check engine NISSAN X-TRAIL 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 846 of 3066

BR-12

BRAKE PIPING AND HOSE

5. Refill brake fluid until new brake fluid comes out of each air bleeder.

6. Afterwards, bleed air.

Removal and Installation of Rear Brake Piping and Brake HoseEFS000C8

REMOVAL

CAUTION:

lDo not allow brake fluid to spill or splash on painted surfaces. Brake fluid can seriously damage

paint. If it gets on a painted surface, wipe it off immediately and wash with water.

lDo not bend or twist the brake hose sharply, or strongly pull it.

lCover brake fluid line connections to prevent dust and other foreign material from entering.

1. Connect a vinyl tube to the air bleeder.

2. Drain brake fluid gradually from the air bleeder of each wheel while depressing the brake pedal.

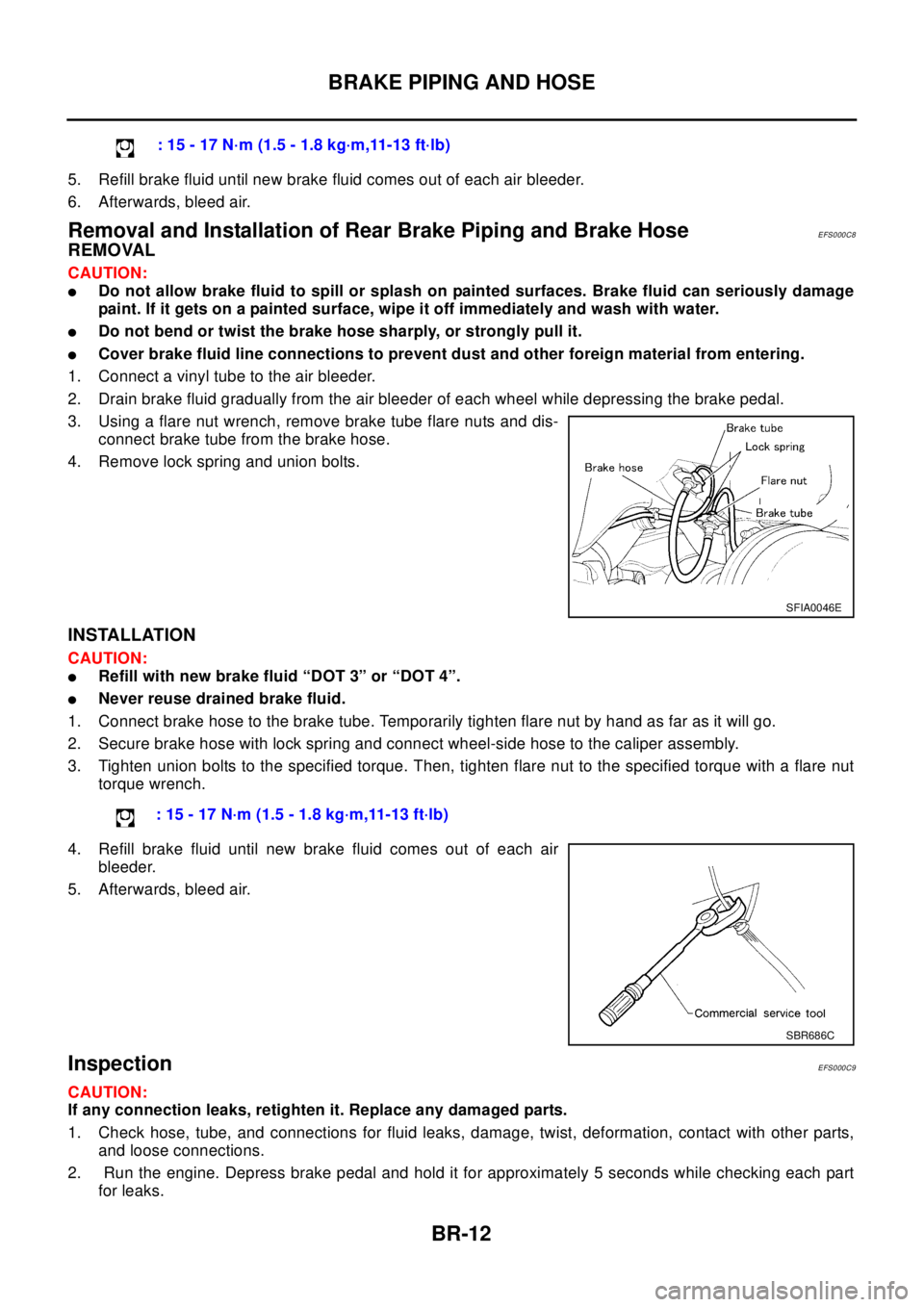

3. Using a flare nut wrench, remove brake tube flare nuts and dis-

connect brake tube from the brake hose.

