NISSAN TIIDA 2008 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2008, Model line: TIIDA, Model: NISSAN TIIDA 2008Pages: 2771, PDF Size: 60.61 MB

Page 2331 of 2771

MAINSHAFT AND GEARS

MT-43

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

MT

N

O

P

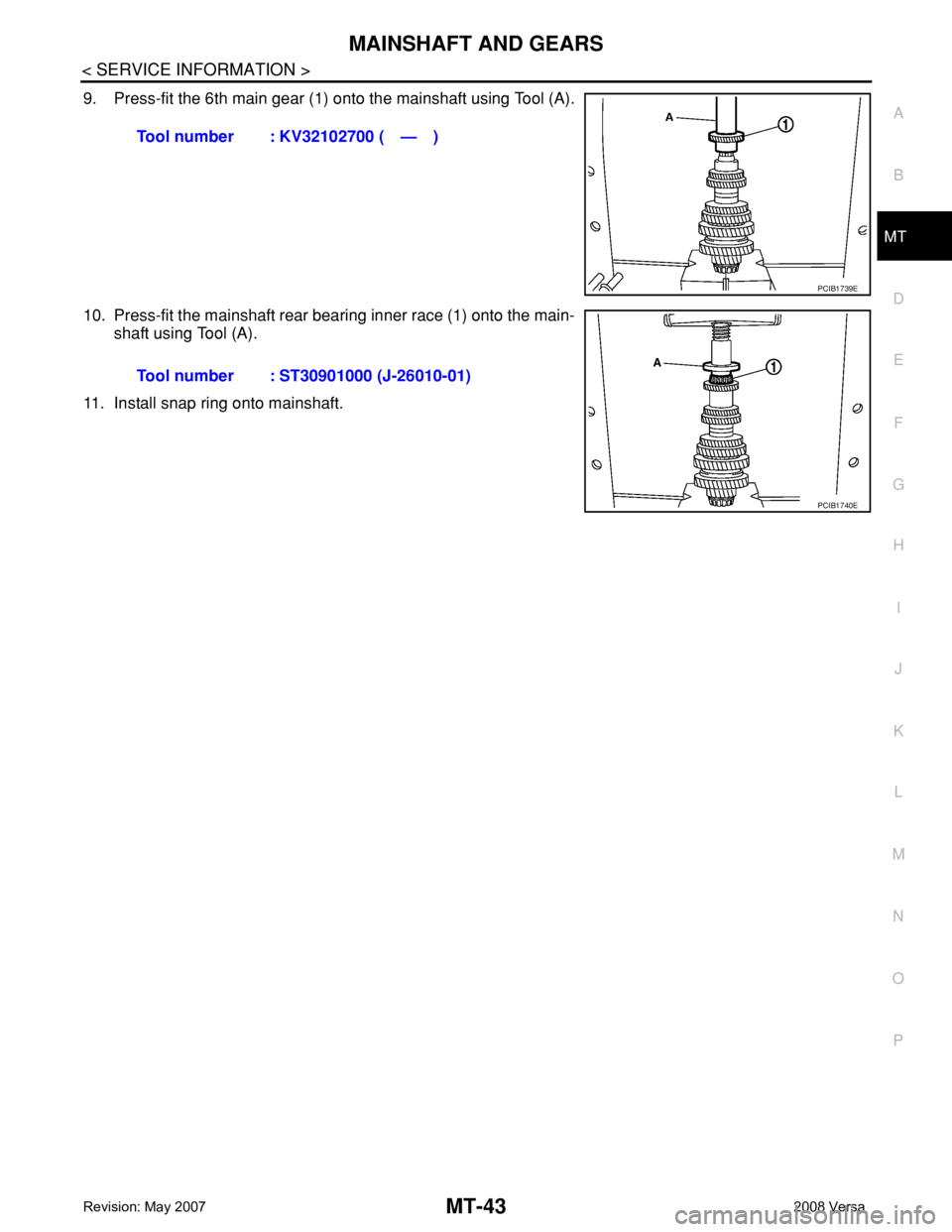

9. Press-fit the 6th main gear (1) onto the mainshaft using Tool (A).

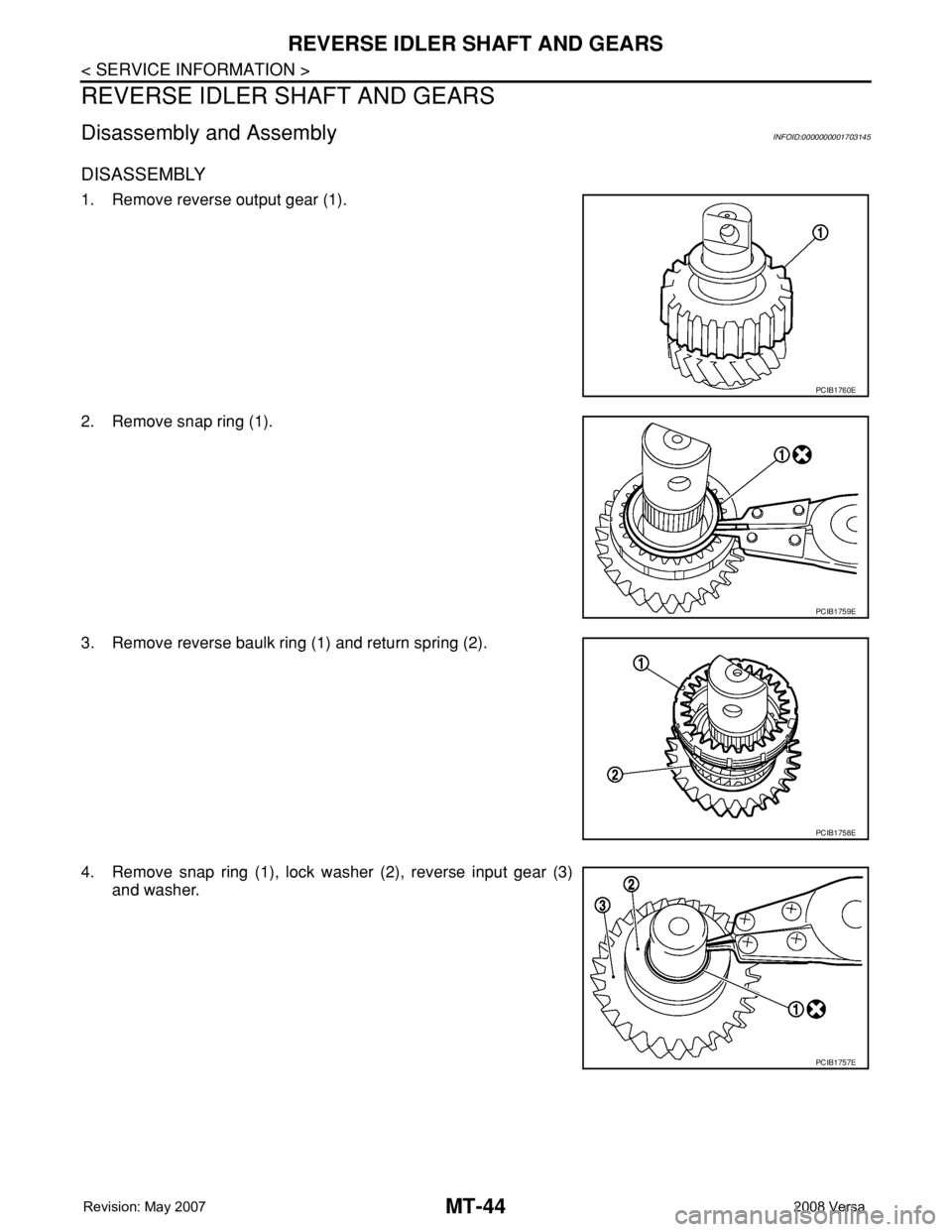

10. Press-fit the mainshaft rear bearing inner race (1) onto the main-

shaft using Tool (A).

11. Install snap ring onto mainshaft.Tool number : KV32102700 ( — )

PCIB1739E

Tool number : ST30901000 (J-26010-01)

