check engine NISSAN X-TRAIL 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 680 of 3066

ATC-102

TROUBLE DIAGNOSIS

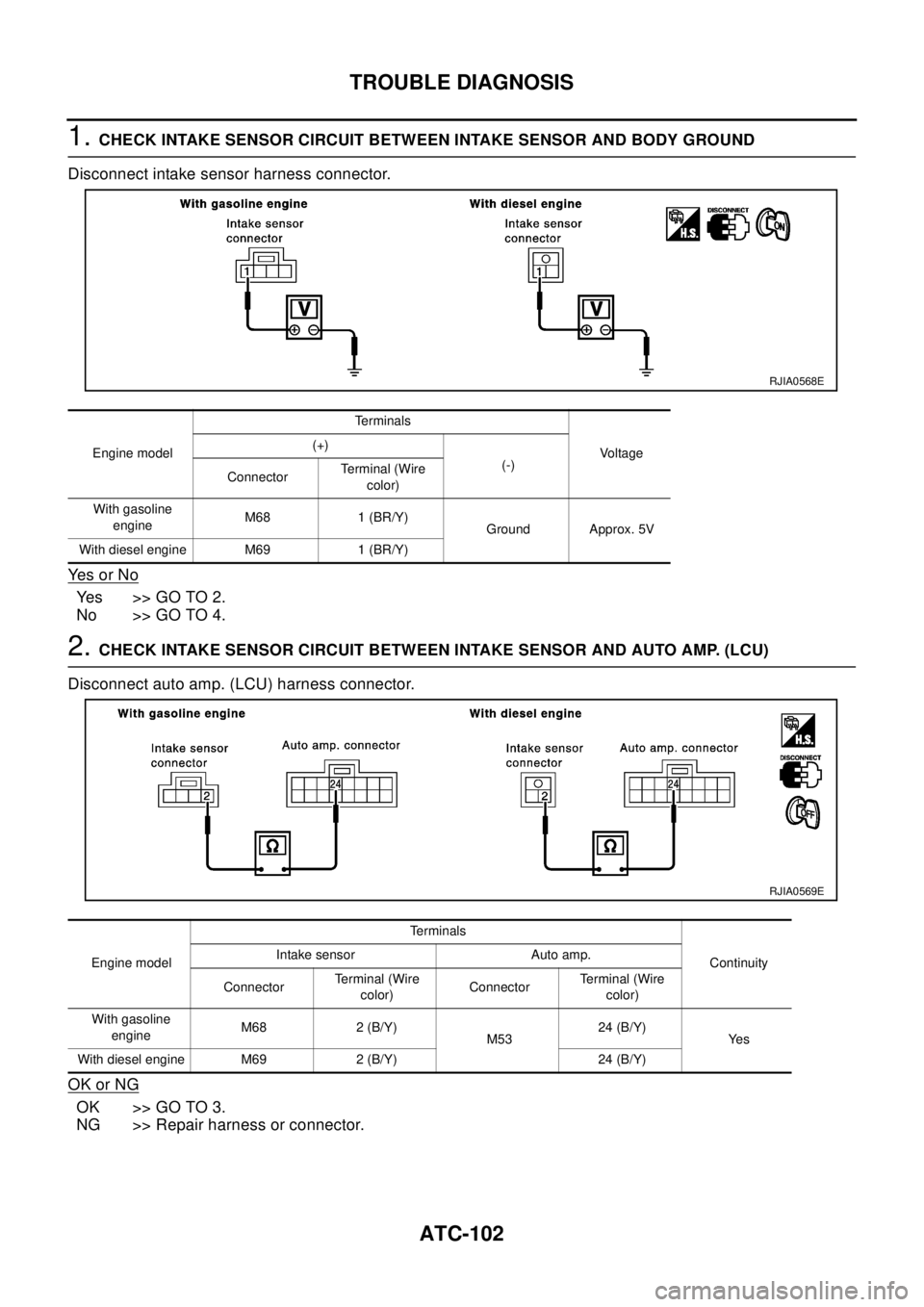

1.CHECK INTAKE SENSOR CIRCUIT BETWEEN INTAKE SENSOR AND BODY GROUND

Disconnect intake sensor harness connector.

Ye s o r N o

Yes >>GOTO2.

No >> GO TO 4.