4. Remove lock spring and union bolts.

INSTALLATION

CAUTION:

lRefill with new brake fluid “DOT 3” or “DOT 4”.

lNever reuse drained brake fluid.

1. Connect brake hose to the brake tube. Temporarily tighten flare nut by hand as far as it will go.

2. Secure brake hose with lock spring and connect wheel-side hose to the caliper assembly.

3. Tighten union bolts to the specified torque. Then, tighten flare nut to the specified torque with a flare nut

torque wrench.

4. Refill brake fluid until new brake fluid comes out of each air

bleeder.

5. Afterwards, bleed air.

InspectionEFS000C9

CAUTION:

If any connection leaks, retighten it. Replace any damaged parts.

1. Check hose, tube, and connections for fluid leaks, damage, twist, deformation, contact with other parts,

and loose connections.

2. Run the engine. Depress brake pedal and hold it for approximately 5 seconds while checking each part

for leaks.:15-17N·m(1.5-1.8kg·m,11-13ft·lb)

SFIA0046E

: 15 - 17 N·m (1.5 - 1.8 kg·m,11-13 ft·lb)

SBR686C

Page 851 of 3066

BRAKE BOOSTER

BR-17

C

D

E

G

H

I

J

K

L

MA

B

BR

BRAKE BOOSTERPFP:47200

On-Vehicle Inspection and ServiceEFS000CC

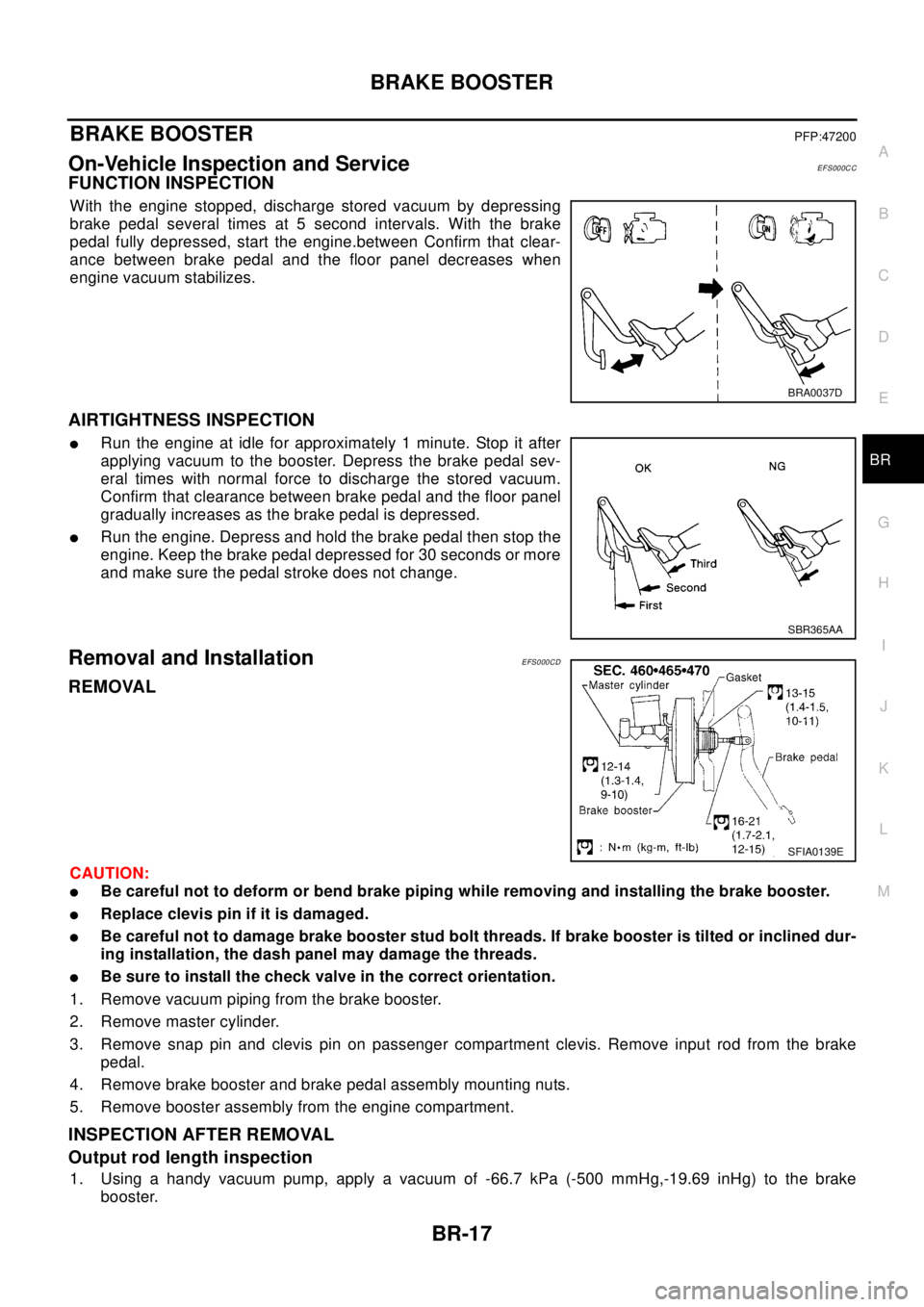

FUNCTION INSPECTION

With the engine stopped, discharge stored vacuum by depressing

brake pedal several times at 5 second intervals. With the brake

pedal fully depressed, start the engine.between Confirm that clear-

ance between brake pedal and the floor panel decreases when

engine vacuum stabilizes.

