NISSAN X-TRAIL 2001 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2001Pages: 3833, PDF Size: 39.49 MB

Page 2971 of 3833

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

RAX-5

C

E

F

G

H

I

J

K

L

MA

B

RAX

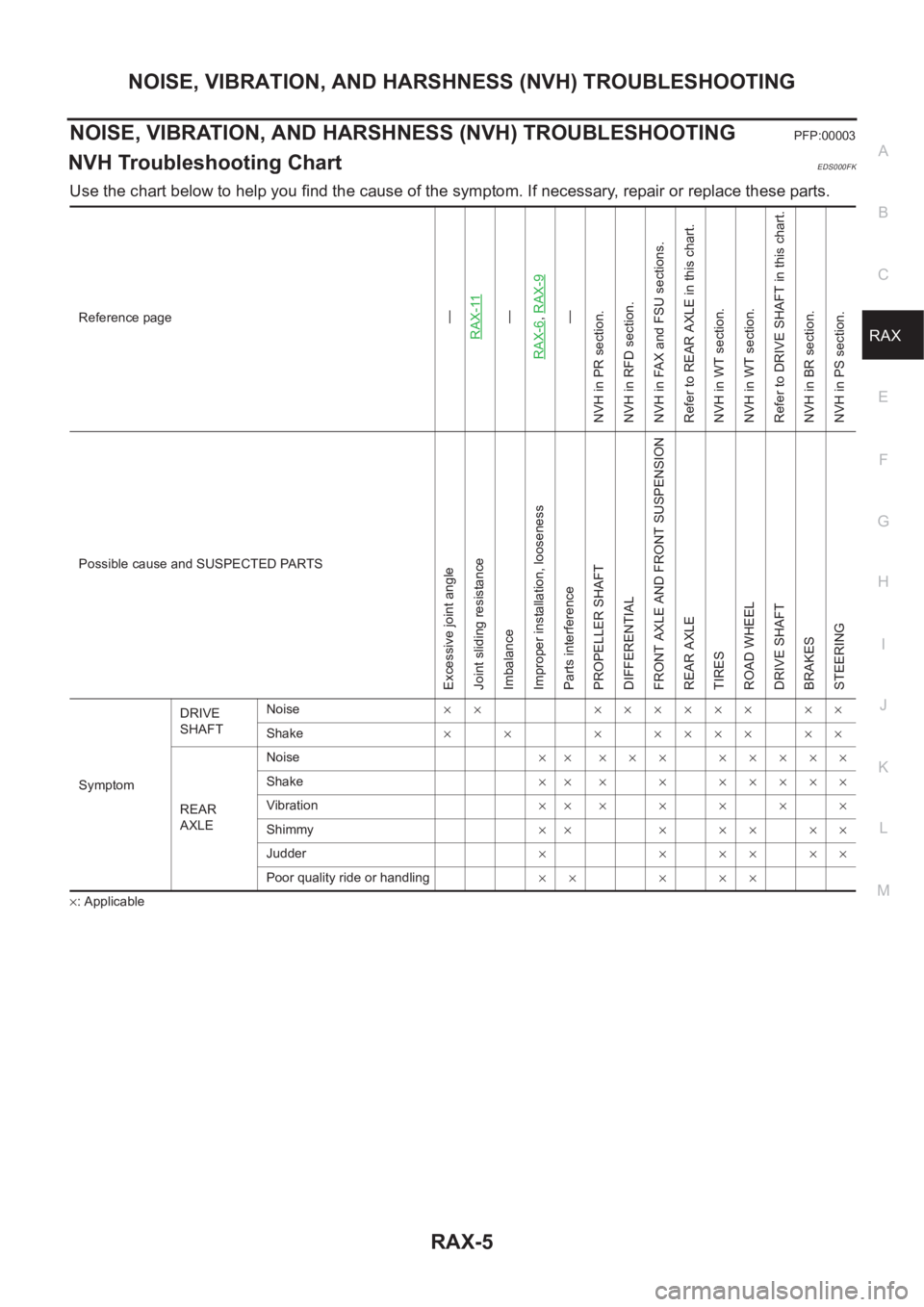

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTINGPFP:00003

NVH Troubleshooting ChartEDS000FK

Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

×: ApplicableReference page

—

RAX-11—

RAX-6,RAX-9—

NVH in PR section.

NVH in RFD section.

NVH in FAX and FSU sections.

Refer to REAR AXLE in this chart.

NVH in WT section.

NVH in WT section.

Refer to DRIVE SHAFT in this chart.

NVH in BR section.

NVH in PS section.

Possible cause and SUSPECTED PARTS

Excessive joint angle

Joint sliding resistance

Imbalance

Improper installation, looseness

Parts interference

PROPELLER SHAFT

DIFFERENTIAL

FRONT AXLE AND FRONT SUSPENSION

REAR AXLE

TIRES

ROAD WHEEL

DRIVE SHAFT

BRAKES

STEERING

SymptomDRIVE

SHAFTNoise×× ×××××× ××

Shake×× ×××××××

REAR

AXLENoise×× ××× ×××××

Shake×× × × ×××××

Vibration×××××××

Shimmy×× × × × × ×

Judder××××××

Poor quality ride or handling×× × ××

Page 2972 of 3833

RAX-6

WHEEL HUB (4WD)

WHEEL HUB (4WD)

