NISSAN TIIDA 2008 Service Repair Manual

TIIDA 2008

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57399/w960_57399-0.png

NISSAN TIIDA 2008 Service Repair Manual

Trending: fog light bulb, fuse chart, stalls, speedometer, Body, fan, fuel pressure

Page 2311 of 2771

TRANSAXLE ASSEMBLY

MT-23

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

MT

N

O

P

DISASSEMBLY

1. Remove drain plug and gasket from clutch housing, and drain oil.

2. Remove filler plug and gasket from transaxle case.

3. Remove CSC from clutch housing.

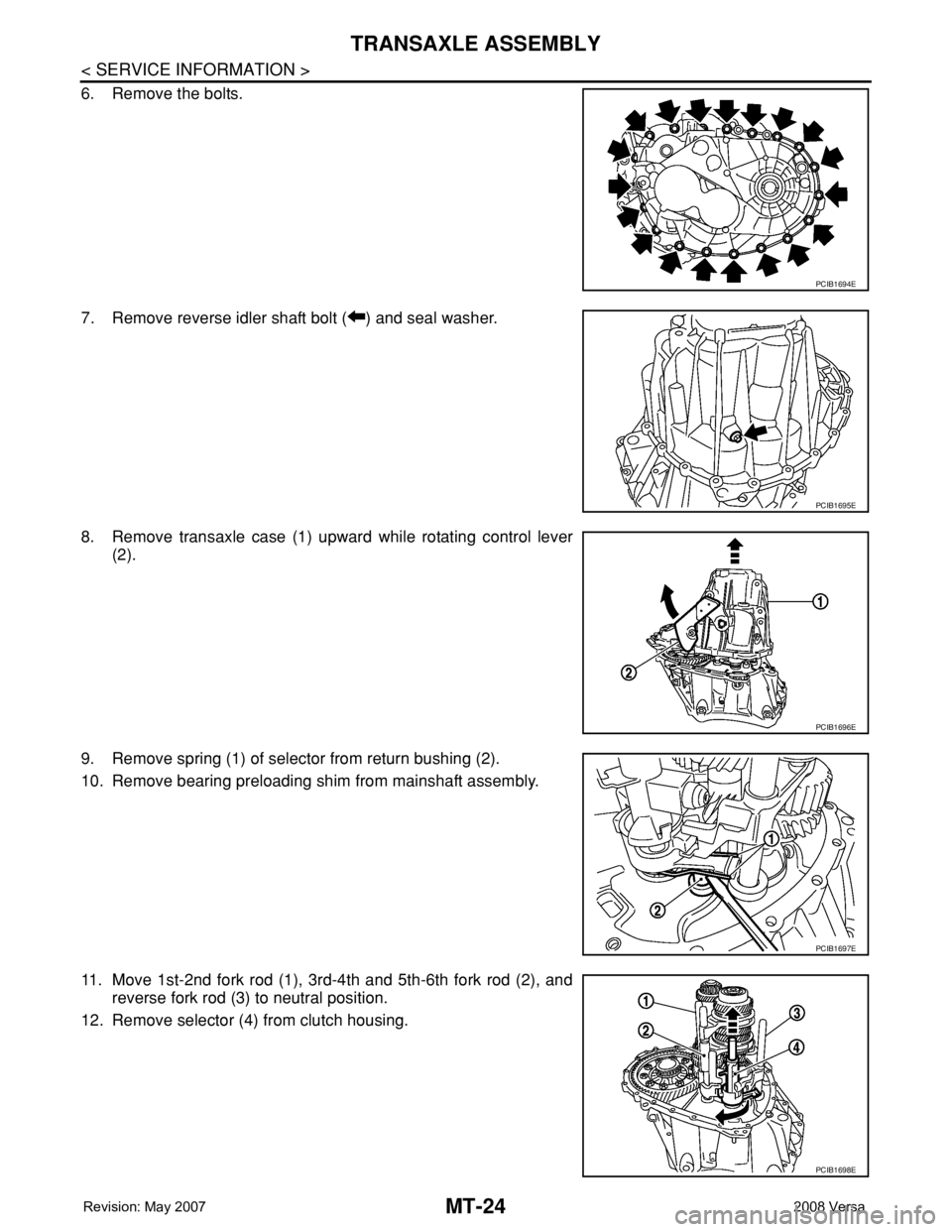

4. Remove retaining pin from shift lever (1) using suitable tool.

5. Remove bracket (2) and position switch (3) from transaxle case.

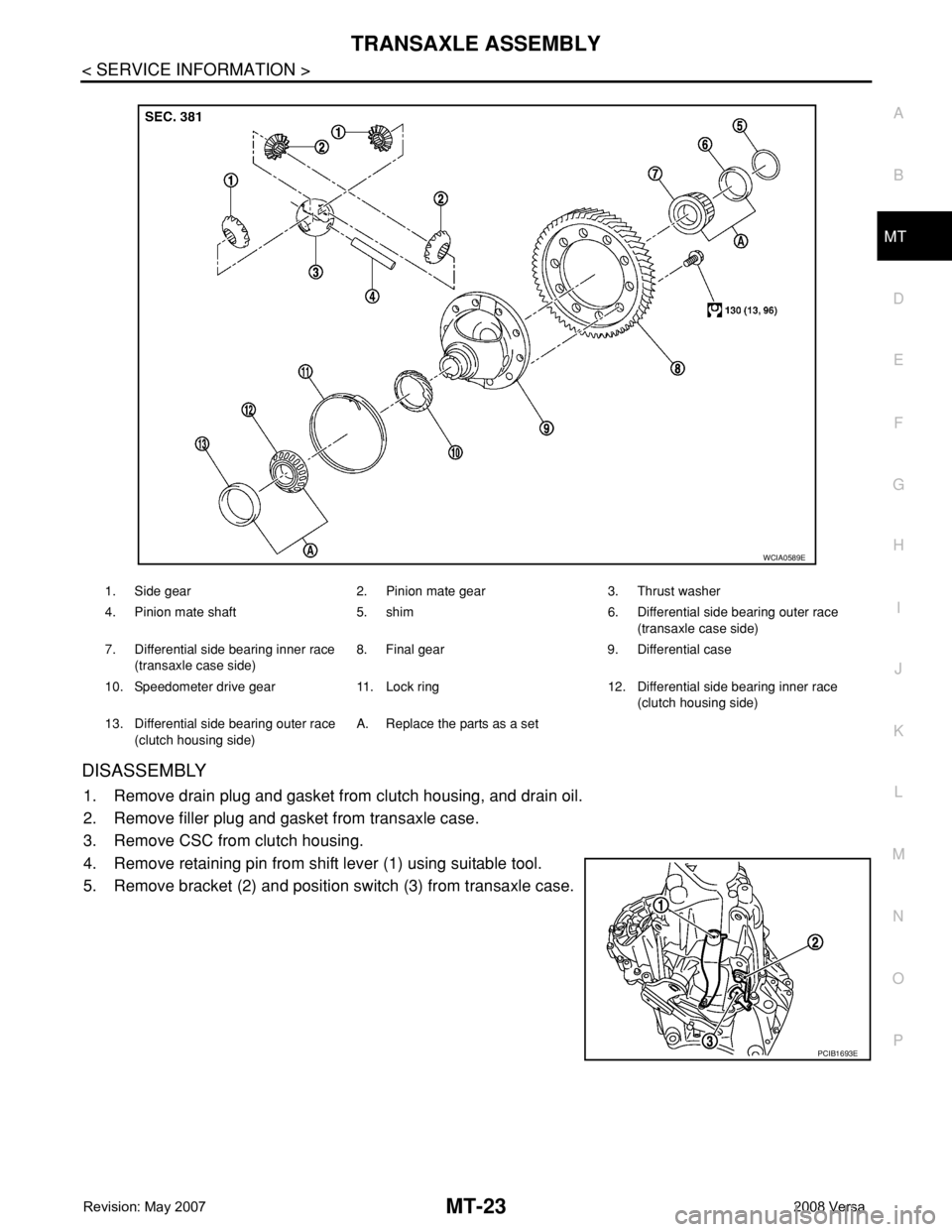

1. Side gear 2. Pinion mate gear 3. Thrust washer

4. Pinion mate shaft 5. shim 6. Differential side bearing outer race

(transaxle case side)

7. Differential side bearing inner race

(transaxle case side)8. Final gear 9. Differential case

10. Speedometer drive gear 11. Lock ring 12. Differential side bearing inner race

(clutch housing side)

