alignment NISSAN TIIDA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 221 of 5883

REAR DISC BRAKE

BR-29

< ON-VEHICLE REPAIR >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

3. Drain brake fluid. Refer to BR-8, "Bleeding Brake System".

4. Remove connecting bolt and torque member bolts using power tool, and remove cylinder body.

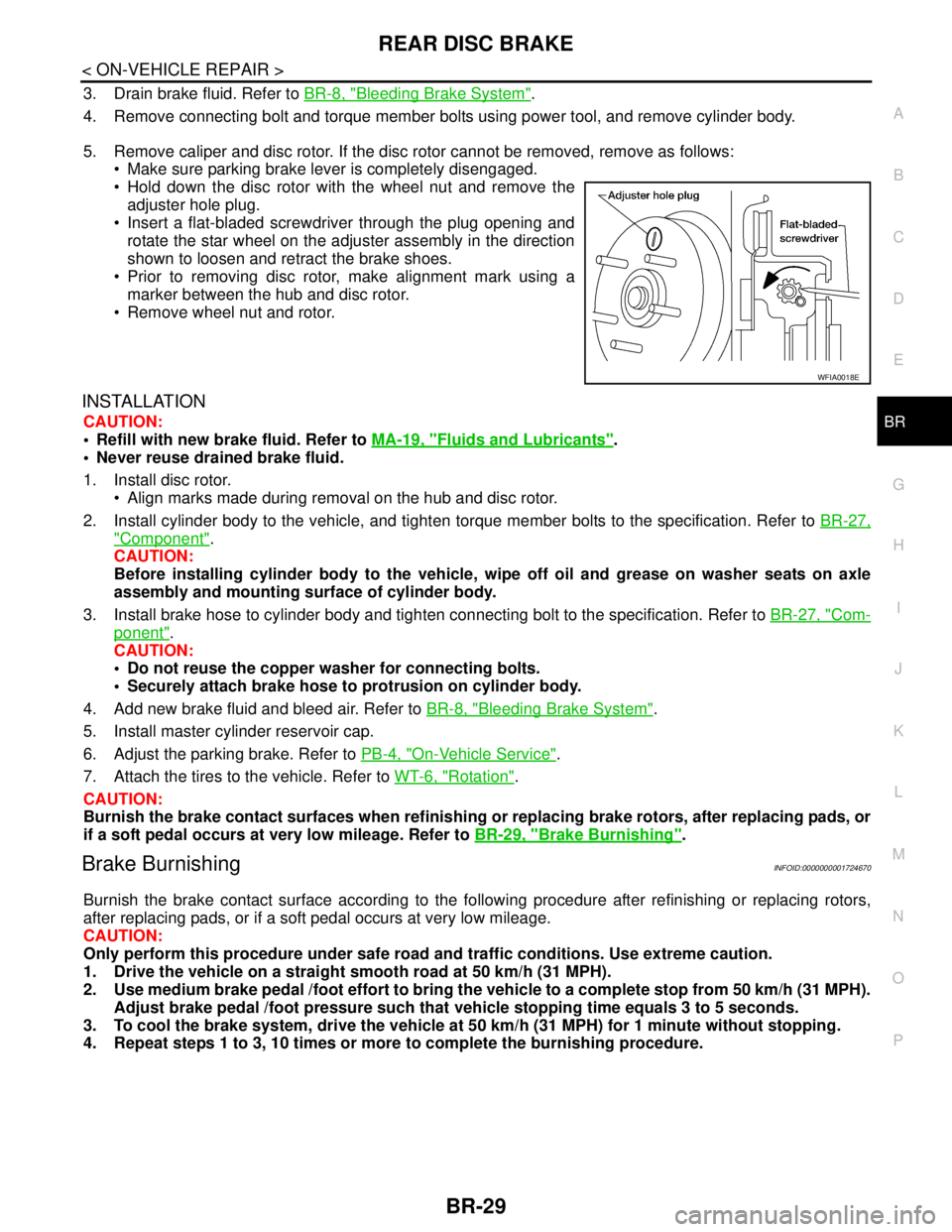

5. Remove caliper and disc rotor. If the disc rotor cannot be removed, remove as follows:

Make sure parking brake lever is completely disengaged.

