NISSAN X-TRAIL 2001 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2001Pages: 3833, PDF Size: 39.49 MB

Page 3591 of 3833

COMBINATION METERS (RHD MODELS)

DI-33

C

D

E

F

G

H

I

J

L

MA

B

DI

Inspection/Engine Speed SignalEKS0030P

1.CHECK ECM OUTPUT

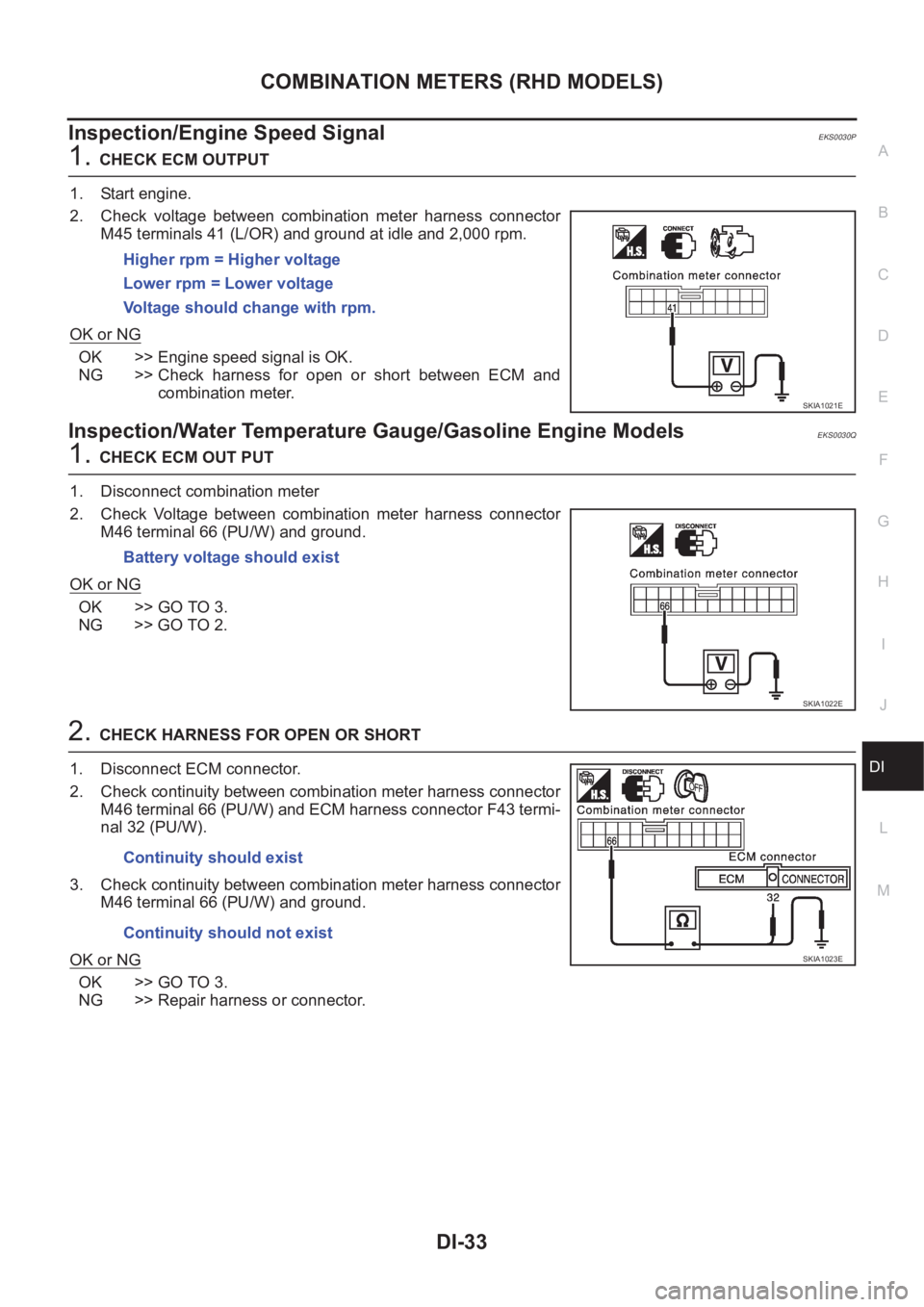

1. Start engine.

2. Check voltage between combination meter harness connector

M45 terminals 41 (L/OR) and ground at idle and 2,000 rpm.

OK or NG

OK >> Engine speed signal is OK.

NG >> Check harness for open or short between ECM and

combination meter.