13. Differential side bearing outer race

(clutch housing side)A. Replace the parts as a set

WCIA0589E

PCIB1693E

Page 2312 of 2771

MT-24

< SERVICE INFORMATION >

TRANSAXLE ASSEMBLY

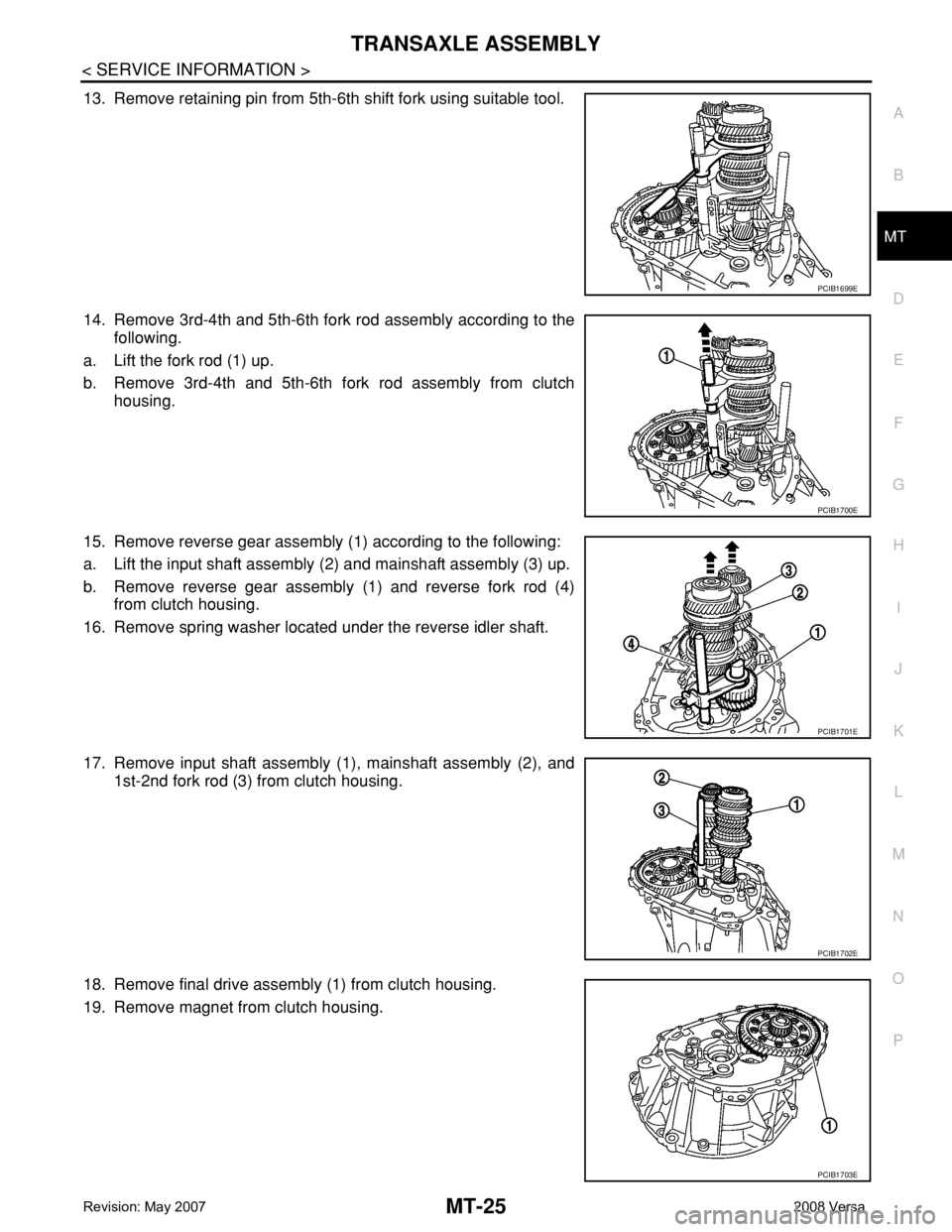

6. Remove the bolts.

7. Remove reverse idler shaft bolt ( ) and seal washer.

8. Remove transaxle case (1) upward while rotating control lever

(2).

9. Remove spring (1) of selector from return bushing (2).

10. Remove bearing preloading shim from mainshaft assembly.

11. Move 1st-2nd fork rod (1), 3rd-4th and 5th-6th fork rod (2), and

