NISSAN TIIDA 2008 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2008, Model line: TIIDA, Model: NISSAN TIIDA 2008Pages: 2771, PDF Size: 60.61 MB

Page 331 of 2771

ASSEMBLY

AT-319

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

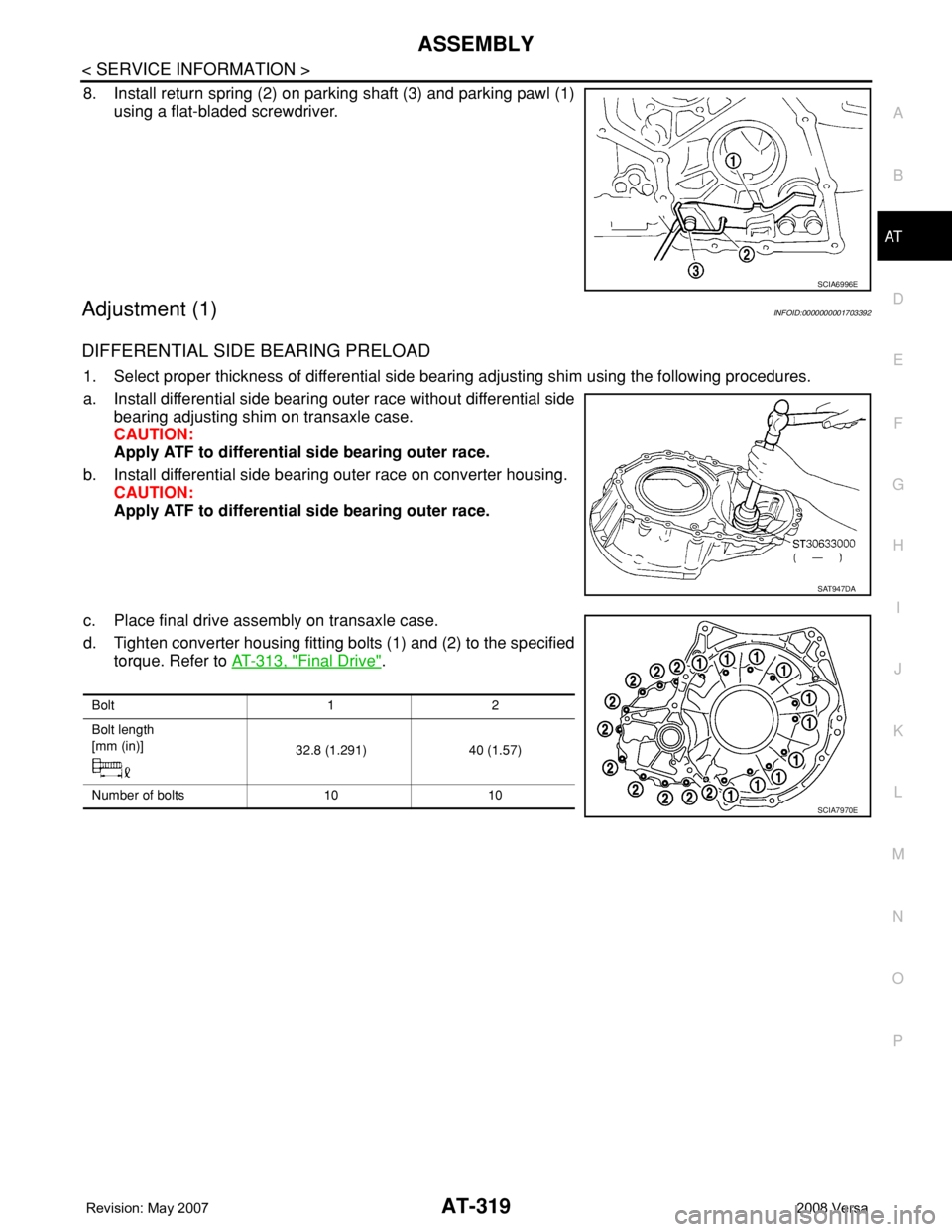

8. Install return spring (2) on parking shaft (3) and parking pawl (1)

using a flat-bladed screwdriver.

