fuel pump NISSAN X-TRAIL 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 2234 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual FUEL LEVEL SENSOR UNIT

FL-19

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

FL

lTo keep clean the connecting portion and to avoid damage

and foreign materials, cover them completely with plastic

bags or something NISSAN X-TRAIL 2003 Electronic Repair Manual FUEL LEVEL SENSOR UNIT

FL-19

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

FL

lTo keep clean the connecting portion and to avoid damage

and foreign materials, cover them completely with plastic

bags or something](/img/5/57402/w960_57402-2233.png)

FUEL LEVEL SENSOR UNIT

FL-19

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

FL

lTo keep clean the connecting portion and to avoid damage

and foreign materials, cover them completely with plastic

bags or something similar.

8. Using a lock ring wrench, remove the lock ring.

9. Remove main fuel level sensor unit and sub fuel level sensor

unit.

CAUTION:

lDo not bend the float arm during removal.

lAvoid impacts such as falling when handling components.

Removal of main fuel level sensor unit:

lRaise the fuel level sensor unit, and remove the jet pump.

lLeave the jet pump on the fuel tank with the fuel hose.

lIf necessary, remove the chamber from the bottom of the fuel

tank.

lRemove the chamber by sliding toward the rear of the vehicle.

Removal of sub fuel level sensor unit:

lRaise and release the sub fuel level sensor unit to remove.

lIf necessary, remove the jet pump inlet from the bottom of the fuel tank.

To remove it, pinch the tabs (2 places).

INSPECTION AFTER REMOVAL

Make sure the fuel pump strainer is free from foreign materials, If any are found, remove them.

INSTALLATION

Install in the reverse order of removal paying attention to the follow-

ing.

lWhen installing the chamber and jet pump, insert them fully until

a click sound of full stopper engagement is heard (for jet pump

inlet).

lConnect the quick connector as follows.

1. Check the connection for damage and foreign materials.

2. Align the connector with the tube, then insert the connector

straight into the tube until a click is heard.

3. After connecting, make sure that the connection is secure by fol-

lowing the steps below.