Inspection/Water Temperature Gauge/Gasoline Engine ModelsEKS0030Q

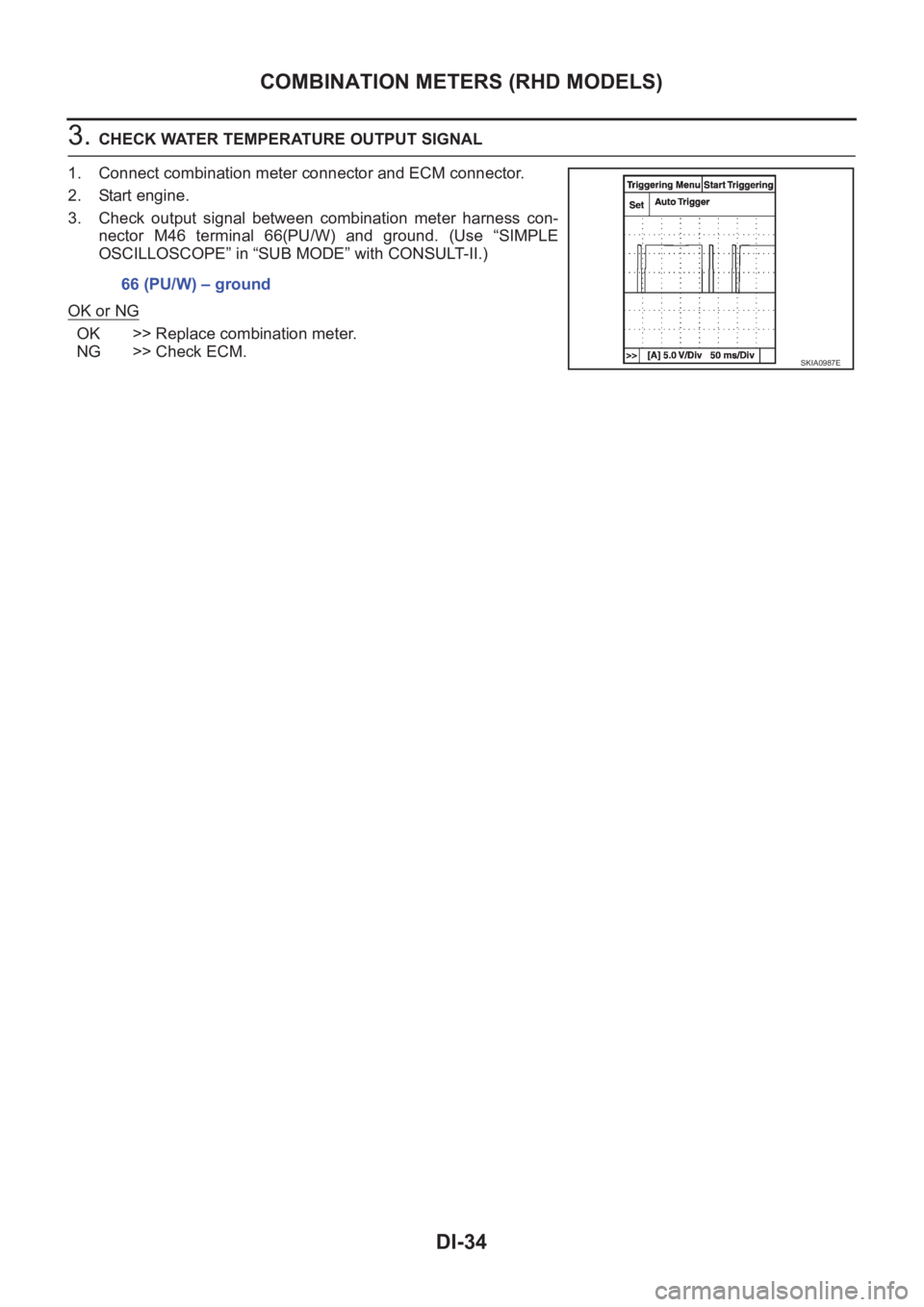

1.CHECK ECM OUT PUT

1. Disconnect combination meter

2. Check Voltage between combination meter harness connector

M46 terminal 66 (PU/W) and ground.

OK or NG

OK >> GO TO 3.

NG >> GO TO 2.

