service indicator NISSAN TIIDA 2007 Service Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 3562 of 5883

![NISSAN TIIDA 2007 Service Service Manual INTAKE DOOR MOTOR

HAC-229

< COMPONENT DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

The intake door motor is attached to the A/C unit assembly. It rotates

so that air is NISSAN TIIDA 2007 Service Service Manual INTAKE DOOR MOTOR

HAC-229

< COMPONENT DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

The intake door motor is attached to the A/C unit assembly. It rotates

so that air is](/img/5/57395/w960_57395-3561.png)

INTAKE DOOR MOTOR

HAC-229

< COMPONENT DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

The intake door motor is attached to the A/C unit assembly. It rotates

so that air is drawn from inlets set by the front air control Motor rota-

tion is conveyed to a lever which activates the intake door.

Intake Door Motor Component Function CheckINFOID:0000000001547334

INSPECTION FLOW

1.CONFIRM SYMPTOM BY PERFORMING OPERATIONAL CHECK - REC ( )

1. Turn mode control dial to vent mode( ).

2. Press REC ( ) switch. The REC ( )indicator should illuminate.

3. Press REC ( ) switch again. The REC ( ) indicator should go out.

4. Listen for intake door position change (you should hear blower sound change slightly).

Can a symptom be duplicated?

YES >> GO TO 3.

NO >> GO TO 2.

2.PERFORM COMPLETE OPERATIONAL CHECK

Perform a complete operational check and check for any symptoms. Refer to HAC-202, "

Operational Check".

Can a symptom be duplicated?

YES >> Refer to HAC-201, "How to Perform Trouble Diagnosis For Quick And Accurate Repair".

NO >> System OK.

3.CHECK FOR SERVICE BULLETINS

Check for any service bulletins.

>> GO TO 4.

4.PERFORM SELF-DIAGNOSIS.

Set in Self-diagnostic mode. Refer to HAC-213, "

Front Air Control Self-Diagnosis".

Are any self-diagnosis codes present?

YES >> Repair as necessary.

NO >> GO TO 5.

5. CHECK AMBIENT SENSOR CIRCUIT

Perform diagnostic procedure for the ambient sensor circuit. Refer to HAC-244, "

Ambient Sensor Diagnosis

Procedure".

YES or NO

YES >> GO TO 7

NO >> Repair as necessary.

6. CHECK IN-VEHICLE SENSOR CIRCUIT

Perform diagnostic procedure for the in-vehicle sensor circuit. Refer to XXXX IN-VEHICLE SENS DIAG.

YES or NO

YES >> GO TO 8

NO >> Repair as necessary.

7. CHECK SUNLOAD SENSOR CIRCUIT

SJIA0814E

Page 4577 of 5883

REAR SUSPENSION ASSEMBLY

RSU-5

< ON-VEHICLE MAINTENANCE >

C

D

F

G

H

I

J

K

L

MA

B

RSU

N

O

P

ON-VEHICLE MAINTENANCE

REAR SUSPENSION ASSEMBLY

On-Vehicle Inspection and ServiceINFOID:0000000001724575

Make sure the mounting conditions (looseness, backlash) of each component and component conditions

(wear, damage) are within specifications.

SHOCK ABSORBER INSPECTION

Check shock absorber for oil leakage, damage and replace it if necessary.

Wheel AlignmentINFOID:0000000001724576

DESCRIPTION

Measure wheel alignment under unladen conditions.

NOTE:

“Unladen conditions” means that fuel, engine coolant, and lubricant are full. Spare tire, jack, hand tools and

mats are in designated positions.

PRELIMINARY

Check the following:

1. Tires for improper air pressure and wear.

2. Road wheels for runout. Refer to WT-5, "

Inspection" .

3. Wheel bearing axial end play. Refer to RAX-5, "

On-Vehicle Inspection and Service" .

4. Shock absorber operation.

5. Each mounting part of suspension for looseness and deformation.

6. Rear suspension beam for cracks, deformation, and other damage.

7. Vehicle height (posture).

GENERAL INFORMATION AND RECOMMENDATIONS

1. A Four-Wheel Thrust Alignment should be performed.

This type of alignment is recommended for any NISSAN vehicle.

The four-wheel “thrust” process helps ensure that the vehicle is properly aligned and the steering wheel

is centered.

The alignment machine itself should be capable of accepting any NISSAN vehicle.

The alignment machine should be checked to ensure that it is level.