PCIB1740E

Page 2332 of 2771

MT-44

< SERVICE INFORMATION >

REVERSE IDLER SHAFT AND GEARS

REVERSE IDLER SHAFT AND GEARS

Disassembly and AssemblyINFOID:0000000001703145

DISASSEMBLY

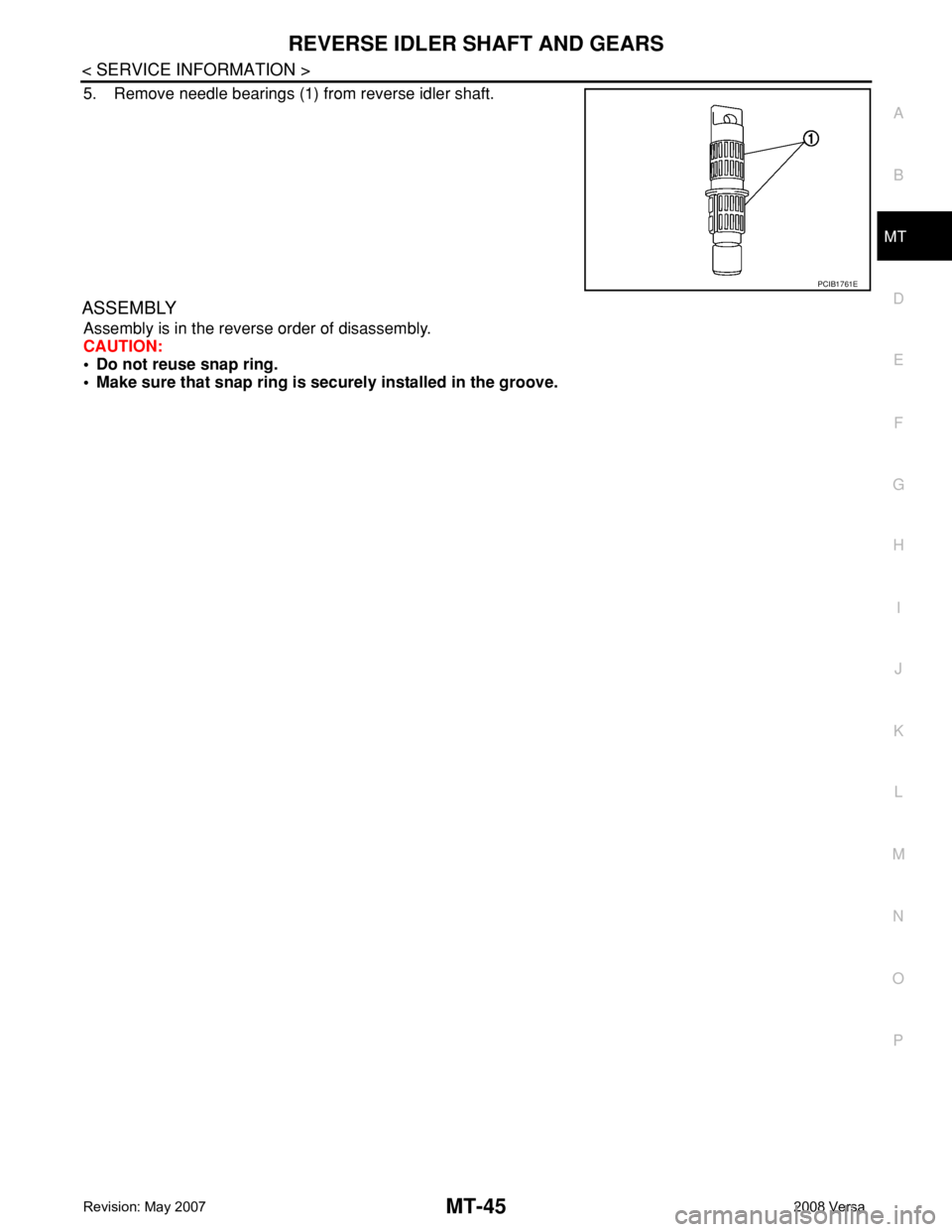

1. Remove reverse output gear (1).

2. Remove snap ring (1).

3. Remove reverse baulk ring (1) and return spring (2).

4. Remove snap ring (1), lock washer (2), reverse input gear (3)

and washer.

PCIB1760E

PCIB1759E

PCIB1758E

PCIB1757E

Page 2333 of 2771

REVERSE IDLER SHAFT AND GEARS

MT-45

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

MT

N

O

P

5. Remove needle bearings (1) from reverse idler shaft.

ASSEMBLY

Assembly is in the reverse order of disassembly.

CAUTION:

• Do not reuse snap ring.

• Make sure that snap ring is securely installed in the groove.