AIRTIGHTNESS INSPECTION

lRun the engine at idle for approximately 1 minute. Stop it after

applying vacuum to the booster. Depress the brake pedal sev-

eral times with normal force to discharge the stored vacuum.

Confirm that clearance between brake pedal and the floor panel

gradually increases as the brake pedal is depressed.

lRun the engine. Depress and hold the brake pedal then stop the

engine. Keep the brake pedal depressed for 30 seconds or more

and make sure the pedal stroke does not change.

Removal and InstallationEFS000CD

REMOVAL

CAUTION:

lBe careful not to deform or bend brake piping while removing and installing the brake booster.

lReplace clevis pin if it is damaged.

lBe careful not to damage brake booster stud bolt threads. If brake booster is tilted or inclined dur-

ing installation, the dash panel may damage the threads.

lBe sure to install the check valve in the correct orientation.

1. Remove vacuum piping from the brake booster.

2. Remove master cylinder.

3. Remove snap pin and clevis pin on passenger compartment clevis. Remove input rod from the brake

pedal.

4. Remove brake booster and brake pedal assembly mounting nuts.

5. Remove booster assembly from the engine compartment.

INSPECTION AFTER REMOVAL

Output rod length inspection

1. Using a handy vacuum pump, apply a vacuum of -66.7 kPa (-500 mmHg,-19.69 inHg) to the brake

booster.

