NISSAN TIIDA 2008 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2008, Model line: TIIDA, Model: NISSAN TIIDA 2008Pages: 2771, PDF Size: 60.61 MB

Page 341 of 2771

ASSEMBLY

AT-329

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

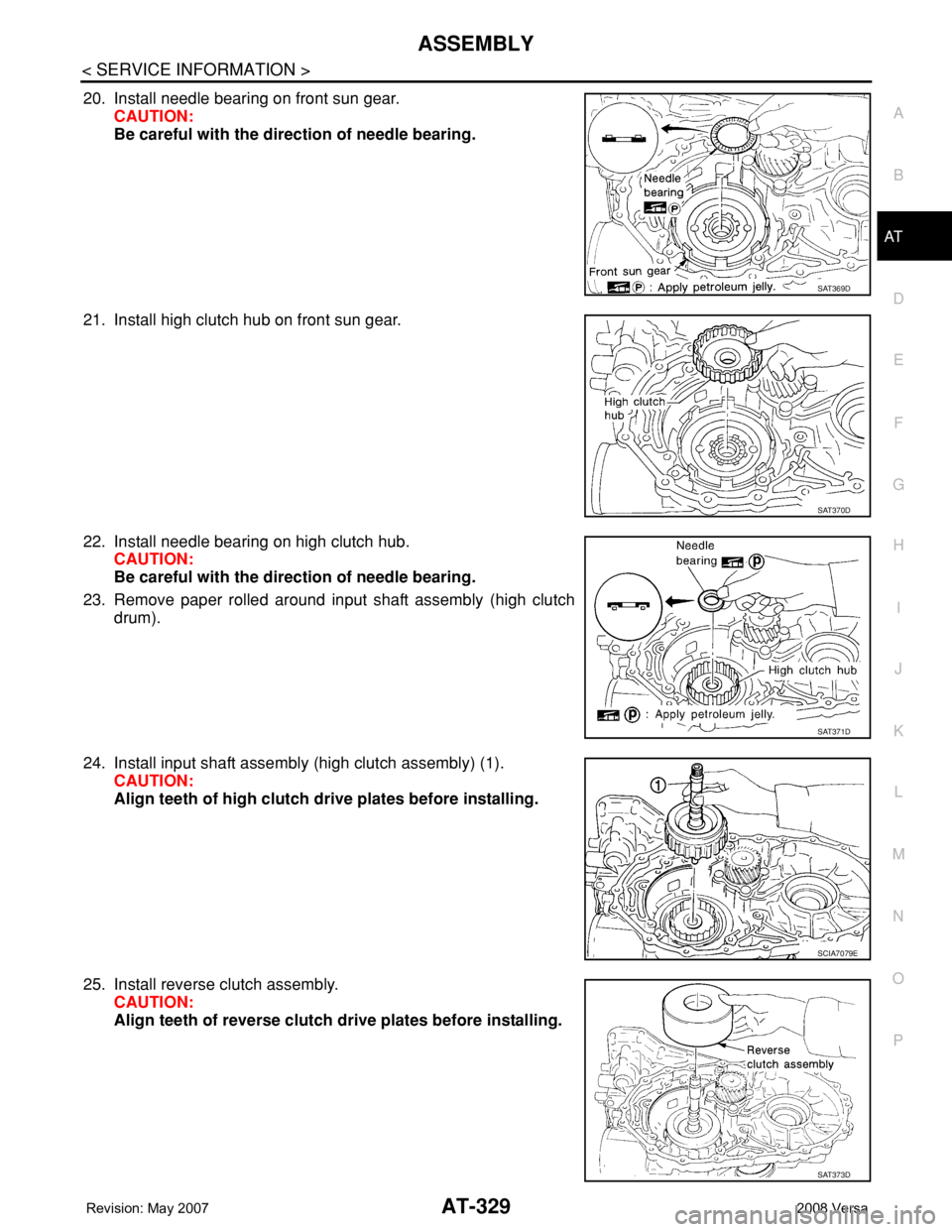

20. Install needle bearing on front sun gear.

CAUTION:

Be careful with the direction of needle bearing.

21. Install high clutch hub on front sun gear.

22. Install needle bearing on high clutch hub.

CAUTION:

Be careful with the direction of needle bearing.

23. Remove paper rolled around input shaft assembly (high clutch

drum).

24. Install input shaft assembly (high clutch assembly) (1).

CAUTION:

Align teeth of high clutch drive plates before installing.

25. Install reverse clutch assembly.

CAUTION:

Align teeth of reverse clutch drive plates before installing.

SAT369D

SAT370D

SAT371D

SCIA7079E

SAT373D

Page 342 of 2771

AT-330

< SERVICE INFORMATION >

ASSEMBLY

Adjustment (2)

