NISSAN TIIDA 2007 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 4531 of 5883

RAX-4

< PREPARATION >

PREPARATION

PREPARATION

PREPARATION

Commercial Service ToolINFOID:0000000001724592

Tool name Description

Power tool Removing wheel nuts

PBIC0190E

Page 4532 of 5883

WHEEL HUB

RAX-5

< ON-VEHICLE MAINTENANCE >

C

E

F

G

H

I

J

K

L

MA

B

RAX

N

O

P

ON-VEHICLE MAINTENANCE

WHEEL HUB

On-Vehicle Inspection and ServiceINFOID:0000000001724590

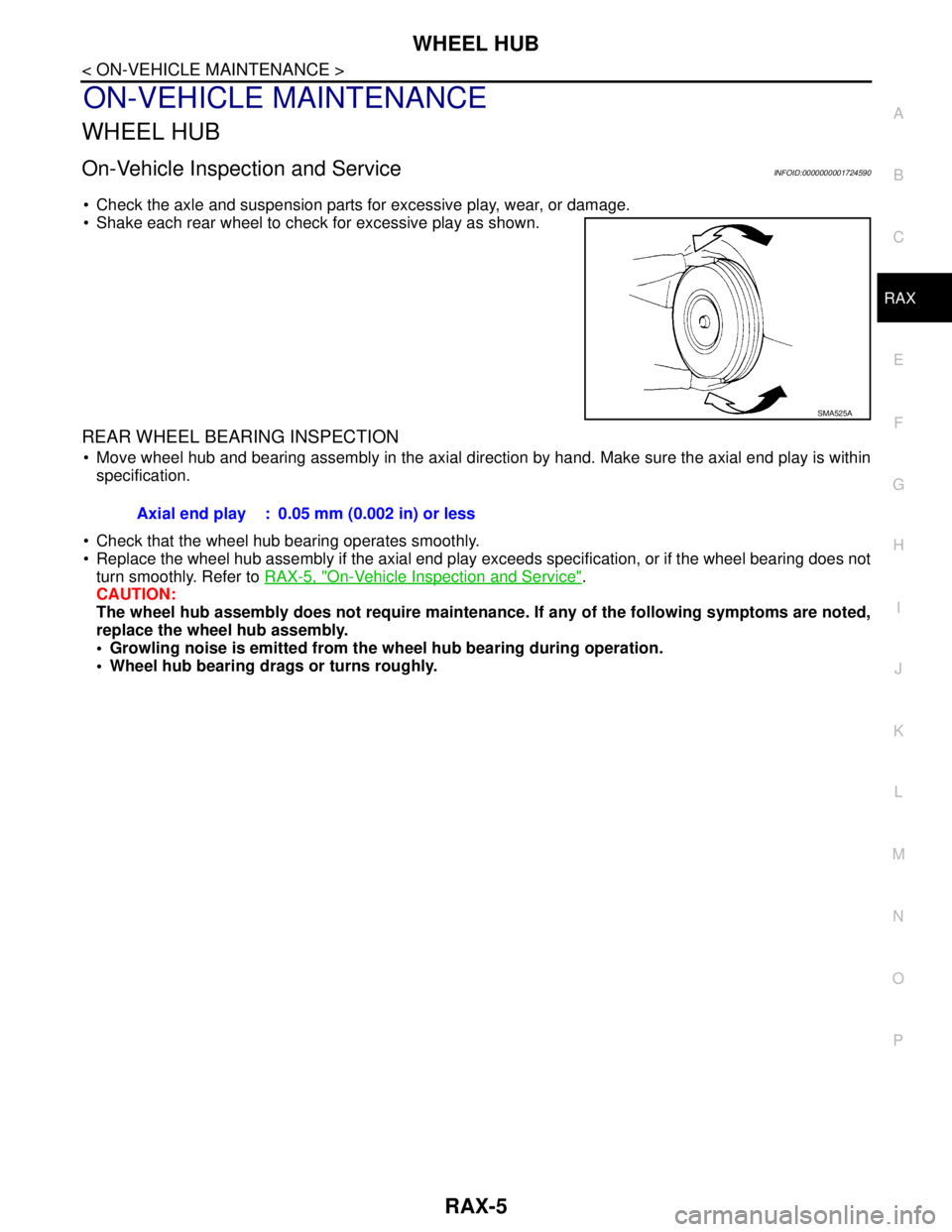

Check the axle and suspension parts for excessive play, wear, or damage.