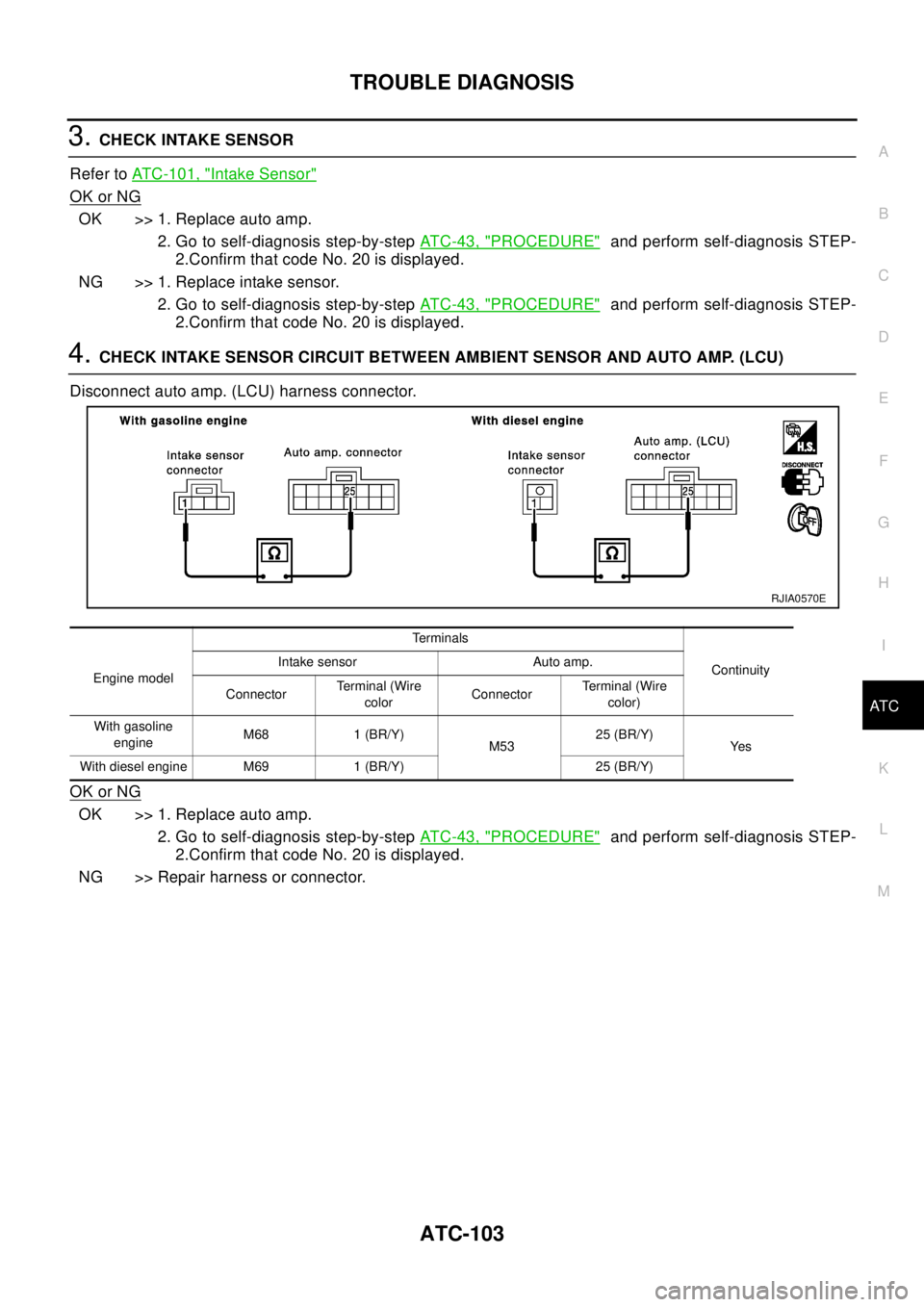

2.CHECK INTAKE SENSOR CIRCUIT BETWEEN INTAKE SENSOR AND AUTO AMP. (LCU)

Disconnect auto amp. (LCU) harness connector.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

Engine modelTe r m i n a l s

Vo l ta g e (+)

(-)

ConnectorTe r m i n a l ( W i r e

color)

With gasoline

engineM68 1 (BR/Y)

Ground Approx. 5V

With diesel engine M69 1 (BR/Y)

RJIA0568E

Engine modelTe r m i n a l s

Continuity Intake sensor Auto amp.

ConnectorTerminal (Wire

color)ConnectorTerminal (Wire

color)

With gasoline

engineM68 2 (B/Y)

M5324 (B/Y)

Ye s

With diesel engine M69 2 (B/Y) 24 (B/Y)

RJIA0569E

Page 681 of 3066

TROUBLE DIAGNOSIS

ATC-103

C

D

E

F

G

H

I

K

L

MA

B

AT C

3.CHECK INTAKE SENSOR

Refer toATC-101, "

Intake Sensor"

OK or NG

OK >> 1. Replace auto amp.

2. Go to self-diagnosis step-by-stepAT C - 4 3 , "

PROCEDURE"and perform self-diagnosis STEP-

2.Confirm that code No. 20 is displayed.

NG >> 1. Replace intake sensor.

2. Go to self-diagnosis step-by-stepAT C - 4 3 , "

PROCEDURE"and perform self-diagnosis STEP-

2.Confirm that code No. 20 is displayed.

4.CHECK INTAKE SENSOR CIRCUIT BETWEEN AMBIENT SENSOR AND AUTO AMP. (LCU)

Disconnect auto amp. (LCU) harness connector.

OK or NG

OK >> 1. Replace auto amp.

2. Go to self-diagnosis step-by-stepAT C - 4 3 , "

PROCEDURE"and perform self-diagnosis STEP-

2.Confirm that code No. 20 is displayed.

NG >> Repair harness or connector.

Engine modelTerminals

Continuity Intake sensor Auto amp.

ConnectorTerminal (Wire

colorConnectorTerminal (Wire

color)

With gasoline

engineM68 1 (BR/Y)

M5325 (BR/Y)

Ye s

With diesel engine M69 1 (BR/Y) 25 (BR/Y)

RJIA0570E

Page 710 of 3066

ATC-132

REFRIGERANT LINES

10. Remove the field coil harness clip using a screwdriver.

11. Then remove the three field coil fixing screws and remove the

field coil.

Inspection

Clutch disc

If the contact surface shows signs of damage due to excessive heat,

replace clutch disc and pulley.

Pulley

Check the appearance of the pulley assembly. If the contact surface

of pulley sows signs of excessive grooving, replace clutch disc and

pulley. The contact surfaces of the pulley assembly should be

cleaned with a suitable solvent before reinstallation.

Coil

Check coil for loose connection or cracked insulation.

INSTALLATION

With Gasoline Engine (CWV-615M Compressor)

1. Install the field coil.

Be sure to align the coil's pin with the hole in the compressor's

front head.