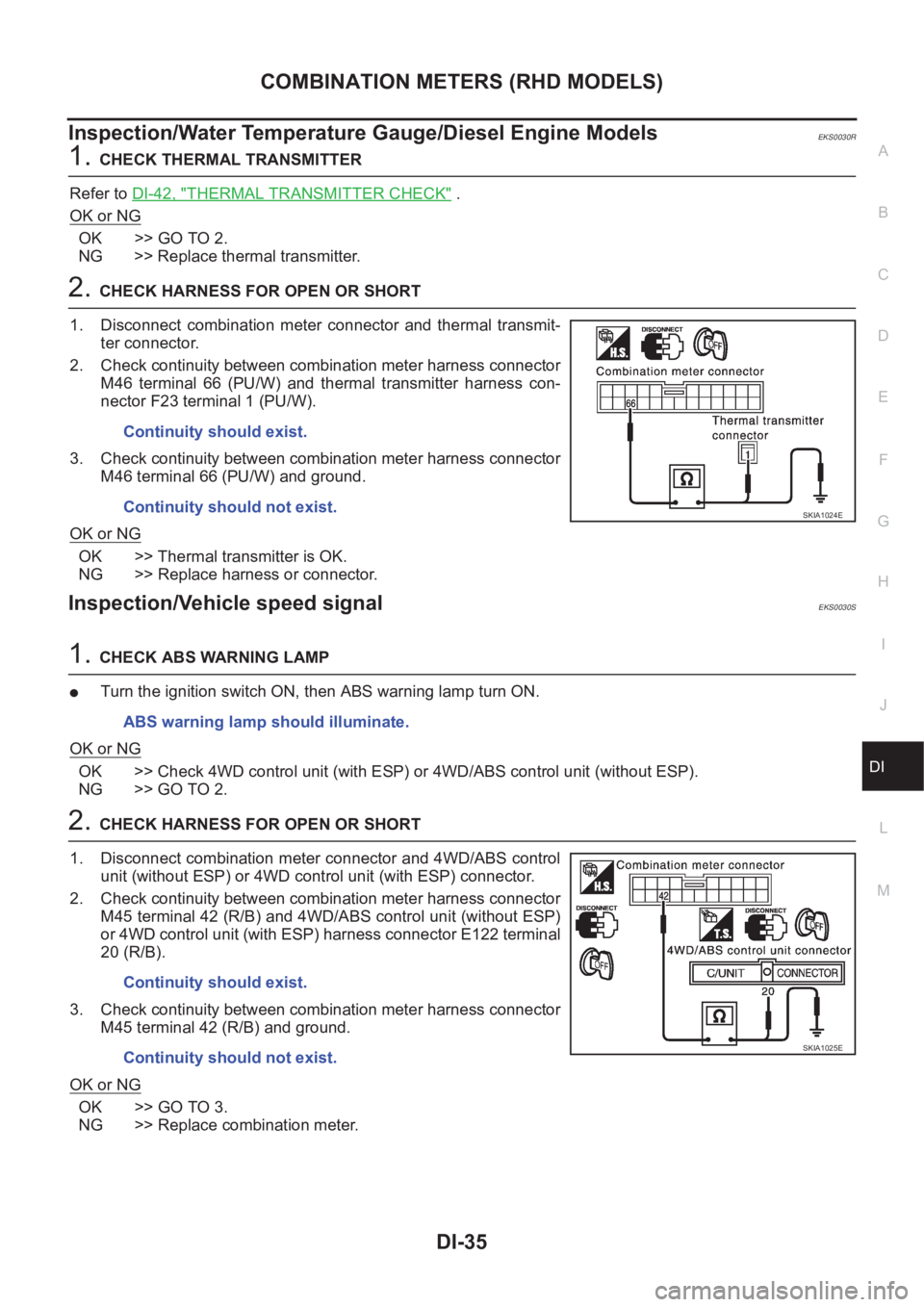

2.CHECK HARNESS FOR OPEN OR SHORT

1. Disconnect ECM connector.

2. Check continuity between combination meter harness connector

M46 terminal 66 (PU/W) and ECM harness connector F43 termi-

nal 32 (PU/W).

3. Check continuity between combination meter harness connector

M46 terminal 66 (PU/W) and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.Higher rpm = Higher voltage

Lower rpm = Lower voltage

Voltage should change with rpm.

SKIA1021E

Battery voltage should exist

SKIA1022E

Continuity should exist

Continuity should not exist

SKIA1023E

Page 3592 of 3833

DI-34

COMBINATION METERS (RHD MODELS)

3. CHECK WATER TEMPERATURE OUTPUT SIGNAL

1. Connect combination meter connector and ECM connector.

2. Start engine.

3. Check output signal between combination meter harness con-

nector M46 terminal 66(PU/W) and ground. (Use “SIMPLE

OSCILLOSCOPE” in “SUB MODE” with CONSULT-II.)

OK or NG

OK >> Replace combination meter.

NG >> Check ECM.66 (PU/W) – ground

SKIA0987E

Page 3593 of 3833

COMBINATION METERS (RHD MODELS)

DI-35

C

D

E

F

G

H

I

J

L

MA

B

DI

Inspection/Water Temperature Gauge/Diesel Engine ModelsEKS0030R

1.CHECK THERMAL TRANSMITTER

Refer to DI-42, "

THERMAL TRANSMITTER CHECK" .

OK or NG

OK >> GO TO 2.

NG >> Replace thermal transmitter.

2.CHECK HARNESS FOR OPEN OR SHORT

1. Disconnect combination meter connector and thermal transmit-

ter connector.

2. Check continuity between combination meter harness connector

M46 terminal 66 (PU/W) and thermal transmitter harness con-

nector F23 terminal 1 (PU/W).

3. Check continuity between combination meter harness connector

M46 terminal 66 (PU/W) and ground.

OK or NG

OK >> Thermal transmitter is OK.

NG >> Replace harness or connector.

Inspection/Vehicle speed signalEKS0030S

1.CHECK ABS WARNING LAMP

●Turn the ignition switch ON, then ABS warning lamp turn ON.

OK or NG

OK >> Check 4WD control unit (with ESP) or 4WD/ABS control unit (without ESP).

NG >> GO TO 2.