INFOID:0000000001703394

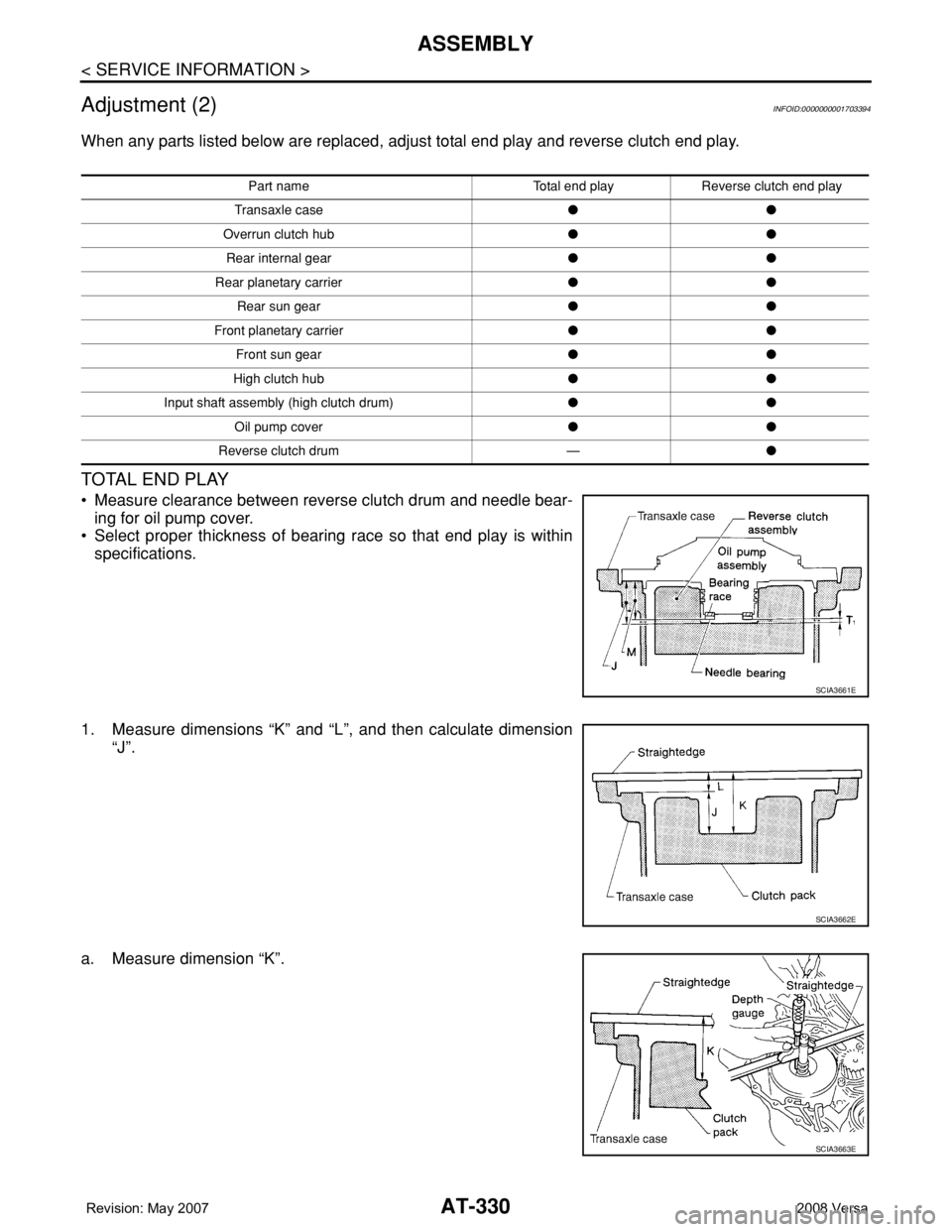

When any parts listed below are replaced, adjust total end play and reverse clutch end play.

TOTAL END PLAY

• Measure clearance between reverse clutch drum and needle bear-

ing for oil pump cover.

• Select proper thickness of bearing race so that end play is within

specifications.

1. Measure dimensions “K” and “L”, and then calculate dimension

“J”.

a. Measure dimension “K”.