2. Make sure the alignment machine is properly calibrated.

Your alignment machine should be regularly calibrated in order to give correct information.

Check with the manufacturer of your specific alignment machine for their recommended Service/Cali-

bration Schedule.

THE ALIGNMENT PROCESS

IMPORTANT: Use only the alignment specifications listed in this Service Manual. Refer to RSU-5, "Wheel

Alignment" .

1. When displaying the alignment settings, many alignment machines use “indicators”: (Green/red, plus or

minus, Go/No Go). Do NOT use these indicators.

The alignment specifications programmed into your alignment machine that operate these indicators

may not be correct.

This may result in an ERROR.

2. Some newer alignment machines are equipped with an optional “Rolling Compensation” method to “com-

pensate” the sensors (alignment targets or head units). Do NOT use this “Rolling Compensation”

method.

Use the “Jacking Compensation” method. After installing the alignment targets or head units, raise the

vehicle and rotate the wheels 1/2 turn both ways.

See Instructions in the alignment machine you are using for more information.

CAMBER INSPECTION

Page 4627 of 5883

SEC-2

Description ..............................................................32

DTC Logic ...............................................................32

Diagnosis Procedure ..............................................32

B2194 ID DISCORD IMMU-I-KEY .....................33

Description ..............................................................33

DTC Logic ...............................................................33

Diagnosis Procedure ..............................................33

B2552 INTELLIGENT KEY ................................34

Description ..............................................................34

DTC Logic ...............................................................34

Diagnosis Procedure ..............................................34

Special Repair Requirement ...................................34

B2590 ID DISCORD BCM-I-KEY .......................35

Description ..............................................................35

DTC Logic ...............................................................35

Diagnosis Procedure ..............................................35

P1610 LOCK MODE ..........................................36

Description ..............................................................36

DTC Logic ...............................................................36

Diagnosis Procedure ..............................................36

POWER SUPPLY AND GROUND CIRCUIT .....37

INTELLIGENT KEY UNIT .........................................37

INTELLIGENT KEY UNIT : Diagnosis Procedure ...37

BCM ...........................................................................38

BCM : Diagnosis Procedure ...................................38

KEY SWITCH .....................................................39

Description ..............................................................39

Component Function Check ...................................39

Diagnosis Procedure ..............................................39

Component Inspection ............................................41

IGNITION KNOB SWITCH .................................42

Description ..............................................................42

Component Function Check ...................................42

Diagnosis Procedure ..............................................42

Component Inspection ............................................44

STOP LAMP SWITCH (A/T) ..............................45

Diagnosis Procedure ..............................................45

STOP LAMP SWITCH (M/T) ..............................47

Diagnosis Procedure ..............................................47

VEHICLE SECURITY INDICATOR ....................49

Description ..............................................................49

Component Function Check .................................49

Diagnosis Procedure ..............................................49

SECURITY SYSTEM PRE-WIRING ..................51

Wiring Diagram - SECURITY SYSTEM PRE-WIR-

ING - .......................................................................

51

ECU DIAGNOSIS ........................................54

BCM (BODY CONTROL MODULE) ..................54

Reference Value .....................................................54

Wiring Diagram - INTELLIGENT KEY SYSTEM/

ENGINE START FUNCTION - ................................

55

Wiring Diagram - NATS - ........................................63

Fail Safe .................................................................68

DTC Inspection Priority Chart ...............................69

DTC Index ..............................................................69

INTELLIGENT KEY UNIT ..................................71

Reference Value .....................................................71

Fail Safe .................................................................71

DTC Inspection Priority Chart ...............................71

DTC Index ..............................................................71

IPDM E/R (INTELLIGENT POWER DISTRI-

BUTION MODULE ENGINE ROOM) .................

73

Reference Value .....................................................73

Fail Safe .................................................................73

DTC Index ..............................................................74

SYMPTOM DIAGNOSIS ............................75

INTELLIGENT KEY SYSTEM/ENGINE

START FUNCTION SYMPTOMS ......................

75

Symptom Table .......................................................75

NATS (NISSAN ANTI-THEFT SYSTEM)

SYMPTOMS .......................................................

76

Symptom Table .......................................................76

ON-VEHICLE MAINTENANCE ..................77

PRE-INSPECTION FOR DIAGNOSTIC ............77

Basic Inspection ......................................................77

Vehicle Security Operation Check ..........................77

ON-VEHICLE REPAIR ...............................79

INTELLIGENT KEY UNIT ..................................79

Removal and Installation .........................................79

WITHOUT INTELLIGENT KEY SYSTEM

BASIC INSPECTION ..................................

