NISSAN TIIDA 2008 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2008, Model line: TIIDA, Model: NISSAN TIIDA 2008Pages: 2771, PDF Size: 60.61 MB

Page 311 of 2771

REPAIR FOR COMPONENT PARTS

AT-299

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

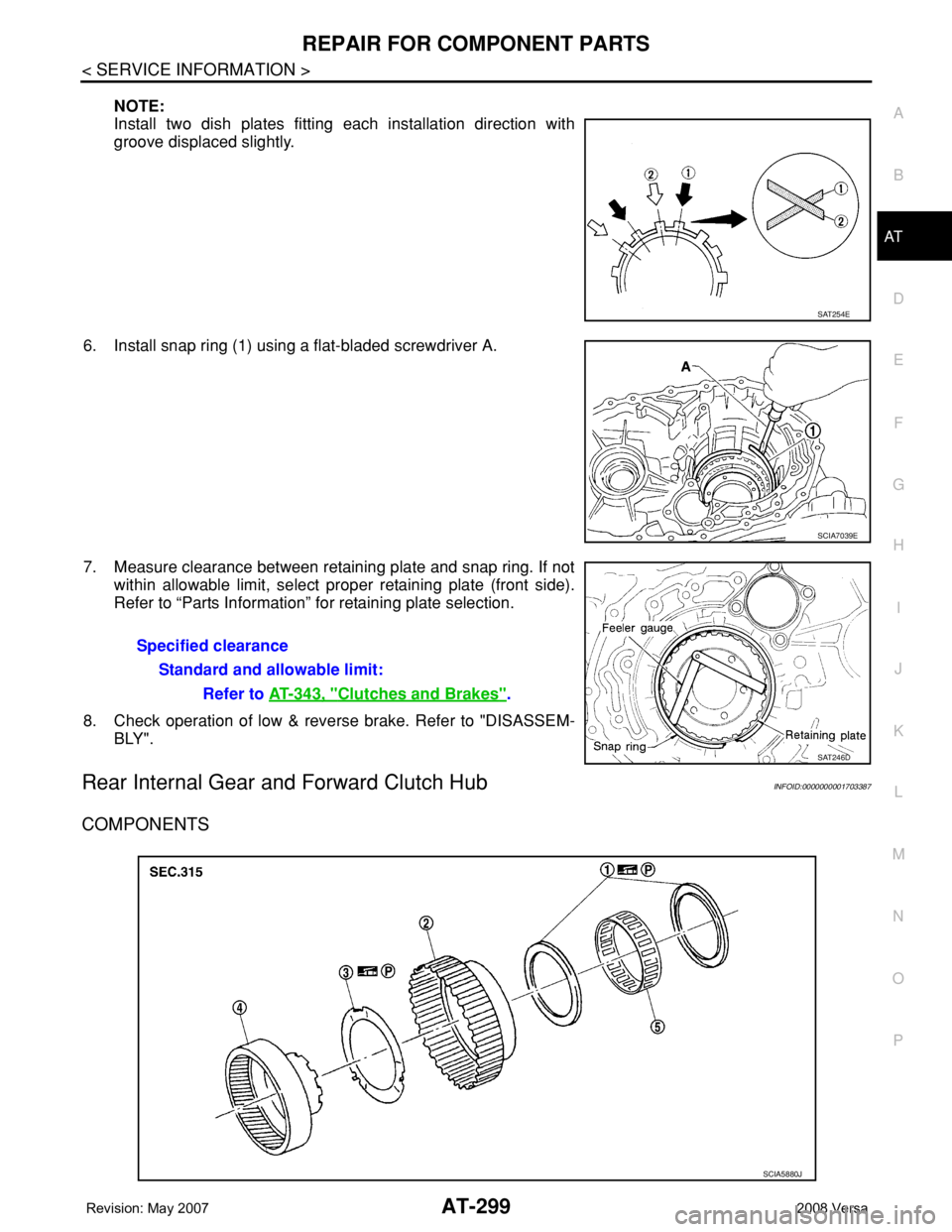

NOTE:

Install two dish plates fitting each installation direction with

groove displaced slightly.

6. Install snap ring (1) using a flat-bladed screwdriver A.

7. Measure clearance between retaining plate and snap ring. If not

within allowable limit, select proper retaining plate (front side).

Refer to “Parts Information” for retaining plate selection.

8. Check operation of low & reverse brake. Refer to "DISASSEM-

BLY".