Adjustment (1)INFOID:0000000001703392

DIFFERENTIAL SIDE BEARING PRELOAD

1. Select proper thickness of differential side bearing adjusting shim using the following procedures.

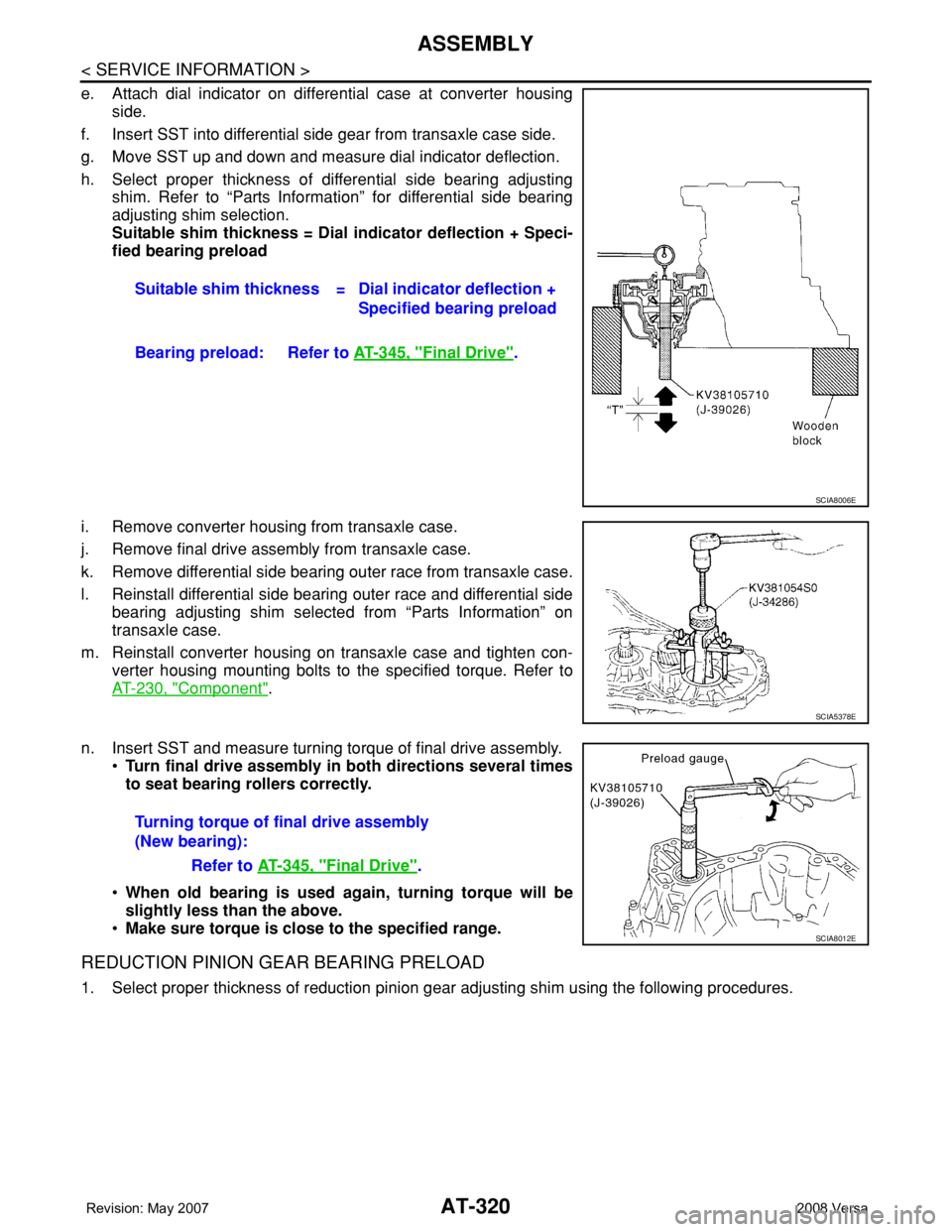

a. Install differential side bearing outer race without differential side

bearing adjusting shim on transaxle case.

CAUTION:

Apply ATF to differential side bearing outer race.

b. Install differential side bearing outer race on converter housing.

CAUTION:

Apply ATF to differential side bearing outer race.

c. Place final drive assembly on transaxle case.

d. Tighten converter housing fitting bolts (1) and (2) to the specified

torque. Refer to AT-313, "

Final Drive".

SCIA6996E

SAT947DA

Bolt 1 2

Bolt length

[mm (in)]

32.8 (1.291) 40 (1.57)

Number of bolts 10 10

SCIA7970E

Page 332 of 2771

AT-320

< SERVICE INFORMATION >

ASSEMBLY

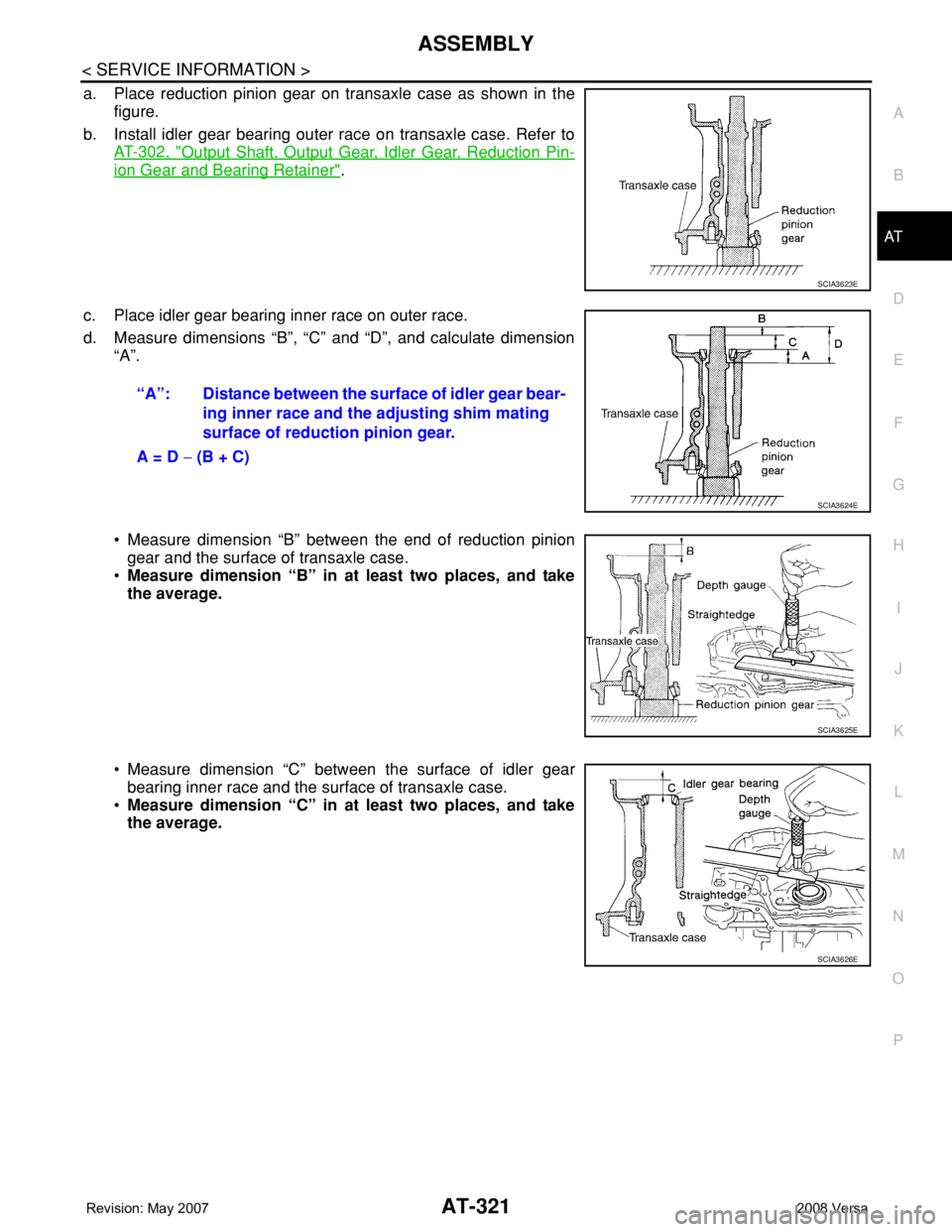

e. Attach dial indicator on differential case at converter housing

side.

f. Insert SST into differential side gear from transaxle case side.

g. Move SST up and down and measure dial indicator deflection.

h. Select proper thickness of differential side bearing adjusting

shim. Refer to “Parts Information” for differential side bearing

adjusting shim selection.