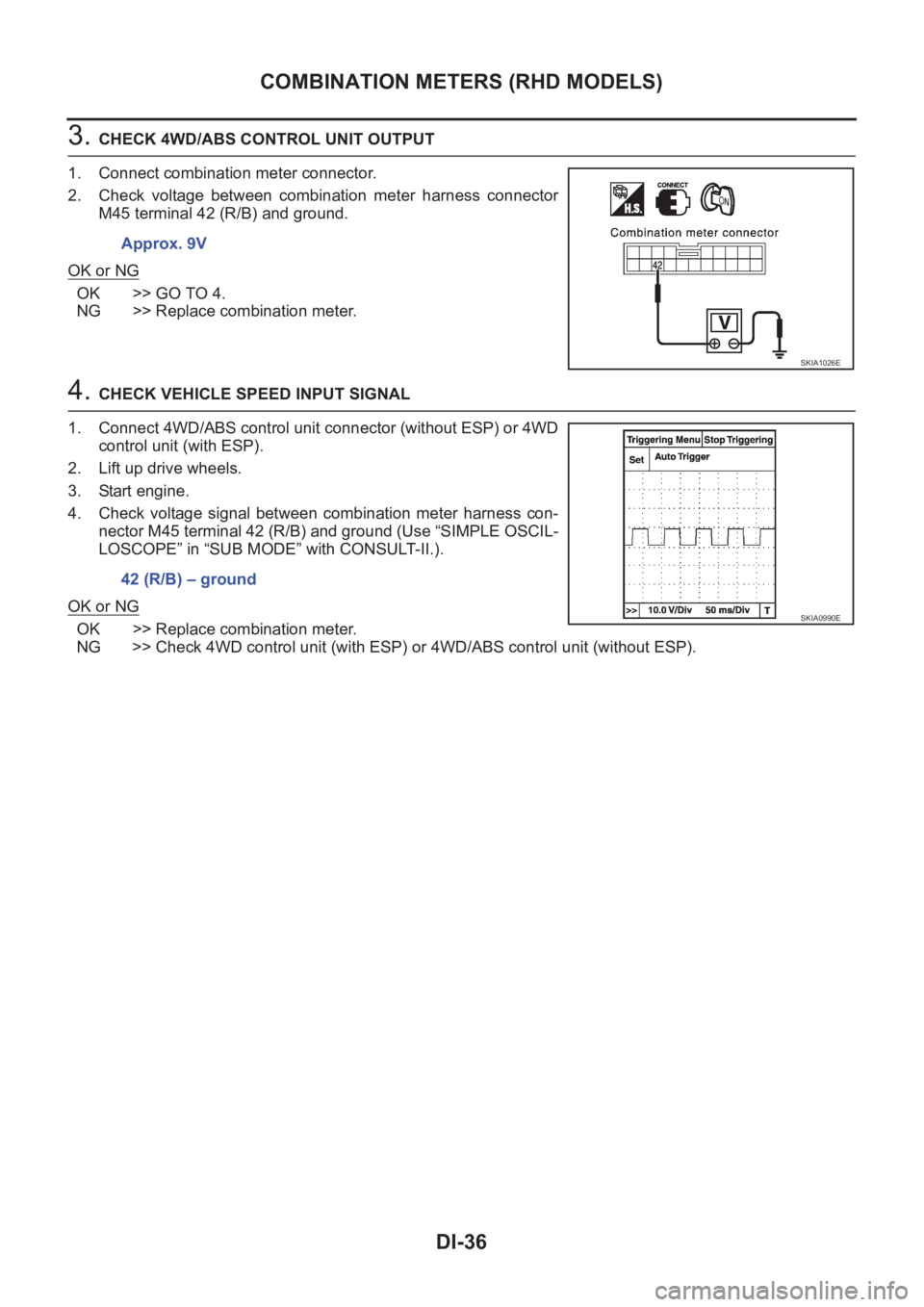

2.CHECK HARNESS FOR OPEN OR SHORT

1. Disconnect combination meter connector and 4WD/ABS control

unit (without ESP) or 4WD control unit (with ESP) connector.

2. Check continuity between combination meter harness connector

M45 terminal 42 (R/B) and 4WD/ABS control unit (without ESP)

or 4WD control unit (with ESP) harness connector E122 terminal

20 (R/B).

3. Check continuity between combination meter harness connector

M45 terminal 42 (R/B) and ground.

OK or NG

OK >> GO TO 3.

NG >> Replace combination meter.Continuity should exist.

Continuity should not exist.

SKIA1024E

ABS warning lamp should illuminate.

Continuity should exist.

Continuity should not exist.

SKIA1025E

Page 3594 of 3833

DI-36

COMBINATION METERS (RHD MODELS)

3. CHECK 4WD/ABS CONTROL UNIT OUTPUT

1. Connect combination meter connector.

2. Check voltage between combination meter harness connector

M45 terminal 42 (R/B) and ground.

OK or NG

OK >> GO TO 4.

NG >> Replace combination meter.

4. CHECK VEHICLE SPEED INPUT SIGNAL

1. Connect 4WD/ABS control unit connector (without ESP) or 4WD

control unit (with ESP).

2. Lift up drive wheels.

3. Start engine.

4. Check voltage signal between combination meter harness con-

nector M45 terminal 42 (R/B) and ground (Use “SIMPLE OSCIL-

LOSCOPE” in “SUB MODE” with CONSULT-II.).

OK or NG

OK >> Replace combination meter.

NG >> Check 4WD control unit (with ESP) or 4WD/ABS control unit (without ESP). Approx. 9V

SKIA1026E

42 (R/B) – ground

SKIA0990E

Page 3595 of 3833

COMBINATION METERS (RHD MODELS)

DI-37

C

D

E

F

G

H

I

J

L

MA

B

DI

Inspection/Fuel Level Sensor UnitEKS0030T

FUEL LEVEL SENSOR UNIT

The following symptoms do not indicate a malfunction.

●Depending on vehicle posture or driving circumstance, the fuel level in the tank varies, and the pointer

may fluctuate.

●If the vehicle is fueled with the ignition switch ON, the pointer will move slowly.

LOW-FUEL WARNING LAMP

Depending on vehicle posture or driving circumstance, the fuel level in the tank varies, and the warning lamp

ON timing may be changed.

1.DIAGNOSIS MODE INSPECTION

Preform the combination meter diagnosis mode. Refer to DI-30, "

Meter/Gauge Operation and Odo/Trip Meter

Segment Check in Diagnosis Mode" .

OK or NG

OK >> GO TO 2.

NG >> Replace combination meter.

2.HARNESS CONNECTOR INSPECTION

1. Turn the ignition switch OFF.

2. Check combination meter, fuel level sensor unit and terminals (meter-side, module-side, and harness-

side) for poor connection and bend.

OK or NG

OK >> GO TO 3.

NG >> Repair terminals or connectors.