Rear Internal Gear and Forward Clutch HubINFOID:0000000001703387

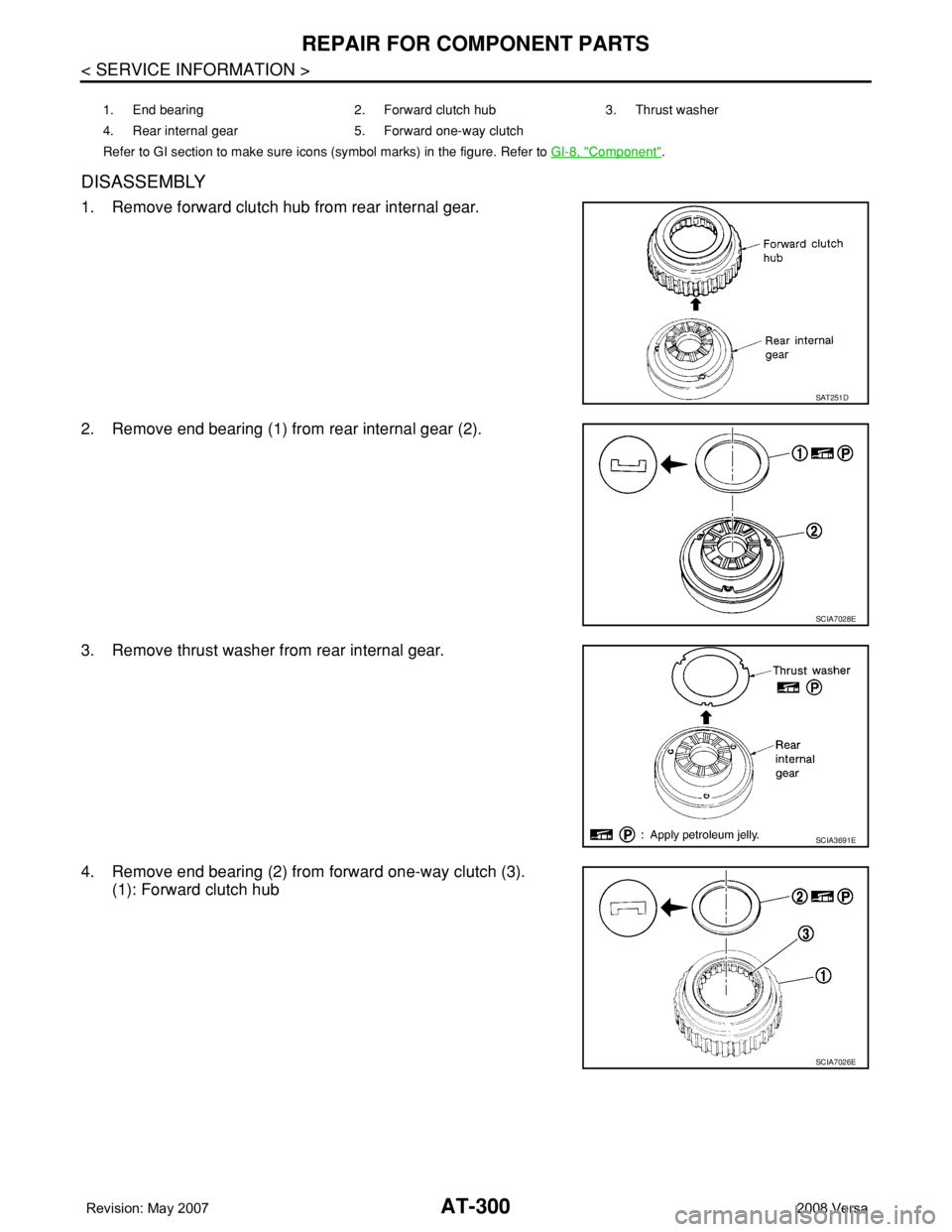

COMPONENTS

SAT254E

SCIA7039E

Specified clearance

Standard and allowable limit:

Refer to AT-343, "

Clutches and Brakes".

SAT246D

SCIA5880J

Page 312 of 2771

AT-300

< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

DISASSEMBLY

1. Remove forward clutch hub from rear internal gear.

2. Remove end bearing (1) from rear internal gear (2).

3. Remove thrust washer from rear internal gear.

4. Remove end bearing (2) from forward one-way clutch (3).

(1): Forward clutch hub

1. End bearing 2. Forward clutch hub 3. Thrust washer

4. Rear internal gear 5. Forward one-way clutch

Refer to GI section to make sure icons (symbol marks) in the figure. Refer to GI-8, "

Component".