2. Install the field coil harness clip using a screwdriver.

RHA074C

RJIA0582E

RJIA0583E

RHA142E

Page 712 of 3066

ATC-134

REFRIGERANT LINES

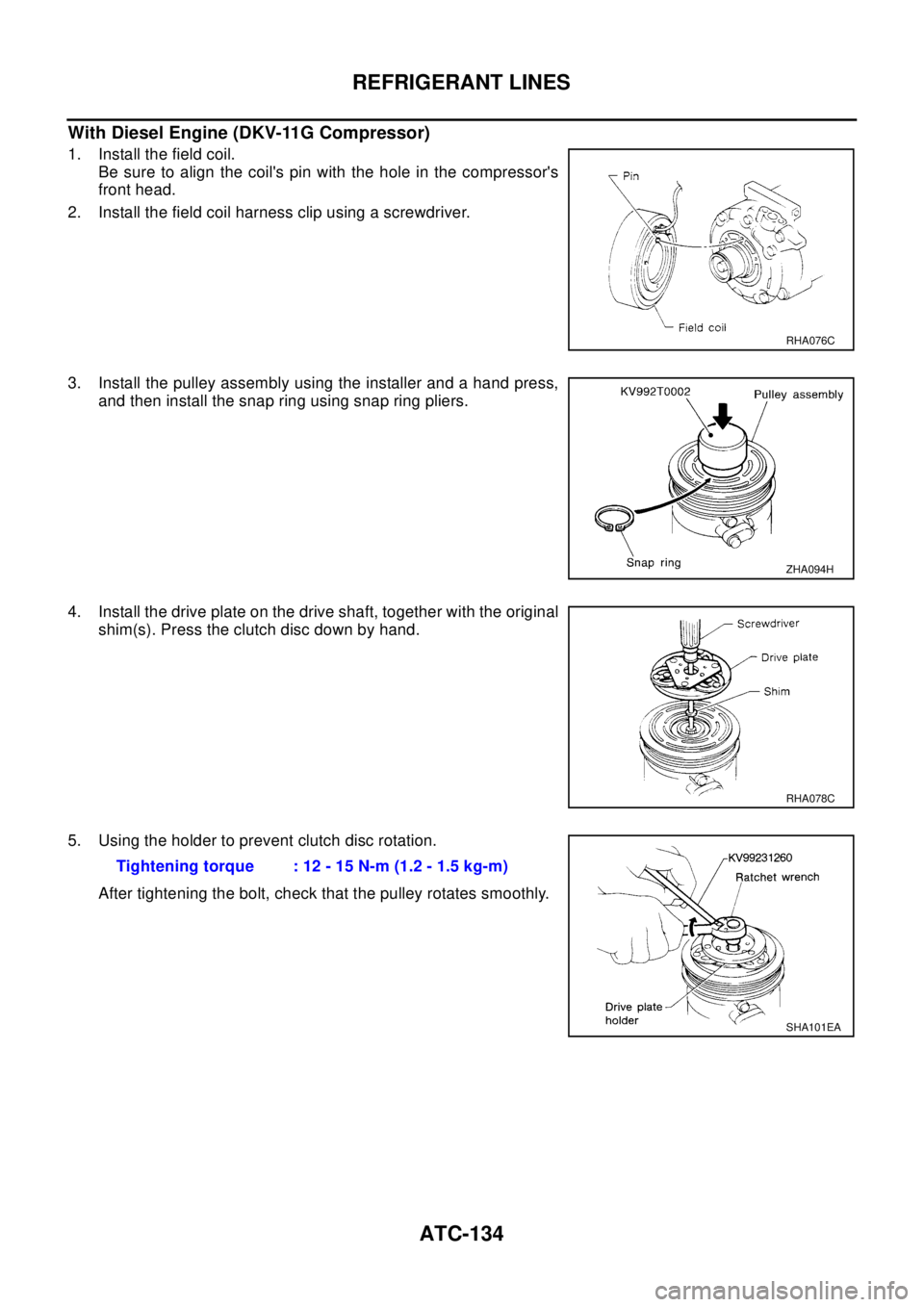

With Diesel Engine (DKV-11G Compressor)

1. Install the field coil.

Be sure to align the coil's pin with the hole in the compressor's

front head.

2. Install the field coil harness clip using a screwdriver.

3. Install the pulley assembly using the installer and a hand press,

and then install the snap ring using snap ring pliers.

4. Install the drive plate on the drive shaft, together with the original

shim(s). Press the clutch disc down by hand.

5. Using the holder to prevent clutch disc rotation.

After tightening the bolt, check that the pulley rotates smoothly.

RHA076C

ZHA094H

RHA078C

Tightening torque : 12 - 15 N-m (1.2 - 1.5 kg-m)