reverse fork rod (3) to neutral position.

12. Remove selector (4) from clutch housing.

PCIB1694E

PCIB1695E

PCIB1696E

PCIB1697E

PCIB1698E

Page 2313 of 2771

TRANSAXLE ASSEMBLY

MT-25

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

MT

N

O

P

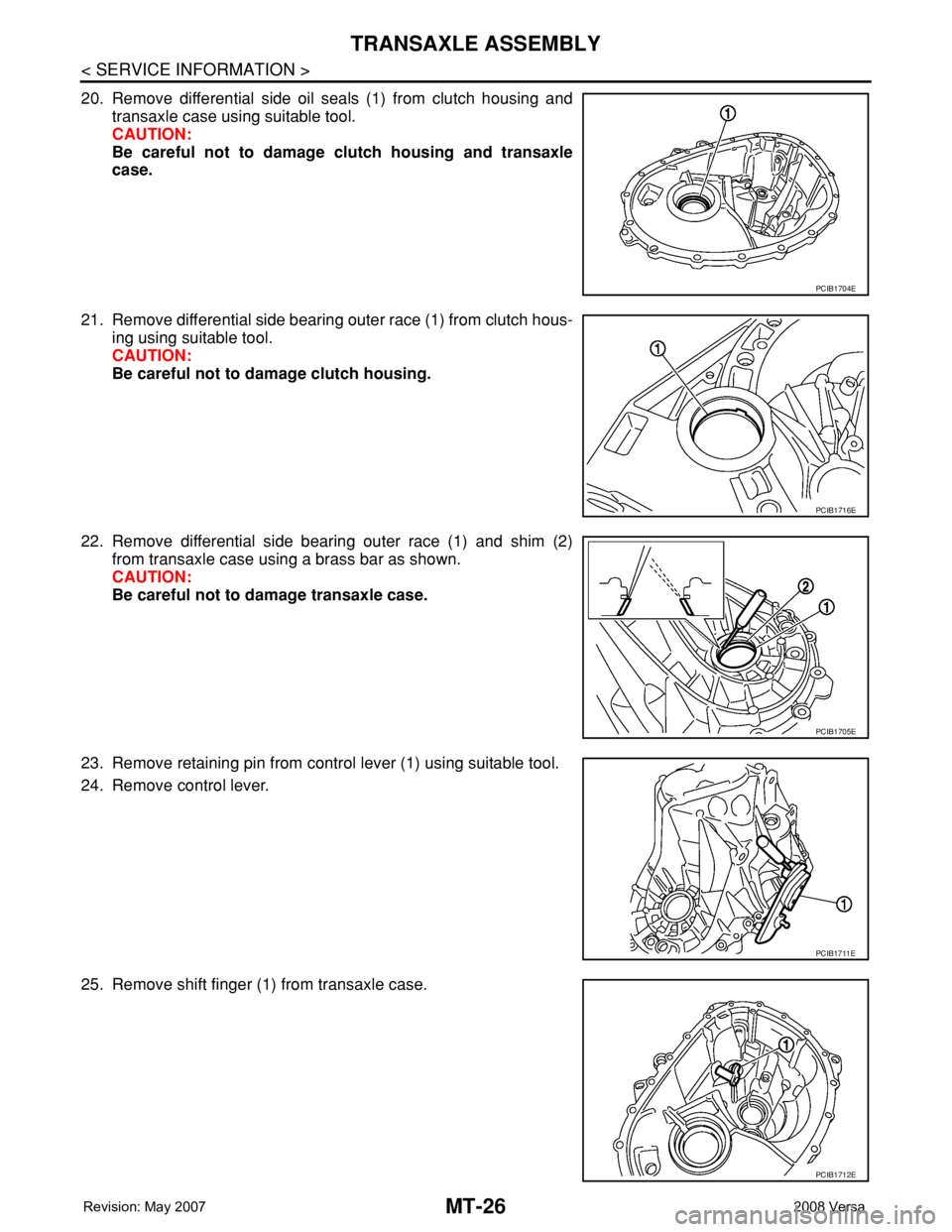

13. Remove retaining pin from 5th-6th shift fork using suitable tool.

14. Remove 3rd-4th and 5th-6th fork rod assembly according to the

following.

a. Lift the fork rod (1) up.

b. Remove 3rd-4th and 5th-6th fork rod assembly from clutch

housing.