SAT251D

SCIA7028E

SCIA3691E

SCIA7026E

Page 313 of 2771

REPAIR FOR COMPONENT PARTS

AT-301

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

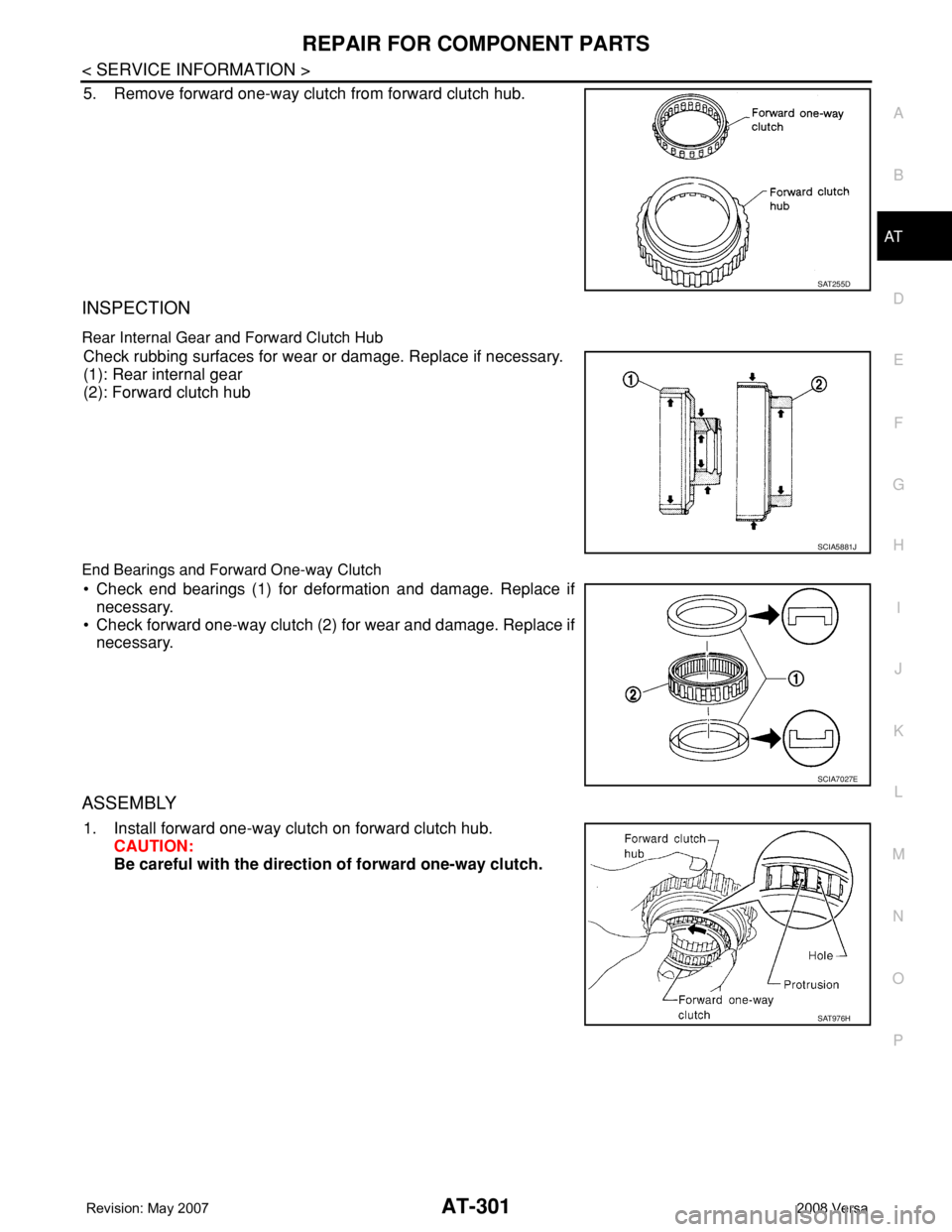

5. Remove forward one-way clutch from forward clutch hub.

INSPECTION

Rear Internal Gear and Forward Clutch Hub

Check rubbing surfaces for wear or damage. Replace if necessary.

(1): Rear internal gear

(2): Forward clutch hub

End Bearings and Forward One-way Clutch

• Check end bearings (1) for deformation and damage. Replace if

necessary.

• Check forward one-way clutch (2) for wear and damage. Replace if

necessary.

ASSEMBLY

1. Install forward one-way clutch on forward clutch hub.

CAUTION:

Be careful with the direction of forward one-way clutch.