SHA101EA

Page 716 of 3066

ATC-138

REFRIGERANT LINES

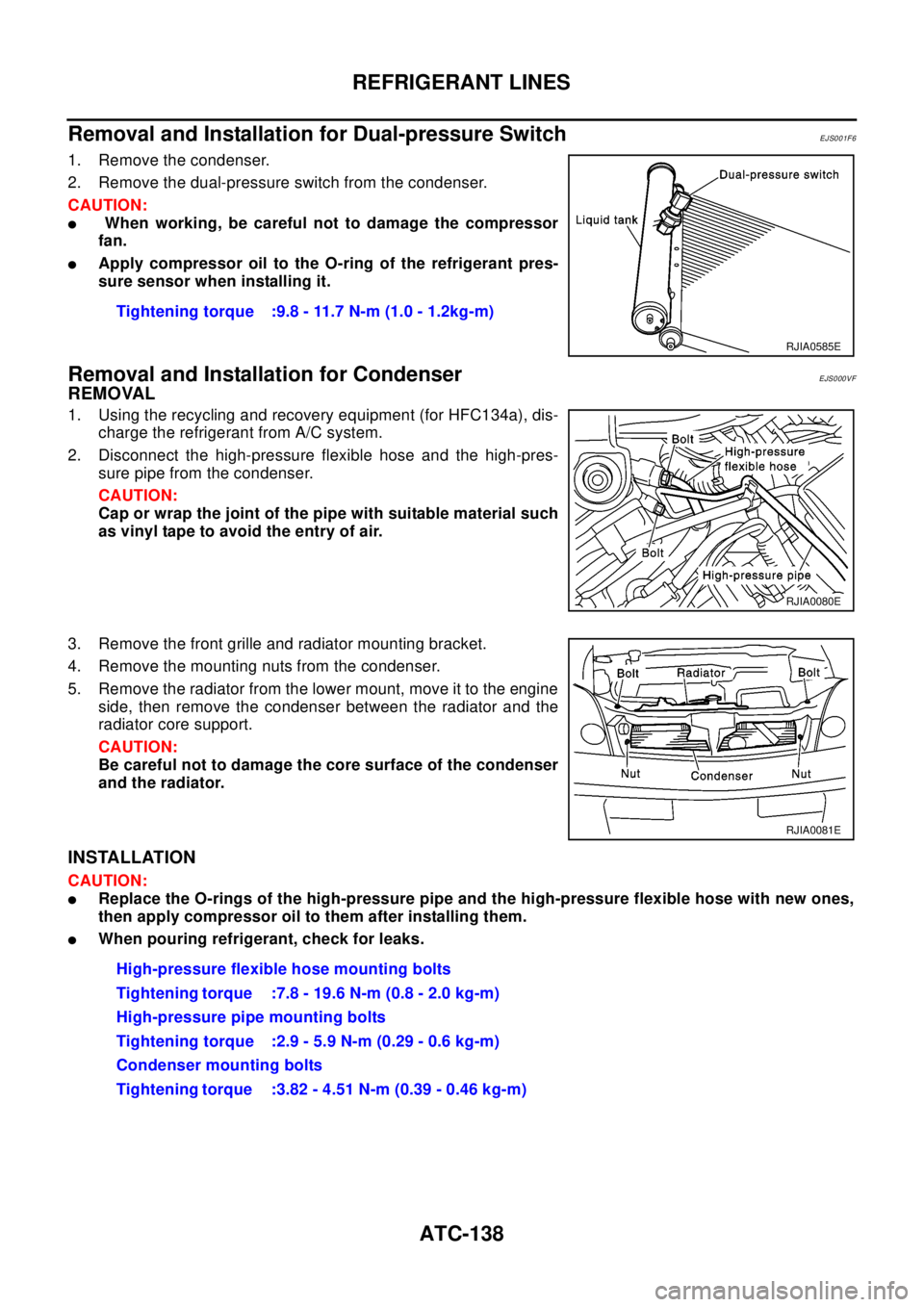

Removal and Installation for Dual-pressure Switch

EJS001F6

1. Remove the condenser.

2. Remove the dual-pressure switch from the condenser.

CAUTION:

lWhen working, be careful not to damage the compressor

fan.

lApply compressor oil to the O-ring of the refrigerant pres-

sure sensor when installing it.

Removal and Installation for CondenserEJS000VF

REMOVAL

1. Using the recycling and recovery equipment (for HFC134a), dis-

charge the refrigerant from A/C system.

2. Disconnect the high-pressure flexible hose and the high-pres-

sure pipe from the condenser.

CAUTION:

Cap or wrap the joint of the pipe with suitable material such

as vinyl tape to avoid the entry of air.

3. Remove the front grille and radiator mounting bracket.

4. Remove the mounting nuts from the condenser.

5. Remove the radiator from the lower mount, move it to the engine

side, then remove the condenser between the radiator and the

radiator core support.

CAUTION:

Be careful not to damage the core surface of the condenser

and the radiator.

INSTALLATION

CAUTION:

lReplace the O-rings of the high-pressure pipe and the high-pressure flexible hose with new ones,

then apply compressor oil to them after installing them.

lWhen pouring refrigerant, check for leaks.Tightening torque :9.8 - 11.7 N-m (1.0 - 1.2kg-m)

RJIA0585E

RJIA0080E

RJIA0081E

High-pressure flexible hose mounting bolts

Tightening torque :7.8 - 19.6 N-m (0.8 - 2.0 kg-m)

High-pressure pipe mounting bolts

Tightening torque :2.9 - 5.9 N-m (0.29 - 0.6 kg-m)

Condenser mounting bolts

Tightening torque :3.82 - 4.51 N-m (0.39 - 0.46 kg-m)

Page 719 of 3066

REFRIGERANT LINES

ATC-141

C

D

E

F

G

H

I

K

L

MA

B

AT C

CAUTION:

Moving the electronic leak detector probe slower and closer to the suspected leak area will improve

the chances of finding a leak.

Checking System for Leaks Using the Fluorescent Leak DetectorEJS000VK

1. Check A/C system for leaks using the UV lamp and safety glasses (J-42220) in a low sunlight area (area

without windows preferable). Illuminate all components, fittings and lines. The dye will appear as a bright

green/yellow area at the point of leakage. Fluorescent dye observed at the evaporator drain opening indi-

cates an evaporator core assembly (tubes, core or TXV) leak.

2. If the suspected area is difficult to see, use an adjustable mirror or wipe the area with a clean shop rag or

cloth, with the UV lamp for dye residue.

3. After the leak is repaired, remove any residual dye using dye cleaner (J-43872) to prevent future misdiag-

nosis.

4. Perform a system performance check and verify the leak repair with an approved electronic refrigerant

leak detector.

NOTE:

Other gases in the work area or substances on the A/C components, for example, anti-freeze, windshield

washer fluid, solvents and lubricants, may falsely trigger the leak detector. Make sure the surfaces to be

checked are clean.

Clean with a dry cloth or blow off with shop air.

Do not allow the sensor tip of the detector to contact with any substance. This can also cause false readings

and may damage the detector.

Dye InjectionEJS000VL

(This procedure is only necessary when recharging the system or when the compressor has seized and was

replaced.)

1. Check A/C system static (at rest) pressure. Pressure must be at least 345 kPa (50 psi).

2. Pour one bottle (1/4 ounce / 7.4 cc) of the A/C refrigerant dye into the injector tool (J-41459).

3. Connect the injector tool to the A/C LOW PRESSURE side service fitting.

4. Start engine and switch A/C ON.

5. When the A/C operating (compressor running), inject one bottle (1/4 ounce / 7.4 cc) of fluorescent dye

through the low-pressure service valve using dye injector tool J-41459 (refer to the manufacture's operat-

ing instructions).