15. Remove reverse gear assembly (1) according to the following:

a. Lift the input shaft assembly (2) and mainshaft assembly (3) up.

b. Remove reverse gear assembly (1) and reverse fork rod (4)

from clutch housing.

16. Remove spring washer located under the reverse idler shaft.

17. Remove input shaft assembly (1), mainshaft assembly (2), and

1st-2nd fork rod (3) from clutch housing.

18. Remove final drive assembly (1) from clutch housing.

19. Remove magnet from clutch housing.

PCIB1699E

PCIB1700E

PCIB1701E

PCIB1702E

PCIB1703E

Page 2314 of 2771

MT-26

< SERVICE INFORMATION >

TRANSAXLE ASSEMBLY

20. Remove differential side oil seals (1) from clutch housing and

transaxle case using suitable tool.

CAUTION:

Be careful not to damage clutch housing and transaxle

case.

21. Remove differential side bearing outer race (1) from clutch hous-

ing using suitable tool.

CAUTION:

Be careful not to damage clutch housing.

22. Remove differential side bearing outer race (1) and shim (2)

from transaxle case using a brass bar as shown.

CAUTION:

Be careful not to damage transaxle case.

23. Remove retaining pin from control lever (1) using suitable tool.

24. Remove control lever.

25. Remove shift finger (1) from transaxle case.

PCIB1704E

PCIB1716E

PCIB1705E

PCIB1711E

PCIB1712E

Page 2315 of 2771

TRANSAXLE ASSEMBLY

MT-27

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

MT

N

O

P

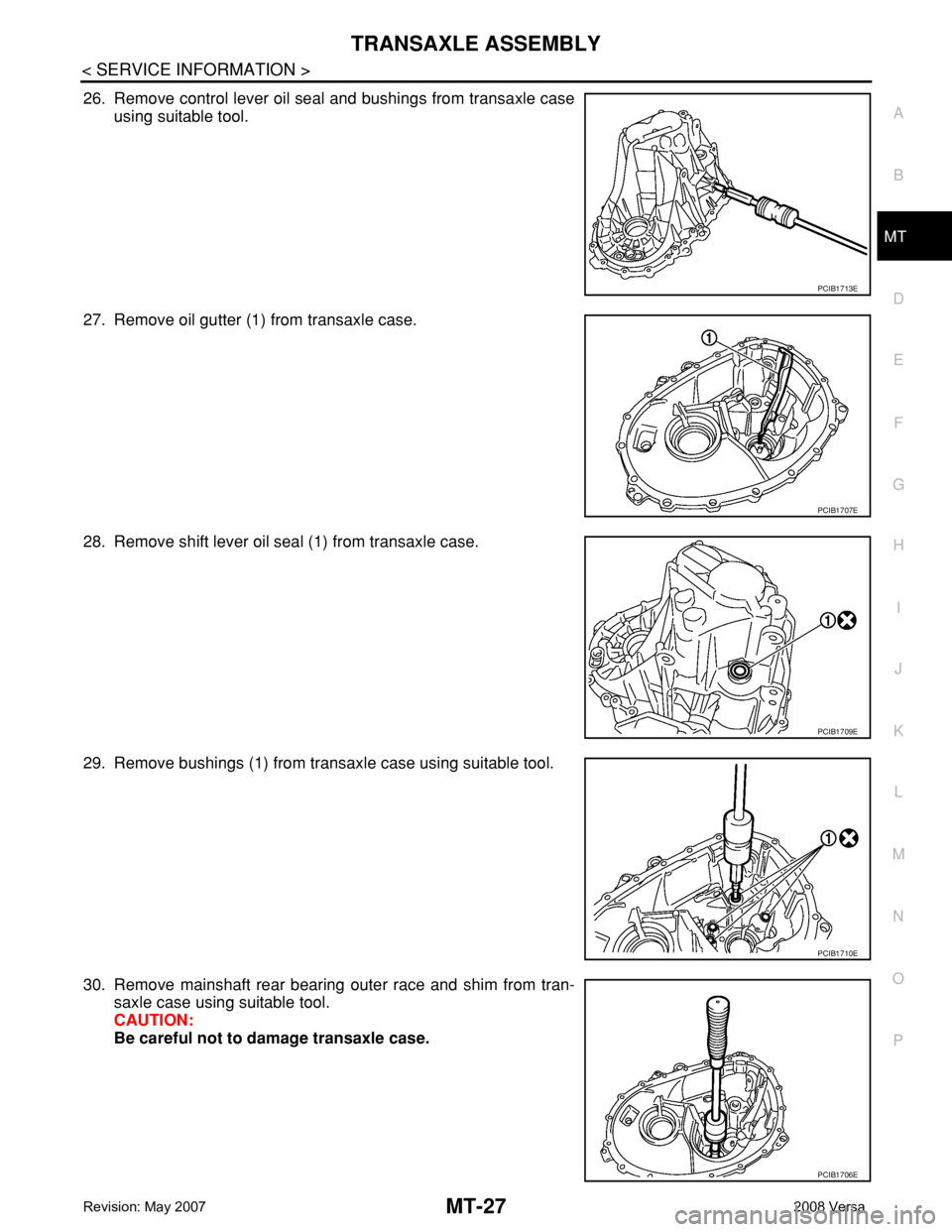

26. Remove control lever oil seal and bushings from transaxle case

using suitable tool.

27. Remove oil gutter (1) from transaxle case.

28. Remove shift lever oil seal (1) from transaxle case.

29. Remove bushings (1) from transaxle case using suitable tool.

30. Remove mainshaft rear bearing outer race and shim from tran-

saxle case using suitable tool.