Suitable shim thickness = Dial indicator deflection + Speci-

fied bearing preload

i. Remove converter housing from transaxle case.

j. Remove final drive assembly from transaxle case.

k. Remove differential side bearing outer race from transaxle case.

l. Reinstall differential side bearing outer race and differential side

bearing adjusting shim selected from “Parts Information” on

transaxle case.

m. Reinstall converter housing on transaxle case and tighten con-

verter housing mounting bolts to the specified torque. Refer to

AT-230, "

Component".

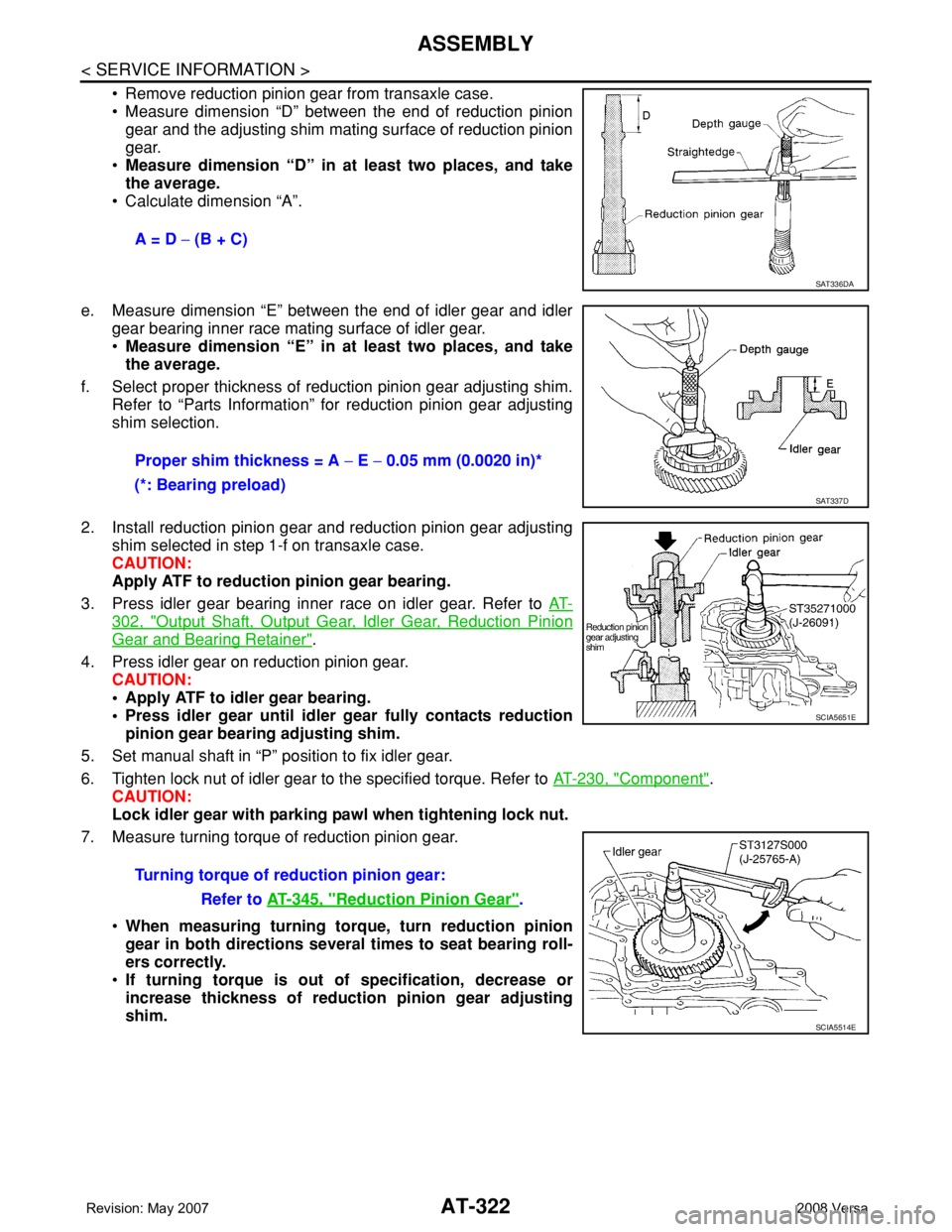

n. Insert SST and measure turning torque of final drive assembly.

•Turn final drive assembly in both directions several times

to seat bearing rollers correctly.

•When old bearing is used again, turning torque will be

slightly less than the above.

•Make sure torque is close to the specified range.

REDUCTION PINION GEAR BEARING PRELOAD

1. Select proper thickness of reduction pinion gear adjusting shim using the following procedures.Suitable shim thickness = Dial indicator deflection +

Specified bearing preload

Bearing preload: Refer to AT-345, "

Final Drive".

SCIA8006E

SCIA5378E

Turning torque of final drive assembly

(New bearing):

Refer to AT-345, "

Final Drive".

SCIA8012E

Page 333 of 2771

ASSEMBLY

AT-321

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

a. Place reduction pinion gear on transaxle case as shown in the

figure.

b. Install idler gear bearing outer race on transaxle case. Refer to

AT-302, "

Output Shaft, Output Gear, Idler Gear, Reduction Pin-

ion Gear and Bearing Retainer".

c. Place idler gear bearing inner race on outer race.

d. Measure dimensions “B”, “C” and “D”, and calculate dimension

“A”.

• Measure dimension “B” between the end of reduction pinion

gear and the surface of transaxle case.

•Measure dimension “B” in at least two places, and take

the average.

• Measure dimension “C” between the surface of idler gear

bearing inner race and the surface of transaxle case.