Part name Total end play Reverse clutch end play

Transaxle case●●

Overrun clutch hub●●

Rear internal gear●●

Rear planetary carrier●●

Rear sun gear●●

Front planetary carrier●●

Front sun gear●●

High clutch hub●●

Input shaft assembly (high clutch drum)●●

Oil pump cover●●

Reverse clutch drum —●

SCIA3661E

SCIA3662E

SCIA3663E

Page 343 of 2771

ASSEMBLY

AT-331

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

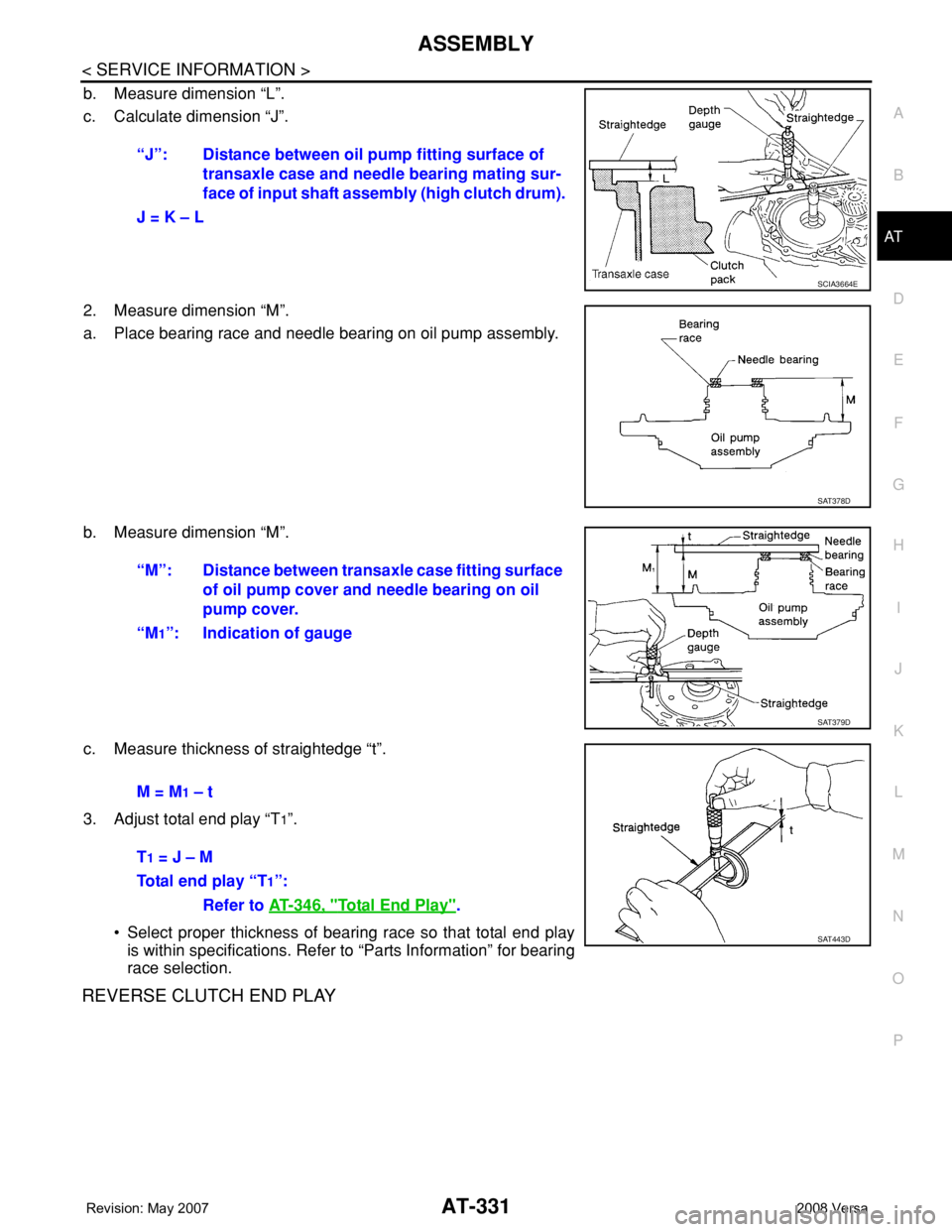

b. Measure dimension “L”.

c. Calculate dimension “J”.

2. Measure dimension “M”.

a. Place bearing race and needle bearing on oil pump assembly.

b. Measure dimension “M”.

c. Measure thickness of straightedge “t”.

3. Adjust total end play “T

1”.

• Select proper thickness of bearing race so that total end play

is within specifications. Refer to “Parts Information” for bearing

race selection.

REVERSE CLUTCH END PLAY

“J”: Distance between oil pump fitting surface of

transaxle case and needle bearing mating sur-

face of input shaft assembly (high clutch drum).

J = K – L

SCIA3664E

SAT378D

“M”: Distance between transaxle case fitting surface

of oil pump cover and needle bearing on oil

pump cover.

“M

1”: Indication of gauge

SAT379D

M = M1 – t

T

1 = J – M

Total end play “T

1”:

Refer to AT-346, "

Total End Play".

SAT443D

Page 344 of 2771

AT-332

< SERVICE INFORMATION >

ASSEMBLY

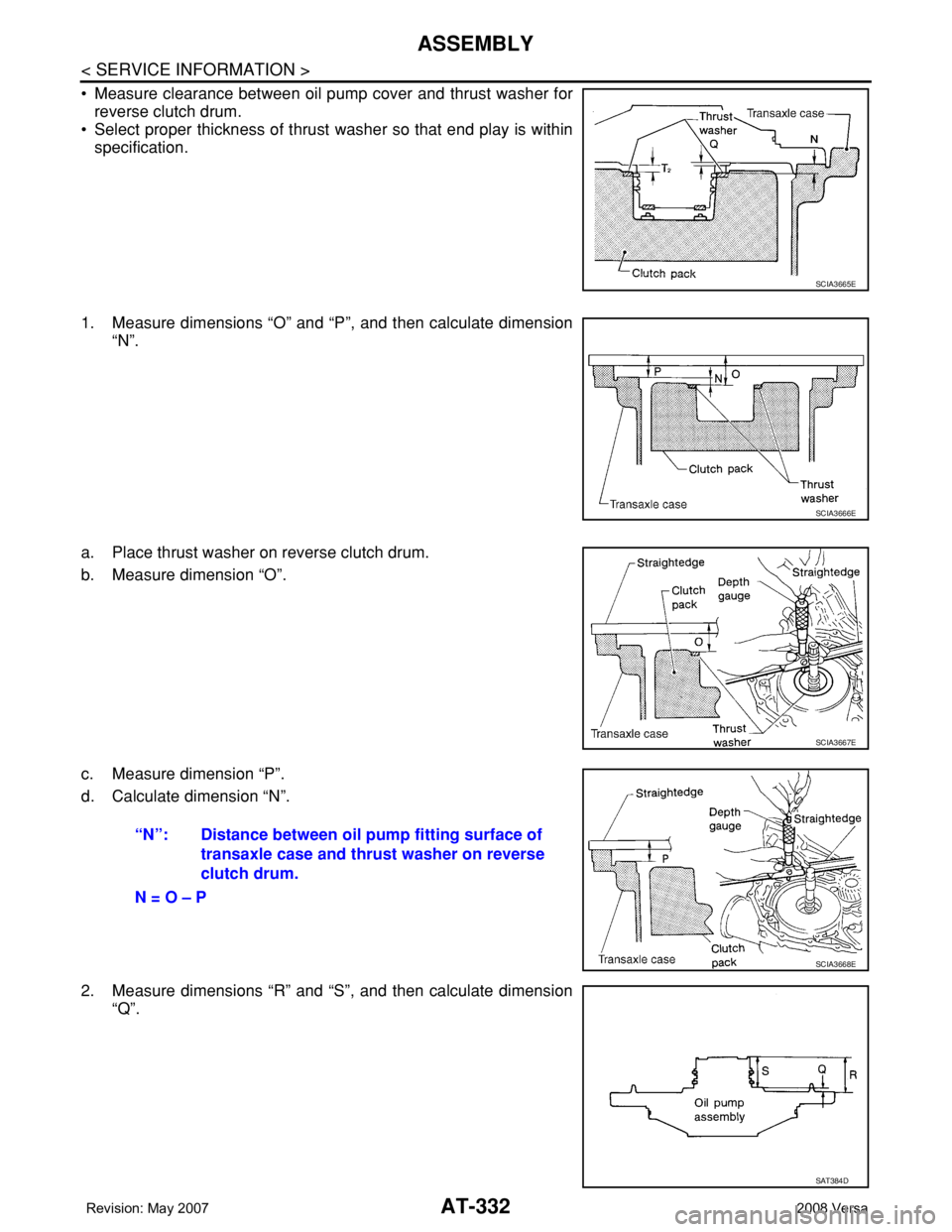

• Measure clearance between oil pump cover and thrust washer for

reverse clutch drum.