PFP:43202

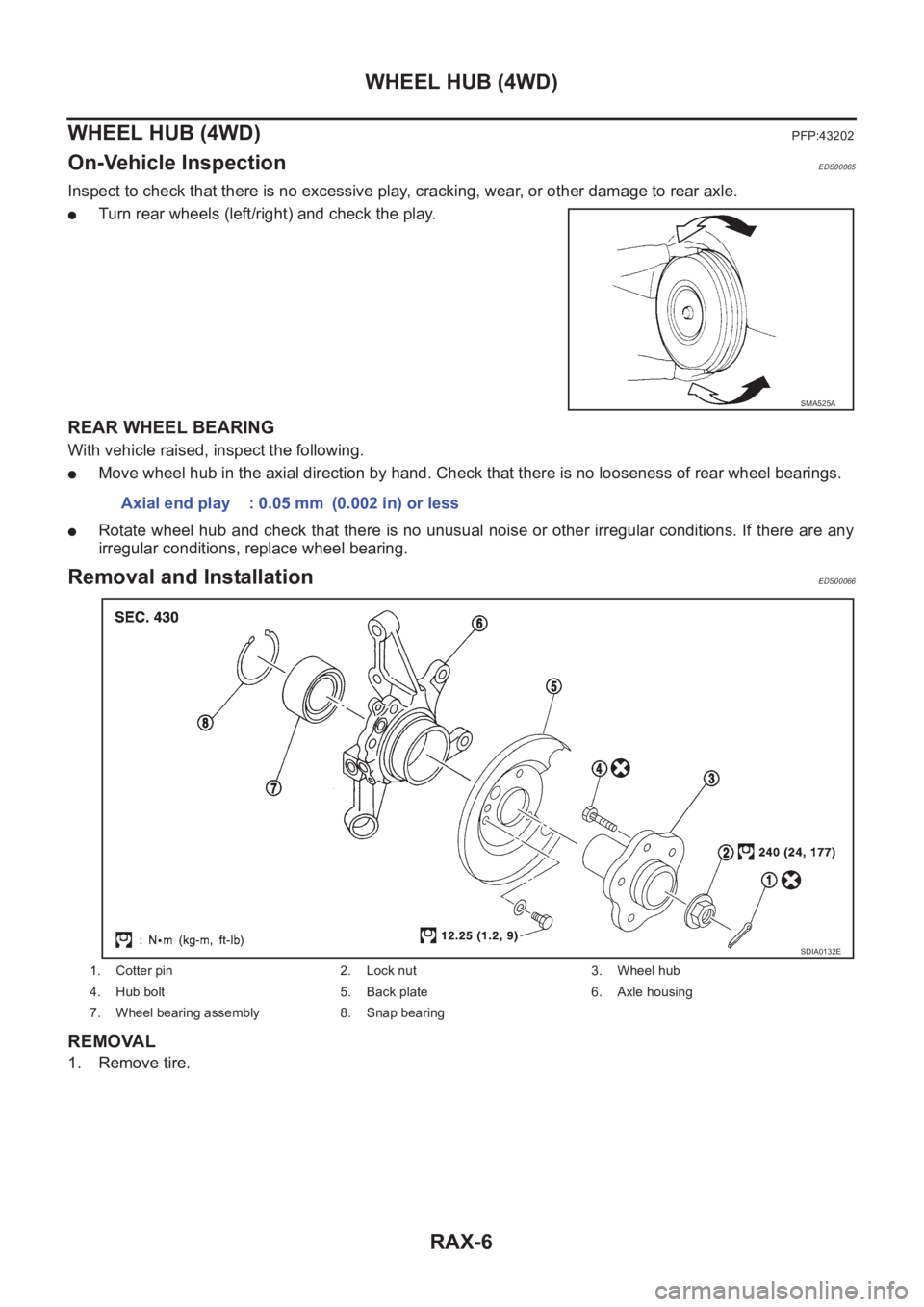

On-Vehicle InspectionEDS00065

Inspect to check that there is no excessive play, cracking, wear, or other damage to rear axle.

●Turn rear wheels (left/right) and check the play.

REAR WHEEL BEARING

With vehicle raised, inspect the following.

●Move wheel hub in the axial direction by hand. Check that there is no looseness of rear wheel bearings.

●Rotate wheel hub and check that there is no unusual noise or other irregular conditions. If there are any

irregular conditions, replace wheel bearing.

Removal and InstallationEDS00066

REMOVAL

1. Remove tire.

SMA525A

Axial end play : 0.05 mm (0.002 in) or less

1. Cotter pin 2. Lock nut 3. Wheel hub

4. Hub bolt 5. Back plate 6. Axle housing

7. Wheel bearing assembly 8. Snap bearing

SDIA0132E

Page 2973 of 3833

WHEEL HUB (4WD)

RAX-7

C

E

F

G

H

I

J

K

L

MA

B

RAX

2. Remove wheel hub lock nuts.

CAUTION:

Discard the old hub lock nuts; replace with new ones.

3. Remove brake caliper from axle housing and hang it up some-

where.

CAUTION:

Avoid depressing the brake pedal while the brake caliper is

removed.

4. Remove disc rotor and parking brake assembly from back plate

and axle housing.

5. Remove ABS wheel speed sensor from axle housing.

6. Remove axle housing from strut.

7. Remove nut and bolt from axle housing side of radius rod.

8. Remove nuts and bolts from axle housing sides of front and rear parallel links. Remove axle housing from

vehicle.

INSTALLATION

●Refer to component parts drawing for tightening torque. For installation, follow removal procedure in

reverse order.