PCIB1761E

Page 2334 of 2771

MT-46

< SERVICE INFORMATION >

FINAL DRIVE

FINAL DRIVE

Disassembly and AssemblyINFOID:0000000001703146

DISASSEMBLY

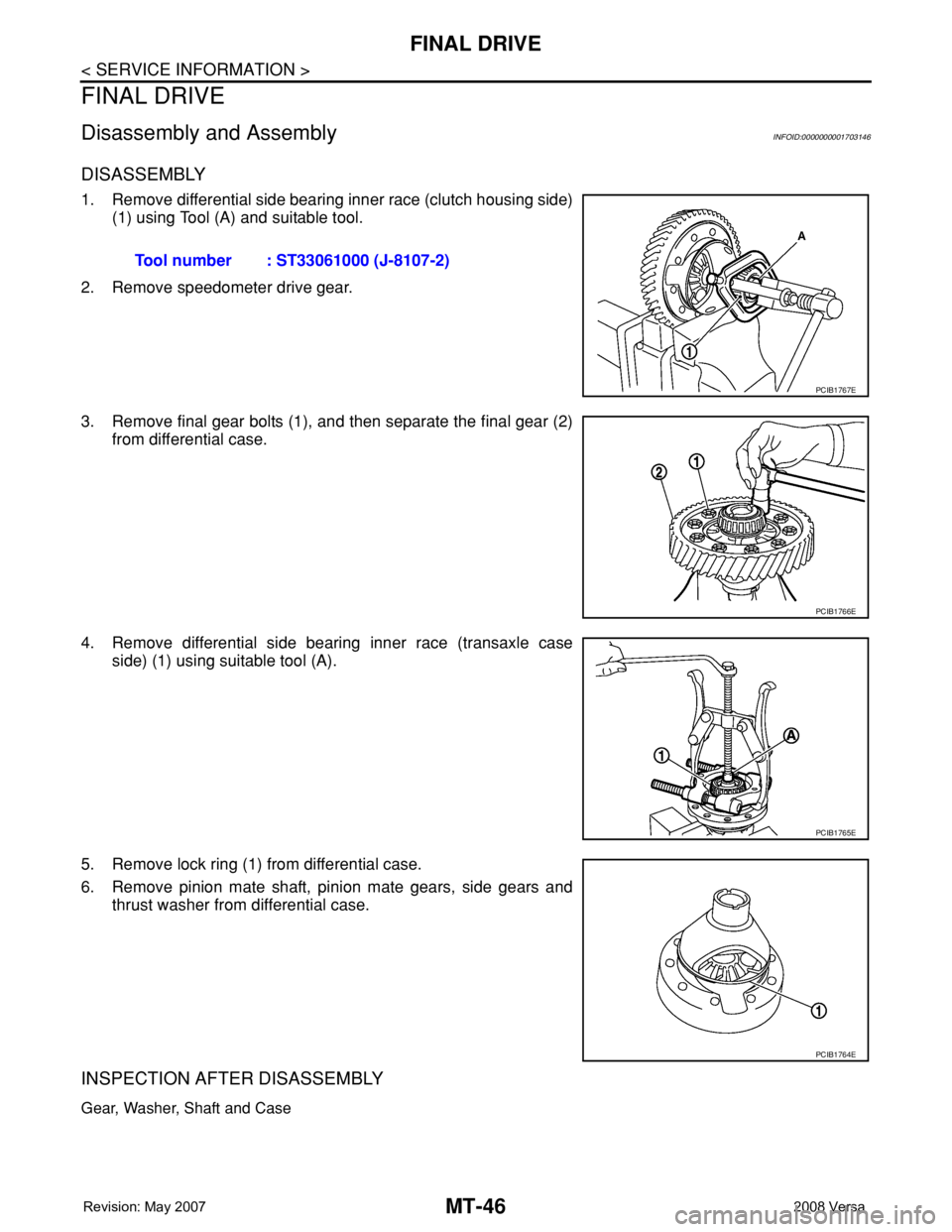

1. Remove differential side bearing inner race (clutch housing side)

(1) using Tool (A) and suitable tool.

2. Remove speedometer drive gear.

3. Remove final gear bolts (1), and then separate the final gear (2)

from differential case.

4. Remove differential side bearing inner race (transaxle case

side) (1) using suitable tool (A).

5. Remove lock ring (1) from differential case.

6. Remove pinion mate shaft, pinion mate gears, side gears and

thrust washer from differential case.

INSPECTION AFTER DISASSEMBLY

Gear, Washer, Shaft and Case

Tool number : ST33061000 (J-8107-2)