•Measure dimension “C” in at least two places, and take

the average.

SCIA3623E

“A”: Distance between the surface of idler gear bear-

ing inner race and the adjusting shim mating

surface of reduction pinion gear.

A = D − (B + C)

SCIA3624E

SCIA3625E

SCIA3626E

Page 334 of 2771

AT-322

< SERVICE INFORMATION >

ASSEMBLY

• Remove reduction pinion gear from transaxle case.

• Measure dimension “D” between the end of reduction pinion

gear and the adjusting shim mating surface of reduction pinion

gear.

•Measure dimension “D” in at least two places, and take

the average.

• Calculate dimension “A”.

e. Measure dimension “E” between the end of idler gear and idler

gear bearing inner race mating surface of idler gear.

•Measure dimension “E” in at least two places, and take

the average.

f. Select proper thickness of reduction pinion gear adjusting shim.

Refer to “Parts Information” for reduction pinion gear adjusting

shim selection.

2. Install reduction pinion gear and reduction pinion gear adjusting

shim selected in step 1-f on transaxle case.

CAUTION:

Apply ATF to reduction pinion gear bearing.

3. Press idler gear bearing inner race on idler gear. Refer to AT-

302, "Output Shaft, Output Gear, Idler Gear, Reduction Pinion

Gear and Bearing Retainer".

4. Press idler gear on reduction pinion gear.

CAUTION:

• Apply ATF to idler gear bearing.

• Press idler gear until idler gear fully contacts reduction

pinion gear bearing adjusting shim.

5. Set manual shaft in “P” position to fix idler gear.

6. Tighten lock nut of idler gear to the specified torque. Refer to AT-230, "

Component".

CAUTION:

Lock idler gear with parking pawl when tightening lock nut.

7. Measure turning torque of reduction pinion gear.

•When measuring turning torque, turn reduction pinion

gear in both directions several times to seat bearing roll-

ers correctly.

•If turning torque is out of specification, decrease or

increase thickness of reduction pinion gear adjusting

shim.A = D − (B + C)

SAT336DA

Proper shim thickness = A − E − 0.05 mm (0.0020 in)*

(*: Bearing preload)

SAT337D

Turning torque of reduction pinion gear:

Refer to AT-345, "

Reduction Pinion Gear".

SCIA5651E

SCIA5514E

Page 335 of 2771

ASSEMBLY

AT-323

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

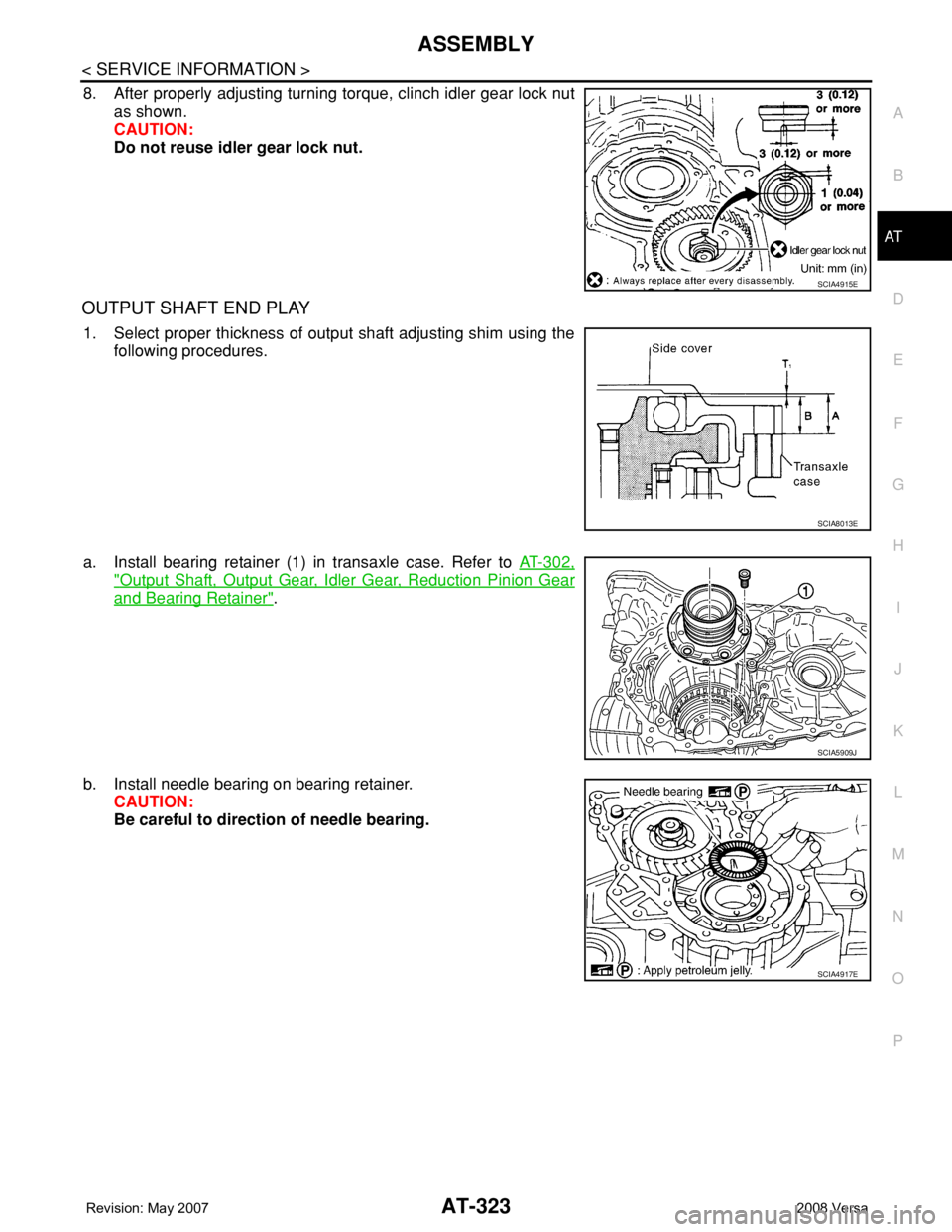

8. After properly adjusting turning torque, clinch idler gear lock nut

as shown.