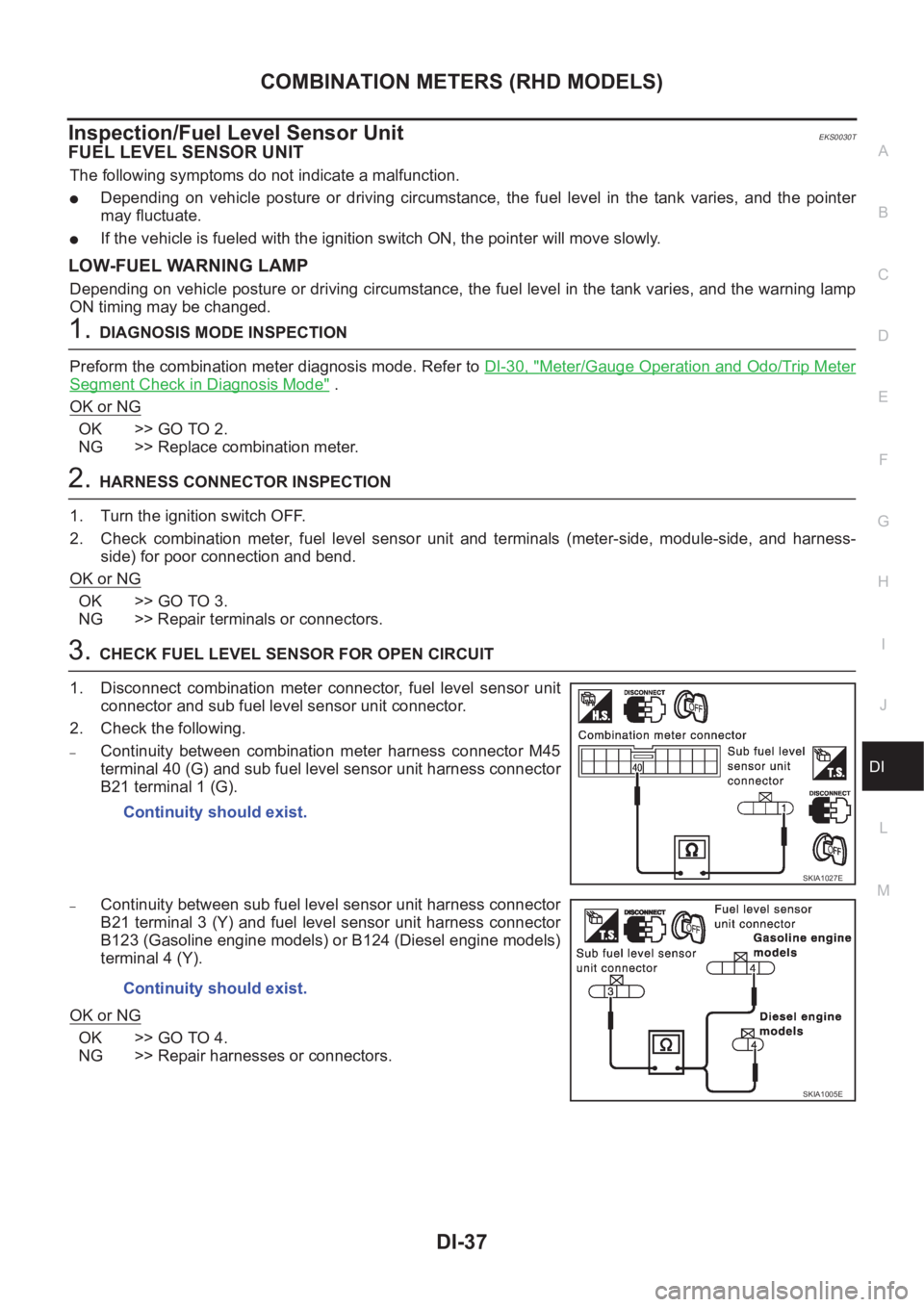

3.CHECK FUEL LEVEL SENSOR FOR OPEN CIRCUIT

1. Disconnect combination meter connector, fuel level sensor unit

connector and sub fuel level sensor unit connector.

2. Check the following.

–Continuity between combination meter harness connector M45

terminal 40 (G) and sub fuel level sensor unit harness connector

B21 terminal 1 (G).

–Continuity between sub fuel level sensor unit harness connector

B21 terminal 3 (Y) and fuel level sensor unit harness connector

B123 (Gasoline engine models) or B124 (Diesel engine models)

terminal 4 (Y).

OK or NG

OK >> GO TO 4.

NG >> Repair harnesses or connectors.Continuity should exist.

SKIA1027E

Continuity should exist.

SKIA1005E

Page 3596 of 3833

DI-38

COMBINATION METERS (RHD MODELS)

