP

NOTE:

Depending on the engine coolant

temperature, ambient temperature,

battery voltage, etc.INHBT

ENG COOLNT T

NOTE:

Diesel engine models

onlyEngine runningApproximately the same as engine

water temperature

ENGINE RPM

NOTE:

Diesel engine models

onlyEngine runningApproximately the same as tachom-

eter reading