80

DIAGNOSIS AND REPAIR WORKFLOW .........80

Work Flow ...............................................................80

INSPECTION AND ADJUSTMENT ...................83

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT ........................................................

83

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Special Repair Requirement .....

83

ECM RE-COMMUNICATING FUNCTION .................83

ECM RE-COMMUNICATING FUNCTION : De-

scription ...................................................................

83

ECM RE-COMMUNICATING FUNCTION : Spe-

cial Repair Requirement .........................................

83

FUNCTION DIAGNOSIS ............................84

Page 4701 of 5883

![NISSAN TIIDA 2007 Service Service Manual SEC-76

< SYMPTOM DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

NATS (NISSAN ANTI-THEFT SYSTEM) SYMPTOMS

NATS (NISSAN ANTI-THEFT SYSTEM) SYMPTOMS

Symptom TableINFOID:0000000001404143

NOTE:

Before performi NISSAN TIIDA 2007 Service Service Manual SEC-76

< SYMPTOM DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

NATS (NISSAN ANTI-THEFT SYSTEM) SYMPTOMS

NATS (NISSAN ANTI-THEFT SYSTEM) SYMPTOMS

Symptom TableINFOID:0000000001404143

NOTE:

Before performi](/img/5/57395/w960_57395-4700.png)

SEC-76

< SYMPTOM DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

NATS (NISSAN ANTI-THEFT SYSTEM) SYMPTOMS

NATS (NISSAN ANTI-THEFT SYSTEM) SYMPTOMS

Symptom TableINFOID:0000000001404143

NOTE:

Before performing the diagnosis in the following table, check “SEC-4, "

Work Flow"”.

Check that vehicle is under the condition shown in “Conditions of vehicle” before starting diagnosis, and

check each symptom.

If the following symptoms are detected, check systems shown in the “Diagnosis/service procedure” column

in this order.

CONDITIONS OF VEHICLE (OPERATING CONDITIONS)

Mechanical key is not inserted into key cylinder.

Ignition knob switch is not depressed.

Symptom Diagnosis/service procedure Reference page

Engine cannot start.1. Check stop lamp switchXX-XX, "*****"

2. Check Intermittent IncidentXX-XX, "*****"

Security indicator does not turn ON or flash.1. Check vehicle security indicatorSEC-492. Check Intermittent IncidentXX-XX, "*****"

Page 4742 of 5883

![NISSAN TIIDA 2007 Service Service Manual NATS (NISSAN ANTI-THEFT SYSTEM) SYMPTOMS

SEC-117

< SYMPTOM DIAGNOSIS >[WITHOUT INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

SEC

N

O

P

NATS (NISSAN ANTI-THEFT SYSTEM) SYMPTOMS

Symptom TableINFOID:000 NISSAN TIIDA 2007 Service Service Manual NATS (NISSAN ANTI-THEFT SYSTEM) SYMPTOMS

SEC-117

< SYMPTOM DIAGNOSIS >[WITHOUT INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

SEC

N

O

P

NATS (NISSAN ANTI-THEFT SYSTEM) SYMPTOMS

Symptom TableINFOID:000](/img/5/57395/w960_57395-4741.png)

NATS (NISSAN ANTI-THEFT SYSTEM) SYMPTOMS

SEC-117

< SYMPTOM DIAGNOSIS >[WITHOUT INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

SEC

N

O

P

NATS (NISSAN ANTI-THEFT SYSTEM) SYMPTOMS

Symptom TableINFOID:0000000001404232

NOTE:

Before performing the diagnosis in the following table, check “SEC-80, "

Work Flow"”.

Check that vehicle is under the condition shown in “Conditions of vehicle” before starting diagnosis, and

check each symptom.

If the following symptoms are detected, check systems shown in the “Diagnosis/service procedure” column

in this order.

CONDITIONS OF VEHICLE (OPERATING CONDITIONS)

Ignition key is not inserted into key cylinder.