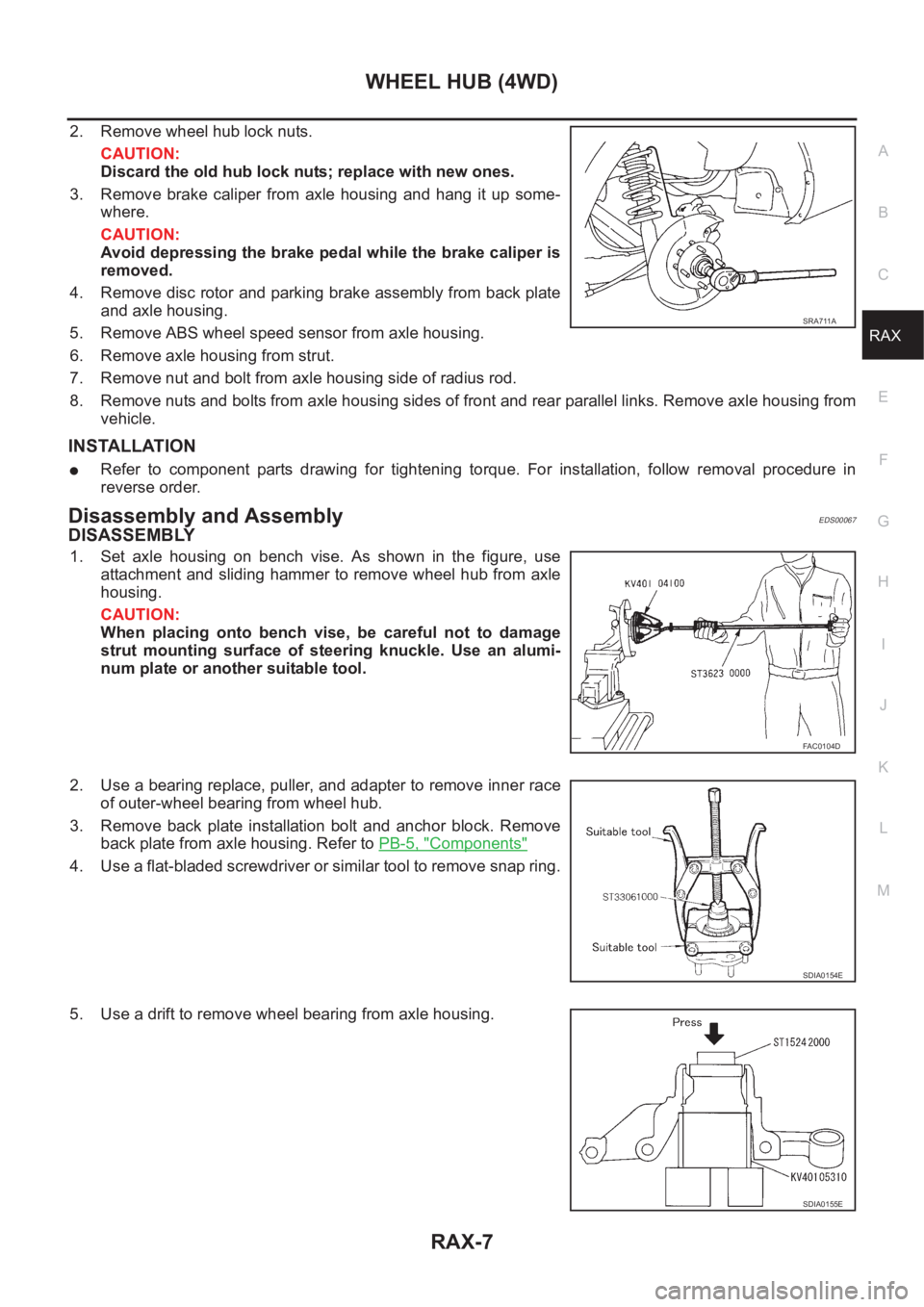

Disassembly and AssemblyEDS00067

DISASSEMBLY

1. Set axle housing on bench vise. As shown in the figure, use

attachment and sliding hammer to remove wheel hub from axle

housing.

CAUTION:

When placing onto bench vise, be careful not to damage

strut mounting surface of steering knuckle. Use an alumi-

num plate or another suitable tool.

2. Use a bearing replace, puller, and adapter to remove inner race

of outer-wheel bearing from wheel hub.

3. Remove back plate installation bolt and anchor block. Remove

back plate from axle housing. Refer to PB-5, "

Components"

4. Use a flat-bladed screwdriver or similar tool to remove snap ring.

5. Use a drift to remove wheel bearing from axle housing.

SRA711A

FAC0104D

SDIA0154E

SDIA0155E

Page 2974 of 3833

RAX-8

WHEEL HUB (4WD)

INSPECTION AFTER DISASSEMBLY

Wheel Hub

●Inspect wheel hub for deformation, cracks, and other damage. If any irregular conditions are found,

replace wheel hub.

Axle Housing

●Inspect axle housing for deformation, cracks, and other damage. If any irregular conditions are found,

replace axle housing.

Snap Ring

●Check snap ring for deformation, cracks, and other damage. If any irregular conditions are found, replace

snap ring.

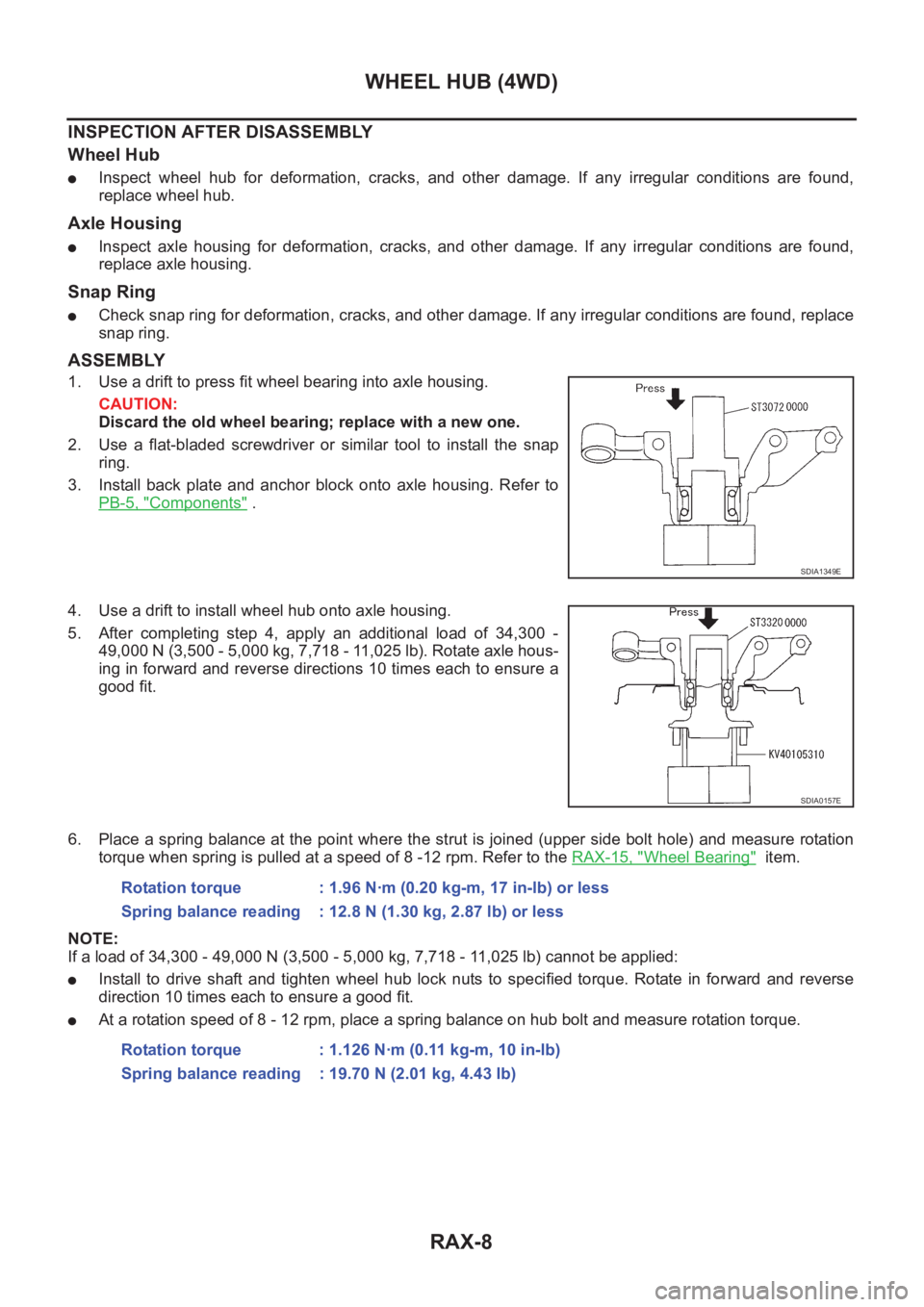

ASSEMBLY

1. Use a drift to press fit wheel bearing into axle housing.

CAUTION:

Discard the old wheel bearing; replace with a new one.