CAUTION:

Do not reuse idler gear lock nut.

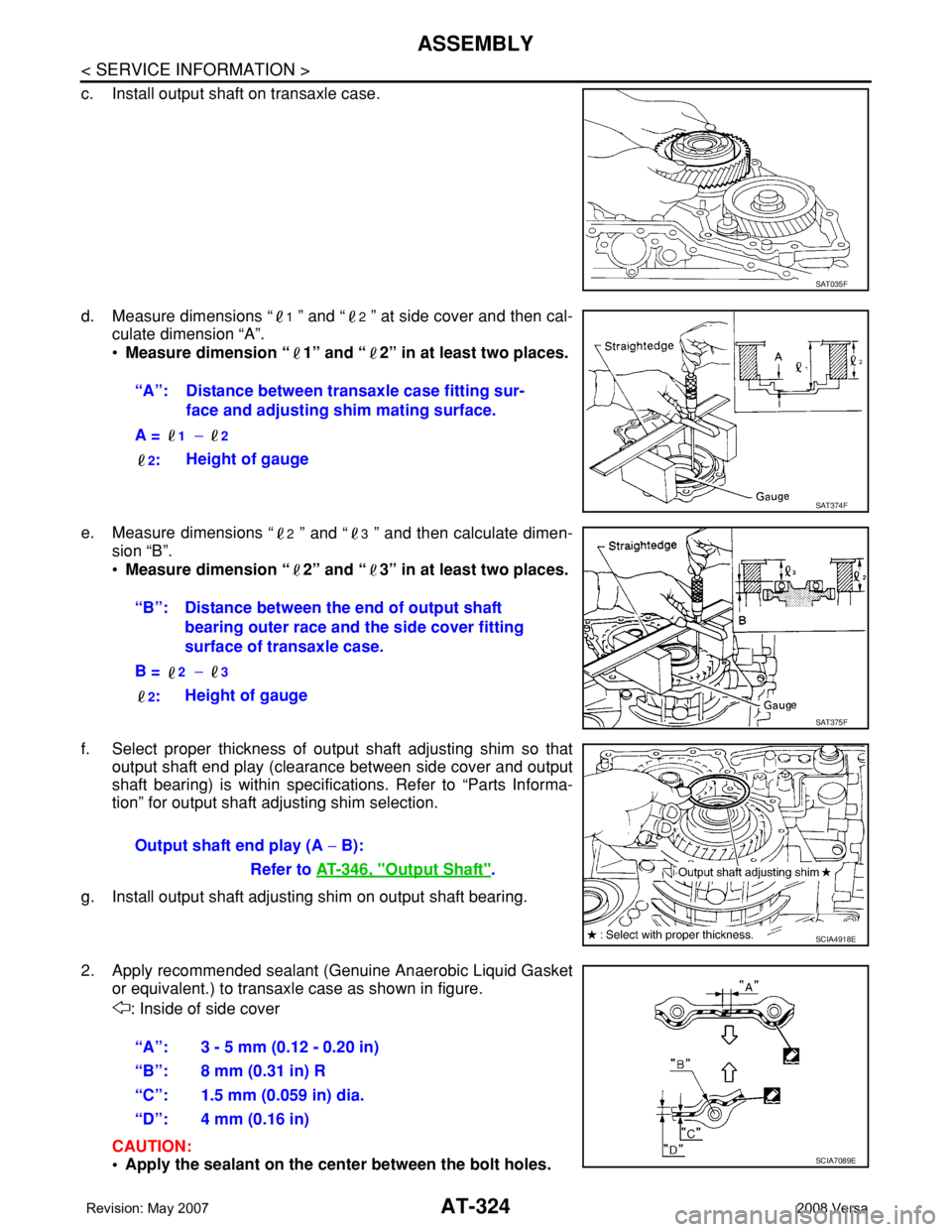

OUTPUT SHAFT END PLAY

1. Select proper thickness of output shaft adjusting shim using the

following procedures.

a. Install bearing retainer (1) in transaxle case. Refer to AT-302,

"Output Shaft, Output Gear, Idler Gear, Reduction Pinion Gear

and Bearing Retainer".

b. Install needle bearing on bearing retainer.

CAUTION:

Be careful to direction of needle bearing.

SCIA4915E

SCIA8013E

SCIA5909J

SCIA4917E

Page 336 of 2771

AT-324

< SERVICE INFORMATION >

ASSEMBLY

c. Install output shaft on transaxle case.

d. Measure dimensions “

1 ” and “2 ” at side cover and then cal-

culate dimension “A”.

•Measure dimension “ 1” and “ 2” in at least two places.

e. Measure dimensions “

2 ” and “3 ” and then calculate dimen-

sion “B”.

•Measure dimension “ 2” and “ 3” in at least two places.

f. Select proper thickness of output shaft adjusting shim so that

output shaft end play (clearance between side cover and output

shaft bearing) is within specifications. Refer to “Parts Informa-

tion” for output shaft adjusting shim selection.

g. Install output shaft adjusting shim on output shaft bearing.