PCIB1767E

PCIB1766E

PCIB1765E

PCIB1764E

Page 2335 of 2771

FINAL DRIVE

MT-47

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

MT

N

O

P

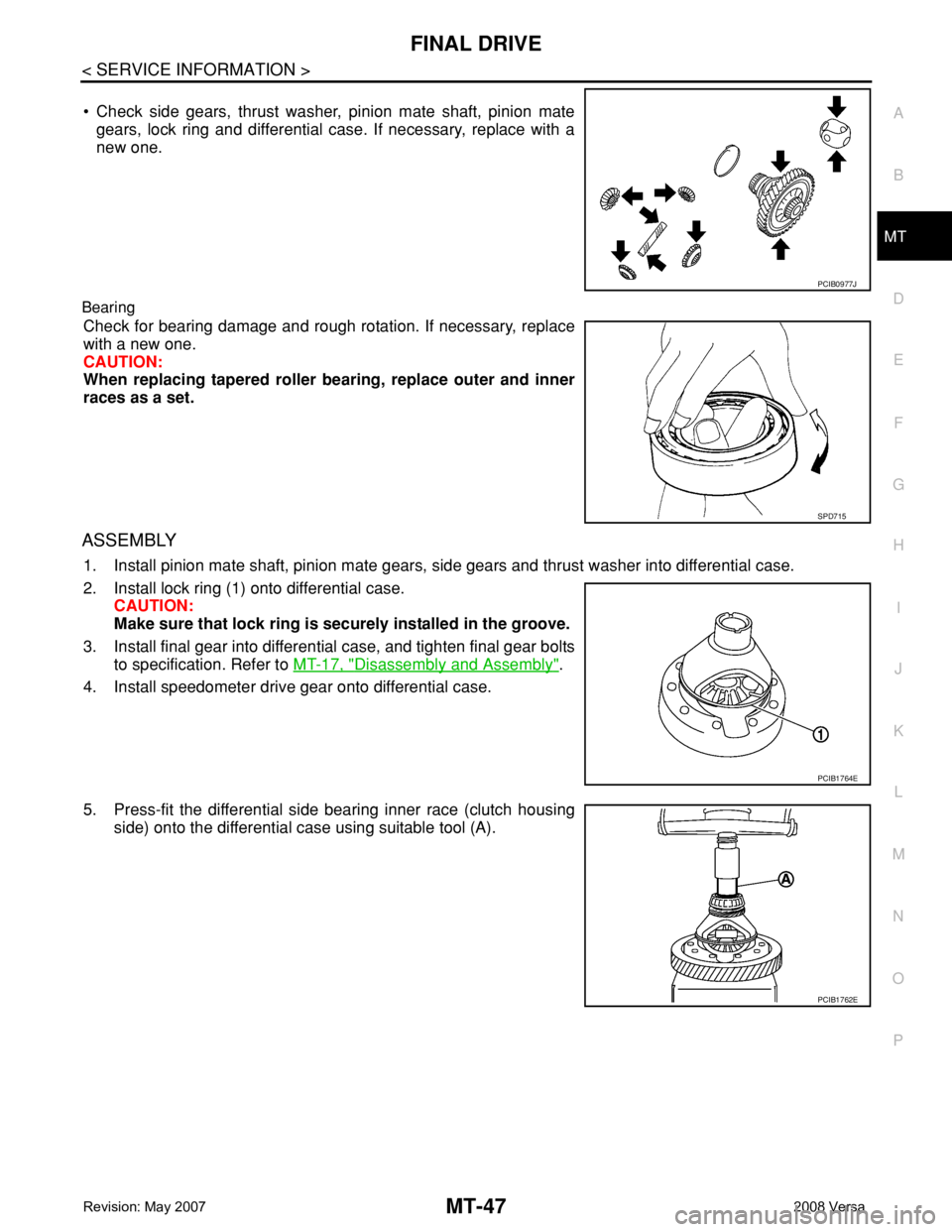

• Check side gears, thrust washer, pinion mate shaft, pinion mate

gears, lock ring and differential case. If necessary, replace with a

new one.

Bearing

Check for bearing damage and rough rotation. If necessary, replace

with a new one.

CAUTION:

When replacing tapered roller bearing, replace outer and inner

races as a set.

