engine control NISSAN TIIDA 2009 Service Manual Online

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 1073 of 4331

CVT

N

O P

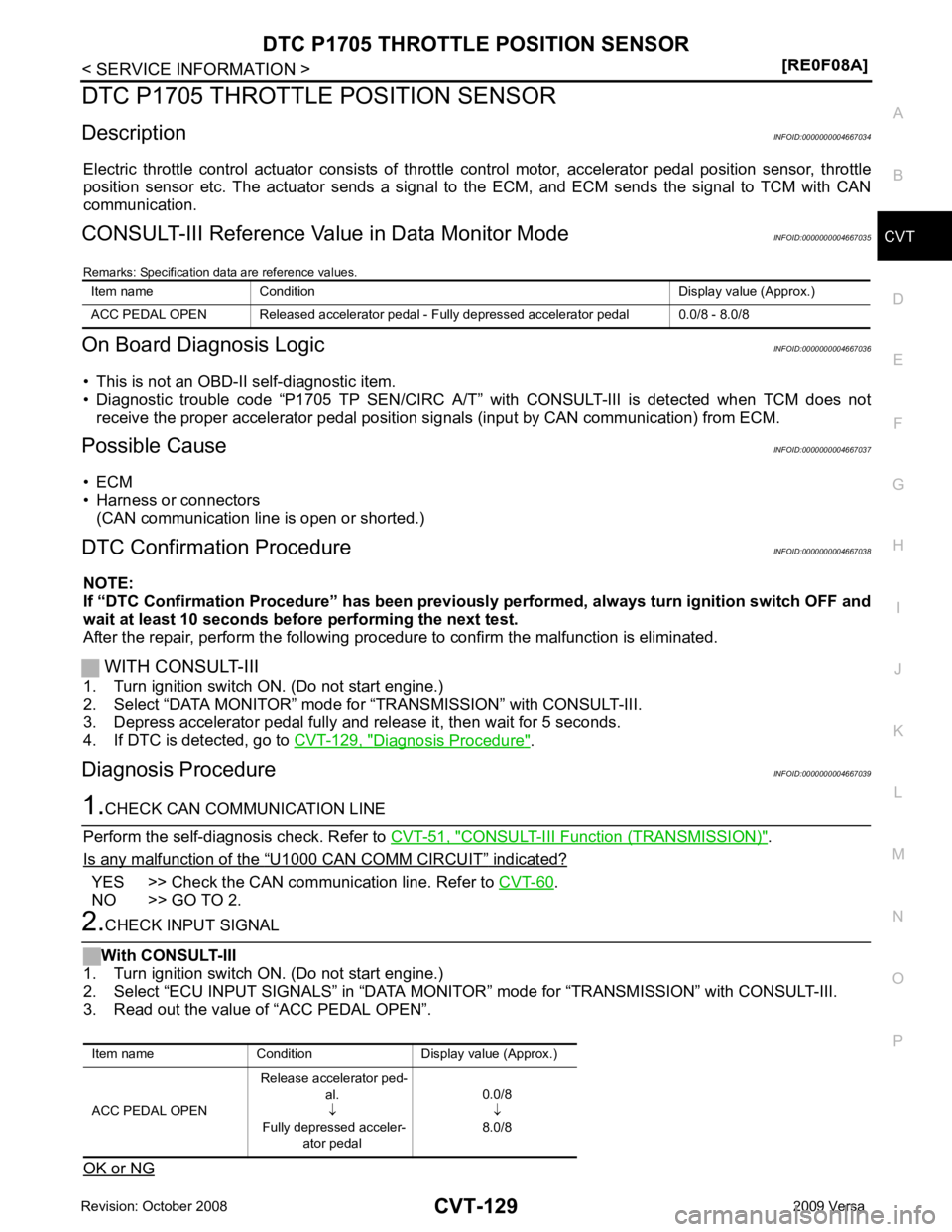

DTC P1705 THROTTLE POSITION SENSOR

Description INFOID:0000000004667034

Electric throttle control actuator consists of throttle control motor, accelerator pedal position sensor, throttle

position sensor etc. The actuator sends a signal to the ECM, and ECM sends the signal to TCM with CAN

communication.

CONSULT-III Reference Val ue in Data Monitor Mode INFOID:0000000004667035

Remarks: Specification data are reference values.

On Board Diagnosis Logic INFOID:0000000004667036

• This is not an OBD-II self-diagnostic item.

• Diagnostic trouble code “P1705 TP SEN/CIRC A/T” with CONSULT-III is detected when TCM does not

receive the proper accelerator pedal position si gnals (input by CAN communication) from ECM.

Possible Cause INFOID:0000000004667037

• ECM

• Harness or connectors

(CAN communication line is open or shorted.)

DTC Confirmation Procedure INFOID:0000000004667038

NOTE:

If “DTC Confirmation Procedure” has been previously performed, alw ays turn ignition switch OFF and

wait at least 10 seconds before performing the next test.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Select “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

3. Depress accelerator pedal fully and release it, then wait for 5 seconds.

4. If DTC is detected, go to CVT-129, " Diagnosis Procedure " .

Diagnosis Procedure INFOID:0000000004667039CONSULT-III Functi

on (TRANSMISSION) " .

Is any malfunction of the “ U1000 CAN COMM CIRCUIT ” indicated?

YES >> Check the CAN communication line. Refer to

CVT-60 .

NO >> GO TO 2. Item name Condition Display value (Approx.)