• Select proper thickness of thrust washer so that end play is within

specification.

1. Measure dimensions “O” and “P”, and then calculate dimension

“N”.

a. Place thrust washer on reverse clutch drum.

b. Measure dimension “O”.

c. Measure dimension “P”.

d. Calculate dimension “N”.

2. Measure dimensions “R” and “S”, and then calculate dimension

“Q”.

SCIA3665E

SCIA3666E

SCIA3667E

“N”: Distance between oil pump fitting surface of

transaxle case and thrust washer on reverse

clutch drum.

N = O – P

SCIA3668E

SAT384D

Page 345 of 2771

ASSEMBLY

AT-333

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

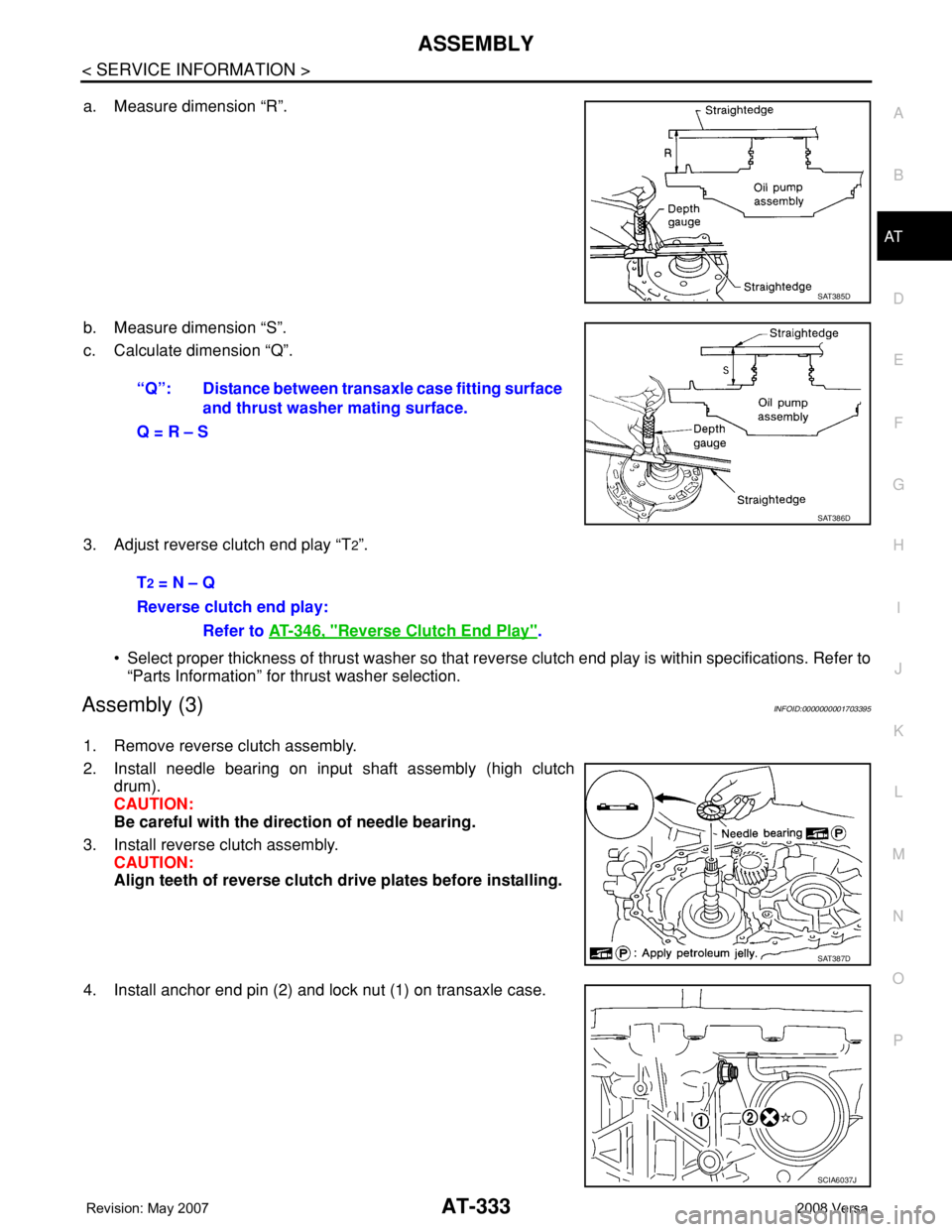

a. Measure dimension “R”.

b. Measure dimension “S”.

c. Calculate dimension “Q”.

3. Adjust reverse clutch end play “T

2”.

• Select proper thickness of thrust washer so that reverse clutch end play is within specifications. Refer to

“Parts Information” for thrust washer selection.