ASSEMBLY

1. Install pinion mate shaft, pinion mate gears, side gears and thrust washer into differential case.

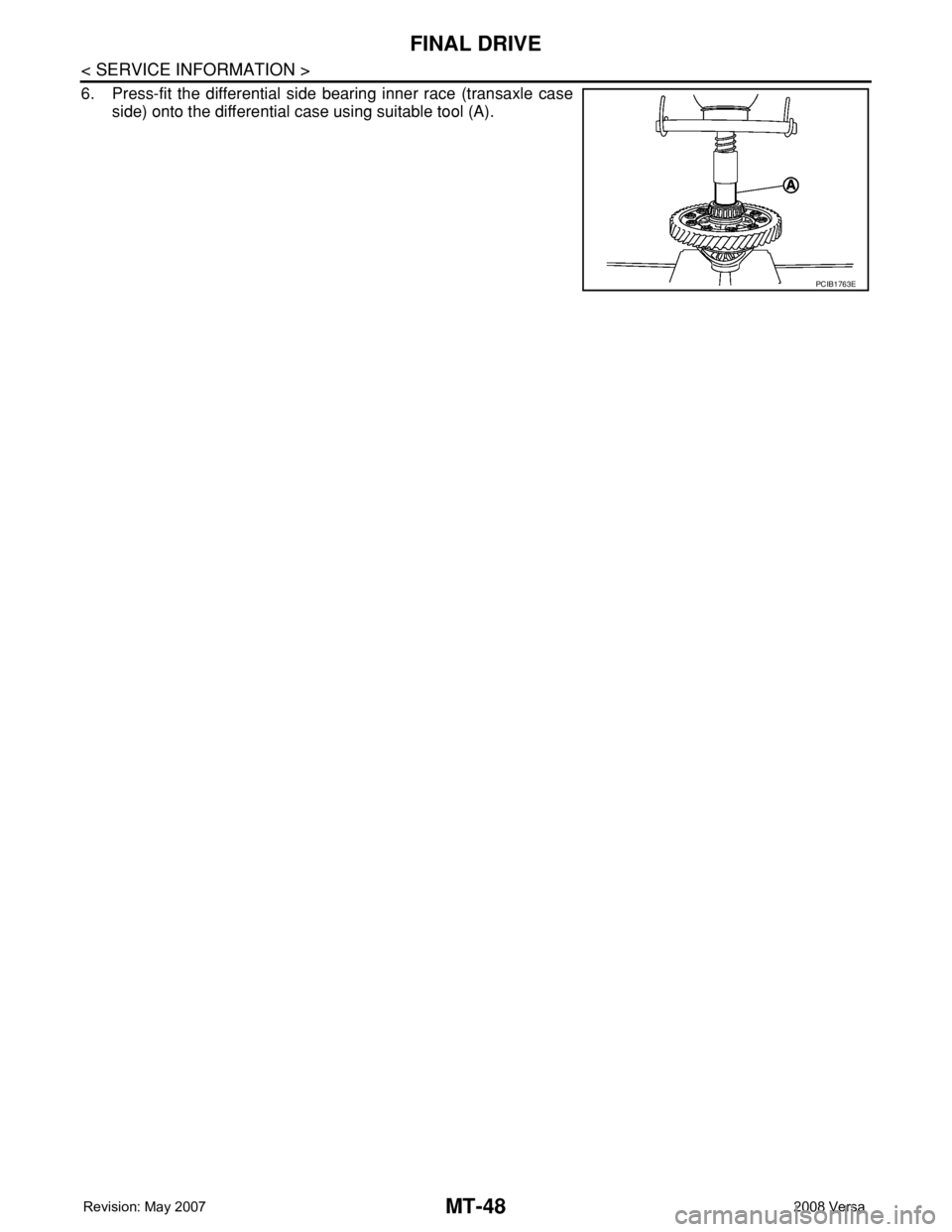

2. Install lock ring (1) onto differential case.

CAUTION:

Make sure that lock ring is securely installed in the groove.

3. Install final gear into differential case, and tighten final gear bolts

to specification. Refer to MT-17, "

Disassembly and Assembly".

4. Install speedometer drive gear onto differential case.

5. Press-fit the differential side bearing inner race (clutch housing

side) onto the differential case using suitable tool (A).

PCIB0977J

SPD715

PCIB1764E

PCIB1762E

Page 2336 of 2771

MT-48

< SERVICE INFORMATION >

FINAL DRIVE

6. Press-fit the differential side bearing inner race (transaxle case

side) onto the differential case using suitable tool (A).