Symptom Diagnosis/service procedure Reference page

Security indicator does not turn ON or flash1. Check vehicle security indicatorXX-XX, "*****"

2. Check Intermittent IncidentXX-XX, "*****"

Page 4777 of 5883

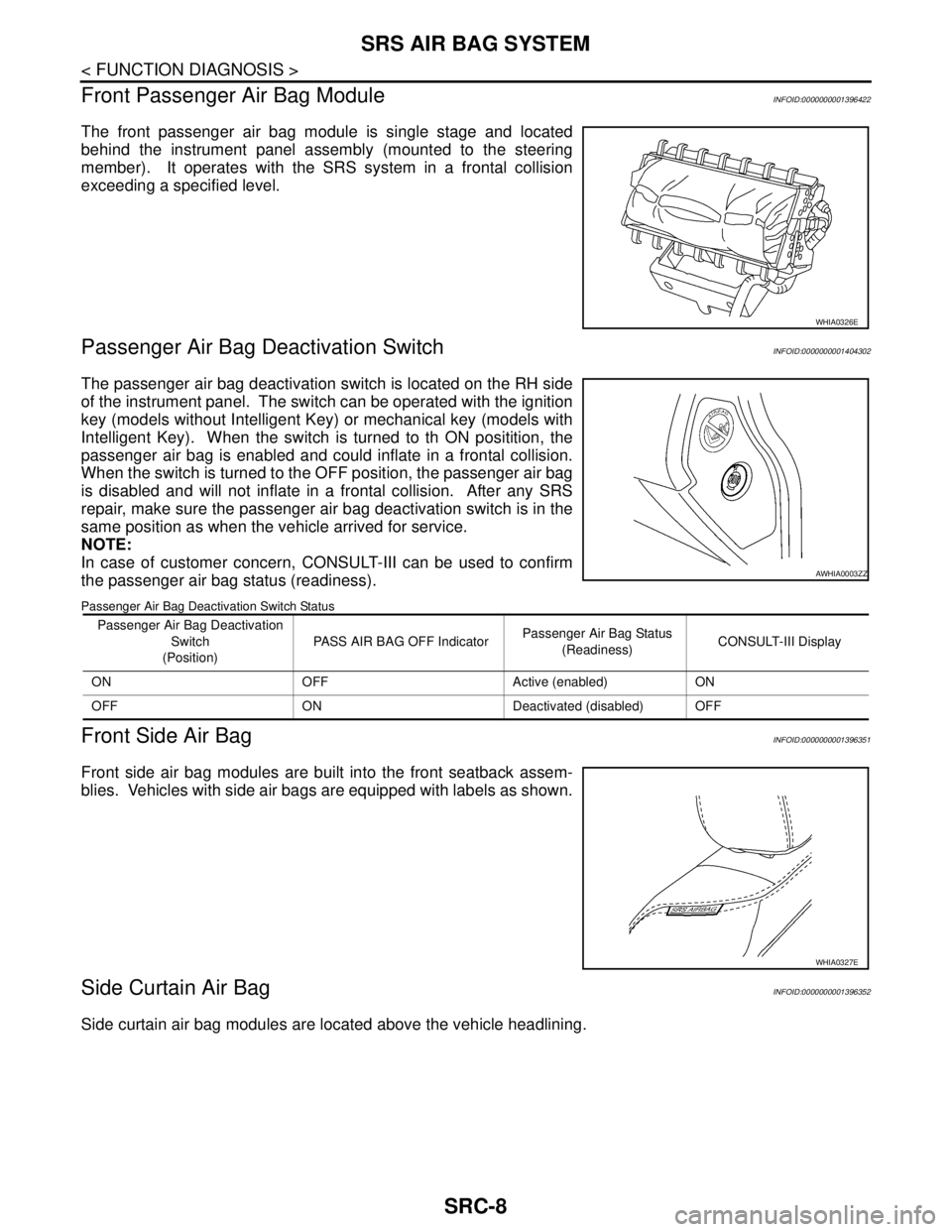

SRC-8

< FUNCTION DIAGNOSIS >

SRS AIR BAG SYSTEM

Front Passenger Air Bag Module

INFOID:0000000001396422

The front passenger air bag module is single stage and located

behind the instrument panel assembly (mounted to the steering

member). It operates with the SRS system in a frontal collision

exceeding a specified level.

Passenger Air Bag Deactivation SwitchINFOID:0000000001404302

The passenger air bag deactivation switch is located on the RH side

of the instrument panel. The switch can be operated with the ignition

key (models without Intelligent Key) or mechanical key (models with

Intelligent Key). When the switch is turned to th ON positition, the

passenger air bag is enabled and could inflate in a frontal collision.