2. Use a flat-bladed screwdriver or similar tool to install the snap

ring.

3. Install back plate and anchor block onto axle housing. Refer to

PB-5, "

Components" .

4. Use a drift to install wheel hub onto axle housing.

5. After completing step 4, apply an additional load of 34,300 -

49,000 N (3,500 - 5,000 kg, 7,718 - 11,025 lb). Rotate axle hous-

ing in forward and reverse directions 10 times each to ensure a

good fit.

6. Place a spring balance at the point where the strut is joined (upper side bolt hole) and measure rotation

torque when spring is pulled at a speed of 8 -12 rpm. Refer to the RAX-15, "

Wheel Bearing" item.

NOTE:

If a load of 34,300 - 49,000 N (3,500 - 5,000 kg, 7,718 - 11,025 lb) cannot be applied:

●Install to drive shaft and tighten wheel hub lock nuts to specified torque. Rotate in forward and reverse

direction 10 times each to ensure a good fit.

●At a rotation speed of 8 - 12 rpm, place a spring balance on hub bolt and measure rotation torque.

SDIA1349E

SDIA0157E

Rotation torque : 1.96 N·m (0.20 kg-m, 17 in-lb) or less

Spring balance reading : 12.8 N (1.30 kg, 2.87 lb) or less

Rotation torque : 1.126 N·m (0.11 kg-m, 10 in-lb)

Spring balance reading : 19.70 N (2.01 kg, 4.43 lb)

Page 2975 of 3833

REAR DRIVE SHAFT

RAX-9

C

E

F

G

H

I

J

K

L

MA

B

RAX

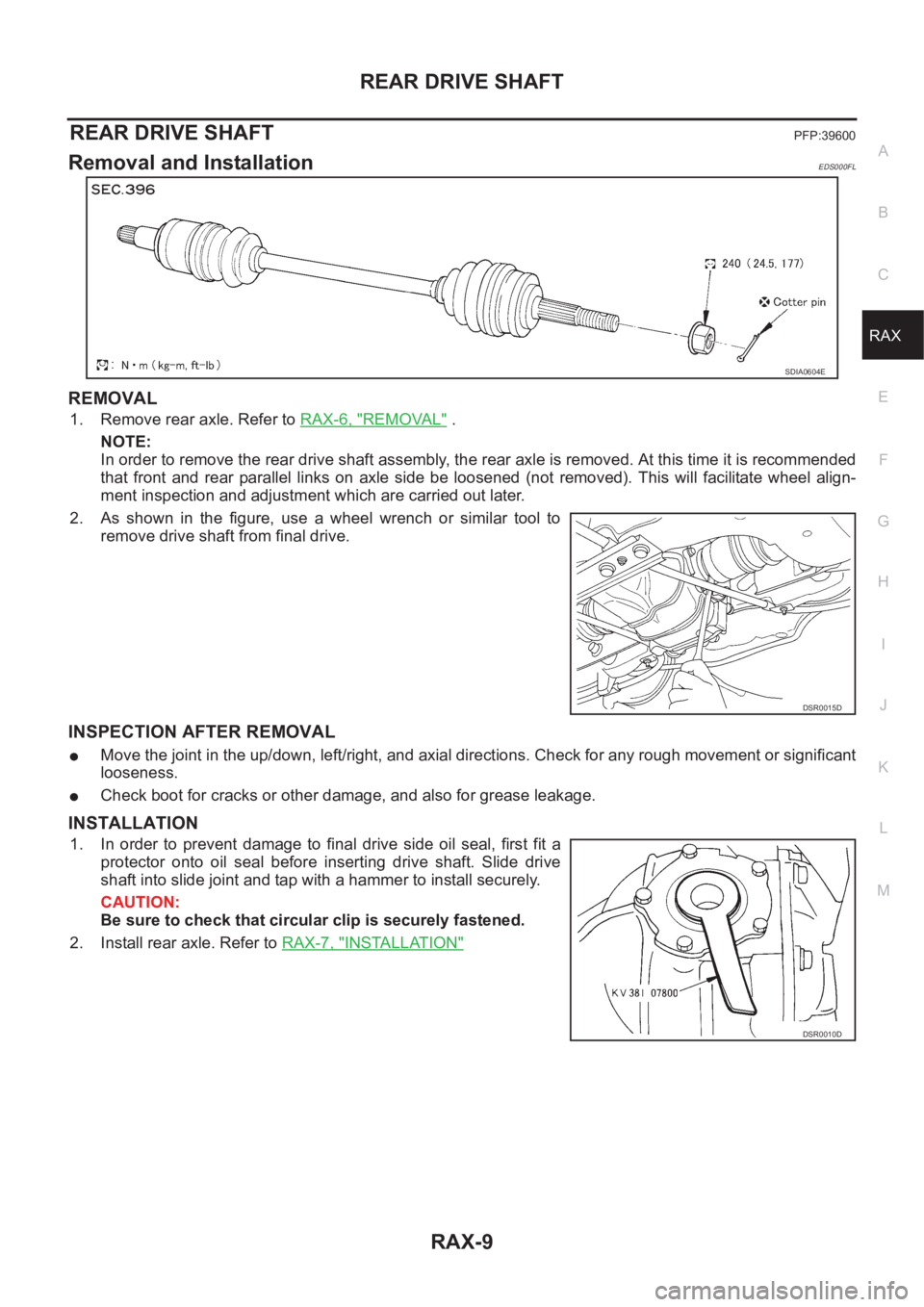

REAR DRIVE SHAFTPFP:39600

Removal and InstallationEDS000FL

REMOVAL

1. Remove rear axle. Refer to RAX-6, "REMOVAL" .

NOTE:

In order to remove the rear drive shaft assembly, the rear axle is removed. At this time it is recommended

that front and rear parallel links on axle side be loosened (not removed). This will facilitate wheel align-

ment inspection and adjustment which are carried out later.

2. As shown in the figure, use a wheel wrench or similar tool to

remove drive shaft from final drive.

INSPECTION AFTER REMOVAL

●Move the joint in the up/down, left/right, and axial directions. Check for any rough movement or significant

looseness.

●Check boot for cracks or other damage, and also for grease leakage.

INSTALLATION

1. In order to prevent damage to final drive side oil seal, first fit a

protector onto oil seal before inserting drive shaft. Slide drive

shaft into slide joint and tap with a hammer to install securely.

CAUTION:

Be sure to check that circular clip is securely fastened.

