NISSAN X-TRAIL 2001 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2001Pages: 3833, PDF Size: 39.49 MB

Page 2011 of 3833

TRANSAXLE ASSEMBLY

MT-35

D

E

F

G

H

I

J

K

L

MA

B

MT

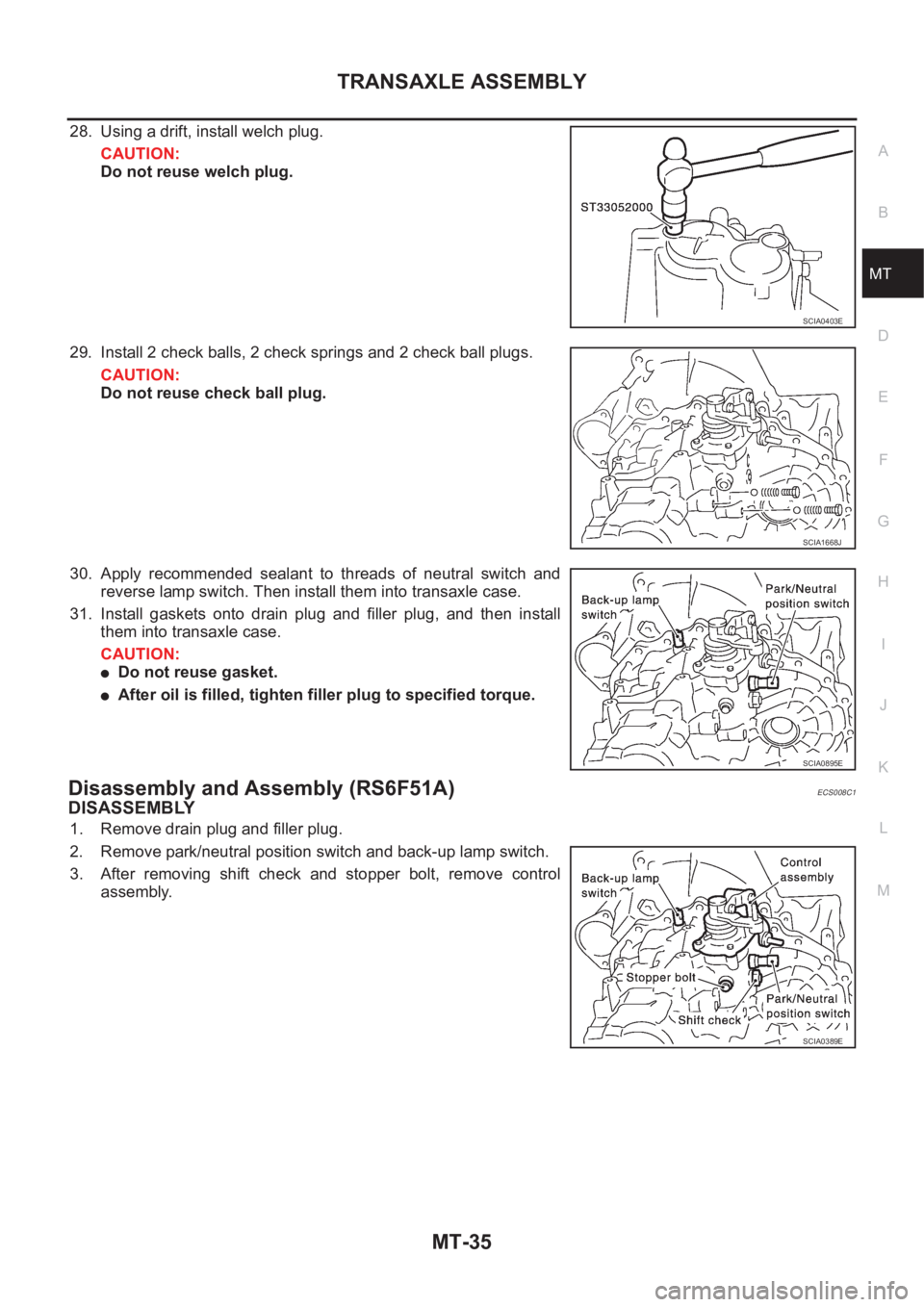

28. Using a drift, install welch plug.

CAUTION:

Do not reuse welch plug.

29. Install 2 check balls, 2 check springs and 2 check ball plugs.

CAUTION:

Do not reuse check ball plug.

30. Apply recommended sealant to threads of neutral switch and

reverse lamp switch. Then install them into transaxle case.

31. Install gaskets onto drain plug and filler plug, and then install

them into transaxle case.

CAUTION:

●Do not reuse gasket.

●After oil is filled, tighten filler plug to specified torque.

Disassembly and Assembly (RS6F51A)ECS008C1

DISASSEMBLY

1. Remove drain plug and filler plug.

2. Remove park/neutral position switch and back-up lamp switch.

3. After removing shift check and stopper bolt, remove control

assembly.