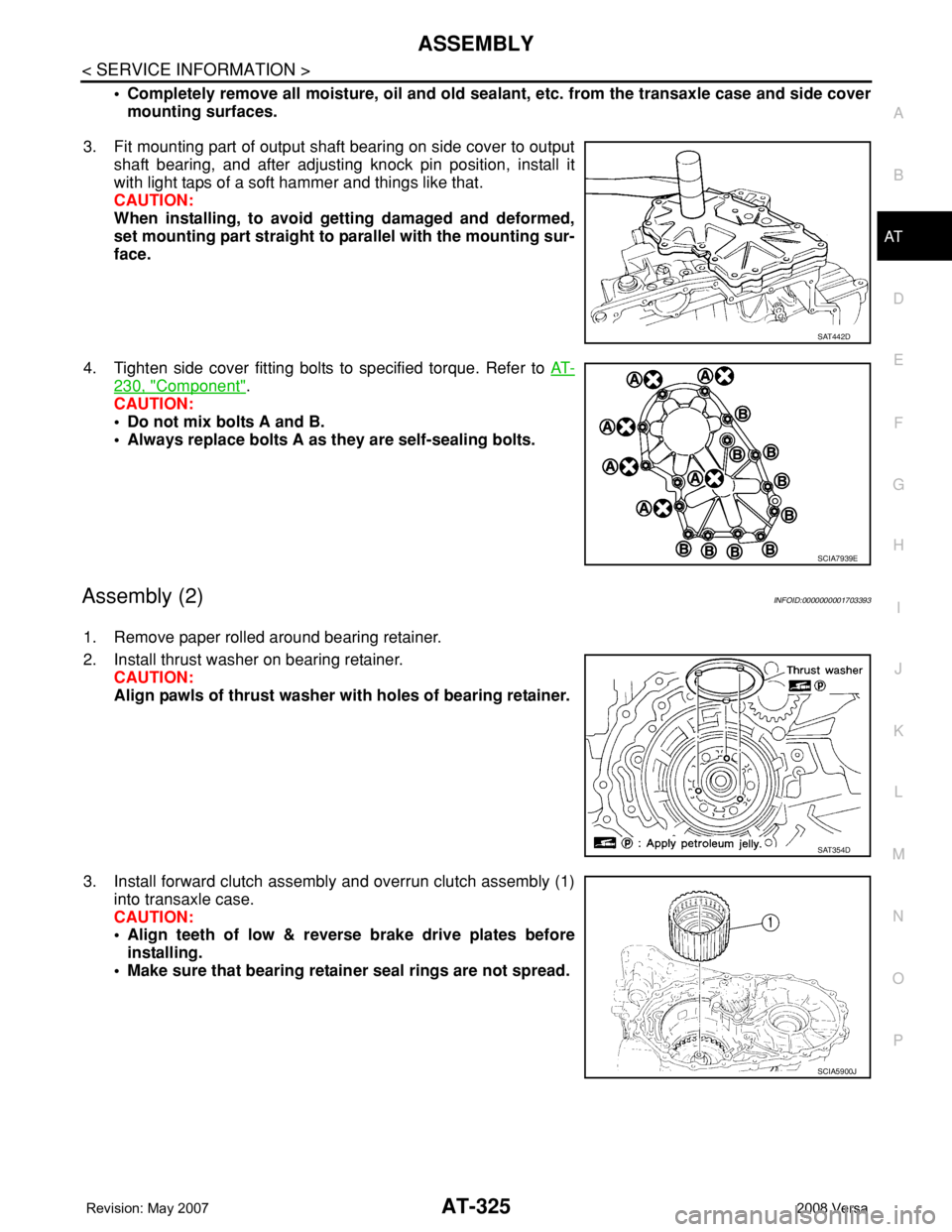

2. Apply recommended sealant (Genuine Anaerobic Liquid Gasket

or equivalent.) to transaxle case as shown in figure.

: Inside of side cover

CAUTION:

• Apply the sealant on the center between the bolt holes.

SAT035F

“A”: Distance between transaxle case fitting sur-

face and adjusting shim mating surface.

A =

1 − 2

2

:Height of gauge

SAT374F

“B”: Distance between the end of output shaft

bearing outer race and the side cover fitting

surface of transaxle case.

B =

2 − 3

2

:Height of gauge

SAT375F

Output shaft end play (A − B):

Refer to AT-346, "

Output Shaft".

SCIA4918E

“A”: 3 - 5 mm (0.12 - 0.20 in)

“B”: 8 mm (0.31 in) R

“C”: 1.5 mm (0.059 in) dia.

“D”: 4 mm (0.16 in)

SCIA7089E

Page 337 of 2771

ASSEMBLY

AT-325

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

• Completely remove all moisture, oil and old sealant, etc. from the transaxle case and side cover

mounting surfaces.

3. Fit mounting part of output shaft bearing on side cover to output

shaft bearing, and after adjusting knock pin position, install it

with light taps of a soft hammer and things like that.

CAUTION:

When installing, to avoid getting damaged and deformed,

set mounting part straight to parallel with the mounting sur-

face.

4. Tighten side cover fitting bolts to specified torque. Refer to AT-

230, "Component".

CAUTION:

• Do not mix bolts A and B.

• Always replace bolts A as they are self-sealing bolts.