BRA0037D

SBR365AA

SFIA0139E

Page 854 of 3066

BR-20

VACUUM LINES

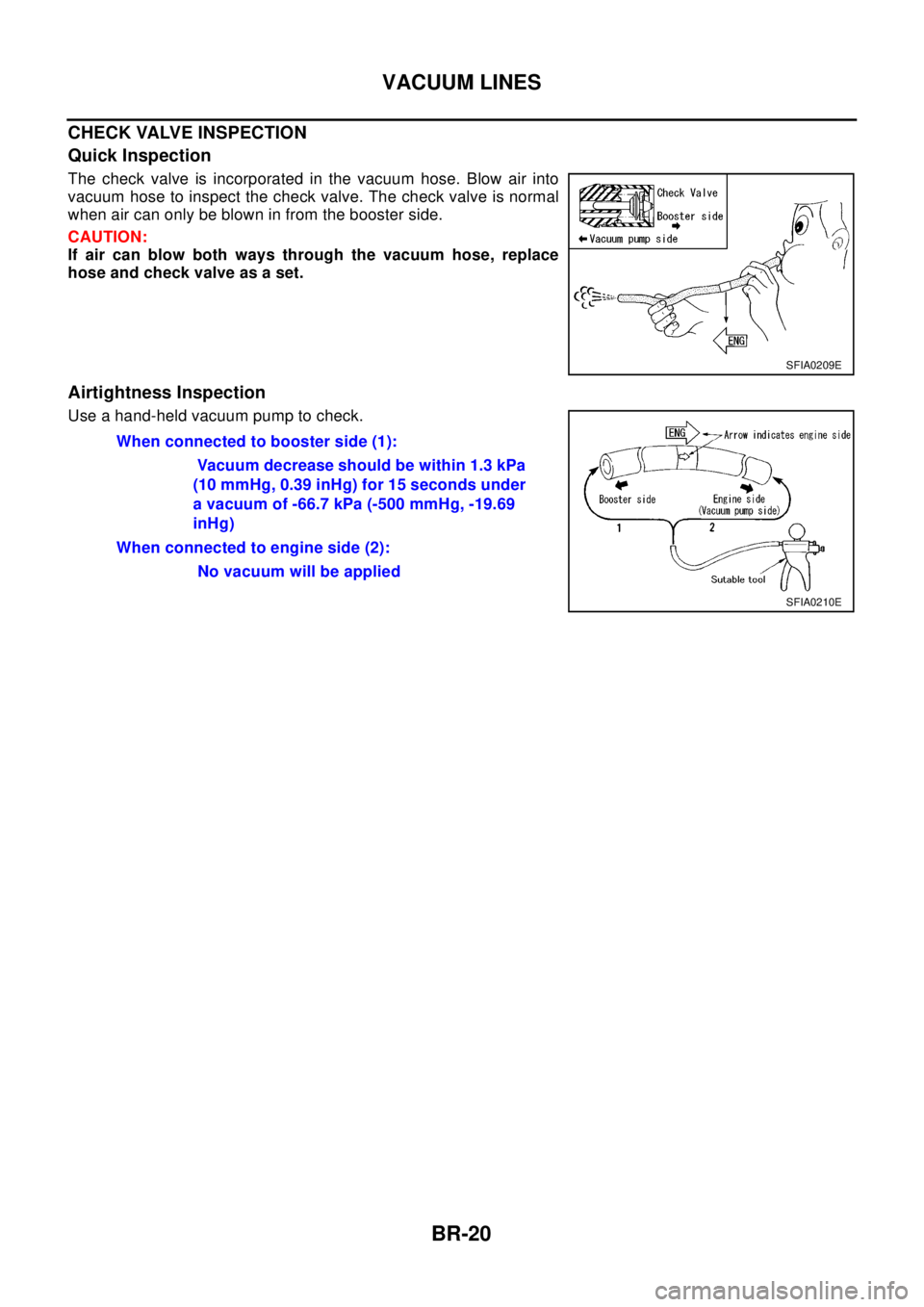

CHECK VALVE INSPECTION

Quick Inspection

The check valve is incorporated in the vacuum hose. Blow air into

vacuum hose to inspect the check valve. The check valve is normal

when air can only be blown in from the booster side.

CAUTION:

If air can blow both ways through the vacuum hose, replace

hose and check valve as a set.

Airtightness Inspection

Use a hand-held vacuum pump to check.

SFIA0209E

When connected to booster side (1):

Vacuum decrease should be within 1.3 kPa

(10 mmHg, 0.39 inHg) for 15 seconds under

a vacuum of -66.7 kPa (-500 mmHg, -19.69

inHg)

When connected to engine side (2):

No vacuum will be applied

SFIA0210E

Page 870 of 3066

BRC-2

ACTUATOR RELAY) TURNS ON/OFF FRE-

QUENTLY ............................................................ 42

ABS warning lamp does not illuminate. (ABS warn-

ing lamp does not come on when the ignition switch

is turned ON.) ......................................................... 42

ABS warning lamp illuminates with ignition ON, but

does not illuminates after a few seconds. (ABS

warning lamp has illuminated.) ............................... 42

4WD warning lamp does not illuminate with ignition

ON. ......................................................................... 43

4WD warning lamp does not go out several seconds

after engine is started. (Drive mode indicator lamp

goes out.) ................................................................ 43

Heavy tight-corner braking symptom occurs when

the vehicle is driven in AUTO mode and the steering

wheel is turned fully to either side after the engine

is started. ................................................................ 44

Drive modes cannot be switched after engine is

started. .................................................................... 45

Wheel driving, 4WD warning lamp flashes rapidly.

(When it flashes for Approx. one minute, then does

not illuminate.) ........................................................ 45

Wheel driving, 4WD warning lamp flashes slowly.

(When it continues to illuminate until engine turns

OFF.) ....................................................................... 45

Vehicle does not enter 4WD mode even though

4WD warning lamp is off. ........................................ 46

Tight-corner braking symptom occurs when the

vehicle is started in AUTO mode (4WD warning lamp

remain OFF). .......................................................... 46

E-TS actuator relay (4WD solenoid actuator relay)

turns ON/OFF frequently. ........................................ 46

Inspection of drive mode change-over switch path... 47

WHEEL SENSORS ................................................... 48

Removal and Installation ........................................ 48

G-SENSOR (4WD MODEL ONLY) ............................ 49

Removal and Installation ........................................ 49

SENSOR ROTOR ...................................................... 50

Removal and Installation ........................................ 50

REMOVAL ........................................................... 50

INSTALLATION .................................................... 50

ACTUATOR ............................................................... 51

Removal and Installation ........................................ 51

REMOVAL ........................................................... 51

INSTALLATION .................................................... 51

ESP/TCS/ABS

PRECAUTIONS ......................................................... 52

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” ................................................................. 52

Precautions for Brake System ................................ 52

Precautions for Brake Control ................................ 52

Precautions for CAN System .................................. 53

FOR INSPECTION .............................................. 53

FOR HARNESS REPAIR .................................... 53ON-VEHICLE SERVICE ............................................54