PBIC0163E

PBIC0240E

SBIA0142E

SBIA0143E

Page 2257 of 3066

GI-4

PRECAUTIONS

General Precautions

EAS000FQ

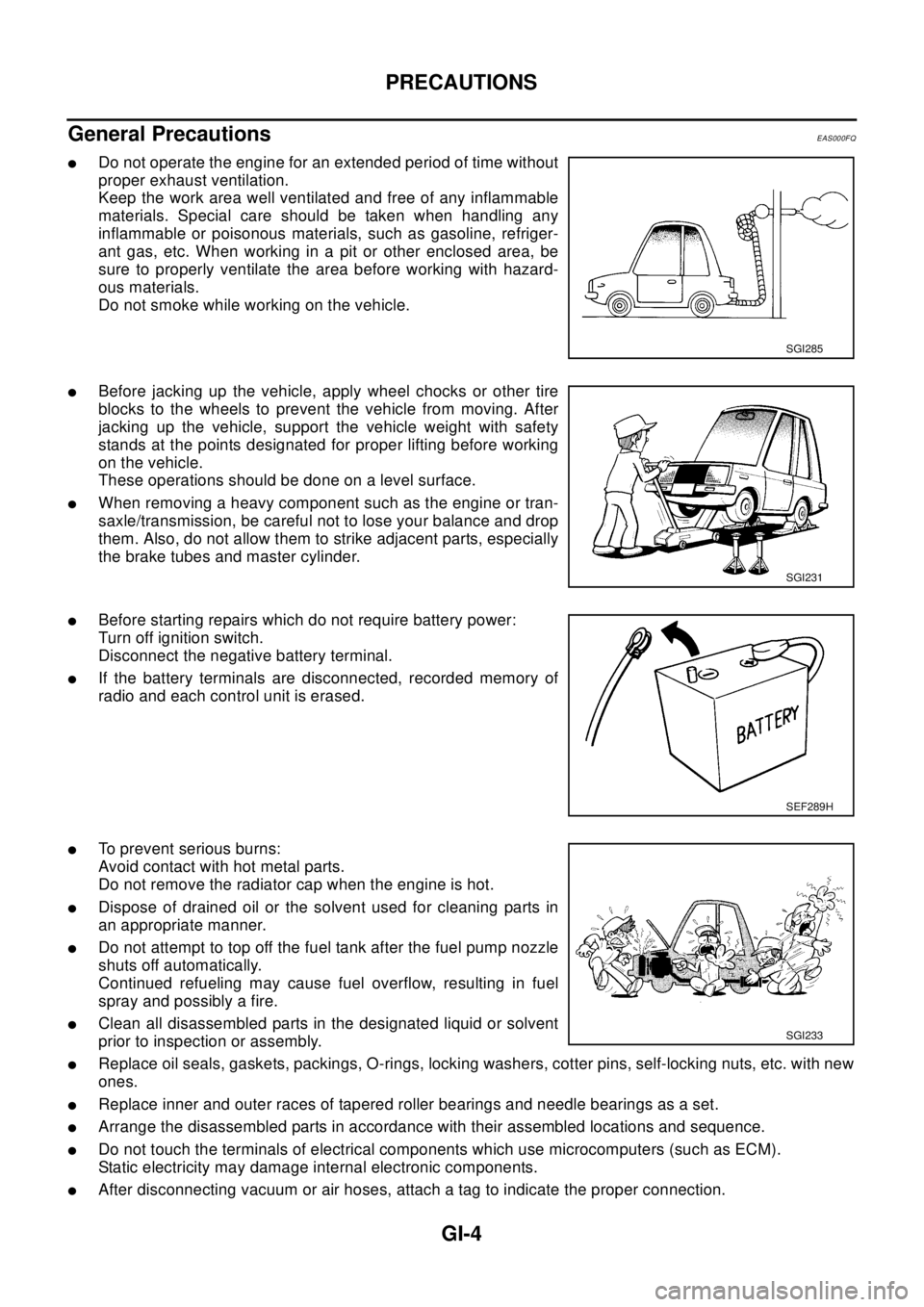

lDo not operate the engine for an extended period of time without

proper exhaust ventilation.

Keep the work area well ventilated and free of any inflammable

materials. Special care should be taken when handling any

inflammable or poisonous materials, such as gasoline, refriger-

ant gas, etc. When working in a pit or other enclosed area, be

sure to properly ventilate the area before working with hazard-

ous materials.

Do not smoke while working on the vehicle.

lBefore jacking up the vehicle, apply wheel chocks or other tire

blocks to the wheels to prevent the vehicle from moving. After

jacking up the vehicle, support the vehicle weight with safety

stands at the points designated for proper lifting before working

on the vehicle.

These operations should be done on a level surface.

lWhen removing a heavy component such as the engine or tran-

saxle/transmission, be careful not to lose your balance and drop

them. Also, do not allow them to strike adjacent parts, especially

the brake tubes and master cylinder.

lBefore starting repairs which do not require battery power:

Turn off ignition switch.

Disconnect the negative battery terminal.

lIf the battery terminals are disconnected, recorded memory of

radio and each control unit is erased.

lTo prevent serious burns:

Avoid contact with hot metal parts.

Do not remove the radiator cap when the engine is hot.

lDispose of drained oil or the solvent used for cleaning parts in

an appropriate manner.

lDo not attempt to top off the fuel tank after the fuel pump nozzle

shuts off automatically.

Continued refueling may cause fuel overflow, resulting in fuel

spray and possibly a fire.

lClean all disassembled parts in the designated liquid or solvent

prior to inspection or assembly.

lReplace oil seals, gaskets, packings, O-rings, locking washers, cotter pins, self-locking nuts, etc. with new

ones.

lReplace inner and outer races of tapered roller bearings and needle bearings as a set.

lArrange the disassembled parts in accordance with their assembled locations and sequence.

lDo not touch the terminals of electrical components which use microcomputers (such as ECM).

Static electricity may damage internal electronic components.

lAfter disconnecting vacuum or air hoses, attach a tag to indicate the proper connection.

SGI285

SGI231

SEF289H

SGI233

Page 2259 of 3066

GI-6

PRECAUTIONS

Precautions for Multiport Fuel Injection System or Engine Control System

EAS000FT

lBefore connecting or disconnecting any harness connector for

the multiport fuel injection system or ECM:

Turn ignition switch to “OFF” position.