Shake each rear wheel to check for excessive play as shown.

REAR WHEEL BEARING INSPECTION

Move wheel hub and bearing assembly in the axial direction by hand. Make sure the axial end play is within

specification.

Check that the wheel hub bearing operates smoothly.

Replace the wheel hub assembly if the axial end play exceeds specification, or if the wheel bearing does not

turn smoothly. Refer to RAX-5, "

On-Vehicle Inspection and Service".

CAUTION:

The wheel hub assembly does not require maintenance. If any of the following symptoms are noted,

replace the wheel hub assembly.

Growling noise is emitted from the wheel hub bearing during operation.

Wheel hub bearing drags or turns roughly.

SMA525A

Axial end play : 0.05 mm (0.002 in) or less

Page 4533 of 5883

RAX-6

< ON-VEHICLE REPAIR >

WHEEL HUB

ON-VEHICLE REPAIR

WHEEL HUB

Removal and InstallationINFOID:0000000001724589

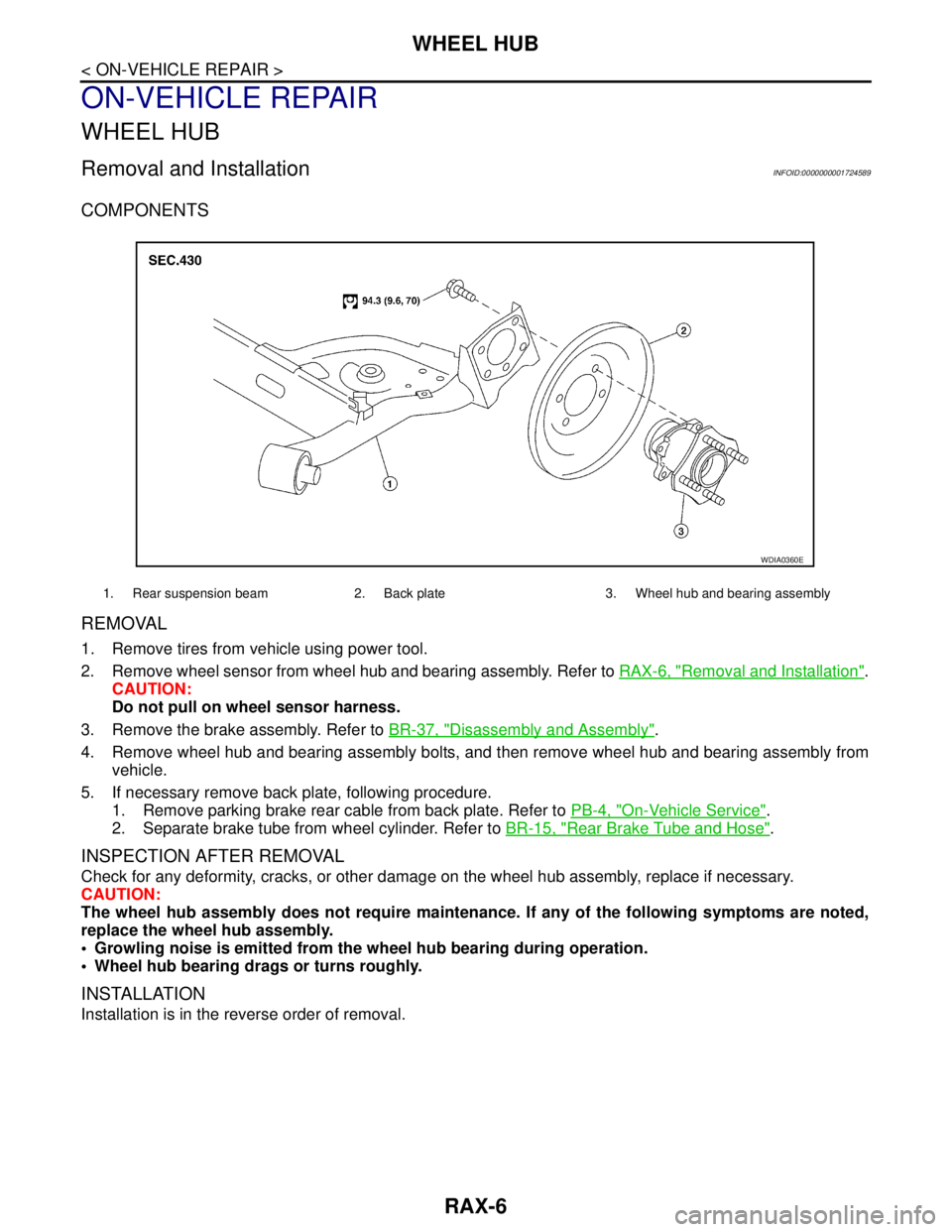

COMPONENTS

REMOVAL

1. Remove tires from vehicle using power tool.

2. Remove wheel sensor from wheel hub and bearing assembly. Refer to RAX-6, "

Removal and Installation".

CAUTION:

Do not pull on wheel sensor harness.

3. Remove the brake assembly. Refer to BR-37, "

Disassembly and Assembly".

4. Remove wheel hub and bearing assembly bolts, and then remove wheel hub and bearing assembly from

vehicle.

5. If necessary remove back plate, following procedure.

1. Remove parking brake rear cable from back plate. Refer to PB-4, "

On-Vehicle Service".

2. Separate brake tube from wheel cylinder. Refer to BR-15, "

Rear Brake Tube and Hose".

INSPECTION AFTER REMOVAL

Check for any deformity, cracks, or other damage on the wheel hub assembly, replace if necessary.

CAUTION:

The wheel hub assembly does not require maintenance. If any of the following symptoms are noted,

replace the wheel hub assembly.

Growling noise is emitted from the wheel hub bearing during operation.

Wheel hub bearing drags or turns roughly.

INSTALLATION

Installation is in the reverse order of removal.

1. Rear suspension beam 2. Back plate 3. Wheel hub and bearing assembly

WDIA0360E

Page 4534 of 5883