Adjustment of Neutral Position of Steering Angle

Sensor .....................................................................54

GENERAL INFORMATION .......................................56

Fail-Safe ..................................................................56

ABS SYSTEM ......................................................56

ESP/TCS SYSTEM ..............................................56

Hydraulic Circuit ......................................................56

ABS Functions ........................................................56

TCS Functions ........................................................57

ESP Functions ........................................................57

System Diagram .....................................................58

CAN COMMUNICATION ...........................................59

System Description .................................................59

FOR M/T MODELS ..............................................59

TROUBLE DIAGNOSIS ............................................60

How to Perform Trouble Diagnoses for Quick and

Accurate Repair ......................................................60

INTRODUCTION .................................................60

WORK FLOW ......................................................61

ASKING COMPLAINTS .......................................62

EXAMPLE OF DIAGNOSIS SHEET ....................62

Component Parts and Harness Connector Location... 63

Schematic ...............................................................64

Wiring Diagram —ESP/TCS/ABS— .....................65

Control Unit Input/Output Signal Standard ..............71

STANDARDS USING A CIRCUIT TESTER AND

OSCILLOSCOPE .................................................71

STANDARDS WITH CONSULT-II ........................75

Functions of CONSULT-II .......................................77

CONSULT-II MAINLY FUNCTION APPLICA-

TION TO ESP/TCS/ABS ......................................77

SELF-DIAGNOSIS ...............................................78

DATA MONITOR ..................................................81

ACTIVE TEST ......................................................84

For Correct and Quick Diagnosis ............................88

PRECAUTIONS FOR TROUBLE DIAGNOSIS ... 88

Basic Inspection ......................................................89

PRELIMINARY CHECK 1: (BRAKE FLUID

LEVEL AND LEAK INSPECTION) .......................89

PRELIMINARY CHECK 2: (INSPECTION FOR

LOOSE POWER SUPPLY TERMINAL) ...............89

PRELIMINARY CHECK 3: (INSPECTION FOR

ABS WARNING LAMP, ESP OFF INDICATOR

LAMP, AND SLIP INDICATOR LAMP) .................89

Inspection 1 Wheel Speed Sensor and Circuit .......90

Inspection 2 Engine System ...................................92

Inspection 3 ESP/TCS/ABS Control Unit System ...92

Inspection 4 Pressure Sensor and the Circuit

between Pressure Sensor and ESP/TCS/ABS Con-

trol Unit. ...................................................................93

Inspection 5 Steering Angle Sensor and the Circuit

between Steering Angle Sensor and ESP/TCS/ABS

Control Unit. ............................................................94

Inspection 6 Yaw Rate Sensor/ Side G sensor and

the Circuit between Yaw Rate Sensor/ Side G sen-

sor and ESP/TCS/ABS Control Unit. ......................95

Inspection 7 Solenoid Valve, ESP Switch-over Sole-

Page 874 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual BRC-6

[4WD/ABS]

ALL MODE 4X4 SYSTEM

ALL MODE 4X4 SYSTEM

PFP:47850

System DescriptionEFS001CJ

ABS FUNCTION

lDuring ABS operation, brake pedal lightly vibrates and its mechanical noise may be heard. Thi NISSAN X-TRAIL 2003 Electronic Repair Manual BRC-6

[4WD/ABS]

ALL MODE 4X4 SYSTEM

ALL MODE 4X4 SYSTEM

PFP:47850

System DescriptionEFS001CJ

ABS FUNCTION

lDuring ABS operation, brake pedal lightly vibrates and its mechanical noise may be heard. Thi](/img/5/57402/w960_57402-873.png)

BRC-6

[4WD/ABS]

ALL MODE 4X4 SYSTEM

ALL MODE 4X4 SYSTEM

PFP:47850

System DescriptionEFS001CJ

ABS FUNCTION

lDuring ABS operation, brake pedal lightly vibrates and its mechanical noise may be heard. This is a nor-

mal condition.

lWhen starting engine, or just after starting vehicle, brake pedal may vibrate. Also motor operating noise

may be heard from engine compartment. This is a normal status of operation check.

lWhen vehicle drives on rough, gravel, or snowy (fresh deep snow) road, the following conditions occur.

Stopping distance may be longer than that of vehicles without ABS.

4WD FUNCTION

lElectronically controlled 4WD is controlled by the same control module as that for ABS (4WD/ABS control

unit). 4WD/ABS control unit controls both electronically-controlled 4WD and ABS, based on input signals

from several sensors.

lIf electrical system-related malfunction occurred in 4WD/ABS system, control unit illuminates the following

lamps: 4WD warning lamp and/or ABS warning lamp on meter control unit assembly. This notifies driver of

malfunction. At the same time, control unit indicates malfunctioning part detected by self-diagnosis with

flashing pattern of LED. Indication on electronic system diagnosis tester (CONSULT) corresponds to this

flashing pattern as shown below.

Control System DiagramEFS001CK

Self-diagnostic test mode Remarks

Result of self-diagnosis Conformable to 4WD/ABS

Data monitor Conformable to 4WD/ABS

Active testChecks ABS solenoid valve ON/OFF, ABS motor ON/OFF, 4WD sole-

noid

Control unit part No. 4WD/ABS control unit

SFIA0350E

Page 886 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual BRC-18

[4WD/ABS]

TROUBLE DIAGNOSIS

Trouble Diagnosis Chart by Symptom

EFS001BF

When ABS and 4WD warning lamps illuminate, perform self-diagnosis.