SCIA0403E

SCIA1668J

SCIA0895E

SCIA0389E

Page 2012 of 3833

MT-36

TRANSAXLE ASSEMBLY

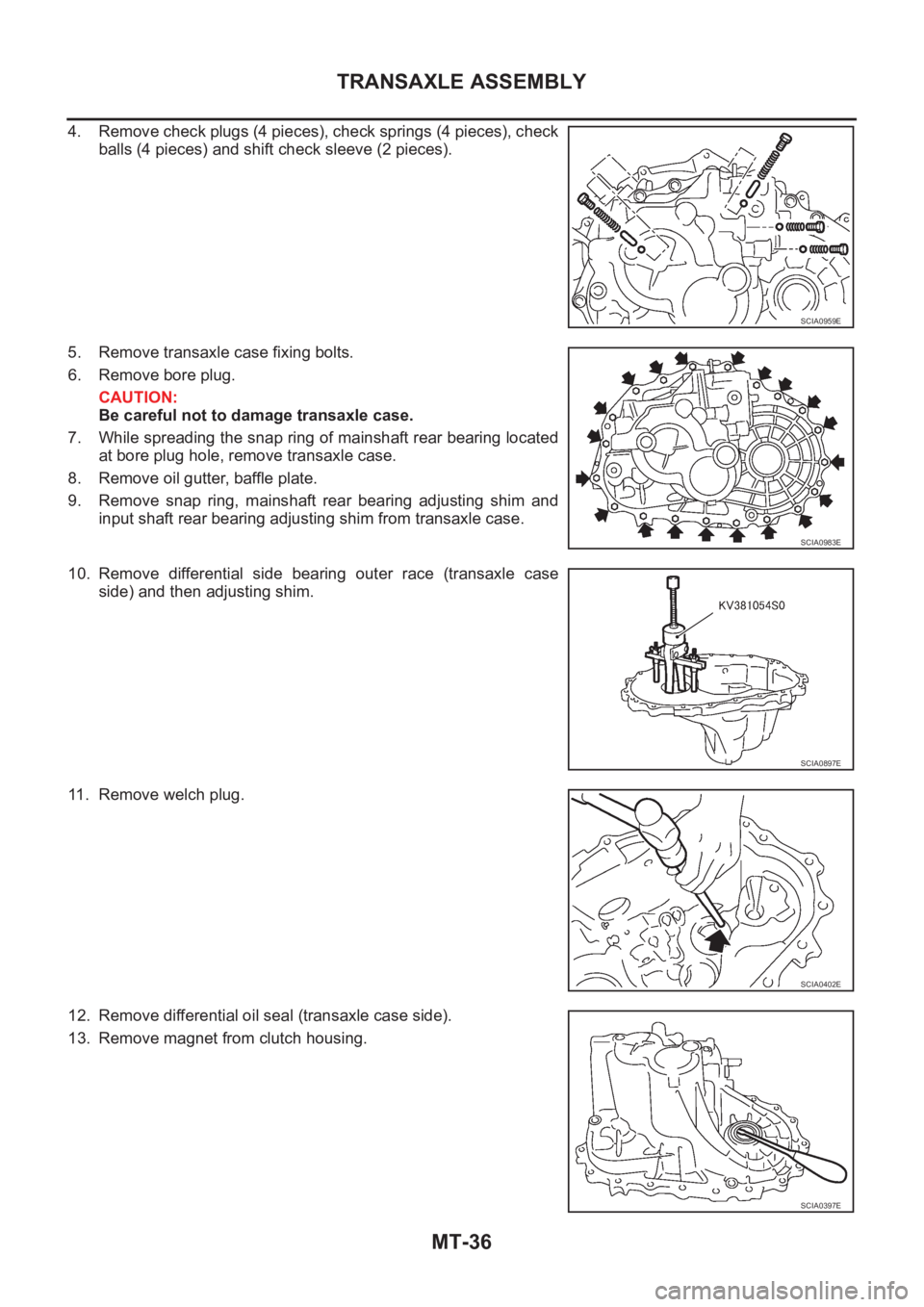

4. Remove check plugs (4 pieces), check springs (4 pieces), check

balls (4 pieces) and shift check sleeve (2 pieces).

5. Remove transaxle case fixing bolts.

6. Remove bore plug.

CAUTION:

Be careful not to damage transaxle case.

7. While spreading the snap ring of mainshaft rear bearing located

at bore plug hole, remove transaxle case.

8. Remove oil gutter, baffle plate.

9. Remove snap ring, mainshaft rear bearing adjusting shim and

input shaft rear bearing adjusting shim from transaxle case.

10. Remove differential side bearing outer race (transaxle case

side) and then adjusting shim.