6. With the engine still running, disconnect the injector tool from the service fitting.

CAUTION:

Be careful the A/C system or replacing a component, pour the dye directly into the open system con-

nection and proceed with the service procedures.

7. Operate the A/C system for a minimum of 20 minutes to mix the dye with the system oil. Depending on the

leak size, operating conditions and location of the leak, it may take from minutes to days for the dye to

penetrate a leak and become visible.

Electronic Refrigerant Leak DetectorEJS000VM

PRECAUTIONS FOR HANDLING LEAK DETECTOR

When performing a refrigerant leak check, use an A/C leak detector

or equivalent. Ensure that the instrument is calibrated and set prop-

erly per the operating instructions.

The leak detector is a delicate device. In order to use the leak detec-

tor properly, read the operating instructions and perform any speci-

fied maintenance.

SHA705EB

Page 720 of 3066

ATC-142

REFRIGERANT LINES

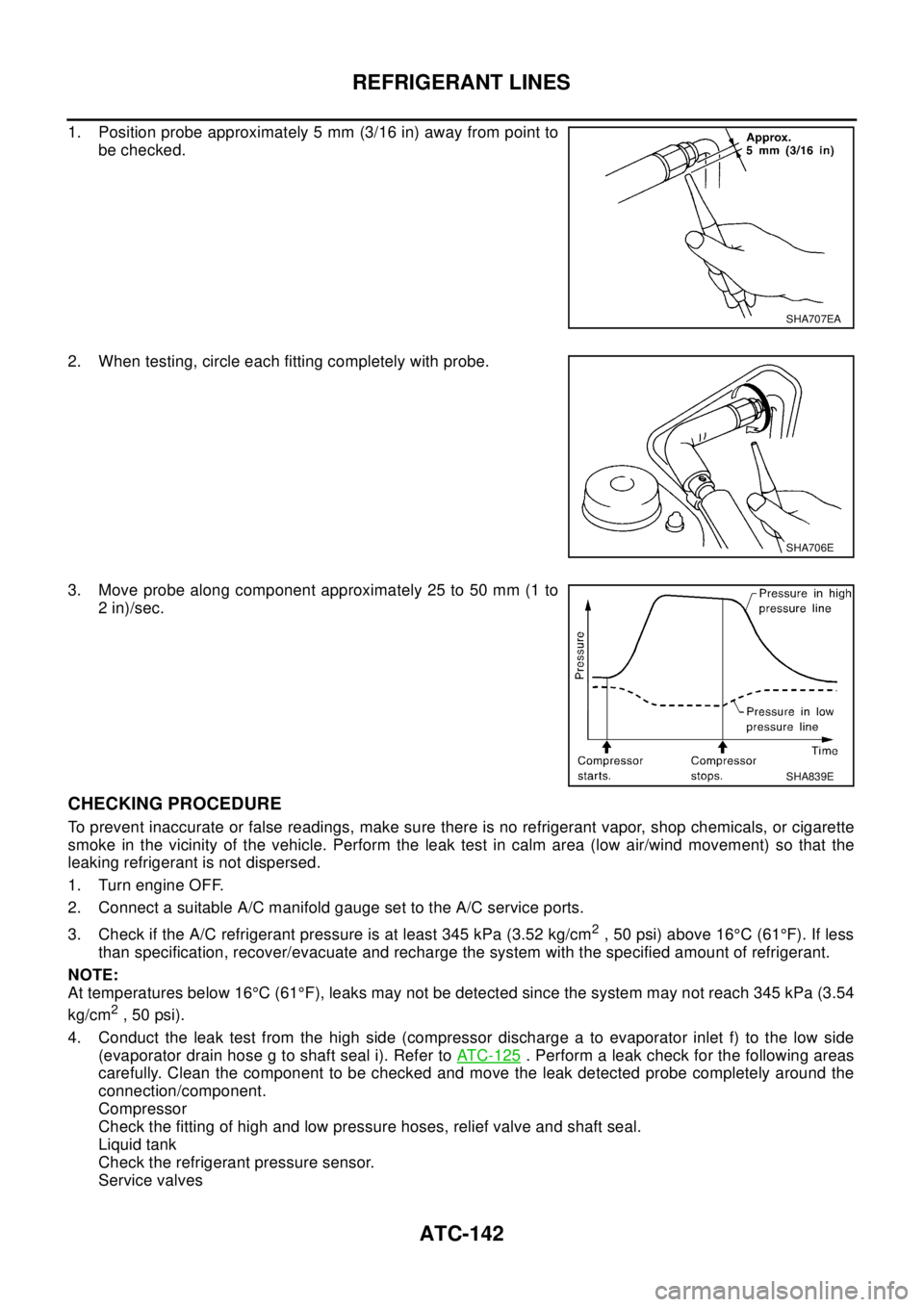

1. Position probe approximately 5 mm (3/16 in) away from point to

be checked.

2. When testing, circle each fitting completely with probe.

3. Move probe along component approximately 25 to 50 mm (1 to

2 in)/sec.

CHECKING PROCEDURE

To prevent inaccurate or false readings, make sure there is no refrigerant vapor, shop chemicals, or cigarette

smoke in the vicinity of the vehicle. Perform the leak test in calm area (low air/wind movement) so that the

leaking refrigerant is not dispersed.

1. Turn engine OFF.

2. Connect a suitable A/C manifold gauge set to the A/C service ports.

3. Check if the A/C refrigerant pressure is at least 345 kPa (3.52 kg/cm

2,50psi)above16°C(61°F).Ifless

than specification, recover/evacuate and recharge the system with the specified amount of refrigerant.

NOTE:

At temperatures below 16°C(61°F), leaks may not be detected since the system may not reach 345 kPa (3.54

kg/cm

2,50psi).