PCIB1763E

Page 2337 of 2771

SHIFT CONTROL

MT-49

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

MT

N

O

P

SHIFT CONTROL

InspectionINFOID:0000000001703147

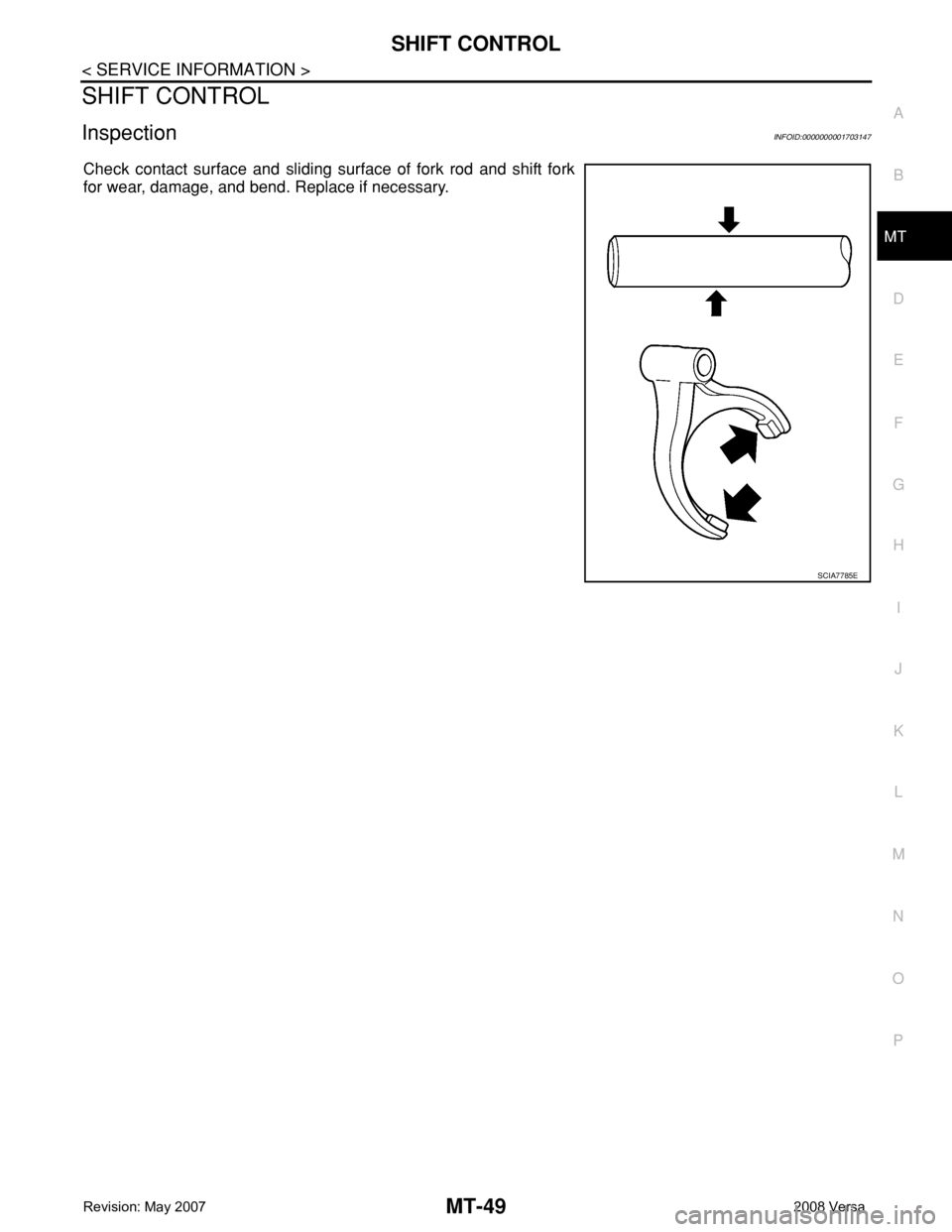

Check contact surface and sliding surface of fork rod and shift fork

for wear, damage, and bend. Replace if necessary.

SCIA7785E

Page 2338 of 2771

MT-50

< SERVICE INFORMATION >

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

General SpecificationINFOID:0000000001703148

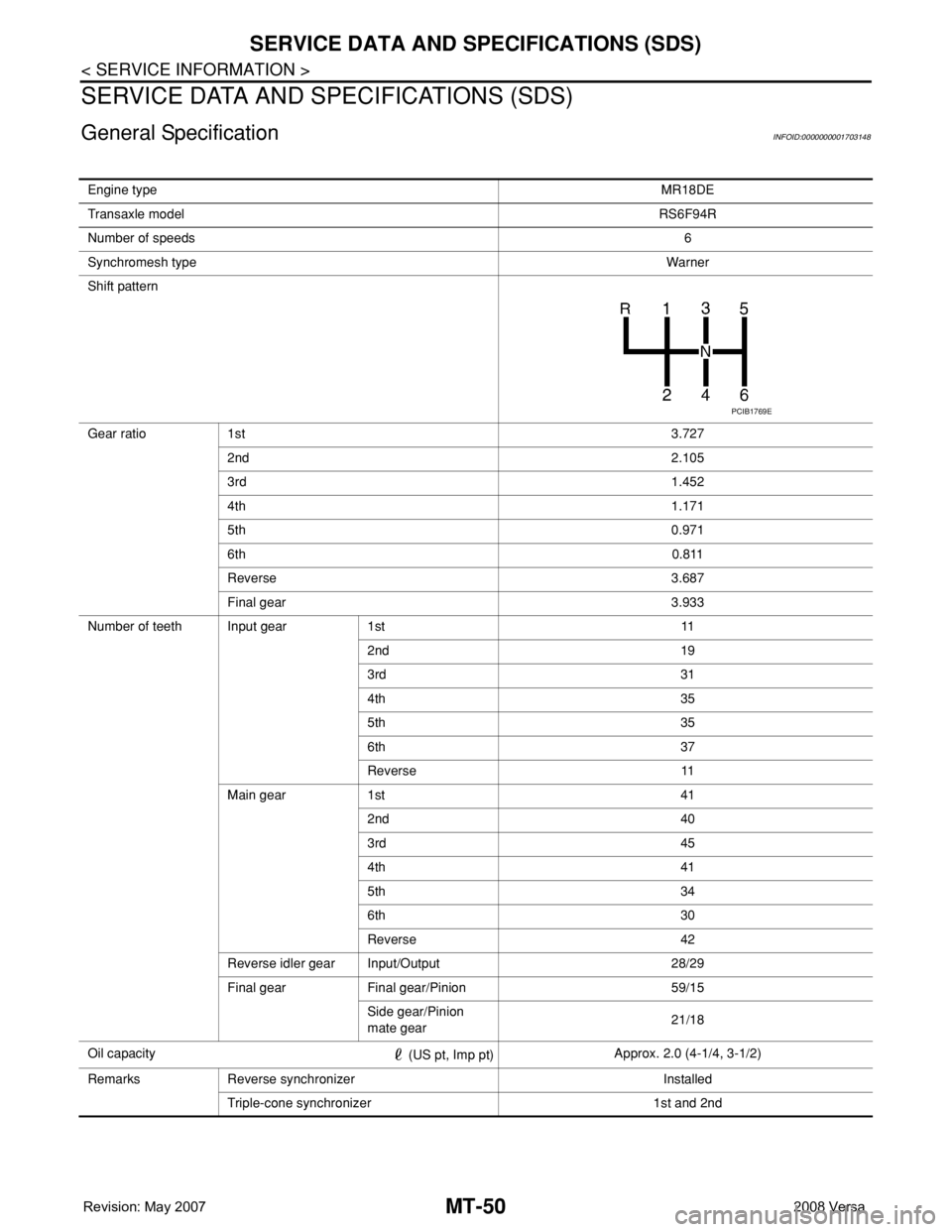

Engine typeMR18DE

Transaxle modelRS6F94R

Number of speeds6

Synchromesh typeWarner

Shift pattern

Gear ratio 1st3.727

2nd2.105

3rd1.452

4th1.171

5th0.971

6th0.811

Reverse 3.687

Final gear 3.933

Number of teeth Input gear 1st 11

2nd 19

3rd 31

4th 35

5th 35

6th 37

Reverse 11

Main gear 1st 41

2nd 40

3rd 45

4th 41

5th 34

6th 30

Reverse 42

Reverse idler gear Input/Output 28/29

Final gear Final gear/Pinion 59/15

Side gear/Pinion

mate gear21/18

Oil capacity

(US pt, Imp pt)Approx. 2.0 (4-1/4, 3-1/2)