SAT255D

SCIA5881J

SCIA7027E

SAT976H

Page 314 of 2771

AT-302

< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

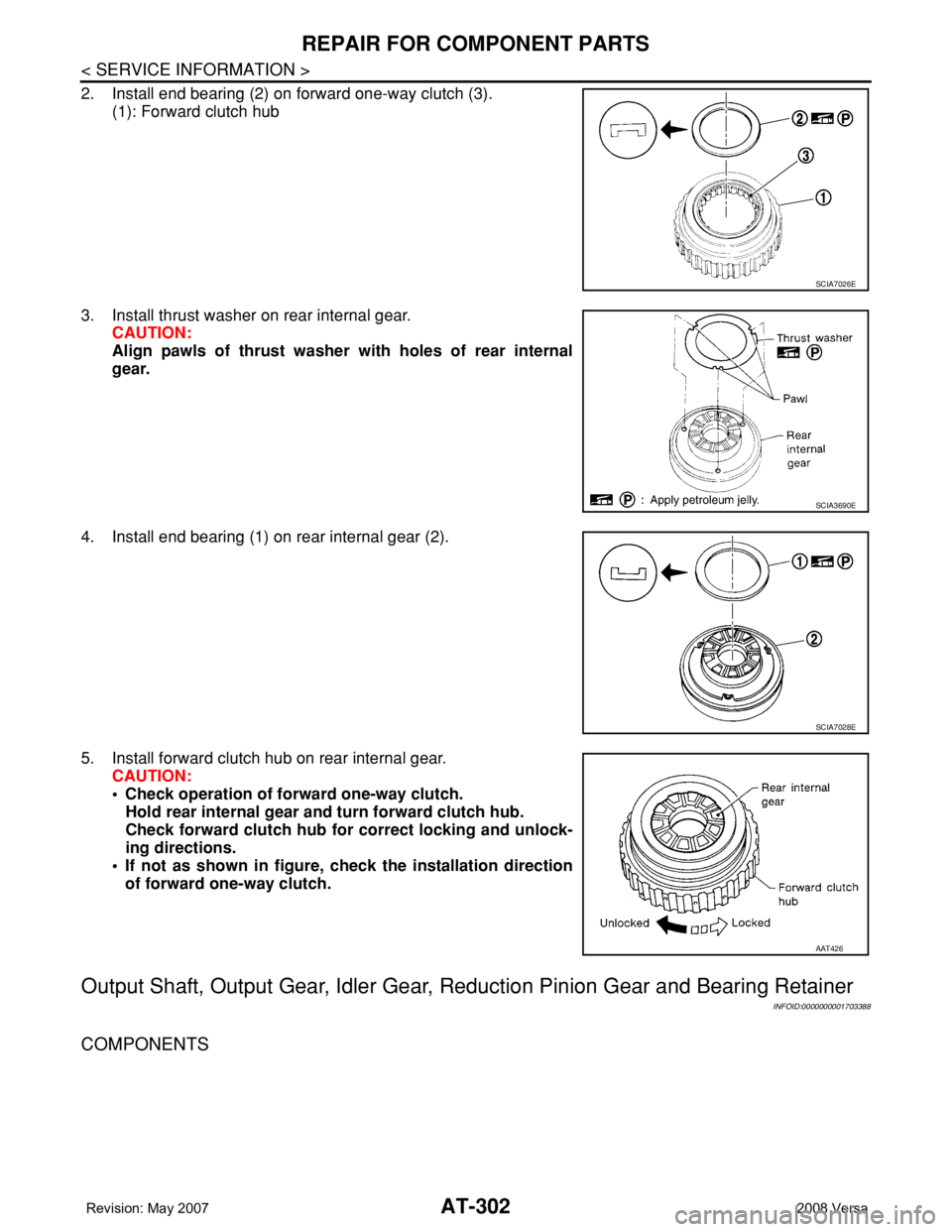

2. Install end bearing (2) on forward one-way clutch (3).

(1): Forward clutch hub

3. Install thrust washer on rear internal gear.

CAUTION:

Align pawls of thrust washer with holes of rear internal

gear.

4. Install end bearing (1) on rear internal gear (2).

5. Install forward clutch hub on rear internal gear.

CAUTION:

• Check operation of forward one-way clutch.

Hold rear internal gear and turn forward clutch hub.

Check forward clutch hub for correct locking and unlock-

ing directions.

• If not as shown in figure, check the installation direction

of forward one-way clutch.

Output Shaft, Output Gear, Idler Gear, Reduction Pinion Gear and Bearing Retainer

INFOID:0000000001703388

COMPONENTS

SCIA7026E

SCIA3690E

SCIA7028E

AAT426

Page 315 of 2771

REPAIR FOR COMPONENT PARTS

AT-303

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

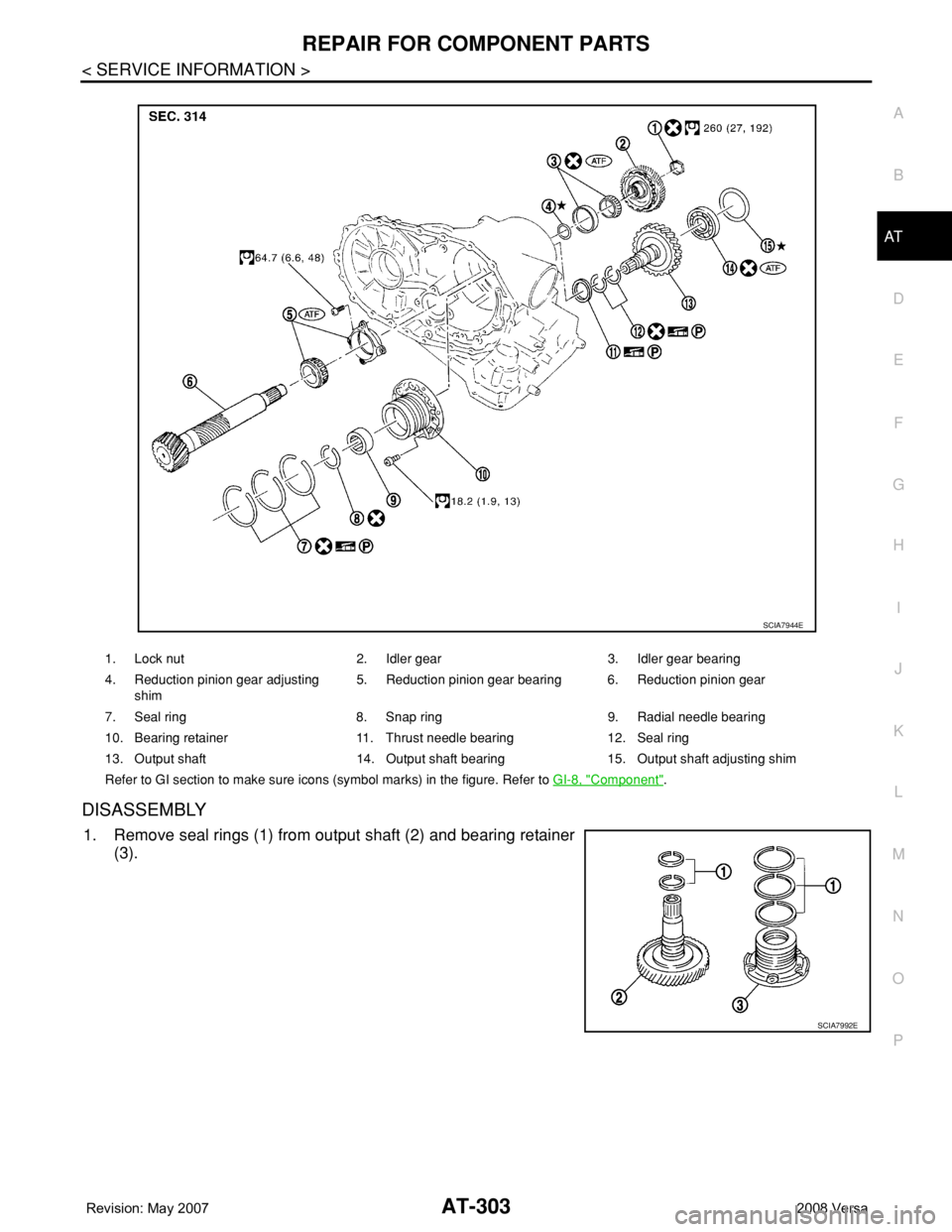

DISASSEMBLY

1. Remove seal rings (1) from output shaft (2) and bearing retainer

(3).