4. Conduct the leak test from the high side (compressor discharge a to evaporator inlet f) to the low side

(evaporator drain hose g to shaft seal i). Refer toATC-125

. Perform a leak check for the following areas

carefully. Clean the component to be checked and move the leak detected probe completely around the

connection/component.

Compressor

Check the fitting of high and low pressure hoses, relief valve and shaft seal.

Liquid tank

Check the refrigerant pressure sensor.

Service valves

SHA707EA

SHA706E

SHA839E

Page 721 of 3066

REFRIGERANT LINES

ATC-143

C

D

E

F

G

H

I

K

L

MA

B

AT C

Check all around the service valves. Ensure service valve caps are secured on the service valves (to pre-

vent leaks).

NOTE:

After removing A/C manifold gauge set from service valves, wipe any residue from valves to prevent any

false readings by leak detector.

Cooling unit (Evaporator)

With engine OFF, turn blower fan on "High" for at least 15 seconds to dissipate any refrigerant trace in the

cooling unit. Wait a minimum of 10 minutes accumulation time (refer to the manufacturer's recommended

procedure for actual wait time) before inserting the leak detector probe into the drain hose.

Keep the probe inserted for at least 10 seconds. Use caution not to contaminate the probe tip with water

or dirt that may be in the drain hose.

5. If a leak detector detects a leak, verify at least once by blowing compressed air into area of suspected

leak, then repeat check as outlined above.

6. Do not stop when one leak is found. Continue to check for additional leaks at all system components.

If no leaks are found, perform steps 7 - 10.

7. Start engine.

8. Set the heater A/C control as follows;

a. A/C switch: ON

b. Face mode

c. Intake position: Recirculation

d. Max cold temperature

e. Fan speed: High

9. Run engine at 1,500 rpm for at least 2 minutes.

10. Turn engine off and perform leak check again following steps 4 through 6 above.

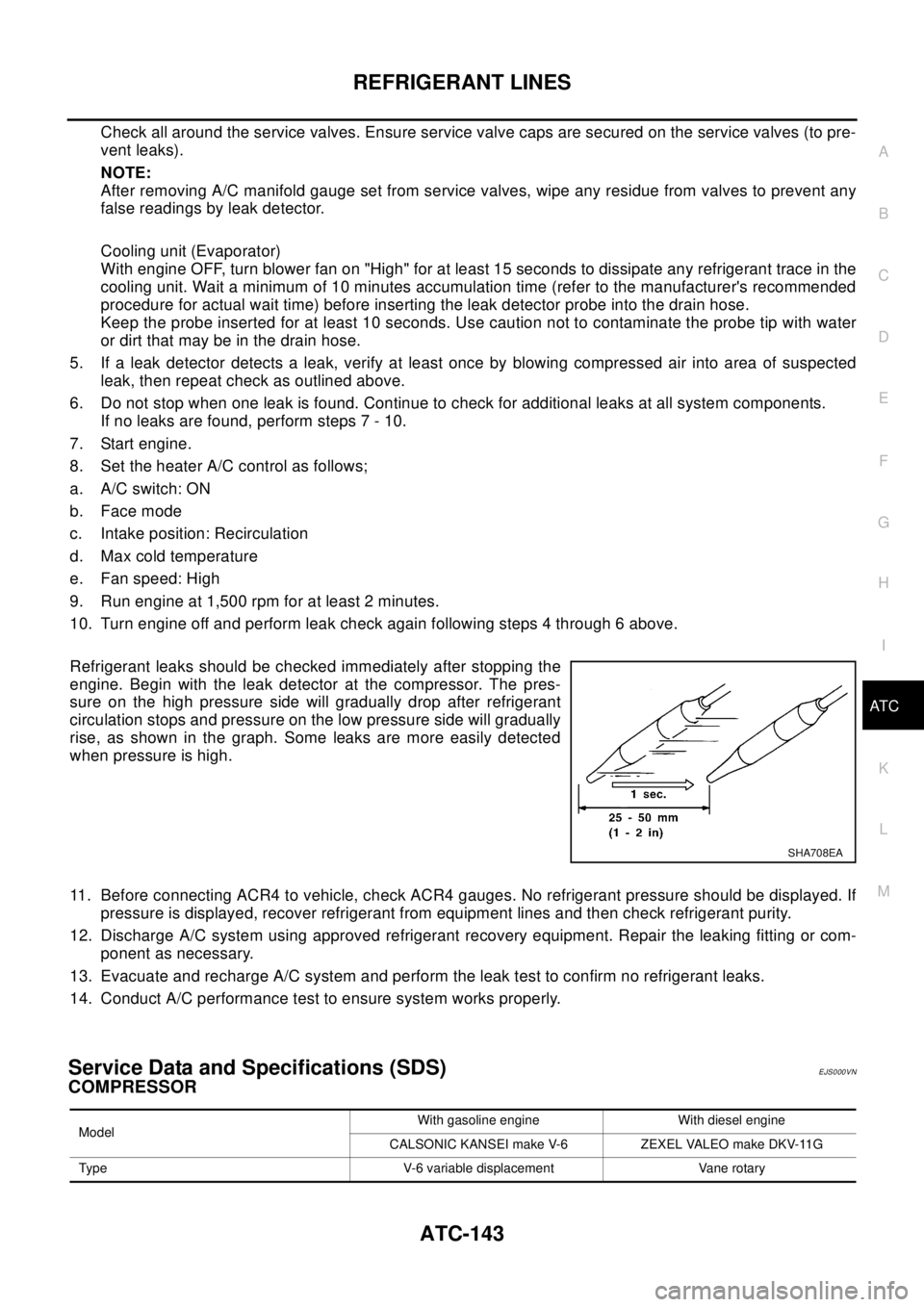

Refrigerant leaks should be checked immediately after stopping the

engine. Begin with the leak detector at the compressor. The pres-

sure on the high pressure side will gradually drop after refrigerant

circulation stops and pressure on the low pressure side will gradually

rise, as shown in the graph. Some leaks are more easily detected

when pressure is high.