2. Install rear axle. Refer to RAX-7, "

INSTALLATION"

SDIA0604E

DSR0015D

DSR0010D

Page 2976 of 3833

RAX-10

REAR DRIVE SHAFT

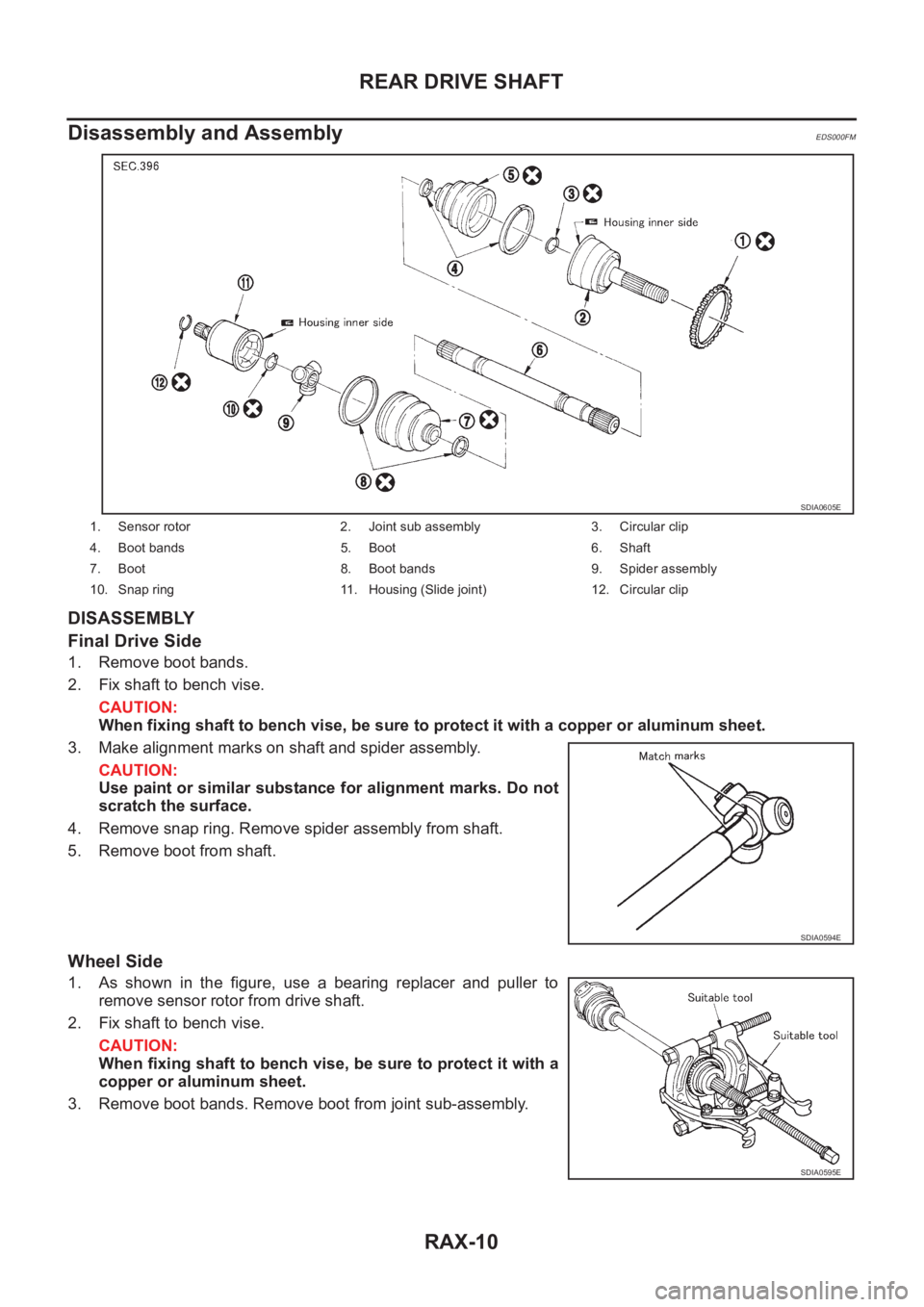

Disassembly and Assembly

EDS000FM

DISASSEMBLY

Final Drive Side

1. Remove boot bands.

2. Fix shaft to bench vise.

CAUTION:

When fixing shaft to bench vise, be sure to protect it with a copper or aluminum sheet.

3. Make alignment marks on shaft and spider assembly.

CAUTION:

Use paint or similar substance for alignment marks. Do not

scratch the surface.

4. Remove snap ring. Remove spider assembly from shaft.

5. Remove boot from shaft.

Wheel Side

1. As shown in the figure, use a bearing replacer and puller to

remove sensor rotor from drive shaft.

2. Fix shaft to bench vise.

CAUTION:

When fixing shaft to bench vise, be sure to protect it with a

copper or aluminum sheet.