11. Remove welch plug.

12. Remove differential oil seal (transaxle case side).

13. Remove magnet from clutch housing.

SCIA0959E

SCIA0983E

SCIA0897E

SCIA0402E

SCIA0397E

Page 2013 of 3833

TRANSAXLE ASSEMBLY

MT-37

D

E

F

G

H

I

J

K

L

MA

B

MT

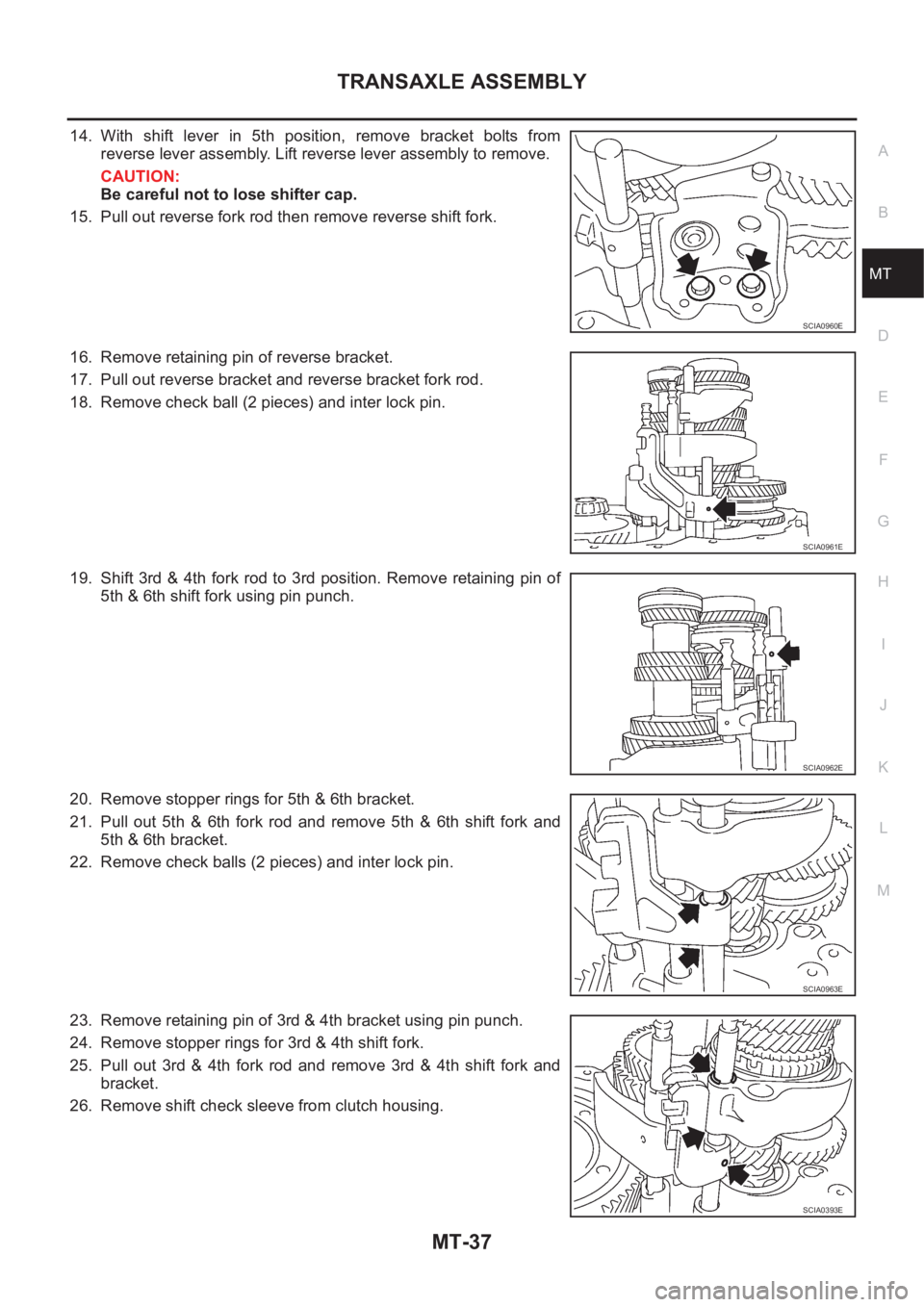

14. With shift lever in 5th position, remove bracket bolts from

reverse lever assembly. Lift reverse lever assembly to remove.

CAUTION:

Be careful not to lose shifter cap.

15. Pull out reverse fork rod then remove reverse shift fork.

16. Remove retaining pin of reverse bracket.

17. Pull out reverse bracket and reverse bracket fork rod.

18. Remove check ball (2 pieces) and inter lock pin.

19. Shift 3rd & 4th fork rod to 3rd position. Remove retaining pin of

5th & 6th shift fork using pin punch.

20. Remove stopper rings for 5th & 6th bracket.

21. Pull out 5th & 6th fork rod and remove 5th & 6th shift fork and

5th & 6th bracket.

22. Remove check balls (2 pieces) and inter lock pin.

23. Remove retaining pin of 3rd & 4th bracket using pin punch.

24. Remove stopper rings for 3rd & 4th shift fork.

25. Pull out 3rd & 4th fork rod and remove 3rd & 4th shift fork and

bracket.

26. Remove shift check sleeve from clutch housing.

SCIA0960E

SCIA0961E

SCIA0962E

SCIA0963E

SCIA0393E

Page 2014 of 3833

MT-38

TRANSAXLE ASSEMBLY

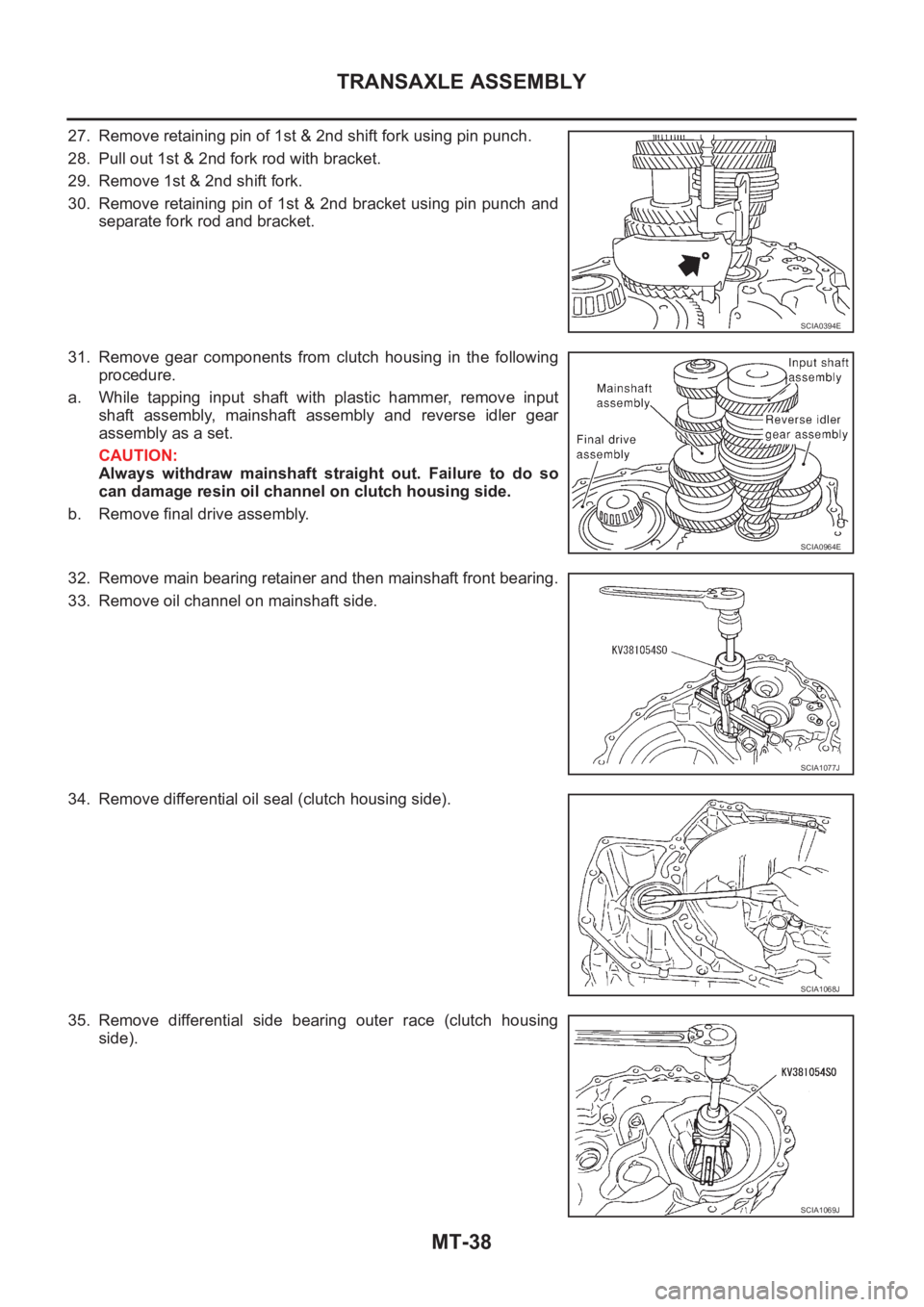

27. Remove retaining pin of 1st & 2nd shift fork using pin punch.

28. Pull out 1st & 2nd fork rod with bracket.

29. Remove 1st & 2nd shift fork.

30. Remove retaining pin of 1st & 2nd bracket using pin punch and

separate fork rod and bracket.