Disconnect negative battery terminal.

Otherwise, there may be damage to ECM.

lBefore disconnecting pressurized fuel line from fuel pump to

injectors, be sure to release fuel pressure.

lBe careful not to jar components such as ECM and mass air

flow sensor.

Precautions for Turbocharger (If Equipped)EAS000FU

The turbocharger turbine revolves at extremely high speeds and

becomes very hot. Therefore, it is essential to maintain a clean sup-

ply of oil flowing through the turbocharger and to follow all required

maintenance instructions and operating procedures.

lAlways use the recommended oil. Follow the instructions for

proper time to change the oil and proper oil level.

lAvoid accelerating engine to a high rpm immediately after start-

ing.

lIf engine had been operating at high rpm for an extended period

of time, let it idle for a few minutes prior to shutting if off.

Precautions for HosesEAS000FV

HOSE REMOVAL AND INSTALLATION

lTo prevent damage to rubber hose, do not pry off rubber hose

with tapered tool or screwdriver.

lTo reinstall the rubber hose securely, make sure that hose inser-

tion length and orientation is correct. (If tube is equipped with

hose stopper, insert rubber hose into tube until it butts up

against hose stopper.)

SGI787

SGI292

SMA019D

SMA020D

Page 2302 of 3066

TERMINOLOGY

GI-49

Nonvolatile random access memory NVRAM ***

On board diagnostic system OBD system Self-diagnosis

Open loop OL Open loop

Oxidation catalyst OC Catalyst

Oxidation catalytic converter system OC system ***

Oxygen sensor O2S Exhaust gas sensor

Park position switch *** Park switch

Park/neutral position switch PNP switchPark/neutral switch

Inhibitor switch

Neutral position switch

Periodic trap oxidizer system PTOX system ***

Positive crankcase ventilation PCV Positive crankcase ventilation

Positive crankcase ventilation valve PCV valve PCV valve

Powertrain control module PCM ***

Programmable read only memory PROM ***

Pulsed secondary air injection control sole-

noid valvePAIRC solenoid valve AIV control solenoid valve

Pulsed secondary air injection system PAIR system Air induction valve (AIV) control