3. Remove boot bands. Remove boot from joint sub-assembly.

1. Sensor rotor 2. Joint sub assembly 3. Circular clip

4. Boot bands 5. Boot 6. Shaft

7. Boot 8. Boot bands 9. Spider assembly

10. Snap ring 11. Housing (Slide joint) 12. Circular clip

SDIA0605E

SDIA0594E

SDIA0595E

Page 2977 of 3833

REAR DRIVE SHAFT

RAX-11

C

E

F

G

H

I

J

K

L

MA

B

RAX

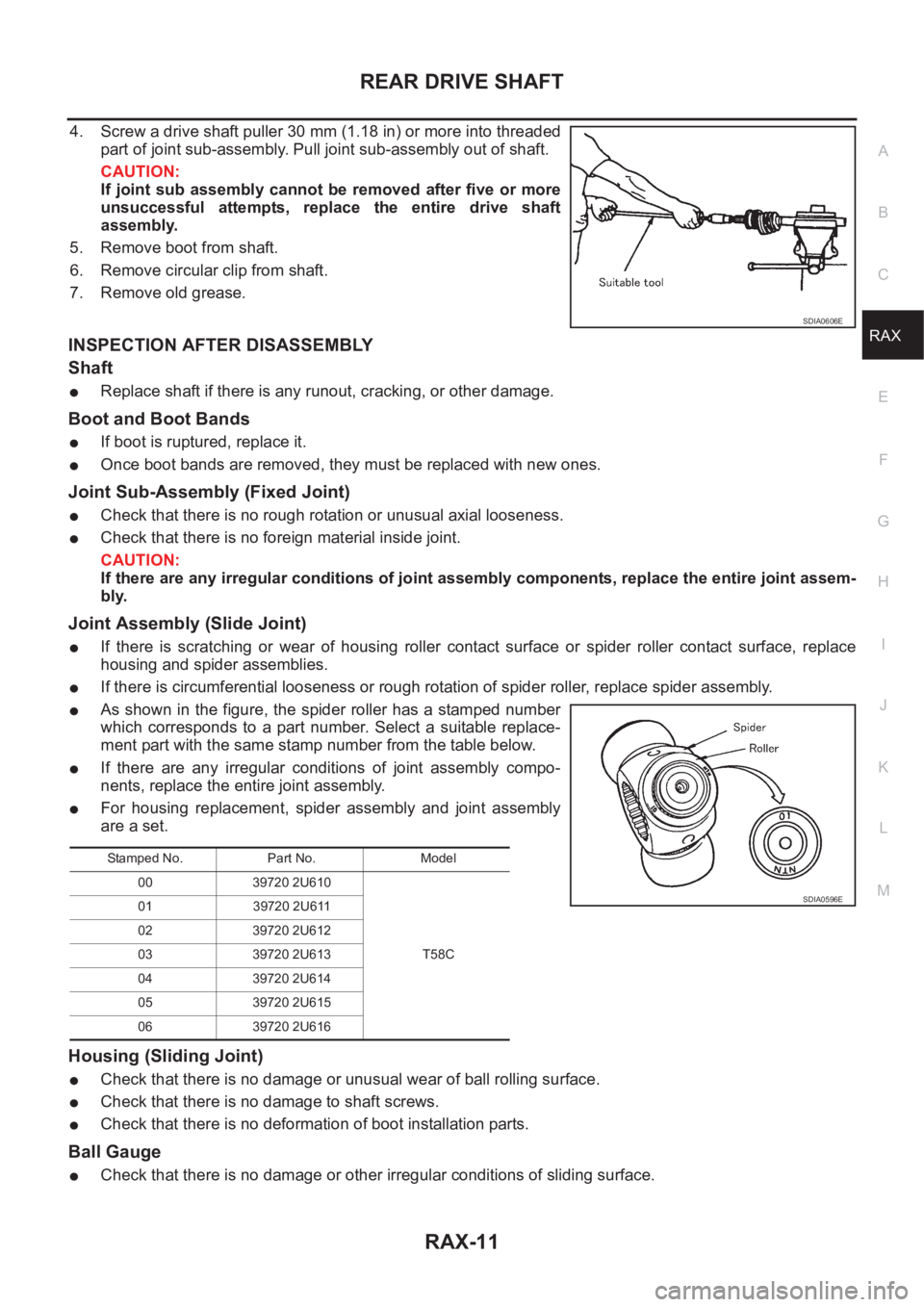

4. Screw a drive shaft puller 30 mm (1.18 in) or more into threaded

part of joint sub-assembly. Pull joint sub-assembly out of shaft.

CAUTION:

If joint sub assembly cannot be removed after five or more

unsuccessful attempts, replace the entire drive shaft

assembly.

5. Remove boot from shaft.

6. Remove circular clip from shaft.

7. Remove old grease.

INSPECTION AFTER DISASSEMBLY

Shaft

●Replace shaft if there is any runout, cracking, or other damage.

Boot and Boot Bands

●If boot is ruptured, replace it.

●Once boot bands are removed, they must be replaced with new ones.

Joint Sub-Assembly (Fixed Joint)

●Check that there is no rough rotation or unusual axial looseness.

●Check that there is no foreign material inside joint.

CAUTION:

If there are any irregular conditions of joint assembly components, replace the entire joint assem-

bly.

Joint Assembly (Slide Joint)

●If there is scratching or wear of housing roller contact surface or spider roller contact surface, replace

housing and spider assemblies.

●If there is circumferential looseness or rough rotation of spider roller, replace spider assembly.

●As shown in the figure, the spider roller has a stamped number

which corresponds to a part number. Select a suitable replace-

ment part with the same stamp number from the table below.

●If there are any irregular conditions of joint assembly compo-

nents, replace the entire joint assembly.

●For housing replacement, spider assembly and joint assembly

are a set.

Housing (Sliding Joint)

●Check that there is no damage or unusual wear of ball rolling surface.

●Check that there is no damage to shaft screws.

●Check that there is no deformation of boot installation parts.

Ball Gauge

●Check that there is no damage or other irregular conditions of sliding surface.

SDIA0606E

Stamped No. Part No. Model

00 39720 2U610

T58C 01 39720 2U611

02 39720 2U612

03 39720 2U613

04 39720 2U614

05 39720 2U615

06 39720 2U616

SDIA0596E

Page 2978 of 3833

RAX-12

REAR DRIVE SHAFT

Steel Ball

●Check that there is no damage or unusual wear.

Inner Case

●Check that there is no damage or other irregular conditions of ball rolling surface.

●Check that there is no damage to serrated part.