ACC PEDAL OPEN Release accelerator ped-

al.↓

Fully depressed acceler- ator pedal 0.0/8

↓

8.0/8

Page 1075 of 4331

CVT

N

O P

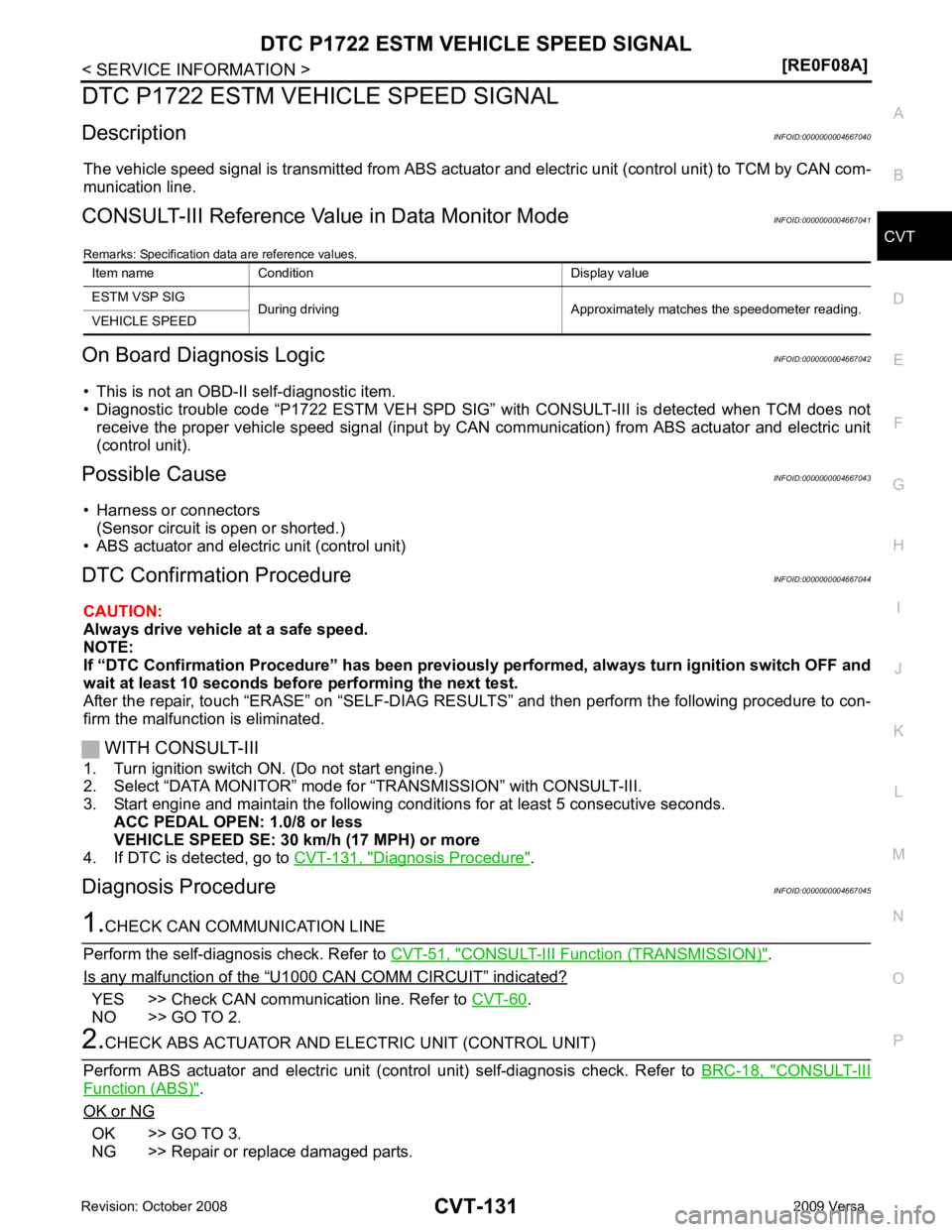

DTC P1722 ESTM VEHICLE SPEED SIGNAL

Description INFOID:0000000004667040

The vehicle speed signal is transmitt ed from ABS actuator and electric unit (control unit) to TCM by CAN com-

munication line.

CONSULT-III Reference Val ue in Data Monitor Mode INFOID:0000000004667041

Remarks: Specification data are reference values.

On Board Diagnosis Logic INFOID:0000000004667042

• This is not an OBD-II self-diagnostic item.

• Diagnostic trouble code “P1722 ESTM VEH SPD SIG” with CONSULT-III is detected when TCM does not

receive the proper vehicle speed signal (input by CAN communication) from ABS actuator and electric unit

(control unit).

Possible Cause INFOID:0000000004667043

• Harness or connectors (Sensor circuit is open or shorted.)

• ABS actuator and electric unit (control unit)

DTC Confirmation Procedure INFOID:0000000004667044

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC Confirmation Procedure” has been previously performed, alw ays turn ignition switch OFF and

wait at least 10 seconds before performing the next test.

After the repair, touch “ERASE” on “SELF-DIAG RESU LTS” and then perform the following procedure to con-

firm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Select “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

3. Start engine and maintain the following conditions for at least 5 consecutive seconds.

ACC PEDAL OPEN: 1.0/8 or less

VEHICLE SPEED SE: 30 km/h (17 MPH) or more

4. If DTC is detected, go to CVT-131, " Diagnosis Procedure " .

Diagnosis Procedure INFOID:0000000004667045CONSULT-III Functi

on (TRANSMISSION) " .

Is any malfunction of the “ U1000 CAN COMM CIRCUIT ” indicated?

YES >> Check CAN communication line. Refer to

CVT-60 .

NO >> GO TO 2. CONSULT-III

Function (ABS) " .

OK or NG OK >> GO TO 3.

NG >> Repair or replace damaged parts.

Item name Condition Display value

ESTM VSP SIG During driving Approximately matches the speedometer reading.