31. Remove gear components from clutch housing in the following

procedure.

a. While tapping input shaft with plastic hammer, remove input

shaft assembly, mainshaft assembly and reverse idler gear

assembly as a set.

CAUTION:

Always withdraw mainshaft straight out. Failure to do so

can damage resin oil channel on clutch housing side.

b. Remove final drive assembly.

32. Remove main bearing retainer and then mainshaft front bearing.

33. Remove oil channel on mainshaft side.

34. Remove differential oil seal (clutch housing side).

35. Remove differential side bearing outer race (clutch housing

side).

SCIA0394E

SCIA0964E

SCIA1077J

SCIA1068J

SCIA1069J

Page 2015 of 3833

TRANSAXLE ASSEMBLY

MT-39

D

E

F

G

H

I

J

K

L

MA

B

MT

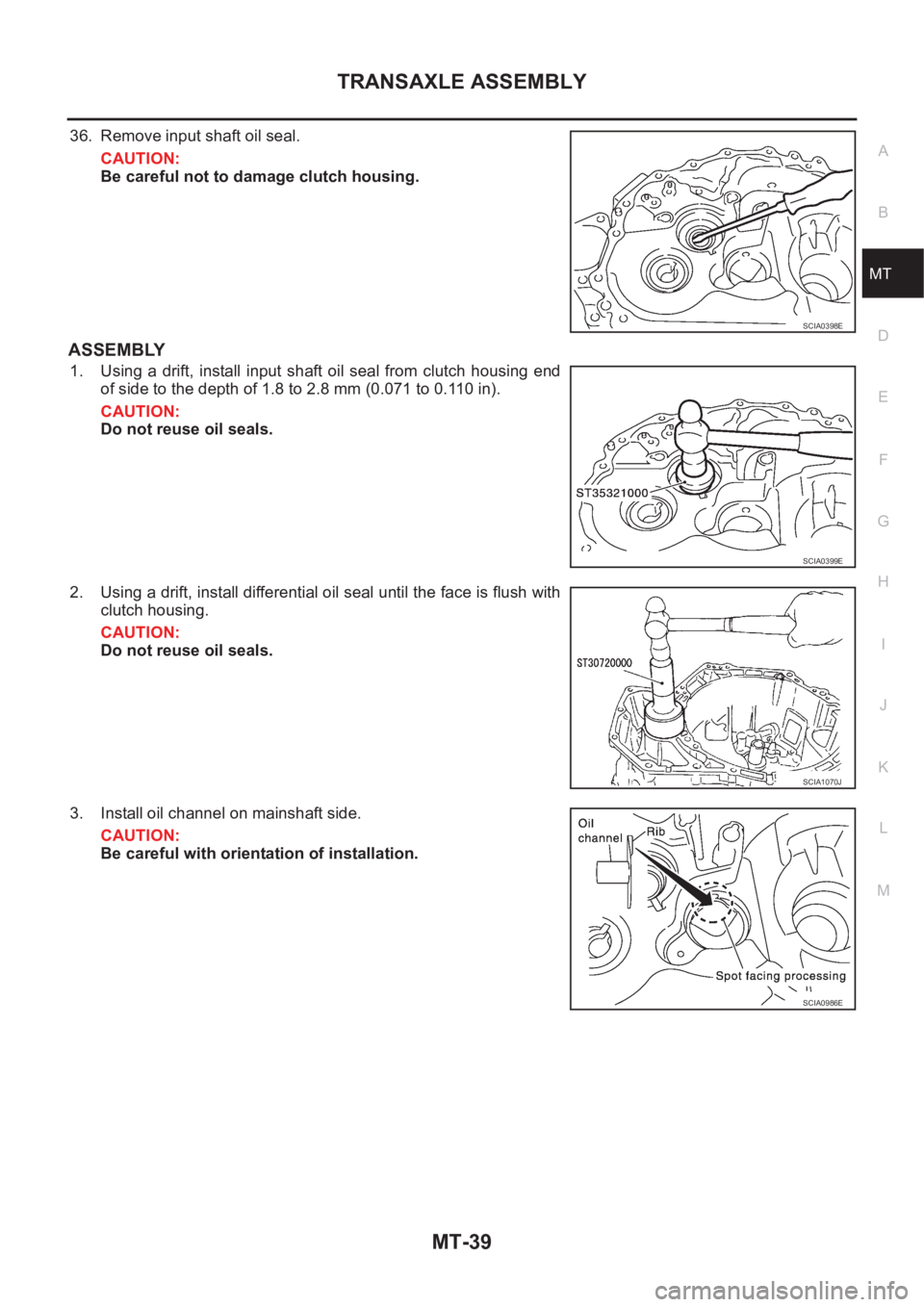

36. Remove input shaft oil seal.

CAUTION:

Be careful not to damage clutch housing.

ASSEMBLY

1. Using a drift, install input shaft oil seal from clutch housing end

of side to the depth of 1.8 to 2.8 mm (0.071 to 0.110 in).

CAUTION:

Do not reuse oil seals.

2. Using a drift, install differential oil seal until the face is flush with

clutch housing.

CAUTION:

Do not reuse oil seals.

3. Install oil channel on mainshaft side.

CAUTION:

Be careful with orientation of installation.