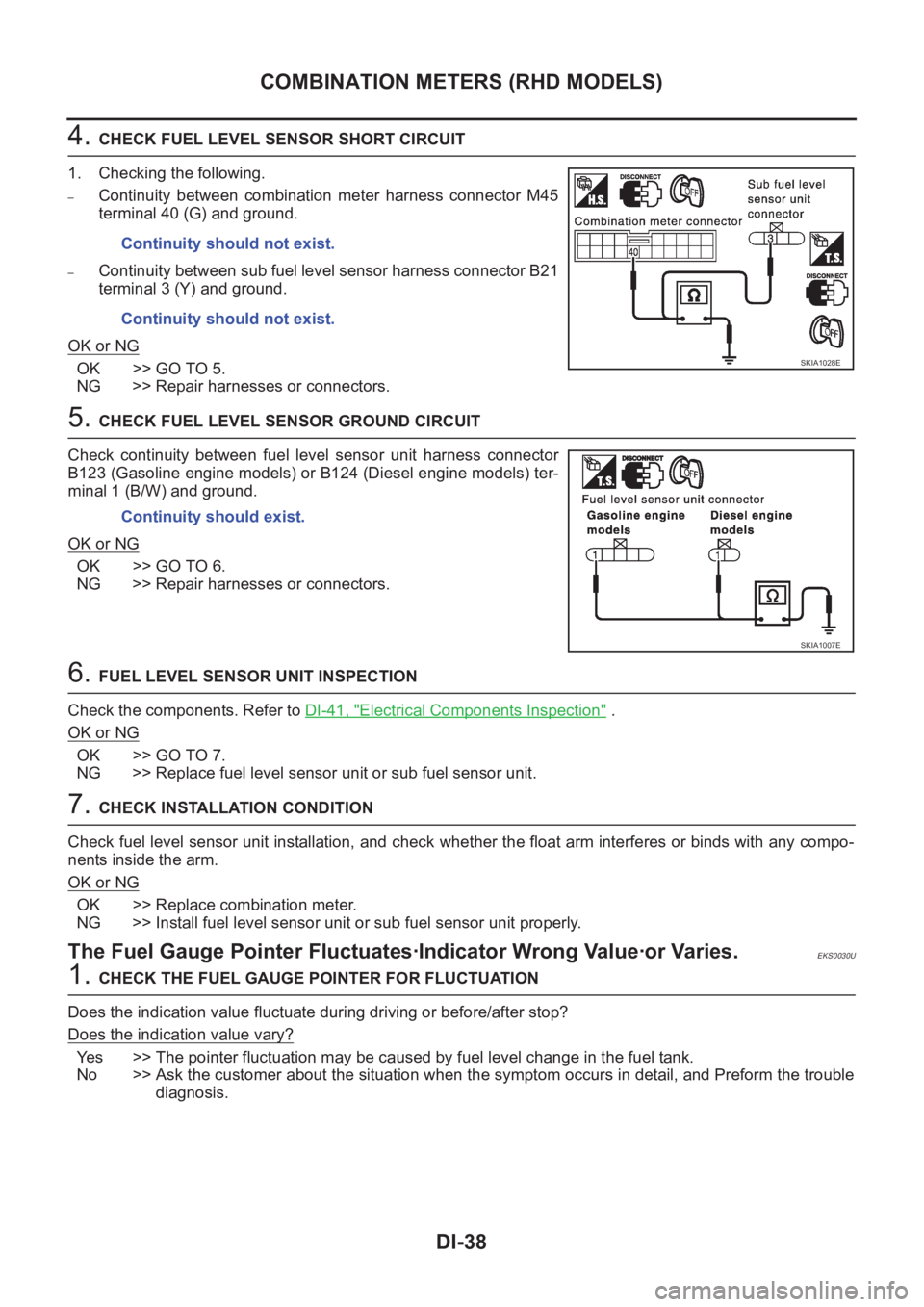

4. CHECK FUEL LEVEL SENSOR SHORT CIRCUIT

1. Checking the following.

–Continuity between combination meter harness connector M45

terminal 40 (G) and ground.

–Continuity between sub fuel level sensor harness connector B21

terminal 3 (Y) and ground.

OK or NG

OK >> GO TO 5.

NG >> Repair harnesses or connectors.

5. CHECK FUEL LEVEL SENSOR GROUND CIRCUIT

Check continuity between fuel level sensor unit harness connector

B123 (Gasoline engine models) or B124 (Diesel engine models) ter-

minal 1 (B/W) and ground.

OK or NG

OK >> GO TO 6.

NG >> Repair harnesses or connectors.

6. FUEL LEVEL SENSOR UNIT INSPECTION

Check the components. Refer to DI-41, "

Electrical Components Inspection" .

OK or NG

OK >> GO TO 7.

NG >> Replace fuel level sensor unit or sub fuel sensor unit.

7. CHECK INSTALLATION CONDITION

Check fuel level sensor unit installation, and check whether the float arm interferes or binds with any compo-

nents inside the arm.

OK or NG

OK >> Replace combination meter.

NG >> Install fuel level sensor unit or sub fuel sensor unit properly.

The Fuel Gauge Pointer Fluctuates·Indicator Wrong Value·or Varies.EKS0030U

1. CHECK THE FUEL GAUGE POINTER FOR FLUCTUATION

Does the indication value fluctuate during driving or before/after stop?

Does the indication value vary?

Yes >> The pointer fluctuation may be caused by fuel level change in the fuel tank.

No >> Ask the customer about the situation when the symptom occurs in detail, and Preform the trouble

diagnosis. Continuity should not exist.

Continuity should not exist.

SKIA1028E

Continuity should exist.

SKIA1007E

Page 3597 of 3833

COMBINATION METERS (RHD MODELS)

DI-39

C

D

E

F

G

H

I

J

L

MA

B

DI

The Fuel Gauge Does Not Move to Full-position.EKS0030V

1.QUESTION 1

Does it take a long time for the pointer to move to Full-position?

Ye s o r N o

Ye s > > G O T O 2 .

No >> GO TO 3.

2.QUESTION 2

Was the vehicle fueled with the ignition switch ON?

Ye s o r N o

Yes >> Be sure to fuel the vehicle with the ignition switch OFF. Otherwise it will take a long time to move

to Full-position because of the characteristic of the fuel gauge.

No >> GO TO 3.

3.QUESTION 3

Is the floor or the vehicle inclined?

Ye s o r N o

Yes >> It may not be filled fully.

No >> GO TO 4.

4.QUESTION 4

During driving, does the fuel gauge pointer move gradually toward E-position?

Ye s o r N o

Yes >> Check the components. Refer to DI-41, "Electrical Components Inspection" .

No >> The float arm may interfere or bind with any of the components in the fuel tank.

The Fuel Gauge Does Not Work.EKS0030W

1.HARNESS CONNECTOR INSPECTION

1. Turn the ignition switch OFF.

2. Check combination meter, fuel level sensor unit, sub fuel level sensor unit and terminals (meter-side,

module-side, and harness-side) for poor connection and bend.

OK or NG

OK >> GO TO 2.

NG >> Repair connector.

2.CHECK INSTALLATION CONDITION

Check fuel level sensor unit or sub fuel level sensor unit installation (refer toFL-4, "

FUEL LEVEL SENSOR

UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY" for QR engine models or FL-17, "FUEL LEVEL SEN-

SOR UNIT" for YD engine models, and check whether the float arm interferes or binds with any components

inside the arm.