VEHICLE SPEED

Page 1077 of 4331

CVT

N

O P

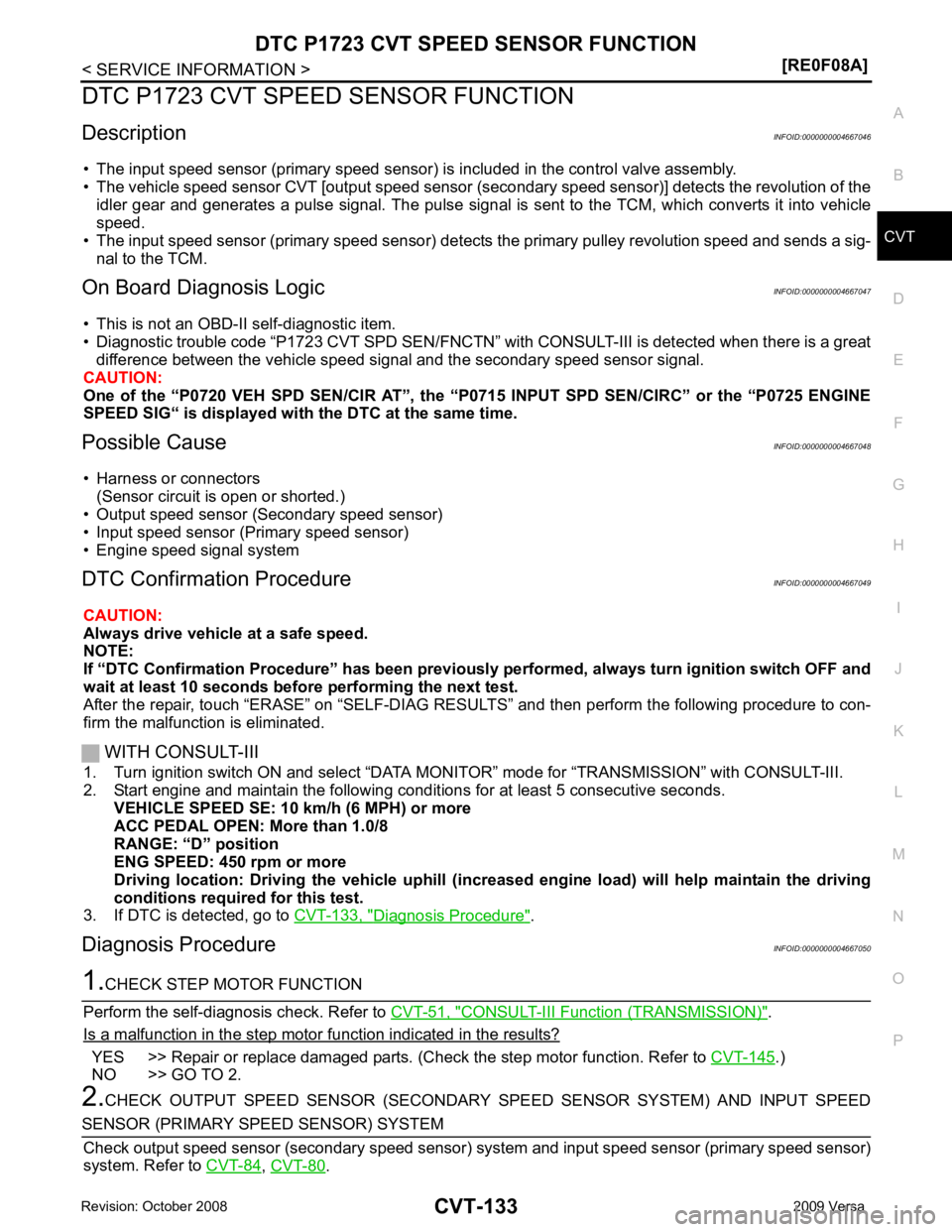

DTC P1723 CVT SPEED SENSOR FUNCTION

Description INFOID:0000000004667046

• The input speed sensor (primary speed sensor) is included in the control valve assembly.

• The vehicle speed sensor CVT [output speed sensor (s econdary speed sensor)] detects the revolution of the

idler gear and generates a pulse signal. The pulse signal is sent to the TCM, which converts it into vehicle

speed.

• The input speed sensor (primary speed sensor) detects the primary pulley revolution speed and sends a sig-

nal to the TCM.

On Board Diagnosis Logic INFOID:0000000004667047

• This is not an OBD-II self-diagnostic item.

• Diagnostic trouble code “P1723 CVT SPD SEN/FNCTN” with CONSULT-III is detected when there is a great

difference between the vehicle speed signal and the secondary speed sensor signal.

CAUTION:

One of the “P0720 VEH SPD SEN/CIR AT”, the “P0715 INPUT SPD SEN/CIRC” or the “P0725 ENGINE

SPEED SIG“ is displayed with the DTC at the same time.

Possible Cause INFOID:0000000004667048

• Harness or connectors (Sensor circuit is open or shorted.)

• Output speed sensor (Secondary speed sensor)

• Input speed sensor (Primary speed sensor)

• Engine speed signal system

DTC Confirmation Procedure INFOID:0000000004667049

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC Confirmation Procedure” has been previously performed, alw ays turn ignition switch OFF and

wait at least 10 seconds before performing the next test.

After the repair, touch “ERASE” on “SELF-DIAG RESU LTS” and then perform the following procedure to con-

firm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON and select “DATA MO NITOR” mode for “TRANSMISSION” with CONSULT-III.

2. Start engine and maintain the following conditions for at least 5 consecutive seconds.

VEHICLE SPEED SE: 10 km/h (6 MPH) or more

ACC PEDAL OPEN: More than 1.0/8

RANGE: “D” position

ENG SPEED: 450 rpm or more

Driving location: Driving the vehic le uphill (increased engine load) will help maintain the driving

conditions required for this test.

3. If DTC is detected, go to CVT-133, " Diagnosis Procedure " .

Diagnosis Procedure INFOID:0000000004667050CONSULT-III Functi

on (TRANSMISSION) " .

Is a malfunction in the step motor function indicated in the results? YES >> Repair or replace damaged parts. (C

heck the step motor function. Refer to CVT-145 .)

NO >> GO TO 2.

2. CHECK OUTPUT SPEED SENSOR (SECONDARY SPEED SENSOR SYSTEM) AND INPUT SPEED ,

CVT-80 .