When the switch is turned to the OFF position, the passenger air bag

is disabled and will not inflate in a frontal collision. After any SRS

repair, make sure the passenger air bag deactivation switch is in the

same position as when the vehicle arrived for service.

NOTE:

In case of customer concern, CONSULT-III can be used to confirm

the passenger air bag status (readiness).

Passenger Air Bag Deactivation Switch Status

Front Side Air BagINFOID:0000000001396351

Front side air bag modules are built into the front seatback assem-

blies. Vehicles with side air bags are equipped with labels as shown.

Side Curtain Air BagINFOID:0000000001396352

Side curtain air bag modules are located above the vehicle headlining.

WHIA0326E

AWHIA0003ZZ

Passenger Air Bag Deactivation

Switch

(Position)PASS AIR BAG OFF IndicatorPassenger Air Bag Status

(Readiness)CONSULT-III Display

ON OFF Active (enabled) ON

OFF ON Deactivated (disabled) OFF

WHIA0327E

Page 4949 of 5883

TM-3

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

DTC TURBINE REVOLUTION SENSOR .........104

Description ............................................................104

CONSULT-III Reference Value in Data Monitor

Mode .....................................................................

104

On Board Diagnosis Logic ....................................104

Possible Cause .....................................................104

DTC Confirmation Procedure ................................104

Diagnosis Procedure .............................................104

CONTROL UNIT (RAM), CONTROL UNIT

(ROM) ...............................................................

108

Description ............................................................108

On Board Diagnosis Logic ....................................108

Possible Cause .....................................................108

DTC Confirmation Procedure ................................108

Diagnosis Procedure .............................................108

MAIN POWER SUPPLY AND GROUND CIR-

CUIT ..................................................................

109

Description ............................................................109

On Board Diagnosis Logic ....................................109

Possible Cause .....................................................109

DTC Confirmation Procedure ................................109

Diagnosis Procedure .............................................109

PNP, OD SWITCH AND CLOSED THROT-

TLE, WIDE OPEN THROTTLE POSITION

SIGNAL CIRCUIT .............................................

111

CONSULT-III Reference Value in Data Monitor

Mode .....................................................................

111

TCM Terminal and Reference Value .....................111

Diagnosis Procedure .............................................111

Component Inspection ..........................................115

A/T SHIFT LOCK SYSTEM ..............................116

Wiring Diagram - A/T Shift Lock System - .............116

Terminals And Reference Values .........................116

Diagnosis Procedure .............................................117

ECU DIAGNOSIS .......................................119

TCM ..................................................................119

Reference Value ...................................................119

Wiring Diagram - A/T CONTROL SYSTEM - ........123

Fail-Safe ................................................................123

DTC Inspection Priority Chart ...............................125

DTC Index .............................................................125

DTC Alphabetical Index ........................................126

SYMPTOM DIAGNOSIS ............................127

SYSTEM SYMPTOM ........................................127

Symptom Chart .....................................................127

OD OFF Indicator Lamp Does Not Come On .......138

Engine Cannot Be Started in "P" and "N" Position ..140

In "P" Position, Vehicle Moves Forward or Back-

ward When Pushed ...............................................

140

In "N" Position, Vehicle Moves ..............................141

Large Shock "N" → "R" Position ...........................142

Vehicle Does Not Creep Backward in "R" Position ..142

Vehicle Does Not Creep Forward in "D", "2" or "1"

Position ..................................................................

144

Vehicle Cannot Be Started from D1 .......................145

A/T Does Not Shift: D1→ D2or Does Not Kick-

down: D

4→ D2 .......................................................146

A/T Does Not Shift: D2→ D3 ..................................148

A/T Does Not Shift: D3→ D4 ..................................149

A/T Does Not Perform Lock-up .............................151

A/T Does Not Hold Lock-up Condition ...................151

Lock-up Is Not Released .......................................152

Engine Speed Does Not Return to Idle (Light

Braking D

4→ D3) ...................................................153

A/T Does Not Shift: D4→ D3, When OD OFF ........154

A/T Does Not Shift: D3→ 22, When Selector Lever

"D" → "2" Position .................................................

155

A/T Does Not Shift: 22→ 11, When Selector Lever

"2" → "1" Position ..................................................

156

Vehicle Does Not Decelerate by Engine Brake .....158

TCM Self-Diagnosis Does Not Activate .................161

PRECAUTION ............................................163

PRECAUTIONS ...............................................163

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...............................................................