1. Lock nut 2. Idler gear 3. Idler gear bearing

4. Reduction pinion gear adjusting

shim5. Reduction pinion gear bearing 6. Reduction pinion gear

7. Seal ring 8. Snap ring 9. Radial needle bearing

10. Bearing retainer 11. Thrust needle bearing 12. Seal ring

13. Output shaft 14. Output shaft bearing 15. Output shaft adjusting shim

Refer to GI section to make sure icons (symbol marks) in the figure. Refer to GI-8, "

Component".

SCIA7944E

SCIA7992E

Page 316 of 2771

AT-304

< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

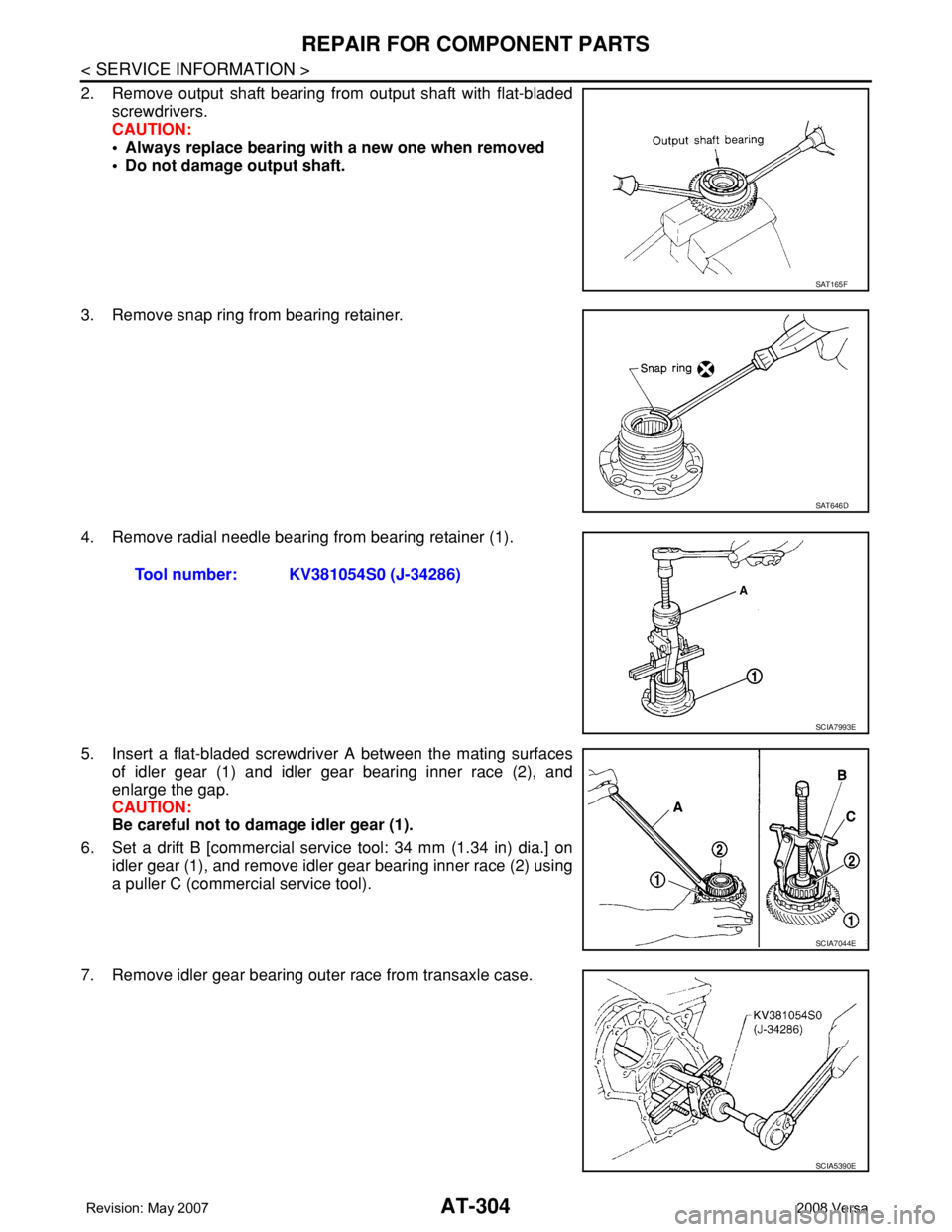

2. Remove output shaft bearing from output shaft with flat-bladed

screwdrivers.

CAUTION:

• Always replace bearing with a new one when removed

• Do not damage output shaft.

3. Remove snap ring from bearing retainer.

4. Remove radial needle bearing from bearing retainer (1).

5. Insert a flat-bladed screwdriver A between the mating surfaces

of idler gear (1) and idler gear bearing inner race (2), and

enlarge the gap.

CAUTION:

Be careful not to damage idler gear (1).

6. Set a drift B [commercial service tool: 34 mm (1.34 in) dia.] on

idler gear (1), and remove idler gear bearing inner race (2) using

a puller C (commercial service tool).