Page 1079 of 4331

CVT

N

O P

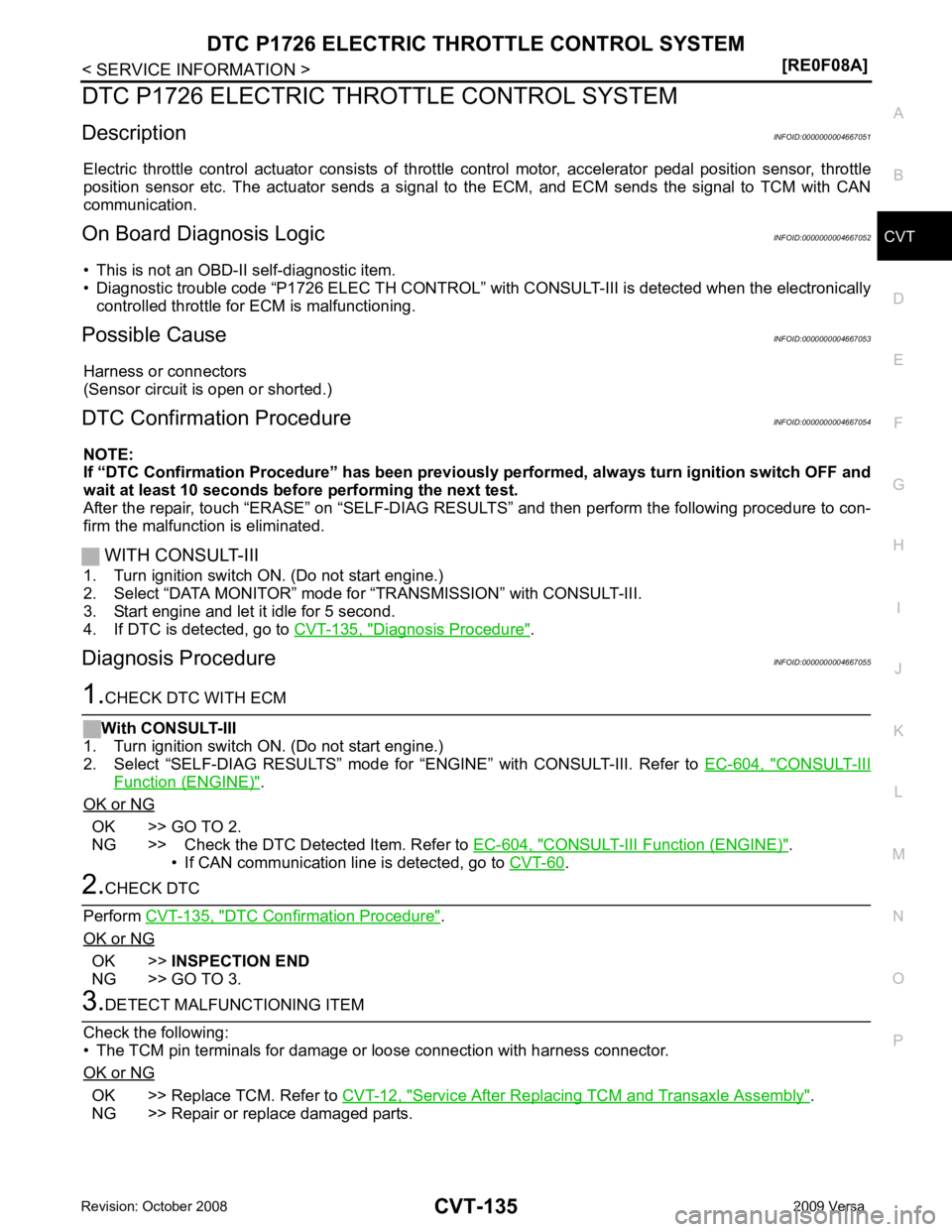

DTC P1726 ELECTRIC TH

ROTTLE CONTROL SYSTEM

Description INFOID:0000000004667051

Electric throttle control actuator consists of throttle control motor, accelerator pedal position sensor, throttle

position sensor etc. The actuator sends a signal to the ECM, and ECM sends the signal to TCM with CAN

communication.

On Board Diagnosis Logic INFOID:0000000004667052

• This is not an OBD-II self-diagnostic item.

• Diagnostic trouble code “P1726 ELEC TH CONTROL” wit h CONSULT-III is detected when the electronically

controlled throttle for ECM is malfunctioning.

Possible Cause INFOID:0000000004667053

Harness or connectors

(Sensor circuit is open or shorted.)

DTC Confirmation Procedure INFOID:0000000004667054

NOTE:

If “DTC Confirmation Procedure” has been previously performed, alw ays turn ignition switch OFF and

wait at least 10 seconds before performing the next test.

After the repair, touch “ERASE” on “SELF-DIAG RESU LTS” and then perform the following procedure to con-

firm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Select “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

3. Start engine and let it idle for 5 second.

4. If DTC is detected, go to CVT-135, " Diagnosis Procedure " .

Diagnosis Procedure INFOID:0000000004667055 CONSULT-III

Function (ENGINE) " .

OK or NG OK >> GO TO 2.

NG >> Check the DTC Detected Item. Refer to EC-604, " CONSULT-III F

unction (ENGINE) " .

• If CAN communication line is detected, go to CVT-60 .

DTC Confirmation Procedure " .

OK or NG OK >>

INSPECTION END

NG >> GO TO 3. OK >> Replace TCM. Refer to

CVT-12, " Service After Replacing TCM and Transaxle Assembly " .

NG >> Repair or replace damaged parts.

Page 1084 of 4331

Diagnosis Procedure " .