Pulsed secondary air injection valve PAIR valve Air induction valve

Random access memory RAM ***

Read only memory ROM ***

Scan tool ST ***

Secondary air injection pump AIR pump ***

Secondary air injection system AIR system ***

Sequential multiport fuel injection system SFI system Sequential fuel injection

Service reminder indicator SRI ***

Simultaneous multiport fuel injection sys-

tem*** Simultaneous fuel injection

Smoke puff limiter system SPL system ***

Supercharger SC ***

Supercharger bypass SCB ***

System readiness test SRT ***

Thermal vacuum valve TVV Thermal vacuum valve

Three way catalyst TWC Catalyst

Three way catalytic converter system TWC system ***

Three way + oxidation catalyst TWC + OC Catalyst

Three way + oxidation catalytic converter

systemTWC + OC system ***

Throttle body TBThrottle chamber

SPI body

Throttle body fuel injection system TBI system Fuel injection control

Throttle position TP Throttle position

Throttle position sensor TPS Throttle sensor

Throttle position switch TP switch Throttle switchNEW TERMNEW ACRONYM /

ABBREVIATIONOLD TERM

Page 2361 of 3066

IDX-4

ALPHABETICAL INDEX

Diagnostic trouble code (DTC) ........................EC-666

Diagnostic trouble code (DTC) for OBD systemEC-12,

EC-38

,EC-379,EC-401,EC-654

Diagnostic trouble code (DTC) inspection priority chart

EC-61

,EC-410

Differential gear (FF M/T) .....................MT-22,MT-27

DLC - Wiring diagram ........................EC-371,EC-646

Door glass ...........................................GW-41,GW-43

Door glass Fitting Adjustment .............GW-41,GW-43

Door lock .................................................BL-54,BL-57

Door mirror ........................................................GW-46

Door trim .............................................................EI-23

Door, front ............................................................BL-8

Door, rear .............................................................BL-8

Drive belt inspection(QR20DE) .........................MA-20

Drive belt inspection(YD22DDTi) ......................MA-27

Drive belt(QR20DE) ..........................................EM-13

Drive belt(YD22DDTi) .....................................EM-110

Drive shaft (front) .............................................FAX-11

Drive shaft (rear) ...............................................RAX-9

Driver air bag ..................................................SRS-27

Dropping resistor (A/T) ......................AT-192,AT-442

DTC work support ..............................................EC-95

DTRL - Wiring diagram .........................................LT-9

Dual pressure switch ........ATC-16,ATC-81,ATC-138

Duct and grilles ...............................ATC-121,MTC-29

E

ECM input/output signal .......................EC-79

,EC-427

ECM power supplyEC-108,EC-256,EC-454,EC-530,

EC-700

ECM relay ........................................................EC-790

ECM/PW - Wiring diagram .................EC-257,EC-531

ECMRLY - Wiring diagram ..............................EC-791

ECTS - Wiring diagram .......EC-143,EC-472,EC-712

EDU - Wiring diagram ......................................EC-756

EGR function ...................................................EC-803

EGR volume control valve ...............................EC-803

EGRC/V - Wiring diagram ................................EC-805

Electric sun roof ...................................................RF-2

Electric throttle control actuator ........EC-271,EC-273,

EC-534

,EC-536

Electrical unit .....................................................PG-73

Electrical units location ......................................PG-64

Electronic drive unit (EDU) ..............................EC-754

Electronic fuel injection pump(YD22DDTi) .....EM-138

Electronic ignition (EI) system .............EC-27,EC-392

Engine control circuit diagramEC-77,EC-425,EC-683

Engine control component parts location ..........EC-73,

EC-421

Engine control module (ECM) ...........EC-249,EC-523,

EC-788

Engine control system diagram and chart ........EC-22,

EC-387

,EC-659

Engine coolant temperature sensor (ECTS) ...EC-141,

EC-470

,EC-711

Engine coolant(QR20DE) ...................................CO-9

Engine coolant(YD22DDTi) ..............................CO-30

Engine fail-safe system .......................EC-62,EC-411

Engine oil filter replacement(QR20DE) .............MA-24

Engine oil filter replacement(YD22DDTi) ..........MA-33

Engine oil replacement(QR20DE) ....................MA-24

Engine oil replacement(YD22DDTi) ..................MA-32

Engine oil(QR20DE) ............................................LU-7

Engine oil(YD22DDTi) .......................................LU-18

Engine removal(QR20DE) ................................EM-61

Engine removal(YD22DDTi) ...........................EM-184

EVAP canister purge volume control solenoid valve ....