SCIA0398E

SCIA0399E

SCIA1070J

SCIA0986E

Page 2016 of 3833

MT-40

TRANSAXLE ASSEMBLY

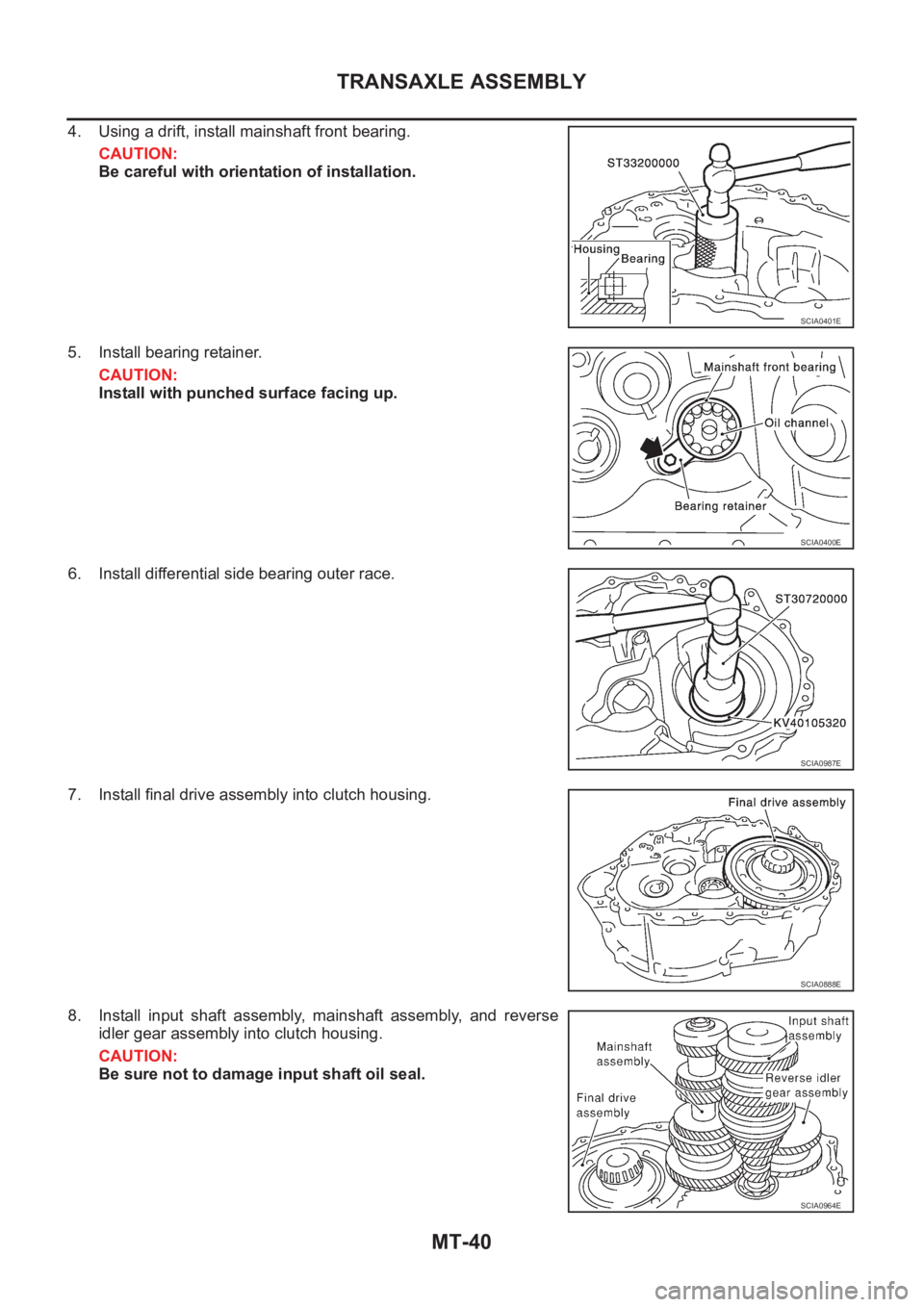

4. Using a drift, install mainshaft front bearing.

CAUTION:

Be careful with orientation of installation.

5. Install bearing retainer.

CAUTION:

Install with punched surface facing up.

6. Install differential side bearing outer race.

7. Install final drive assembly into clutch housing.

8. Install input shaft assembly, mainshaft assembly, and reverse

idler gear assembly into clutch housing.

CAUTION:

Be sure not to damage input shaft oil seal.