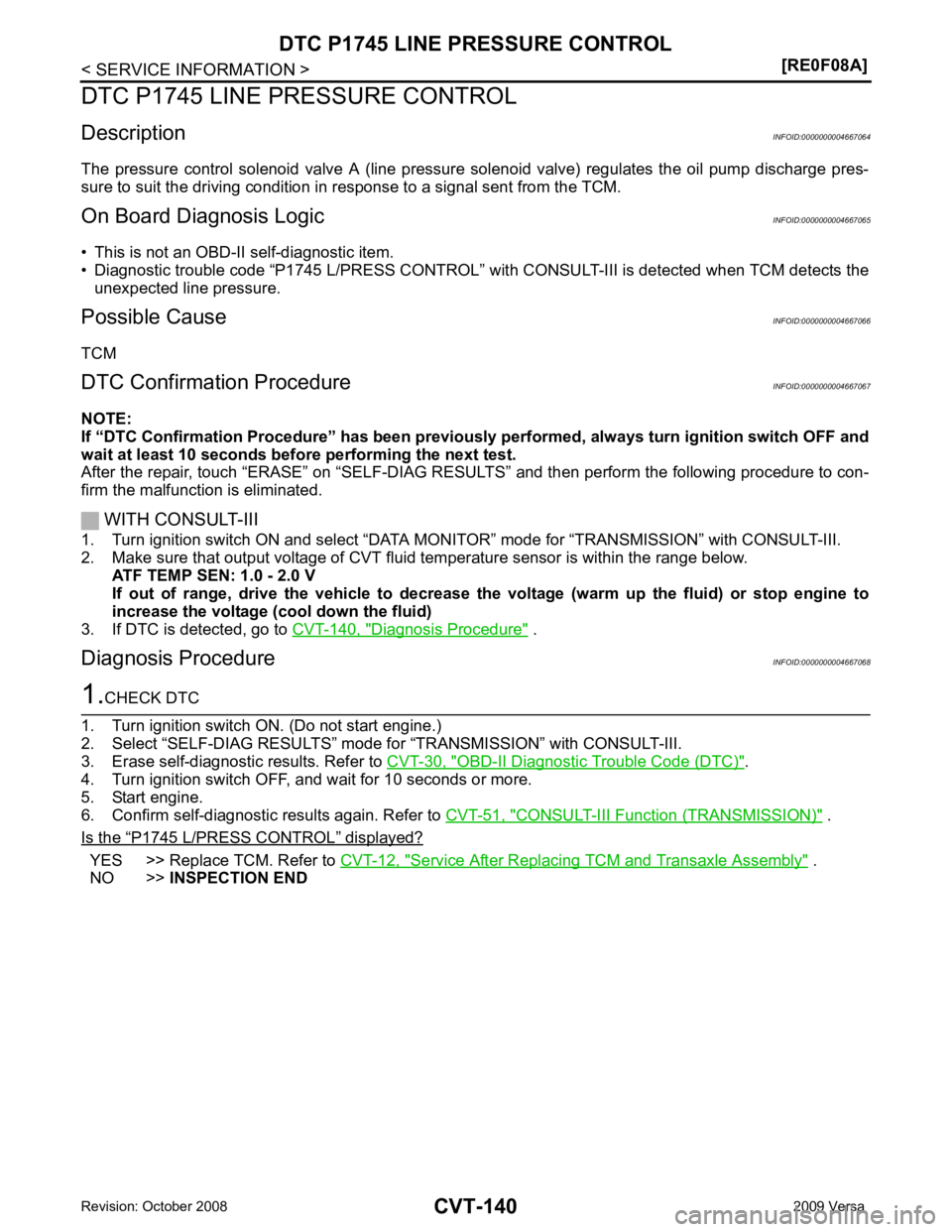

Diagnosis Procedure INFOID:0000000004667068OBD-II Diagnostic Trouble Code (DTC) " .

4. Turn ignition switch OFF, and wait for 10 seconds or more.

5. Start engine.

6. Confirm self-diagnostic results again. Refer to CVT-51, " CONSULT-III Function (TRANSMISSION) " .

Is the “ P1745 L/PRESS CONTROL ” displayed?

YES >> Replace TCM. Refer to

CVT-12, " Service After Replacing TCM and Transaxle Assembly " .

NO >> INSPECTION END

Page 1089 of 4331

CVT

N

O P

DTC P1778 STEP MOTOR - FUNCTION

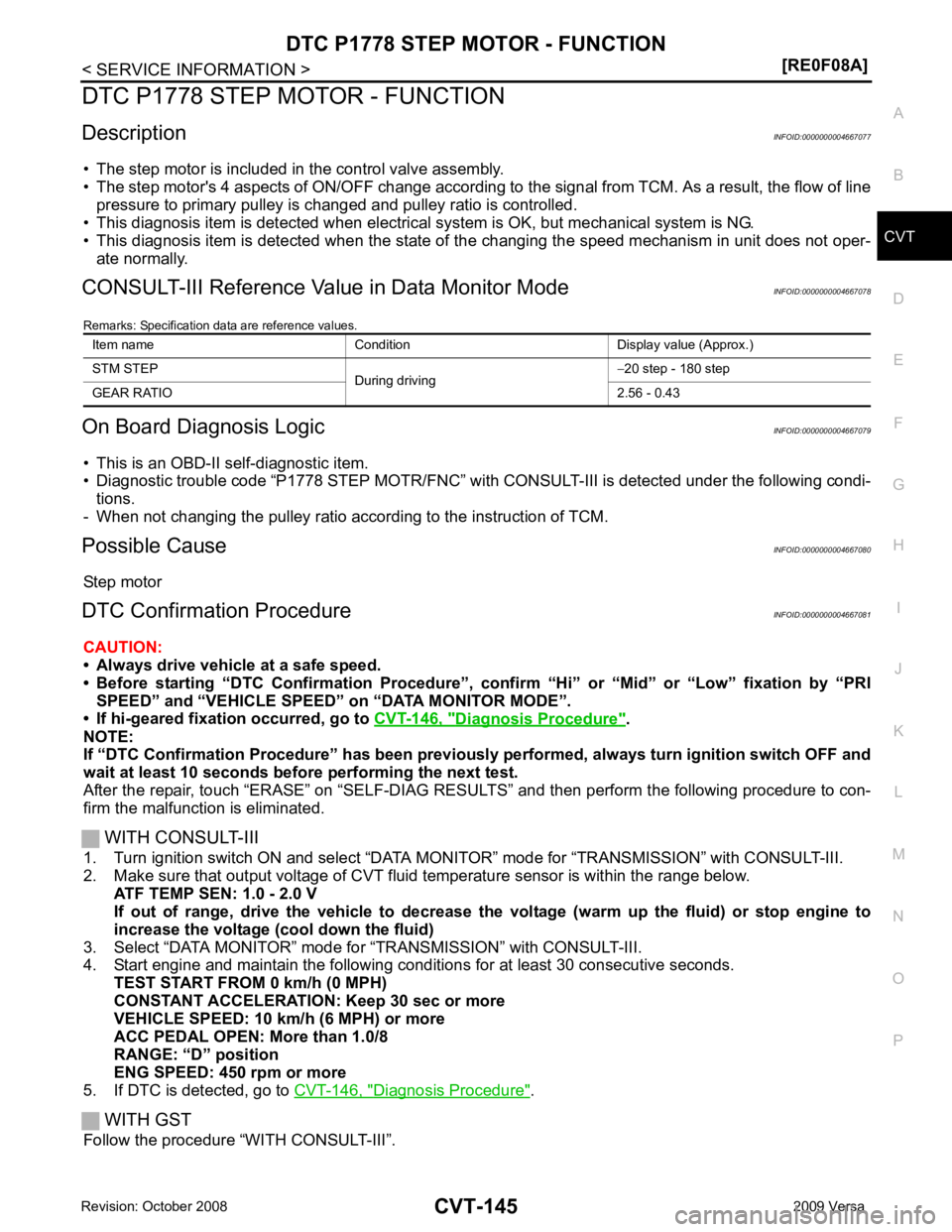

Description INFOID:0000000004667077

• The step motor is included in the control valve assembly.