EC-233

,EC-372,EC-601,EC-649

EVAP vapor lines inspection(QR20DE) ............MA-26

Evaporative emission (EVAP) systemEC-372,EC-647

Evaporator ....................................................ATC-139

Exhaust manifold(QR20DE) .............................EM-22

Exhaust manifold(YD22DDTi) .........................EM-119

Exhaust system ...................................................EX-2

Exhaust system inspection .....................EX-2,MA-35

Expansion valve ............................................ATC-140

ExteriorEI-13,EI-14,EI-16,EI-17,EI-18,EI-19,EI-21,

EI-22

F

F/FOG - Wiring diagram .........................LT-33

,LT-34

F/PUMP - Wiring diagram .................EC-354,EC-629

Fan control amp. .............................ATC-70,ATC-113

Fan switch ........................................ATC-27,MTC-17

FIAR - Wiring diagram .....................................EC-778

Final drive (FF M/T) ..............................MT-22,MT-27

Final drive disassembly ..................................RFD-11

Final drive removal and installation ................RFD-11

Finisher, interior - See Trim ......................EI-23,EI-25

Finisher, rear panel .............................................EI-22

Floor trim .............................................................EI-28

Fluid temperature sensor (A/T) ........................AT-141

Fluids ................................................................MA-17

Fluorescent leak detector .............................ATC-141

Flywheel (clutch) ................................................CL-15

Flywheel runout(QR20DE) ................................EM-89

Flywheel runout(YD22DDTi) ...........................EM-208

Fog lamp, front ...................................................LT-33

Fork rod (M/T) .......................................MT-21,MT-26

Freeze frame data ..............................EC-39,EC-402

FRO2 - Wiring diagram ....................................EC-582

FRO2/H - Wiring diagram ................................EC-569

Front bumper ........................................................EI-6

Front disc brake .................................................BR-21

Front door ............................................................BL-8

Front Door Trim ..................................................EI-23

Front fog lamp ....................................................LT-33

Front passenger air bag ..................................SRS-33

Front seat .............................................................SE-7

Front seat belt ......................................................SB-3

Front seat belt pre-tensioner .....SB-2,SRS-3,SRS-38

Front side air bag ............................................SRS-35

Front suspension ..............................................FSU-5

Page 2362 of 3066

IDX-5

A

C

D

E

F

G

H

I

J

K

L B

IDX

ALPHABETICAL INDEX

Front washer ......................................................WW-4

Front wiper .........................................................WW-4

FTS - Wiring diagram ......................................EC-752

Fuel check valve ..............................................EC-372

Fuel cut control (at no load high engine speed)EC-28,

EC-393

,EC-662

Fuel filler lid ........................................................BL-64

Fuel filter ..........................................................EC-664

Fuel filter replacement(QR20DE) .........................FL-4

Fuel filter replacement(YD22DDTi) .......FL-15,MA-30

Fuel gauge ..................................................DI-4,DI-22

Fuel injection control system ...........................EC-660

Fuel injection system .........................EC-194,EC-200

Fuel injector .....................................................EC-727

Fuel injector adjustment resistor ......................EC-777

Fuel injector and fuel tube(QR20DE) ................EM-29

Fuel injector and fuel tube(YD22DDTi) ............EM-135

Fuel leak ..........................................................EC-781

Fuel line inspection(QR20DE) .................FL-3,MA-23

Fuel line inspection(YD22DDTi) ............FL-14,MA-30

Fuel pressure check ............................EC-34,EC-399

Fuel pressure release ..........................EC-34,EC-399

Fuel pressure relief valve ................................EC-665

Fuel pump ..........................................EC-352,EC-627

Fuel pump and gauge(QR20DE) ..........................FL-4

Fuel system(QR20DE) .........................................FL-3

Fuel system(YD22DDTi) .....................................FL-14

Fuel tank(QR20DE) ..............................................FL-9

Fuel tank(YD22DDTi) .........................................FL-21

Fuel temperature sensor .................................EC-751

Fuse ...................................................................PG-12

Fuse and fusible link box ...................................PG-77

Fusible link .........................................................PG-12

G

Gear components (M/T) .......................MT-19

,MT-24

Generator ..........................................................SC-12

Generator - See Alternator ................................SC-12

Generic scan tool (GST) ....................................EC-96

Glass ..................................................GW-41,GW-43

GLOW - Wiring diagram ..................................EC-797

Glow plug .........................................................EC-796

Glow plug(YD22DDTi) .....................................EM-130

Glow relay ........................................................EC-796

Grease ...............................................................MA-17

Grille - See Exterior .............................................EI-11

Ground distribution ............................................PG-13

G-sensor .............................................................TF-50

H

H/AIM - Wiring diagram ......................................LT-15

H/LAMP - Wiring diagram ...........................LT-4,LT-5

H/MIRROR - Wiring diagram ............................GW-10

Harness connector ............................................PG-70

Harness layout ...................................................PG-29

Headlamp .............................................................LT-4

Headlamp aiming control ....................................LT-15

Headlamp leveler - See Headlamp aiming control .......