11. Before connecting ACR4 to vehicle, check ACR4 gauges. No refrigerant pressure should be displayed. If

pressure is displayed, recover refrigerant from equipment lines and then check refrigerant purity.

12. Discharge A/C system using approved refrigerant recovery equipment. Repair the leaking fitting or com-

ponent as necessary.

13. Evacuate and recharge A/C system and perform the leak test to confirm no refrigerant leaks.

14. Conduct A/C performance test to ensure system works properly.

Service Data and Specifications (SDS)EJS000VN

COMPRESSOR

SHA708EA

ModelWith gasoline engine With diesel engine

CALSONIC KANSEI make V-6 ZEXEL VALEO make DKV-11G

Type V-6 variable displacement Vane rotary

Page 734 of 3066

AV-12

AUDIO

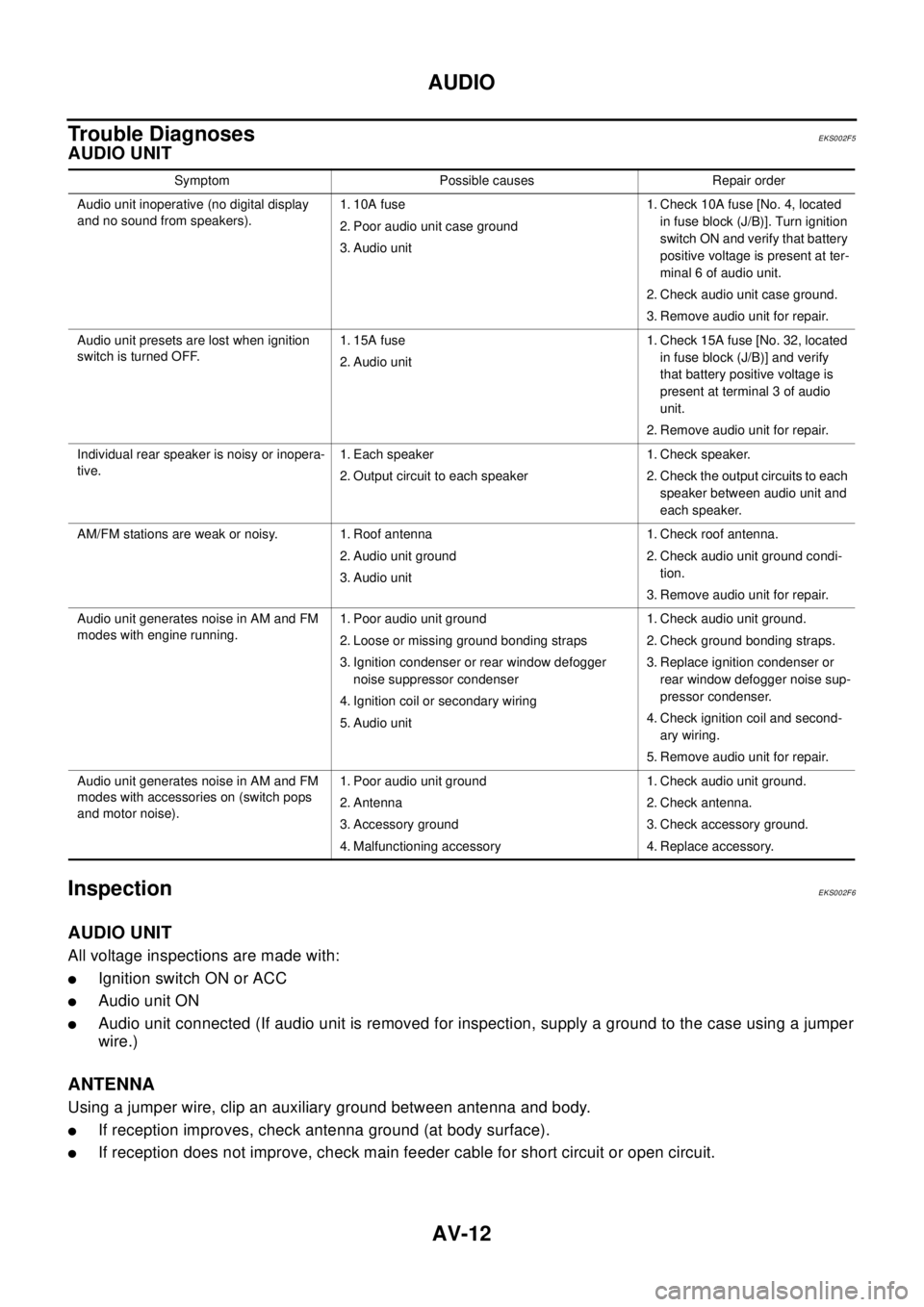

Trouble Diagnoses

EKS002F5

AUDIO UNIT

InspectionEKS002F6

AUDIO UNIT

All voltage inspections are made with:

lIgnition switch ON or ACC

lAudio unit ON

lAudio unit connected (If audio unit is removed for inspection, supply a ground to the case using a jumper

wire.)

ANTENNA

Using a jumper wire, clip an auxiliary ground between antenna and body.

lIf reception improves, check antenna ground (at body surface).

lIf reception does not improve, check main feeder cable for short circuit or open circuit.

Symptom Possible causes Repair order

Audio unit inoperative (no digital display

and no sound from speakers).1. 10A fuse

2. Poor audio unit case ground

3. Audio unit1. Check 10A fuse [No. 4, located

in fuse block (J/B)]. Turn ignition

switch ON and verify that battery

positive voltage is present at ter-

minal 6 of audio unit.

2. Check audio unit case ground.

3. Remove audio unit for repair.

Audio unit presets are lost when ignition

switch is turned OFF.1. 15A fuse

2. Audio unit1. Check 15A fuse [No. 32, located

in fuse block (J/B)] and verify

that battery positive voltage is

present at terminal 3 of audio

unit.