Hold down the disc rotor with the wheel nut and remove the

adjuster hole plug.

Insert a flat-bladed screwdriver through the plug opening and

rotate the star wheel on the adjuster assembly in the direction

shown to loosen and retract the brake shoes.

Prior to removing disc rotor, make alignment mark using a

marker between the hub and disc rotor.

Remove wheel nut and rotor.

INSTALLATION

CAUTION:

Refill with new brake fluid. Refer to MA-19, "

Fluids and Lubricants".

Never reuse drained brake fluid.

1. Install disc rotor.

Align marks made during removal on the hub and disc rotor.

2. Install cylinder body to the vehicle, and tighten torque member bolts to the specification. Refer to BR-27,

"Component".

CAUTION:

Before installing cylinder body to the vehicle, wipe off oil and grease on washer seats on axle

assembly and mounting surface of cylinder body.

3. Install brake hose to cylinder body and tighten connecting bolt to the specification. Refer to BR-27, "

Com-

ponent".

CAUTION:

Do not reuse the copper washer for connecting bolts.

Securely attach brake hose to protrusion on cylinder body.

4. Add new brake fluid and bleed air. Refer to BR-8, "

Bleeding Brake System".

5. Install master cylinder reservoir cap.

6. Adjust the parking brake. Refer to PB-4, "

On-Vehicle Service".

7. Attach the tires to the vehicle. Refer to WT-6, "

Rotation".

CAUTION:

Burnish the brake contact surfaces when refinishing or replacing brake rotors, after replacing pads, or

if a soft pedal occurs at very low mileage. Refer to BR-29, "

Brake Burnishing".

Brake BurnishingINFOID:0000000001724670

Burnish the brake contact surface according to the following procedure after refinishing or replacing rotors,

after replacing pads, or if a soft pedal occurs at very low mileage.

CAUTION:

Only perform this procedure under safe road and traffic conditions. Use extreme caution.

1. Drive the vehicle on a straight smooth road at 50 km/h (31 MPH).

2. Use medium brake pedal /foot effort to bring the vehicle to a complete stop from 50 km/h (31 MPH).

Adjust brake pedal /foot pressure such that vehicle stopping time equals 3 to 5 seconds.

3. To cool the brake system, drive the vehicle at 50 km/h (31 MPH) for 1 minute without stopping.

4. Repeat steps 1 to 3, 10 times or more to complete the burnishing procedure.

WFIA0018E

Page 239 of 5883

![NISSAN TIIDA 2007 Service Repair Manual BRC-6

< BASIC INSPECTION >[ABS]

DIAGNOSIS AND REPAIR WORKFLOW

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORKFLOW

Work FlowINFOID:0000000001731351

PRECAUTIONS FOR DIAGNOSIS

If steering angle sensor, steeri NISSAN TIIDA 2007 Service Repair Manual BRC-6

< BASIC INSPECTION >[ABS]

DIAGNOSIS AND REPAIR WORKFLOW

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORKFLOW

Work FlowINFOID:0000000001731351

PRECAUTIONS FOR DIAGNOSIS

If steering angle sensor, steeri](/img/5/57395/w960_57395-238.png)

BRC-6

< BASIC INSPECTION >[ABS]

DIAGNOSIS AND REPAIR WORKFLOW

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORKFLOW

Work FlowINFOID:0000000001731351

PRECAUTIONS FOR DIAGNOSIS

If steering angle sensor, steering system parts, suspension system parts, ABS actuator and electric unit (con-

trol unit) or tires have been replaced, or if wheel alignment has been adjusted, be sure to adjust neutral posi-

tion of steering angle sensor before driving. Refer to BRC-90, "

ADJUSTMENT OF STEERING ANGLE

SENSOR NEUTRAL POSITION : Description".