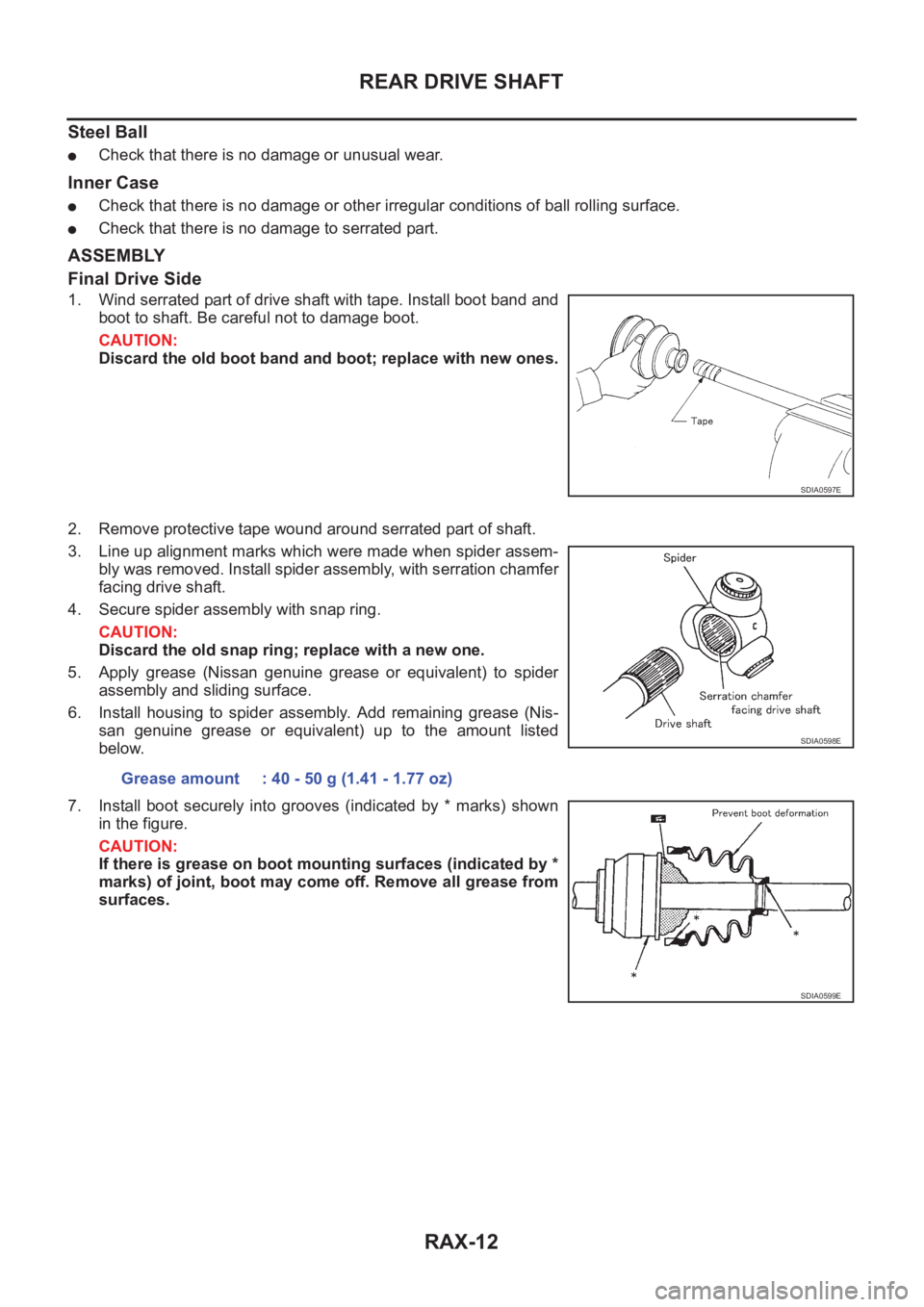

ASSEMBLY

Final Drive Side

1. Wind serrated part of drive shaft with tape. Install boot band and

boot to shaft. Be careful not to damage boot.

CAUTION:

Discard the old boot band and boot; replace with new ones.

2. Remove protective tape wound around serrated part of shaft.

3. Line up alignment marks which were made when spider assem-

bly was removed. Install spider assembly, with serration chamfer

facing drive shaft.

4. Secure spider assembly with snap ring.

CAUTION:

Discard the old snap ring; replace with a new one.

5. Apply grease (Nissan genuine grease or equivalent) to spider

assembly and sliding surface.

6. Install housing to spider assembly. Add remaining grease (Nis-

san genuine grease or equivalent) up to the amount listed

below.

7. Install boot securely into grooves (indicated by * marks) shown

in the figure.

CAUTION:

If there is grease on boot mounting surfaces (indicated by *

marks) of joint, boot may come off. Remove all grease from

surfaces.

SDIA0597E

Grease amount : 40 - 50 g (1.41 - 1.77 oz)

SDIA0598E

SDIA0599E

Page 2979 of 3833

REAR DRIVE SHAFT

RAX-13

C

E

F

G

H

I

J

K

L

MA

B

RAX

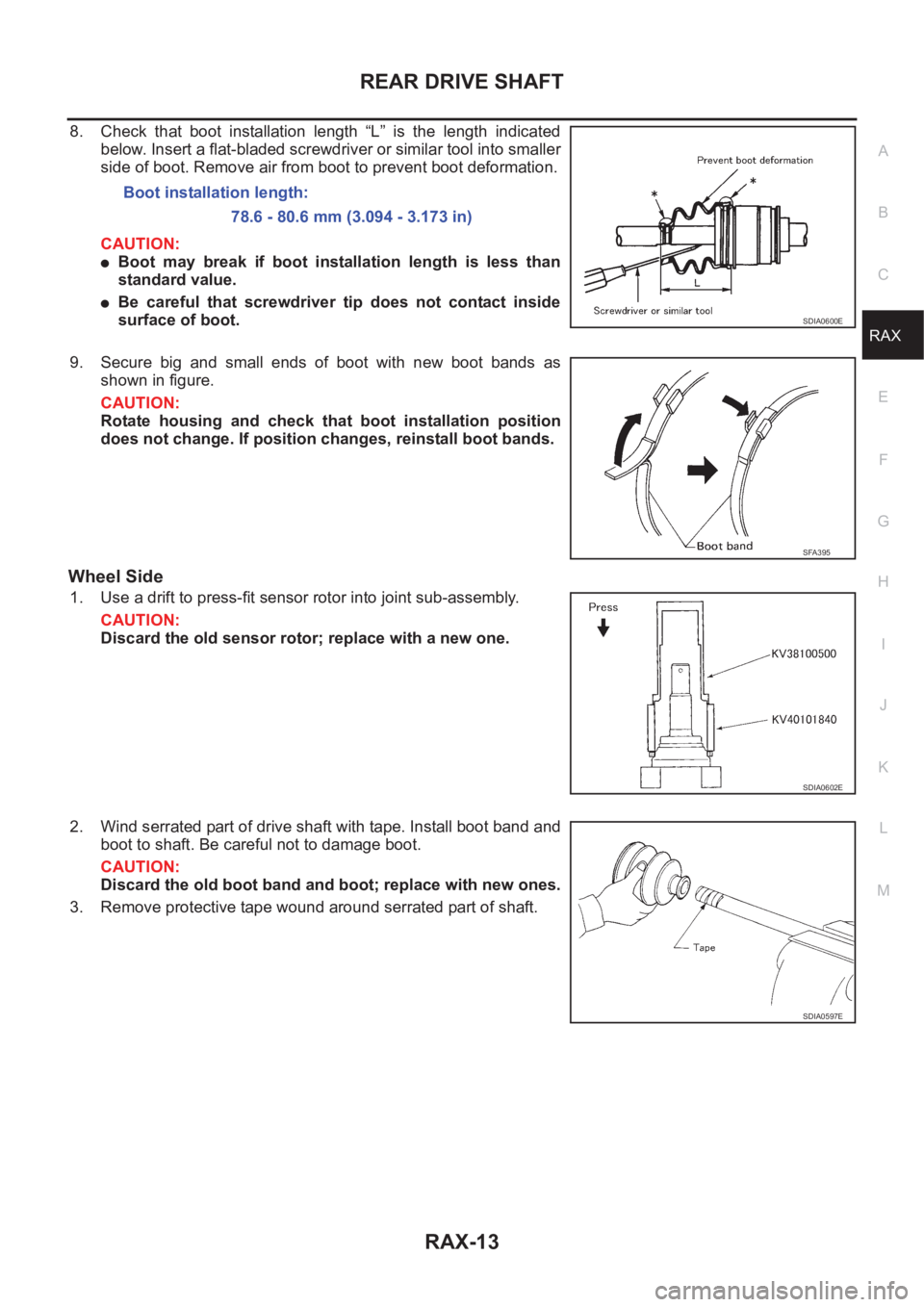

8. Check that boot installation length “L” is the length indicated

below. Insert a flat-bladed screwdriver or similar tool into smaller

side of boot. Remove air from boot to prevent boot deformation.