OK or NG

OK >> Fuel level sensor unit is OK.

NG >> Check fuel level sensor unit or sub fuel level sensor unit. Refer to DI-41, "

Electrical Components

Inspection" .

Page 3598 of 3833

DI-40

COMBINATION METERS (RHD MODELS)

Low Fuel Warning Lamp Illuminate or Not Illuminate

EKS0030X

1. DIAGNOSIS MODE INSPECTION

Preform combination meter diagnosis mode. Refer to DI-30, "

Meter/Gauge Operation and Odo/Trip Meter

Segment Check in Diagnosis Mode" .

OK or NG

OK >> Check fuel level sensor unit or sub fuel level sensor unit. Refer to DI-41, "Electrical Components

Inspection" .

NG >> Replace combination meter.

Page 3599 of 3833

COMBINATION METERS (RHD MODELS)

DI-41

C

D

E

F

G

H

I

J

L

MA

B

DI

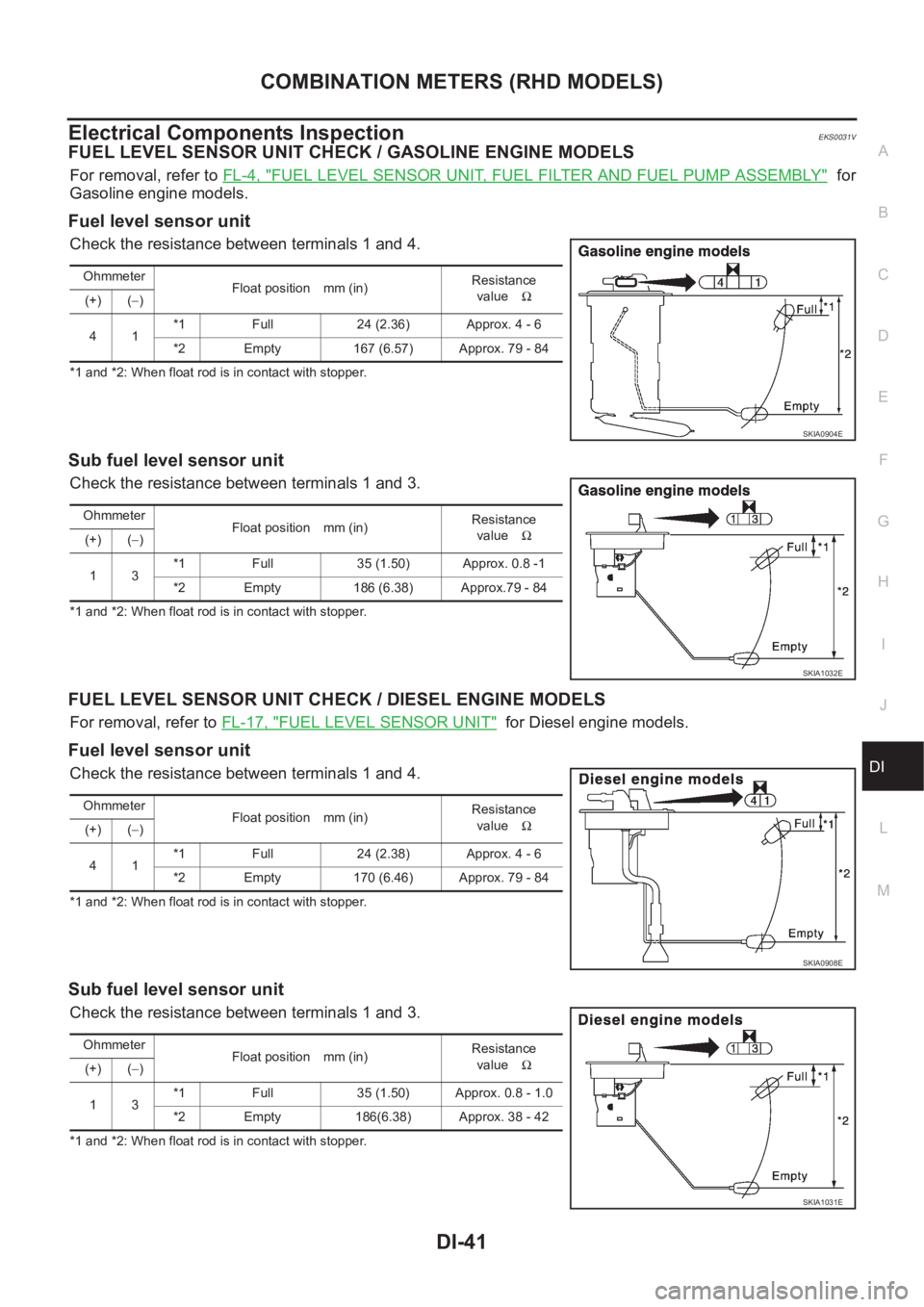

Electrical Components InspectionEKS0031V

FUEL LEVEL SENSOR UNIT CHECK / GASOLINE ENGINE MODELS

For removal, refer to FL-4, "FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY" for

Gasoline engine models.

Fuel level sensor unit

Check the resistance between terminals 1 and 4.

*1 and *2: When float rod is in contact with stopper.

Sub fuel level sensor unit

Check the resistance between terminals 1 and 3.

*1 and *2: When float rod is in contact with stopper.

FUEL LEVEL SENSOR UNIT CHECK / DIESEL ENGINE MODELS

For removal, refer to FL-17, "FUEL LEVEL SENSOR UNIT" for Diesel engine models.

Fuel level sensor unit

Check the resistance between terminals 1 and 4.

*1 and *2: When float rod is in contact with stopper.

Sub fuel level sensor unit

Check the resistance between terminals 1 and 3.