Page 243 of 5883

![NISSAN TIIDA 2007 Service Repair Manual BRC-10

< BASIC INSPECTION >[ABS]

INSPECTION AND ADJUSTMENT

INSPECTION AND ADJUSTMENT

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT : Description

INFOID: NISSAN TIIDA 2007 Service Repair Manual BRC-10

< BASIC INSPECTION >[ABS]

INSPECTION AND ADJUSTMENT

INSPECTION AND ADJUSTMENT

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT : Description

INFOID:](/img/5/57395/w960_57395-242.png)

BRC-10

< BASIC INSPECTION >[ABS]

INSPECTION AND ADJUSTMENT

INSPECTION AND ADJUSTMENT

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT : Description

INFOID:0000000001731353

After replacing the ABS actuator and electric unit (control unit), perform the following procedures:

Neutral position adjustment for the steering angle sensor

Calibration of the decel G sensor

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT : Special Repair Re-

quirement

INFOID:0000000001731354

1.PERFORM THE NEUTRAL POSITION ADJUSTMENT FOR THE STEERING ANGLE SENSOR

Perform the neutral position adjustment for the steering angle sensor.

>> Refer to BRC-90, "

ADJUSTMENT OF STEERING ANGLE SENSOR NEUTRAL POSITION : Spe-

cial Repair Requirement", GO TO 2

2.PERFORM CALIBRATION OF THE DECEL G SENSOR

Perform calibration of the decel G sensor.

>> Refer to BRC-92, "

CALIBRATION OF DECEL G SENSOR : Special Repair Requirement".

ADJUSTMENT OF STEERING ANGLE SENSOR NEUTRAL POSITION

ADJUSTMENT OF STEERING ANGLE SENSOR NEUTRAL POSITION : Description

INFOID:0000000001731355

Refer to the table below to determine if adjustment of steering angle sensor neutral position is required.

×: Required –: Not required

ADJUSTMENT OF STEERING ANGLE SENSOR NEUTRAL POSITION : Special Re-

pair Requirement

INFOID:0000000001731356

ADJUSTMENT OF STEERING ANGLE SENSOR NEUTRAL POSITION

CAUTION:

To adjust neutral position of steering angle sensor, make sure to use CONSULT-III

(Adjustment cannot be done without CONSULT-III)

1.ALIGN THE VEHICLE STATUS

Stop vehicle with front wheels in straight-ahead position.

Situation Adjustment of steering angle sensor neutral position

Removing/Installing ABS actuator and electric unit (control unit) —

Replacing ABS actuator and electric unit (control unit)×

Removing/Installing steering angle sensor×

Replacing steering angle sensor×

Removing/Installing steering components×

Replacing steering components×

Removing/Installing suspension components×

Replacing suspension components×

Change tires to new ones—

Tire rotation—

Adjusting wheel alignment×

Page 244 of 5883

![NISSAN TIIDA 2007 Service Repair Manual INSPECTION AND ADJUSTMENT

BRC-11

< BASIC INSPECTION >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

>> GO TO 2

2.PERFORM THE NEUTRAL POSITION ADJUSTMENT FOR THE STEERING ANGLE SENSOR

1. On the CONSULT-III scr NISSAN TIIDA 2007 Service Repair Manual INSPECTION AND ADJUSTMENT

BRC-11

< BASIC INSPECTION >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

>> GO TO 2

2.PERFORM THE NEUTRAL POSITION ADJUSTMENT FOR THE STEERING ANGLE SENSOR

1. On the CONSULT-III scr](/img/5/57395/w960_57395-243.png)

INSPECTION AND ADJUSTMENT

BRC-11

< BASIC INSPECTION >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

>> GO TO 2

2.PERFORM THE NEUTRAL POSITION ADJUSTMENT FOR THE STEERING ANGLE SENSOR

1. On the CONSULT-III screen, touch “WORK SUPPORT” and “ST ANG SEN ADJUSTMENT” in order.

2. Touch “START”.

CAUTION:

Do not touch steering wheel while adjusting steering angle sensor.

3. After approximately 10 seconds, touch “END”.

NOTE:

After approximately 60 seconds, it ends automatically.

4. Turn ignition switch OFF, then turn it ON again.

CAUTION:

Be sure to perform above operation.

>> GO TO 3

3.CHECK DATA MONITOR

1. Run vehicle with front wheels in straight-ahead position, then stop.

2. Select “DATA MONITOR”. Then make sure “STR ANGLE SIG” is within 0±2.5°.

Is the steering angle within the specified range?