Remarks Reverse synchronizer Installed

Triple-cone synchronizer 1st and 2nd

PCIB1769E

Page 2339 of 2771

MTC-1

AIR CONDITIONER

C

D

E

F

G

H

I

K

L

M

SECTION MTC

A

B

MTC

N

O

P

CONTENTS

MANUAL AIR CONDITIONER

SERVICE INFORMATION ............................3

PRECAUTIONS ...................................................3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

3

Precaution for Procedure without Cowl Top Cover ......3

Precaution for Working with HFC-134a (R-134a) ......3

General Refrigerant Precaution ................................4

Oil Precaution ............................................................4

Precaution for Refrigerant Connection ......................4

Precaution for Service of Compressor ......................7

Precaution for Service Equipment .............................7

Precaution for Leak Detection Dye ...........................9

PREPARATION ..................................................10

Special Service Tool ...............................................10

HFC-134a (R-134a) Service Tool and Equipment ....10

Commercial Service Tool ........................................13

REFRIGERATION SYSTEM ..............................14

Refrigerant Cycle ....................................................14

Refrigerant System Protection ................................14

Component Part Location .......................................15

OIL ......................................................................16

Maintenance of Oil Quantity in Compressor ...........16

AIR CONDITIONER CONTROL .........................19

Control Operation ....................................................19

Discharge Air Flow ..................................................20

System Description .................................................20

CAN Communication System Description ...............21

TROUBLE DIAGNOSIS .....................................22

CONSULT-III Function (BCM) .................................22

How to Perform Trouble Diagnosis for Quick and

Accurate Repair ......................................................

22

Component Parts and Harness Connector Loca-

tion ..........................................................................

23

Schematic ...............................................................25

Wiring Diagram - Heater - .......................................26

Wiring Diagram - A/C,M - ........................................27

Operational Check ...................................................30

Mode Door ...............................................................31

Air Mix Door .............................................................32

Intake Door ..............................................................33

Front Blower Motor Circuit .......................................33

Magnet Clutch Circuit (If Equipped) .........................37

Insufficient Cooling ..................................................45

Insufficient Heating ..................................................52

Noise .......................................................................53

CONTROLLER ..................................................55

Removal and Installation .........................................55

Disassembly and Assembly .....................................56

THERMO CONTROL AMPLIFIER ....................57

Removal and Installation .........................................57

A/C UNIT ASSEMBLY ......................................58

Removal and Installation .........................................58

Disassembly and Assembly .....................................60

BLOWER MOTOR ............................................62

Removal and Installation .........................................62

INTAKE DOOR ..................................................63

Intake Door Cable Adjustment .................................63

AIR MIX DOOR .................................................64

Air Mix Door Cable Adjustment ...............................64

MODE DOOR ....................................................65

Mode Door Cable Adjustment .................................65

BLOWER FAN RESISTOR ...............................66

Removal and Installation .........................................66

HEATER CORE .................................................67

Removal and Installation .........................................67

AIR CONDITIONER FILTER .............................68

Removal and Installation .........................................68

Page 2340 of 2771

MTC-2

DUCTS AND GRILLES ......................................69

Removal and Installation ........................................69

REFRIGERANT LINES ......................................74

HFC-134a (R-134a) Service Procedure .................74

Component .............................................................76

Removal and Installation of Compressor ................78

Removal and Installation of Low-Pressure Flexi-

ble Hose .................................................................

79

Removal and Installation of High-pressure Flexi-

ble Hose .................................................................

80

Removal and Installation of High-pressure Pipe ....81

Removal and Installation of Refrigerant Pressure

Sensor ....................................................................

81

Removal and Installation of Condenser ..................82

Removal and Installation of Liquid Tank .................82

Removal and Installation of Evaporator ..................83

Removal and Installation of Expansion Valve .........84

Checking of Refrigerant Leaks ................................84

Checking System for Leaks Using the Fluorescent

Leak Detector ..........................................................

85

Dye Injection ...........................................................85

Electronic Refrigerant Leak Detector ......................85

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

88

Compressor ............................................................88

Oil ............................................................................88

Refrigerant ..............................................................88

Engine Idling Speed ................................................88

Belt Tension ............................................................88