LT-15

Headlamp washer ............................................WW-19

Headlining - See Roof trim ..................................EI-29

Heated oxygen sensor 1 ....EC-160,EC-166,EC-174,

EC-284

,EC-290,EC-490,EC-581

Heated oxygen sensor 1 heater .........EC-120,EC-568

Heated oxygen sensor 2 ....EC-181,EC-187,EC-296,

EC-303

,EC-587

Heated oxygen sensor 2 heater .........EC-125,EC-573

Heated seat ...............................................SE-3,SE-5

HEATER - Wiring diagram ................................MTC-6

Heater and cooling unit (Heater core) ............ATC-115

Heater mirror .....................................................GW-10

Heater system - Wiring diagram .......................MTC-6

Heater unit (heater core) ..ATC-120,MTC-23,MTC-26

HFC134a (R134a) system precaution ...............ATC-4

HFC134a (R134a) system service procedureATC-123

HFC134a (R134a) system service tools ..........ATC-12

HFC134a system service equipment precautionATC-8

HO2S1 - Wiring diaram ......EC-122,EC-162,EC-169,

EC-177

,EC-492

HO2S2 - Wiring diagram ....EC-183,EC-190,EC-299,

EC-306

HO2S2H - Wiring diagram ...............................EC-127

Hood ....................................................................BL-4

Horn .................................................................WW-23

HORN - Wiring diagram ...................................WW-23

How to erase DTC ...........................................EC-666

HowtoeraseDTCforOBDsystem .....EC-46,EC-402

I

IATS - Wiring diagram .....................................EC-138

IATSEN - Wiring diagram ................................EC-578

Identification .....................................................ATC-10

Idle air volume learning ........................EC-31,EC-396

Idle speed .............................EC-64,EC-412,EC-672

IGN/SG - Wiring diagram .................................EC-335

Ignition coil .........................................EC-334,EC-592

Ignition coil(QR20DE) .......................................EM-27

Ignition control system .......................EC-334,EC-592

Ignition timing .......................................EC-64,EC-412

IGNSYS - Wiring diagram ................................EC-593

ILL - Wiring diagram ...........................................LT-45

Illumination ..........................................................LT-45

In vehicle sensor ...............ATC-95,ATC-97,ATC-106

INJECT - Wiring diagram ....EC-344,EC-619,EC-730

Injection nozzle(YD22DDTi) ...........................EM-135

Injector ...............................................EC-343,EC-618

Input shaft (FF M/T) ..............................MT-19,MT-24

Instrument panel ...................................................IP-3

INT/L - Wiring diagram ........................................LT-65

Intake air temparature sensor ............EC-136,EC-577

Intake door control linkage adjustment ............ATC-66

Intake door motorATC-64,ATC-112,MTC-10,MTC-22

Intake manifold(QR20DE) .................................EM-17

Page 2363 of 3066

IDX-6

ALPHABETICAL INDEX

Intake manifold(YD22DDTi) ............................EM-115

Intake sensor ................................ATC-101,ATC-108

Intake valve timing control .................EC-117,EC-608

Intake valve timing control solenoid valve ......EC-266,

EC-608

Interior .......................EI-23,EI-25,EI-26,EI-28,EI-29

Interior lamp ........................................................LT-55

Interior lamp on-off control ......................LT-55,LT-56

ISO 15031-5 Mode 1 - 9 ....................................EC-36

IVC - Wiring diagram .......................................EC-268

IVC/V - Wiring diagram ....................................EC-610

J

Joint connector (J/C) .............................PG-72

,PG-76

K

Keyless entry system - See Multi-remote control system

BL-45

Knock sensor (KS) .............................EC-212,EC-496

KS - Wiring diagram ...........................EC-214,EC-498

L

LAN system circuit ...........................................ATC-56

License lamp .......................................................LT-30

Line pressure solenoid valve ...........................AT-179

Line pressure test (A/T) .......................AT-68,AT-290

Liquid gasket application(QR20DE) ....................EM-6

Liquid gasket application(YD22DDTi) .............EM-103

LOAD - Wiring diagram ......................EC-363,EC-638