Symptom Condition Check items Reference page

When igni NISSAN X-TRAIL 2003 Electronic Repair Manual BRC-18

[4WD/ABS]

TROUBLE DIAGNOSIS

Trouble Diagnosis Chart by Symptom

EFS001BF

When ABS and 4WD warning lamps illuminate, perform self-diagnosis.

Symptom Condition Check items Reference page

When igni](/img/5/57402/w960_57402-885.png)

BRC-18

[4WD/ABS]

TROUBLE DIAGNOSIS

Trouble Diagnosis Chart by Symptom

EFS001BF

When ABS and 4WD warning lamps illuminate, perform self-diagnosis.

Symptom Condition Check items Reference page

When ignition switch is turned ON,

drive mode indicator lamp does not illu-

minate for Approx. 1 second (drive

mode lamp check)IGN-ON

lBlown drive mode indicator lamp bulb

lBlown fuse between ignition and drive mode

indicator lamp

lOpen circuit of wiring between ignition and

drive mode indicator lampBRC-42

ABS warning lamp does not illuminate

with ignition ON. (ABS warning lamp

check)IGN-ON

lBlown ABS warning lamp bulb

lBlown fuse between ignition and ABS warning

lamp.

lOpen circuit of wiring between ignition and

ABS warning lamp.

lMalfunction in ABS systemBRC-42

ABS warning lamp illuminates with

ignition ON, but does not illuminates

after a few seconds. (ABS warning

lamp has not illuminated.)IGN-ONl4WD/ABS control unit connector discon-

nected

lMalfunction in ABS systemBRC-42

4WD warning lamp does not illuminate

with ignition ON.IGN-ON

lBlown 4WD warning lamp bulb

lBlown fuse between ignition and 4WD warn-

ing lamp

lOpen circuit in wire between ignition and 4WD

warning lamp

lOpen circuit in wire between 4WD warning

lamp and 4WD actuator relay

lDisconnected 4WD actuator relay

lOpen circuit in wire between 4WD actuator

relay and body groundBRC-43

4WD warning lamp does not go out

several seconds after engine is started.

(Drive mode indicator lamp goes out.)Engine runningl4WD/ABS control unit connector discon-

nected

lMalfunction present in 4WD systemBRC-43

Heavy tight-corner braking symptom

occurs when vehicle is driven in the fol-

lowing conditions: AUTO mode and

steering wheel is turned fully to either

sides after engine is started (Note 1,

Note 2).lEngine run-

ning

lAUTO mode

lSteering

wheel fully

turned

lOperation is not in AUTO mode (in 2WD or

LOCK mode).

lThrottle position signal error

lMechanical malfunction of electronically con-

trolled coupling

lMalfunction present in 4WD systemBRC-44

Drive modes cannot be switched after

engine is started.Engine running

lDrive mode change-over switch is discon-

nected.

lOpen circuit between drive mode change-over

switch and 4WD /ABS control unit

lOpen circuit between drive mode change-over

switch and body groundBRC-45

Vehicle running, 4WD warning lamp

flashes rapidly. (When it flashes for

Approx. One minute, then does not illu-

minate.) Rapid flashing: Two times

flashing per 1 secondEngine running

(to other than

2WD mode)Protection function was activated due to heavy

load to electronically controlled coupling. (4WD

system is not malfunctioning.)BRC-45

Page 887 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual TROUBLE DIAGNOSIS

BRC-19

[4WD/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

CAUTION:

1. Light tight-corner braking symptom may occur depending on driving conditions in AUTO mode.

This is not malfunction.

2. Heavy t NISSAN X-TRAIL 2003 Electronic Repair Manual TROUBLE DIAGNOSIS

BRC-19

[4WD/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

CAUTION:

1. Light tight-corner braking symptom may occur depending on driving conditions in AUTO mode.

This is not malfunction.

2. Heavy t](/img/5/57402/w960_57402-886.png)

TROUBLE DIAGNOSIS

BRC-19

[4WD/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

CAUTION:

1. Light tight-corner braking symptom may occur depending on driving conditions in AUTO mode.

This is not malfunction.

2. Heavy tight-corner braking symptom occurs when vehicle is driven in the following conditions:

LOCK mode, steering wheel is turned fully to either sides, and accelerator pedal was depressed.

4WD/ABS Control Unit Input/Output Signal StandardEFS001BG

4WD/ABS CONTROL UINT CONNECTOR TERMINAL ARRANGEMENT

CAUTION:

When ignition switch is turned to ON with connectors of 4WD/ABS control unit and actuator con-

nected.

REFERENCE STANDARD TABLE

Specifications defined by circuit tester

Vehicle running, 4WD warning lamp

flashes slowly. (When it flashes for

Approx. One minute, then does not illu-

minate.)Slow flashing: One flashing

per 2 secondslEngine run-

ning

lDriving at

vehicle speed

30km/hTire size is different for front and rear of vehicle.BRC-45

Vehicle does not enter 4WD mode

even though 4WD warning lamp is off.Engine runningMechanical malfunction of electronically con-

trolled coupling (Mechanical engagement of

clutch is not possible.)BRC-46

Symptom Condition Check items Reference page

SFIA0351E

Terminal No.