7. Remove idler gear bearing outer race from transaxle case.

SAT165F

SAT646D

Tool number: KV381054S0 (J-34286)

SCIA7993E

SCIA7044E

SCIA5390E

Page 317 of 2771

REPAIR FOR COMPONENT PARTS

AT-305

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

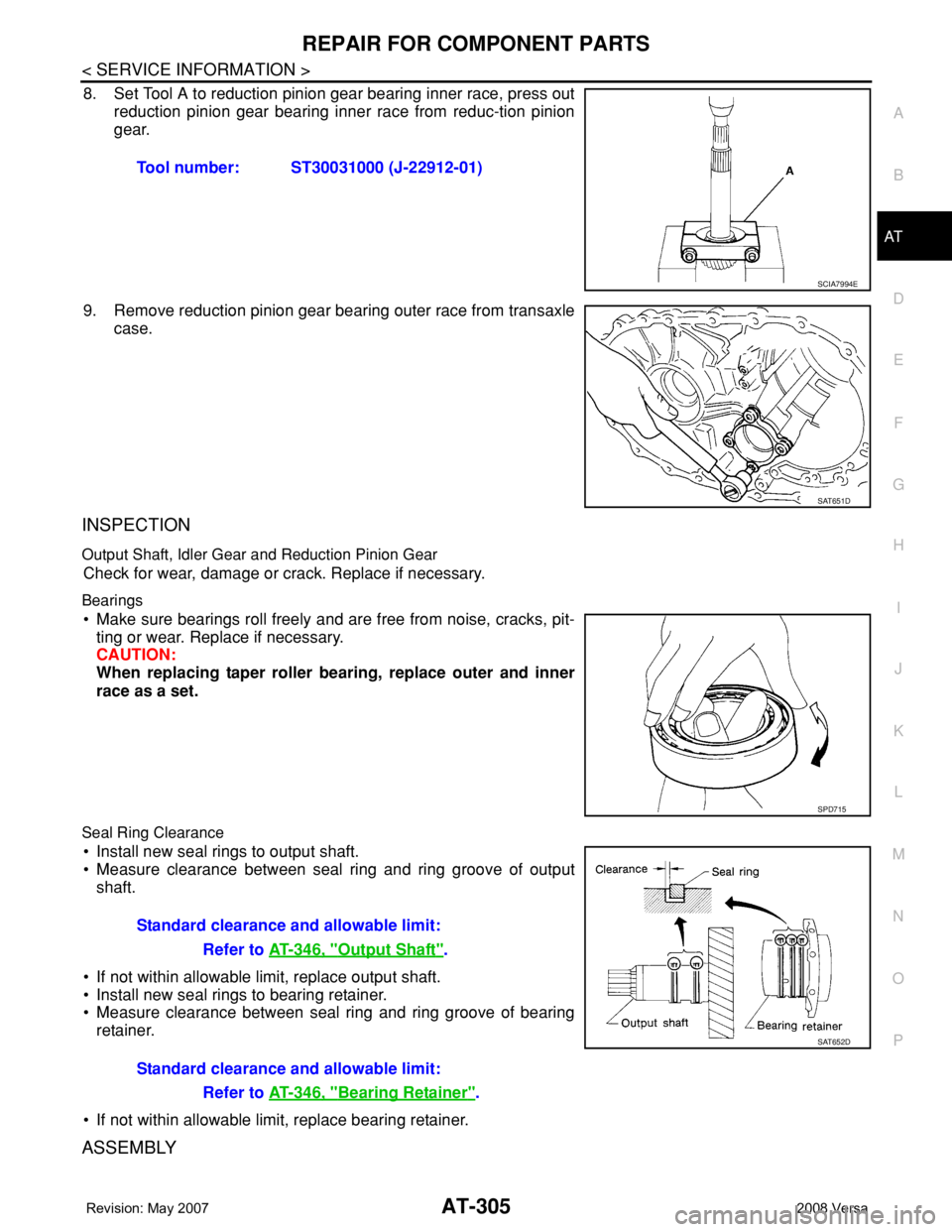

8. Set Tool A to reduction pinion gear bearing inner race, press out

reduction pinion gear bearing inner race from reduc-tion pinion

gear.

9. Remove reduction pinion gear bearing outer race from transaxle

case.

INSPECTION

Output Shaft, Idler Gear and Reduction Pinion Gear

Check for wear, damage or crack. Replace if necessary.

Bearings

• Make sure bearings roll freely and are free from noise, cracks, pit-

ting or wear. Replace if necessary.

CAUTION:

When replacing taper roller bearing, replace outer and inner

race as a set.

Seal Ring Clearance

• Install new seal rings to output shaft.

• Measure clearance between seal ring and ring groove of output

shaft.

• If not within allowable limit, replace output shaft.

• Install new seal rings to bearing retainer.

• Measure clearance between seal ring and ring groove of bearing

retainer.

• If not within allowable limit, replace bearing retainer.

ASSEMBLY

Tool number: ST30031000 (J-22912-01)

SCIA7994E

SAT651D

SPD715

Standard clearance and allowable limit:

Refer to AT-346, "

Output Shaft".

Standard clearance and allowable limit:

Refer to AT-346, "

Bearing Retainer".