YES >> GO TO 4

NO >> Perform the neutral position adjustment for the steering angle sensor again, GO TO 1

4.ERASE THE SELF-DIAGNOSIS MEMORY

Erase the self-diagnosis memory of the ABS actuator and electric unit (control unit) and ECM.

ABS actuator and electric unit (control unit): Refer to BRC-25, "

CONSULT-III Function (ABS)".

ECM, refer to:

-EC-107, "

CONSULT-III Function" (HR16DE with EURO-OBD)

-EC-462, "

CONSULT-III Function" (HR16DE without EURO-OBD)

-EC-772, "

CONSULT-III Function" (MR18DE)

-EC-1104, "

Diagnosis Description" (K9K)

Are the memories erased?

YES >> INSPECTION END

NO >> Check the items indicated by the self-diagnosis.

CALIBRATION OF DECEL G SENSOR

CALIBRATION OF DECEL G SENSOR : DescriptionINFOID:0000000001731357

Refer to the table below to determine if calibration of the decel G sensor is required.

×: Required –: Not required

Situation Calibration of decel G sensor

Removing/Installing ABS actuator and electric unit (control unit) —

Replacing ABS actuator and electric unit (control unit)×

Removing/Installing steering angle sensor×

Replacing steering angle sensor×

Removing/Installing steering components×

Replacing steering components×

Removing/Installing suspension components×

Replacing suspension components×

Change tires to new ones—

Tire rotation—

Adjusting wheel alignment×

Page 319 of 5883

![NISSAN TIIDA 2007 Service Repair Manual BRC-86

< BASIC INSPECTION >[ESP/TCS/ABS]

DIAGNOSIS AND REPAIR WORKFLOW

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORKFLOW

Work FlowINFOID:0000000001731359

PRECAUTIONS FOR DIAGNOSIS

If steering angle senso NISSAN TIIDA 2007 Service Repair Manual BRC-86

< BASIC INSPECTION >[ESP/TCS/ABS]

DIAGNOSIS AND REPAIR WORKFLOW

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORKFLOW

Work FlowINFOID:0000000001731359

PRECAUTIONS FOR DIAGNOSIS

If steering angle senso](/img/5/57395/w960_57395-318.png)

BRC-86

< BASIC INSPECTION >[ESP/TCS/ABS]

DIAGNOSIS AND REPAIR WORKFLOW

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORKFLOW

Work FlowINFOID:0000000001731359

PRECAUTIONS FOR DIAGNOSIS

If steering angle sensor, steering system parts, suspension system parts, ABS actuator and electric unit (con-

trol unit) or tires have been replaced, or if wheel alignment has been adjusted, be sure to adjust neutral posi-

tion of steering angle sensor before driving. Refer to BRC-90, "

ADJUSTMENT OF STEERING ANGLE

SENSOR NEUTRAL POSITION : Description".

Page 323 of 5883

![NISSAN TIIDA 2007 Service Repair Manual BRC-90

< BASIC INSPECTION >[ESP/TCS/ABS]

INSPECTION AND ADJUSTMENT

INSPECTION AND ADJUSTMENT

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT : Description NISSAN TIIDA 2007 Service Repair Manual BRC-90

< BASIC INSPECTION >[ESP/TCS/ABS]

INSPECTION AND ADJUSTMENT

INSPECTION AND ADJUSTMENT

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT : Description](/img/5/57395/w960_57395-322.png)

BRC-90

< BASIC INSPECTION >[ESP/TCS/ABS]

INSPECTION AND ADJUSTMENT

INSPECTION AND ADJUSTMENT

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT : Description

INFOID:0000000001731361

After replacing the ABS actuator and electric unit (control unit), perform the following procedures:

Neutral position adjustment for the steering angle sensor

Calibration of the decel G sensor

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT : Special Repair Re-

quirement

INFOID:0000000001731362

1.PERFORM THE NEUTRAL POSITION ADJUSTMENT FOR THE STEERING ANGLE SENSOR

Perform the neutral position adjustment for the steering angle sensor.