Location of electrical units .................................PG-64

Lock, door ...............................................BL-54,BL-57

Lubricant (R134a) A/C ........................ATC-5,ATC-21

Lubricants .........................................................MA-17

Lubrication circuit (engine)(QR20DE) ..................LU-5

Lubrication circuit (engine)(YD22DDTi) .............LU-17

Lubrication-locks, hinges and hood latches ......MA-42

M

M/T major overhaul ...............................MT-27

,MT-35

M/T oil replacement ...........................................MT-11

M/T removal and installation ..............................MT-16

MAFS - Wiring diagram .....EC-132,EC-262,EC-466,

EC-708

Magnet clutch .................................ATC-73,ATC-129

MAIN - Wiring diagram .......EC-108,EC-454,EC-701

Mainshaft (M/T) .....................................MT-19,MT-24

Major overhaul (Transfer) ..................................TF-14

Malfunction indicator (MI) ...EC-252,EC-526,EC-667

Malfunction indicator lamp (MIL) ..........EC-48,EC-404

Mass air flow sensor (MAFS) ............EC-130,EC-260,

EC-463

,EC-706

Master cylinder (brake) ......................................BR-13

Master cylinder (clutch) ........................................CL-9

METER - Wiring diagram ...........................DI-8,DI-26

MIL - Wiring diagram ........................EC-253,EC-527

MIL/DL - Wiring diagram ..................................EC-825

MIRROR - Wiring diagram ...............................GW-47

Mirror defogger ................................................GW-10

Mirror, door ......................................................GW-46

Mirror, out side .................................................GW-46

Misfire ..............................................................EC-206

Mode door control linkage adjustment ...........ATC-61,

ATC-118

,MTC-8,MTC-27

Mode door motor ............................ATC-58,ATC-118

Molding - See Exterior ........GW-3,EI-14,EI-16,EI-17

Mud guard - See Exterior ....................................EI-16

MULTI - Wiring diagram .....................................BL-47

Multiport fuel injection (MFI) system ...EC-24,EC-389

Multi-remote control system ...............................BL-45

N

NATS - Wiring diagram ......................................BL-72

NATS (Nissan anti-theft system) .......................BL-70

NVH troubleshooting (BR) .........................BR-5,PB-2

NVH troubleshooting (CL) ....................................CL-4

NVH troubleshooting (EM)(QR20DE) ...............EM-11

NVH troubleshooting (EM)(YD22DDTi) ..........EM-108

NVH troubleshooting (FSU) ..............................FSU-4

NVH troubleshooting (M/T) .................................MT-8

NVH troubleshooting (PR) .................................FAX-6

NVH troubleshooting (RA) ................................RAX-5

NVH troubleshooting (RAX) ..............................RAX-5

NVH troubleshooting (RSU) ..............................RSU-4

NVH troubleshooting (ST) ....................................PS-4

NVH troubleshooting (Transfer) ...........................TF-7

NVH troubleshooting (WT) ..................................WT-2

O

Oil cooler (engine)(QR20DE) .............................LU-13

Oil cooler (engine)(YD22DDTi) ..........................LU-25

Oil filter(QR20DE) ................................................LU-9

Oil filter(YD22DDTi) ...........................................LU-20

Oil pan (engine)(QR20DE) ...............................EM-24

Oil pan (engine)(YD22DDTi) ...........................EM-125

Oil pressure (engine)(QR20DE) ..........................LU-7

Oil pressure (engine)(YD22DDTi) ......................LU-18

Oil pump (engine)(QR20DE) .............................LU-10

Oil pump (engine)(YD22DDTi) ...........................LU-23

Oil pump regulator valve (engine)(QR20DE) .....LU-11

Oil pump regulator valve (engine)(YD22DDTi) ..LU-24

On board diagnostic system ...............EC-36,EC-401

Operating cylinder (clutch) .................................CL-11

Out side mirror .................................................GW-46

Overdrive control switch ....................AT-265,AT-387

Overheat ..........................................................EC-761

Oversize piston(QR20DE) ................................EM-85

Oversize piston(YD22DDTi) ...........................EM-204

Page 2526 of 3066

MA-34

ENGINE MAINTENANCE (YD22DDTI)