Location Standard (note 1)(Note) Check

points when result

was malfunctioning +-

3.

109Power supply Ignition switch ONBattery voltage (Approx.

12V)Control unit power

supply circuit

Page 888 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual BRC-20

[4WD/ABS]

TROUBLE DIAGNOSIS

11 5

Body

groundGround -Control unit ground

path 11 3

111

108

106

104

13 Stop lamp signalDepress the brake pedal.

Release brake pedal.Battery voltage (Approx.

12V)

A NISSAN X-TRAIL 2003 Electronic Repair Manual BRC-20

[4WD/ABS]

TROUBLE DIAGNOSIS

11 5

Body

groundGround -Control unit ground

path 11 3

111

108

106

104

13 Stop lamp signalDepress the brake pedal.

Release brake pedal.Battery voltage (Approx.

12V)

A](/img/5/57402/w960_57402-887.png)

BRC-20

[4WD/ABS]

TROUBLE DIAGNOSIS

11 5

Body

groundGround -Control unit ground

path 11 3

111

108

106

104

13 Stop lamp signalDepress the brake pedal.

Release brake pedal.Battery voltage (Approx.

12V)

Approx. 0VStop lamp switch

and path

5ABS MOTOR

RELAYABS motor actuated

(byactivetestmodeofCONSULT)

ABS motor stopped (Ignition switch is in

ON)Approx. 2 V or less

Battery voltage (Approx.

12V)ABS motor, motor

relay and harness

17ABS ACTUATOR

RELAYWhen actuator relay is active.

(the engine running)

When actuator relay is inactive.

(In fail-safe mode, before starting

engine)Approx. 2 V or less

Battery voltage (Approx.

12V)ABS actuator relay

and harness

11 6Front RH wheel IN

solenoid

Actuator is activated (by active test

mode of CONSULT) or actuator relay is

not activated

(In fail-safe mode, before starting

engine)

Actuator is not activated and actuator

relay is activated (Vehicle stopped with

engine running)Approx. 0V

Battery voltage (Approx.

12V)ABS solenoid valve

path 11 4Front RH wheel

OUT solenoid

11 2Front LH wheel IN

solenoid

11 0Front LH wheel

OUT solenoid

107Rear RH wheel IN

solenoid

105Rear RH wheel

OUT solenoid

103Rear LH wheel IN

solenoid

101Rear LH wheel

OUT solenoid

74WD warning lamp

(Note 2)4WD warning lamp ON

4WD warning lamp OFFApprox. 0V

Battery voltage (Approx.

12V)4WD warning lamp

and harness

4ABS warning lamp

(Note 3)ABS warning lamp ON

ABS warning lamp OFFApprox. 0V

Battery voltage (Approx.

12V)ABS warning lamp

and path

16AUTO indicator

lampAUTO indicator lamp ON

AUTO indicator lamp OFFApprox. 0V

Battery voltage (Approx.

12V)AUTO indicator

lamp and harness

6LOCK indicator

lampLOCK indicator lamp ON

LOCK indicator lamp OFFApprox. 0V

Battery voltage (Approx.

12V)LOCK indicator

lamp and harness

46 37 FR RH SENSOR

At vehicle rotating (Approx. 30km/h)Pulse generation

Approx. 200HzSpeed sensor and

harness 34 43FR LH SENSOR

[OPEN]

36 45 RR RH SENSOR

44 35 RR LH SENSOR Te r m i n a l N o .

Location Standard (note 1)(Note) Check

points when result

was malfunctioning +-

Page 889 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual TROUBLE DIAGNOSIS

BRC-21

[4WD/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

CAUTION:

1. If a circuit tester for measuring voltage is used for the check, do not forcibly extend any connector

terminals.

CAUTION:

2. 4 NISSAN X-TRAIL 2003 Electronic Repair Manual TROUBLE DIAGNOSIS

BRC-21

[4WD/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

CAUTION:

1. If a circuit tester for measuring voltage is used for the check, do not forcibly extend any connector

terminals.

CAUTION:

2. 4](/img/5/57402/w960_57402-888.png)

TROUBLE DIAGNOSIS

BRC-21

[4WD/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

CAUTION:

1. If a circuit tester for measuring voltage is used for the check, do not forcibly extend any connector

terminals.

CAUTION:

2. 4WD warning lamp ON/OFF timing

CAUTION:

3. ABS warning lamp ON/OFF timing

CAUTION:

4. Unit name is indicated by the name used in circuit diagram (4WD solenoid valve). However, it is “E-

TS solenoid” in CONSULT-II data.