CAUTION:

Be careful not to damage transaxle case.

PCIB1713E

PCIB1707E

PCIB1709E

PCIB1710E

PCIB1706E

Page 2316 of 2771

MT-28

< SERVICE INFORMATION >

TRANSAXLE ASSEMBLY

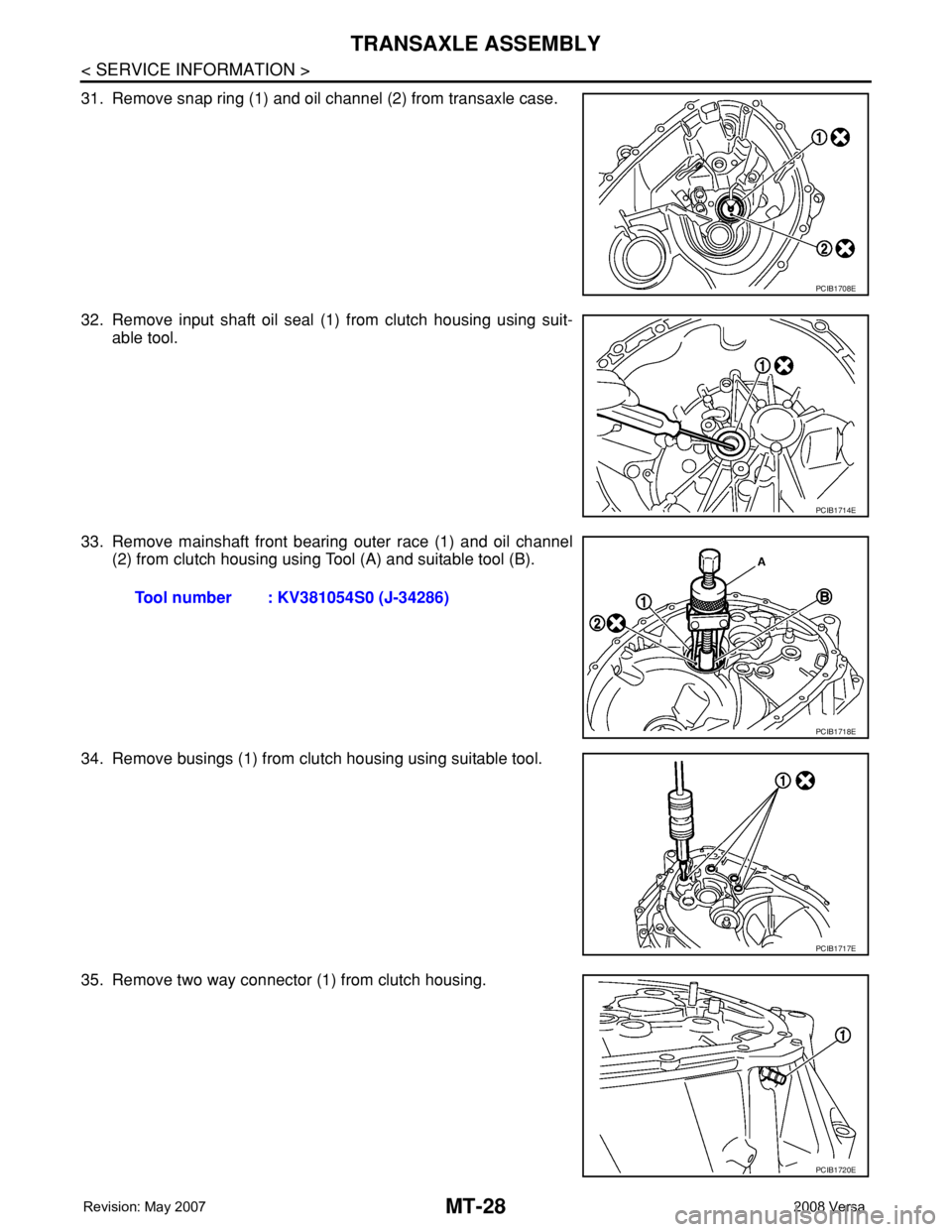

31. Remove snap ring (1) and oil channel (2) from transaxle case.

32. Remove input shaft oil seal (1) from clutch housing using suit-

able tool.

33. Remove mainshaft front bearing outer race (1) and oil channel

(2) from clutch housing using Tool (A) and suitable tool (B).

34. Remove busings (1) from clutch housing using suitable tool.

35. Remove two way connector (1) from clutch housing.

PCIB1708E

PCIB1714E

Tool number : KV381054S0 (J-34286)