>> Refer to BRC-90, "

ADJUSTMENT OF STEERING ANGLE SENSOR NEUTRAL POSITION : Spe-

cial Repair Requirement", GO TO 2

2.PERFORM CALIBRATION OF THE DECEL G SENSOR

Perform calibration of the decel G sensor.

>> Refer to BRC-92, "

CALIBRATION OF DECEL G SENSOR : Special Repair Requirement".

ADJUSTMENT OF STEERING ANGLE SENSOR NEUTRAL POSITION

ADJUSTMENT OF STEERING ANGLE SENSOR NEUTRAL POSITION : Description

INFOID:0000000001731363

Refer to the table below to determine if adjustment of steering angle sensor neutral position is required.

×: Required –: Not required

ADJUSTMENT OF STEERING ANGLE SENSOR NEUTRAL POSITION : Special Re-

pair Requirement

INFOID:0000000001731364

ADJUSTMENT OF STEERING ANGLE SENSOR NEUTRAL POSITION

CAUTION:

To adjust neutral position of steering angle sensor, make sure to use CONSULT-III

(Adjustment cannot be done without CONSULT-III)

1.ALIGN THE VEHICLE STATUS

Stop vehicle with front wheels in straight-ahead position.

Situation Adjustment of steering angle sensor neutral position

Removing/Installing ABS actuator and electric unit (control unit) —

Replacing ABS actuator and electric unit (control unit)×

Removing/Installing steering angle sensor×

Replacing steering angle sensor×

Removing/Installing steering components×

Replacing steering components×

Removing/Installing suspension components×

Replacing suspension components×

Change tires to new ones—

Tire rotation—

Adjusting wheel alignment×

Page 324 of 5883

![NISSAN TIIDA 2007 Service Repair Manual INSPECTION AND ADJUSTMENT

BRC-91

< BASIC INSPECTION >[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

>> GO TO 2

2.PERFORM THE NEUTRAL POSITION ADJUSTMENT FOR THE STEERING ANGLE SENSOR

1. On the CONSULT NISSAN TIIDA 2007 Service Repair Manual INSPECTION AND ADJUSTMENT

BRC-91

< BASIC INSPECTION >[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

>> GO TO 2

2.PERFORM THE NEUTRAL POSITION ADJUSTMENT FOR THE STEERING ANGLE SENSOR

1. On the CONSULT](/img/5/57395/w960_57395-323.png)

INSPECTION AND ADJUSTMENT

BRC-91

< BASIC INSPECTION >[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

>> GO TO 2

2.PERFORM THE NEUTRAL POSITION ADJUSTMENT FOR THE STEERING ANGLE SENSOR

1. On the CONSULT-III screen, touch “WORK SUPPORT” and “ST ANG SEN ADJUSTMENT” in order.

2. Touch “START”.

CAUTION:

Do not touch steering wheel while adjusting steering angle sensor.

3. After approximately 10 seconds, touch “END”.

NOTE:

After approximately 60 seconds, it ends automatically.

4. Turn ignition switch OFF, then turn it ON again.

CAUTION:

Be sure to perform above operation.

>> GO TO 3

3.CHECK DATA MONITOR

1. Run vehicle with front wheels in straight-ahead position, then stop.

2. Select “DATA MONITOR”. Then make sure “STR ANGLE SIG” is within 0±2.5°.

Is the steering angle within the specified range?

YES >> GO TO 4

NO >> Perform the neutral position adjustment for the steering angle sensor again, GO TO 1

4.ERASE THE SELF-DIAGNOSIS MEMORY

Erase the self-diagnosis memory of the ABS actuator and electric unit (control unit) and ECM.

ABS actuator and electric unit (control unit): Refer to BRC-25, "

CONSULT-III Function (ABS)".

ECM, refer to:

-EC-107, "

CONSULT-III Function" (HR16DE with EURO-OBD)

-EC-462, "

CONSULT-III Function" (HR16DE without EURO-OBD)

-EC-772, "

CONSULT-III Function" (MR18DE)

-EC-1104, "

Diagnosis Description" (K9K)

Are the memories erased?

YES >> INSPECTION END

NO >> Check the items indicated by the self-diagnosis.