SAT652D

Page 318 of 2771

AT-306

< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

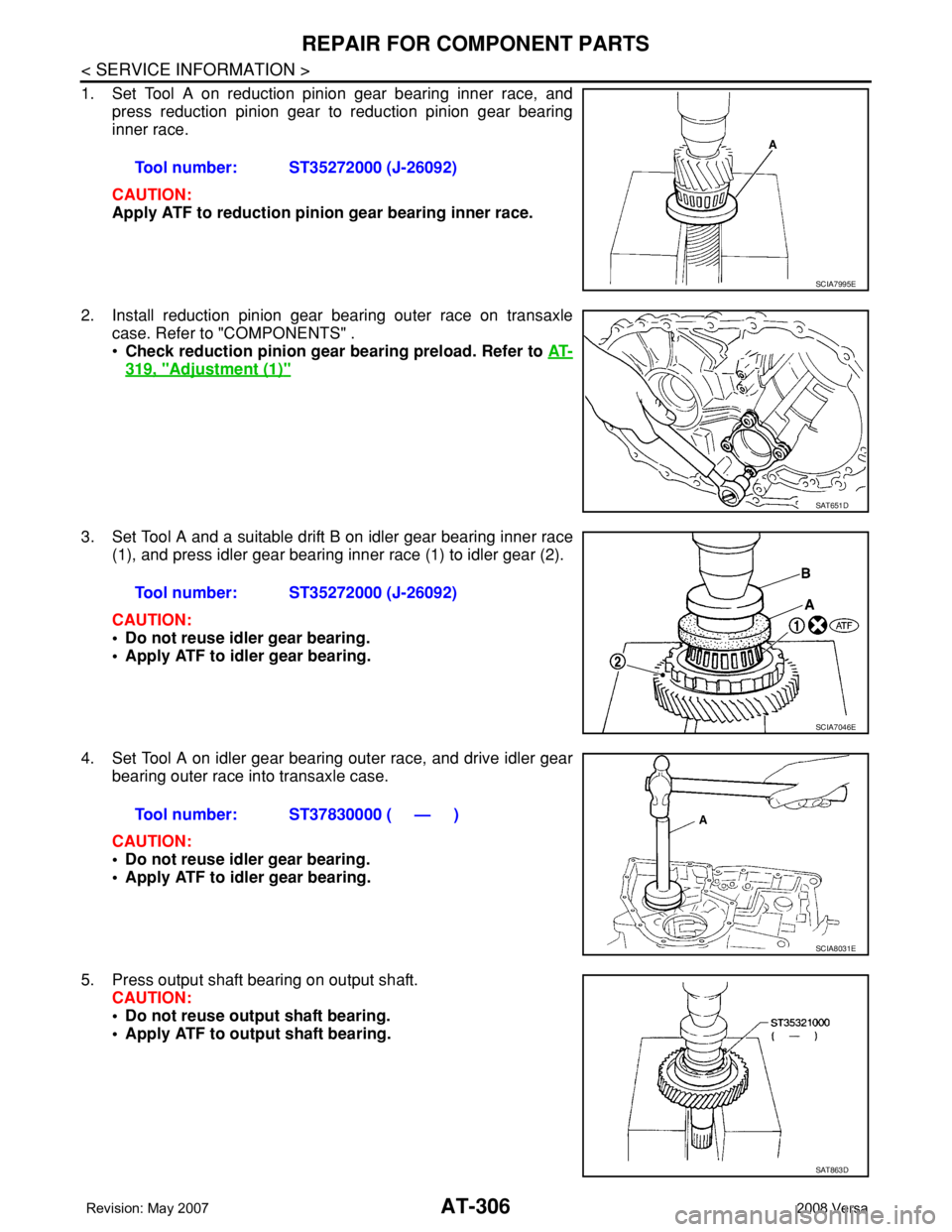

1. Set Tool A on reduction pinion gear bearing inner race, and

press reduction pinion gear to reduction pinion gear bearing

inner race.

CAUTION:

Apply ATF to reduction pinion gear bearing inner race.

2. Install reduction pinion gear bearing outer race on transaxle

case. Refer to "COMPONENTS" .

•Check reduction pinion gear bearing preload. Refer to AT-

319, "Adjustment (1)"

3. Set Tool A and a suitable drift B on idler gear bearing inner race

(1), and press idler gear bearing inner race (1) to idler gear (2).

CAUTION:

• Do not reuse idler gear bearing.

• Apply ATF to idler gear bearing.

4. Set Tool A on idler gear bearing outer race, and drive idler gear

bearing outer race into transaxle case.

CAUTION:

• Do not reuse idler gear bearing.

• Apply ATF to idler gear bearing.

5. Press output shaft bearing on output shaft.

CAUTION:

• Do not reuse output shaft bearing.

• Apply ATF to output shaft bearing.Tool number: ST35272000 (J-26092)

SCIA7995E

SAT651D

Tool number: ST35272000 (J-26092)

SCIA7046E

Tool number: ST37830000 ( — )

SCIA8031E

SAT863D

Page 319 of 2771

![NISSAN TIIDA 2008 Service Repair Manual REPAIR FOR COMPONENT PARTS

AT-307

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

6. Set drift [commercial service tool] on radial needle bearing, and

press radial needle bearing into bearing NISSAN TIIDA 2008 Service Repair Manual REPAIR FOR COMPONENT PARTS

AT-307

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

6. Set drift [commercial service tool] on radial needle bearing, and

press radial needle bearing into bearing](/img/5/57399/w960_57399-318.png)

REPAIR FOR COMPONENT PARTS

AT-307

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

6. Set drift [commercial service tool] on radial needle bearing, and

press radial needle bearing into bearing retainer.