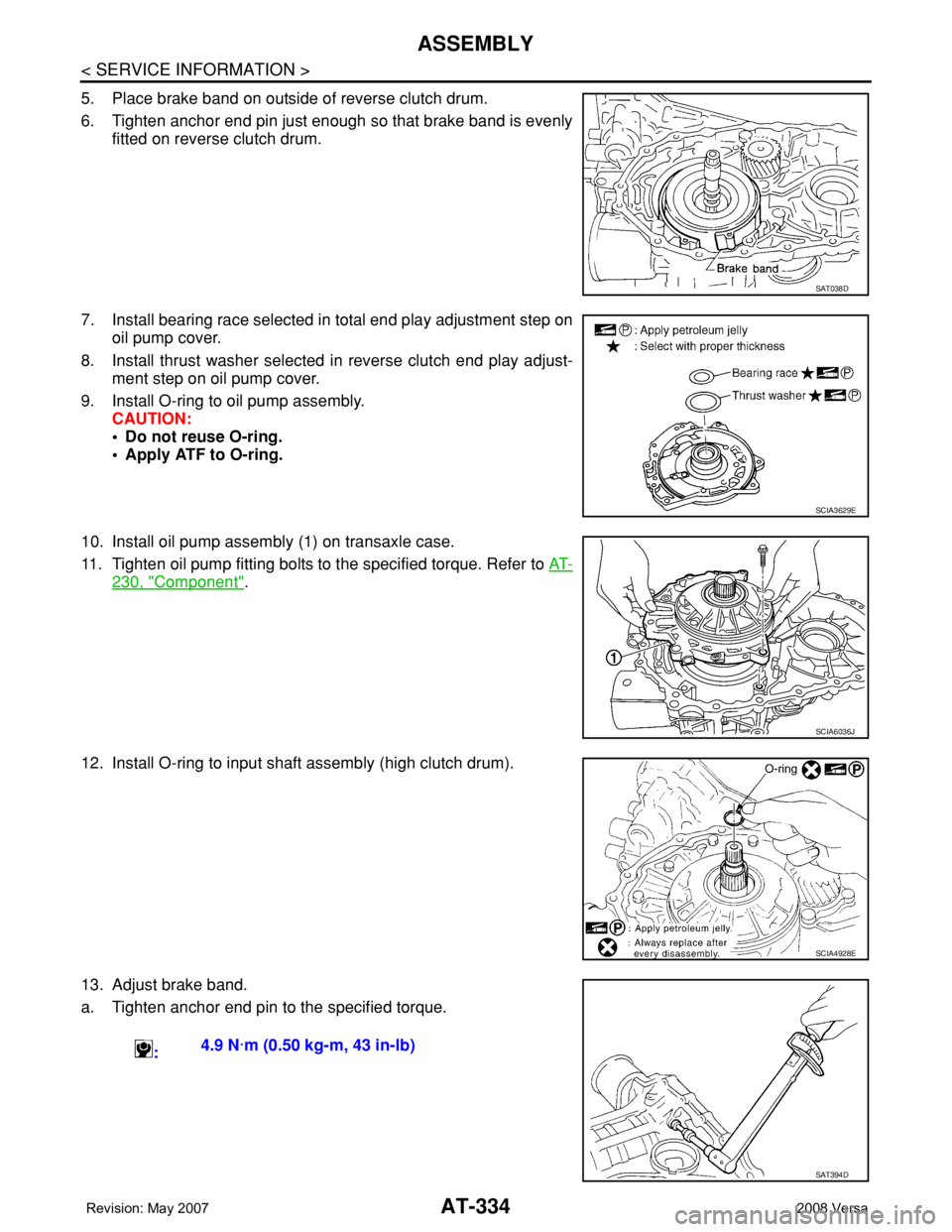

Assembly (3)INFOID:0000000001703395

1. Remove reverse clutch assembly.

2. Install needle bearing on input shaft assembly (high clutch

drum).

CAUTION:

Be careful with the direction of needle bearing.

3. Install reverse clutch assembly.

CAUTION:

Align teeth of reverse clutch drive plates before installing.

4. Install anchor end pin (2) and lock nut (1) on transaxle case.

SAT385D

“Q”: Distance between transaxle case fitting surface

and thrust washer mating surface.

Q = R – S

SAT386D

T2 = N – Q

Reverse clutch end play:

Refer to AT-346, "

Reverse Clutch End Play".