SCIA0401E

SCIA0400E

SCIA0987E

SCIA0888E

SCIA0964E

Page 2017 of 3833

TRANSAXLE ASSEMBLY

MT-41

D

E

F

G

H

I

J

K

L

MA

B

MT

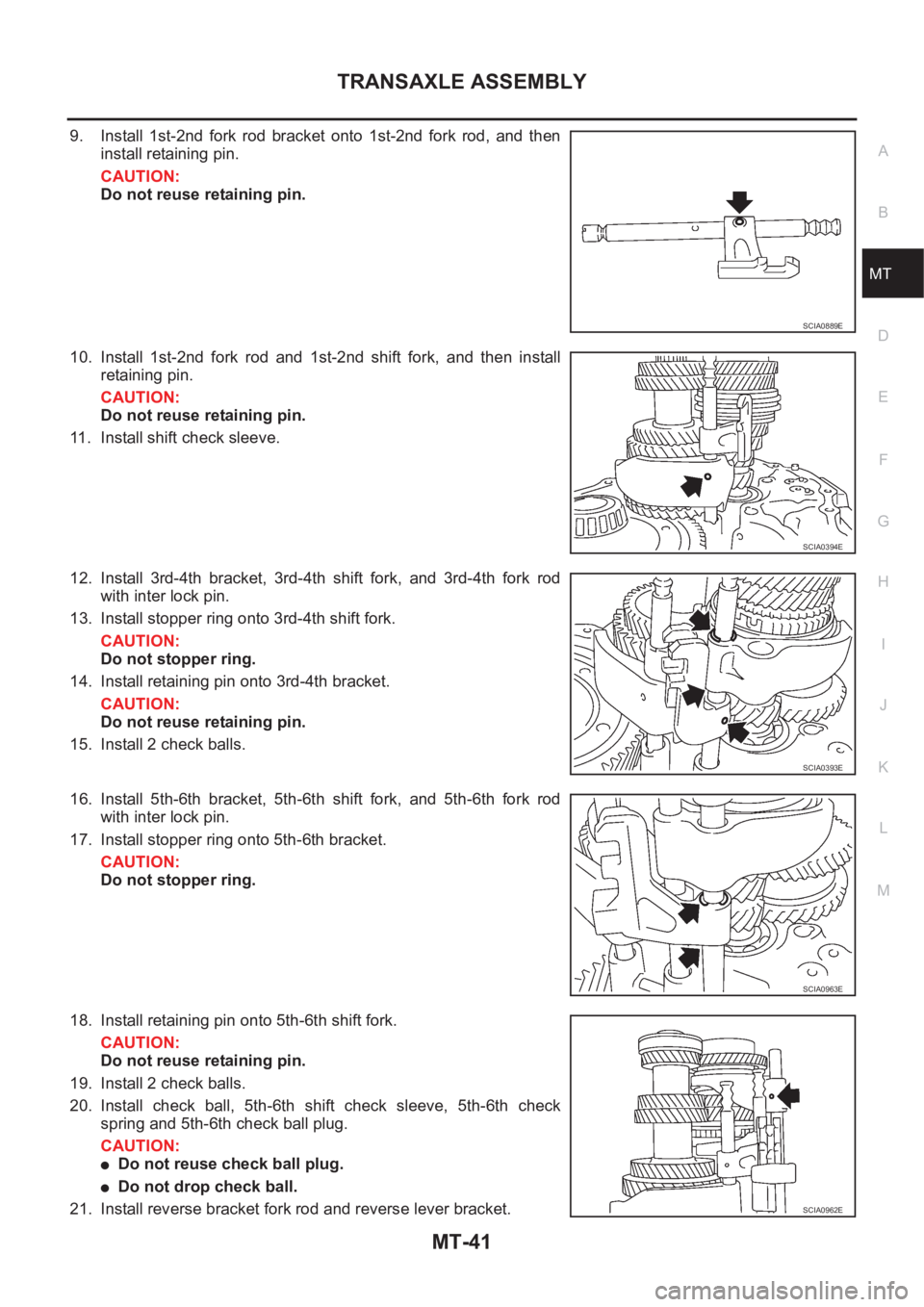

9. Install 1st-2nd fork rod bracket onto 1st-2nd fork rod, and then

install retaining pin.

CAUTION:

Do not reuse retaining pin.

10. Install 1st-2nd fork rod and 1st-2nd shift fork, and then install

retaining pin.

CAUTION:

Do not reuse retaining pin.

11. Install shift check sleeve.

12. Install 3rd-4th bracket, 3rd-4th shift fork, and 3rd-4th fork rod

with inter lock pin.

13. Install stopper ring onto 3rd-4th shift fork.

CAUTION:

Do not stopper ring.

14. Install retaining pin onto 3rd-4th bracket.

CAUTION:

Do not reuse retaining pin.

15. Install 2 check balls.

16. Install 5th-6th bracket, 5th-6th shift fork, and 5th-6th fork rod

with inter lock pin.

17. Install stopper ring onto 5th-6th bracket.

CAUTION:

Do not stopper ring.

18. Install retaining pin onto 5th-6th shift fork.

CAUTION:

Do not reuse retaining pin.

19. Install 2 check balls.

20. Install check ball, 5th-6th shift check sleeve, 5th-6th check

spring and 5th-6th check ball plug.

CAUTION:

●Do not reuse check ball plug.

●Do not drop check ball.