• The step motor's 4 aspects of ON/OFF change according to the signal from TCM. As a result, the flow of line

pressure to primary pulley is changed and pulley ratio is controlled.

• This diagnosis item is detected when electrical system is OK, but mechanical system is NG.

• This diagnosis item is detected when the state of the changing the speed mechanism in unit does not oper-

ate normally.

CONSULT-III Reference Val ue in Data Monitor Mode INFOID:0000000004667078

Remarks: Specification data are reference values.

On Board Diagnosis Logic INFOID:0000000004667079

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P1778 STEP MOTR/FNC” with CO NSULT-III is detected under the following condi-

tions.

- When not changing the pulley ratio according to the instruction of TCM.

Possible Cause INFOID:0000000004667080

Step motor

DTC Confirmation Procedure INFOID:0000000004667081

CAUTION:

• Always drive vehicle at a safe speed.

• Before starting “DTC Confirmation Procedure”, confirm “Hi” or “Mid” or “Low” fixation by “PRI SPEED” and “VEHICLE SPEED” on “DATA MONITOR MODE”.

• If hi-geared fixation occurred, go to CVT-146, " Diagnosis Procedure " .

NOTE:

If “DTC Confirmation Procedure” has been previously performed, alw ays turn ignition switch OFF and

wait at least 10 seconds before performing the next test.

After the repair, touch “ERASE” on “SELF-DIAG RESU LTS” and then perform the following procedure to con-

firm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON and select “DATA MO NITOR” mode for “TRANSMISSION” with CONSULT-III.

2. Make sure that output voltage of CVT fluid temperature sensor is within the range below.

ATF TEMP SEN: 1.0 - 2.0 V

If out of range, drive the vehicle to decrease the voltage (warm up the fluid) or stop engine to

increase the voltage (c ool down the fluid)

3. Select “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

4. Start engine and maintain the following conditions for at least 30 consecutive seconds.

TEST START FROM 0 km/h (0 MPH)

CONSTANT ACCELERATION: Keep 30 sec or more

VEHICLE SPEED: 10 km/h (6 MPH) or more

ACC PEDAL OPEN: More than 1.0/8

RANGE: “D” position

ENG SPEED: 450 rpm or more

5. If DTC is detected, go to CVT-146, " Diagnosis Procedure " .

WITH GST

Follow the procedure “WITH CONSULT-III”. Item name Condition Display value (Approx.)

STM STEP During driving−

20 step - 180 step

GEAR RATIO 2.56 - 0.43

Page 1119 of 4331

![NISSAN TIIDA 2009 Service Manual Online SHIFT CONTROL SYSTEM

CVT-175

< SERVICE INFORMATION >

[RE0F08A] D

E

F

G H

I

J

K L

M A

B CVT

N

O P

1. Set selector lever knob (1) in “N” position.

2. Slide knob cover (2) downward.

3. Pull out lock NISSAN TIIDA 2009 Service Manual Online SHIFT CONTROL SYSTEM

CVT-175

< SERVICE INFORMATION >

[RE0F08A] D

E

F

G H

I

J

K L

M A

B CVT

N

O P

1. Set selector lever knob (1) in “N” position.

2. Slide knob cover (2) downward.

3. Pull out lock](/img/5/57398/w960_57398-1118.png)

SHIFT CONTROL SYSTEM

CVT-175

< SERVICE INFORMATION >

[RE0F08A] D

E

F

G H

I

J

K L

M A

B CVT

N

O P

1. Set selector lever knob (1) in “N” position.

2. Slide knob cover (2) downward.

3. Pull out lock pin (3) from selector lever knob (1).

4. Remove selector lever knob (1) and knob cover (2) as a set from selector lever.

CAUTION:

Do not push selector button.

INSTALLATION 1. Insert lock pin (1) to selector lever knob (2).

2. Install knob cover (3) to selector lever knob (2).

3. Set selector lever in “N” position.

4. Install selector lever knob onto selector lever until a click is felt. CAUTION:

• Do not tilt selector lever knob when installing. Install it

straight, and do not tap or ap ply any shock to install it.

• Do not push selector button.

Adjustment of CVT Position INFOID:0000000004667111

CAUTION:

Make sure that parking brake is applied before adjustment.

1. Loosen the control cable nut (A) and place the manual lever (1) in “P” position.

2. Place selector lever in “P” position.

3. Push the control cable (2) in with a load of 9.8 N (approximately 1 kg, 2.2 lb). Release the control cable and temporarily tighten

the control cable nut.

NOTE:

Do not move the manual lever. Make sure the manual lever

stays in the “P” position.

4. Tighten the control cable nut. CAUTION:

Secure the manual lever when tightening nut.

5. Check the operation of the CVT. Refer to CVT-175, " Checking of CVT Position " .

Checking of CVT Position INFOID:0000000004667112

1. Place selector lever in “P” position, and tu rn ignition switch ON. (Do not start engine.)

2. Make sure selector lever can be shifted to other than “P” position when brake pedal is depressed. Also

make sure selector lever can be shifted from “P” position only when brake pedal is depressed.