Assembly (2)INFOID:0000000001703393

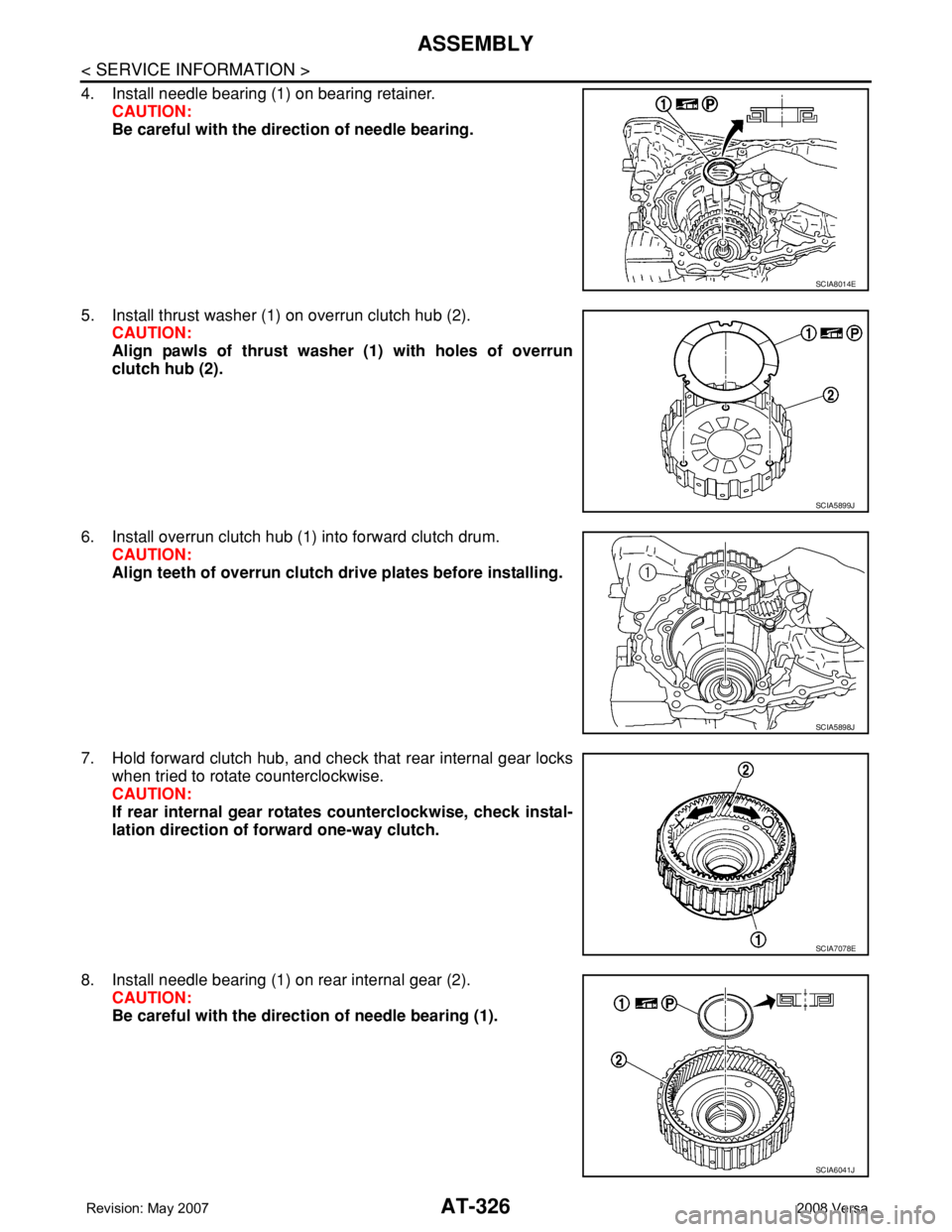

1. Remove paper rolled around bearing retainer.

2. Install thrust washer on bearing retainer.

CAUTION:

Align pawls of thrust washer with holes of bearing retainer.

3. Install forward clutch assembly and overrun clutch assembly (1)

into transaxle case.

CAUTION:

• Align teeth of low & reverse brake drive plates before

installing.

• Make sure that bearing retainer seal rings are not spread.

SAT442D

SCIA7939E

SAT354D

SCIA5900J

Page 338 of 2771

AT-326

< SERVICE INFORMATION >

ASSEMBLY

4. Install needle bearing (1) on bearing retainer.

CAUTION:

Be careful with the direction of needle bearing.

5. Install thrust washer (1) on overrun clutch hub (2).

CAUTION:

Align pawls of thrust washer (1) with holes of overrun

clutch hub (2).

6. Install overrun clutch hub (1) into forward clutch drum.

CAUTION:

Align teeth of overrun clutch drive plates before installing.

7. Hold forward clutch hub, and check that rear internal gear locks

when tried to rotate counterclockwise.

CAUTION:

If rear internal gear rotates counterclockwise, check instal-

lation direction of forward one-way clutch.

8. Install needle bearing (1) on rear internal gear (2).

CAUTION:

Be careful with the direction of needle bearing (1).