2. Remove audio unit for repair.

Individual rear speaker is noisy or inopera-

tive.1. Each speaker

2. Output circuit to each speaker1. Check speaker.

2. Check the output circuits to each

speaker between audio unit and

each speaker.

AM/FM stations are weak or noisy. 1. Roof antenna

2. Audio unit ground

3. Audio unit1. Check roof antenna.

2. Check audio unit ground condi-

tion.

3. Remove audio unit for repair.

Audio unit generates noise in AM and FM

modes with engine running.1. Poor audio unit ground

2. Loose or missing ground bonding straps

3. Ignition condenser or rear window defogger

noise suppressor condenser

4. Ignition coil or secondary wiring

5. Audio unit1. Check audio unit ground.

2. Check ground bonding straps.

3. Replace ignition condenser or

rear window defogger noise sup-

pressor condenser.

4. Check ignition coil and second-

ary wiring.

5. Remove audio unit for repair.

Audio unit generates noise in AM and FM

modes with accessories on (switch pops

and motor noise).1. Poor audio unit ground

2. Antenna

3. Accessory ground

4. Malfunctioning accessory1. Check audio unit ground.

2. Check antenna.

3. Check accessory ground.

4. Replace accessory.

Page 820 of 3066

BL-76

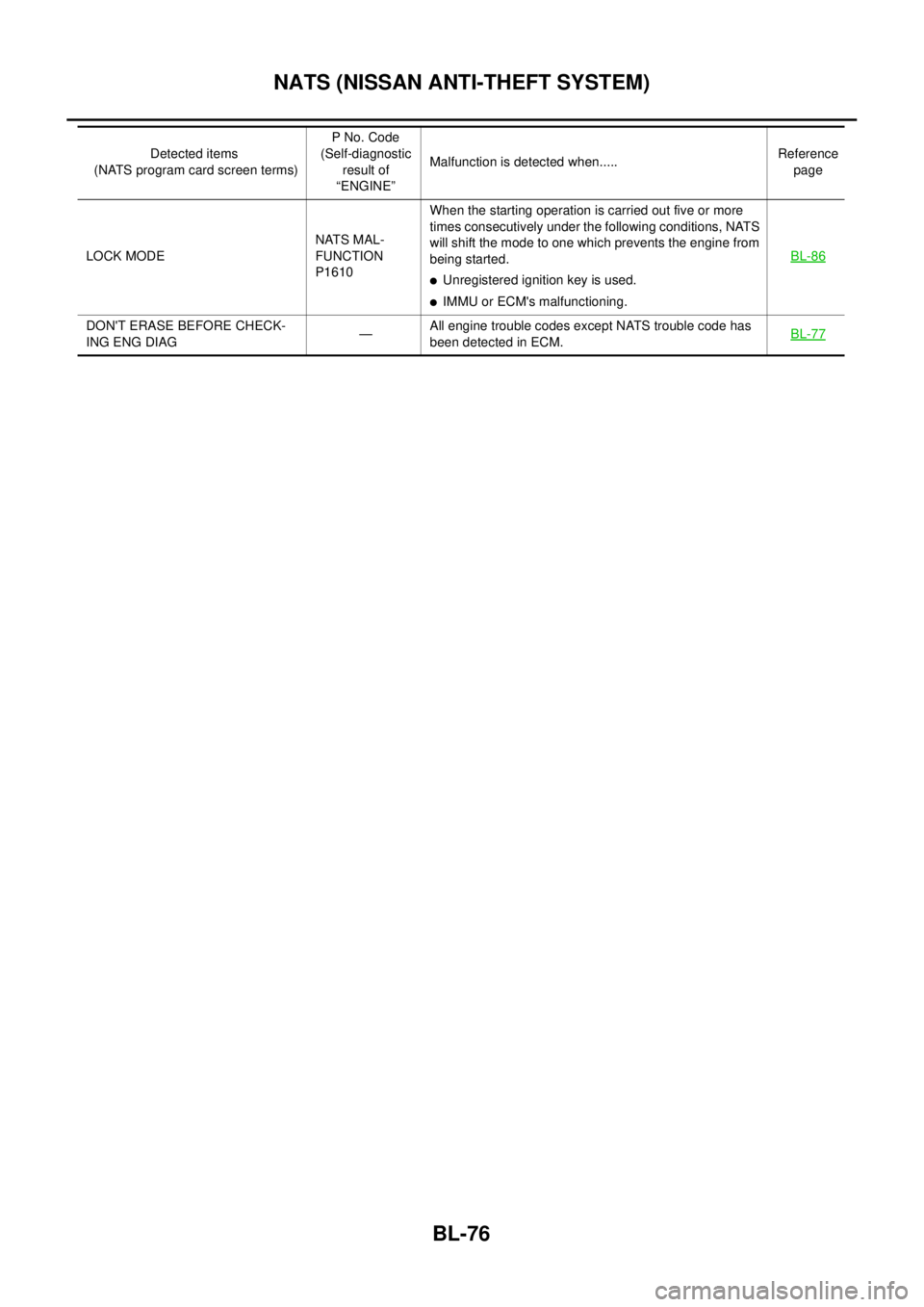

NATS (NISSAN ANTI-THEFT SYSTEM)

LOCK MODENATS MAL-

FUNCTION

P1610When the starting operation is carried out five or more

times consecutively under the following conditions, NATS

will shift the mode to one which prevents the engine from

being started.

lUnregistered ignition key is used.

lIMMU or ECM's malfunctioning.BL-86

DON'T ERASE BEFORE CHECK-

ING ENG DIAG—All engine trouble codes except NATS trouble code has

been detected in ECM.BL-77

Detected items

(NATS program card screen terms)PNo.Code

(Self-diagnostic

result of

“ENGINE”Malfunction is detected when.....Reference

page