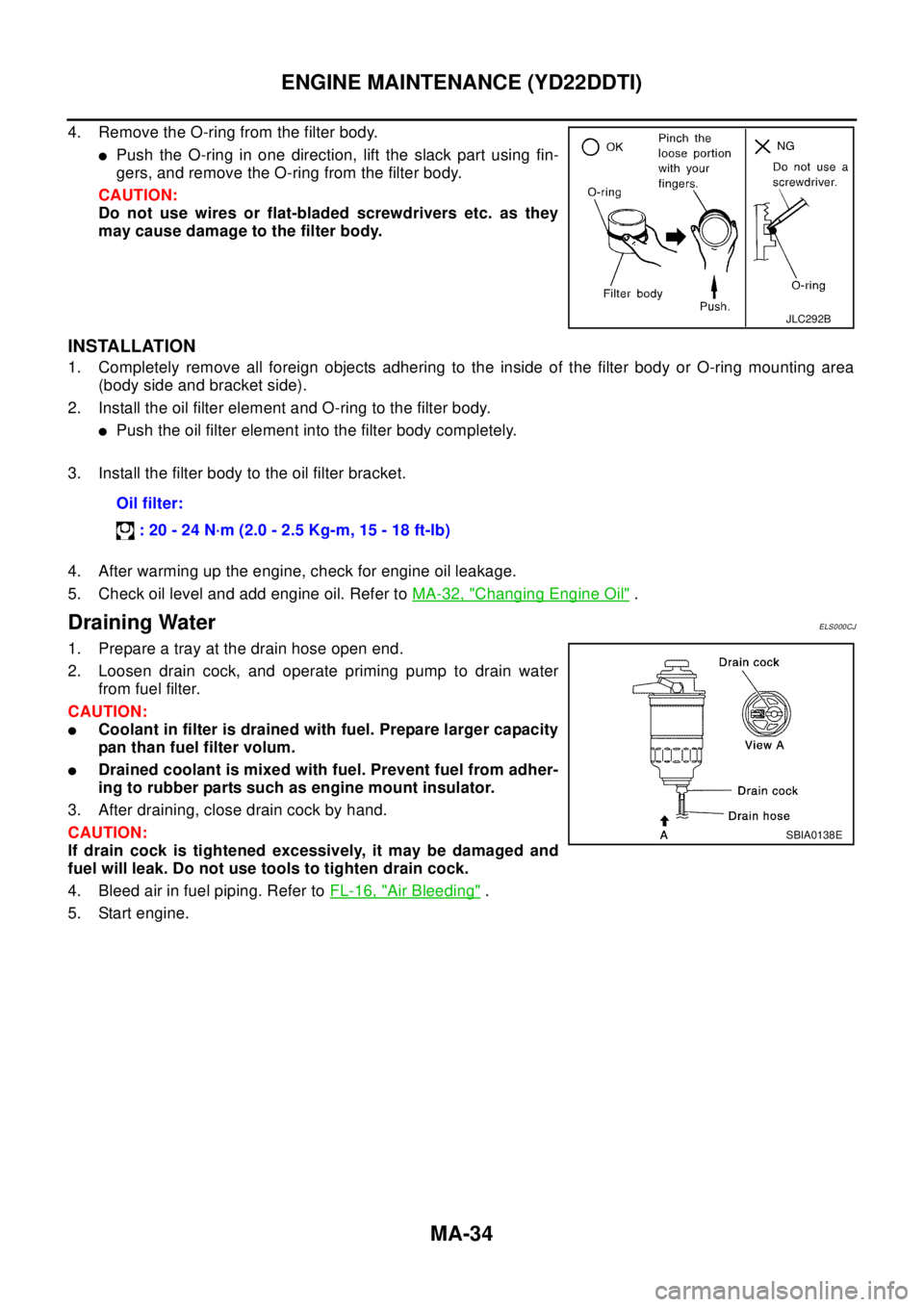

4. Remove the O-ring from the filter body.

lPush the O-ring in one direction, lift the slack part using fin-

gers, and remove the O-ring from the filter body.

CAUTION:

Do not use wires or flat-bladed screwdrivers etc. as they

may cause damage to the filter body.

INSTALLATION

1. Completely remove all foreign objects adhering to the inside of the filter body or O-ring mounting area

(body side and bracket side).

2. Install the oil filter element and O-ring to the filter body.

lPush the oil filter element into the filter body completely.

3. Install the filter body to the oil filter bracket.

4. After warming up the engine, check for engine oil leakage.

5. Check oil level and add engine oil. Refer toMA-32, "

Changing Engine Oil".

Draining WaterELS000CJ

1. Prepare a tray at the drain hose open end.

2. Loosen drain cock, and operate priming pump to drain water

from fuel filter.

CAUTION:

lCoolant in filter is drained with fuel. Prepare larger capacity

pan than fuel filter volum.

lDrained coolant is mixed with fuel. Prevent fuel from adher-

ing to rubber parts such as engine mount insulator.

3. After draining, close drain cock by hand.

CAUTION:

If drain cock is tightened excessively, it may be damaged and

fuel will leak. Do not use tools to tighten drain cock.

4. Bleed air in fuel piping. Refer toFL-16, "

Air Bleeding".

5. Start engine.

JLC292B

Oil filter:

:20-24N·m(2.0-2.5Kg-m,15-18ft-lb)

SBIA0138E