3. Move the selector lever and check for excessive effort, sticking, noise or rattle.

4. Confirm the selector lever stops at each position with the feel of engagement when it is moved through all

the positions. Check that t he actual position of the selector lever matches the position shown by the shift

position indicator and the manual lever on the transaxle. SCIA6971E

SCIA6972E

Control cable nut: Refer to

CVT-171, " Removal

and Installation " . WCIA0608E

Page 1131 of 4331

CVT

N

O P

SERVICE INFORMATION

INDEX FOR DTC

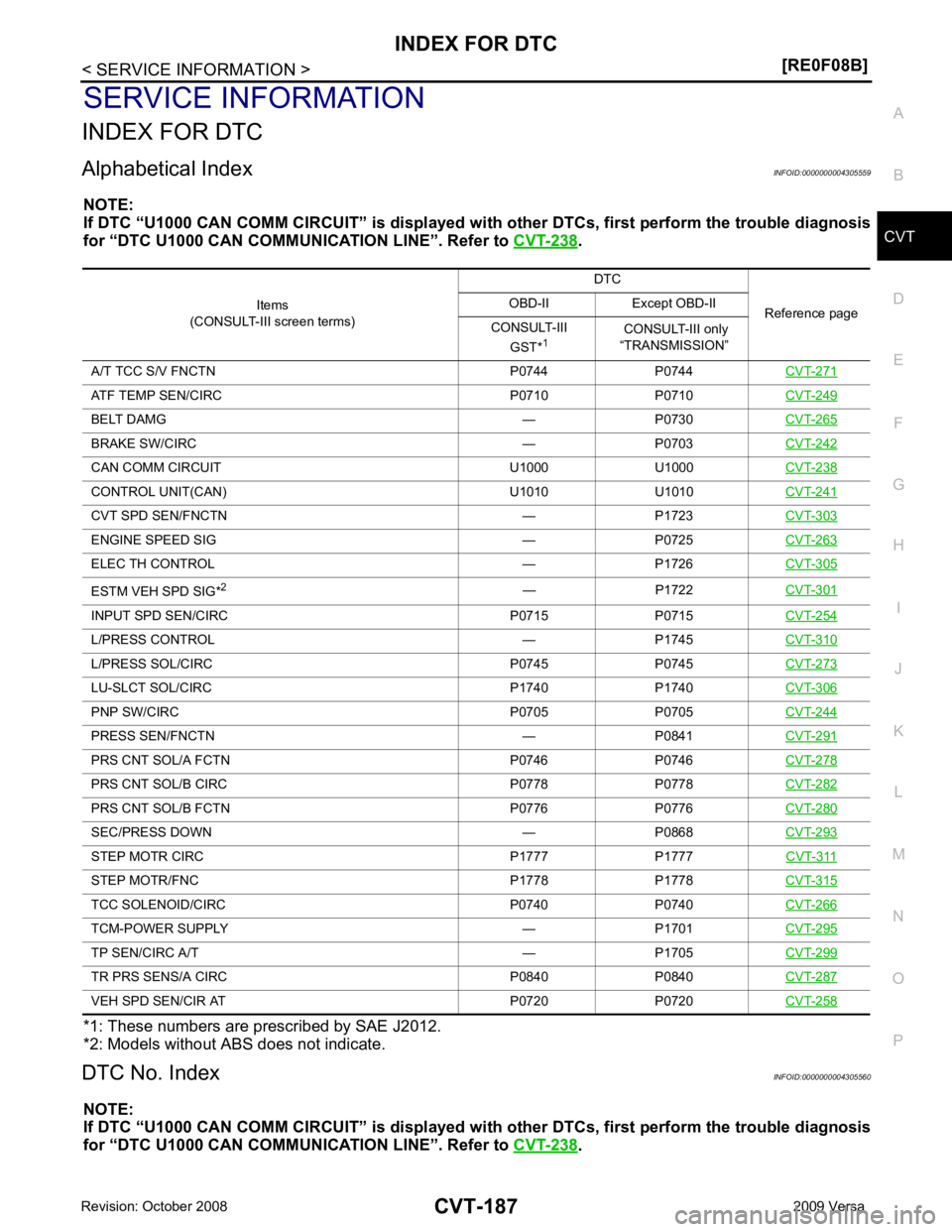

Alphabetical Index INFOID:0000000004305559

NOTE:

If DTC “U1000 CAN COMM CIRCUIT” is displayed with other DTCs, first perform the trouble diagnosis

for “DTC U1000 CAN COMMUNICATION LINE”. Refer to CVT-238 .

*1: These numbers are prescribed by SAE J2012.

*2: Models without ABS does not indicate.

DTC No. Index INFOID:0000000004305560

NOTE:

If DTC “U1000 CAN COMM CIRCUIT” is displayed with other DTCs, first perform the trouble diagnosis

for “DTC U1000 CAN COMMUNICATION LINE”. Refer to CVT-238 .

Items

(CONSULT-III screen terms) DTC

Reference page

OBD-II Except OBD-II

CONSULT-III GST* 1 CONSULT-III only

“TRANSMISSION”