SAT387D

SCIA6037J

Page 346 of 2771

AT-334

< SERVICE INFORMATION >

ASSEMBLY

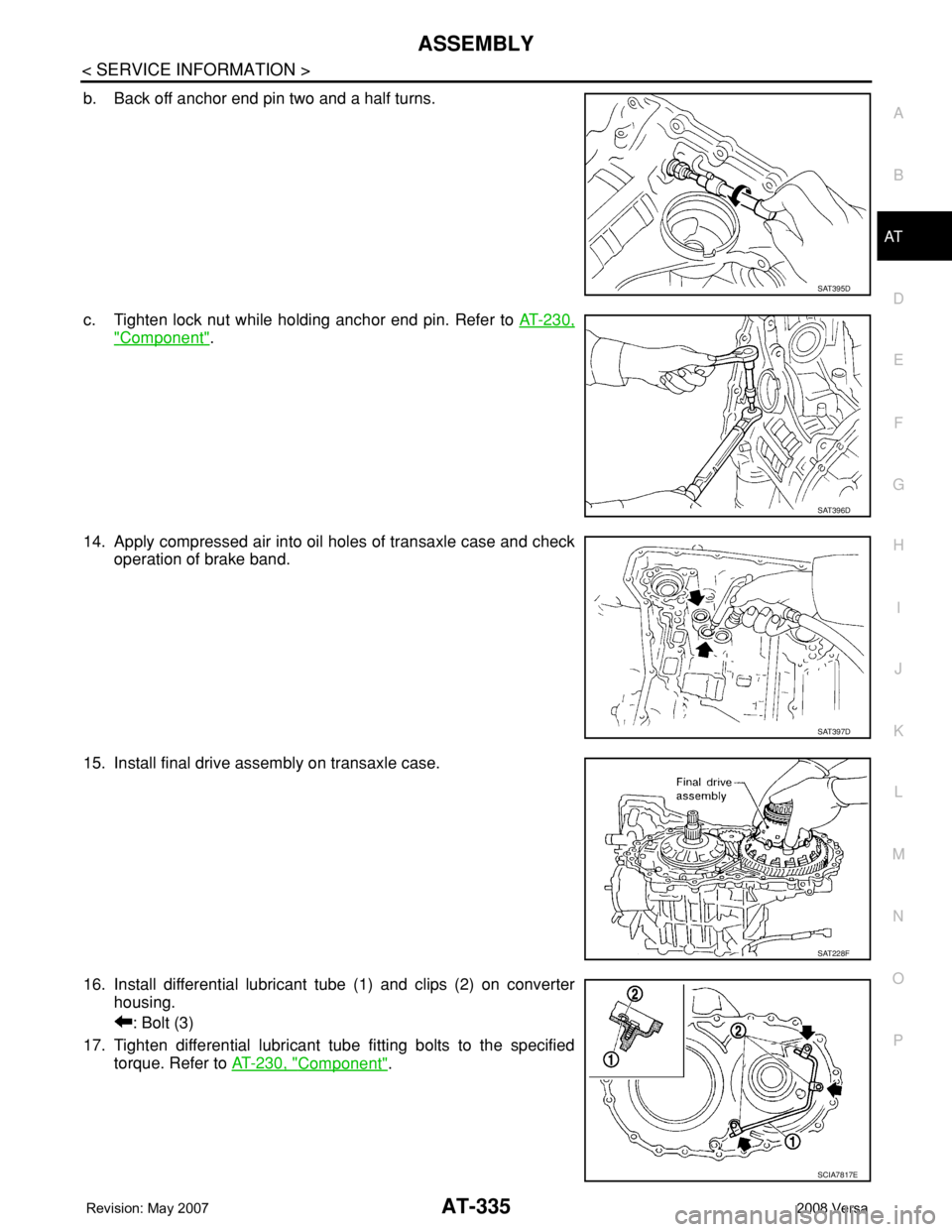

5. Place brake band on outside of reverse clutch drum.

6. Tighten anchor end pin just enough so that brake band is evenly

fitted on reverse clutch drum.

7. Install bearing race selected in total end play adjustment step on

oil pump cover.

8. Install thrust washer selected in reverse clutch end play adjust-

ment step on oil pump cover.

9. Install O-ring to oil pump assembly.

CAUTION:

• Do not reuse O-ring.

• Apply ATF to O-ring.

10. Install oil pump assembly (1) on transaxle case.

11. Tighten oil pump fitting bolts to the specified torque. Refer to AT-

230, "Component".

12. Install O-ring to input shaft assembly (high clutch drum).

13. Adjust brake band.

a. Tighten anchor end pin to the specified torque.

SAT038D

SCIA3629E

SCIA6036J

SCIA4928E

:4.9 N·m (0.50 kg-m, 43 in-lb)

SAT394D

Page 347 of 2771

ASSEMBLY

AT-335

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

b. Back off anchor end pin two and a half turns.

c. Tighten lock nut while holding anchor end pin. Refer to AT-230,

"Component".

14. Apply compressed air into oil holes of transaxle case and check

operation of brake band.

15. Install final drive assembly on transaxle case.

16. Install differential lubricant tube (1) and clips (2) on converter

housing.

: Bolt (3)

17. Tighten differential lubricant tube fitting bolts to the specified

torque. Refer to AT-230, "

Component".