PCIB1718E

PCIB1717E

PCIB1720E

Page 2317 of 2771

TRANSAXLE ASSEMBLY

MT-29

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

MT

N

O

P

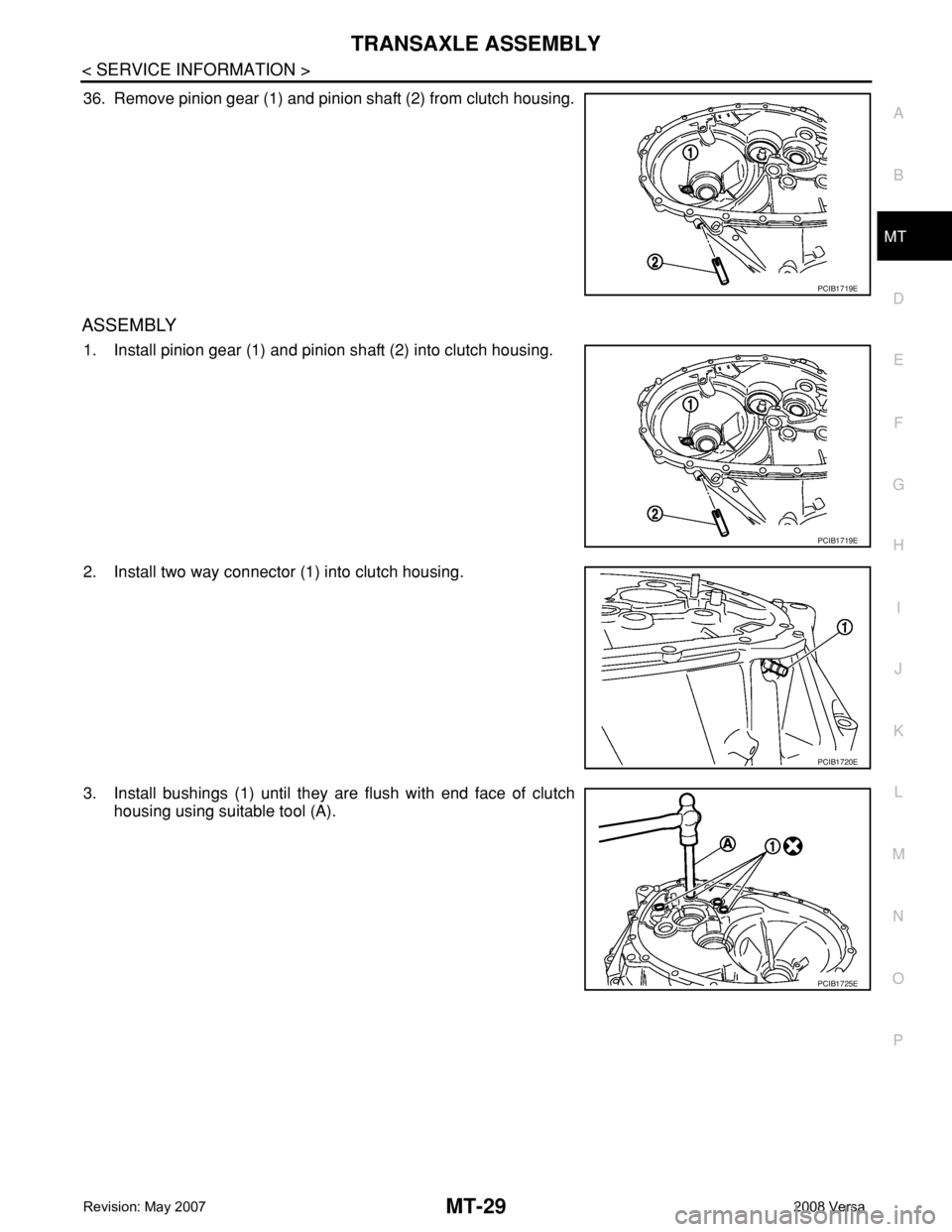

36. Remove pinion gear (1) and pinion shaft (2) from clutch housing.

ASSEMBLY

1. Install pinion gear (1) and pinion shaft (2) into clutch housing.

2. Install two way connector (1) into clutch housing.

3. Install bushings (1) until they are flush with end face of clutch

housing using suitable tool (A).