SCIA8014E

SCIA5899J

SCIA5898J

SCIA7078E

SCIA6041J

Page 339 of 2771

ASSEMBLY

AT-327

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

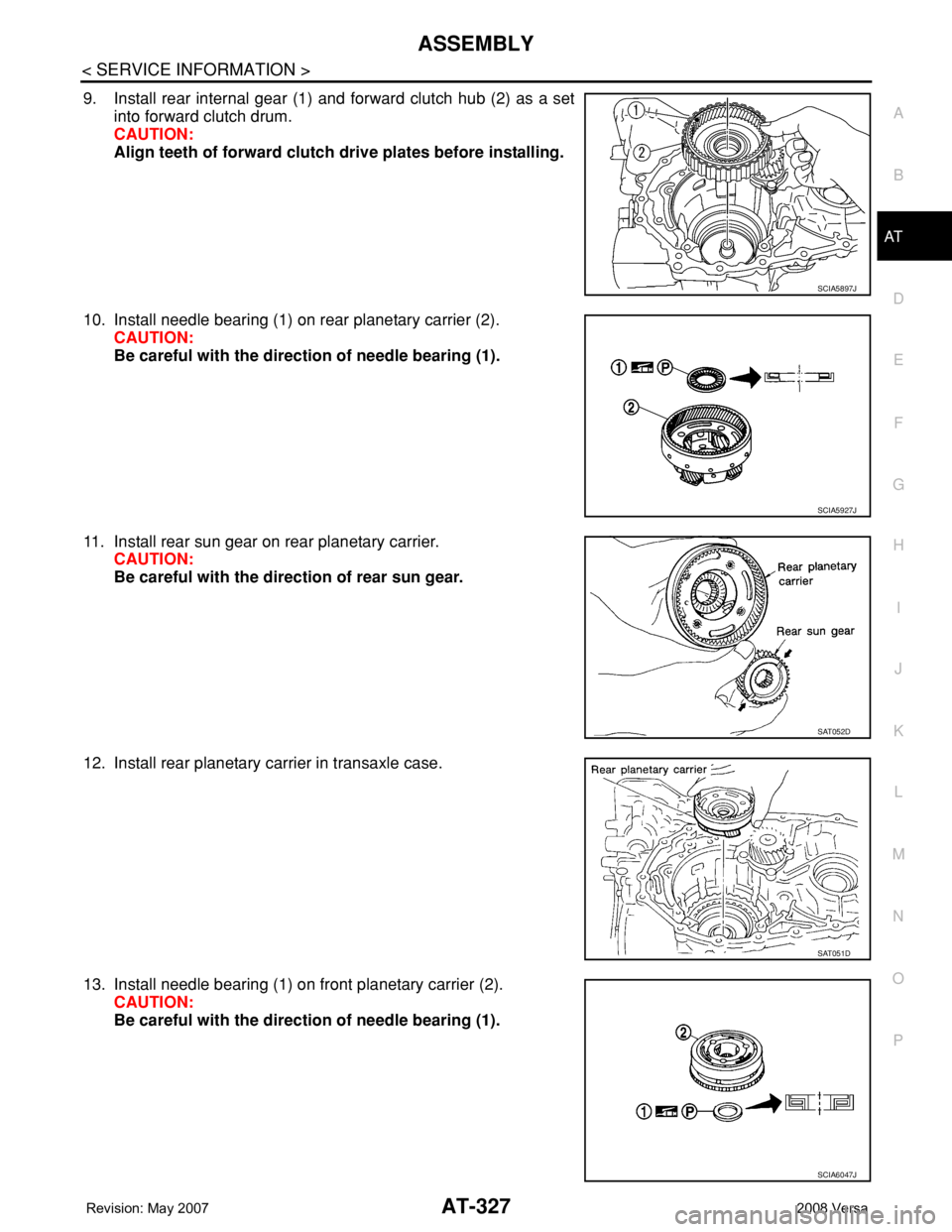

9. Install rear internal gear (1) and forward clutch hub (2) as a set

into forward clutch drum.

CAUTION:

Align teeth of forward clutch drive plates before installing.

10. Install needle bearing (1) on rear planetary carrier (2).

CAUTION:

Be careful with the direction of needle bearing (1).

11. Install rear sun gear on rear planetary carrier.

CAUTION:

Be careful with the direction of rear sun gear.

12. Install rear planetary carrier in transaxle case.

13. Install needle bearing (1) on front planetary carrier (2).

CAUTION:

Be careful with the direction of needle bearing (1).

SCIA5897J

SCIA5927J

SAT052D

SAT051D

SCIA6047J

Page 340 of 2771

AT-328

< SERVICE INFORMATION >

ASSEMBLY

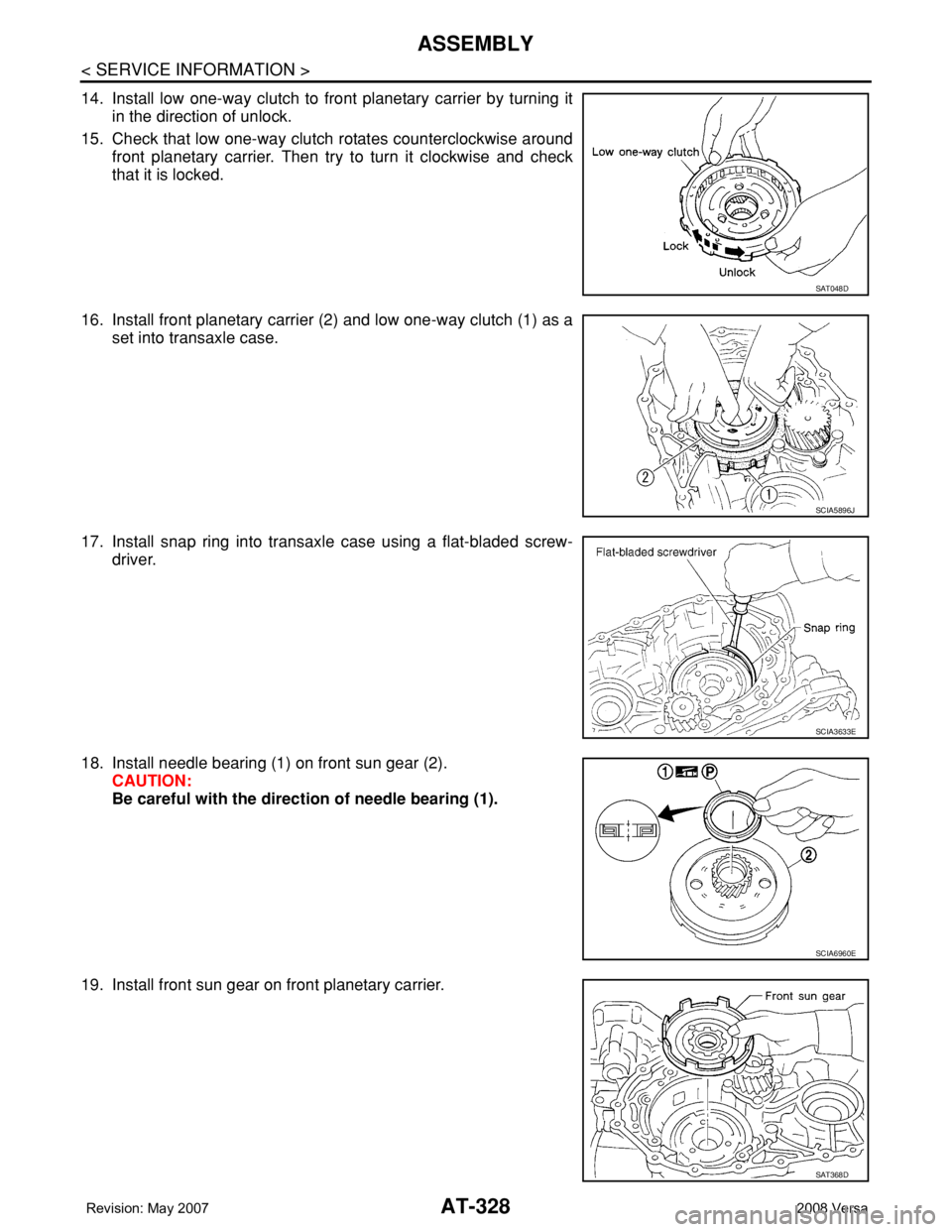

14. Install low one-way clutch to front planetary carrier by turning it

in the direction of unlock.

15. Check that low one-way clutch rotates counterclockwise around

front planetary carrier. Then try to turn it clockwise and check

that it is locked.

16. Install front planetary carrier (2) and low one-way clutch (1) as a

set into transaxle case.

17. Install snap ring into transaxle case using a flat-bladed screw-

driver.

18. Install needle bearing (1) on front sun gear (2).

CAUTION:

Be careful with the direction of needle bearing (1).

19. Install front sun gear on front planetary carrier.

SAT048D

SCIA5896J

SCIA3633E

SCIA6960E

SAT368D