Specifications defined by CONSULT

102

Body ground

4WD solenoid valve

(E-TS solenoid

valve)At vehicle stop engine idlingBattery voltage (Approx.

12V)4WD actuator relay

solenoid valve and

harness

18 4WD actuator relay At vehicle stop engine idling 2 V or lower4WD actuator relay

and harness

2

4G - sensor power

supply

At ignition switch ON (vehicle horizontal

stop condition)Approx. 8 V

G -sensor and har-

ness

32Longitudinal G -

sensorApprox. 2.5V

41 G -sensor ground Approx. 0V

22Throttle position

sensorWide open throttle

Closed throttleApprox. 4.0 V

Approx. 0.5 VThrottle position

sensor and har-

ness

24Parking brake

switchIn parking position

In other than parking position-Parking brake

switch and harness

26Drive mode

change-over switch

AUTODrive mode change-over switch: 2WD

Drive mode change-over switch: other

than 2WDSW ON: Approx. 0 V

SW OFF: Approx. 5 VDrive mode

change-over switch

and path

27Drive mode

change-over switch

LOCKDrive mode change-over switch: LOCK

Drive mode change-over switch: other

than LOCKSW ON: Approx. 0 V

SW OFF: Approx. 5 VDrive mode

change-over switch

and path

ON: When ignition switch is turned ON (before engine starts) or when malfunction is

detected

OFF: After engine is started (When the system is in normal condition)

ON: When ignition switch is turned ON (before engine starts) or when malfunction is

detected

OFF: After engine is started (When the system is in normal condition)

Terminal No.

Location Standard (note 1)(Note) Check

points when result

was malfunctioning +-

Items to be monitored ContentsData monitor

(Reference)

Check points when result

was malfunctioning ConditionReference values in

normal operation

Wheel speed sensor

FR,

FL, RR, RL (km/h)Vehicle wheel speedWhen the vehicle is

stopped0km/h

Wheel speed sensor and

harness

While driving (note:1)Almost in accordance

with speedometer dis-

play (within±10%)

LONGITUDINAL G-

SENSOR (4WD mod-

els)G -sensor operating

conditionWith vehicle stopped

on flat road.plus; 0.15 G G -sensor and harness

Page 891 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual TROUBLE DIAGNOSIS

BRC-23

[4WD/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

CAUTION:

1. Check air pressure of tire under normal condition.

2. ABS warning lamp ON/OFF timing

CONSULT-II FunctionsEFS001BH

CONSULT-II F NISSAN X-TRAIL 2003 Electronic Repair Manual TROUBLE DIAGNOSIS

BRC-23

[4WD/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

CAUTION:

1. Check air pressure of tire under normal condition.

2. ABS warning lamp ON/OFF timing

CONSULT-II FunctionsEFS001BH

CONSULT-II F](/img/5/57402/w960_57402-890.png)

TROUBLE DIAGNOSIS

BRC-23

[4WD/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

CAUTION:

1. Check air pressure of tire under normal condition.

2. ABS warning lamp ON/OFF timing

CONSULT-II FunctionsEFS001BH

CONSULT-II FUNCTION APPLICATION TABLE

4WD MODE MONI-

TOROutput condition of

drive mode indicator

lamp signalEngine running, vehi-

cle stoppedUsing drive mode

change-over switchDrive mode indicator lamp

and path

IMPROPER SIZE

TIRE MONITOR (mm)Improper size tire

installed condition- 0-4,4-8Front/Rear tire size differ-

ence, wear condition

PARKING BRAKE

SWITCH (ON/OFF)Parking brake switch

operating conditionParking brake

depressedON

Parking brake switch and

harness

Parking brake not

depressedOFF

METER OUTPUT

(km/h)Output condition of

vehicle speed for

speedometerWheel stopped 0 km/h

Speed meter and harness

Vehicle runningAlmost in accordance

with the wheel speed

sensor display

ON: When ignition switch is turned ON (before engine starts) or when malfunction is

detected

OFF: After engine is started (When the system is in normal condition)

Item Self-diagnosis Data monitor Active test

FR RH SENSOR´´-

FR LH SENSOR [OPEN]´´-

RR RH SENSOR´´-

RR LH SENSOR´´-

Speed sensor´--

Stop lamp switch -´-

FR RH IN ABS SOL´´´

FR RH OUT ABS SOL´´´

FR LH IN ABS SOL´´´

FR LH OUT ABS SOL´´´

RR RH IN ABS SOL´´´

RR RH OUT ABS SOL´´´

RR LH IN ABS SOL´´´

RR LH OUT ABS SOL´´´

ABS ACTUATOR RELAY´´-

ABS MOTOR RELAY´´´

ABS warning lamp -´-

Battery voltage´´-

Control module´--

ABS MOTOR´-´

Longitudinal G -sensor´´-

4WD solenoid valve´´´

4WD actuator relay -´-

Engine speed signal -´-

Throttle position sensor´´-