SAT395D

SAT396D

SAT397D

SAT228F

SCIA7817E

Page 348 of 2771

AT-336

< SERVICE INFORMATION >

ASSEMBLY

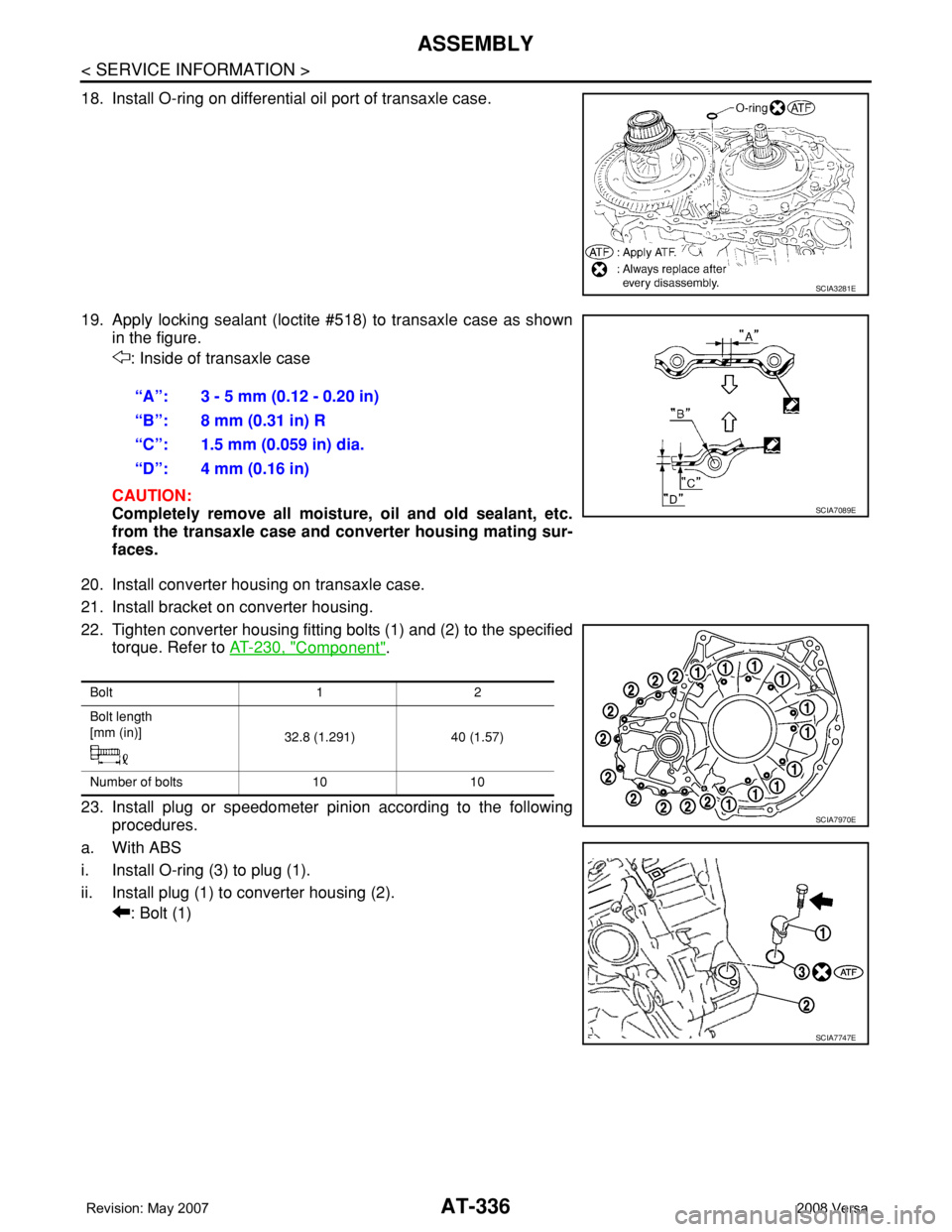

18. Install O-ring on differential oil port of transaxle case.

19. Apply locking sealant (loctite #518) to transaxle case as shown

in the figure.

: Inside of transaxle case

CAUTION:

Completely remove all moisture, oil and old sealant, etc.

from the transaxle case and converter housing mating sur-

faces.

20. Install converter housing on transaxle case.

21. Install bracket on converter housing.

22. Tighten converter housing fitting bolts (1) and (2) to the specified

torque. Refer to AT-230, "

Component".

23. Install plug or speedometer pinion according to the following

procedures.

a. With ABS

i. Install O-ring (3) to plug (1).

ii. Install plug (1) to converter housing (2).

: Bolt (1)

SCIA3281E

“A”: 3 - 5 mm (0.12 - 0.20 in)

“B”: 8 mm (0.31 in) R

“C”: 1.5 mm (0.059 in) dia.

“D”: 4 mm (0.16 in)

SCIA7089E

Bolt 1 2

Bolt length

[mm (in)]

32.8 (1.291) 40 (1.57)

Number of bolts 10 10

SCIA7970E

SCIA7747E

Page 349 of 2771

ASSEMBLY

AT-337

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

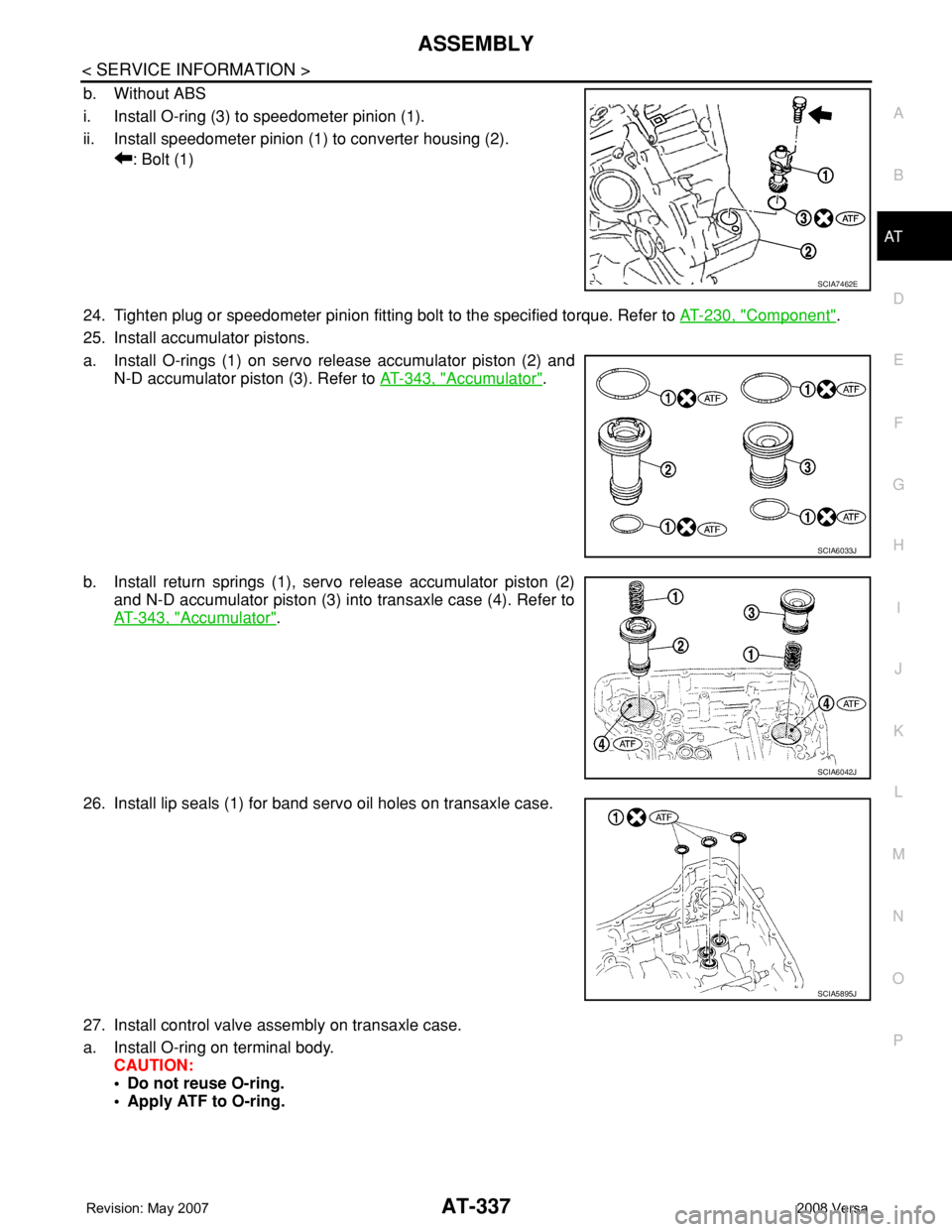

b. Without ABS

i. Install O-ring (3) to speedometer pinion (1).

ii. Install speedometer pinion (1) to converter housing (2).