SERVICE DATA AND SPECIFICATIONS (SDS)

RAX-7

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

E

F

G

H

I

J

K

L

MA

B

RAX

N

O

P

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Wheel BearingINFOID:0000000001724587

Axial end play0.05 mm (0.002 in) or less

Page 4535 of 5883

RF-1

BODY EXTERIOR, DOORS, ROOF & VEHICLE SECURITY

C

D

E

F

G

H

I

J

L

M

SECTION RF

A

B

RF

N

O

P

CONTENTS

ROOF

PRECAUTION ...............................................3

PRECAUTIONS ...................................................3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

3

PREPARATION ............................................4

PREPARATION ...................................................4

Commercial Service Tool ..........................................4

BASIC INSPECTION ....................................5

DIAGNOSIS AND REPAIR WORKFLOW ..........5

Work Flow .................................................................5

INSPECTION AND ADJUSTMENT .....................7

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT ..........................................................

7

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Description ..................................

7

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Special Repair Requirement .......

7

FUNCTION DIAGNOSIS ...............................8

SUNROOF SYSTEM ...........................................8

System Diagram .......................................................8

System Description ...................................................8

Component Parts Location ......................................9

Component Description ............................................9

DIAGNOSIS SYSTEM (BCM) ............................10

COMMON ITEM .........................................................10

COMMON ITEM : CONSULT-III Function (BCM -

COMMON ITEM) .....................................................

10

RETAINED PWR .......................................................10

RETAINED PWR : CONSULT-III Function (BCM -

RETAINED PWR) ...................................................