CAUTION:

●Boot may break if boot installation length is less than

standard value.

●Be careful that screwdriver tip does not contact inside

surface of boot.

9. Secure big and small ends of boot with new boot bands as

shown in figure.

CAUTION:

Rotate housing and check that boot installation position

does not change. If position changes, reinstall boot bands.

Wheel Side

1. Use a drift to press-fit sensor rotor into joint sub-assembly.

CAUTION:

Discard the old sensor rotor; replace with a new one.

2. Wind serrated part of drive shaft with tape. Install boot band and

boot to shaft. Be careful not to damage boot.

CAUTION:

Discard the old boot band and boot; replace with new ones.

3. Remove protective tape wound around serrated part of shaft.Boot installation length:

78.6 - 80.6 mm (3.094 - 3.173 in)

SDIA0600E

SFA395

SDIA0602E

SDIA0597E

Page 2980 of 3833

RAX-14

REAR DRIVE SHAFT

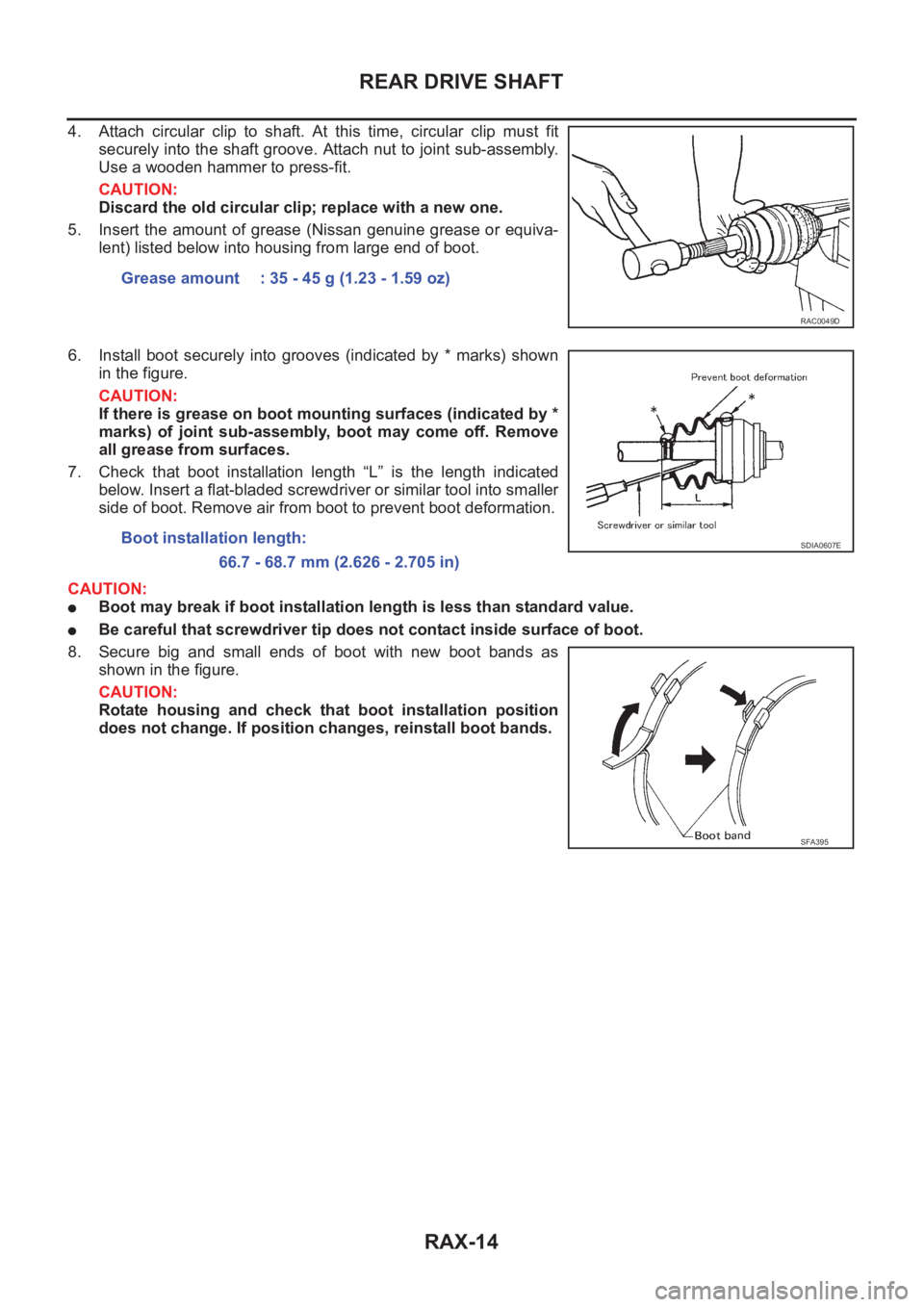

4. Attach circular clip to shaft. At this time, circular clip must fit

securely into the shaft groove. Attach nut to joint sub-assembly.

Use a wooden hammer to press-fit.

CAUTION:

Discard the old circular clip; replace with a new one.

5. Insert the amount of grease (Nissan genuine grease or equiva-

lent) listed below into housing from large end of boot.

6. Install boot securely into grooves (indicated by * marks) shown

in the figure.

CAUTION:

If there is grease on boot mounting surfaces (indicated by *

marks) of joint sub-assembly, boot may come off. Remove

all grease from surfaces.

7. Check that boot installation length “L” is the length indicated

below. Insert a flat-bladed screwdriver or similar tool into smaller

side of boot. Remove air from boot to prevent boot deformation.

CAUTION:

●Boot may break if boot installation length is less than standard value.

●Be careful that screwdriver tip does not contact inside surface of boot.

8. Secure big and small ends of boot with new boot bands as

shown in the figure.

CAUTION:

Rotate housing and check that boot installation position

does not change. If position changes, reinstall boot bands.Grease amount : 35 - 45 g (1.23 - 1.59 oz)

RAC0049D

Boot installation length:

66.7 - 68.7 mm (2.626 - 2.705 in)SDIA0607E

SFA395