7. Install snap ring to bearing retainer.

8. After packing ring grooves with petroleum jelly, carefully install

new seal rings (1) on output shaft (2) and bearing retainer (3).

CAUTION:

Roll paper around seal rings to prevent seal rings from

spreading.

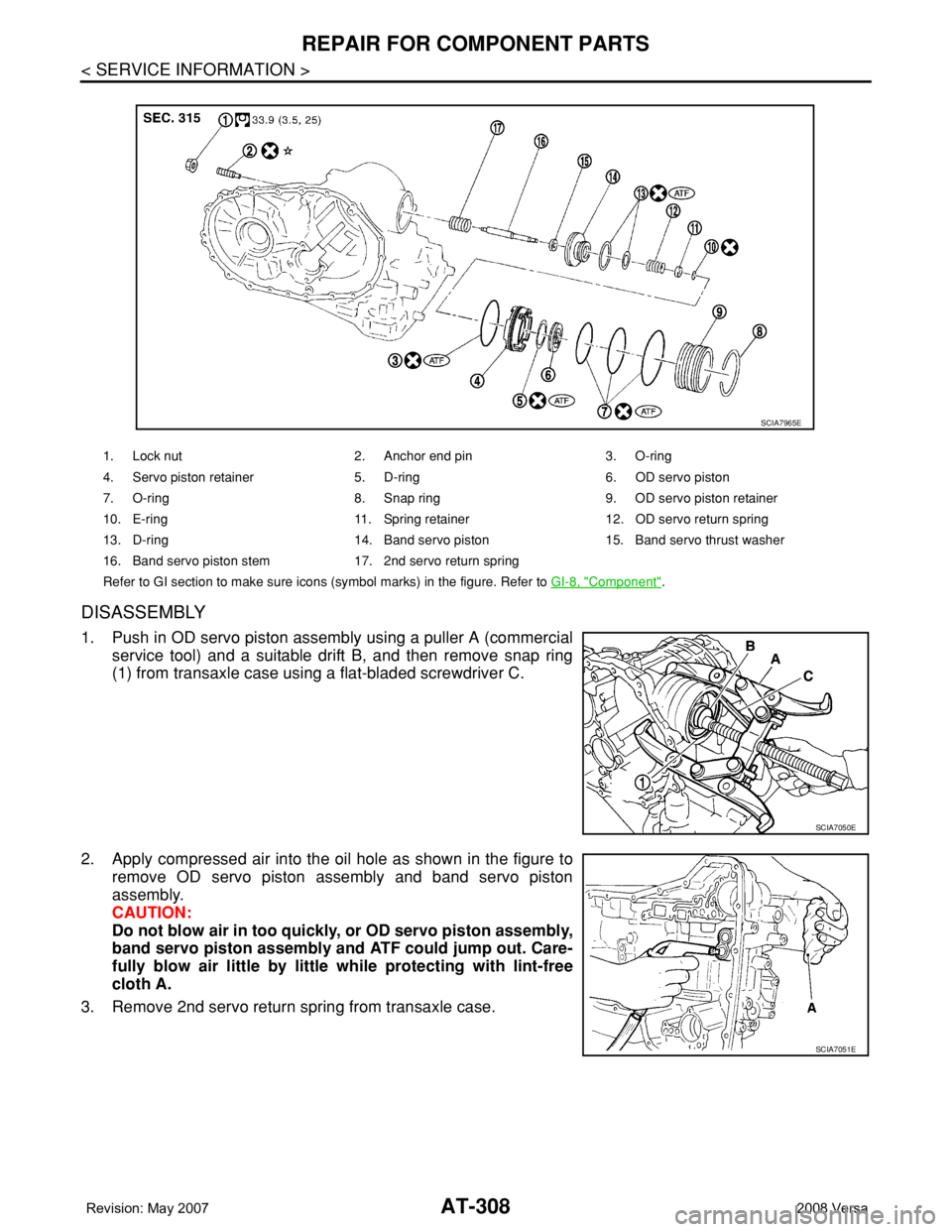

Band Servo Piston AssemblyINFOID:0000000001703389

COMPONENTS

SAT658D

SAT659D

SCIA7996E

SCIA8011E

Page 320 of 2771

AT-308

< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

DISASSEMBLY

1. Push in OD servo piston assembly using a puller A (commercial

service tool) and a suitable drift B, and then remove snap ring

(1) from transaxle case using a flat-bladed screwdriver C.

2. Apply compressed air into the oil hole as shown in the figure to

remove OD servo piston assembly and band servo piston

assembly.

CAUTION:

Do not blow air in too quickly, or OD servo piston assembly,

band servo piston assembly and ATF could jump out. Care-

fully blow air little by little while protecting with lint-free

cloth A.

3. Remove 2nd servo return spring from transaxle case.

1. Lock nut 2. Anchor end pin 3. O-ring

4. Servo piston retainer 5. D-ring 6. OD servo piston

7. O-ring 8. Snap ring 9. OD servo piston retainer

10. E-ring 11. Spring retainer12. OD servo return spring

13. D-ring 14. Band servo piston 15. Band servo thrust washer

16. Band servo piston stem 17. 2nd servo return spring

Refer to GI section to make sure icons (symbol marks) in the figure. Refer to GI-8, "

Component".

SCIA7965E

SCIA7050E

SCIA7051E