10

COMPONENT DIAGNOSIS .........................11

POWER SUPPLY AND GROUND CIRCUIT ....11

SUNROOF MOTOR ASSEMBLY ..............................11

SUNROOF MOTOR ASSEMBLY :

Diagnosis Procedure ..............................................

11

SUNROOF MOTOR ASSEMBLY : Special Repair

Requirement ............................................................

12

SUNROOF SWITCH CIRCUIT ..........................13

Description ...............................................................13

Component Function Check ..................................13

Diagnosis Procedure ...............................................13

DOOR SWITCH .................................................15

Description ...............................................................15

Component Function Check ....................................15

Diagnosis Procedure ...............................................15

ECU DIAGNOSIS .........................................17

BCM (BODY CONTROL MODULE) .................17

Reference Value ......................................................17

SUNROOF SYSTEM .........................................18

Reference Value ......................................................18

Wiring Diagram ........................................................19

SYMPTOM DIAGNOSIS ..............................24

SQUEAK AND RATTLE TROUBLE DIAG-

NOSES ..............................................................

24

Work Flow ................................................................24

Generic Squeak and Rattle Troubleshooting ...........26

Diagnostic Worksheet ..............................................28

ON-VEHICLE REPAIR .................................30

SUNROOF SYSTEM .........................................30

Inspection ................................................................30

Fitting Adjustment ....................................................32

Exploded View .........................................................34

Page 4536 of 5883

RF-2

Removal and Installation ........................................35

Page 4537 of 5883

PRECAUTIONS

RF-3

< PRECAUTION >

C

D

E

F

G

H

I

J

L

MA

B

RF

N

O

P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001731063

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the “SRS AIRBAG” and

“SEAT BELT” of this Service Manual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SRS AIRBAG”.

Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

Page 4538 of 5883

RF-4

< PREPARATION >

PREPARATION

PREPARATION

PREPARATION

Commercial Service ToolINFOID:0000000001724409

Tool name Description

Engine ear Locating the noise

SIIA0995E

Page 4539 of 5883

DIAGNOSIS AND REPAIR WORKFLOW

RF-5

< BASIC INSPECTION >

C

D

E

F

G

H

I

J

L

MA

B

RF

N

O

P

BASIC INSPECTION

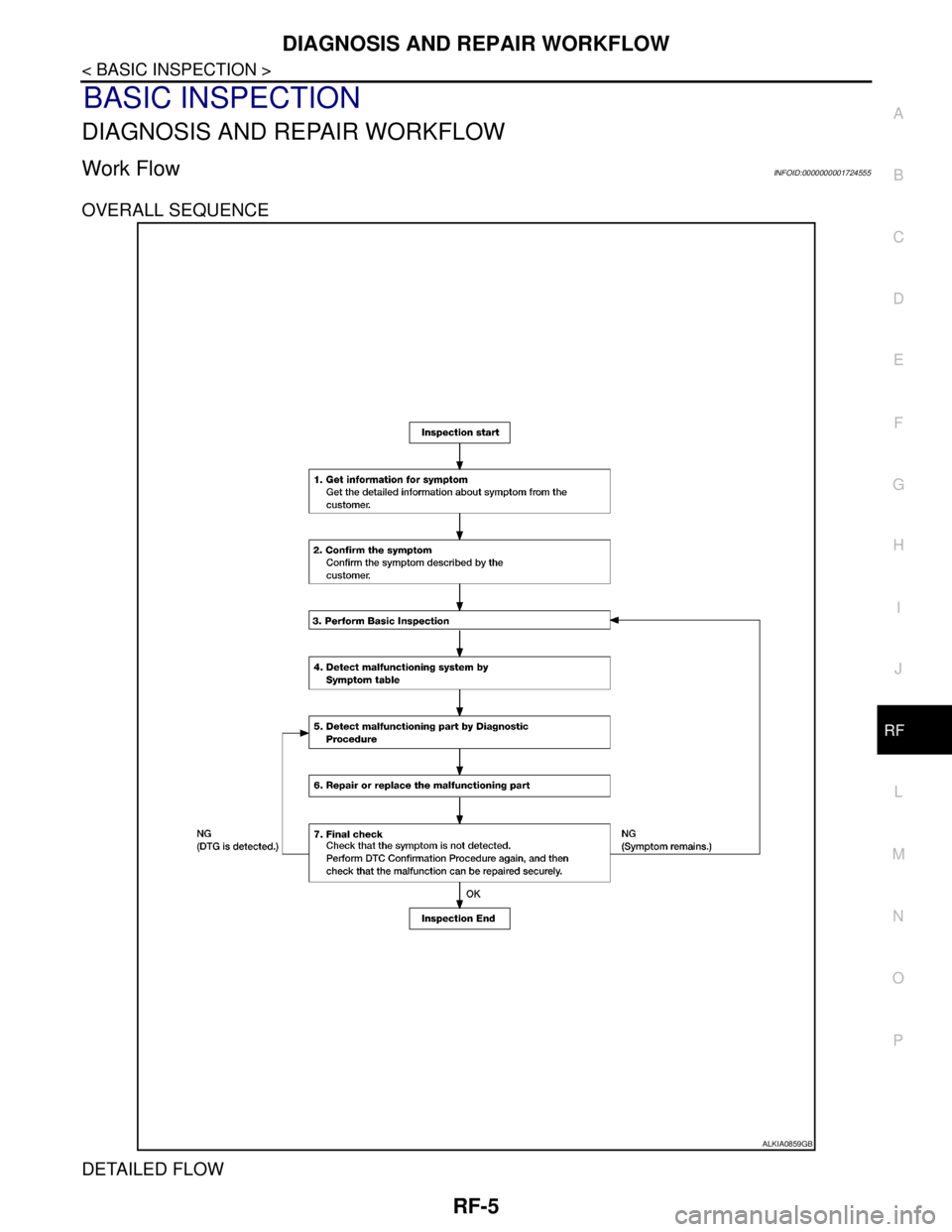

DIAGNOSIS AND REPAIR WORKFLOW

Work FlowINFOID:0000000001724555

OVERALL SEQUENCE

DETAILED FLOW

ALKIA0859GB

Page 4540 of 5883

RF-6

< BASIC INSPECTION >

DIAGNOSIS AND REPAIR WORKFLOW

1. GET INFORMATION FOR SYMPTOM

Get the detailed information from the customer about the symptom (the condition and the environment when

the incident/malfunction occurred).

>> GO TO 2

2. CONFIRM THE SYMPTOM

Confirm the symptom described by the customer.

Verify relation between the symptom and the condition when the symptom is detected.

>> GO TO 3

3. PERFORM BASIC INSPECTION

Perform XX-XX, "*****"

.

Inspection End>>GO TO 4

4. DETECT MALFUNCTIONING SYSTEM BY SYMPTOM DIAGNOSIS

Detect malfunctioning system according to symptom diagnosis based on the confirmed symptom in step 4,

and determine the trouble diagnosis order based on possible causes and symptom.

>> GO TO 5

5. DETECT MALFUNCTIONING PART BY DIAGNOSTIC PROCEDURE

Inspect according to Diagnostic Procedure of the system.

NOTE:

The Diagnostic Procedure described based on open circuit inspection. A short circuit inspection is also

required for the circuit check in the Diagnostic Procedure.

Is malfunctioning part detected?

YES >> GO TO 6

NO >> Check voltage of related BCM terminals using CONSULT-III.

6. REPAIR OR REPLACE THE MALFUNCTIONING PART

1. Repair or replace the malfunctioning part.

2. Reconnect parts or connectors disconnected during Diagnostic Procedure.

>> GO TO 7

7. FINAL CHECK

When symptom was described from the customer, refer to confirmed symptom in step 3 or 4, and check that

the symptom is not detected.

Does the symptom reappear?

YES >> GO TO 5

NO >> Inspection End.