A/T TCC S/V FNCTN P0744 P0744 CVT-271ATF TEMP SEN/CIRC P0710 P0710

CVT-249BELT DAMG — P0730

CVT-265BRAKE SW/CIRC — P0703

CVT-242CAN COMM CIRCU

IT U1000 U1000 CVT-238CONTROL UNIT(CAN) U1010 U1010

CVT-241CVT SPD SEN/FNCTN — P1723

CVT-303ENGINE SPEED SIG — P0725

CVT-263ELEC TH CONTROL — P1726

CVT-305ESTM VEH SPD SIG*

2

— P1722CVT-301INPUT SPD SEN/CIRC P0715 P0715

CVT-254L/PRESS CONTROL — P1745

CVT-310L/PRESS SOL/CIRC P0745 P0745

CVT-273LU-SLCT SOL/CIRC P1740 P1740

CVT-306PNP SW/CIRC P0705 P0705

CVT-244PRESS SEN/FNCTN — P0841

CVT-291PRS CNT SOL/A FCTN P0746 P0746

CVT-278PRS CNT SOL/B CIRC P0778 P0778

CVT-282PRS CNT SOL/B FCTN P0776 P0776

CVT-280SEC/PRESS DOWN — P0868

CVT-293STEP MOTR CIRC P1777 P1777

CVT-311STEP MOTR/FNC P1778 P1778

CVT-315TCC SOLENOID/CIRC P0740 P0740

CVT-266TCM-POWER SUPPLY — P1701

CVT-295TP SEN/CIRC A/T — P1705

CVT-299TR PRS SENS/A CIRC P0840 P0840

CVT-287VEH SPD SEN/CIR AT P0720 P0720

CVT-258

Page 1132 of 4331

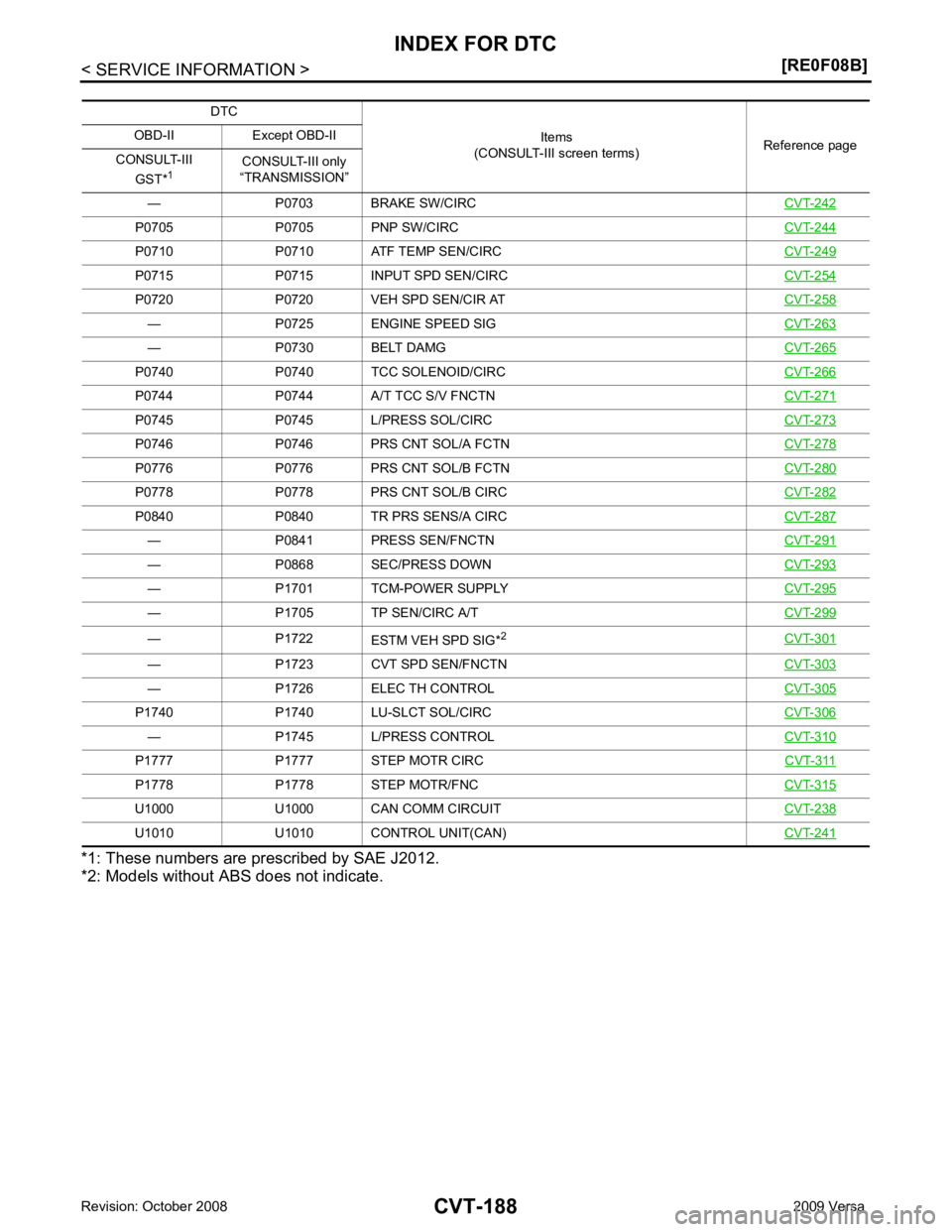

P0705 P0705 PNP SW/CIRC

CVT-244P0710 P0710 ATF TEMP SEN/CIRC

CVT-249P0715 P0715 INPUT SPD SEN/CIRC

CVT-254P0720 P0720 VEH SPD SEN/CIR AT

CVT-258— P0725 ENGINE SPEED SIG

CVT-263— P0730 BELT DAMG

CVT-265P0740 P0740 TCC SOLENOID/CIRC

CVT-266P0744 P0744 A/T TCC S/V FNCTN

CVT-271P0745 P0745 L/PRESS SOL/CIRC

CVT-273P0746 P0746 PRS CNT SOL/A FCTN

CVT-278P0776 P0776 PRS CNT SOL/B FCTN

CVT-280P0778 P0778 PRS CNT SOL/B CIRC

CVT-282P0840 P0840 TR PRS SENS/A CIRC

CVT-287— P0841 PRESS SEN/FNCTN

CVT-291— P0868 SEC/PRESS DOWN

CVT-293— P1701 TCM-POWER SUPPLY

CVT-295— P1705 TP SEN/CIRC A/T

CVT-299— P1722

ESTM VEH SPD SIG*2

CVT-301— P1723 CVT SPD SEN/FNCTN

CVT-303— P1726 ELEC TH CONTROL

CVT-305P1740 P1740 LU-SLCT SOL/CIRC

CVT-306— P1745 L/PRESS CONTROL

CVT-310P1777 P1777 STEP MOTR CIRC

CVT-311P1778 P1778 STEP MOTR/FNC

CVT-315U1000 U1000 CAN COMM CIRCUIT

CVT-238U1010 U1010 CONTROL UNIT(CAN)

CVT-241

Page 1133 of 4331

CVT

N

O P

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER" INFOID:0000000004800720

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wh eel Rotation After Battery Disconnect

INFOID:0000000004305562

NOTE:

• This Procedure is applied only to models with Intell igent Key system and NVIS/IVIS (NISSAN/INFINITI

VEHICLE IMMOBILIZER SYSTEM - NATS).

• Remove and install all control units after disconnecti ng both battery cables with the ignition knob in the

″ LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NVIS/IVIS, an electrically controlled steering lock

mechanism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE 1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.