CALIBRATION OF DECEL G SENSOR

CALIBRATION OF DECEL G SENSOR : DescriptionINFOID:0000000001731365

Refer to the table below to determine if calibration of the decel G sensor is required.

×: Required –: Not required

Situation Calibration of decel G sensor

Removing/Installing ABS actuator and electric unit (control unit) —

Replacing ABS actuator and electric unit (control unit)×

Removing/Installing steering angle sensor×

Replacing steering angle sensor×

Removing/Installing steering components×

Replacing steering components×

Removing/Installing suspension components×

Replacing suspension components×

Change tires to new ones—

Tire rotation—

Adjusting wheel alignment×

Page 469 of 5883

CL-4

< SERVICE INFORMATION >

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

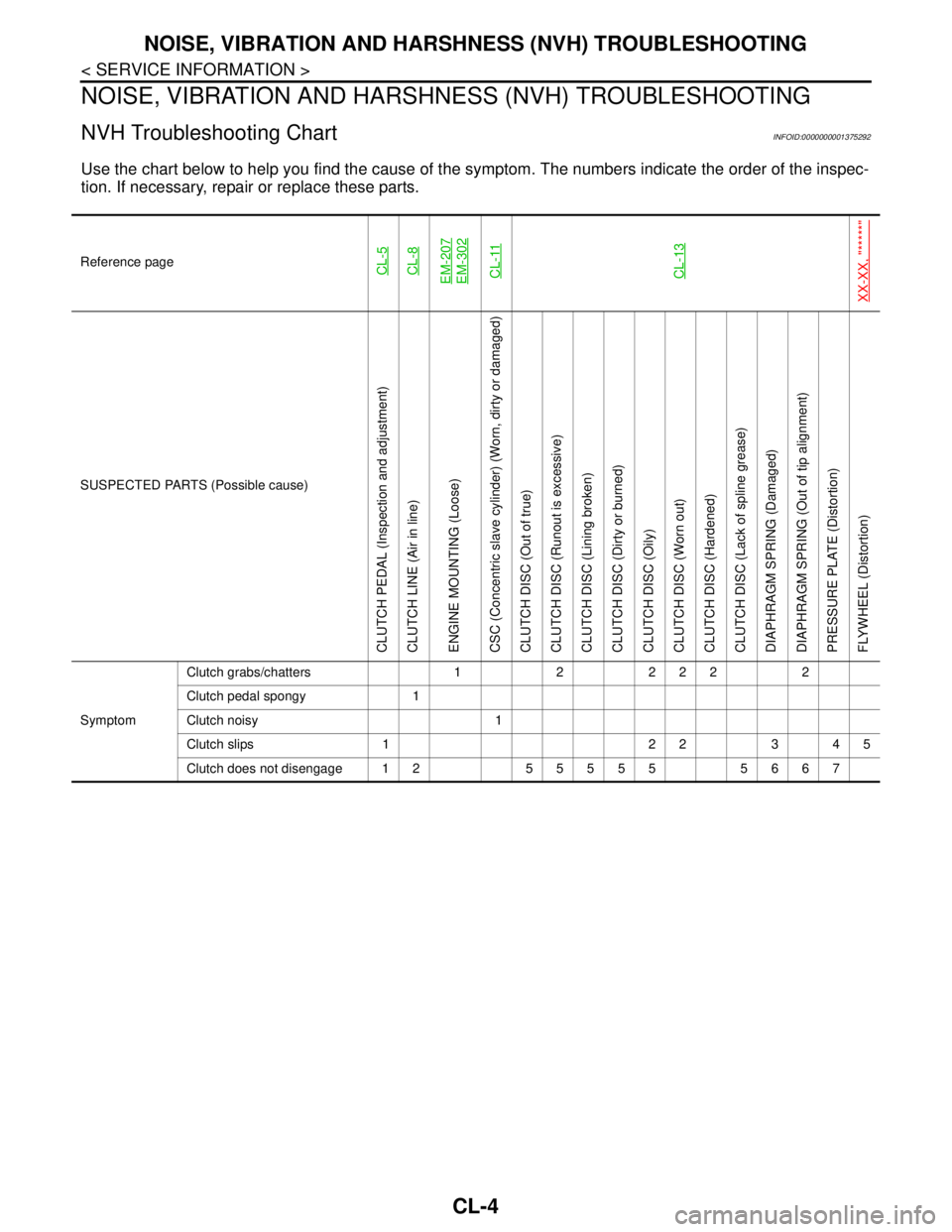

NVH Troubleshooting ChartINFOID:0000000001375292

Use the chart below to help you find the cause of the symptom. The numbers indicate the order of the inspec-

tion. If necessary, repair or replace these parts.