163

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect .................................

163

Precaution for On Board Diagnosis (OBD) System

of A/T and Engine (For Type1 Only) ......................

163

Precaution .............................................................164

Service Notice or Precaution .................................165

Wiring Diagram and Trouble Diagnosis .................165

PREPARATION .........................................166

PREPARATION ...............................................166

Special Service Tool ..............................................166

Commercial Service Tool ......................................169

ON-VEHICLE MAINTENANCE ..................171

A/T FLUID .......................................................171

Checking A/T Fluid ................................................171

Changing A/T Fluid ................................................171

A/T Fluid Cooler Cleaning .....................................172

STALL TEST ...................................................175

Inspection and Judgment ......................................175

LINE PRESSURE TEST ..................................178

Inspection and Judgment ......................................178

ROAD TEST ....................................................180

Description .............................................................180

Check Before Engine Is Started ............................180

Check at Idle ..........................................................181

Cruise Test - Part 1 ...............................................183

Cruise Test - Part 2 ...............................................185

Cruise Test - Part 3 ...............................................186

Vehicle Speed When Shifting Gears .....................188

Page 5109 of 5883

![NISSAN TIIDA 2007 Service Service Manual PRECAUTIONS

TM-163

< PRECAUTION >[TYPE 1 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSION NISSAN TIIDA 2007 Service Service Manual PRECAUTIONS

TM-163

< PRECAUTION >[TYPE 1 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSION](/img/5/57395/w960_57395-5108.png)

PRECAUTIONS

TM-163

< PRECAUTION >[TYPE 1 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001696264

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

Precaution Necessary for Steering Wheel Rotation After Battery Disconnect

INFOID:0000000001696265

NOTE:

This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK″ position.

Always use CONSULT-II to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery power is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables.

NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

5. When the repair work is completed, return the ignition switch to the ″LOCK″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of all control units using CONSULT-II.

Precaution for On Board Diagnosis (OBD) System of A/T and Engine (For Type1 Only)

INFOID:0000000001696266

The ECM has an on board diagnostic system. It will light up the malfunction indicator lamp (MIL) to warn the

driver of a malfunction causing emission deterioration.

CAUTION:

Page 5111 of 5883

![NISSAN TIIDA 2007 Service Service Manual PRECAUTIONS

TM-165

< PRECAUTION >[TYPE 1 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

Before assembly, apply a coat of recommended ATF to all parts. Apply petroleum jelly to protect O-rings and

s NISSAN TIIDA 2007 Service Service Manual PRECAUTIONS

TM-165

< PRECAUTION >[TYPE 1 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

Before assembly, apply a coat of recommended ATF to all parts. Apply petroleum jelly to protect O-rings and

s](/img/5/57395/w960_57395-5110.png)

PRECAUTIONS

TM-165

< PRECAUTION >[TYPE 1 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

Before assembly, apply a coat of recommended ATF to all parts. Apply petroleum jelly to protect O-rings and

seals, or hold bearings and washers in place during assembly. Do not use grease.

Extreme care should be taken to avoid damage to O-rings, seals and gaskets when assembling.

After overhaul, refill the A/T with new ATF.

When the A/T drain plug is removed, only some of the fluid is drained. Old A/T fluid will remain in torque con-

verter and ATF cooling system.

Always follow the procedures under “Changing A/T Fluid” in the AT section when changing A/T fluid. Refer to

XX-XX, "*****"

, XX-XX, "*****".

Service Notice or PrecautionINFOID:0000000001696268

TORQUE CONVERTER SERVICE

The torque converter should be replaced under any of the following conditions:

External leaks in the hub weld area.

Converter hub is scored or damaged.

Converter pilot is broken, damaged or fits poorly into crankshaft.

Steel particles are found after flushing the cooler and cooler lines.

Pump is damaged or steel particles are found in the converter.

Vehicle has TCC shudder and/or no TCC apply. Replace only after all hydraulic and electrical diagnoses

have been made. (Converter clutch material may be glazed.)

Converter is contaminated with engine coolant containing antifreeze.

Internal malfunction of stator roller clutch.

Heavy clutch debris due to overheating (blue converter).

Steel particles or clutch lining material found in fluid filter or on magnet when no internal parts in unit are

worn or damaged — indicates that lining material came from converter.

The torque converter should not be replaced if:

The fluid has an odor, is discolored, and there is no evidence of metal or clutch facing particles.