: Bolt (1)

24. Tighten plug or speedometer pinion fitting bolt to the specified torque. Refer to AT-230, "

Component".

25. Install accumulator pistons.

a. Install O-rings (1) on servo release accumulator piston (2) and

N-D accumulator piston (3). Refer to AT-343, "

Accumulator".

b. Install return springs (1), servo release accumulator piston (2)

and N-D accumulator piston (3) into transaxle case (4). Refer to

AT-343, "

Accumulator".

26. Install lip seals (1) for band servo oil holes on transaxle case.

27. Install control valve assembly on transaxle case.

a. Install O-ring on terminal body.

CAUTION:

• Do not reuse O-ring.

• Apply ATF to O-ring.

SCIA7462E

SCIA6033J

SCIA6042J

SCIA5895J

Page 350 of 2771

AT-338

< SERVICE INFORMATION >

ASSEMBLY

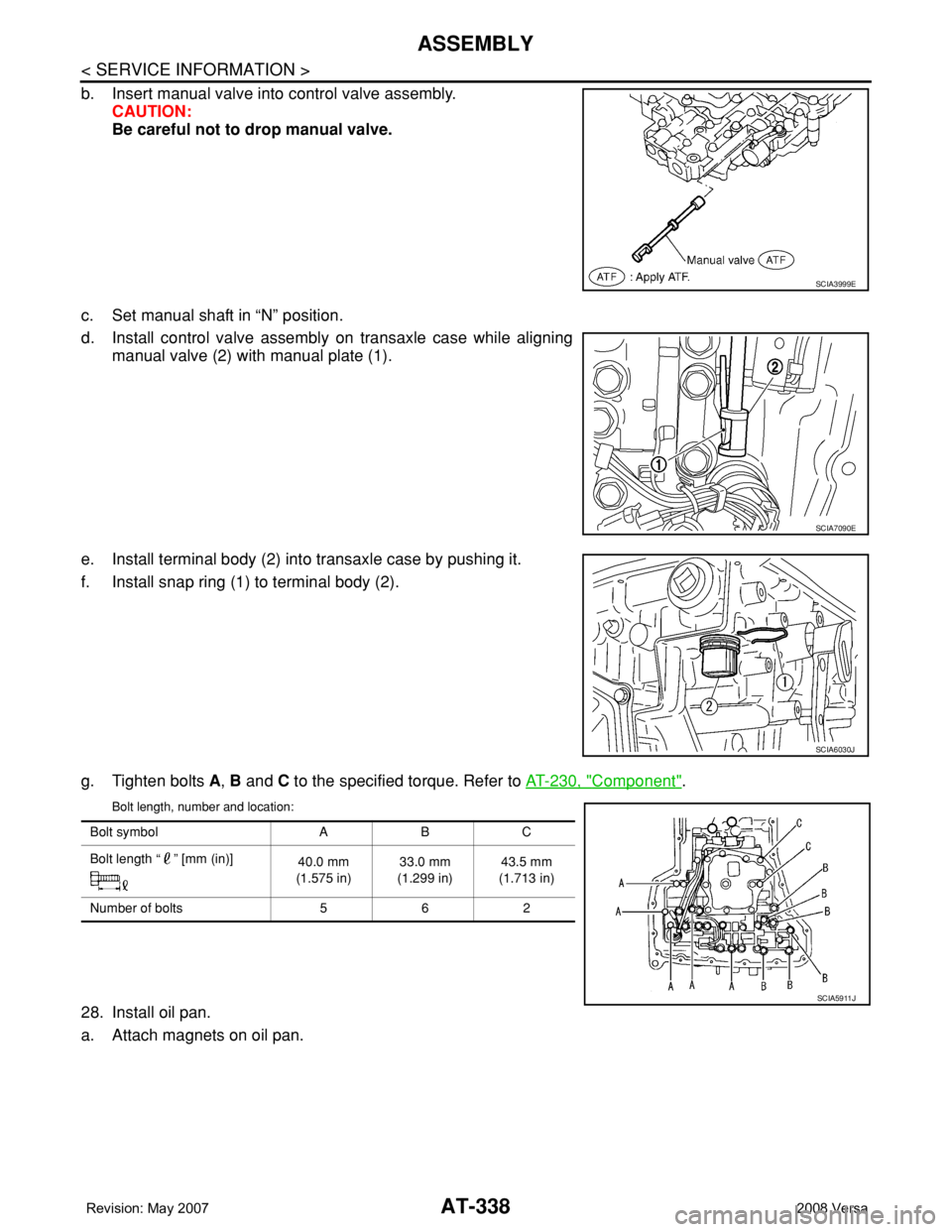

b. Insert manual valve into control valve assembly.

CAUTION:

Be careful not to drop manual valve.

c. Set manual shaft in “N” position.

d. Install control valve assembly on transaxle case while aligning

manual valve (2) with manual plate (1).

e. Install terminal body (2) into transaxle case by pushing it.

f. Install snap ring (1) to terminal body (2).

g. Tighten bolts A, B and C to the specified torque. Refer to AT-230, "

Component".

Bolt length, number and location:

28. Install oil pan.

a. Attach magnets on oil pan.

SCIA3999E

SCIA7090E

SCIA6030J

Bolt symbol A B C

Bolt length “ ” [mm (in)]

40.0 mm

(1.575 in)33.0 mm

(1.299 in)43.5 mm

(1.713 in)

Number of bolts 5 6 2

SCIA5911J