Reference pageCL-5CL-8EM-207EM-302CL-11CL-13

XX-XX, "*****"

SUSPECTED PARTS (Possible cause)

CLUTCH PEDAL (Inspection and adjustment)

CLUTCH LINE (Air in line)

ENGINE MOUNTING (Loose)

CSC (Concentric slave cylinder) (Worn, dirty or damaged)

CLUTCH DISC (Out of true)

CLUTCH DISC (Runout is excessive)

CLUTCH DISC (Lining broken)

CLUTCH DISC (Dirty or burned)

CLUTCH DISC (Oily)

CLUTCH DISC (Worn out)

CLUTCH DISC (Hardened)

CLUTCH DISC (Lack of spline grease)

DIAPHRAGM SPRING (Damaged)

DIAPHRAGM SPRING (Out of tip alignment)

PRESSURE PLATE (Distortion)

FLYWHEEL (Distortion)

SymptomClutch grabs/chatters 1 2 2 2 2 2

Clutch pedal spongy 1

Clutch noisy 1

Clutch slips 1 2 2 3 4 5

Clutch does not disengage 12 55555 5667

Page 793 of 5883

![NISSAN TIIDA 2007 Service Repair Manual DLK-204

< SYMPTOM DIAGNOSIS >[WITH I-KEY, WITHOUT SUPER LOCK]

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under t NISSAN TIIDA 2007 Service Repair Manual DLK-204

< SYMPTOM DIAGNOSIS >[WITH I-KEY, WITHOUT SUPER LOCK]

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under t](/img/5/57395/w960_57395-792.png)

DLK-204

< SYMPTOM DIAGNOSIS >[WITH I-KEY, WITHOUT SUPER LOCK]

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Inspection ProcedureINFOID:0000000001396664

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. Cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicon spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or rattle. If you saturate the area with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation procedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the areas with felt cloth tape or insulator foam blocks to

repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid dumpers out of adjustment

2. Trunk lid striker out of adjustment

3. Trunk lid torsion bars knocking together

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sunvisor shaft shaking in the holder

3. Front or rear windshield touching headlining and squeaking

Page 1022 of 5883

![NISSAN TIIDA 2007 Service Repair Manual SQUEAK AND RATTLE TROUBLE DIAGNOSES

DLK-433

< SYMPTOM DIAGNOSIS >[WITH I-KEY & SUPER LOCK]

C

D

E

F

G

H

I

J

L

MA

B

DLK

N

O

P

Confirm that the cause of a noise is repaired by test driving the vehicle. O NISSAN TIIDA 2007 Service Repair Manual SQUEAK AND RATTLE TROUBLE DIAGNOSES

DLK-433

< SYMPTOM DIAGNOSIS >[WITH I-KEY & SUPER LOCK]

C

D

E

F

G

H

I

J

L

MA

B

DLK

N

O

P

Confirm that the cause of a noise is repaired by test driving the vehicle. O](/img/5/57395/w960_57395-1021.png)

SQUEAK AND RATTLE TROUBLE DIAGNOSES

DLK-433

< SYMPTOM DIAGNOSIS >[WITH I-KEY & SUPER LOCK]

C

D

E

F

G

H

I

J

L

MA

B

DLK

N

O

P

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Inspection ProcedureINFOID:0000000001396892

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. Cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicon spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or rattle. If you saturate the area with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation procedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the areas with felt cloth tape or insulator foam blocks to

repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid dumpers out of adjustment

2. Trunk lid striker out of adjustment

3. Trunk lid torsion bars knocking together

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sunvisor shaft shaking in the holder

3. Front or rear windshield touching headlining and squeaking