*1 and *2: When float rod is in contact with stopper.Ohmmeter

Float position mm (in)Resistance

valueΩ

(+) (−)

41*1 Full 24 (2.36) Approx. 4 - 6

*2 Empty 167 (6.57) Approx. 79 - 84

SKIA0904E

Ohmmeter

Float position mm (in)Resistance

valueΩ

(+) (−)

13*1 Full 35 (1.50) Approx. 0.8 -1

*2 Empty 186 (6.38) Approx.79 - 84

SKIA1032E

Ohmmeter

Float position mm (in)Resistance

valueΩ

(+) (−)

41*1 Full 24 (2.38) Approx. 4 - 6

*2 Empty 170 (6.46) Approx. 79 - 84

SKIA0908E

Ohmmeter

Float position mm (in)Resistance

valueΩ

(+) (−)

13*1 Full 35 (1.50) Approx. 0.8 - 1.0

*2 Empty 186(6.38) Approx. 38 - 42

SKIA1031E

Page 3600 of 3833

DI-42

COMBINATION METERS (RHD MODELS)

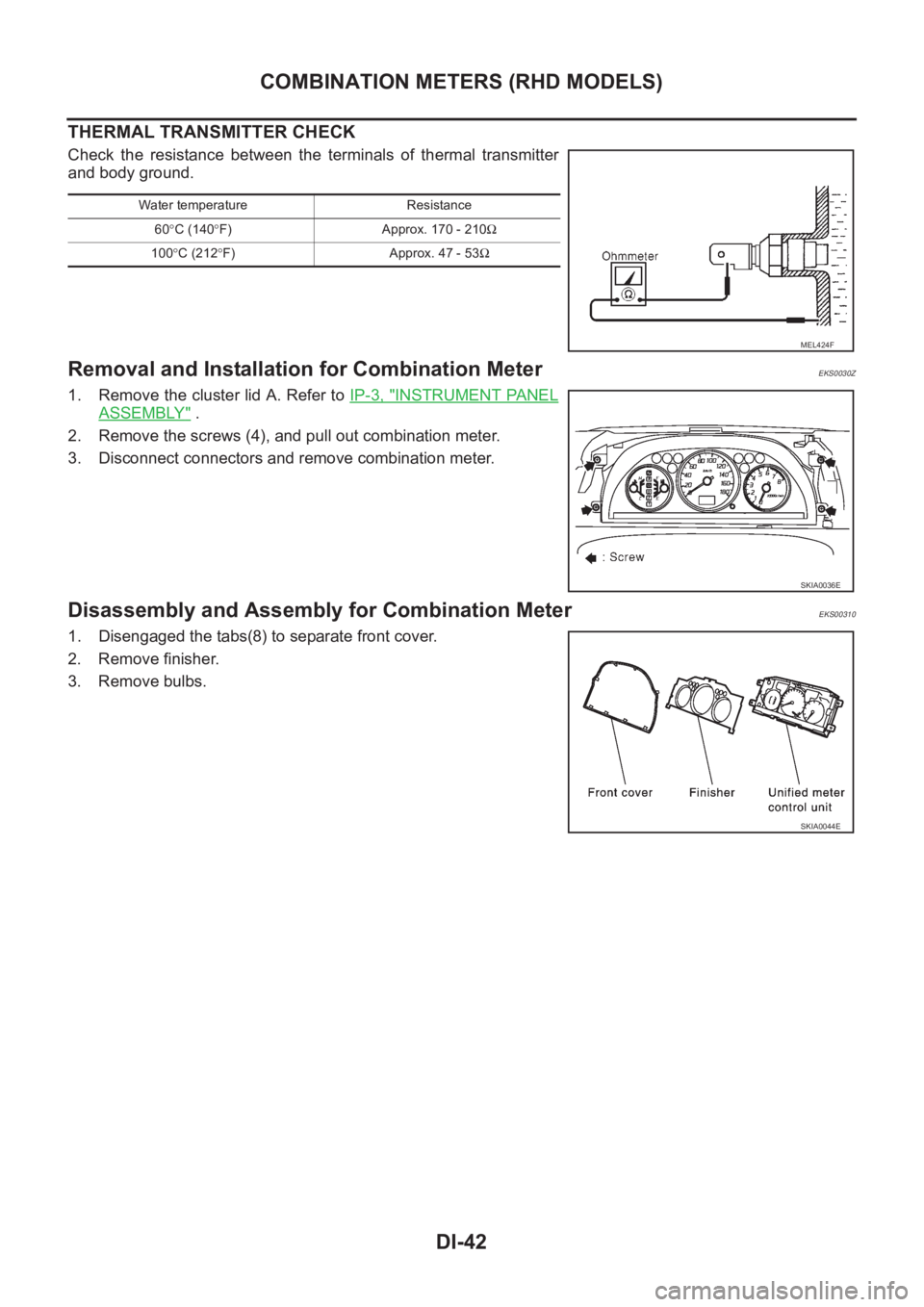

THERMAL TRANSMITTER CHECK

Check the resistance between the terminals of thermal transmitter

and body ground.

Removal and Installation for Combination MeterEKS0030Z

1. Remove the cluster lid A. Refer to IP-3, "INSTRUMENT PANEL

ASSEMBLY" .

2. Remove the screws (4), and pull out combination meter.

3. Disconnect connectors and remove combination meter.

Disassembly and Assembly for Combination MeterEKS00310

1. Disengaged the tabs(8) to separate front cover.

2. Remove finisher.

3. Remove bulbs.

Water temperature Resistance

60°C (140°F) Approx. 170 - 210Ω

100°C (212°F) Approx. 47 - 53Ω

MEL424F

SKIA0036E

SKIA0044E