The threads in one or more of the converter bolt holes are damaged.

A/T malfunction did not display evidence of damaged or worn internal parts, steel particles or clutch plate lin-

ing material in unit and inside the fluid filter.

Vehicle has been exposed to high mileage (only). The exception may be where the torque converter clutch

dampener plate lining has seen excess wear by vehicles operated in heavy and/or constant traffic, such as

taxi, delivery or police use.

OBD SELF-DIAGNOSIS (FOR TYPE 1 ONLY)

A/T self-diagnosis is performed by the TCM in combination with the ECM. The results can be read through

the blinking pattern of the OD OFF indicator lamp or the malfunction indicator lamp (MIL). Refer to the table

on XX-XX, "*****"

for the indicator used to display each self-diagnostic result.

The self-diagnostic results indicated by the MIL are automatically stored in both the ECM and TCM memo-

ries.

Always perform the procedure “HOW TO ERASE DTC” on XX-XX, "*****"

to complete the repair and

avoid unnecessary blinking of the MIL.

The following self-diagnostic items can be detected using ECM self-diagnostic results mode* only when the

OD OFF indicator lamp does not indicate any malfunctions.

-PNP switch

- A/T 1st, 2nd, 3rd, or 4th gear function

*: For details of OBD, refer to XX-XX, "*****"

.

Wiring Diagram and Trouble DiagnosisINFOID:0000000001696269

When reading wiring diagrams, refer to the following:

XX-XX, "*****"

XX-XX, "*****"

When performing trouble diagnosis, refer to the following:

XX-XX, "*****"

XX-XX, "*****"

Page 5273 of 5883

![NISSAN TIIDA 2007 Service Service Manual DIAGNOSIS AND REPAIR WORKFLOW

TM-327

< BASIC INSPECTION >[TYPE 2 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

>> GO TO 3.

3.ROAD TEST

Perform “ROAD TEST”. Refer to TM-482, "

Description".

>> GO NISSAN TIIDA 2007 Service Service Manual DIAGNOSIS AND REPAIR WORKFLOW

TM-327

< BASIC INSPECTION >[TYPE 2 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

>> GO TO 3.

3.ROAD TEST

Perform “ROAD TEST”. Refer to TM-482, "

Description".

>> GO](/img/5/57395/w960_57395-5272.png)

DIAGNOSIS AND REPAIR WORKFLOW

TM-327

< BASIC INSPECTION >[TYPE 2 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

>> GO TO 3.

3.ROAD TEST

Perform “ROAD TEST”. Refer to TM-482, "

Description".

>> GO TO 4.

4.PERFORM SELF-DIAGNOSTIC PROCEDURE

Perform “Self-Diagnosis Procedure”. Refer to TM-348, "

CONSULT-III Function (TRANSMISSION)" or TM-350,

"Diagnosis Procedure without CONSULT-III".

>> GO TO 5.

5.CHECK SYMPTOM 2

Try to confirm the symptom described by the customer.

Is any malfunction present?

YES >> GO TO 6.

NO >> INSPECTION END

6.CHECK SYMPTOM 3

Try to confirm the symptom described by the customer.

Is any malfunction present?

YES >> GO TO 2.

NO >> INSPECTION END

Diagnostic Work SheetINFOID:0000000001728327

INFORMATION FROM CUSTOMER

KEY POINTSWHAT..... Vehicle and A/T model

WHEN..... Date, Frequencies

WHERE..... Road conditions

HOW..... Operating conditions, Symptoms

DIAGNOSTIC WORK SHEET

Customer name MR/MS Model and Year VIN

Trans. Model Engine Mileage

Malfunction Date Manuf. Date In Service Date

Frequency❏ Continuous❏ Intermittent ( times a day)

Symptoms❏ Vehicle does not move. (❏ Any position❏ Particular position)

❏ No up-shift (❏ 1st → 2nd❏ 2nd → 3rd❏ 3rd → 4th ❏ 4th → 5th)

❏ No down-shift (❏ 5th → 4th ❏ 4th → 3rd❏ 3rd → 2nd❏ 2nd → 1st)

❏ Lock-up malfunction

❏ Shift point too high or too low.

❏ Shift shock or slip (❏ N → D❏ N → R❏ Lock-up❏ Any drive position)

❏ Noise or vibration

❏ No kick down

❏ No pattern select

❏ Others

()

Malfunction indicator lamp (MIL)❏ Continuously lit❏ Not lit