PCIB1719E

PCIB1719E

PCIB1720E

PCIB1725E

Page 2318 of 2771

MT-30

< SERVICE INFORMATION >

TRANSAXLE ASSEMBLY

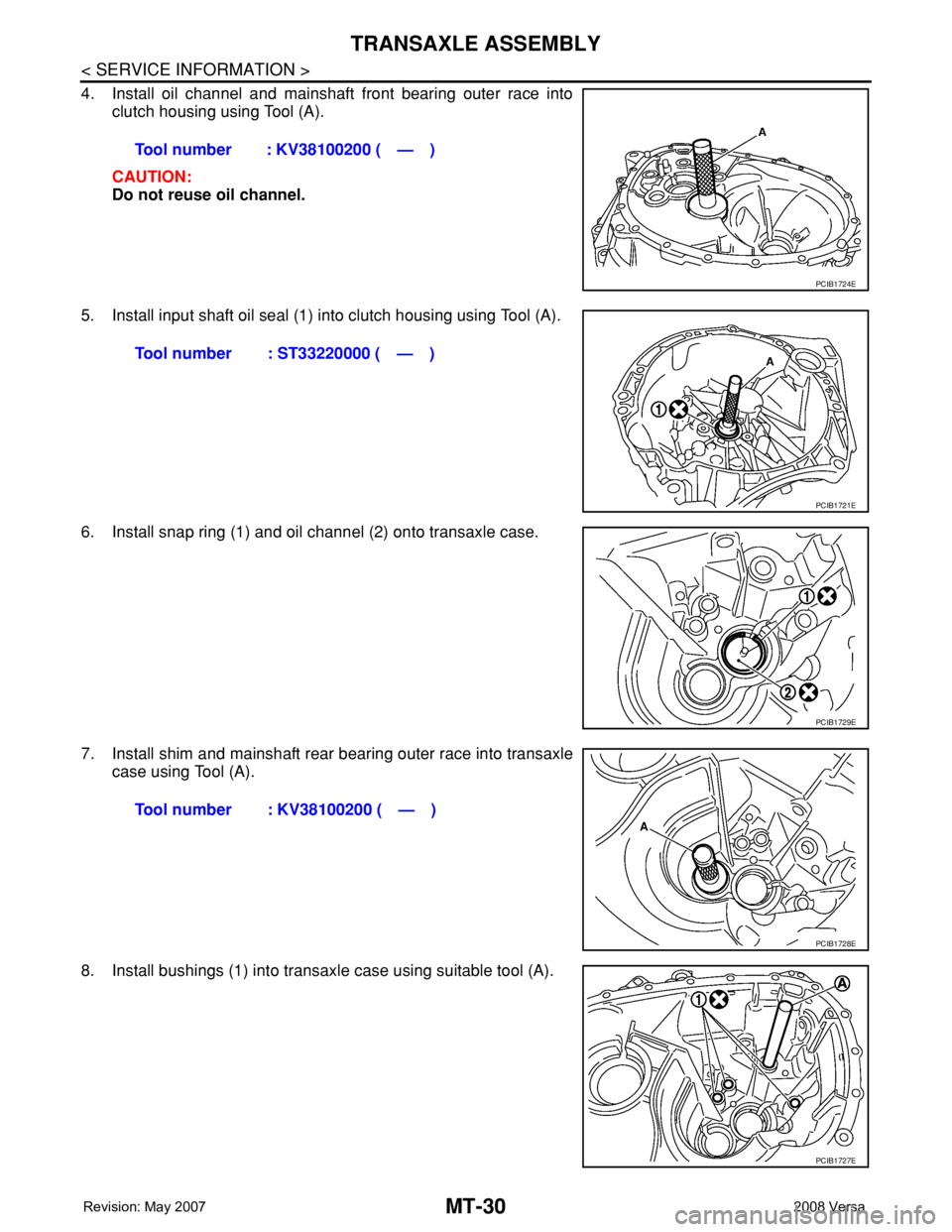

4. Install oil channel and mainshaft front bearing outer race into

clutch housing using Tool (A).

CAUTION:

Do not reuse oil channel.

5. Install input shaft oil seal (1) into clutch housing using Tool (A).

6. Install snap ring (1) and oil channel (2) onto transaxle case.

7. Install shim and mainshaft rear bearing outer race into transaxle

case using Tool (A).

8. Install bushings (1) into transaxle case using suitable tool (A).Tool number : KV38100200 ( — )

PCIB1724E

Tool number : ST33220000 ( — )

PCIB1721E

PCIB1729E

Tool number : KV38100200 ( — )

PCIB1728E

PCIB1727E

Page 2319 of 2771

TRANSAXLE ASSEMBLY

MT-31

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

MT

N

O

P

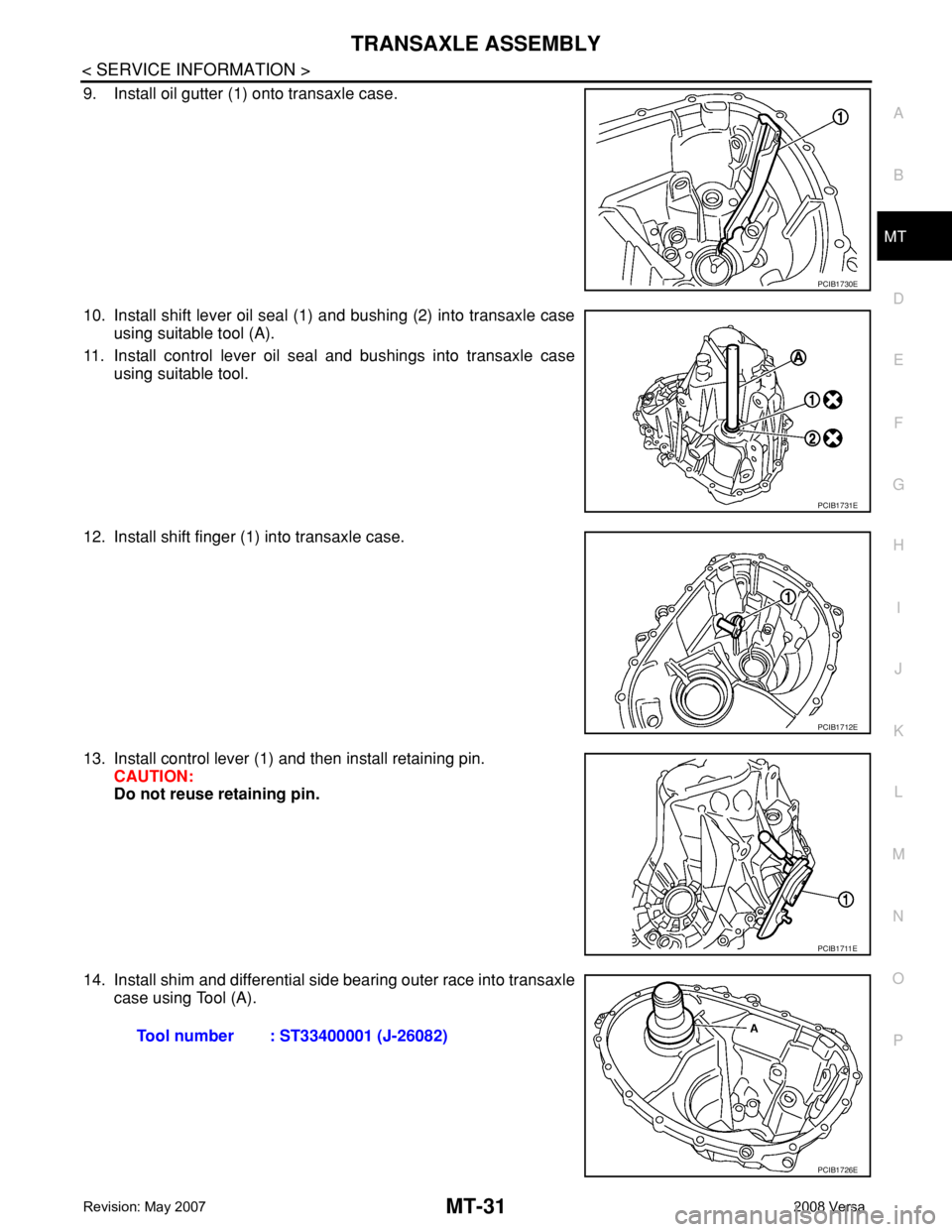

9. Install oil gutter (1) onto transaxle case.

10. Install shift lever oil seal (1) and bushing (2) into transaxle case

using suitable tool (A).