21. Install reverse bracket fork rod and reverse lever bracket.

SCIA0889E

SCIA0394E

SCIA0393E

SCIA0963E

SCIA0962E

Page 2018 of 3833

MT-42

TRANSAXLE ASSEMBLY

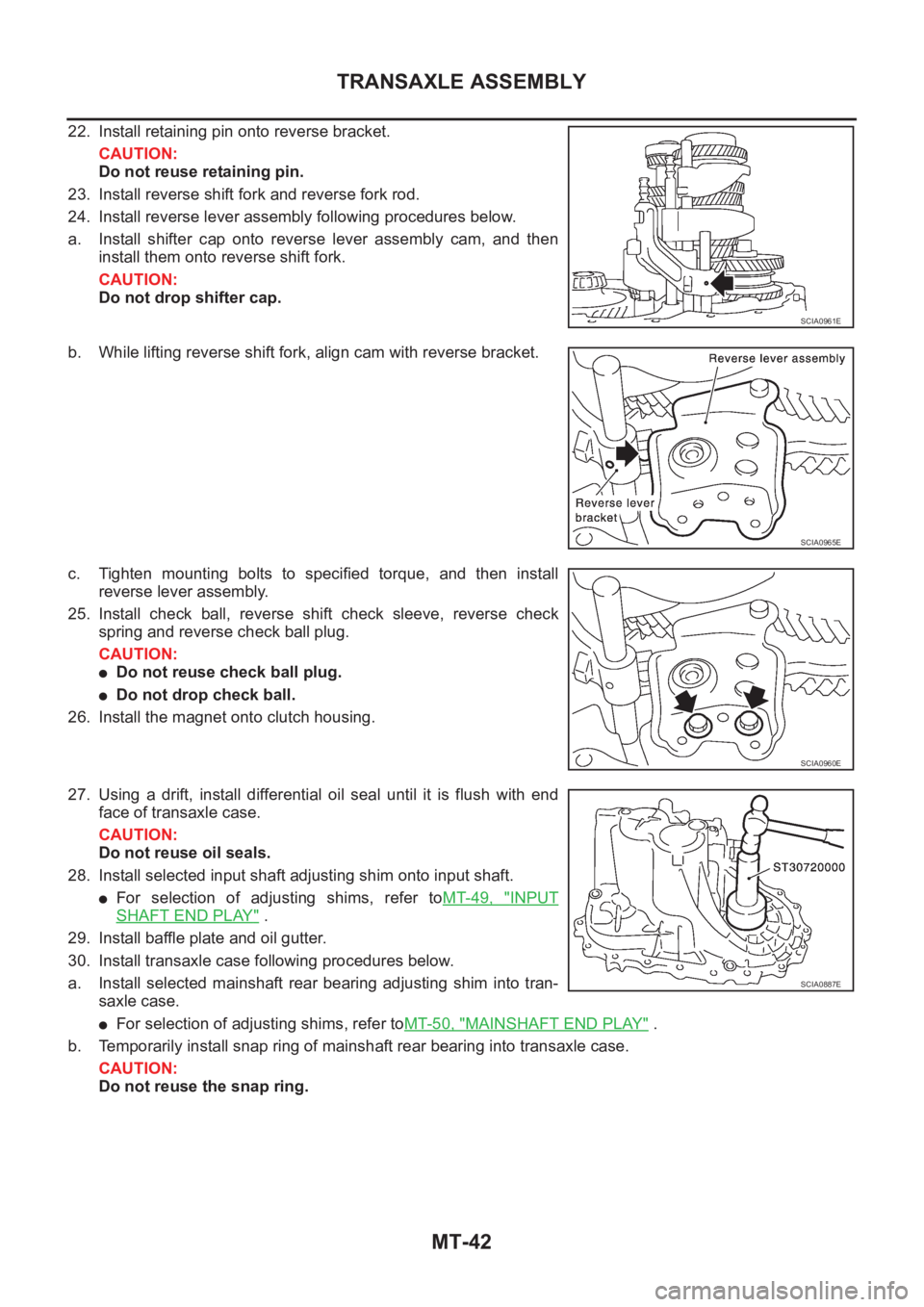

22. Install retaining pin onto reverse bracket.

CAUTION:

Do not reuse retaining pin.

23. Install reverse shift fork and reverse fork rod.

24. Install reverse lever assembly following procedures below.

a. Install shifter cap onto reverse lever assembly cam, and then

install them onto reverse shift fork.

CAUTION:

Do not drop shifter cap.

b. While lifting reverse shift fork, align cam with reverse bracket.

c. Tighten mounting bolts to specified torque, and then install

reverse lever assembly.

25. Install check ball, reverse shift check sleeve, reverse check

spring and reverse check ball plug.

CAUTION:

●Do not reuse check ball plug.

●Do not drop check ball.

26. Install the magnet onto clutch housing.

27. Using a drift, install differential oil seal until it is flush with end

face of transaxle case.

CAUTION:

Do not reuse oil seals.

28. Install selected input shaft adjusting shim onto input shaft.

●For selection of adjusting shims, refer toMT-49, "INPUT

SHAFT END PLAY" .

29. Install baffle plate and oil gutter.

30. Install transaxle case following procedures below.

a. Install selected mainshaft rear bearing adjusting shim into tran-

saxle case.

●For selection of adjusting shims, refer toMT-50, "MAINSHAFT END PLAY" .

b. Temporarily install snap ring of mainshaft rear bearing into transaxle case.

CAUTION:

Do not reuse the snap ring.

SCIA0961E

SCIA0965E

SCIA0960E

SCIA0887E

Page 2019 of 3833

TRANSAXLE ASSEMBLY

MT-43

D

E

F

G

H

I

J

K

L

MA

B

MT

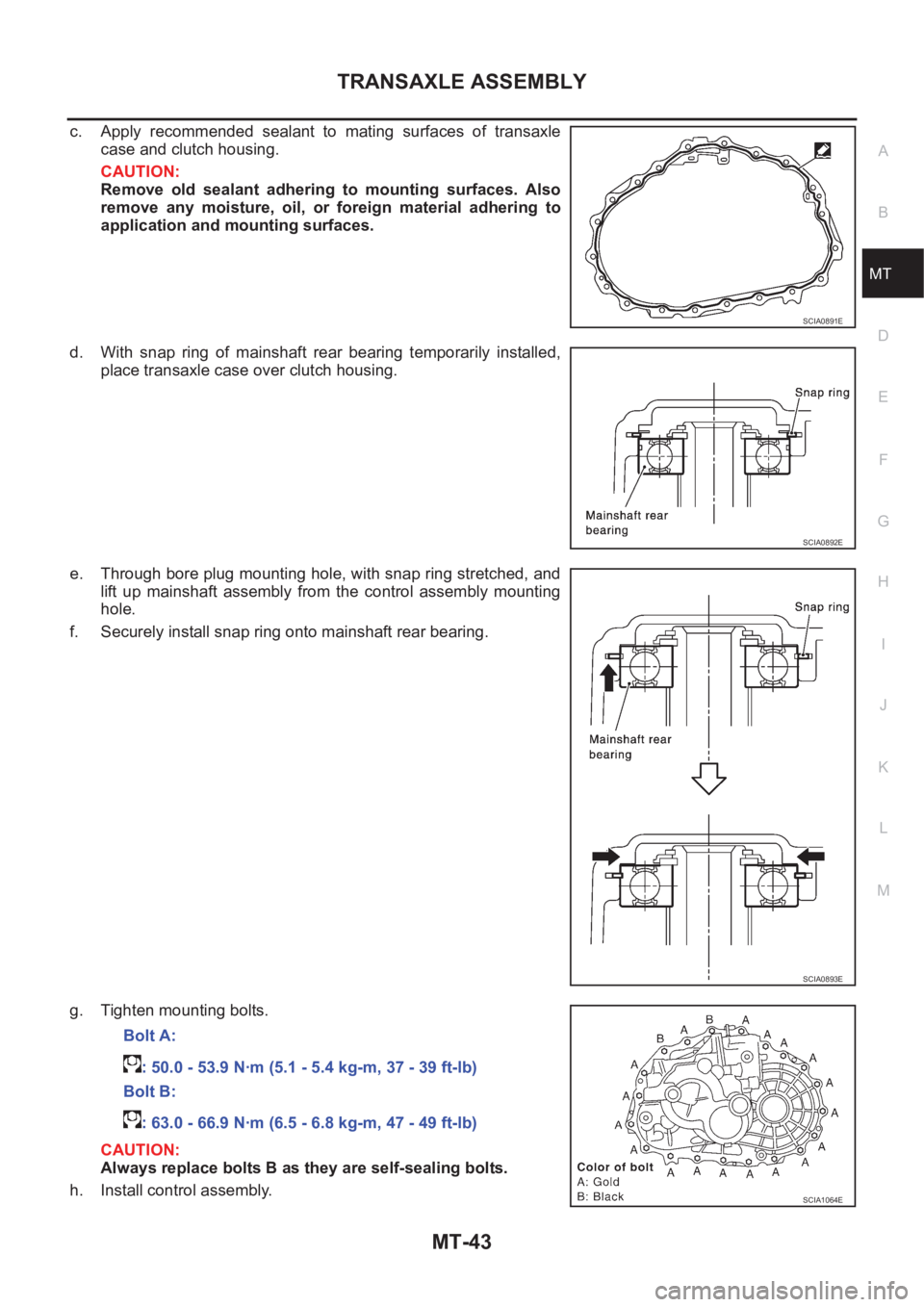

c. Apply recommended sealant to mating surfaces of transaxle

case and clutch housing.