11. Install control lever oil seal and bushings into transaxle case

using suitable tool.

12. Install shift finger (1) into transaxle case.

13. Install control lever (1) and then install retaining pin.

CAUTION:

Do not reuse retaining pin.

14. Install shim and differential side bearing outer race into transaxle

case using Tool (A).

PCIB1730E

PCIB1731E

PCIB1712E

PCIB1711E

Tool number : ST33400001 (J-26082)

PCIB1726E

Page 2320 of 2771

MT-32

< SERVICE INFORMATION >

TRANSAXLE ASSEMBLY

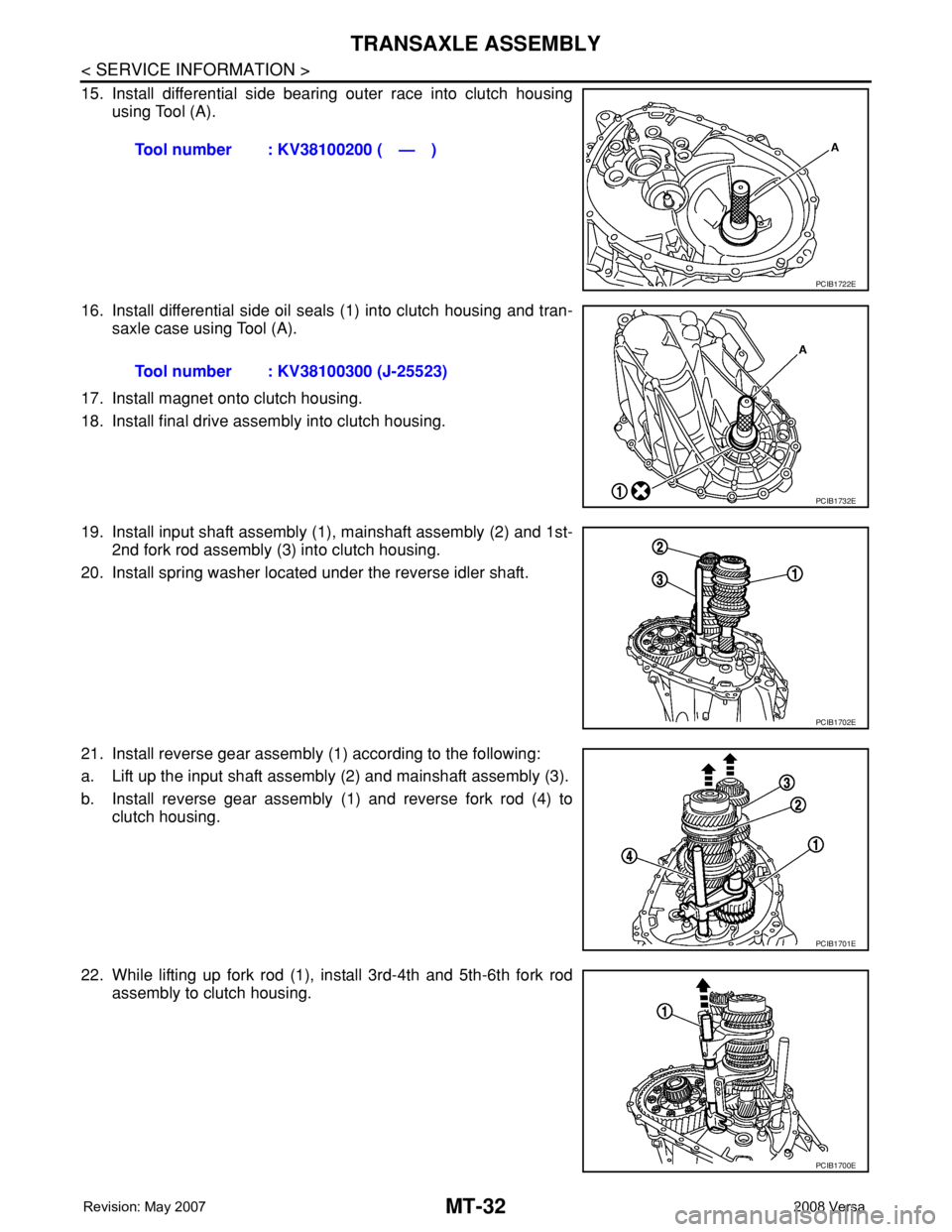

15. Install differential side bearing outer race into clutch housing

using Tool (A).

16. Install differential side oil seals (1) into clutch housing and tran-

saxle case using Tool (A).

17. Install magnet onto clutch housing.

18. Install final drive assembly into clutch housing.

19. Install input shaft assembly (1), mainshaft assembly (2) and 1st-

2nd fork rod assembly (3) into clutch housing.

20. Install spring washer located under the reverse idler shaft.

21. Install reverse gear assembly (1) according to the following:

a. Lift up the input shaft assembly (2) and mainshaft assembly (3).

b. Install reverse gear assembly (1) and reverse fork rod (4) to

clutch housing.

22. While lifting up fork rod (1), install 3rd-4th and 5th-6th fork rod

assembly to clutch housing. Tool number : KV38100200 ( — )

PCIB1722E

Tool number : KV38100300 (J-25523)

PCIB1732E

PCIB1702E

PCIB1701E

PCIB1700E

Trending: rsu, wheel bolt torque, seat adjustment, Engine oil, jack, adding oil, fuel fill door release