CAUTION:

Remove old sealant adhering to mounting surfaces. Also

remove any moisture, oil, or foreign material adhering to

application and mounting surfaces.

d. With snap ring of mainshaft rear bearing temporarily installed,

place transaxle case over clutch housing.

e. Through bore plug mounting hole, with snap ring stretched, and

lift up mainshaft assembly from the control assembly mounting

hole.

f. Securely install snap ring onto mainshaft rear bearing.

g. Tighten mounting bolts.

CAUTION:

Always replace bolts B as they are self-sealing bolts.

h. Install control assembly.

SCIA0891E

SCIA0892E

SCIA0893E

Bolt A:

: 50.0 - 53.9 N·m (5.1 - 5.4 kg-m, 37 - 39 ft-lb)

Bolt B:

: 63.0 - 66.9 N·m (6.5 - 6.8 kg-m, 47 - 49 ft-lb)

SCIA1064E

Page 2020 of 3833

MT-44

TRANSAXLE ASSEMBLY

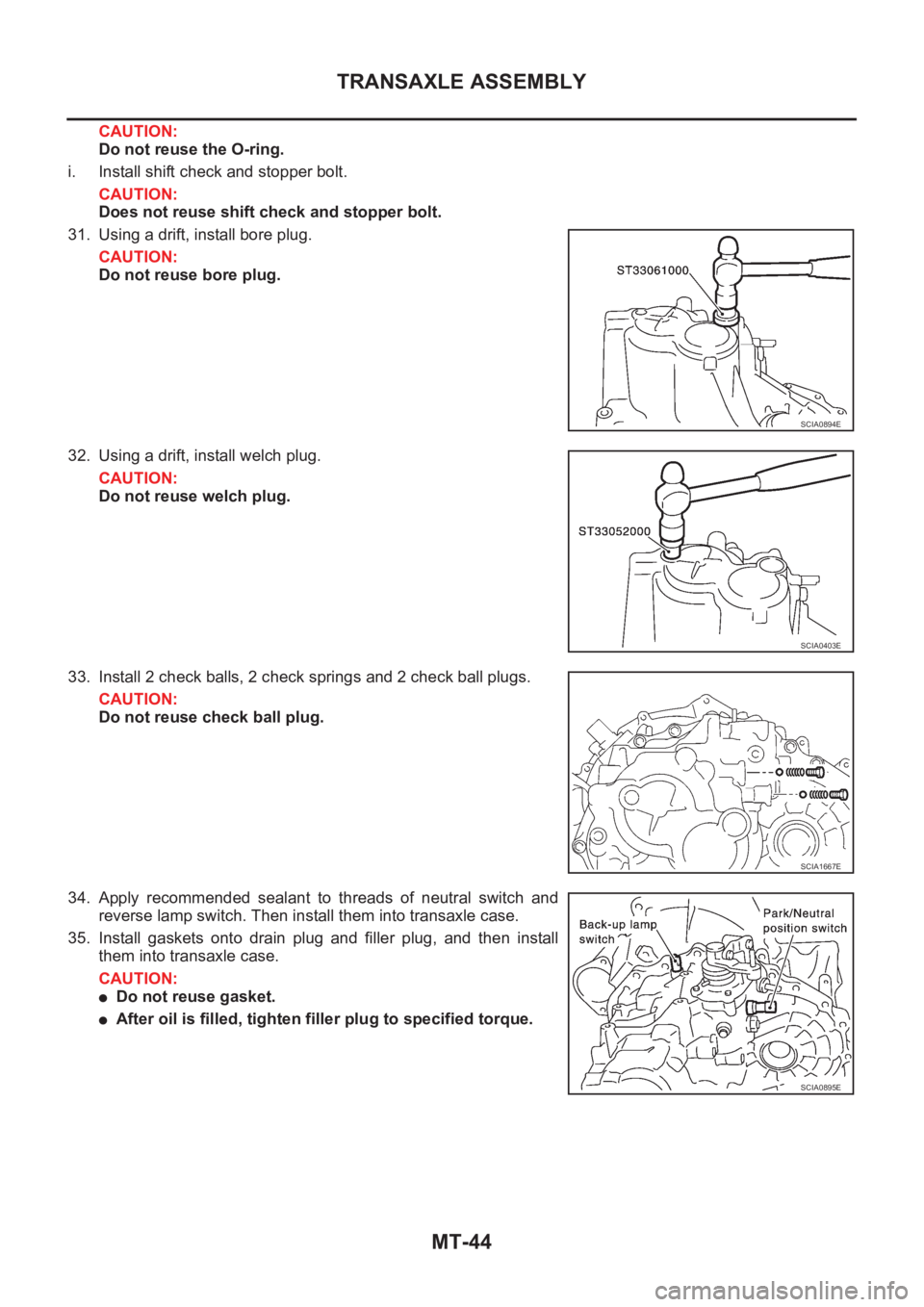

CAUTION:

Do not reuse the O-ring.

i. Install shift check and stopper bolt.

CAUTION:

Does not reuse shift check and stopper bolt.

31. Using a drift, install bore plug.

CAUTION:

Do not reuse bore plug.

32. Using a drift, install welch plug.

CAUTION:

Do not reuse welch plug.

33. Install 2 check balls, 2 check springs and 2 check ball plugs.

CAUTION:

Do not reuse check ball plug.

34. Apply recommended sealant to threads of neutral switch and

reverse lamp switch. Then install them into transaxle case.

35. Install gaskets onto drain plug and filler plug, and then install

them into transaxle case.

CAUTION:

●Do not reuse gasket.

●After oil is filled, tighten filler plug to specified torque.

SCIA0894E

SCIA0403E

SCIA1667E

SCIA0895E